Safety Risk Assessment of Double-Line Tunnel Crossings Beneath Existing Tunnels in Complex Strata

Abstract

1. Introduction

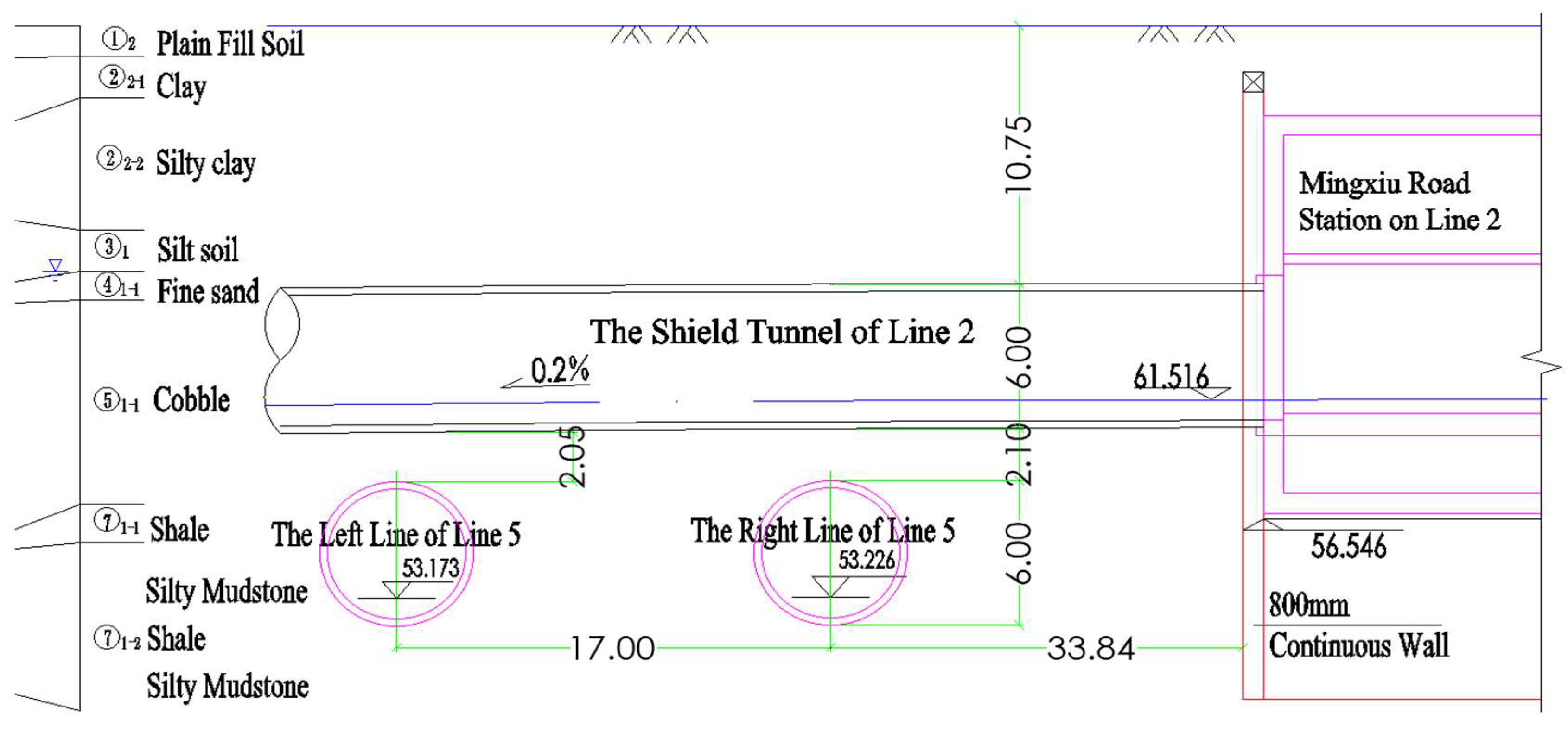

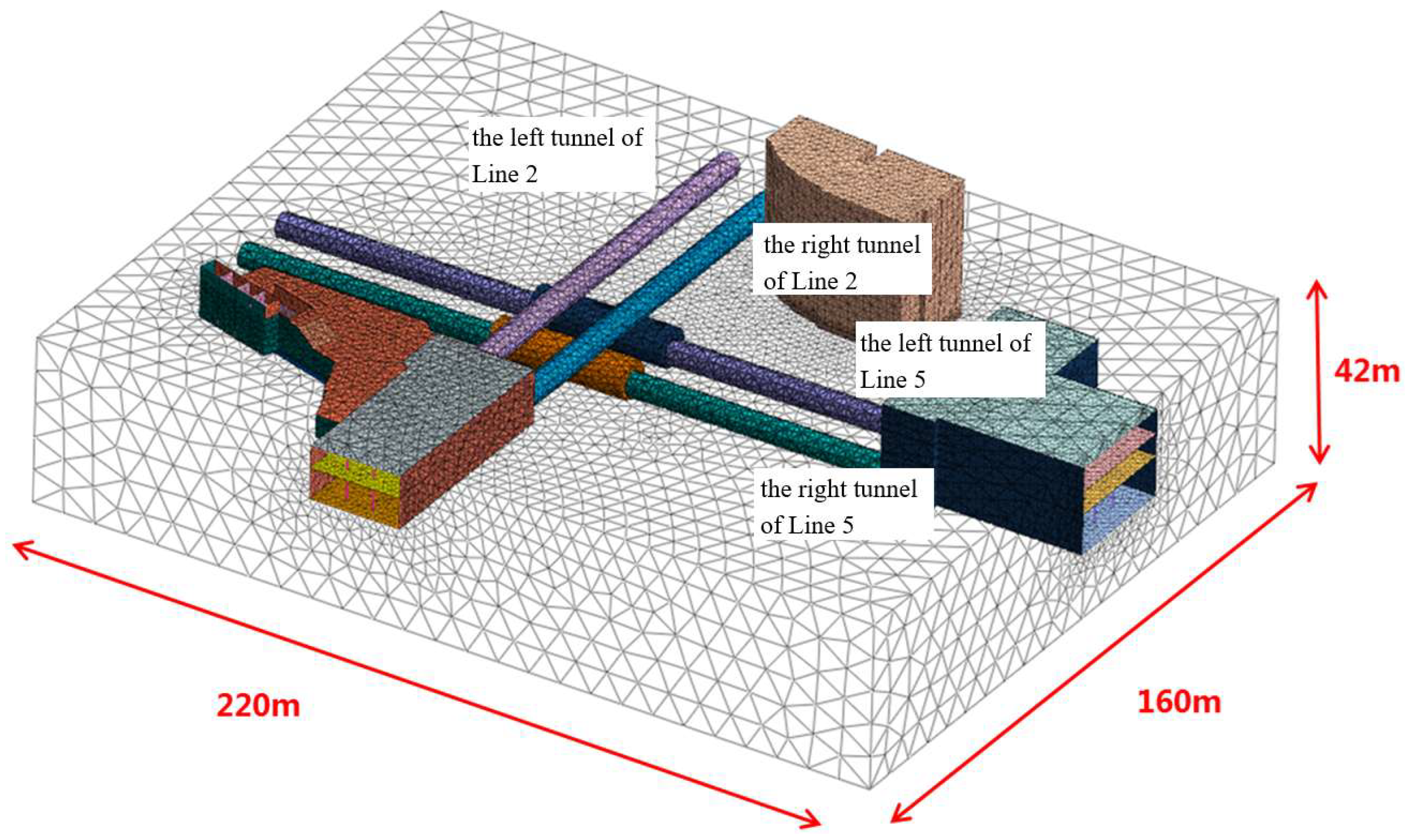

2. Project Overview and Geological Conditions

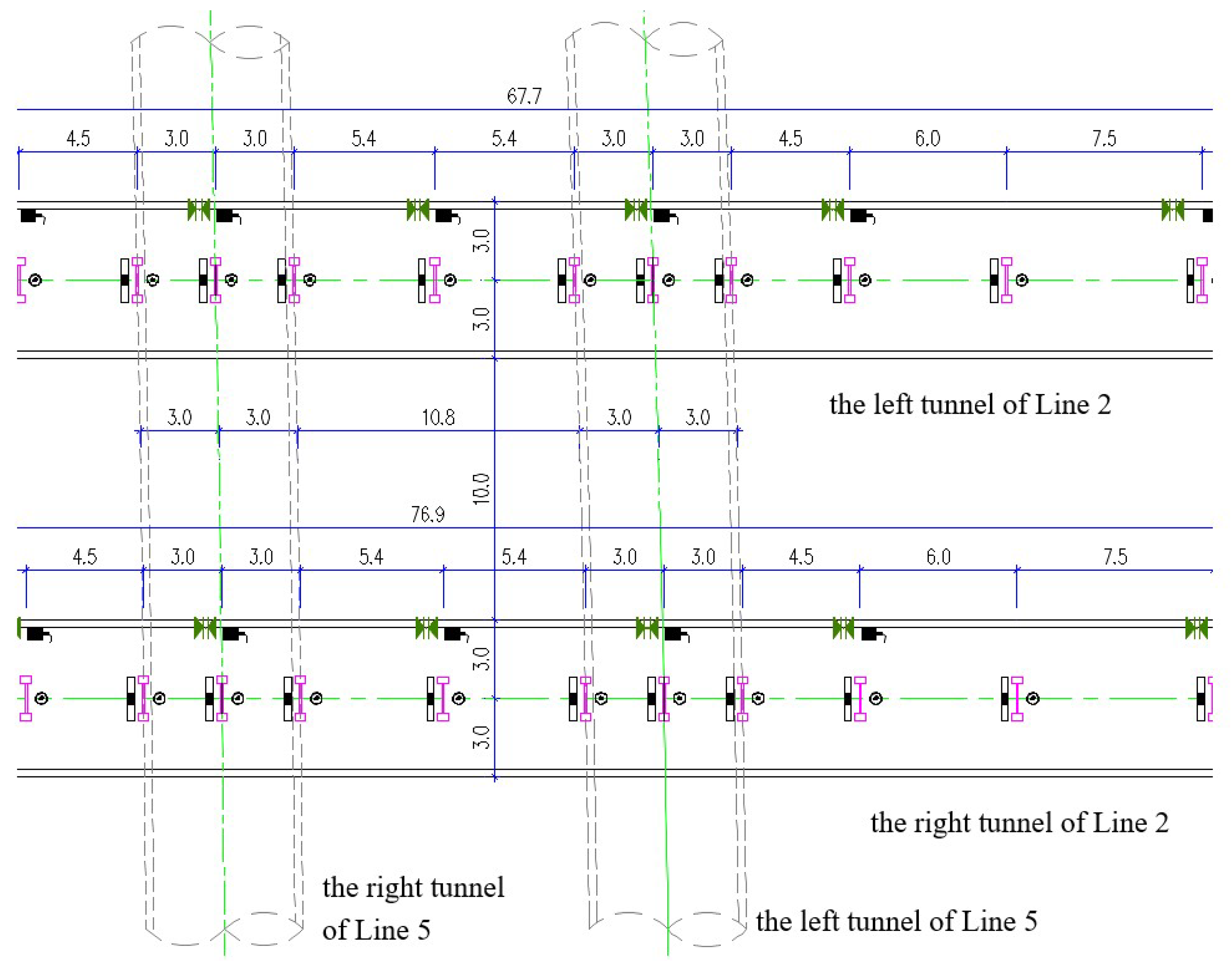

2.1. Project Overview

2.2. Geological Conditions

3. Safety Assessment of the Existing Tunnel

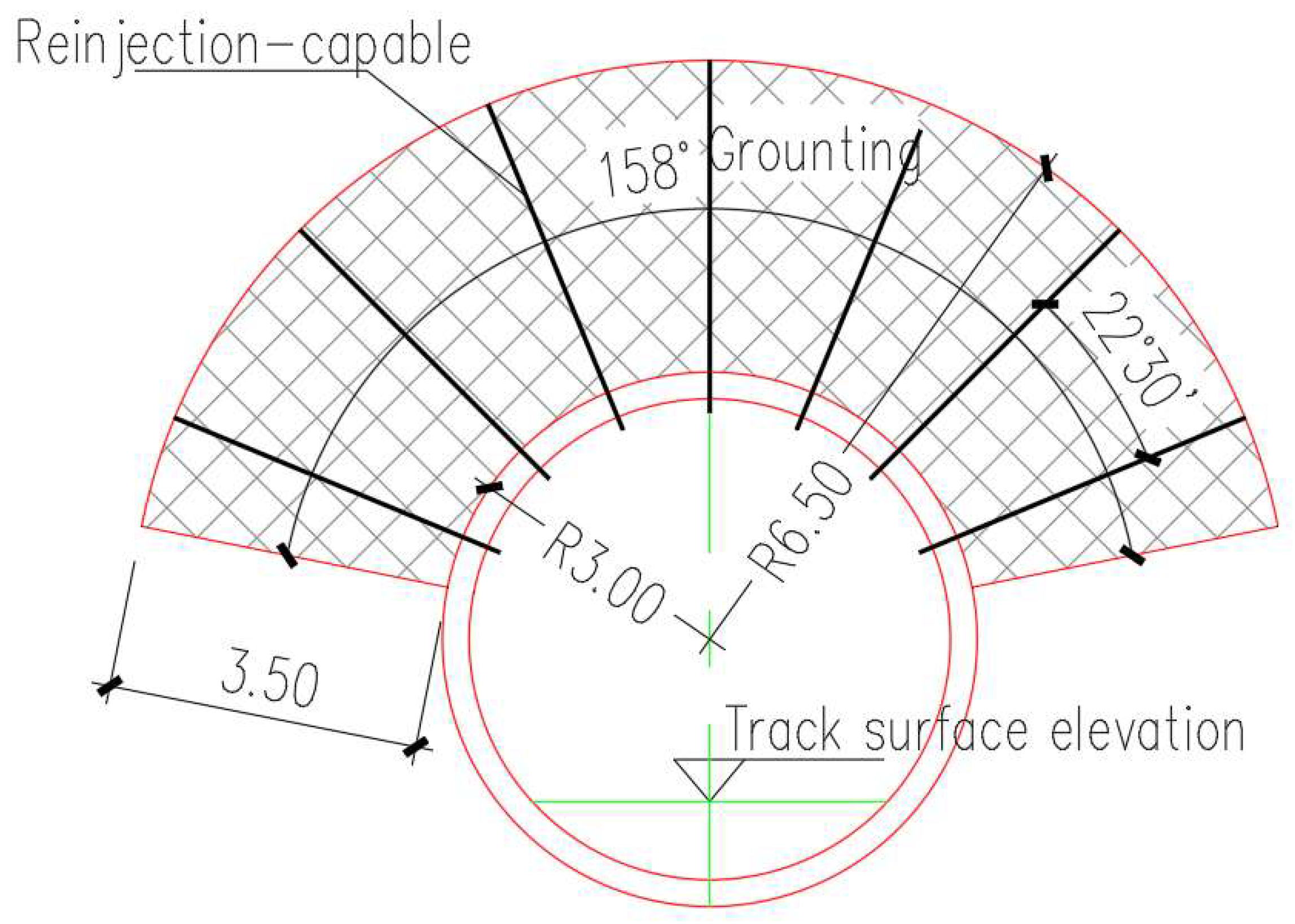

3.1. Reinforcement Methods for the Existing Tunnel

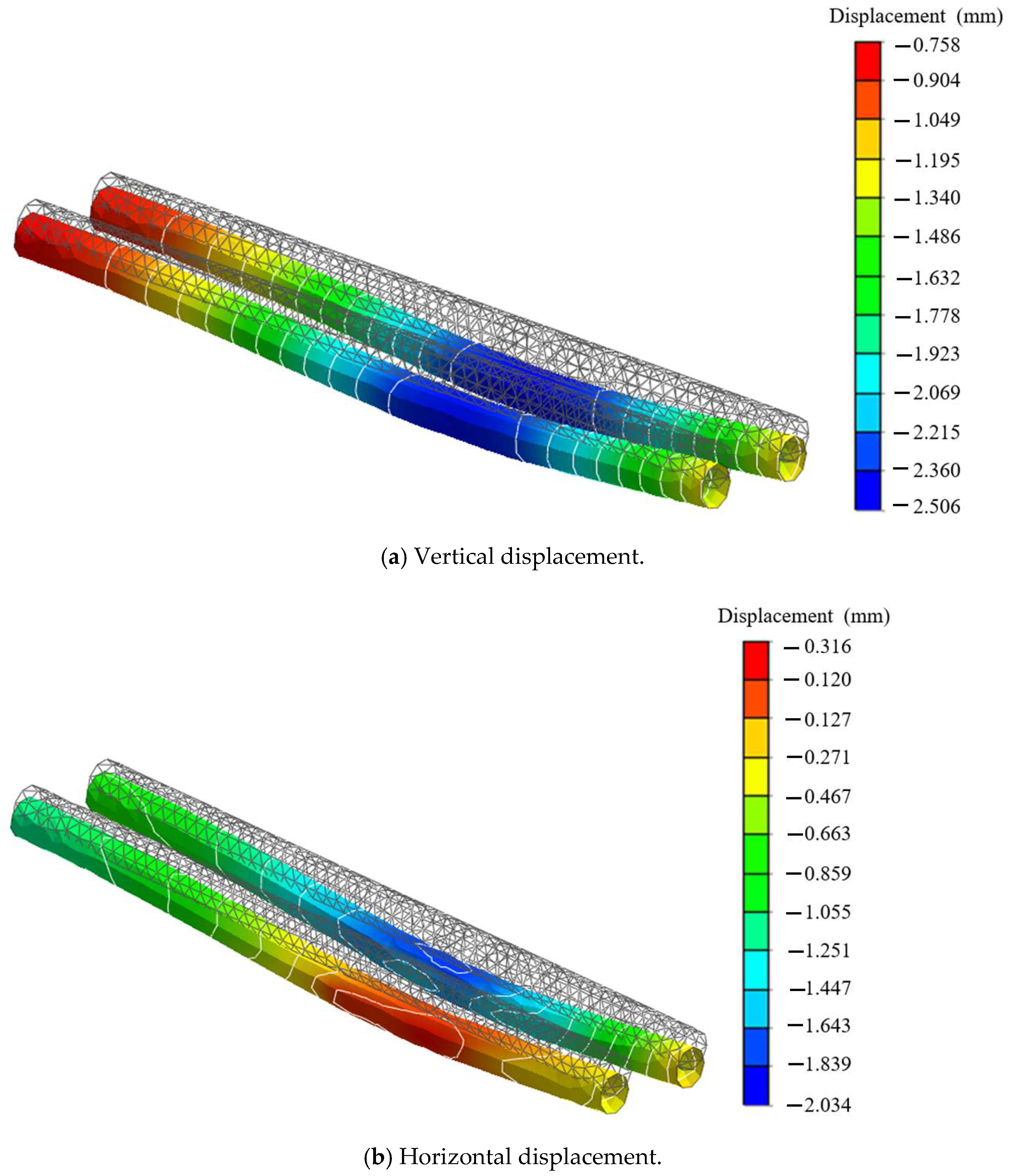

3.2. Deformation Patterns of the Existing Tunnel

4. Shield Posture and Parameter Optimization for the New Tunnel

4.1. Shield Machine Selection

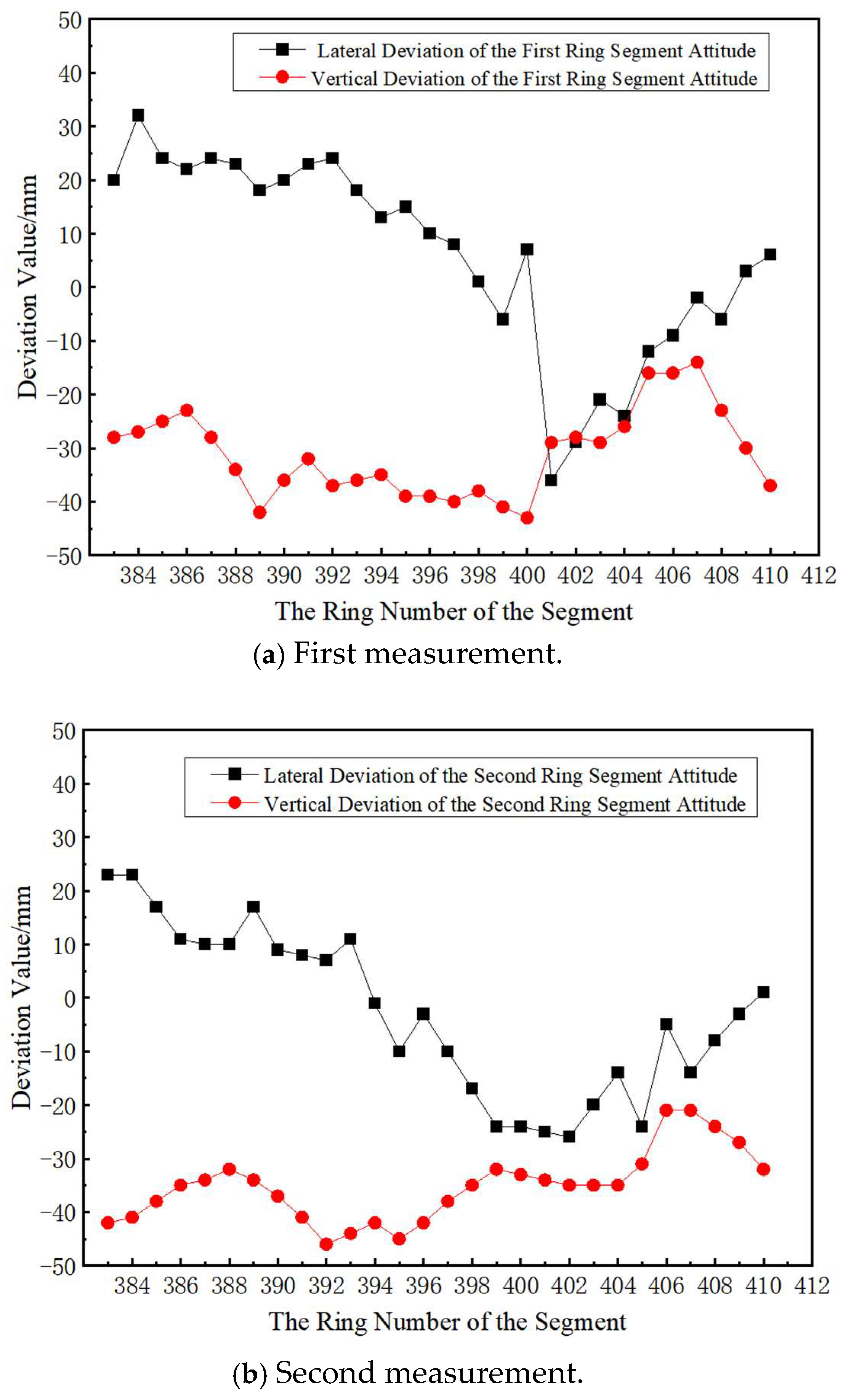

