The Research Review on Life Cycle Carbon Emissions in the Operational Process of Modular Buildings

Abstract

1. Introduction

2. Methods

2.1. Search Strategy

- ((“Modular construction” OR “Modular buildings” OR “Prefabricated building” OR “Off-site construction”) AND (“operation phase” OR “building performance” OR “building operation” OR “post-construction”) AND (“life cycle CE” OR “LCA” OR “life cycle” OR “life cycle performance” OR “carbon footprint” OR “carbon reduction” OR “CE” OR “carbon management” OR “sustainability” OR “environmental impact assessment”))

2.2. Eligibility Criteria

- Examination of the CE from the operating stage of modular buildings, energy use, equipment use, and maintenance.

- CE assessments using LCA methods, covering all stages from production, transportation, installation, operation, maintenance to demolition.

- Exploration of carbon reduction measures and management technologies such as energy-saving measures, use of renewable energy, and use of smart building technologies.

- Comprehensive optimization of CE management in modular buildings from social, economic, and ecological perspectives.

- Research unrelated to the operational phase or life cycle management of modular buildings.

- Research that focuses solely on individual factors such as building materials, structures, or equipment (e.g., CE analysis of high-efficiency materials or individual building equipment) without addressing overall CE management.

- Studies on non-modular building types (e.g., traditional or non-modular buildings’ CE).

- Research unrelated to energy management or CE (e.g., studies on building comfort, market analysis, climate change predictions, etc.).

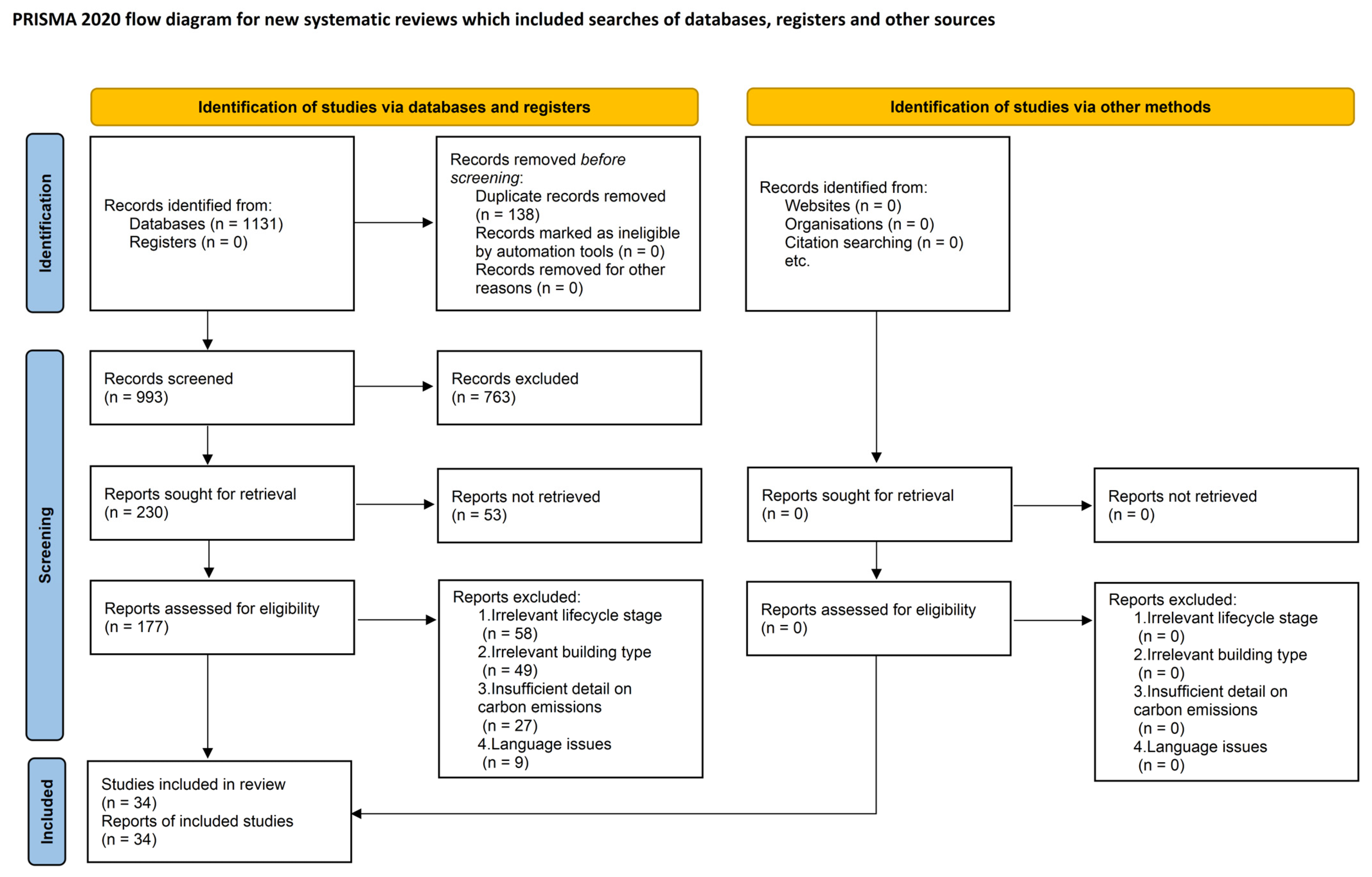

2.3. Selection Process

2.4. Data Items

2.5. Synthesis Methods

- Design and construction phase: Encompasses early design decisions and construction planning.

- Production, transportation, and on-site installation phases: Covers off-site prefabrication, logistics, and modular assembly.

- Operational phase: Includes energy consumption and maintenance during the building’s use.

- Dismantling and disposal phase: Considers the EoL management of modular components, including transportation, waste handling, and disposal.

- Lifecycle phase: Applies to studies addressing the entire life cycle (cradle-to-grave) impacts without isolating specific phases.

