Analysis of Carbon Emission Characteristics and Influencing Factors of Cement Industry in Hebei Province

Abstract

1. Introduction

2. Methods and Data Sources

2.1. Cement Industry Carbon Emission Accounting Method

2.2. STIRPAT Model

2.2.1. Model Construction

2.2.2. Variable Selection

- Population factors

- 2.

- Economic factors

- 3.

- Technological factors

- 4.

- Industry factors

2.3. Scenario Analysis Method

2.3.1. Scenario Setting

2.3.2. Parameter Setting

- Population size

- 2.

- Per capita GDP

- 3.

- Urbanization rate

- 4.

- Industrial structure

- 5.

- Energy intensity

- 6.

- Energy consumption structure

- 7.

- Cement production and cement consumption structure

2.4. Data Sources

3. Results and Analysis

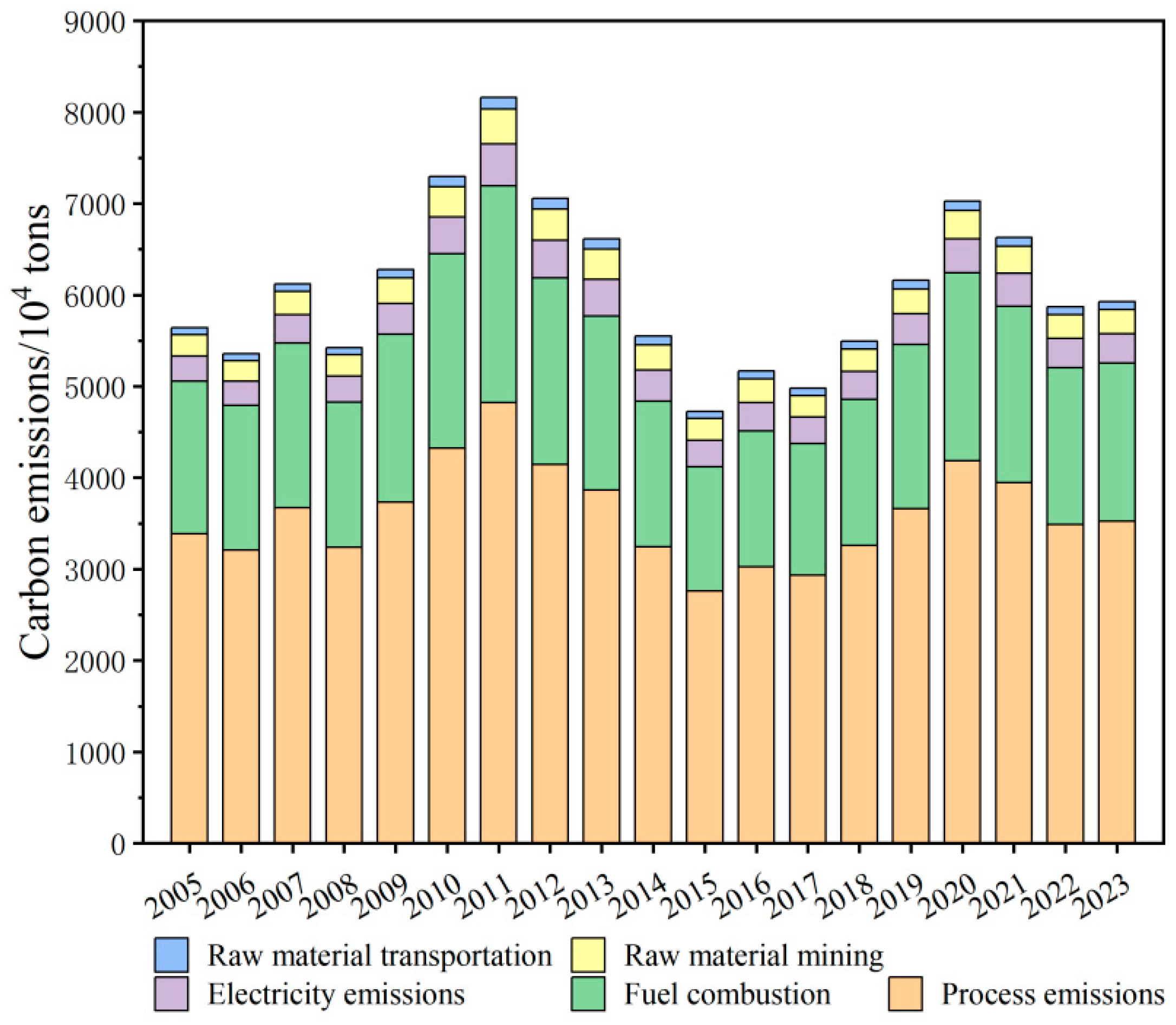

3.1. Carbon Emissions from the Cement Industry in Hebei Province

3.2. STIRPAT Model Regression Analysis

3.2.1. SPSS Multiple Linear Regression Analysis

3.2.2. Ridge Regression Analysis

3.2.3. Analysis of Influencing Factors

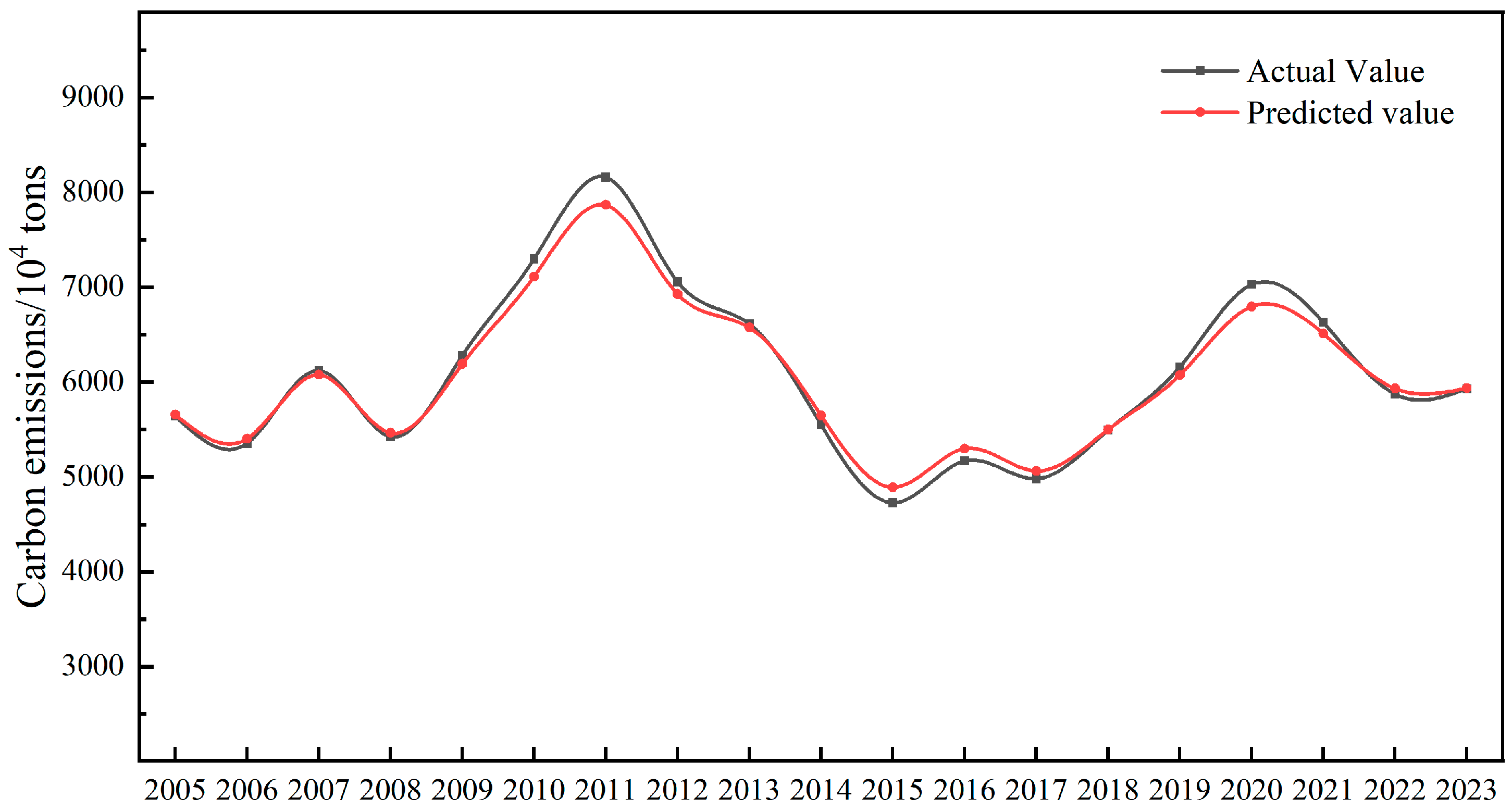

3.2.4. Regression Equation Fitting

3.3. Carbon Emission Forecast Analysis of the Cement Industry in Hebei Province

3.4. Sensitivity Analysis

3.5. Uncertainty Analysis

3.6. Analysis of Emission Reduction Strategies

4. Discussion

5. Conclusions

- The cement industry’s carbon emissions in Hebei Province fluctuated from 2005 to 2023. The primary sources of emissions are process-related carbonate decomposition (accounting for 58.4–60.1%) and fuel combustion (28.7–29.6%). Therefore, efforts to conserve energy and reduce emissions should prioritize the clinker calcination stage and promote the adoption of alternative raw materials and fuel substitution technologies.