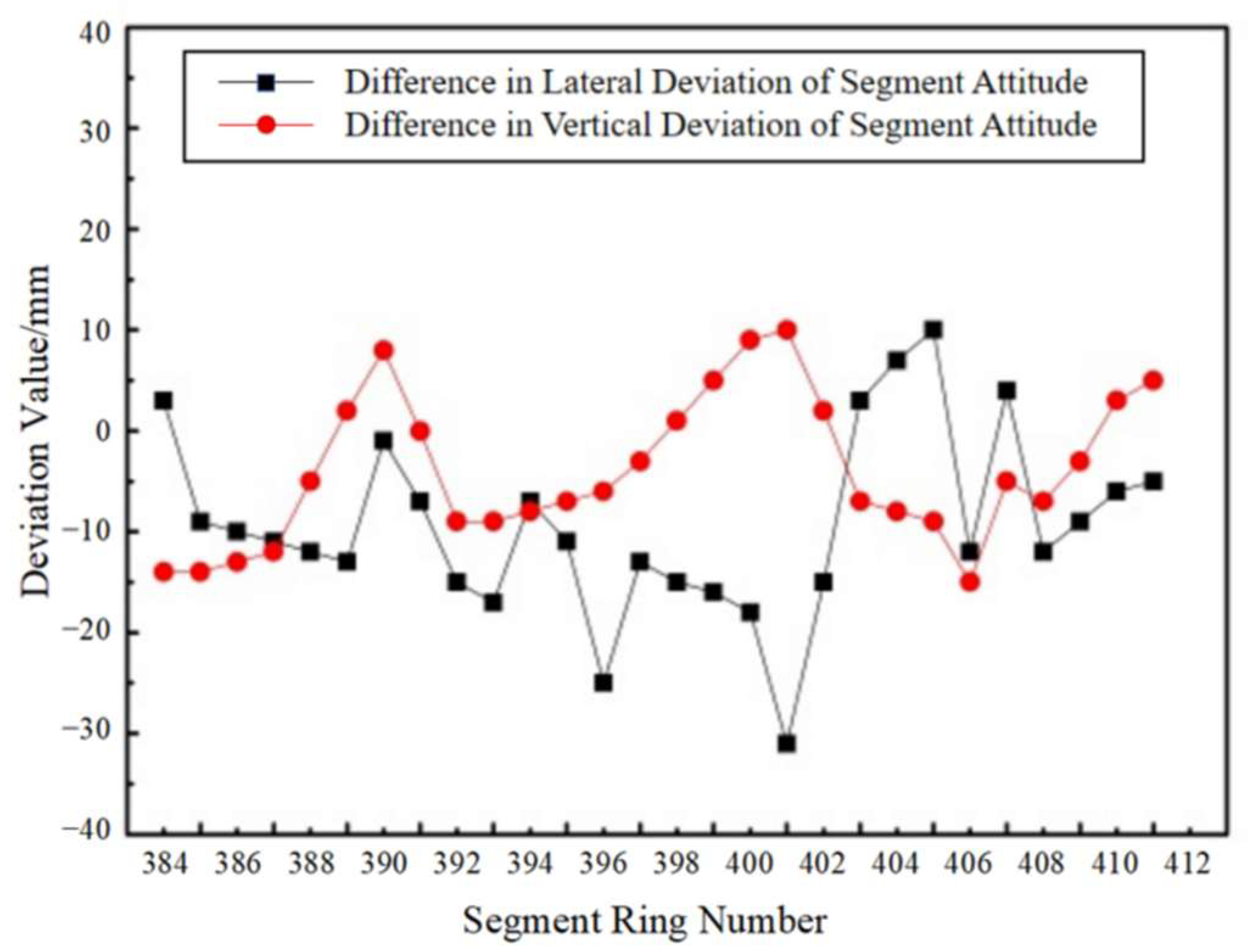

4.2. Characteristics of Shield Posture

4.3. Parameter Optimization

5. Safety Monitoring of the Crossing Section

5.1. Layout of Monitoring Points

5.2. Monitoring Results and Analysis

6. Conclusions

- (1)

- Engineering involving the construction of new tunnels at close proximity beneath existing tunnels poses extremely high safety risks, especially under complex geological conditions characterized by “soft-over-hard” strata, where construction uncertainties are significantly increased. Using refined risk assessment and control measures, major risk sources during the construction process were successfully identified and effectively managed. Comprehensive technical measures, including