2.6. Bias and Certainty Assessment

3. Results

3.1. Study Selection

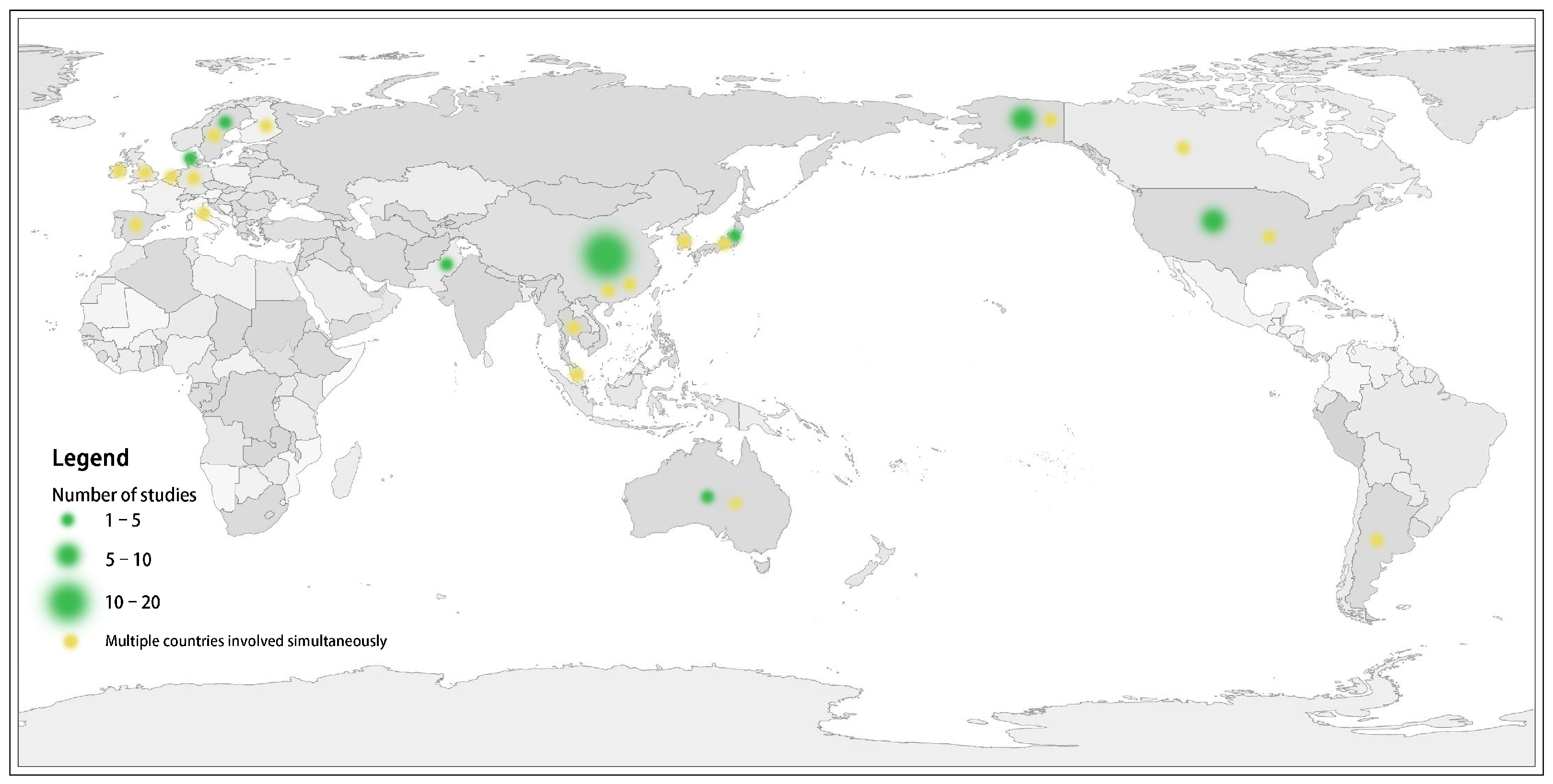

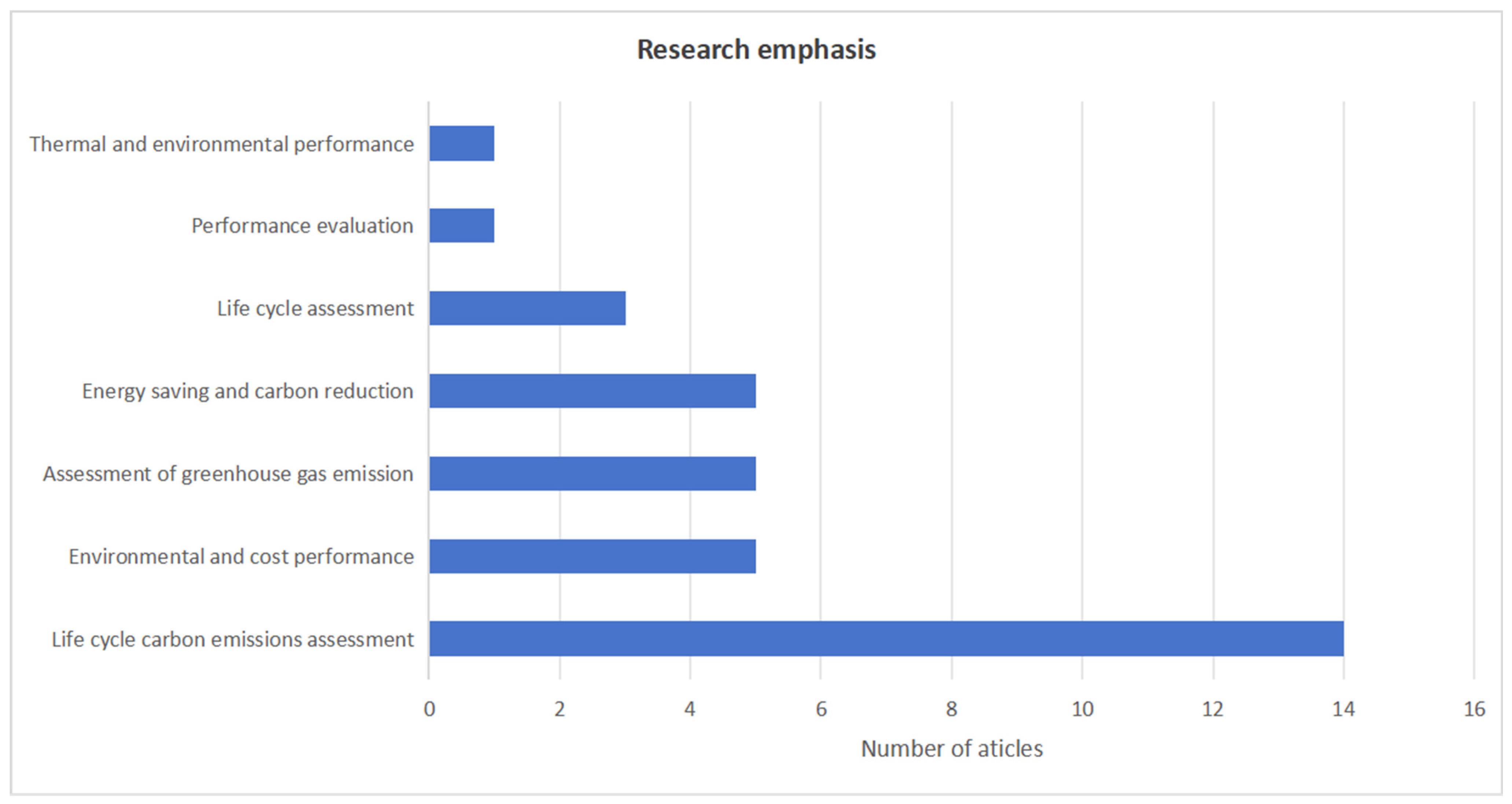

3.2. Study Characteristics

3.3. Risk of Bias in Studies

4. Discussion

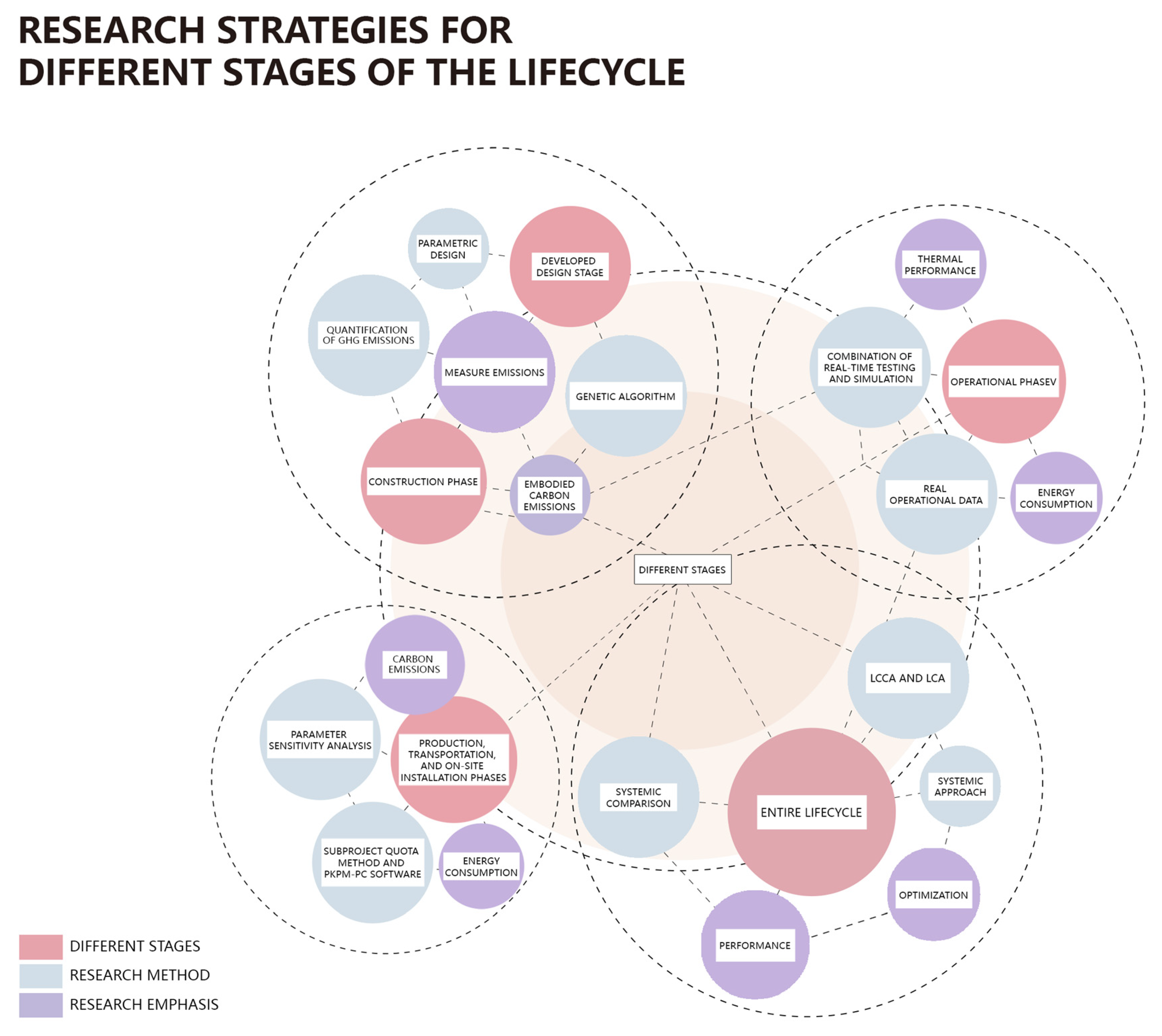

4.1. Research Strategies for Different Stages of the Life Cycle and the Necessity of Individual Studies

4.2. Research Characteristics and Regional Differences at Each Life Cycle Stage

4.2.1. Stage-Specific Characteristics of CE Research

4.2.2. Comparative Analysis of Operational Carbon Efficiency

4.2.3. Regional Differences in Modular Building Carbon Research and Mitigation Strategies

4.3. Deficiencies and Challenges in Research on the Operational Phase

- Data Scarcity and Simulation Uncertainty: Among the 34 studies reviewed, none provided a comprehensive longitudinal analysis involving continuous, multi-year measurement of actual operational energy performance. Instead, most research relied on simulation approaches using software tools like EnergyPlus, eQUEST, or BIM-integrated LCA platforms. Only a limited number of studies, such as Hou et al., have combined simulations with short-term empirical data, including thermal monitoring and blower-door testing [54]. This reliance on simulated or assumed data underscores the shortage of long-term empirical evidence, especially in regions with variable climates, resulting in considerable uncertainties in operational energy predictions. The scarcity of comprehensive operational data is not merely due to practical constraints—such as data accessibility and the high costs associated with extended monitoring—but also reflects a historical research orientation that has inadequately addressed long-term operational performance in modular construction.

