Abstract

This study improved the thermal damping of concrete with rice husk ash (RHA)–fly ash (FA) matrix and three phase-change material (PCM) aggregates with phase change temperatures between −15 and 5 °C, which are expected to reduce winter energy consumption in cold regions when used as building envelope structures. Firstly, the strength of concrete was studied. Secondly, the dynamic and transient thermal response of concrete was evaluated through thermal conductivity and thermal diffusivity. Based on nuclear magnetic resonance experiments, the changes in the pore volume and fractal dimension of RHA–FA matrix and PCM aggregate added to concrete were studied. Through correlation analysis, a macroscopic performance prediction model based on pore characteristics was obtained. The results indicated that the incorporation of PCM aggregate reduced concrete strength, while an appropriate RHA–FA matrix contributed to enhancing concrete strength. Both the PCM aggregate and RHA–FA matrix were beneficial for improving the thermal damping properties of concrete. For 15% RHA–30% FA 100% PCM concrete, the thermal conductivity can be reduced by 53%, the thermal diffusivity can be reduced by 64%, the limiting temperature decreased by 5.5 °C, and the thermal damping coefficient increased by 48%. The nuclear magnetic resonance test results showed that PCM aggregate increased the pore volume and decreased the fractal dimension, while an appropriate RHA–FA matrix helped to reduce the pore volume. The macroscopic properties of RHA–FA–PCM aggregate concrete were highly correlated with the capillary pore volume and fractal dimension. A two-parameter prediction model based on pore characteristics can effectively predict the macroscopic properties of concrete.

1. Introduction

Under the challenge of energy depletion, countries have made various efforts to conserve energy, including strategies such as reducing building energy consumption and enhancing energy efficiency [1,2,3,4,5,6]. As places where people live and work, buildings consume more than 50% of their total energy for cooling and heating [7,8,9,10]. Therefore, energy savings in building cooling and heating will significantly reduce total energy consumption. During the winter in cold regions, people use heat sources to improve indoor thermal comfort, which also results in a significant consumption of energy. The building envelope connects the interior and exterior; 70% of thermal energy loss is caused by the envelope [11,12,13,14]. Improving the thermal damping performance of the building envelope will hopefully reduce energy consumption in winter and increase indoor temperatures.

Rice husk ash (RHA) has great potential for producing thermal insulation materials due to their material characteristics [15,16,17,18]. Rice husk is a type of agricultural waste, with a sizable amount of more than 40 million tons per year in China [19]. It has been used as the primary fuel source for generating power from biomass material [20,21]. Rice husk exhibits high pozzolanic activity after burning and has been utilized as a substitution for cement in numerous countries [22]. Due to its high content of amorphous silica, pozzolanic activity, and specific surface area, RHA is considered a supplementary cementitious material that enhances the mechanical and durability properties of concrete [23,24,25]. Previous studies on RHA have primarily aimed at enhancing mechanical and durability properties, with little attention to the impact of thermal properties, which are crucial for reducing energy consumption in buildings [26,27,28].

Energy storage systems are considered as one of the promising solutions for addressing energy consumption in buildings [29,30]. Phase-change materials (PCMs) have a high energy storage capacity because of latent heat. The incorporation of PCM aggregate into the building envelope results in reduced indoor temperature fluctuations, which will reduce the energy consumption of the buildings. Currently, there are some studies on composite walls with PCM. Xu et al. [31] studied a novel concrete block containing PEG/SiO2. The results indicated that the use of PCM reduces indoor temperature fluctuations. Sayyar et al. [32] evaluated the thermal performance of gypsum wallboards incorporated with nano-PCM. The incorporation of nano-PCM enabled them to reduce the interior temperature fluctuations, leading to a 79% decrease in energy consumption in a numerical model.

The extensive use of micro-/nano-encapsulated PCM leads to increased costs and a significant decrease in the strength. In contrast, macro-encapsulated PCM, such as encapsulation in porous aggregates, has a relatively small impact on the mechanical properties after incorporation. Therefore, high additions of PCM composites in concrete can be achieved using the macro-encapsulation method. Macro-encapsulation has attracted the interest of researchers because of its cost and ability to be used directly as aggregate. Cui et al. [33] developed hollow steel balls to encapsulate octadecane and used them to replace 0% to 100% of coarse aggregate. The results showed that incorporating PCM balls into concrete panels enabled a reduction in indoor temperature by a range of 3–6%. Sukontasukkul et al. [34] impregnated PCM into lightweight aggregate and replaced natural coarse aggregate at 0~100% by volume. The latent heat of concrete increased by 64%, which is beneficial for the storage of thermal energy.

The above research indicates that the thermal damping performance of concrete can be improved by utilizing the latent heat of PCM aggregates and the sensible heat of the thermal damping matrix. However, most studies investigate the matrix or aggregate separately.

Although several studies have investigated the effects of combining a matrix and aggregates on the thermal performance of concrete, most research has been limited to temperatures around 25 °C, aiming to improve indoor thermal comfort during summer [35,36]. There is limited research on building envelope materials capable of restricting extreme temperatures under cold season conditions.

This study investigates the potential of dual-modified concrete by combining phase-change material (PCM) aggregates and a rice husk ash–fly ash (RHA–FA) matrix to enhance thermal damping for energy efficient concrete. Dynamic and static thermal response tests were conducted to examine the influence of varying PCM aggregate and RHA–FA matrix dosages on thermal conductivity, thermal diffusivity, temperature–time curves, and temperature difference–time curves. The thermal damping characteristics were evaluated using the decrement factor and thermal damping coefficient. Nuclear magnetic resonance (NMR) tests were performed to analyze the effects of PCM aggregates and RHA–FA matrix on pore distribution, pore volume, and fractal dimension in different concrete specimens. Correlation analysis revealed the pore mechanisms underlying thermal response variations, while appropriate pore structure parameters were employed to predict macroscopic physical properties such as thermal conductivity. The above research provides theoretical reference for applying PCM aggregate and RHA–FA matrix incorporated into concrete as building envelope materials in cold regions.

2. Materials and Experiment

2.1. Materials

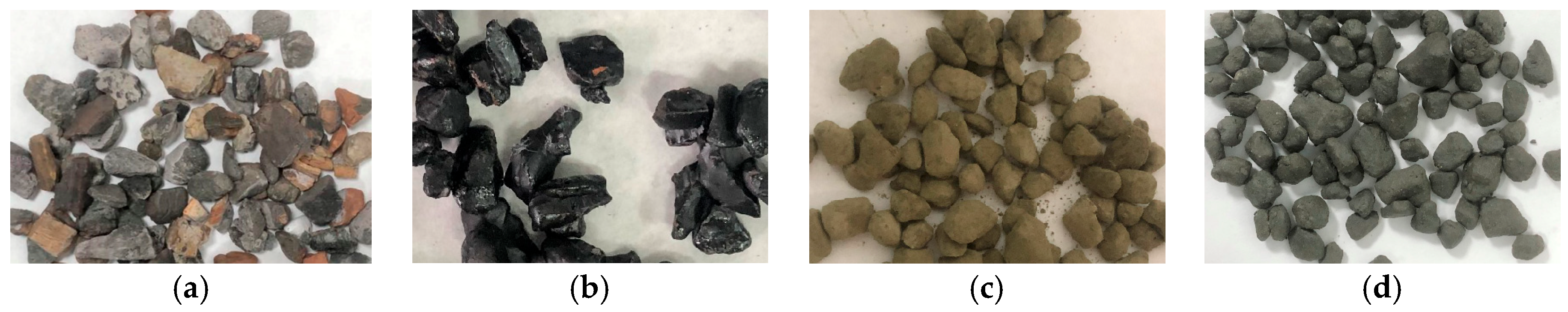

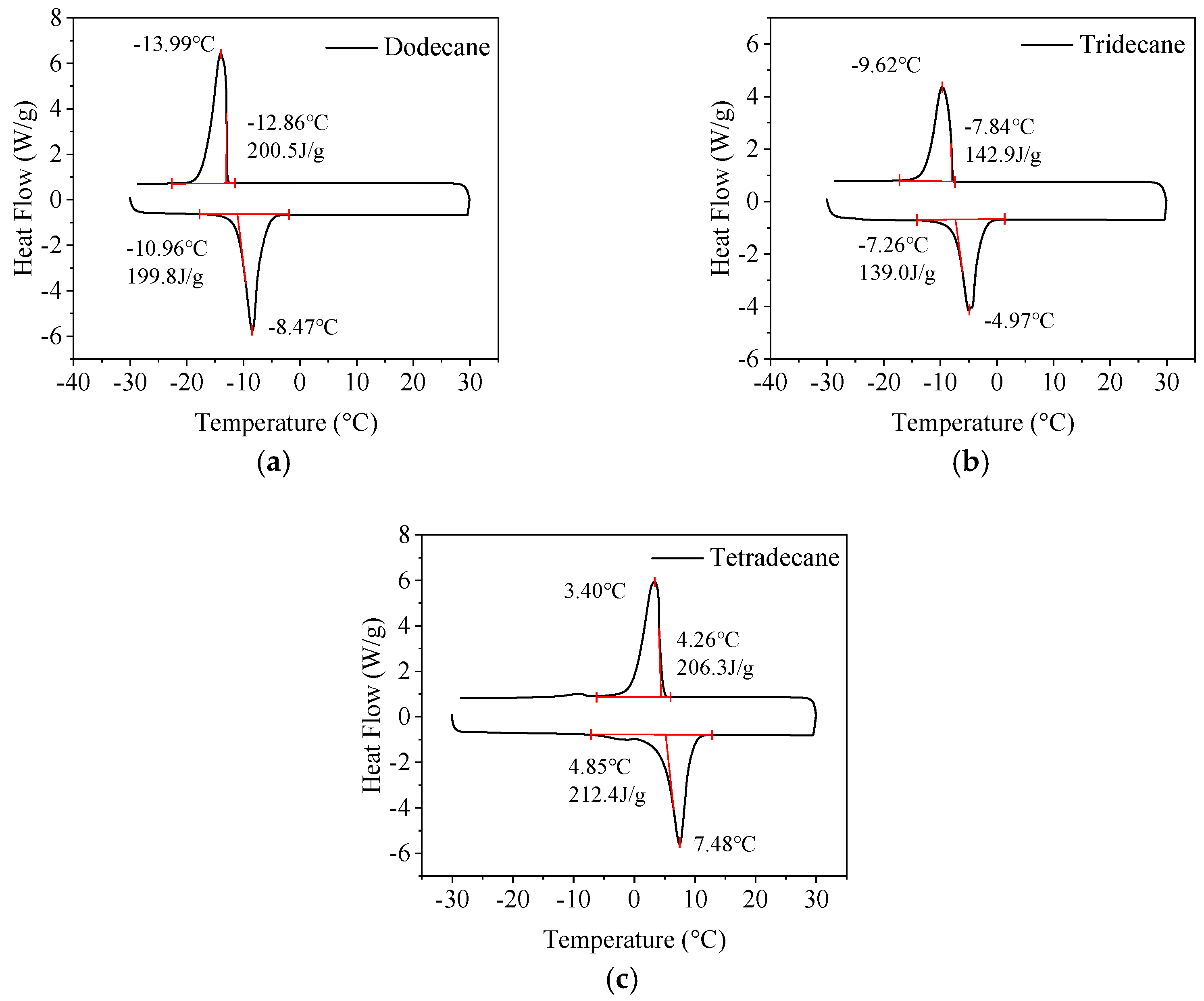

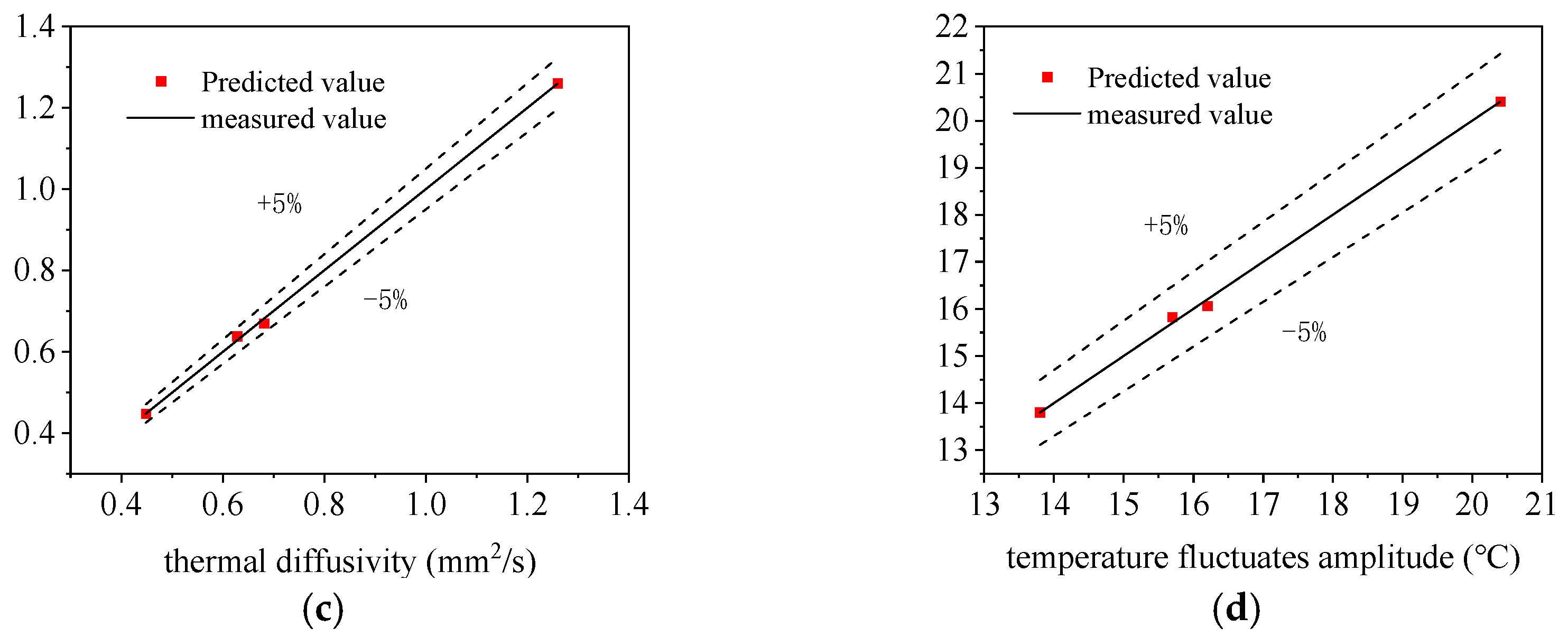

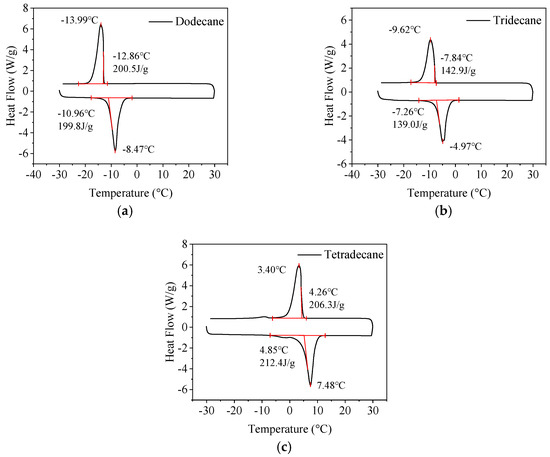

Shale ceramsite was used to prepare low-temperature PCM aggregate. Shale ceramsite particle size is 5~20 mm, which conforms to a continuous gradation. Dodecane, tridecane, and tetradecane were encapsulated in ceramsite to produce three types of PCM aggregates. The phase-change temperatures of the three PCMs were −15 °C to 5 °C. Epoxy resin composites and cement powder were used to prevent leakage [37,38,39]. The morphology of the aggregates is presented in Figure 1. The relative masses of the components in the aggregates are listed in Table 1. The properties of PCMs the were measured through the differential scanning calorimetry (DSC); the results are depicted in Figure 2.