optimized shield machine selection, improved lining design, interlayer soil reinforcement, the dynamic adjustment of shield parameters, and the precise measurement of shield posture, enhanced the efficiency of shield tunneling and construction safety.

- (2)

- By employing three-dimensional finite element software to model and simulate the construction process of the new tunnel crossing beneath the existing tunnel, the stress and deformation characteristics of the existing tunnel structure under various working conditions were analyzed. The numerical simulation results were validated against on-site monitoring data, clarifying the reinforcement and monitoring scope for both the existing and new tunnels.

- (3)

- Through the analysis of monitoring and measurement data during the shield crossing process, the maximum settlement of the existing tunnel was predicted and controlled. The actual maximum settlement measured was −2.55 mm, and all cumulative deformations were within the monitoring control values, demonstrating that the selected type of shield machine and its tunneling parameters fully met the requirements for shield tunneling construction in complex strata. This study also provides a reference for the settlement and deformation control of similar projects.

7. Future Work

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, K.; Zhang, Z.; Chen, H.; Hu, Z. Experimental investigation on rheological properties and diffusion-related performance of clay shock slurry for excavation gap filling during shield tunnelling. Tunn. Undergr. Space Technol. 2024, 146, 105660. [Google Scholar] [CrossRef]

- Jin, D.; Yuan, D.; Li, X.; Zheng, H. Analysis of the settlement of an existing tunnel induced by shield tunneling underneath. Tunn. Undergr. Space Technol. 2018, 81, 209–220. [Google Scholar] [CrossRef]

- Shan, Y.; Wang, G.; Lin, W.; Zhou, S.; Rackwitz, F. Analytical solution of the evolution of railway subgrade settlement induced by shield tunnelling beneath considering soil stress release. Tunn. Undergr. Space Technol. 2025, 162, 106607. [Google Scholar] [CrossRef]

- Chen, Y.; Lin, H.; Liu, B. Review of Research Progresses and Application of Geothermal Disaster Prevention on Large-Buried Tunnels. Appl. Sci. 2022, 12, 10950. [Google Scholar] [CrossRef]

- Wu, S.; Zhang, X.; Lin, Z.; Wang, J.; Zhang, F.; Gao, H. Influence law and determination method of jack lifting load on existing station settlement. Case Stud. Constr. Mater. 2025, 22, e04180. [Google Scholar] [CrossRef]

- Li, J.; Fang, X.; Yang, Y. Analysis of the Impact of the New Two-Lane Shield Tunnel Underpass on the Existing Tunnels. Appl. Sci. 2025, 15, 2642. [Google Scholar] [CrossRef]

- Huang, W.; Liu, W.; Ou, M.-T.; Zhao, L. Numerical Analysis of Disturbance Control in a Four-Hole Parallel Tunnel Crossing Beneath Existing Tunnels. Geotech. Geol. Eng. 2025, 43, 75. [Google Scholar] [CrossRef]