- Complexity and Variability of Operational Phase: The operational stage involves complexities beyond simple energy consumption, including equipment maintenance, operational efficiency, and overall system performance. These aspects depend heavily on external factors such as climate variability and occupant behavior, complicating accurate prediction and measurement. Additionally, privacy concerns further limit access to operational performance data, creating barriers to effectively assessing and managing CEs. Consequently, despite energy efficiency measures implemented during the design and construction stages, controlling operational-phase emissions remains challenging without standardized processes and robust management practices.

- Lack of Comparisons with Traditional Buildings: Although modular construction is widely recognized for its lower CEs during the construction phase, comprehensive comparative analyses of operational carbon performance against traditional buildings remain limited. Such comparisons are essential, especially regarding long-term energy efficiency, maintenance demands, and other operational characteristics. The current shortage of comparative studies restricts the scope and depth of LCA involving modular buildings.

- Technological Limitations and Development Potential: Modular construction and building design have evolved considerably, but optimization solutions for the operating stage have been underdeveloped, notably in the areas of energy management, optimization of the equipment, and sustainable use. Technological limitation also constrains the scale of associated research.

- Energy Efficiency and Renewable Energy Challenges: Reducing CEs through energy efficiency measures and the use of renewable energy is the primary approach at the operating stage of modular buildings. Yet, numerous modular buildings continue to encounter technical and financial impediments at the early design stage. Consequently, even when the structure incorporates energy-efficient insulation mechanisms for energy savings, the actual benefit of these measures largely hinges upon their implementation at the construction stage and the operating stage.

- Insufficient Policy Frameworks: Reducing carbon in the operational phase also needs extensive policy support and industry standards, which are currently lacking in most countries and regions. The absence of these frameworks slows the advancement of research and implementation in this field.

4.4. Future Research Direction

- Enhance Empirical Research and LCA Model Precision: Current studies largely depend on simulations rather than measured empirical data, introducing uncertainties into operational CE assessments. Future research should prioritize long-term, real-world monitoring of modular buildings under varied climatic conditions to validate and refine LCA models. Employing hybrid LCA methodologies—combining process-based and input–output analyses—is also recommended. Such integrated approaches capture direct and indirect emissions more effectively, especially across complex modular supply chains.

- Develop Multidimensional Assessment Frameworks: Besides conventional LCA modeling, adopting multidimensional assessment frameworks would enable a more comprehensive evaluation of the various factors influencing CEs across modular buildings’ life cycle. For example, Xu et al. proposed a sustainable benchmarking framework integrating topic mining and knowledge graph technologies [90]. This approach systematically identifies emission sources throughout the design, construction, and operation phases, supporting multi-level CE indexing and targeted energy optimization at each life cycle stage. Additionally, Liu and Zhou introduced an extended input–output framework emphasizing supply-demand interactions [91]. Their approach analyzes CE transfer effects along modular construction industry chains, including transportation and material supply sectors, thereby facilitating more precise emission assessments across interconnected industries.

- Enhance Operational Performance through Intelligent Technologies: Emerging intelligent building management technologies provide promising solutions for carbon management in modular buildings. For instance, Chen et al. applied Visual Question Answering (VQA) combined with deep learning algorithms, integrating image recognition and data analytics to improve energy efficiency management [92]. Leveraging AI technology during the operation phase can enable real-time energy consumption monitoring and dynamic adjustments of building systems, thus optimizing energy utilization patterns. Similarly, Liu and Zhou proposed energy efficiency optimization methods originally developed for transportation, providing valuable foundational insights for modular construction applications [91]. Additionally, advanced deep learning models, such as graph neural networks, have demonstrated significant potential for enhancing energy efficiency. Integrating such intelligent systems with optimized lighting and high-performance HVAC technologies could further ensure optimal energy use and carbon mitigation during modular buildings’ operational phase.

- Embed low-carbon Design Thinking at Early Stages: Integrating low-carbon design strategies from the early design stage is crucial. Gong et al. suggest adopting methodologies such as Quality Function Deployment (QFD) to align customer demands with low-carbon objectives throughout the modular building design [93]. This approach ensures user needs and environmental goals are comprehensively addressed. Moreover, the deep integration of high-performance building envelopes and passive design strategies within prefabrication systems can significantly enhance life cycle energy efficiency, effectively minimizing CEs from initial planning to operational phases.

- Advance Material and Technological Innovation: Advancing material innovation and technological integration is essential to unlock the carbon reduction potential of modular construction. Zhao et al. emphasize that incorporating green design concepts and energy-efficient technologies within modular structures significantly reduces life cycle energy consumption [94]. Bio-based materials, such as cross-laminated timber (CLT), substantially lower embodied carbon [95], while recycled steel and concrete composites enhance resource circularity [96]. In addition, innovative insulation solutions and phase-change materials can effectively improve buildings’ thermal performance [97]. Technologically, 3D printing, automated module fabrication, and digital twin technologies offer precise control, reduced waste, and enhanced carbon efficiency [98]. Future research should further explore synergies among advanced materials, modular system optimization, and emerging low-carbon technologies to maximize environmental performance throughout the building life cycle.

- Promote Policy–Technology Synergies and Industry Capacity-building: Furthermore, the study should also strengthen the synergy between policy and technology, promote government reforms in policy incentives, green building certification, and industry standards, improve the technical standards and guidelines for modular building design, and promote the establishment of related training systems to enhance the acceptance and application of the technology in the industry [99]. This will better support the low-carbon transformation of modular building technology in the operation phase. In terms of policy incentives, Smart City Pilot Policies (SCPP), as a policy tool to promote low-carbon development, plays an important role in managing CEs from modular buildings. Aiting Xu et al. demonstrated that SCPP can effectively reduce CEs from industrial enterprises by strengthening environmental regulation and promoting green technology innovation. In a similar vein, modular buildings, as integral components of smart cities, can facilitate the implementation of green building technologies and curtail CE contingent on policy interventions [100]. A carbon efficiency trap was found by Tong Li et al. in the research of CEs from 5G networks, which could also be observed during the operational phase of modular buildings [101]. Additionally, Li et al. identify a carbon-efficiency trap in energy-intensive technologies, analogous to issues potentially emerging in modular building operations when energy demands are mismatched. Implementing deep reinforcement learning and advanced energy management systems, such as the DeepEnergy approach [102], represents a viable strategy to overcome such inefficiencies and optimize energy performance.

- Foster Cross-Industry Collaboration for Systemic Decarbonization: Regarding the cross-industry synergy, the importance of such collaborative efforts in the reduction of CEs was emphasized by Xiao Liu and Xiaoyong Zhou, particularly in conjunction with industries such as building material suppliers and transportation companies [91]. Furthermore, a reduction in CEs during the production, transportation, and construction phases of modular buildings can be realized based on the collaboration with suppliers of low-carbon materials and green transportation companies. For instance, the selection of building materials with minimal CEs, alongside the utilization of low-carbon transportation methods, can contribute to the mitigation of the carbon footprint of buildings from the beginning. As mentioned in the framework proposed by Xiaofeng Xu et al., the implementation of a cross-industry collaboration demonstrates promising potential in the optimization of the management of CEs within various industries [90]. Additionally, this framework contributes to the promotion of a comprehensive assessment and collaborative management based on multi-dimensional data and indicators. Moreover, the low-carbon progress of the modular buildings and the green transformation of the building industry chains would be further accelerated by this cross-industry collaboration.

- Leverage EoL Potential and Circularity: Although this study primarily addresses operational emissions, the EoL stage represents a critical yet underexplored opportunity in modular construction. Off-site manufactured modules inherently facilitate disassembly, reuse, and recycling, presenting substantial potential to reduce embodied carbon and minimize waste. Future modular designs should systematically incorporate design-for-disassembly (DfD) principles to allow structural components to be easily separated, reused, or recycled without significant deterioration. Additionally, circular economy strategies such as material passports and standardization of modular elements can further enable closed-loop material circulation. While these circular approaches have gained traction in European modular timber systems [56,80], their application in Asian contexts remains limited. Hence, future research should prioritize EoL modeling and implement comprehensive material tracking systems post-occupancy, supporting the development of climate-resilient and resource-efficient modular buildings globally.