- Among the influencing factors, seven factors, such as cement production (elasticity coefficient 0.234), per capita GDP (0.205), and population size (0.178), are positively correlated with carbon emissions. At the same time, energy intensity (−0.056) suppresses the growth of emissions through technological progress. This indicates that output, economy, and urbanization are key driving forces. Technological progress and structural adjustment are the main paths for reducing emissions.

- The carbon emission prediction results indicate that the cement industry in Hebei Province peaked in 2020, reaching 70.29 million tCO2e. Under all three scenarios, carbon emissions exhibit a downward trend to varying extents. The enhanced low-carbon scenario demonstrates the most substantial reduction, with emissions projected to decline to 34.95 million tCO2e by 2035, a decrease of 9.25 million tCO2e compared to the baseline scenario. This highlights the significant potential of coordinated policy intervention and technological innovation in accelerating emission reduction efforts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wang, Y.; Yi, H.; Tang, X.; Wang, Y.; An, H.; Liu, J. Historical trend and decarbonization pathway of China’s cement industry: A literature review. Sci. Total Environ. 2023, 891, 164580. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Cui, J.X.; Nie, Q.; Xiao, Y.; Ni, Y.L. A Study on the Carbon Neutrality Pathways of China’s Cement Industry, 2023. China Building Materials Science Research Institute Co., LTD. 2023. Available online: https://www.efchina.org/Reports-en/report-cip-20230913-en (accessed on 10 January 2025).

- Chen, F.; Lou, T. Low-carbon cement development in Europe and America: Technology, policy and definition. China Cem. 2024, 12, 12–19. [Google Scholar]