- Lei, M.-F.; Shi, Y.-B.; Tang, Q.-L.; Sun, N.-X.; Tang, Z.-H.; Gong, C.-J. Construction control technology of a four-hole shield tunnel passing through pile foundations of an existing bridge: A case study. J. Cent. South Univ. 2023, 30, 2360–2373. [Google Scholar] [CrossRef]

- Pang, Y.; Lin, H.; Cao, P.; Meng, G. The Influence of Overlying High-Speed Rail Dynamic Loads on the Stability of Shield Tunnel Faces During Excavation. Appl. Sci. 2025, 15, 2567. [Google Scholar] [CrossRef]

- Zhang, X.; Lin, Y.; Pan, Z.; Jiang, X. Risk assessment of water inrush in deep-buried karst tunnel with rich water based on combined weighting method. Earth Sci. Inform. 2025, 18, 28. [Google Scholar] [CrossRef]

- Ter-Martirosyan, A.Z.; Anzhelo, G.O.; Rud, V.V. The Influence of Metro Tunnel Construction Parameters on the Settlement of Surrounding Buildings. Appl. Sci. 2024, 14, 6435. [Google Scholar] [CrossRef]

- Gan, X.; Yu, J.; Bezuijen, A.; Gong, X.; Wang, C. Tunneling-induced longitudinal responses of existing tunnel with discontinuities in structure stiffness. Transp. Geotech. 2023, 42, 101113. [Google Scholar] [CrossRef]

- Liu, B.; Li, T.; Chang, W.; Han, Y.; Fu, C.; Yu, Z. Mechanical response of horseshoe-shaped tunnel lining to undercrossing construction of a new subway station. Tunn. Undergr. Space Technol. 2022, 128, 104652. [Google Scholar] [CrossRef]

- Guo, P.; Gong, X.; Wang, Y.; Lin, H.; Zhao, Y. Analysis of observed performance of a deep excavation straddled by shallowly buried pressurized pipelines and underneath traversed by planned tunnels. Tunn. Undergr. Space Technol. 2023, 132, 104946. [Google Scholar] [CrossRef]

- Zhang, D.-M.; Xie, X.-C.; Huang, Z.-K.; Peng, M.-Z.; Zhu, H.-X. Observed response of maglev structure undercrossed by three shield tunnels in soft soil. Undergr. Space 2022, 7, 636–661. [Google Scholar] [CrossRef]

- Xun, X.; Zhang, J.; Yuan, Y. Multi-Information Fusion Based on BIM and Intuitionistic Fuzzy D-S Evidence Theory for Safety Risk Assessment of Undersea Tunnel Construction Projects. Buildings 2022, 12, 1802. [Google Scholar] [CrossRef]

- Huang, H.-W.; Gao, T.-R.; Zhang, D.-M.; Jiang, Q.-H.; Jia, J.-W. A hybrid approach for modifying tunneling-induced response in existing multi-tunnel environment. Comput. Geotech. 2025, 179, 106921. [Google Scholar] [CrossRef]

- Yang, W.; Zhang, D.; Wang, A. Field measurement analysis of the influence of simultaneous construction of river channel and bridge on existing double shield tunnels. Undergr. Space 2022, 7, 812–832. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, Z.; Dong, J.; Wang, B.; Wang, C. Study on the Impact of Groundwater and Soil Parameters on Tunnel Deformation and Sensitivity Analysis. Appl. Sci. 2024, 14, 8196. [Google Scholar] [CrossRef]

- Han, Y.; Xu, Q.; Cui, Y. Deformation of Existing Shield Tunnel Adjacent to Deep Excavations: Simulation and Monitoring Analysis. Appl. Sci. 2024, 14, 4153. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, G.; Liu, Q.; Chen, Z.; Wang, Z.; Niu, X. Vehicle-induced dynamic response characteristics of a new subway tunnel closely undercrossing the existing subway. Soil Dyn. Earthq. Eng. 2023, 164, 107579. [Google Scholar] [CrossRef]

- Huang, F.; Wang, Y.; Zhang, M.; Jiang, W.; Ji, H.; Pan, Q. Model test study of punching shear failure mode of the bearing stratum induced by tunneling beneath an existing pile. Tunn. Undergr. Space Technol. 2025, 158, 106459. [Google Scholar] [CrossRef]

- Chen, H.; Liu, J.; Shen, G.Q.; Feng, Z. Control of existing tunnel deformation caused by shield adjacent undercrossing construction using interpretable machine learning and multiobjective optimization. Autom. Constr. 2025, 170, 105943. [Google Scholar] [CrossRef]

- Liu, W.; Chen, Y.; Liu, T.; Liu, W.; Li, J.; Chen, Y. Shield tunneling efficiency and stability enhancement based on interpretable machine learning and multi-objective optimization. Undergr. Space 2025, 22, 320–336. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, W.; Duan, K.; Zuo, J.; Li, M.; Zhang, X.; Huang, X.; Liang, X. Intelligent prediction and optimization of ground settlement induced by shield tunneling construction. Tunn. Undergr. Space Technol. 2025, 160, 106486. [Google Scholar] [CrossRef]

- Chen, H.; Liu, J.; Shen, Q.G.; Li, T.; Liu, Y. Data-driven joint multiobjective prediction and optimization for tunnel-induced adjacent bridge pier displacement: A case study in China. Eng. Appl. Artif. Intell. 2025, 142, 109616. [Google Scholar] [CrossRef]