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Maximillian, J.; Brusseau, M.L.; Glenn, E.P.; Matthias, A.D. Chapter 25—Pollution and Environmental Perturbations in the Global System. In Environmental and Pollution Science; Elsevier: Amsterdam, The Netherlands, 2019; pp. 457–476. ISBN 978-0-12-814719-1. [Google Scholar]

- Mora, C.; Spirandelli, D.; Franklin, E.C.; Lynham, J.; Kantar, M.B.; Miles, W.; Smith, C.Z.; Freel, K.; Moy, J.; Louis, L.V.; et al. Broad Threat to Humanity from Cumulative Climate Hazards Intensified by Greenhouse Gas Emissions. Nat. Clim. Chang. 2018, 8, 1062–1071. [Google Scholar] [CrossRef]

- Yang, M.; Chen, L.; Msigwa, G.; Tang, K.H.D.; Yap, P.-S. Implications of COVID-19 on Global Environmental Pollution and Carbon Emissions with Strategies for Sustainability in the COVID-19 Era. Sci. Total Environ. 2022, 809, 151657. [Google Scholar] [CrossRef] [PubMed]

- Zhao, X.; Shang, Y.; Song, M. Industrial Structure Distortion and Urban Ecological Efficiency from the Perspective of Green Entrepreneurial Ecosystems. Socio-Econ. Plan. Sci. 2020, 72, 100757. [Google Scholar] [CrossRef]

- Chu, Z.; Cheng, M.; Yu, N.N. A Smart City Is a Less Polluted City. Technol. Forecast. Social Chang. 2021, 172, 121037. [Google Scholar] [CrossRef]

- Li, X.; Damartzis, T.; Stadler, Z.; Moret, S.; Meier, B.; Friedl, M.; Maréchal, F. Decarbonization in Complex Energy Systems: A Study on the Feasibility of Carbon Neutrality for Switzerland in 2050. Front. Energy Res. 2020, 8, 549615. [Google Scholar] [CrossRef]

- Salvia, M.; Reckien, D.; Pietrapertosa, F.; Eckersley, P.; Spyridaki, N.-A.; Krook-Riekkola, A.; Olazabal, M.; De Gregorio Hurtado, S.; Simoes, S.G.; Geneletti, D.; et al. Will Climate Mitigation Ambitions Lead to Carbon Neutrality? An Analysis of the Local-Level Plans of 327 Cities in the EU. Renew. Sustain. Energy Rev. 2021, 135, 110253. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P.; Roser, M. CO2 and Greenhouse Gas Emissions. Our World Data 2023. Available online: https://ourworldindata.org/co2-and-greenhouse-gas-emissions (accessed on 5 June 2025).

- Zhang, J.T.; Zhang, L. Preliminary discussion on the development of carbon capture, utilization and storage towards the goal of carbon neutralization. Therm. Power Gener. 2021, 50, 1–6. [Google Scholar] [CrossRef]

- Röck, M.; Saade, M.R.M.; Balouktsi, M.; Rasmussen, F.N.; Birgisdottir, H.; Frischknecht, R.; Habert, G.; Lützkendorf, T.; Passer, A. Embodied GHG Emissions of Buildings—The Hidden Challenge for Effective Climate Change Mitigation. Appl. Energy 2020, 258, 114107. [Google Scholar] [CrossRef]

- GBPN. Bindu 2019 Global Status Report for Buildings and Construction; GBPN: Paris, France, 2019. [Google Scholar]

- China Association of Building Energy Efficiency; Institute of Urban and Rural Development, Chongqing University. China Urban and Rural Construction Sector Carbon Emission Research Report (2024 Edition); China Association of Building Energy Efficiency: Chongqing, China, 2024. [Google Scholar]

- Chen, X.; Shuai, C.; Wu, Y.; Zhang, Y. Analysis on the Carbon Emission Peaks of China’s Industrial, Building, Transport, and Agricultural Sectors. Sci. Total Environ. 2020, 709, 135768. [Google Scholar] [CrossRef]

- Hu, F.; Zheng, X. Carbon Emission of Energy Efficient Residential Building. Procedia Eng. 2015, 121, 1096–1102. [Google Scholar] [CrossRef]

- Kumanayake, R.; Luo, H. Life Cycle Carbon Emission Assessment of a Multi-Purpose University Building: A Case Study of Sri Lanka. Front. Eng. 2018, 5, 381–393. [Google Scholar] [CrossRef]

- Lu, K.; Jiang, X.; Tam, V.W.Y.; Li, M.; Wang, H.; Xia, B.; Chen, Q. Development of a Carbon Emissions Analysis Framework Using Building Information Modeling and Life Cycle Assessment for the Construction of Hospital Projects. Sustainability 2019, 11, 6274. [Google Scholar] [CrossRef]

- Yang, X.; Zhang, S.; Wang, K. Quantitative Study of Life Cycle Carbon Emissions from 7 Timber Buildings in China. Int. J. Life Cycle Assess. 2021, 26, 1721–1734. [Google Scholar] [CrossRef]

- Guo, H.; Liu, Y.; Chang, W.-S.; Shao, Y.; Sun, C. Energy Saving and Carbon Reduction in the Operation Stage of Cross Laminated Timber Residential Buildings in China. Sustainability 2017, 9, 292. [Google Scholar] [CrossRef]

- Li, D.; Cui, P.; Lu, Y. Development of an Automated Estimator of Life-Cycle Carbon Emissions for Residential Buildings: A Case Study in Nanjing, China. Habitat. Int. 2016, 57, 154–163. [Google Scholar] [CrossRef]

- Ma, J.-J.; Du, G.; Zhang, Z.-K.; Wang, P.-X.; Xie, B.-C. Life Cycle Analysis of Energy Consumption and CO2 Emissions from a Typical Large Office Building in Tianjin, China. Build. Environ. 2017, 117, 36–48. [Google Scholar] [CrossRef]

- Mago, P.J.; Hueffed, A.K. Evaluation of a Turbine Driven CCHP System for Large Office Buildings under Different Operating Strategies. Energy Build. 2010, 42, 1628–1636. [Google Scholar] [CrossRef]

- Mousa, M.; Luo, X.; McCabe, B. Utilizing BIM and Carbon Estimating Methods for Meaningful Data Representation. Procedia Eng. 2016, 145, 1242–1249. [Google Scholar] [CrossRef]

- Zhang, D.; Evangelisti, S.; Lettieri, P.; Papageorgiou, L.G. Economic and Environmental Scheduling of Smart Homes with Microgrid: DER Operation and Electrical Tasks. Energy Convers. Manag. 2016, 110, 113–124. [Google Scholar] [CrossRef]

- Atmaca, A.; Atmaca, N. Life Cycle Energy (LCEA) and Carbon Dioxide Emissions (LCCO2A) Assessment of Two Residential Buildings in Gaziantep, Turkey. Energy Build. 2015, 102, 417–431. [Google Scholar] [CrossRef]

- Gustavsson, L.; Joelsson, A.; Sathre, R. Life Cycle Primary Energy Use and Carbon Emission of an Eight-Storey Wood-Framed Apartment Building. Energy Build. 2010, 42, 230–242. [Google Scholar] [CrossRef]

- Huang, L.; Liu, Y.; Krigsvoll, G.; Johansen, F. Life Cycle Assessment and Life Cycle Cost of University Dormitories in the Southeast China: Case Study of the University Town of Fuzhou. J. Clean. Prod. 2018, 173, 151–159. [Google Scholar] [CrossRef]

- Rosselló-Batle, B.; Moià, A.; Cladera, A.; Martínez, V. Energy Use, CO2 Emissions and Waste throughout the Life Cycle of a Sample of Hotels in the Balearic Islands. Energy Build. 2010, 42, 547–558. [Google Scholar] [CrossRef]

- Tumminia, G.; Guarino, F.; Longo, S.; Ferraro, M.; Cellura, M.; Antonucci, V. Life Cycle Energy Performances and Environmental Impacts of a Prefabricated Building Module. Renew. Sustain. Energy Rev. 2018, 92, 272–283. [Google Scholar] [CrossRef]

- Boyd, N.; Khalfan, M.M.A.; Maqsood, T. Off-site construction of apartment buildings. J. Archit. Eng. 2013, 19, 51–57. [Google Scholar] [CrossRef]

- Badir, Y.F.; Kadir, M.R.A.; Hashim, A.H. Industrialized Building Systems Construction in Malaysia. J. Archit. Eng. 2002, 8, 19–23. [Google Scholar] [CrossRef]

- Kasperzyk, C.; Kim, M.-K.; Brilakis, I. Automated Re-Prefabrication System for Buildings Using Robotics. Autom. Constr. 2017, 83, 184–195. [Google Scholar] [CrossRef]

- Rogan, A.L.; Lawson, R.M.; Bates-Brkljac, N. Rogan: Value and Benefits Assessment of Modular Construction. Available online: https://scholar.google.com/scholar_lookup?title=Value%20and%20benefits%20assessment%20of%20modular%20construction&author=A.L.%20Rogan&publication_year=2000 (accessed on 18 January 2025).