Figure 1.

Morphology of (a) Shale ceramsite, (b) PCM aggregate with epoxy resin, (c) PCM aggregate with cement powder, (d) PCM aggregate.

Table 1.

The relative mass of each component in the PCM aggregate.

Figure 2.

DSC curve of (a) dodecane, (b) tridecane, and (c) tetradecane.

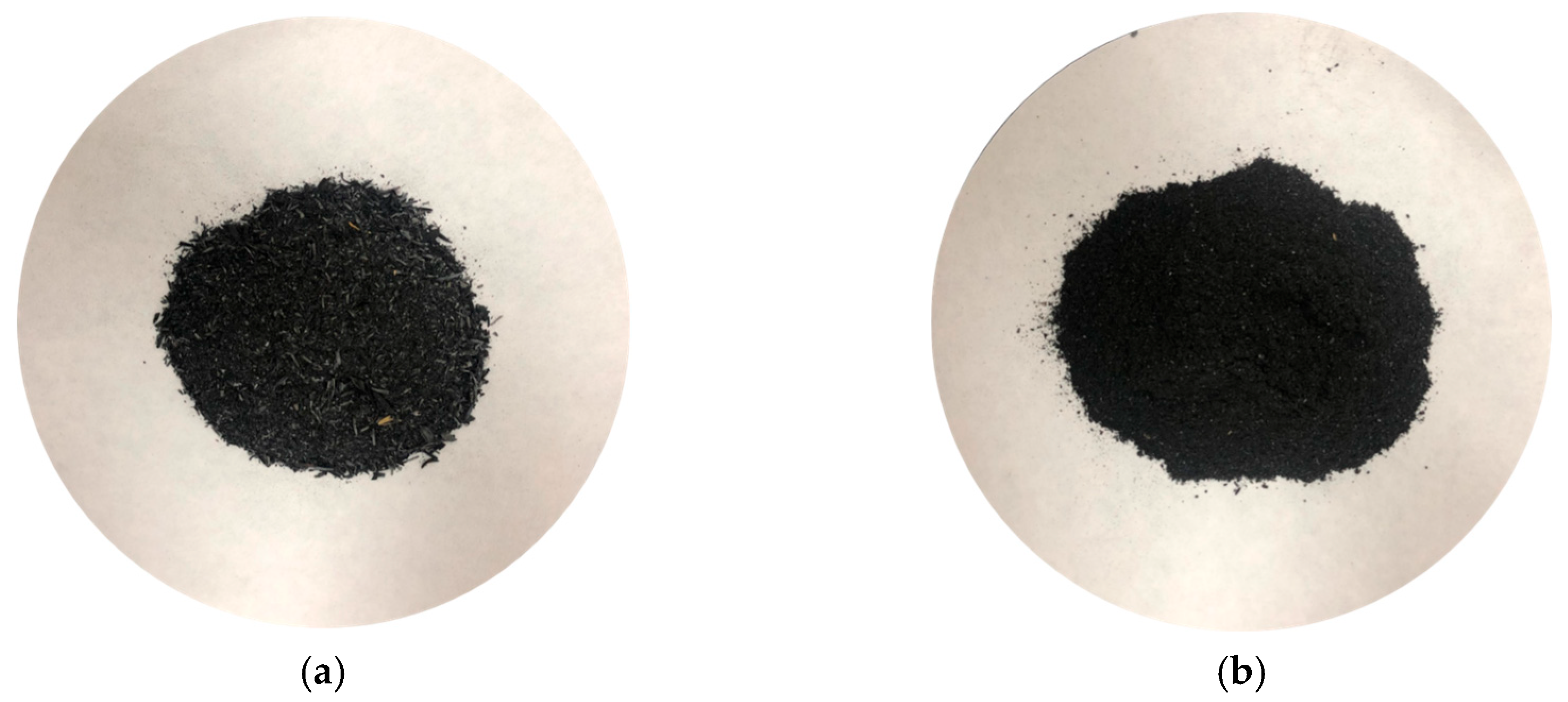

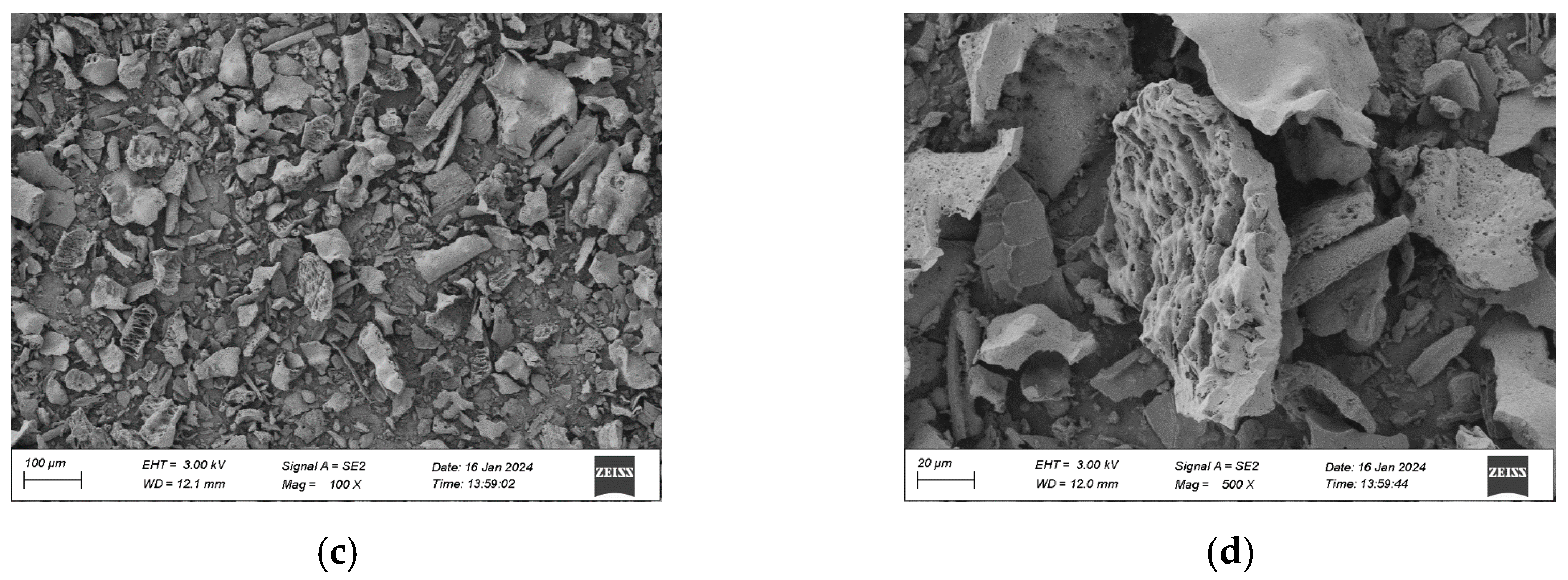

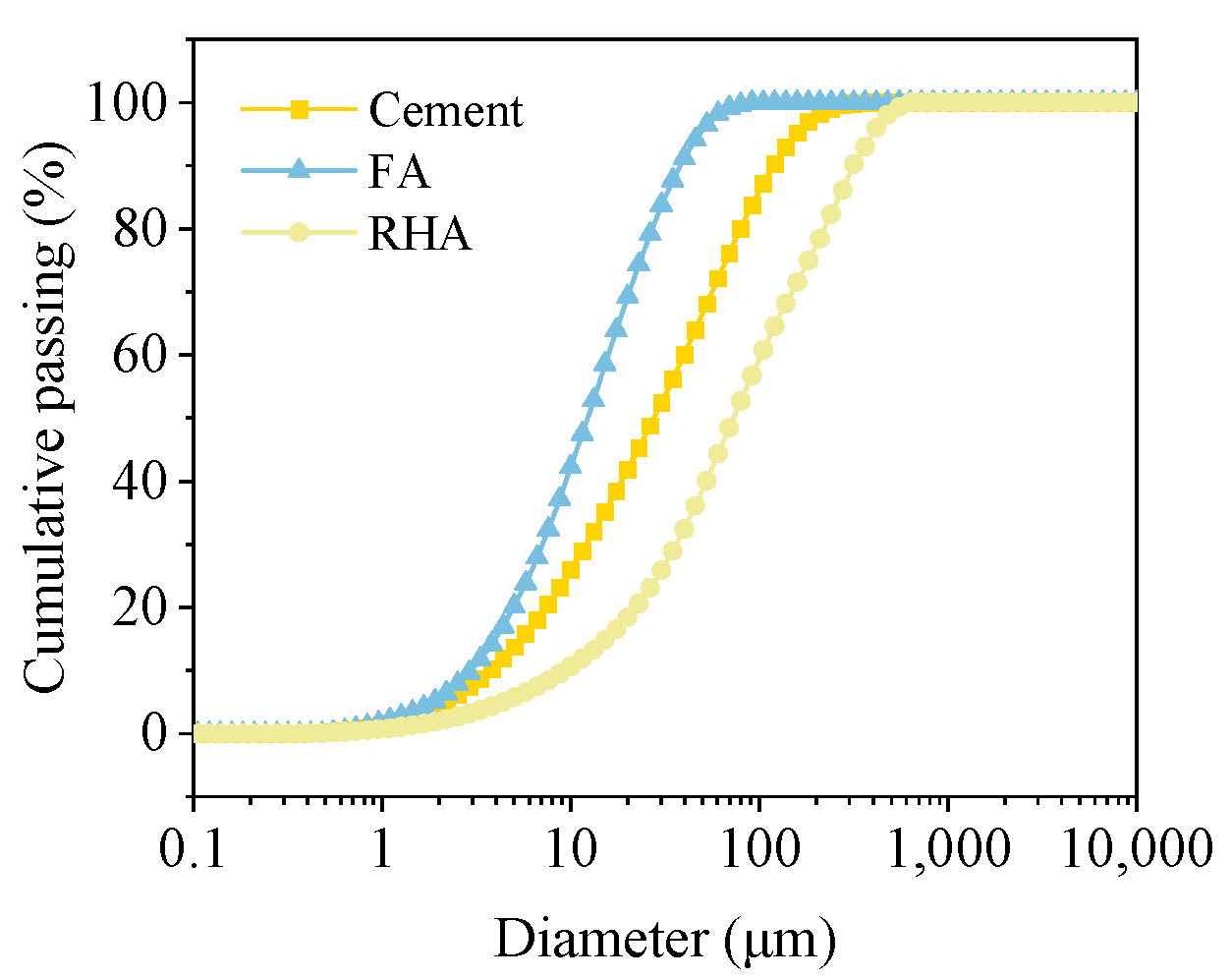

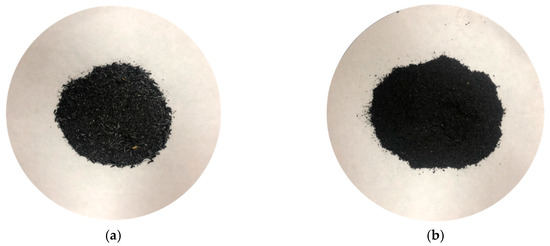

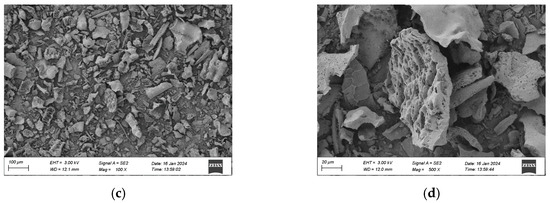

While rice husk ash (RHA) exhibits low thermal conductivity, its direct incorporation into concrete significantly compromises workability. To address this limitation, combining RHA with fly ash forms a rice husk ash–fly ash (RHA–FA) composite matrix. Rice husk was calcined at a temperature of 600 °C to obtain RHA (Figure 3a). Studies have shown that finer RHA exhibits higher pozzolanic activity [40]. Therefore, RHA was milled for 90 min (Figure 3b). The electron microscope images are shown in Figure 3c,d. The compositions of RHA, FA, and cement were tested by X-ray fluorescence, as presented in Table 2. The size distribution was tested by a laser particle size analyzer, as displayed in Figure 4.

Figure 3.

(a) RHA without milling, (b) RHA with milling, and (c,d) SEM image of RHA.

Table 2.

Composition of cementitious material (wt.%).

Figure 4.

Particle size distribution of RHA, FA, and cement.

2.2. Concrete Preparation

The optimal thermal damping performance of PCM concrete is achieved when three PCM aggregates are mixed; the mass ratio of the three PCM aggregates is 4:3:3 [41]. After mixing at this ratio, they are added to concrete and replaced with 0–100% natural coarse aggregate by volume. To further improve the thermal damping properties of the cement matrix, RHA was used to replace cement in 100% PCM aggregate concrete. However, RHA increased the yield stress and viscosity of the cement paste, negatively impacting the flowability [42]. Fly ash (FA) can promote flowability. This is due to the small size and spherical shape of FA, which reduces the friction between cement and aggregate, resulting in an increased workability of fresh concrete. Previous research [43] has suggested that the substitution of RHA up to 15% is appropriate. In this paper, RHA was used to replace cement by mass at 5%, 10% and 15%. Fly ash was used to replace cement by mass at substitution rates of 10%, 20%, and 30%. The specific mixes are presented in Table 3.

Table 3.

Mixing ratio of concrete (kg/m3).

2.3. Experiment

2.3.1. Compressive Strength

The test was conducted on a hydraulic universal testing machine. The compressive strengths at 7 d and 28 d were tested. Each strength value was calculated as the average of at least three specimens. The test sample was a 100 mm cubic specimen.