- Guo, T.; Li, S.; Lu, B.; Wang, Z.; Cao, W.; Liu, S. Research on gradual optimization of slurry mixture ratio for shield tunnel backfill grouting based on fuzzy mathematics. Constr. Build. Mater. 2024, 456, 139319. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, C.; Bian, X. Prediction of maximum ground surface settlement induced by shield tunneling using XGBoost algorithm with golden-sine seagull optimization. Comput. Geotech. 2023, 154, 105156. [Google Scholar] [CrossRef]

- Ma, S.; Zhou, Z.; Duan, Z.; Huang, Z.; He, B.; An, P.; Li, J. Study on the Influence Characteristics of Excavation Face Instability of New Tunnels Orthogonally Crossing Existing Tunnels. Appl. Sci. 2024, 14, 10521. [Google Scholar] [CrossRef]

- Liu, X.; Jiang, A.; Fang, Q.; Wan, Y.; Li, J.; Guo, X. Spatiotemporal Deformation of Existing Pipeline Due to New Shield Tunnelling Parallel Beneath Considering Construction Process. Appl. Sci. 2022, 12, 500. [Google Scholar] [CrossRef]

- Cetindemir, O. Nonlinear Constitutive Soil Models for the Soil-Structure Interaction Modeling Issues with Emphasis on Shallow Tunnels: A Review. Arab. J. Sci. Eng. 2023, 48, 12657–12691. [Google Scholar] [CrossRef]

- Mao, Z.; Ding, T.; Hu, F.; Ye, S.; Ding, L.; Zhang, X.; Li, P.; Li, N. The Impact of Different Excavation Support Structures on the Deformation and Stability of Adjacent Station and Tunnels. Buildings 2025, 15, 493. [Google Scholar] [CrossRef]

- Zheng, F.; Li, W.; Song, Z.; Wang, J.; Zhang, Y.; Liu, N.; Xiao, K.; Wang, Y. Construction Stability Analysis and Field Monitoring of Shallowly Buried Large-Section Tunnels in Loess Strata. Water 2024, 16, 2192. [Google Scholar] [CrossRef]

- Liu, H.; Ma, W.; Kang, M.; Fu, Y.; Yan, T.; Liu, H.; Zhao, B. Study on the Distribution Law of External Water Pressure with Limited Discharge during Shield Construction of Soft Rock Tunnel in Western Henan Province. Appl. Sci. 2024, 14, 5698. [Google Scholar] [CrossRef]

- Robert, D.J. A Modified Mohr-Coulomb Model to Simulate the Behavior of Pipelines in Unsaturated Soils. Comput. Geotech. 2017, 91, 146–160. [Google Scholar] [CrossRef]

- Vicente da Silva, M. Nonlinear Mohr–Coulomb yield criterion: Integration in ADMM-based finite element limit analysis formulation and application to slope stability assessment. Comput. Geotech. 2025, 177, 106897. [Google Scholar] [CrossRef]

| Stratum | Thickness (m) | Density (g/cm3) | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|---|

| Plain Fill Soil | 2 | 1.94 | 16 | 11 |

| Silty Clay | 3 | 2.00 | 25 | 13.5 |

| Silt | 1 | 2.05 | 6 | 17 |

| Fine Sand | 7 | 2.10 | 2 | 20 |

| Gravel | 8 | 2.06 | 0 | 34 |

| Mudstone | 17 | 2.13 | 85 | 17.5 |

| Monitoring Item | Cumulative Control Value | Deformation Rate Control Value |

|---|---|---|

| Vertical Displacement of Tunnel Structure | +3mm, −5mm | ±2 mm per single measurement, settlement rate reaching 1 mm/day |

| Horizontal Displacement of Tunnel Structure | ±4mm | |

| Convergence of Tunnel Structure | ±5mm | |

| Vertical Displacement of Track Bed | +3mm, −5mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ren, B.; Hu, S.; Hu, M.; Chen, Z.; Lin, H. Safety Risk Assessment of Double-Line Tunnel Crossings Beneath Existing Tunnels in Complex Strata. Buildings 2025, 15, 2103. https://doi.org/10.3390/buildings15122103

Ren B, Hu S, Hu M, Chen Z, Lin H. Safety Risk Assessment of Double-Line Tunnel Crossings Beneath Existing Tunnels in Complex Strata. Buildings. 2025; 15(12):2103. https://doi.org/10.3390/buildings15122103

Chicago/Turabian StyleRen, Bafeng, Shengbin Hu, Min Hu, Zhi Chen, and Hang Lin. 2025. "Safety Risk Assessment of Double-Line Tunnel Crossings Beneath Existing Tunnels in Complex Strata" Buildings 15, no. 12: 2103. https://doi.org/10.3390/buildings15122103

APA StyleRen, B., Hu, S., Hu, M., Chen, Z., & Lin, H. (2025). Safety Risk Assessment of Double-Line Tunnel Crossings Beneath Existing Tunnels in Complex Strata. Buildings, 15(12), 2103. https://doi.org/10.3390/buildings15122103