- IEA. CO2 Emissions in 2022; International Energy Agency: Paris, France, 2023; Available online: https://iea.blob.core.windows.net/assets/3c8fa115-35c4-4474-b237-1b00424c8844/CO2Emissionsin2022.pdf (accessed on 3 April 2023).

- Wang, X.C.; Zhao, T.T.; Wang, Q.; Su, H.; Liang, G.; Zu, Z.H.; Gao, X.Y. Practical experience of carbon emission right trading system in cement industry. Cement 2025, 2, 28–34. [Google Scholar]

- The Ministry of Ecology and Environment. The national carbon emission right trading market covers the cement, steel, electrolytic aluminum industry work plan. China Cem. 2024, 10, 11–14. [Google Scholar]

- Ministry of Ecology and Environment, PRC. The Relevant Person in Charge of the Department of Climate Change of the Ministry of Ecology and Environment Answered the “National Carbon Emission Trading Market Coverage of Iron and Steel, Cement, and Aluminum Smelting Industries Work Plan”. Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2025. Available online: https://www.mee.gov.cn/ywdt/zbft/202503/t20250326_1104767.shtml (accessed on 14 May 2025).

- He, J.Y.; He, J.; Wang, Y.; Fan, Y.; Shi, H.; Cai, B.; Yan, G. Pathway of Carbon Emissions Peak for Cement Industry in China. Res. Environ. Sci. 2022, 35, 347–355. [Google Scholar]

- Cheng, D.; Reiner, D.M.; Yang, F.; Cui, C.; Meng, J.; Shan, Y.; Liu, Y.; Tao, S.; Guan, D. Projecting future carbon emissions from cement production in developing countries. Nat. Commun. 2023, 14, 8213. [Google Scholar] [CrossRef]

- Shang, C.J.; Wu, C.G.; Lu, L.L.; Yao, K.Q.; Wang, Z.H.; Wang, J.F. Carbon emission accounting of aluminum sulfate cement. Cement 2023, 1, 13–17. [Google Scholar]