2.3.2. Thermal Constant Test

The thermal constants were tested using a HotDisk thermal constants analyzer. The HotDisk sensor is a nickel foil probe sealed between two thin sheets of Kapton. The sensor was placed in two identical concrete cubic specimens. The sensor functioned as a heat source as well. To ensure good contact between the samples and the probes, the test surfaces of the two pieces of concrete were polished before the test. During the test, an electric current was passed through the probes, causing the temperature to rise. The heat generated was then diffused to the surrounding area.

2.3.3. Temperature–Time Curve

A constant-temperature and -humidity environment test machine can simulate high- and low-temperature environments. The dynamic thermal response of concrete in a cold environment was simulated by placing concrete specimens in the test machine. The minimum temperature setting for this test was −18 °C, and the maximum temperature setting was 8 °C. The temperature in concrete was monitored by a K-type thermocouple embedded in the specimen; the concrete specimen had dimensions of 100 mm × 100 mm × 100 mm, and the other side of the thermocouple was the data recorder, which recorded data every minute. The surface temperature of concrete, as recorded, reflects the external environmental temperature, while the center temperature of concrete can be described as the room temperature inside a 50 mm concrete wall.

2.3.4. NMR Test

Concrete is a porous material, and the internal pore space distribution of concrete can be determined using low-field nuclear magnetic resonance (NMR) techniques. The principle of the NMR technique is to change the spin of the atoms inside by sending radio frequency pulses through an instrument. Hydrogen or helium atoms are ideal for NMR tests; hence, the concrete must be filled with water or gas [44]. In this study, the concrete’s interior is saturated with moisture, and a pulse signal is applied by electromagnetic induction. The hydrogen atoms in the concrete moisture undergo a spin, generating a signal strength. When the magnetic field is switched off, the atoms gradually return to their original state, and this decay process is quantified using the transverse relaxation, which correlates with size. Two hundred relaxation data points were collected, and T2 spectrums were derived through inverse analysis. The T2 spectrums contain two crucial parameters: the horizontal axis represents relaxation time, and the vertical axis represents signal strength.

3. Results and Discussion

3.1. Strength

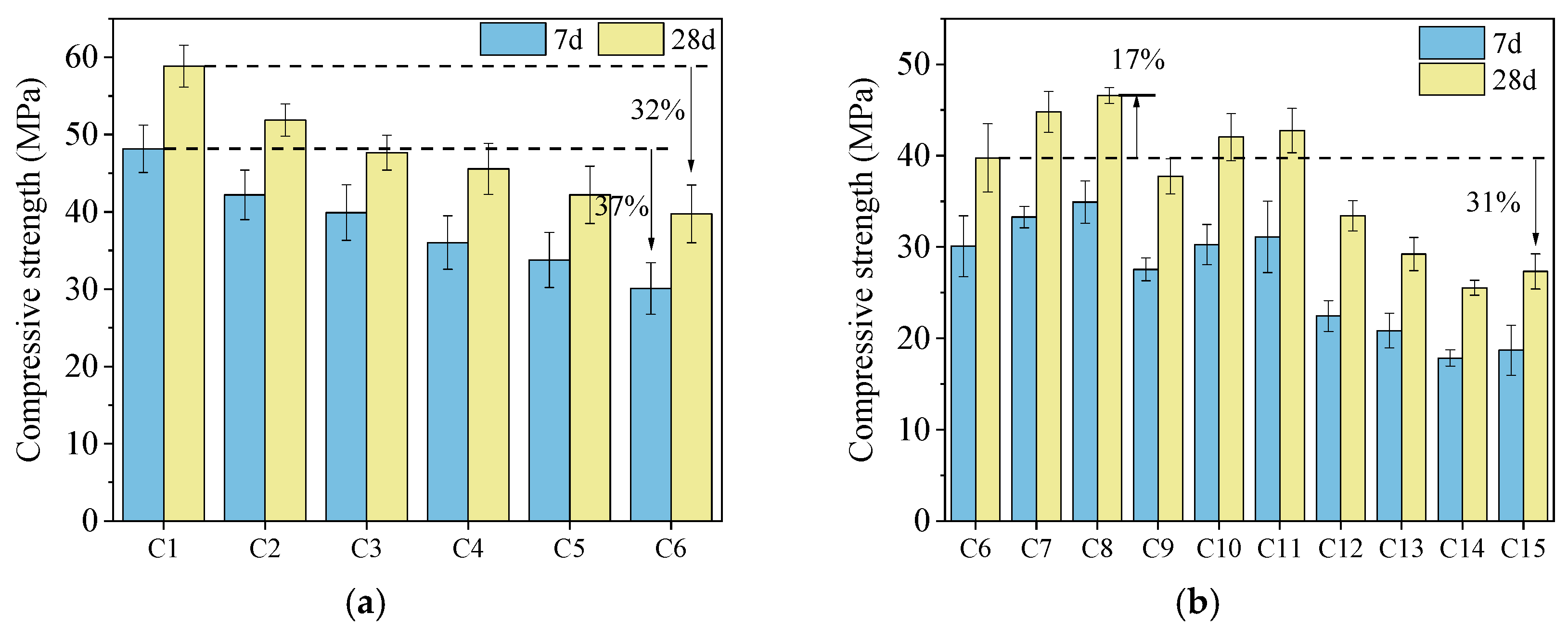

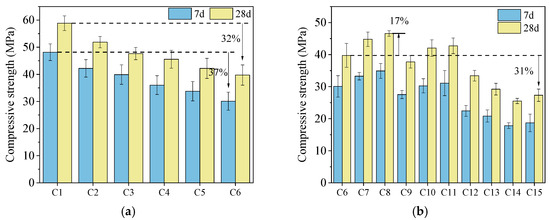

The strength of concrete after replacing coarse aggregate by volume with PCM aggregate is shown in Figure 5a, and the compressive strength of concrete after replacing cement by mass with RHA and FA is shown in Figure 5b. The strength of concrete decreased as the 0% to 100% coarse aggregate was replaced by PCM aggregate. The 7 d and 28 d compressive strengths of 100% PCM aggregate concrete decreased by 37.53% and 32.46%, respectively. The main reason for the decrease in the strength of PCM aggregate concrete is that the strength of PCM aggregate is lower than that of natural aggregate.

Figure 5.

Compressive strength of concrete after incorporating (a) PCM aggregate, (b) RHA and FA.

An enhancement of 10.60% in 7 d strength and 12.70% in 28 d strength was observed in the 100% PCM aggregate concrete integrated with 5% RHA and 10% FA, compared to the reference concrete. The high early strength of 100% PCM concrete with incorporated RHA–FA matrix is attributed to the fact that RHA, FA, and cement have different particle sizes, which improves the void structure of concrete, resulting in a denser structure [45]. In the later stages, the amorphous silica in RHA and FA reacts with calcium hydroxide, a product of cement hydration, to further hydrate and form more C-S-H gels. On the other hand, the pore structure of RHA can serve as nucleation sites for hydration products and restrict the growth of undesirable crystals during hydration. The combined effect of the two will enhance the mechanical properties of concrete [46,47,48]. The highest mechanical properties were observed when the contents of RHA and FA in concrete were both 10%, achieving compressive strengths of 34.92 MPa at 7 d and 46.57 MPa at 28 d. The high strength may be partly attributed to the pozzolanic influence and be partly due to the filling influence [49].

Variations in the amount of RHA–FA matrix also affect the mechanical properties. In the 10% and 20% FA groups, using 10% RHA resulted in the highest strength, with an increase ranging from 7.55% to 17.19% compared to the reference concrete. In the 30% FA group, 5% RHA was found to be the most favorable for strength. However, strength was 26.47% lower than ordinary concrete. The introduction of 15% RHA led to a decrease in strength ranging from 5.06% to 31.25%. In the 5% and 15% RHA groups, an FA addition amount of 10% was found to be most favorable for strength. The difference with the reference concrete ranged from −5.06% to 17.19%. At an FA addition amount of 20%, the difference with the reference concrete ranged from −15.93% to 7.55%. The decrease in strength was more significant at an FA addition amount of 30%, ranging from −26.47% to −35.76%, compared to the control concrete. When the dosage of RHA and FA exceeds the optimal dosage, there was a significant negative impact on the strength. This can be mainly attributed to the higher cement replacement rate, which leads to a reduction in cement hydration products and insufficient calcium hydroxide to react with the active components, thereby limiting the formation of C-S-H gel.

3.2. Thermal Constant

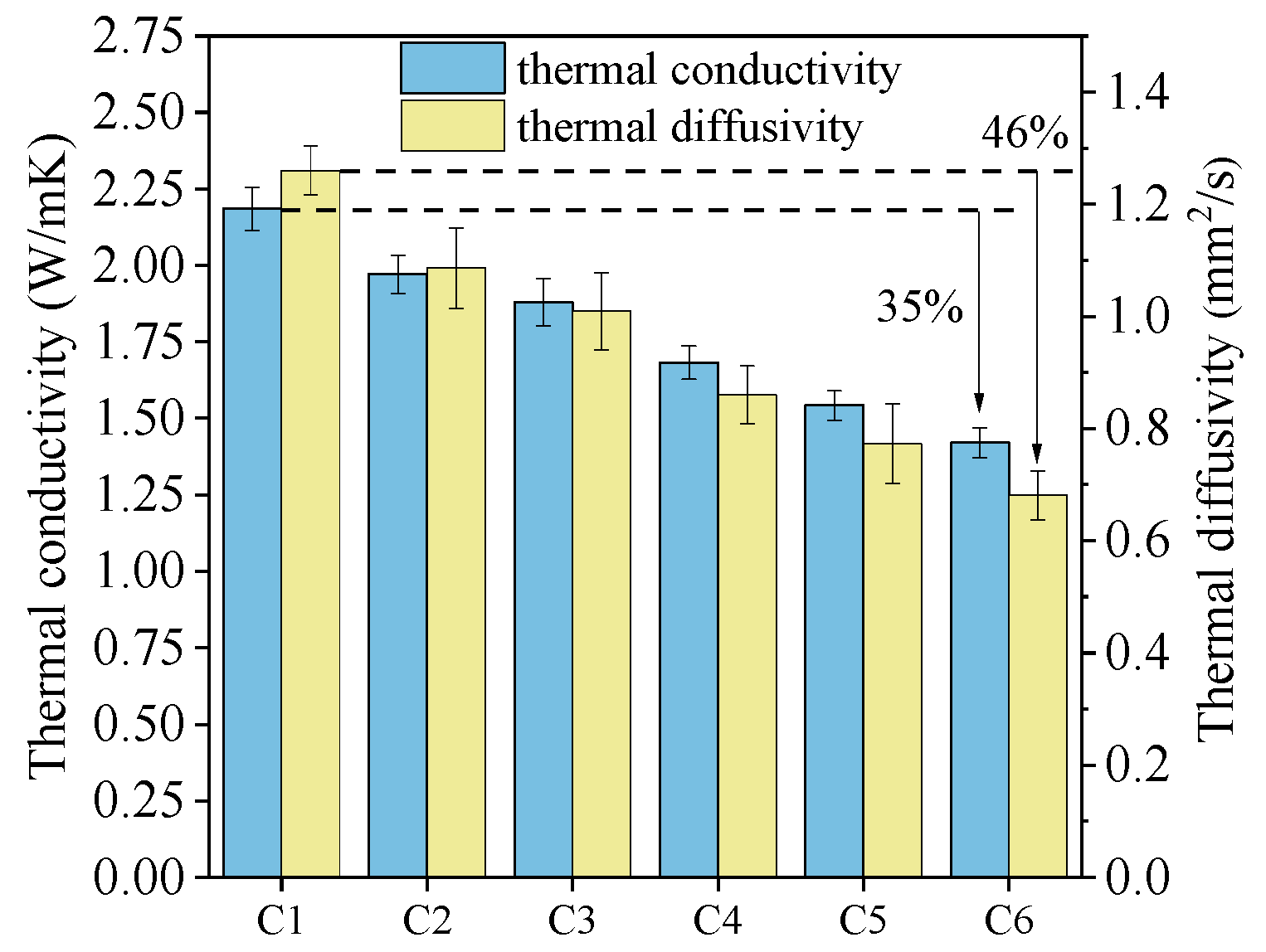

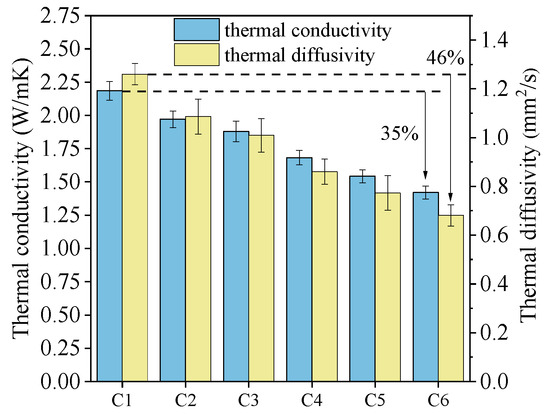

Figure 6 shows the thermal properties of concrete with different amounts of PCM aggregate. Both thermal properties of the 100% PCM aggregate concrete (thermal conductivity and diffusivity) decreased by 35.01% and 45.95%, respectively, compared to the control concrete. Experimental results demonstrate that PCM aggregates enhances the thermal damping capacity of concrete, effectively attenuating temperature fluctuations through latent heat absorption release mechanisms.

Figure 6.

Thermal conductivity and diffusivity of concrete after incorporating PCM aggregate.