- Annan, C.D.; Youssef, M.A.; El-Naggar, M.H. Effect of Directly Welded Stringer-To-Beam Connections on the Analysis and Design of Modular Steel Building Floors. Adv. Struct. Eng. 2009, 12, 373–383. [Google Scholar] [CrossRef]

- Lacey, A.W.; Chen, W.; Hao, H.; Bi, K. Structural Response of Modular Buildings—An Overview. J. Build. Eng. 2018, 16, 45–56. [Google Scholar] [CrossRef]

- Steinhardt, D.A.; Manley, K. Adoption of Prefabricated Housing–the Role of Country Context. Sustain. Cities Soc. 2016, 22, 126–135. [Google Scholar] [CrossRef]

- Li, H.X.; Al-Hussein, M.; Lei, Z.; Ajweh, Z. Risk Identification and Assessment of Modular Construction Utilizing Fuzzy Analytic Hierarchy Process (AHP) and Simulation. Can. J. Civ. Eng. 2013, 40, 1184–1195. [Google Scholar] [CrossRef]

- Kildsgaard, I.; Jarnehammar, A.; Widheden, A.; Wall, M. Energy and Environmental Performance of Multi-Story Apartment Buildings Built in Timber Construction Using Passive House Principles. Buildings 2013, 3, 258–277. [Google Scholar] [CrossRef]

- Srisangeerthanan, S.; Hashemi, M.J.; Rajeev, P.; Gad, E.; Fernando, S. Numerical Study on the Effects of Diaphragm Stiffness and Strength on the Seismic Response of Multi-Story Modular Buildings. Eng. Struct. 2018, 163, 25–37. [Google Scholar] [CrossRef]

- Lawson, M.; Ogden, R.; Goodier, C. Lawson: Design in Modular Construction; CRC Press: Boca Raton, FL, USA, 2014; ISBN 978-0-203-87078-5. [Google Scholar]

- Arif, M.; Egbu, C. Making a Case for Offsite Construction in China. Eng. Constr. Archit. Manag. 2010, 17, 536–548. [Google Scholar] [CrossRef]

- Pons, O. 18—Assessing the Sustainability of Prefabricated Buildings. In Eco-Efficient Construction and Building Materials; Pacheco-Torgal, F., Cabeza, L.F., Labrincha, J., de Magalhães, A., Eds.; Woodhead Publishing: Cambridge, UK, 2014; pp. 434–456. ISBN 978-0-85709-767-5. [Google Scholar]

- Li, Y.; Zhang, X. Web-Based Construction Waste Estimation System for Building Construction Projects. Autom. Constr. 2013, 35, 142–156. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Gao, X.F.; Tam, C.M.; Chan, C.H. New Approach in Measuring Water Absorption of Recycled Aggregates. Constr. Build. Mater. 2008, 22, 364–369. [Google Scholar] [CrossRef]

- Jaillon, L.; Poon, C.S.; Chiang, Y.H. Quantifying the Waste Reduction Potential of Using Prefabrication in Building Construction in Hong Kong. Waste Manag. 2009, 29, 309–320. [Google Scholar] [CrossRef]

- Lawson, R.M.; Ogden, R.G.; Bergin, R. Application of Modular Construction in High-Rise Buildings. J. Archit. Eng. 2012, 18, 148–154. [Google Scholar] [CrossRef]

- Kamali, M.; Hewage, K. Life Cycle Performance of Modular Buildings: A Critical Review. Renew. Sustain. Energy Rev. 2016, 62, 1171–1183. [Google Scholar] [CrossRef]

- Ahn, Y.H.; Kim, K.-T. Sustainability in Modular Design and Construction: A Case Study of ‘The Stack. ’ Int. J. Sustain. Build. Technol. Urban. Dev. 2014, 5, 250–259. [Google Scholar] [CrossRef]

- Nahmens, I.; Ikuma, L.H. Effects of Lean Construction on Sustainability of Modular Homebuilding. J. Archit. Eng. 2012, 18, 155–163. [Google Scholar] [CrossRef]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; The PRISMA Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement an Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Lu, M.; Lai, J. Review on Carbon Emissions of Commercial Buildings. Renew. Sustain. Energy Rev. 2020, 119, 109545. [Google Scholar] [CrossRef]

- Sartori, I.; Hestnes, A.G. Energy Use in the Life Cycle of Conventional and Low-Energy Buildings: A Review Article. Energy Build. 2007, 39, 249–257. [Google Scholar] [CrossRef]

- Hong, J.; Shen, G.Q.; Feng, Y.; Lau, W.S.; Mao, C. Greenhouse Gas Emissions during the Construction Phase of a Building: A Case Study in China. J. Clean. Prod. 2015, 103, 249–259. [Google Scholar] [CrossRef]

- Hou, M.; Lin, Y.; Wang, Q.; He, X.; Zheng, Y.; Shen, P. Operational Energy Saving and Carbon Reduction Benefits of Concrete MiC Building’s Envelope. In Novel Technology and Whole-Process Management in Prefabricated Building; Xiang, P., Zuo, L., Eds.; Springer: Singapore, 2024. [Google Scholar]

- Sharma, A.; Saxena, A.; Sethi, M.; Shree, V. Varun Life Cycle Assessment of Buildings: A Review. Renew. Sustain. Energy Rev. 2011, 15, 871–875. [Google Scholar] [CrossRef]

- Tavares, V.; Gregory, J.; Kirchain, R.; Freire, F. What Is the Potential for Prefabricated Buildings to Decrease Costs and Contribute to Meeting EU Environmental Targets? Build. Environ. 2021, 206, 108382. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, Y.; Gao, W.; Kuroki, S. Life Cycle Environmental and Cost Performance of Prefabricated Buildings. Sustainability 2020, 12, 2609. [Google Scholar] [CrossRef]

- Zhu, H.; Hong, J.; Shen, G.Q.; Mao, C.; Zhang, H.; Li, Z. The Exploration of the Life-Cycle Energy Saving Potential for Using Prefabrication in Residential Buildings in China. Energy Build. 2018, 166, 561–570. [Google Scholar] [CrossRef]

- Ji, Y.; Li, K.; Liu, G.; Shrestha, A.; Jing, J. Comparing Greenhouse Gas Emissions of Precast In-Situ and Conventional Construction Methods. J. Clean. Prod. 2018, 173, 124–134. [Google Scholar] [CrossRef]

- Faludi, J.; Lepech, M.D.; Loisos, G. Using Life Cycle Assessment Methods to Guide Architectural Decision-Making for Sustainable Prefabricated Modular Buildings. J. Green. Build. 2012, 7, 151–170. [Google Scholar] [CrossRef]

- Li, X.; Xie, W.; Xu, L.; Li, L.; Jim, C.Y.; Wei, T. Holistic Life-Cycle Accounting of Carbon Emissions of Prefabricated Buildings Using LCA and BIM. Energy Build. 2022, 266, 112136. [Google Scholar] [CrossRef]

- Teng, Y.; Li, K.; Pan, W.; Ng, T. Reducing Building Life Cycle Carbon Emissions through Prefabrication: Evidence from and Gaps in Empirical Studies. Build. Environ. 2018, 132, 125–136. [Google Scholar] [CrossRef]

- Vasishta, T.; Hashem Mehany, M.; Killingsworth, J. Comparative Life Cycle Assesment (LCA) and Life Cycle Cost Analysis (LCCA) of Precast and Cast–in–Place Buildings in United States. J. Build. Eng. 2023, 67, 105921. [Google Scholar] [CrossRef]

- Aye, L.; Ngo, T.; Crawford, R.H.; Gammampila, R.; Mendis, P. Life Cycle Greenhouse Gas Emissions and Energy Analysis of Prefabricated Reusable Building Modules. Energy Build. 2012, 47, 159–168. [Google Scholar] [CrossRef]

- Mao, C.; Shen, Q.; Shen, L.; Tang, L. Comparative Study of Greenhouse Gas Emissions between Off-Site Prefabrication and Conventional Construction Methods: Two Case Studies of Residential Projects. Energy Build. 2013, 66, 165–176. [Google Scholar] [CrossRef]

- Samani, P.; Gregory, J.; Leal, V.; Mendes, A.; Correia, N. Lifecycle Cost Analysis of Prefabricated Composite and Masonry Buildings: Comparative Study. J. Archit. Eng. 2018, 24, 05017012. [Google Scholar] [CrossRef]

- Ferdous, W.; Bai, Y.; Ngo, T.D.; Manalo, A.; Mendis, P. New Advancements, Challenges and Opportunities of Multi-Storey Modular Buildings—A State-of-the-Art Review. Eng. Struct. 2019, 183, 883–893. [Google Scholar] [CrossRef]

- Du, Q.; Bao, T.; Li, Y.; Huang, Y.; Shao, L. Impact of Prefabrication Technology on the Cradle-to-Site CO2 Emissions of Residential Buildings. Clean. Techn Environ. Policy 2019, 21, 1499–1514. [Google Scholar] [CrossRef]