- Won, K. Green Cement: Comparative Assessment of Portland Cement Alternatives to Reduce Carbon Dioxide Emissions. In Proceedings of the 2024 IEEE Integrated STEM Education Conference (ISEC), Princeton, NJ, USA, 9 March 2024; pp. 1–4. [Google Scholar]

- Liang, Y.; Gao, Z.H.; Xu, X.D.; Xu, C.F.; Jia, B.Y. Analysis of carbon emission driving factors and carbon emission reduction path research in Hebei Province. J. North China Univ. Sci. Technol. 2024, 24, 45–53. [Google Scholar]

- Du, T.; Wang, J.; Wang, H.M.; Tian, X.; Yue, Q.; Tanikawa, H. CO2 emissions from the Chinese cement sector: Analysis from both the supply and demand sides. J. Ind. Ecol. 2020, 24, 923–934. [Google Scholar] [CrossRef]

- Shan, Y.L.; Zhou, Y.; Meng, J.; Mi, Z.; Liu, J.; Guan, D. Peak cement-related CO2 emissions and the changes in drivers in China. J. Ind. Ecol. 2019, 23, 959–971. [Google Scholar] [CrossRef]

- Ministry of Ecology and Environment, PRC. Notice on the Issuance of Four National Technical Specifications for the Carbon Emission Trading Market, Including the “Guidelines for Accounting and Reporting of Enterprise Greenhouse Gas Emissions—Cement Industry (CETS-AG-02.01-V01-2024”). Ministry of Ecology and Environment of the People’s Republic of China: Beijing, China, 2024. Available online: https://www.mee.gov.cn/xxgk2018/xxgk/xxgk06/202409/t20240914_1086067.html (accessed on 8 November 2024).

- Cai, B.F.; Zhu, S.L.; Yu, S.M.; Dong, H.M.; Zhang, C.Y.; Wang, K.C.; Zhu, J.H.; Gao, Q.X.; Fang, S.X.; Pan, X.B.; et al. Interpretation of the IPCC 2006 National Greenhouse Gas Inventory Guidelines 2019 Revised Edition. Environ. Eng. 2019, 37, 1–11. [Google Scholar]

- GB/T51366-2019; Standard for Building Carbon Emission Calculation. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019.

- Yu, H.Y.; Yang, H.; Zhang, H.; Zeng, J. Research of carbon emission of cement in life cycle. Sichuan Build. Mater. 2017, 43, 1–3. [Google Scholar]

- Zhang, X.C. Quantitative Analysis and Calculation of Building Carbon Emission and Evaluation Method of Low-Carbon Building Structure. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2018. [Google Scholar]

- Qin, Y.X. Study on Carbon Footprint Accounting of Cement Products. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2020. [Google Scholar]

- Wei, J.X.; Geng, Y.B.; Wang, S. Identification of factors influencing CO2 emission estimation from Chinese cement industry and determination of their uncertainty. Acta Sci. Circumstantiae 2016, 36, 4234–4244. [Google Scholar]

- Qi, Y.Y.; Ke, S.Q.; Gao, Y.L.; Wang, D. Discussion on the dominant factors and solutions of waste heat power generation in cement kiln. Cem. Guide New Epoch 2017, 6, 57–60. [Google Scholar]

- Rao, C.; Huang, Q.; Chen, L.; Goh, M.; Hu, Z. Forecasting the carbon emissions in Hubei Province under the background of carbon neutrality: A novel STIRPAT extended model with ridge regression and scenario analysis. Environ. Sci. Pollut. Res. 2023, 30, 57460–57480. [Google Scholar] [CrossRef] [PubMed]

- People’s Government of Hebei Province. Extraordinary Achievements in Energy Development-Remarkable Results in Energy Conservation and Consumption Reduction: The Eighth Report of the Series on the Economic and Social Development Achievements of Hebei Province in the 75th Anniversary of the Founding of the People’s Republic of China. People’s Government of Hebei Province: Shijiazhuang, China, 2024. Available online: https://www.hebei.gov.cn/columns/8f4946b5-3fd6-4fc4-b170-380a3e300a6a/202410/09/ffd77ee8-e79c-4a5c-b25f-e94dca0d0ffd.html (accessed on 14 May 2025).