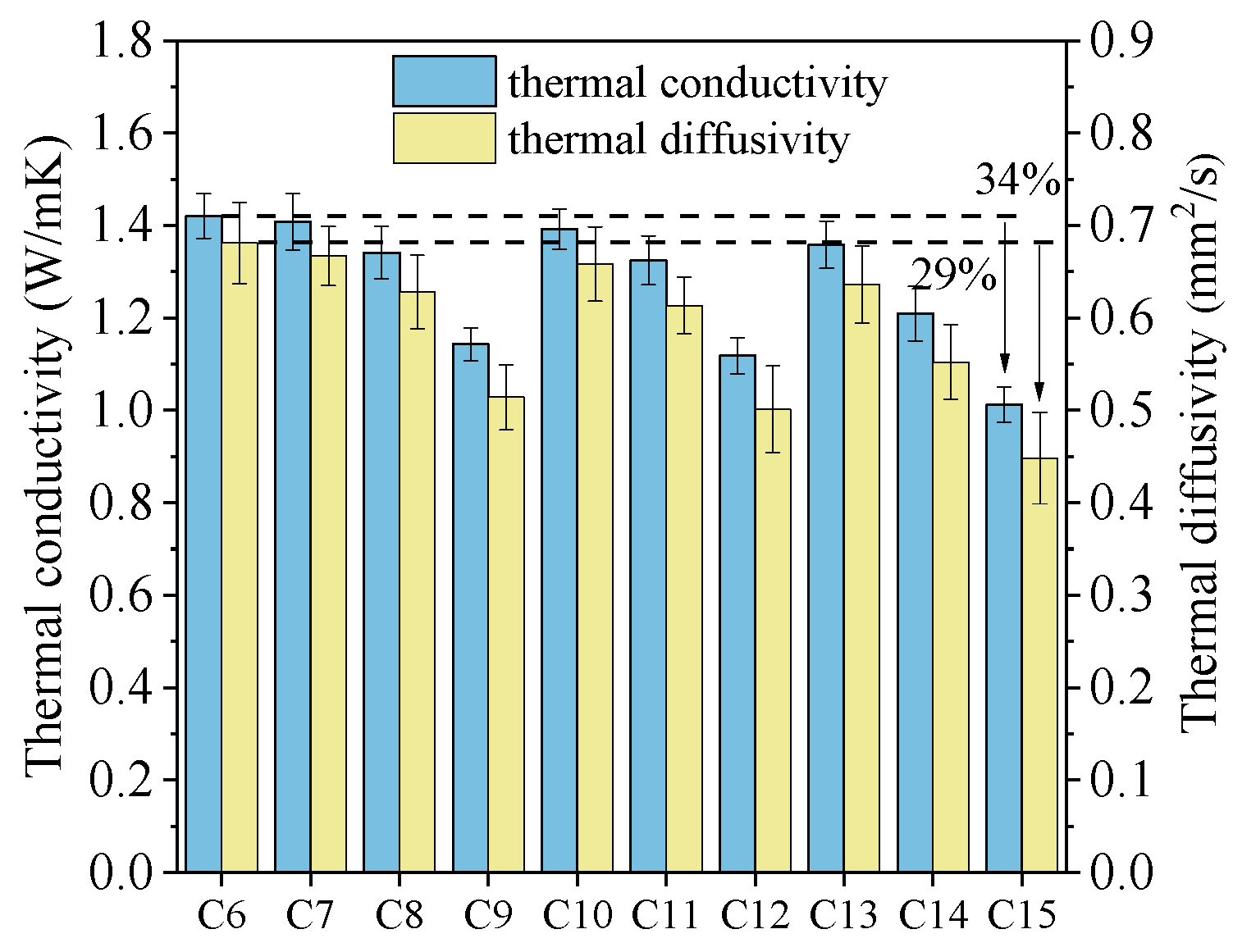

Figure 7 illustrates the thermal regulation efficacy of the RHA–FA matrix in PCM aggregate concrete. Compared to the reference concrete (without RHA–FA matrix), the 100% PCM aggregate concrete incorporated with 5% RHA and 10% FA exhibited reductions of 0.92% in thermal conductivity and 2.06% in thermal diffusivity under ambient conditions. The results show that the thermal damping is improved by incorporating the RHA–FA matrix. Compared with the 5% RHA, the thermal conductivity of the 15% RHA in concrete decreased by 18.76~25.48%, while its thermal diffusivity decreased by 22.94~29.56%. Similarly, the 30% FA exhibited reductions in thermal conductivity (3.48~11.46%) and thermal diffusivity (4.65~12.84%) compared to the 10% FA. The results indicate that RHA is more effective in reducing the thermal conductivity and improving its thermal damping compared to FA. Therefore, the improvement of concrete insulation performance is due to the addition of RHA. In addition, changes in pore structure can also affect the thermal constant values.

Figure 7.

Thermal conductivity and diffusivity of PCM concrete after incorporating RHA and FA.

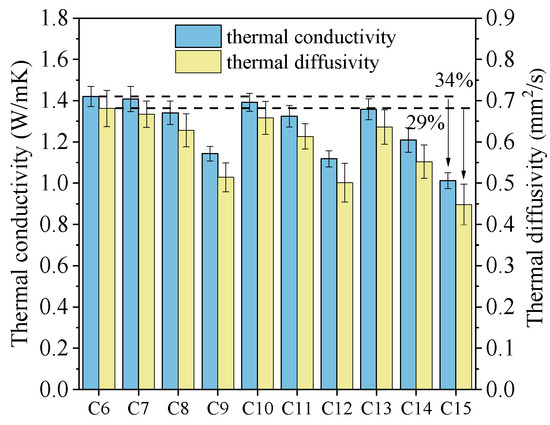

3.3. Dynamic Thermal Response

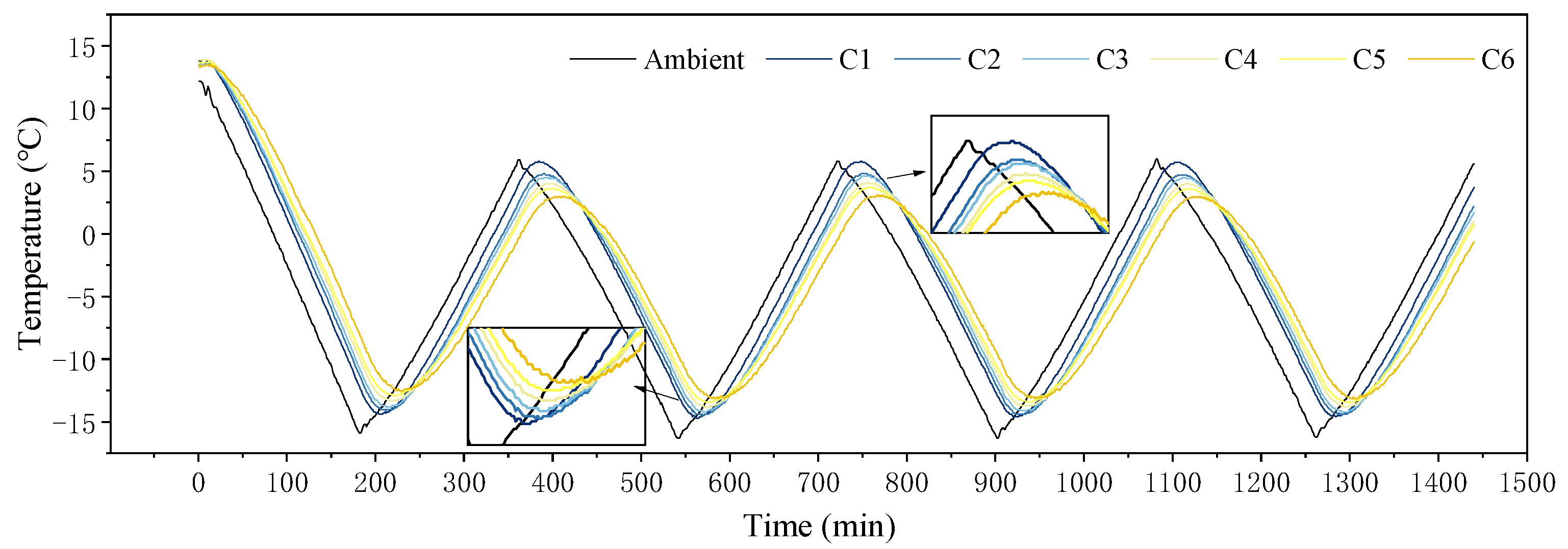

Figure 8 illustrates the time–temperature evolution of concrete specimens with varying PCM aggregate incorporation rates (0~100%) under ambient thermal conditions. These concrete specimens were subjected to temperature cycling in an ambient test machine. During the temperature drop process, all samples began to cool down. The ordinary concrete decreased at a higher rate than the PCM aggregate concrete. The time to reach the minimum temperature of the PCM aggregate concrete was delayed by 23~48 min compared to the control concrete. During the heating process, the thermal response of the PCM concrete was also slower than that of the ordinary concrete. The time of peak temperature exhibited a 26~51 min delay, correlating with the latent heat storage of PCM aggregates during phase change process. The temperature difference–time curves of PCM aggregate concrete were presented in Figure 9. The thermal damping of concrete increased with the content of PCM aggregate increased. The minimum temperature of 100% PCM concrete was 3.3 °C higher than ordinary concrete when the temperature decreased, while the extreme temperature of 100% PCM aggregate concrete was 4.5 °C lower than that of ordinary concrete when the temperature increased. Temperature difference analysis indicate that incorporating PCM aggregate can reduce the peak temperature of concrete.

Figure 8.

Time–temperature curve of concrete after incorporating PCM aggregate.

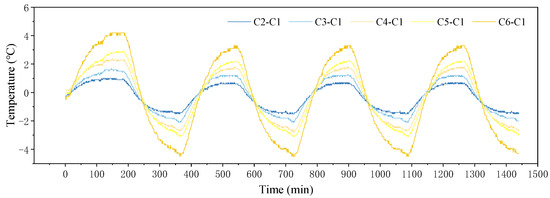

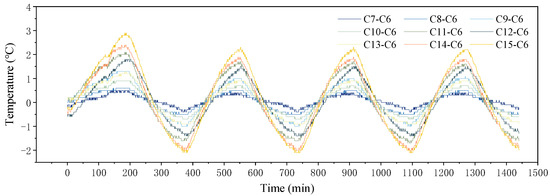

Figure 9.

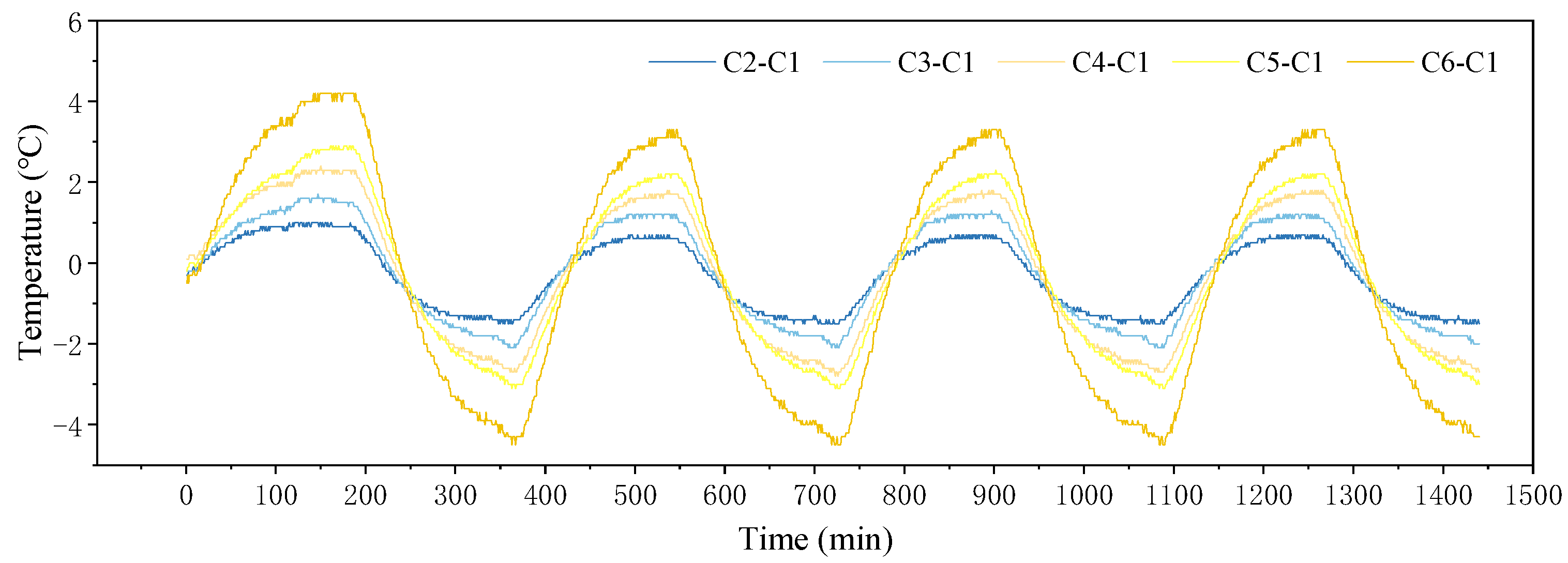

Temperature difference between PCM aggregate concrete and ordinary concrete.

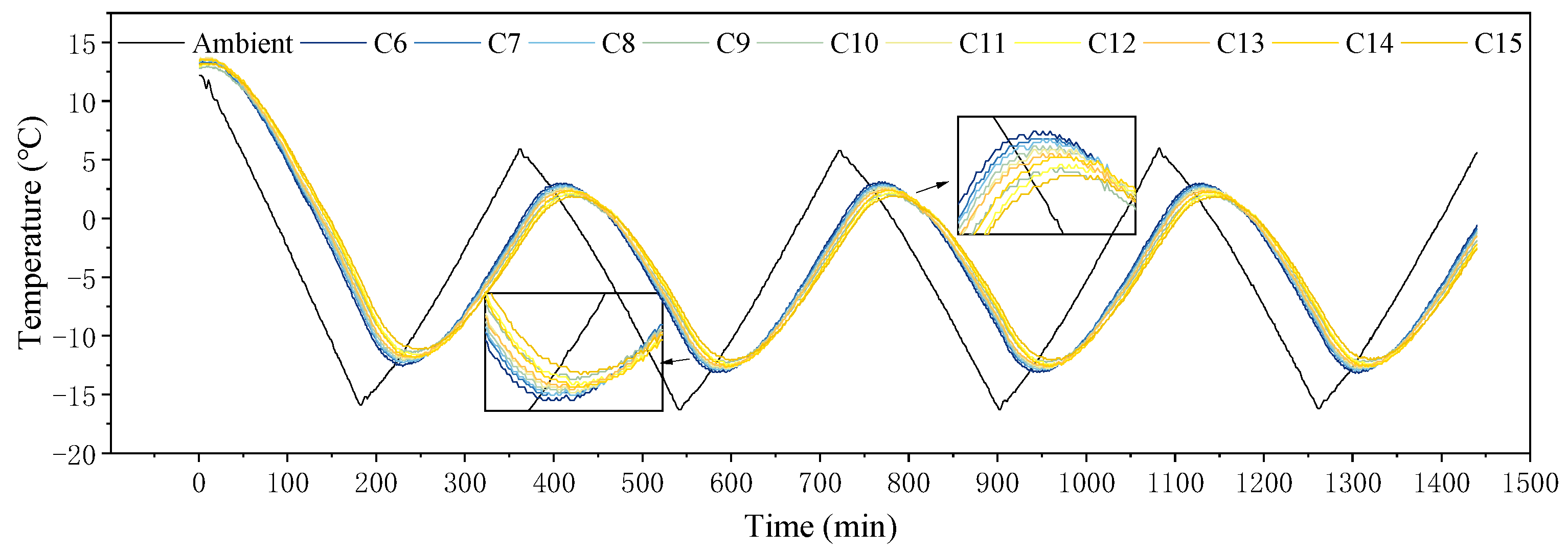

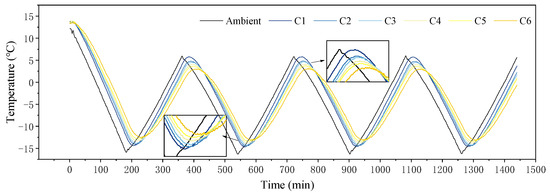

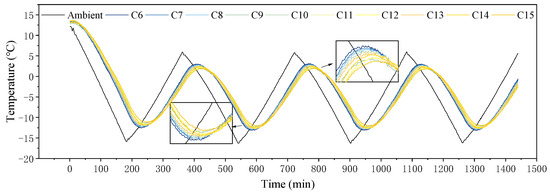

Figure 10 depicts the time–temperature profiles of RHA–FA modified concrete under thermal cycles. The composite exhibited pronounced thermal hysteresis during ambient temperature fluctuations, with the hysteresis magnitude strongly dependent on RHA–FA content. Specifically, compared to RHA-free concrete, the 15% RHA concrete exhibited a 7~21 min delay in reaching peak temperature. The higher the content of FA, the more slowly the temperature decreases and the greater the thermal damping. Compared to FA-free concrete, the 30% RHA concrete exhibited a 5 to 21 min delay in reaching peak temperature. This delay is attributed to the lower thermal properties of RHA–FA matrix, which improves the thermal insulation properties. Figure 11 shows the temperature difference–time curves of RHA–FA matrix PCM concrete. During the cooling phase, the RHA–FA matrix-modified concrete exhibited a reduced cooling rate. Specifically, the extreme temperature of 15% RHA concrete exceeded the control group by 1.5–2.3 °C, while that of 30% FA concrete exceeded the control group by 0.9–2.3 °C. During temperature rise, the concrete containing 15% RHA experienced a slower increase in temperature, with the peak temperature being 1.4~2.1 °C lower than that of the reference concrete. Concrete with 30% fly ash exhibited a similar trend, with peak temperatures also being 0.9~2.1 °C lower.