- Satola, D.; Kristiansen, A.B.; Houlihan-Wiberg, A.; Gustavsen, A.; Ma, T.; Wang, R.Z. Comparative Life Cycle Assessment of Various Energy Efficiency Designs of a Container-Based Housing Unit in China: A Case Study. Build. Environ. 2020, 186, 107358. [Google Scholar] [CrossRef]

- Yu, S.; Liu, Y.; Wang, D.; Bahaj, A.S.; Wu, Y.; Liu, J. Review of Thermal and Environmental Performance of Prefabricated Buildings: Implications to Emission Reductions in China. Renew. Sustain. Energy Rev. 2021, 137, 110472. [Google Scholar] [CrossRef]

- Pervez, H.; Ali, Y.; Petrillo, A. A Quantitative Assessment of Greenhouse Gas (GHG) Emissions from Conventional and Modular Construction: A Case of Developing Country. J. Clean. Prod. 2021, 294, 126210. [Google Scholar] [CrossRef]

- Zhou, W. Carbon Emission Estimation of Prefabricated Buildings Based on Life Cycle Assessment Model. NEPT 2021, 20, 147–152. [Google Scholar] [CrossRef]

- Tian, Y.; Spatari, S. Environmental Life Cycle Evaluation of Prefabricated Residential Construction in China. J. Build. Eng. 2022, 57, 104776. [Google Scholar] [CrossRef]

- Aghasizadeh, S.; Tabadkani, A.; Hajirasouli, A.; Banihashemi, S. Environmental and Economic Performance of Prefabricated Construction: A Review. Environ. Impact Assess. Rev. 2022, 97, 106897. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, L.; Yu, M. Comparison and Analysis of Carbon Emissions of Traditional, Prefabricated, and Green Material Buildings in Materialization Stage. J. Clean. Prod. 2023, 406, 137152. [Google Scholar] [CrossRef]

- Greer, F.; Horvath, A. Modular Construction’s Capacity to Reduce Embodied Carbon Emissions in California’s Housing Sector. Build. Environ. 2023, 240, 110432. [Google Scholar] [CrossRef]

- Cai, K.; Wang, H.; Wang, J.; Bai, J.; Zuo, J.; Chan, K.; Lai, K.; Song, Q. Mitigating Lifecycle GHG Emissions of Building Sector through Prefabricated Light-Steel Buildings in Comparison with Traditional Cast-in-Place Buildings. Resour. Conserv. Recycl. 2023, 194, 107007. [Google Scholar] [CrossRef]

- Chen, Q.; Mao, P. Life Cycle Carbon Emission Assessment of Prefabricated Buildings: A Case Study in Nantong, China. Available online: https://link-springer-com-s.webvpn.cumt.edu.cn:8118/chapter/10.1007/978-981-99-3626-7_98 (accessed on 28 January 2025).

- Huang, Y.; Wang, A. Research on Carbon Emission of Prefabricated Structure in China. Buildings 2023, 13, 1348. [Google Scholar] [CrossRef]

- Li, J.; Andersen, L.V.; Hudert, M.M. The Potential Contribution of Modular Volumetric Timber Buildings to Circular Construction: A State-of-the-Art Review Based on Literature and 60 Case Studies. Sustainability 2023, 15, 16203. [Google Scholar] [CrossRef]

- Arslan, D.; Sharples, S.; Mohammadpourkarbasi, H.; Khan-Fitzgerald, R. Carbon Analysis, Life Cycle Assessment, and Prefabrication: A Case Study of a High-Rise Residential Built-to-Rent Development in the UK. Energies 2023, 16, 973. [Google Scholar] [CrossRef]

- Guaygua, B.; Sánchez-Garrido, A.J.; Yepes, V. Life Cycle Assessment of Seismic Resistant Prefabricated Modular Buildings. Heliyon 2024, 10, e39458. [Google Scholar] [CrossRef] [PubMed]

- Xiang, Y.; Mahamadu, A.-M.; Florez-Perez, L.; Wu, Y. Design Optimisation towards Lower Embodied Carbon of Prefabricated Buildings: Balancing Standardisation and Customisation. Dev. Built Environ. 2024, 18, 100413. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, S.; Pan, W. Systematic Initial Embodied Carbon Assessment of Concrete Modular High-Rise Residential Buildings: A Case in Hong Kong. Build. Environ. 2024, 265, 111917. [Google Scholar] [CrossRef]

- Jiang, X.; Bai, X. Carbon emissions of cast-in-place and prefabricated buildings: A comparative analysis and carbon reduction strategy. E3S Web Conf. 2024, 546, 01009. [Google Scholar] [CrossRef]

- Wen, X.; Teng, Y.; Shen, G.Q. Extended End-of-Life Carbon Assessment and Savings: A Case Study of Steel-Framed Modular Buildings in Hong Kong. Build. Environ. 2024, 266, 112056. [Google Scholar] [CrossRef]

- Crawford, R.H. Validation of a Hybrid Life-Cycle Inventory Analysis Method. J. Environ. Manag. 2008, 88, 496–506. [Google Scholar] [CrossRef]

- Suh, S.; Huppes, G. Methods for Life Cycle Inventory of a Product. J. Clean. Prod. 2005, 13, 687–697. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, H.; Wang, Q.; Hua, T.; Xue, H. A Review and Scientometric Analysis of Global Research on Prefabricated Buildings. Adv. Civil. Eng. 2021, 2021, 8869315. [Google Scholar] [CrossRef]

- Xu, X.; Liu, Z.; Liu, W.; Pei, C.; Wu, X.; Nie, Z. A Sustainable Development Benchmarking Framework for Energy Companies Based on Topic Mining and Knowledge Graph: The Case of Oil and Gas Industry. Renew. Sustain. Energy Rev. 2024, 196, 114350. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, X. Determinants of Carbon Emissions from Road Transportation in China: An Extended Input-Output Framework with Production-Theoretical Approach. Energy 2025, 316, 134493. [Google Scholar] [CrossRef]

- Chen, Y.; Li, Q.; Liu, J. Innovating Sustainability: VQA-Based AI for Carbon Neutrality Challenges. Researchgate 2024, 36, 22. [Google Scholar] [CrossRef]

- Gong, Q.; Wu, J.; Jiang, Z.; Hu, M.; Chen, J.; Cao, Z. An Integrated Design Method for Remanufacturing Scheme Considering Carbon Emission and Customer Demands. J. Clean. Prod. 2024, 476, 143681. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, L.; Peng, L.; Zhou, H.; Hu, F. Enterprise Pollution Reduction through Digital Transformation? Evidence from Chinese Manufacturing Enterprises. Technol. Soc. 2024, 77, 102520. [Google Scholar] [CrossRef]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life Cycle Assessment (LCA) of Cross-Laminated Timber (CLT) Produced in Western Washington: The Role of Logistics and Wood Species Mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef]

- Wang, B.; Yan, L.; Fu, Q.; Kasal, B. A Comprehensive Review on Recycled Aggregate and Recycled Aggregate Concrete. Resour. Conserv. Recycl. 2021, 171, 105565. [Google Scholar] [CrossRef]

- Dardouri, S.; Mankai, S.; Almoneef, M.M.; Mbarek, M.; Sghaier, J. Energy Performance Based Optimization of Building Envelope Containing PCM Combined with Insulation Considering Various Configurations. Energy Rep. 2023, 10, 895–909. [Google Scholar] [CrossRef]

- Wu, P.; Wang, J.; Wang, X. A Critical Review of the Use of 3-D Printing in the Construction Industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Ma, Q.; Zhang, Y.; Hu, F.; Zhou, H. Can the Energy Conservation and Emission Reduction Demonstration City Policy Enhance Urban Domestic Waste Control? Evidence from 283 Cities in China. Cities 2024, 154, 105323. [Google Scholar] [CrossRef]

- Xu, A.; Wang, W.; Zhu, Y. Does Smart City Pilot Policy Reduce CO2 Emissions from Industrial Firms? Insights from China. J. Innov. Knowl. 2023, 8, 100367. [Google Scholar] [CrossRef]

- Li, T.; Yu, L.; Ma, Y.; Duan, T.; Huang, W.; Zhou, Y.; Jin, D.; Li, Y.; Jiang, T. Carbon Emissions of 5G Mobile Networks in China. Nat. Sustain. 2023, 6, 1620–1631. [Google Scholar] [CrossRef]

- Li, T.; Li, Y. Artificial Intelligence for Reducing the Carbon Emissions of 5G Networks in China. Nat. Sustain. 2023, 6, 1522–1523. [Google Scholar] [CrossRef]