- Gao, X.D. Mid-term review and outlook of the fourteenth Five-year Plan for green and low-carbon development of cement industry. China Cem. 2024, 4, 6–15. [Google Scholar]

- Chen, W.; Dong, J.H. A negative population growth in the global perspective. Northwest Popul. J. 2025, 46, 29–41. [Google Scholar]

- Li, M.; Chang, S. Population Scale and Structure Forecast and Development Strategy of Hebei Province for the Next 30 Years. Econ. Forum 2025, 1, 5–16. [Google Scholar]

- Lu, K. BP World Energy Outlook 2019 Chinese Version Released. China Pet. Petrochem. 2019, 8, 1. [Google Scholar]

- International Energy Agency (IEA). Cement Technology Roadmap Plots Path to Cutting CO2 Emissions 24% by 2050, 2018. IEA. Available online: https://www.iea.org/news/cement-technology-roadmap-plots-path-to-cutting-co2-emissions-24-by-2050 (accessed on 24 December 2024).

- Guo, X.L.; Li, Y.X.; Yuan, S.T. Life cycle assessment of cement and its research progress in low environmental load. J. Build. Mater. 2023, 26, 660–669+677. [Google Scholar]

- Wu, C.H.; Yu, X.H.; Gao, J.Z.; Yan, H.C.; Lu, G.T.; Yan, H. Carbon emission accounting and reduction analysis of waste collaborative disposal in typical cement kilns. Environ. Eng. 2023, 41, 30–36+60. [Google Scholar]

- Hu, D.; Guo, Z.; Wang, Z.; Xiao, Q. Metabolism analysis and eco-environmental impact assessment of two typical cement production systems in Chinese enterprises. Ecol. Inform. 2015, 26, 70–77. [Google Scholar] [CrossRef]

- Bayane, B.M.; Qiu, Y. Transport infrastructure development in China. J. Sustain. Dev. Transp. Logist. 2017, 2, 29–39. [Google Scholar] [CrossRef][Green Version]

- Mohammadi, S. A test of harmful multicollinearity: A generalized ridge regression approach. Commun. Stat. Theory Methods 2022, 51, 724–743. [Google Scholar] [CrossRef]

- Ma, D. Analysis of the Fuel Ethanol Life Cycle Based on SimaPro. Master’s Thesis, Qingdao University of Science and Technology, Qingdao, China, 2020. [Google Scholar]

- Fu, C.; Liang, J.; Yang, G.; Alwahed Dagestani, A.; Liu, W.; Luo, X.; Zeng, B.; Wu, H.; Huang, M.; Lin, L.; et al. Research on the life cycle evaluation of cement preparation process for whole industrial solid waste raw materials. J. Environ. Sci. 2021, 41, 5190–5199. [Google Scholar]

- Zhang, X.M.; Zhuang, G.Y.; Liu, J. Uncertainty analysis of urban greenhouse gas inventory. Environ. Econ. Res. 2018, 3, 8–18+149. [Google Scholar]

- Guo, Y.; Luo, L.; Liu, T.; Hao, L.; Li, Y.; Liu, P.; Zhu, T. A review of low-carbon technologies and projects for the global cement industry. J. Environ. Sci. 2024, 136, 682–697. [Google Scholar] [CrossRef] [PubMed]

- Dong, J.C.; Wang, X.Y.; Cai, B.F.; Wang, J.; Liu, H.; Yang, L.; Xia, C.; Lei, Y. Mitigation technologies and marginal abatement cost curves for cement industry in China. Environ. Eng. 2021, 39, 15–22. [Google Scholar]

- Ding, M.R. Analysis on the Current Situation of Carbon Emissions and Key Reduction Pathways in the Cement Industry. China Cem. 2021, 7, 46–49+98. [Google Scholar]

- World Business Council for Sustainable Development (WBCSD); International Energy Agency (IEA). Technology Roadmap: Low-Carbon Transition in the Cement Industry, 2018. WBCSD and IEA. Available online: https://www.iea.org/reports/technology-roadmap-low-carbon-transition-in-the-cement-industry (accessed on 16 February 2025).