Figure 10.

Time–temperature curve of concrete after incorporating RHA and FA.

Figure 11.

Temperature difference between PCM aggregate concrete with and without RHA–FA.

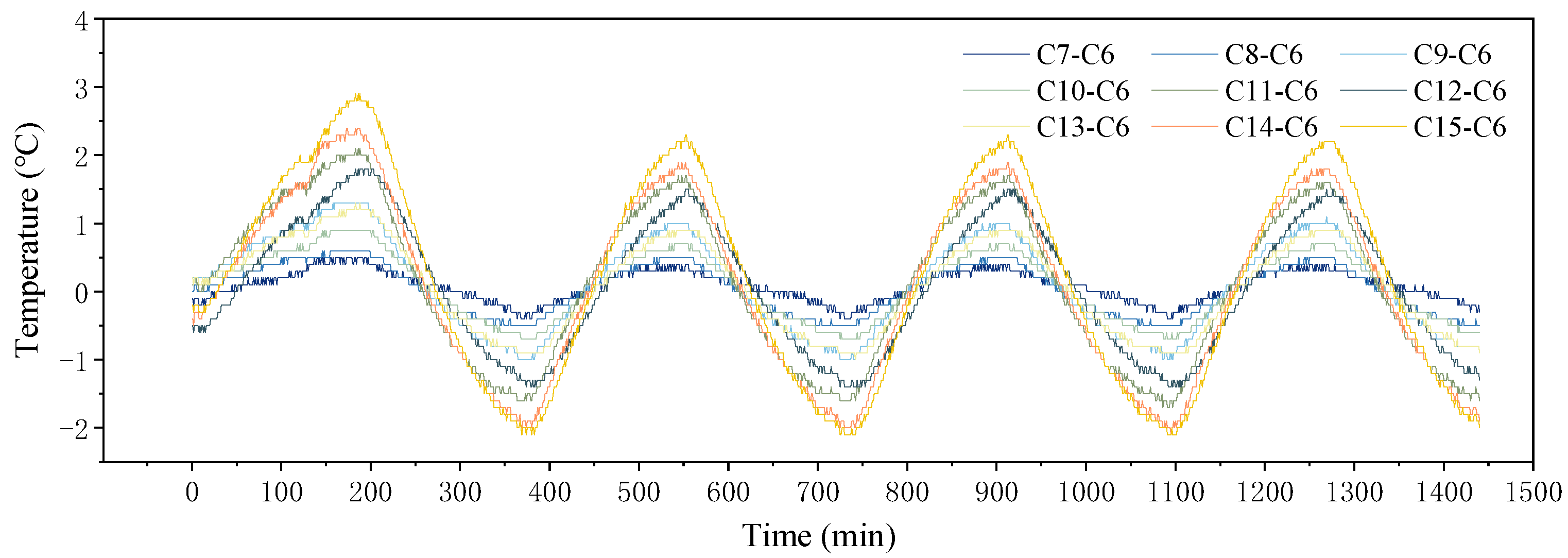

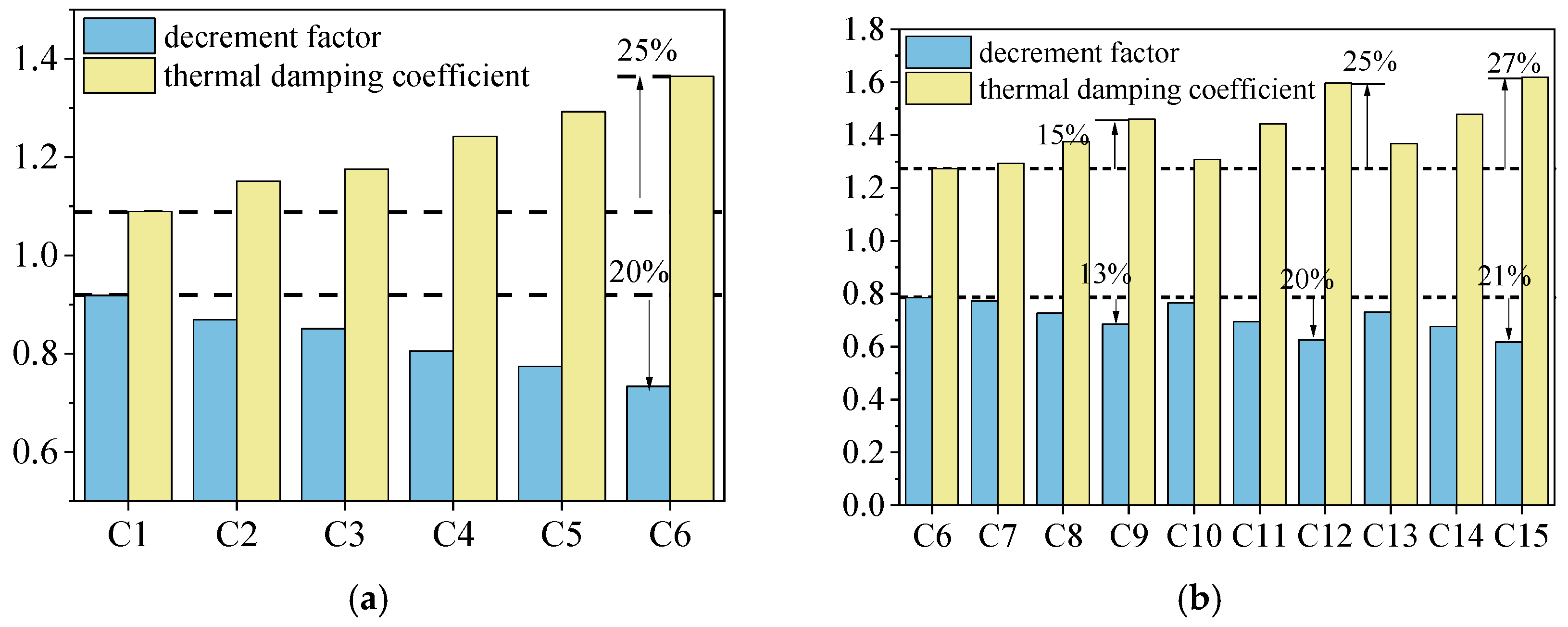

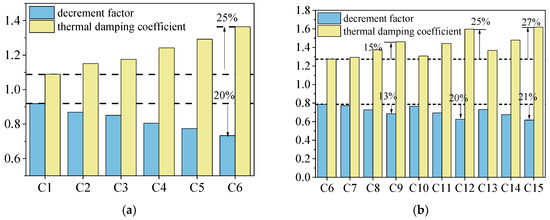

In order to quantify the thermal damping performance of concrete with different contents of PCM aggregate and RHA–FA matrix, a decrement factor and thermal damping coefficient were introduced. The decrement factor was defined as the ratio of the temperature fluctuation amplitude in concrete to that of the ambient environment, while the thermal damping coefficient was the reciprocal of the decrement factor. Figure 12a,b presents the decrement factors and thermal damping coefficients of PCM aggregate-incorporated concrete and RHA–FA matrix incorporated concrete, respectively.

Figure 12.

Decrement factor and thermal damping coefficient of concrete. (a) The influence of PCM aggregates. (b) The influence of RHA–FA matrix.

The thermal damping coefficient of concrete was related to the content of PCM aggregate. With the increase in PCM aggregate substitution, the thermal damping coefficient increased. For concrete completely mixed with 100% PCM aggregate, the thermal damping coefficient can be increased by 25%. The RHA–FA matrix further enhanced the thermal damping coefficient of PCM concrete. Compared to PCM concrete C6 without the addition of the RHA–FA matrix, the thermal damping coefficient of PCM concrete with 15% RHA can be increased by more than 15%; in particular, the thermal damping coefficient of 15% RHA–30% FA PCM concrete can be increased by 27%.