- Ziaesaeidi, P.; Noroozinejad Farsangi, E. Fostering Social Sustainability: Inclusive Communities through Prefabricated Housing. Buildings 2024, 14, 1750. [Google Scholar] [CrossRef]

| Criteria | Details |

|---|---|

| Literature sources | Databases, search, engine, specialized websites |

| Fields | Engineering, environmental science, energy, materials science, social sciences, multidisciplinary |

| Research Methods | Quantitative research (LCA, life cycle carbon emissions assessment), qualitative research (case studies, policy analysis, etc.), technical application research. |

| Study period | 2005–2025 |

| Language | English |

| Document types | Article, review, conference paper, book chapter, book, and conference review |

| Keywords | (“Modular construction” OR “Modular buildings” OR “Prefabricated building” OR “Off-site construction”) AND (“operation phase” OR “building performance” OR “building operation” OR “post-construction”) AND (“life cycle carbon emissions” OR “life cycle assessment” OR “life cycle” OR “life cycle performance” OR “carbon footprint” OR “carbon reduction” OR “carbon emission” OR “carbon management” OR “sustainability” OR “environmental impact assessment”) |

| Study | Data Type | Description | Tool/Method | Remarks |

|---|---|---|---|---|

| Hou et al., 2024 [54] | Simulated + Measured | EnergyPlus + real-time thermal and airflow tests; deviation: ±1.2 °C, ±16 lx | EnergyPlus + sensors | High credibility due to field verification |

| Zhu et al., 2018 [58] | Simulated Only | DesignBuilder simulation of multiple operational scenarios, no field validation | DesignBuilder | No real-world calibration |

| Ji et al., 2018 [59] | Simulated Only | Pure simulation using EnergyPlus, no measured data | EnergyPlus | Lacks empirical support, potential bias |

| Faludi et al., 2012 [60] | Simulated Only | Scenario-based modeling with PV integration, no empirical validation | LCA + PV scenario model | Innovative scenario but not validated |

| No. | Research Stage | Key Findings | Research Emphasis | Research Method | Study Area | Reference |

|---|---|---|---|---|---|---|

| 1 | Life Cycle | Research highlights that the operational phase, especially energy use, dominates a building’s life cycle, while the construction phase, particularly material production and transport, also significantly impacts the environment. The article reviews LCA findings for residential and commercial buildings, underscoring the importance of integrating LCA into design to minimize environmental impact. | LCA | Review | Multiple countries | Sharma et al., 2011 [55] |

| 2 | Life Cycle | The study finds that prefabricated buildings have significant advantages in reducing raw material use and waste, but they have higher embedded energy. Steel-structured buildings, with their reuse potential, can greatly reduce environmental impact. Although prefabricated buildings have higher embedded emissions, their overall greenhouse gas emissions over the lifecycle are still lower than traditional buildings, especially when considering future material reuse. | Assessment of greenhouse gas emission | LCA | Australia | Aye et al., 2012 [64] |

| 3 | Operational phase | The study finds that for highly energy-efficient modular buildings, minimizing energy impact during the operational phase is crucial, as it has the greatest environmental impact across the building’s lifecycle. As buildings approach net-zero energy standards, manufacturing-related CEs and resource consumption become more significant, while transportation and waste management impacts are less important. Energy efficiency and clean energy generation are key design considerations for high-performance buildings. | LCA | LCA | USA | Faludi et al., 2012 [60] |

| 4 | Production, transportation, and on-site installation phases | The semi-precast method reduces greenhouse gas emissions by about 3.2% compared to conventional construction methods. The largest source of emissions is embedded greenhouse gas emissions from building materials, which account for more than 85% of total emissions. The negative impact of transporting prefabricated parts offsets some of the emission reductions. | Assessment of greenhouse gas emission | The process-based quantitative model | China | Mao et al., 2013 [65] |

| 5 | Life Cycle | Modular buildings have advantages over traditional construction methods in multiple sustainability dimensions (environmental, economic, and social), particularly in energy efficiency and CEs. | LCA | Review and LCA | Multiple countries | Kamali & Hewage, 2016 [46] |

| 6 | Life Cycle | The study finds that the precast in situ construction method reduces GHG emissions by approximately 3.1% compared to conventional methods. The primary source of GHG emissions is the embodied GHG in building materials, with additional emissions from material transportation and operational energy consumption. The precast method reduces emissions by minimizing the use of construction materials, especially concrete and bricks. | Assessment of greenhouse gas emission | Quantitative model | China | Ji et al., 2018 [59] |

| 7 | Life Cycle | The study compares the lifecycle costs of prefabricated composite buildings versus traditional masonry buildings in different locations (Los Angeles, San Francisco, and El Paso). It is concluded that while prefabricated buildings may be economical to construct initially, their total life cycle costs are higher in the long run due to higher operating and maintenance costs. At the same time, location and climate factors have a significant impact on the lifecycle cost of buildings. | Environmental and cost performance | Life cycle cost analysis (LCCA) | USA | Samani et al., 2018 [66] |

| 8 | Production, transportation, and on-site installation phases | The study shows that although most prefabricated buildings show advantages in reducing CEs, some cases have increased emissions due to factors like the lack of material reuse. Especially in the use of steel and wood structures, the recycling potential of materials affects the final carbon emission performance. | Life cycle CE assessment | Systematic Literature Review (PRISMA) | Multiple countries | Teng et al., 2018 [62] |

| 9 | Life Cycle | Prefabricated buildings exhibit environmental benefits during the operational phase due to enhanced thermal performance, although the energy reduction potential is lower during the embodiment phase. | Energy saving and carbon reduction | LCA | China | Zhu et al., 2018 [58] |

| 10 | Life Cycle | The study shows that prefabricated buildings can significantly reduce construction time, save costs, and perform excellently in terms of environmental impact. However, despite their advantages in reducing resource waste and improving efficiency, the widespread adoption of prefabricated buildings still faces challenges in design, labor, transportation, and initial capital. | Performance evaluation | Review | Multiple countries | Ferdous et al., 2019 [67] |

| 11 | Production, transportation, and on-site installation phases | The study shows that although the CEs of fully prefabricated buildings are lower than those of traditional buildings, excessive prefabrication increases CEs in the production and transportation phases. The most effective emission reduction strategy is partial prefabrication (such as prefabricated floor slabs and stairs), rather than fully prefabricating all components. | life cycle CE assessment | LCA | China | Du et al., 2019 [68] |

| 12 | Life Cycle | Prefabricated buildings show lower energy consumption and CEs at all stages, especially during the operational phase, where improved thermal insulation significantly reduces air conditioning energy use and CEs. Additionally, prefabricated buildings outperform traditional buildings in resource use efficiency and waste reduction. The study also shows that an optimal assembly rate (around 60%) plays an important role in optimizing CEs and costs. | Environmental and cost performance | LCA | Japan | Wang et al., 2020 [57] |

| 13 | Life Cycle | Net zero energy design has the lowest life cycle impact. The life cycle impact of off-grid design is significantly higher than that of net zero energy design. Reuse of container structures significantly reduces life cycle impacts. Climate change is less sensitive to life cycle effects. | Energy saving and carbon reduction | LCA | China | Satola et al., 2020 [69] |

| 14 | Life Cycle | Prefabrication can reduce the environmental impact of buildings at the end of their useful life, with the potential to reduce overall construction costs and increase productivity in the construction industry. Global warming potential and non-renewable energy use are significantly reduced when prefabricated methods are adopted. | Environmental and cost performance | LCA | EU-27 | Tavares et al., 2021 [56] |

| 15 | Life Cycle | Through life cycle analysis and thermal performance assessment, the study shows that prefabricated walls can significantly improve building energy efficiency and reduce greenhouse gas emissions, especially during building renovation and updates. | Thermal and environmental performance | LCA and Thermal Performance Assessment | China | Yu et al., 2021 [70] |

| 16 | Construction Phase | This paper quantitatively assesses the GHG emissions of modular and traditional buildings, demonstrating the advantages of modular buildings in reducing greenhouse gas emissions. Particularly in the production and transportation of building materials, modular buildings significantly reduce GHG emissions by minimizing material waste and using low-density materials. | Assessment of greenhouse gas emission | Quantification of GHG Emissions | Pakistan | Pervez et al., 2021 [71] |

| 17 | Production, transportation, and on-site installation phases | The study shows that in the production, transportation, and on-site installation phases, the main source of CEs in prefabricated buildings is the production phase, particularly the production of concrete and rebar. | Life cycle CE assessment | LCA | China | Zhou, 2021 [72] |

| 18 | Life Cycle | This paper analyzes five representative residential prefabricated building projects, using LCA and BIM technologies to assess CEs and compare them with traditional buildings. The study shows that prefabricated buildings have lower CEs at multiple stages, especially in the production of building materials and the construction phase, demonstrating significant carbon reduction potential. | Life cycle CE assessment | BIM and LAC | China | Li et al., 2022 [61] |

| 19 | Production, transportation, and on-site installation phases | This paper compares the environmental performance of prefabricated and traditional buildings in China using LCA, covering the stages of material production, transportation, and on-site construction. The study shows that prefabricated buildings perform better on several environmental impact indicators, particularly in energy consumption and greenhouse gas emissions. | Energy saving and carbon reduction | (LCA | China | Tian & Spatari, 2022 [73] |