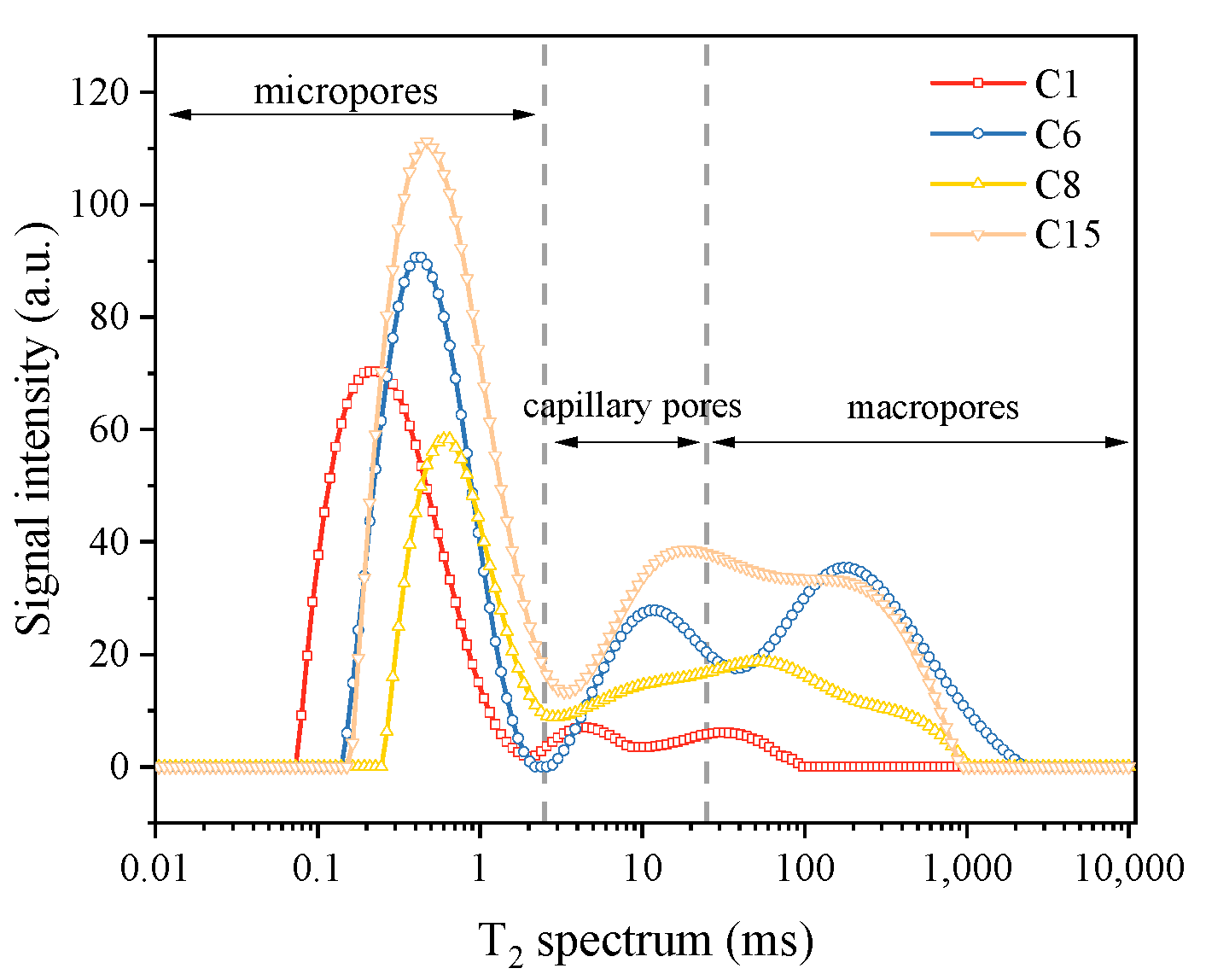

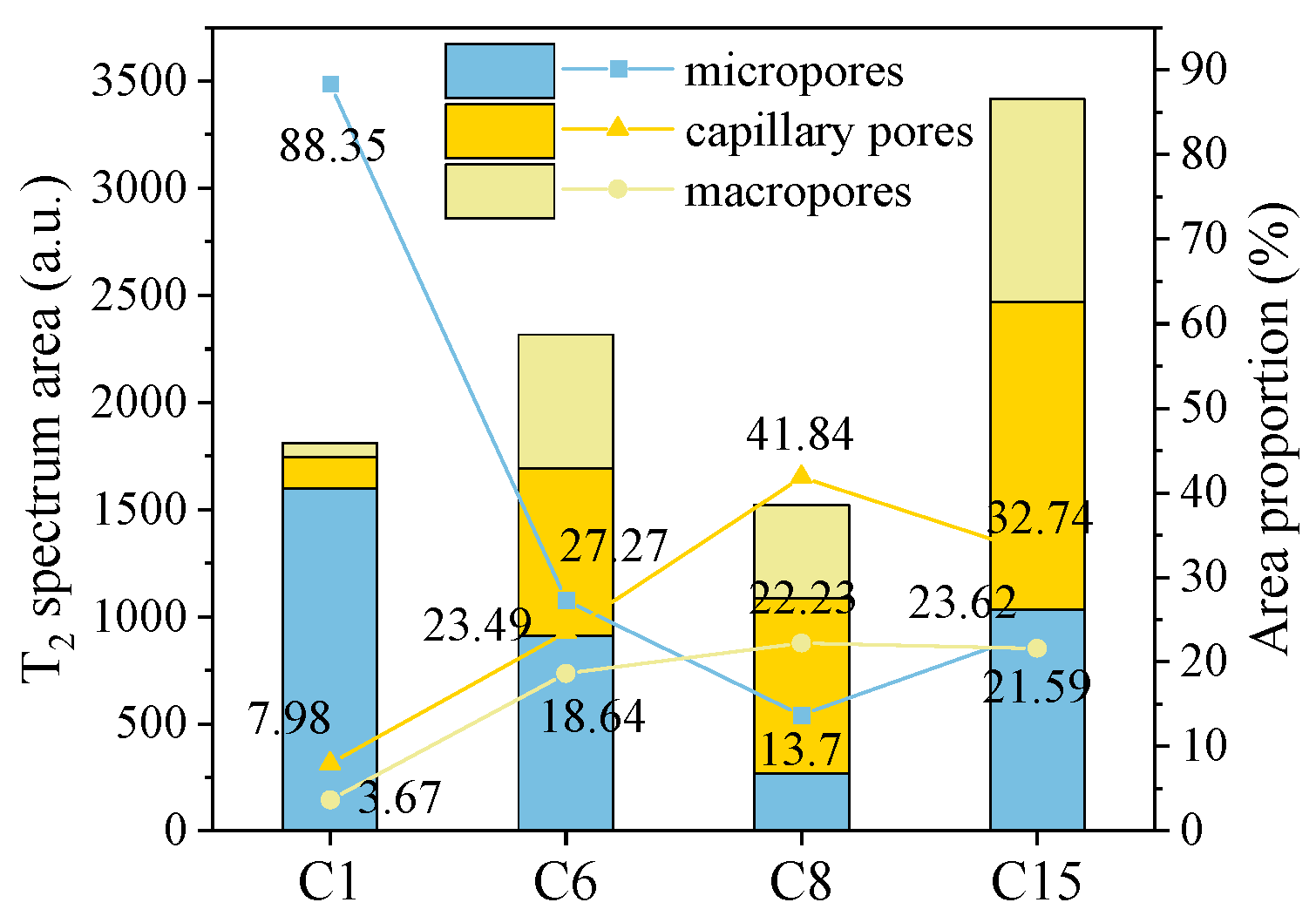

3.4. NMR Test

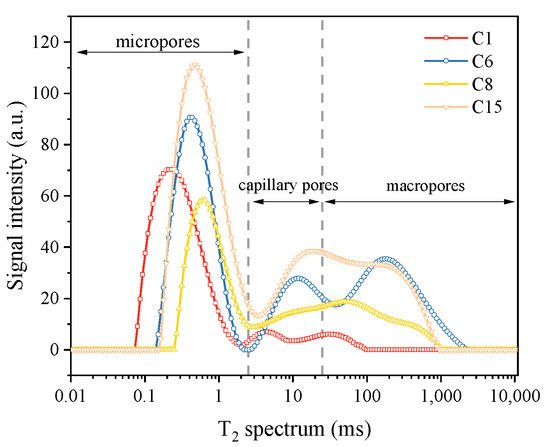

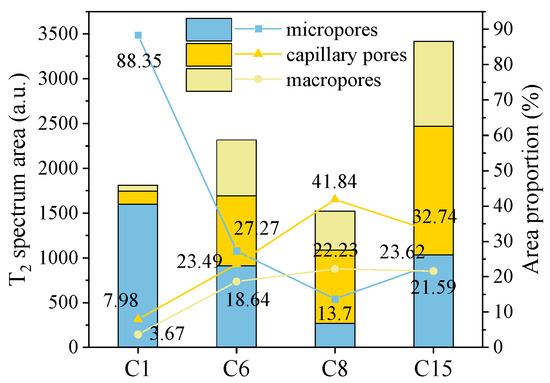

Pores are classified into micropores, capillary pores, and macropores based on transverse relaxation time, with pore diameters of less than 0.1 μm, 0.1 μm to 1 μm, and greater than 1 μm, respectively. Their transverse relaxation times are less than 2.5 ms, 2.5 ms to 25 ms, and greater than 25 ms [50,51], respectively. In the T2 spectrum, three signal peaks can be observed, which, from left to right, correspond to micropores, capillary pores, and macropores.

Figure 13 shows the T2 spectrum of concrete integrated with PCM aggregate and RHA–FA matrix. Figure 14 shows the total T2 spectrum intensity of different pores and the volume percentage of various pores in different concrete mixes mentioned above. T2 spectrum intensity is linearly correlated with pore volume, so it can be used to characterize the pore volume. Compared to ordinary concrete C1, concrete C6 contains 100% phase-change aggregates. The T2 spectrum exhibited rightward shifts in all three peaks, indicating a trend of pore enlargement across all categories. The micropore volume decreased slightly, while the capillary pores and macropore volumes increased, with their respective proportions increasing to 23.49% and 18.64%, respectively. After replacing natural coarse aggregate with 100% PCM aggregate, the surrounding water–cement ratio increases, which reduces the flowability of the concrete and makes it easier to capture air. Due to the combined effects of these factors, the volume of capillary pores and macropores increases, which is also one of the reasons for the decrease in concrete strength when PCM aggregates replace 100% natural coarse aggregates.

Figure 13.

T2 spectra of different concretes.

Figure 14.

T2 spectrum area and the percentage of pores.

Compared with the control concrete C6, some cement in concrete C8 was replaced by 10% RHA and 10% FA. The intensity of each signal peak in the T2 spectrum of the latter decreases, and the signal peaks of capillary pores and macropores become flatter, indicating a more uniform distribution of capillary pores and macropores. After replacing cement with appropriate amounts of RHA and FA, the total pore volume decreased by 41.43%, the micropore volume decreased by 70.57%, the capillary pore volume increased by 4.34%, and the macropore volume decreased by 30.16%. The proportion of capillary pores to macropores increased, which can be attributed to the decrease in total volume. The reduction in porosity is due to the filling effect and pozzolanic effects resulting from the incorporation of RHA–FA matrix into concrete. Their particle sizes are different from the cement particles, and a higher compactness of the cementitious material can be obtained by mixing them. At the same time, the pozzolanic effect of the two can lead to secondary hydration reactions, which make the density of C-S-H gel higher, thus reducing the micropore volume. The improvement in flow performance reduces the macropore volume. The increase in capillary pore volume is due to the evaporation of water absorbed by RHA.

However, there is an optimal dosage for RHA and FA, which can also be seen from the macroscopic physical properties of concrete mentioned above. The cement in concrete C15 was replaced by 15% RHA and 30% FA; compared with the control concrete C6, the strengths of the micropore and capillary pore signals in T2 spectrum increased, and the total pore volume increased by 31.24%, indicating that excessive RHA and FA is not conducive to reducing pore volume. The micropore volume increased by 13.64%, which was due to the reduction in C-S-H gel generated by cement when RHA and FA replaced cement. The volume of capillary pores and macropores increased by 82.91% and 51.99%, respectively, with their respective proportions rising to 32.74% and 21.59%. Based on the T2 spectrum, the increase in pore volume is the result of the increase in capillary pores and the evolution of some capillary pores into macropores. RHA has strong water absorption properties, and, when mixed into concrete, it absorbs the surrounding water, causing an increase in local water–cement ratio. Therefore, the volume of capillary pores related to water evaporation increases and tends to evolve into macropores. The excessive addition of RHA and FA cannot compensate for their adverse effects on pores when replacing cement, resulting in an increase in pore volume. This is also an important reason why the strength of concrete C15 is less than the reference concrete C6.

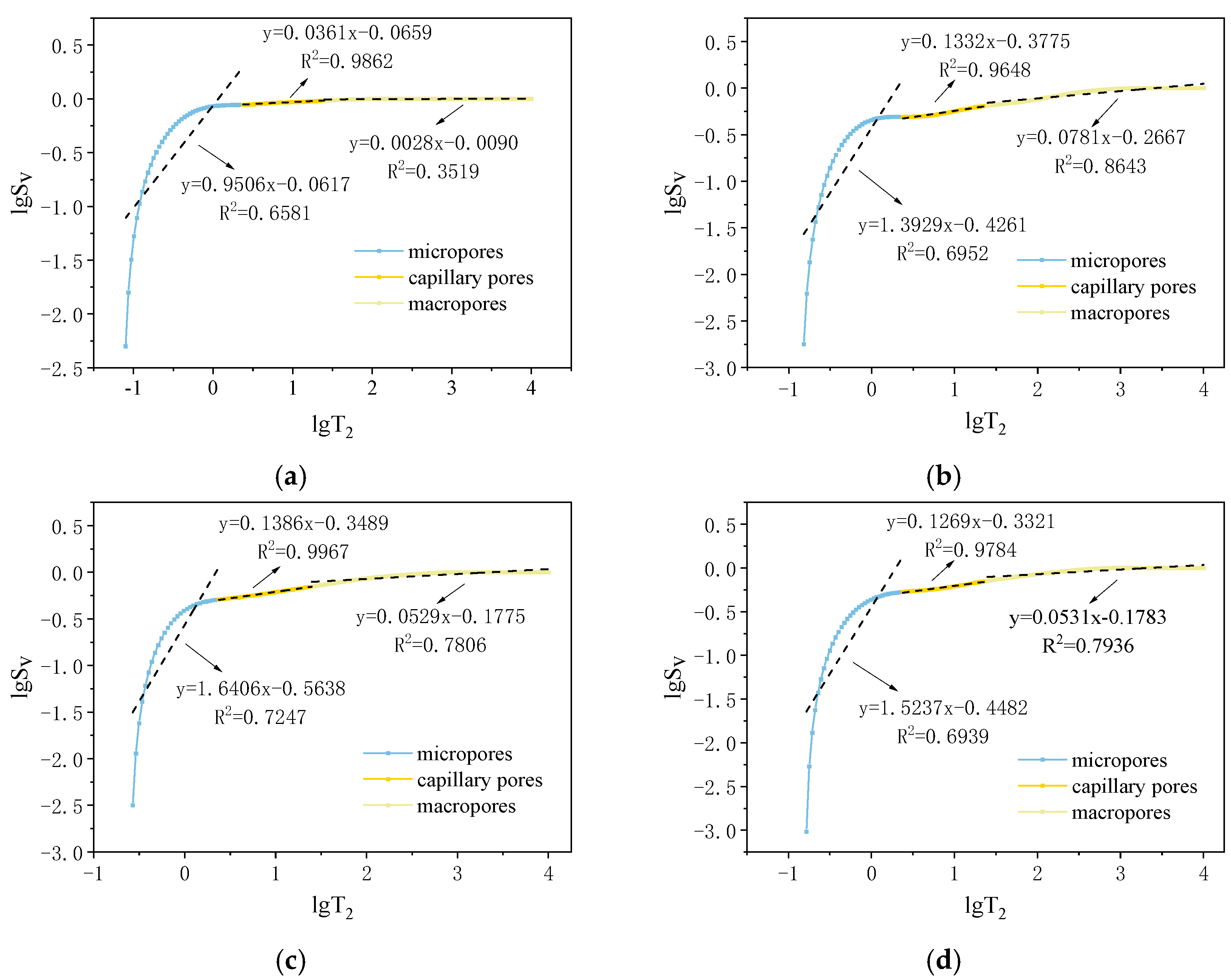

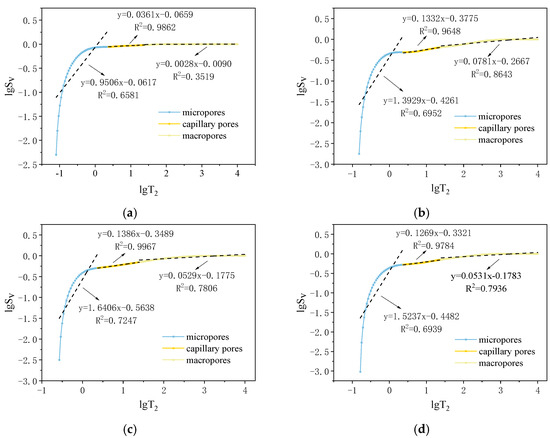

3.5. Fractal Dimension

Pore structure is complex, and the complexity of pores can be quantitatively analyzed through fractal dimension. The fractal dimension of concrete can be obtained through NMR T2 spectra. The relationship between fractal dimension and the T2 spectrum can be described by Equation (1) [52,53,54].

where Sv is the percentage of cumulative pore volume to total pore volume when it is less than T2 value, D is the fractal dimension, and T2max is the maximum relaxation time.

The relationship between lg Sv and lg T2 of the concrete specimen is plotted in Figure 15. The relationship between lg Sv and lg T2 can be obtained by two-segment linear fitting, i.e., the NMR fractal dimensions are obtained by fitting the data on both sides of the T2cutoff value separately. In this study, the T2cutoff values were set to 2.5 ms and 25 ms, respectively. The micropore fractal dimension Dmicro was obtained by fitting the portion less than 2.5 ms, the capillary fractal dimension Dcapillary was obtained by fitting the portion between 2.5 ms and 25 ms, and the macropore fractal dimension Dmacro was obtained by fitting the portion greater than 25 ms. The fractal dimension is obtained from Equation (1). Table 4 lists the fractal dimensions of different concrete specimens. K represents the relative growth rate. The table shows that not all values of Dmicro are between 2 and 3, which has lost the theoretical significance of Euclidean geometry. However, the values of Dcapillary and Dmacro are both within this range, demonstrating good fractal characteristics, indicating that the fractal dimension of capillary pores and macropores can effectively demonstrate the complexity of pore structure.

Figure 15.

Curve of lgT2 and lg Sv for different concretes. (a) C1. (b) C6. (c) C8. (d) C15.

Table 4.

The fractal dimension of different concretes.

After the addition of PCM aggregates, Dcapillary was reduced by 3.28%, and Dmacro was reduced by 2.51%. This is due to the gradual evolution of capillary pores and macropores towards larger sizes after the addition of PCM aggregates, resulting in interconnected pores and a decrease in pore structure complexity, which caused a reduction in fractal dimension. In 10% RHA, 10% FA, 100% PCM concrete, Dcapillary slightly decreased, while Dmacro increased by 0.86%. The slight decrease in Dcapillary may be related to the total pore volume in concrete C8, leading to a slight reduction in the calculated fractal dimension of capillary pores. The increase in Dmacro is the impact of FA, which reduces the quantity of macropores, making the pore structure more complex. The excessive replacement of cement with RHA and FA has a certain effect on pore complexity, with Dmacro increasing by 0.86%, which is caused by the reduced complexity due to fewer macropores. Compared to the addition of PCM aggregates, the addition of RHA and FA has a smaller impact on the complexity of pore structure in concrete.