| 20 | Life Cycle | The environmental performance of prefabricated buildings mainly focuses on reducing CEs, improving energy efficiency, reducing material consumption, and lowering air and noise pollution. The production and construction phases of the life cycle contribute the most to environmental impact and cost, while research on the use phase and end-of-life stage is relatively limited. | Environmental and cost performance | LCA | Multiple countries | Aghasizadeh et al., 2022 [74] |

| 21 | Life Cycle | Prefabricated buildings are superior in life cycle environmental performance over poured in site (CIP) systems, with a 21% lower total life cycle cost and greater economic efficiency. | Environmental and cost performance | LCA | USA | Vasishta et al., 2023 [63] |

| 22 | Production, transportation, and on-site installation phases | Prefabricated buildings have higher initial CEs than conventional buildings. Despite their higher CEs, prefabricated buildings outperform conventional and green material buildings on the sustainability index. The study suggests that prefabricated buildings are more conducive to reducing environmental load and promoting carbon emission reduction. | Life cycle CE assessment | Carbon Emission Emergy Factor mode | China | Zhao et al., 2023 [75] |

| 23 | Production, transportation, and on-site installation phases | This paper uses LCA to analyze the differences in greenhouse gas emissions between modular housing built in California factories and traditional construction methods. The study finds that modular buildings can reduce GHG emissions while meeting housing demand, with higher emission reduction potential in certain areas of California due to the location of factories and transportation factors. | Assessment of greenhouse gas emission | LCA | USA | Greer & Horvath, 2023 [76] |

| 24 | Life Cycle | The study emphasizes the comparison of CEs between prefabricated light-steel buildings and traditional cast-in-place buildings, promoting prefabrication technology as a better solution for reducing GHG emissions in the building sector | Life cycle CE assessment | LCA | China | Cai et al., 2023 [77] |

| 25 | Life Cycle | This study develops a life cycle carbon emission calculation system to quantify emissions from prefabricated buildings at each stage. An empirical analysis of a Nantong prefabricated building project reveals that the operational phase contributes the most to CEs, followed by the production and processing phases. The study suggests strategies to reduce emissions, including increasing assembly rates, adopting low-energy construction methods, and utilizing renewable energy sources such as solar panels. | Life cycle CE assessment | LCA | China | Chen & Peng Mao, 2023 [78] |

| 26 | Production, transportation, and on-site installation phases | The study finds that although prefabricated structures have higher CEs during production and transportation, CEs can be effectively reduced by increasing the assembly rate, particularly by reducing on-site labor and machinery energy consumption. | Life cycle CE assessment | Carbon Emission Estimation | China | Huang & Wang, 2023 [79] |

| 27 | Life Cycle | Modular timber structures have strong carbon storage capacity, and replacing concrete with wood can significantly reduce CEs. The wood in a single module stores an average of approximately 13.42 tons of CO2. | Life cycle CE assessment | Review | Europe | J. Li et al., 2023 [80] |

| 28 | Life Cycle | The study analyzes a prefabricated high-rise residential building in London, finding that modular construction achieved approximately 10% lower life-cycle CEs than traditional cast-in-place methods. The study underscores the potential of modular strategies to meet low-carbon benchmarks while identifying limitations in current industry datasets on embodied and operational emissions. | Energy saving and carbon reduction | LCA | United Kingdom | Arslan et al., 2023 [81] |

| 29 | Life Cycle | The study compares seismic-resistant modular structural systems through cradle-to-grave LCA, finding that steel volumetric modules with dry connections performed best in life cycle carbon and sustainability. Operational energy was standardized across systems, highlighting the role of structural design in carbon outcomes. | Life cycle CE assessment | LCA | Spain | Guaygua Quillupangui et al., 2024 [82] |

| 30 | Developed design stage | Standardization does not always reduce embodied CEs; the combination of standardization and customization can effectively reduce the carbon emission of prefabricated parts. Improving the adaptability of templates is more effective in reducing carbon than standardizing elements. | Life cycle CE assessment | Genetic algorithm | China | Xiang et al., 2024 [83] |

| 31 | Production, transportation, and on-site installation phases | Concrete modular buildings have lower CEs during the construction phase, but the CEs in the initial phase are more complex compared to traditional construction methods, influenced by building layout and height. Optimizing module design, particularly addressing the “double-panel issue,” can significantly reduce CEs and provide practical recommendations for future carbon emission assessment and reduction in modular buildings. | Life cycle CE assessment | LCA | China | Zhang et al., 2024 [84] |

| 32 | Life Cycle | Prefabricated buildings have lower CEs over their life cycle compared to cast-in-place buildings, with the main sources of CEs being building materials in the construction phase and energy consumption in the operational phase. | Life cycle CE assessment | Carbon emission factor method | China | Jiang & Bai, 2024 [85] |

| 33 | Operational phase | Concrete prefabricated buildings (MiC) can significantly reduce energy consumption and CEs compared to traditional buildings during the operation phase, especially through optimizing the design of the building envelope, improving thermal insulation performance, and rational selection of building materials. These measures help the building achieve greater energy efficiency | Energy saving and carbon reduction | Combination of Real-time Testing and Simulation | China | Hou et al., 2024 [54] |

| 34 | Dismantling, transportation, waste handling and waste disposal stages | In the end-of-life (EoL) phase, steel-framed modular buildings have significant carbon reduction potential. By achieving a higher module reuse rate, CEs can be significantly reduced, especially for steel modular buildings, where module reuse plays a crucial role. | Life cycle CE assessment | LCA | China | Wen et al., 2024 [86] |

| No. | Year | Number of Articles (n = 34) |

|---|---|---|

| 1 | 2011 | 1 |

| 2 | 2012 | 2 |

| 3 | 2013 | 1 |

| 4 | 2016 | 1 |

| 6 | 2018 | 4 |

| 7 | 2019 | 2 |

| 8 | 2020 | 2 |

| 9 | 2021 | 4 |

| 10 | 2022 | 3 |

| 11 | 2023 | 8 |

| 12 | 2024 | 6 |

| Study | Country | Bias Type(s) | Bias Level | Author Acknowledged? | Impact Summary |

|---|---|---|---|---|---|

| Ji et al. 2018 [59] | China | Methodological, Scope | High | No | Simulation only, lacks validation and operational data |

| Hou et al. 2024 [54] | China | Methodological | Moderate | No | Empirical envelope data, but lacks scenario sensitivity |

| Zhu et al. 2018 [58] | China | Geographic, Scope | Moderate | Yes | Limited to North China, no longitudinal validation |

| Wang et al. 2020 [57] | China | Low | Low | Yes | Balanced LCA with hybrid data model |

| Tavares et al. 2022 [56] | EU | Geographic | Moderate | Yes | EU stock-level projection; no global generalization |

| Kamali & Hewage, 2016 [46] | Canada | Low | Low | Yes | Methodologically robust review across dimensions |

| Ferdous et al. 2019 [67] | Australia | Geographic | Moderate | No | Focused on Melbourne; limited global transferability |

| Li et al. 2023 [80] | Denmark | Financial, Geographic | High | Partially | Case-based review of government-funded projects |

| Aye et al. 2012 [64] | Australia | Methodological | Moderate | Partially | Lacks calibration for reuse scenarios |

| Sharma et al. 2011 [55] | India | Low | Low | Yes | Transparent LCA across full building life cycle |

| Region | Primary Strategy | Key Focus | Typical Methods |

|---|---|---|---|

| China | Policy-driven promotion of prefabrication and modular construction | Construction-phase emission control, envelope insulation, MiC system optimization | Energy simulation + short-term empirical validation; LCA; hybrid modeling |

| Europe (e.g., Denmark, Sweden) | Circular economy integration and EoL recovery | Material reuse, design for disassembly, full life cycle closure | Hybrid LCA; disassembly scenario modeling |

| North America | Operational energy optimization and passive design | HVAC systems, building envelope, renewable integration | Simulation-based LCA; occupant behavior modeling |

| Australia | Life cycle cost–carbon trade-offs | Balancing embodied and operational carbon; economic analysis | Simulation + cost-benefit LCA modeling |

| Japan | Precision industrialized timber systems | Timber modular prefabrication; thermal insulation; compact forms | Envelope modeling; material-specific analysis |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Y.; Xiang, L.; Shang, K. The Research Review on Life Cycle Carbon Emissions in the Operational Process of Modular Buildings. Buildings 2025, 15, 2085. https://doi.org/10.3390/buildings15122085

Hu Y, Xiang L, Shang K. The Research Review on Life Cycle Carbon Emissions in the Operational Process of Modular Buildings. Buildings. 2025; 15(12):2085. https://doi.org/10.3390/buildings15122085

Chicago/Turabian StyleHu, Yupei, Luyao Xiang, and Kai Shang. 2025. "The Research Review on Life Cycle Carbon Emissions in the Operational Process of Modular Buildings" Buildings 15, no. 12: 2085. https://doi.org/10.3390/buildings15122085

APA StyleHu, Y., Xiang, L., & Shang, K. (2025). The Research Review on Life Cycle Carbon Emissions in the Operational Process of Modular Buildings. Buildings, 15(12), 2085. https://doi.org/10.3390/buildings15122085