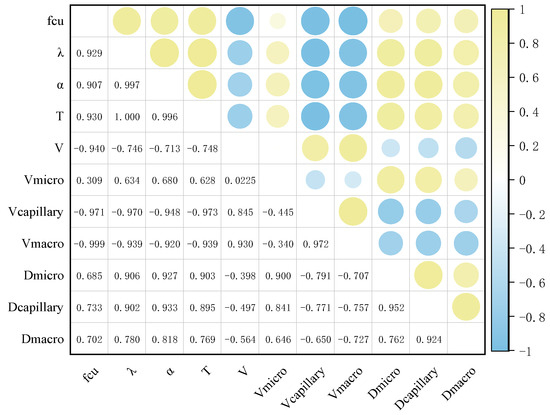

3.6. Correlation Analysis

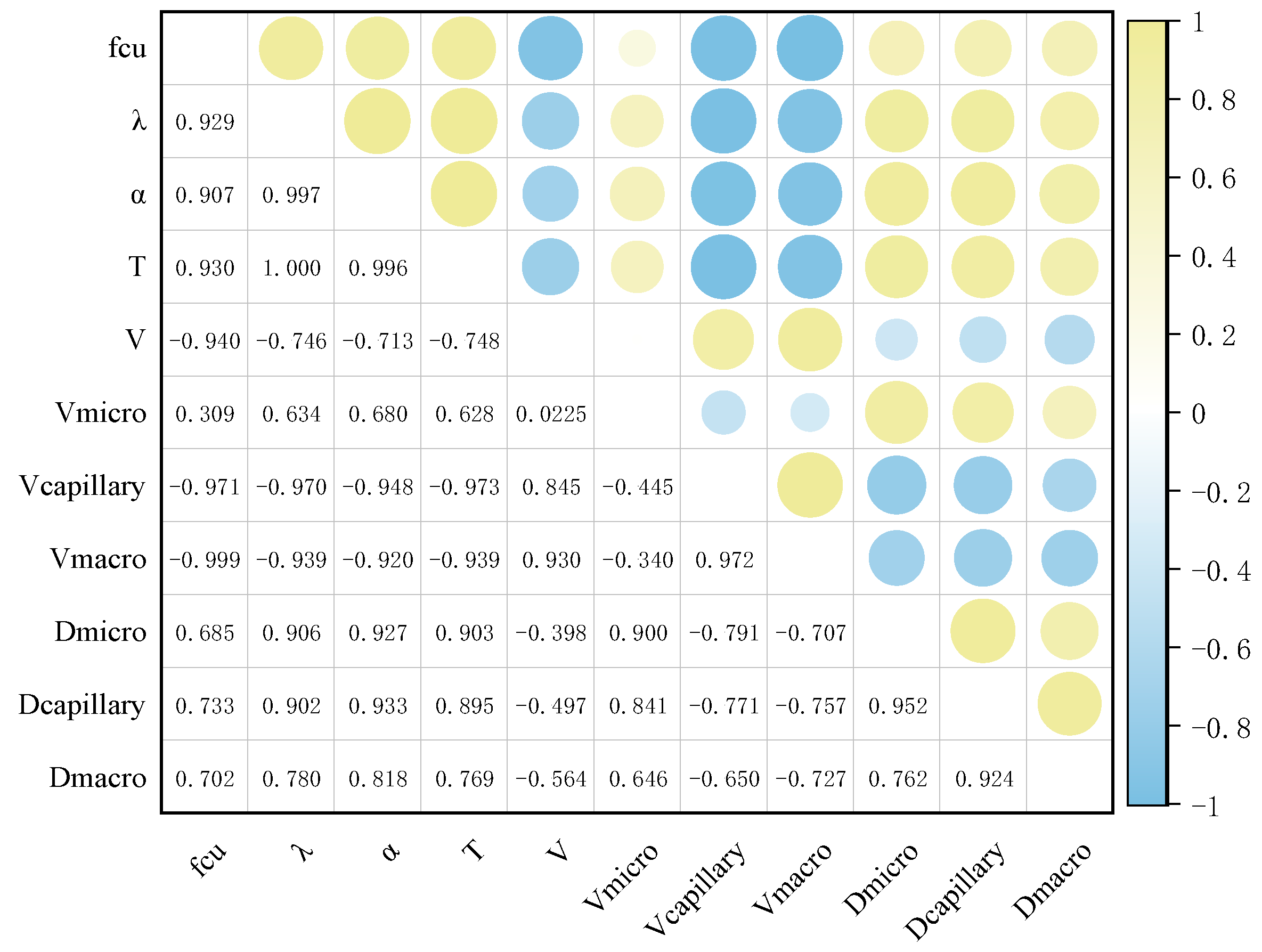

In this study, Pearson correlation analysis was employed to evaluate the degree of correlation between the macroscopic properties of concrete and its microscopic pore structure. The Pearson coefficient was used to assess the correlation between two datasets. When the absolute value of the correlation coefficient approaches 1, this indicates a strong correlation between the two datasets [55,56]. The objective of this subsection is to establish a relationship between macroscopic and microscopic indicators. Given the numerous parameters of the pore structure, considering all of them would be cumbersome; therefore, a correlation analysis was conducted to screen the parameters. Table 5 lists the macroscopic and microscopic performance parameters of concrete. A single-factor correlation analysis was performed between the aforementioned macroscopic performance indicators and pore structure parameters, with the results shown in Figure 16.

Table 5.

Macroscopic and microscopic data of concrete.

Figure 16.

Correlation coefficient between all parameters.

In Figure 16, the size of the circle represents the strength of correlation, with yellow indicating positive correlation and blue indicating negative correlation. The strength, thermal conductivity, thermal diffusivity, and temperature fluctuation amplitude of concrete incorporating PCM aggregates and the RHA–FA matrix exhibit strong correlations with pore volume and fractal dimension. Overall, these properties show a higher correlation with the volume and fractal dimension of capillary pores. The coefficients of correlation between strength, thermal conductivity, thermal diffusivity, and temperature fluctuation amplitude with capillary pore volume are 0.971, 0.970, 0.948, and 0.973, respectively. The coefficients of correlation between these four macroscopic properties and capillary pore fractal dimension are 0.733, 0.902, 0.933, and 0.895, respectively. In this study, the volume and fractal dimension of capillary pores can characterize the physical properties of concrete. Based on the above parameters, the relationship expression between macroscopic physical properties and microscopic pore structure parameters is assumed to follow Equation (2).

In the formula, P is predicted value; a, b, c are coefficients; Vcapillary is capillary pore volume; Dcapillary is the fractal dimension of capillary pores.

The results of the multiple linear regression analysis are shown in Table 6, where the fitting coefficient is higher when predicting the macroscopic physical properties of concrete using both pore volume and fractal dimension as dual parameters. The macroscopic performance prediction models based on dual parameters of pore structure are presented in Equations (3)–(6).

Table 6.

Multivariate fitting results.

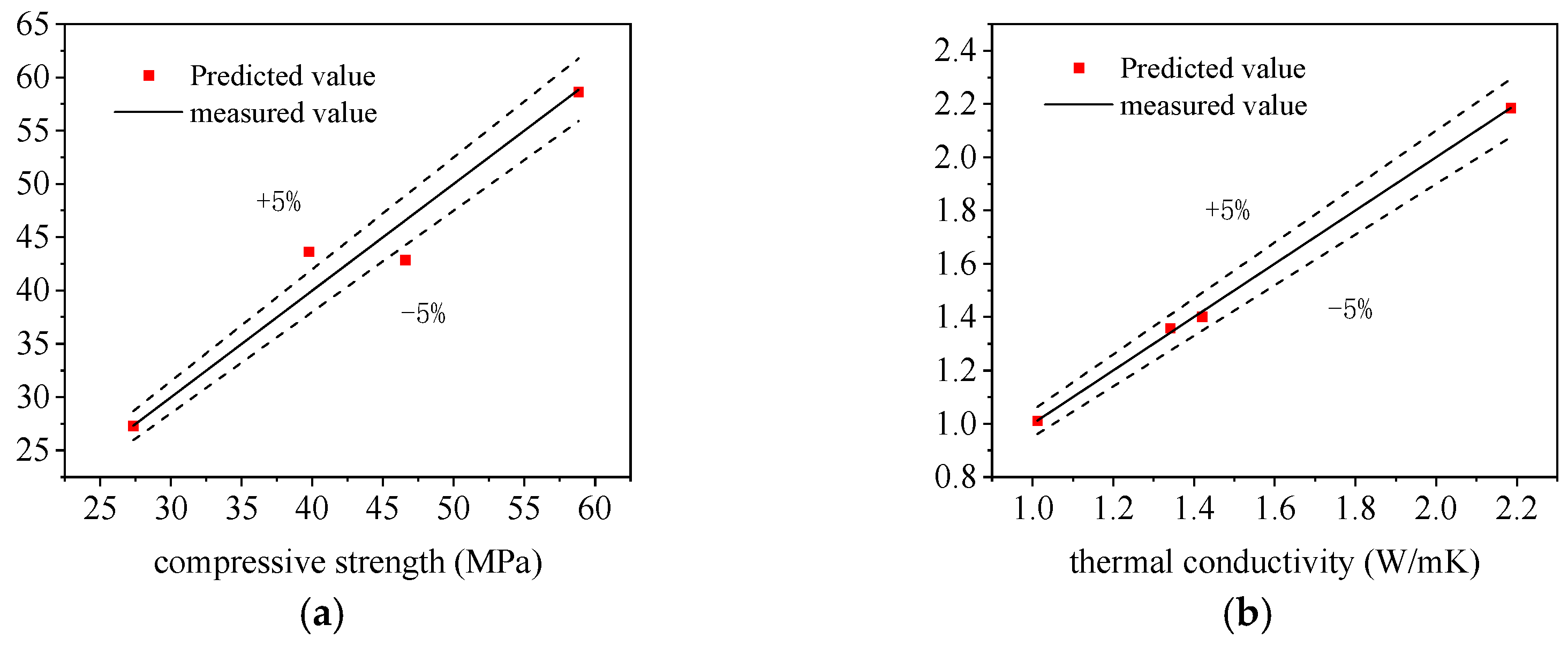

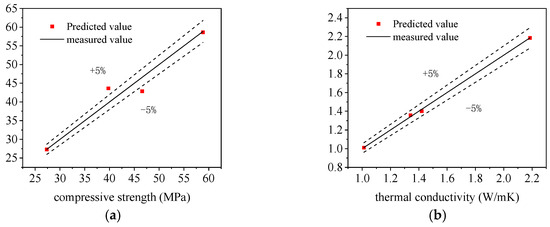

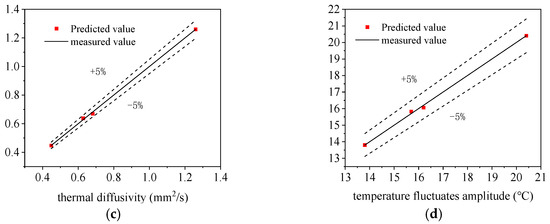

To validate the accuracy of the macroscopic performance prediction model, the predicted values obtained from the prediction model were compared with the measured values, as shown in Figure 17. The results indicate that the predicted values for strength, thermal conductivity, thermal diffusivity, and temperature fluctuation amplitude are in close agreement with the measured values, with minimal error. This demonstrates that the established prediction model can accurately predict the macroscopic properties of concrete with PCM aggregate and the RHA–FA matrix.

Figure 17.

Comparison between predicted and measured macroscopic performance values of concrete. (a) compressive strength. (b) thermal conductivity. (c) thermal diffusivity. (d) temperature fluctuates amplitude.

4. Conclusions

Cement matrix and aggregate influence the thermal properties of concrete; in this study, the thermal response of concrete under different PCM aggregates and RHA–FA matrix contents was analyzed to investigate its feasibility as an insulating material for thermal envelopes in cold regions.

The experimental study systematically adjusted the replacement amounts of PCM aggregate, RHA, and FA, investigating the effects of 0–100% PCM aggregate, 5–15% RHA, and 10–30% FA on concrete strength, thermal conductivity, thermal diffusivity, time–temperature curves, time–temperature difference curves, and damping coefficient. Based on nuclear magnetic resonance (NMR) tests, the study analyzed the impacts of different PCM aggregates and RHA–FA matrix compositions on the pore distribution, volume, and fractal dimension. Through correlation analysis, suitable pore structure parameters were identified, and a macroscopic performance prediction model with two parameters was established. The main conclusions are as follows:

- Due to the low strength of PCM aggregates, their incorporation into concrete has some adverse effects. However, the RHA–FA matrix exhibits filling and pozzolanic effects, and their addition helps to mitigate the reduction in PCM concrete strength. Compared to control concrete, the strength of concrete incorporated with 100% PCM aggregate and a 10% RHA–10% FA matrix increased by 17%;

- The thermal constants of concrete decrease after incorporating PCM aggregate, with the degree of reduction depending on the replacement rate. The incorporation of 100% PCM aggregates into concrete results in a 35% reduction in thermal conductivity and a 46% decrease in thermal diffusivity. An increase in RHA content leads to a decrease in thermal conductivity and thermal diffusivity, while FA has a smaller impact on thermal performance. Compared to ordinary concrete, the 15%RHA–30%FA–100%PCM aggregate concrete exhibits a 53% reduction in thermal conductivity and a 64% reduction in thermal diffusivity;

- The incorporation of PCM aggregates and the RHA–FA matrix significantly alters the dynamic thermal response of concrete, resulting in reduced temperature change rates and fluctuation ranges. The 15%RHA–30%FA–100%PCM aggregate concrete experiences a 5.5 °C reduction in peak temperature, a 70 min delay in reaching peak temperature, and a 48% increase in damping coefficient;

- The addition of PCM aggregates increases the pore volume and decreases the fractal dimension of concrete. An appropriate amount of RHA–FA matrix helps to reduce pore volume, particularly macropores and capillary pores, increasing the fractal dimension. However, an excessive addition of RHA–FA matrix will have adverse effects on pore volume;

- Correlation analysis indicates that strength, thermal diffusivity, thermal conductivity, and temperature fluctuation are highly related to capillary pore volume and capillary pore fractal dimension. A two-parameter model based on pore structure characteristics can effectively predict the macroscopic properties of RHA–FA PCM aggregate concrete.

Author Contributions

Conceptualization, M.Z. and S.G.; methodology, M.Z. and J.X.; software, L.W.; validation, M.X., M.Z. and S.G.; formal analysis, H.Y.; investigation, M.Z.; resources, M.Z.; data curation, S.G.; writing—original draft preparation, M.Z.; writing—review and editing, M.Z. and S.G.; visualization, J.X.; supervision, L.W. and M.X.; project administration, M.Z.; funding acquisition, M.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Scientific Research Program for Youth Innovation Team Construction of Shaanxi Provincial Department of Education (22JP098).

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors would like to acknowledge the financial support received from the Scientific Research Program for Youth Innovation Team Construction of Shaanxi Provincial Department of Education (22JP098, 24JP201), and Natural Science Basic Research Program of Shaanxi Province (Program No. 2024JC-YBMS-439).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Liu, Y.; Wu, H.; Gao, Y.; Wang, W.; Wang, Z. Influence of macadamia nutshell particles on the apparent density and mechanical behavior of cement-based mortars. Constr. Build. Mater. 2024, 411, 134600. [Google Scholar] [CrossRef]

- Gholamibozanjani, G.; Farid, M. Application of an active PCM storage system into a building for heating/cooling load reduction. Energy 2020, 210, 118572. [Google Scholar] [CrossRef]

- Gao, S.; Cui, X.; Kang, S.; Ding, Y. Sustainable applications for utilizing molybdenum tailings in concrete. J. Clean. Prod. 2020, 266, 122020. [Google Scholar] [CrossRef]

- Gao, S.; Li, J.; Nishiwaki, T.; Ding, Y.; Wang, J.-x. Structural implementation of recycled lump prepared from waste concrete after elevated temperatures: Mechanical and environmental performances. Structures 2024, 67, 106970. [Google Scholar] [CrossRef]

- Yang, Y.; Chen, H.; Peng, J.; Dong, Y. Machine learning-based probabilistic prediction model for chloride concentration in the interfacial zone of precast and cast-in-place concrete structures. Structures 2025, 72, 108224. [Google Scholar] [CrossRef]

- Gao, S.; Peng, Z.; Wang, X.D.; Liu, J.P. Compressive behavior of circular hollow and concrete-filled steel tubular stub columns under atmospheric corrosion. Steel Compos. Struct. 2019, 33, 615–627. [Google Scholar]

- Lee, K.O.; Medina, M.A.; Raith, E.; Sun, X. Assessing the integration of a thin phase change material (PCM) layer in a residential building wall for heat transfer reduction and management. Appl. Energy 2015, 137, 699–706. [Google Scholar] [CrossRef]

- Li, W.; Zhou, Y.; Cetin, K.S.; Yu, S.; Wang, Y.; Liang, B. Developing a landscape of urban building energy use with improved spatiotemporal representations in a cool-humid climate. Build. Environ. 2018, 136, 107–117. [Google Scholar] [CrossRef]

- Hekimoğlu, G.; Nas, M.; Ouikhalfan, M.; Sarı, A.; Tyagi, V.V.; Sharma, R.K.; Kurbetci, Ş.; Saleh, T.A. Silica fume/capric acid-stearic acid PCM included-cementitious composite for thermal controlling of buildings: Thermal energy storage and mechanical properties. Energy 2021, 219, 119588. [Google Scholar] [CrossRef]

- Gao, S.; Zhao, G.; Guo, L.; Zhou, L.; Yuan, K. Utilization of coal gangue as coarse aggregates in structural concrete. Constr. Build. Mater. 2021, 268, 121212. [Google Scholar] [CrossRef]

- Strzałkowski, J.; Sikora, P.; Chung, S.-Y.; Elrahman, M.A. Thermal performance of building envelopes with structural layers of the same density: Lightweight aggregate concrete versus foamed concrete. Build. Environ. 2021, 196, 107799. [Google Scholar] [CrossRef]

- Jiang, L.; Gao, Y.; Zhuang, C.; Feng, C.; Zhang, X.; Guan, J. Experiment verification and simulation optimization of phase change material cool roof in summer—A case study of Chongqing, China. Energy 2024, 293, 130613. [Google Scholar] [CrossRef]

- Cárdenas-Ramírez, C.; Gómez, M.A.; Jaramillo, F.; Cardona, A.F.; Fernández, A.G.; Cabeza, L.F. Experimental steady-state and transient thermal performance of materials for thermal energy storage in building applications: From powder SS-PCMs to SS-PCM-based acrylic plaster. Energy 2022, 250, 123768. [Google Scholar] [CrossRef]

- Gao, S.; Li, W.; Yuan, K.; Rong, C. Properties and application of thixotropic cement paste backfill with molybdenum tailings. J. Clean. Prod. 2023, 391, 136169. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Gamage, J.C.P.H.; De Silva, G.I.P.; Navaratnam, S. Development of sustainable mortar using waste rice husk ash from rice mill plant: Physical and thermal properties. J. Build. Eng. 2021, 43, 102614. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Navaratnam, S.; Gamage, J.C.P.H.; Thamboo, J.; Siddique, R.; Zhang, J.; Zhang, G. Thermal and environmental impact analysis of rice husk ash-based mortar as insulating wall plaster. Constr. Build. Mater. 2021, 283, 122744. [Google Scholar] [CrossRef]

- Kheradmand, M.; Azenha, M.; de Aguiar, J.L.B.; Castro-Gomes, J. Experimental and numerical studies of hybrid PCM embedded in plastering mortar for enhanced thermal behaviour of buildings. Energy 2016, 94, 250–261. [Google Scholar] [CrossRef]

- Gao, S. Life cycle sustainability assessment of concrete-filled steel tubular frames in earthquake regions. Eng. Struct. 2025, 328, 119761. [Google Scholar] [CrossRef]

- Bie, R.-S.; Song, X.-F.; Liu, Q.-Q.; Ji, X.-Y.; Chen, P. Studies on effects of burning conditions and rice husk ash (RHA) blending amount on the mechanical behavior of cement. Cem. Concr. Compos. 2015, 55, 162–168. [Google Scholar] [CrossRef]

- Prasara-A, J.; Gheewala, S.H. Sustainable utilization of rice husk ash from power plants: A review. J. Clean. Prod. 2017, 167, 1020–1028. [Google Scholar] [CrossRef]

- Magotra, V.K.; Lee, S.J.; Inamdar, A.I.; Kang, T.W.; Walke, P.D.; Hogan, S.C.; Kim, D.Y.; Saratale, G.D.; Saratale, R.G.; Purkayastha, A.; et al. Development of white brick fuel cell using rice husk ash agricultural waste for sustainable power generation: A novel approach. Renew. Energy 2021, 179, 1875–1883. [Google Scholar] [CrossRef]

- Antiohos, S.K.; Tapali, J.G.; Zervaki, M.; Sousa-Coutinho, J.; Tsimas, S.; Papadakis, V.G. Low embodied energy cement containing untreated RHA: A strength development and durability study. Constr. Build. Mater. 2013, 49, 455–463. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, W.; Liu, H.; Lin, X.; Zhang, R. A compressive strength prediction model based on the hydration reaction of cement paste by rice husk ash. Constr. Build. Mater. 2022, 340, 127841. [Google Scholar] [CrossRef]

- Faried, A.S.; Mostafa, S.A.; Tayeh, B.A.; Tawfik, T.A. The effect of using nano rice husk ash of different burning degrees on ultra-high-performance concrete properties. Constr. Build. Mater. 2021, 290, 123279. [Google Scholar] [CrossRef]

- Cordeiro, G.C.; Filho, R.D.T.; Tavares, L.M.; Fairbairn, E.D.M.R.; Hempel, S. Influence of particle size and specific surface area on the pozzolanic activity of residual rice husk ash. Cem. Concr. Compos. 2011, 33, 529–534. [Google Scholar] [CrossRef]

- Onyenokporo, N.C.; Taki, A.; Montalvo, L.Z.; Oyinlola, M. Thermal performance characterization of cement-based masonry blocks incorporating rice husk ash. Constr. Build. Mater. 2023, 398, 132481. [Google Scholar] [CrossRef]

- Sandhu, R.K.; Siddique, R. Influence of rice husk ash (RHA) on the properties of self-compacting concrete: A review. Constr. Build. Mater. 2017, 153, 751–764. [Google Scholar] [CrossRef]

- Thomas, B.S. Green concrete partially comprised of rice husk ash as a supplementary cementitious material—A comprehensive review. Renew. Sustain. Energy Rev. 2018, 82, 3913–3923. [Google Scholar] [CrossRef]

- Barreneche, C.; Navarro, L.; de Gracia, A.; Fernández, A.I.; Cabeza, L.F. In situ thermal and acoustic performance and environmental impact of the introduction of a shape-stabilized PCM layer for building applications. Renew. Energy 2016, 85, 281–286. [Google Scholar] [CrossRef]

- Pirasaci, T.; Sunol, A. Potential of phase change materials (PCM) for building thermal performance enhancement: PCM-composite aggregate application throughout Turkey. Energy 2024, 292, 130589. [Google Scholar] [CrossRef]

- Xu, T.; Chen, Q.; Zhang, Z.; Gao, X.; Huang, G. Investigation on the properties of a new type of concrete blocks incorporated with PEG/SiO2 composite phase change material. Build. Environ. 2016, 104, 172–177. [Google Scholar] [CrossRef]

- Sayyar, M.; Weerasiri, R.R.; Soroushian, P.; Lu, J. Experimental and numerical study of shape-stable phase-change nanocomposite toward energy-efficient building constructions. Energy Build. 2014, 75, 249–255. [Google Scholar] [CrossRef]

- Cui, H.; Tang, W.; Qin, Q.; Xing, F.; Liao, W.; Wen, H. Development of structural-functional integrated energy storage concrete with innovative macro-encapsulated PCM by hollow steel ball. Appl. Energy 2017, 185, 107–118. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Uthaichotirat, P.; Sangpet, T.; Sisomphon, K.; Newlands, M.; Siripanichgorn, A.; Chindaprasirt, P. Thermal properties of lightweight concrete incorporating high contents of phase change materials. Constr. Build. Mater. 2019, 207, 431–439. [Google Scholar] [CrossRef]

- Remesar, J.C.; Vera, S.; Lopez, M. Assessing and understanding the interaction between mechanical and thermal properties in concrete for developing a structural and insulating material. Constr. Build. Mater. 2017, 132, 353–364. [Google Scholar] [CrossRef]

- Wu, D.; Rahim, M.; El Ganaoui, M.; Djedjig, R.; Bennacer, R.; Liu, B. Experimental investigation on the hygrothermal behavior of a new multilayer building envelope integrating PCM with bio-based material. Build. Environ. 2021, 201, 107995. [Google Scholar] [CrossRef]

- Kheradmand, M.; Castro-Gomes, J.; Azenha, M.; Silva, P.D.; de Aguiar, J.L.B.; Zoorob, S.E. Assessing the feasibility of impregnating phase change materials in lightweight aggregate for development of thermal energy storage systems. Constr. Build. Mater. 2015, 89, 48–59. [Google Scholar] [CrossRef]

- Mohseni, E.; Tang, W.; Wang, S. Development of thermal energy storage lightweight structural cementitious composites by means of macro-encapsulated PCM. Constr. Build. Mater. 2019, 225, 182–195. [Google Scholar] [CrossRef]

- Ying, H.; Wang, S.; Lu, Z.; Liu, B.; Zhao, N.; Liu, K.; Quan, X. Incorporation of multi-stage phase change material aggregates into concrete: Effect of aggregate replacement on mechanical-thermal properties and pore structure change. Constr. Build. Mater. 2024, 411, 134355. [Google Scholar] [CrossRef]

- Ahsan, M.B.; Hossain, Z. Supplemental use of rice husk ash (RHA) as a cementitious material in concrete industry. Constr. Build. Mater. 2018, 178, 1–9. [Google Scholar] [CrossRef]

- Ying, H.; Wang, S.; Lu, Z.; Liu, B.; Cui, L.; Quan, X.; Liu, K.; Zhao, N. Development and thermal response of concrete incorporated with multi-stage phase change materials-aggregates for application in seasonally frozen regions. J. Build. Eng. 2023, 71, 106562. [Google Scholar] [CrossRef]

- Jittin, V.; Bahurudeen, A. Evaluation of rheological and durability characteristics of sugarcane bagasse ash and rice husk ash based binary and ternary cementitious system. Constr. Build. Mater. 2022, 317, 125965. [Google Scholar] [CrossRef]

- Padhi, R.S.; Patra, R.K.; Mukharjee, B.B.; Dey, T. Influence of incorporation of rice husk ash and coarse recycled concrete aggregates on properties of concrete. Constr. Build. Mater. 2018, 173, 289–297. [Google Scholar] [CrossRef]

- Rifai, H.; Staude, A.; Meinel, D.; Illerhaus, B.; Bruno, G. In-situ pore size investigations of loaded porous concrete with non-destructive methods. Cem. Concr. Res. 2018, 111, 72–80. [Google Scholar] [CrossRef]

- Torres-Carrasco, M.; Reinosa, J.J.; de la Rubia, M.A.; Reyes, E.; Peralta, F.A.; Fernández, J.F. Critical aspects in the handling of reactive silica in cementitious materials: Effectiveness of rice husk ash vs nano-silica in mortar dosage. Constr. Build. Mater. 2019, 223, 360–367. [Google Scholar]

- Hu, L.; He, Z.; Shao, Y.; Cai, X.; Zhang, S. Microstructure and properties of sustainable cement-based materials using combustion treated rice husk ash. Constr. Build. Mater. 2021, 294, 123482. [Google Scholar] [CrossRef]

- de Sensale, G.R.; Ribeiro, A.B.; Gonçalves, A. Effects of RHA on autogenous shrinkage of Portland cement pastes. Cem. Concr. Compos. 2008, 30, 892–897. [Google Scholar] [CrossRef]

- Sata, V.; Jaturapitakkul, C.; Kiattikomol, K. Influence of pozzolan from various by-product materials on mechanical properties of high-strength concrete. Constr. Build. Mater. 2007, 21, 1589–1598. [Google Scholar] [CrossRef]

- Ganesan, K.; Rajagopal, K.; Thangavel, K. Rice husk ash blended cement: Assessment of optimal level of replacement for strength and permeability properties of concrete. Constr. Build. Mater. 2008, 22, 1675–1683. [Google Scholar]

- Li, Y.; Ma, H.; Wen, L.; Yuan, J.; Zhang, Y.; Li, Y.; Zhou, H.; Chen, J. Influence of pore size distribution on concrete cracking with different AEA content and curing age using acoustic emission and low-field NMR. J. Build. Eng. 2022, 58, 105059. [Google Scholar]

- Zhou, S.; Liu, D.; Cai, Y.; Yao, Y. Fractal characterization of pore–fracture in low-rank coals using a low-field NMR relaxation method. Fuel 2016, 181, 218–226. [Google Scholar] [CrossRef]

- Guo, H.; Li, H.; Wang, H.; Wei, L.; Li, Y. Mechanisms of whisker-toughened hybrid fiber concrete based on fractal dimension and radar model. Constr. Build. Mater. 2024, 416, 134877. [Google Scholar] [CrossRef]

- Fu, J.-X.; Wang, K.; Wang, J. Internal pore evolution and early hydration characterization of fly ash cement backfill. J. Build. Eng. 2023, 72, 106716. [Google Scholar] [CrossRef]

- Yin, T.; Jin, L.; Liu, K.; Fan, D.; Dong, E.; Yu, R. Fractal evolution model of proton spatial distribution in low water/binder cement-based composites (LW/B-CC) during early-age hydration process. Constr. Build. Mater. 2024, 427, 136287. [Google Scholar] [CrossRef]

- Jin, S.; Zhang, J.; Han, S. Fractal analysis of relation between strength and pore structure of hardened mortar. Constr. Build. Mater. 2017, 135, 1–7. [Google Scholar] [CrossRef]

- Lin, H.; Takasu, K.; Suyama, H.; Koyamada, H.; Liu, S. A study on properties, static and dynamic elastic modulus of recycled concrete under the influence of modified fly ash. Constr. Build. Mater. 2022, 347, 128585. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).