- Elistratkin, M.; Salnikova, A.; Alfimova, N.; Kozhukhova, N.; Pospelova, E. Hollow Concrete Block Based on High-Strength Concrete as a Tool for Reducing the Carbon Footprint in Construction. J. Compos. Sci. 2024, 8, 358. [Google Scholar] [CrossRef]

| Variable | Symbol | Unit | Explanation |

|---|---|---|---|

| Carbon emission | I | Ten thousand tons | Hebei province cement industry carbon emissions |

| Population size | p | Ten thousand people | Total population of Hebei Province |

| GDP per capita | A | Yuan/person | Regional GDP/Total population |

| Urbanization rate | U | % | Urban population/Total population |

| Industrial structure | IS | % | Output value of the secondary industry/Regional GDP |

| Energy intensity | T | Tons tce/ ten thousand yuan | Total energy consumption/Regional GDP |

| Energy consumption structure | ES | % | Coal energy usage/ Total energy usage |

| Cement consumption structure | CS | % | Clinker production/ Cement production |

| Cement production | B | Ten thousand tons | Cement production of Hebei Province |

| Parameter Category | Scene | 2024–2025 | 2026–2030 | 2030–2035 |

|---|---|---|---|---|

| Population size | Baseline scenario | −0.35% | −0.35% | −0.30% |

| Low-carbon scenario | −0.30% | −0.25% | −0.20% | |

| Enhanced low-carbon scenario | −0.25% | −0.20% | −0.15% | |

| GDP per capita | Baseline scenario | 6.00% | 5.50% | 5.00% |

| Low-carbon scenario | 5.50% | 5.00% | 4.60% | |

| Enhanced low-carbon scenario | 5.00% | 4.80% | 4.40% | |

| Urbanization rate | Baseline scenario | 1.76% | 0.96% | 0.56% |

| Low-carbon scenario | 1.26% | 0.90% | 0.55% | |

| Enhanced low-carbon scenario | 0.90% | 0.85% | 0.50% | |

| Industrial structure | Baseline scenario | −1.13% | −1.13% | −1.13% |

| Low-carbon scenario | −1.20% | −1.50% | −1.80% | |

| Enhanced low-carbon scenario | −1.25% | −1.60% | −1.90% | |

| Energy intensity | Baseline scenario | −3.00% | −3.00% | −3.00% |

| Low-carbon scenario | −3.30% | −3.20% | −3.10% | |

| Enhanced low-carbon scenario | −3.50% | −3.40% | −3.30% | |

| Energy consumption structure | Baseline scenario | −2.35% | −2.35% | −2.35% |

| Low-carbon scenario | −2.50% | −2.80% | −3.00% | |

| Enhanced low-carbon scenario | −2.80% | −3.00% | −3.50% | |

| Cement consumption structure | Baseline scenario | −2.50% | −2.70% | −2.90% |

| Low-carbon scenario | −2.80% | −2.90% | −3.10% | |

| Enhanced low-carbon scenario | −3.00% | −3.10% | −3.20% | |

| Cement production | Baseline scenario | −0.26% | −0.16% | −0.16% |

| Low-carbon scenario | −0.24% | −0.24% | −0.24% | |

| Enhanced low-carbon scenario | −0.29% | −0.29% | −0.29% |

| Year | P | A | U | IS | T | ES | CS | B |

|---|---|---|---|---|---|---|---|---|

| 2005 | 6851.00 | 12,845 | 37.69 | 47.00 | 2.26 | 91.82 | 71.55 | 8850.04 |

| 2006 | 6898.00 | 14,609 | 38.77 | 47.51 | 2.17 | 91.59 | 70.66 | 8492.68 |

| 2007 | 6943.00 | 17,561 | 40.25 | 48.13 | 1.94 | 92.36 | 70.28 | 9758.28 |

| 2008 | 6989.00 | 20,385 | 41.90 | 49.17 | 1.71 | 92.31 | 67.57 | 8953.00 |

| 2009 | 7034.00 | 21,831 | 43.74 | 46.81 | 1.66 | 92.51 | 65.30 | 10,684.55 |

| 2010 | 7193.60 | 25,308 | 43.94 | 47.05 | 1.46 | 89.71 | 63.17 | 12,790.21 |

| 2011 | 7231.86 | 29,647 | 45.59 | 48.05 | 1.31 | 89.09 | 62.02 | 14,533.91 |

| 2012 | 7262.00 | 31,844 | 46.60 | 47.32 | 1.25 | 88.86 | 59.01 | 13,131.84 |

| 2013 | 7287.59 | 33,346 | 48.02 | 46.08 | 1.22 | 88.69 | 56.69 | 12,747.38 |

| 2014 | 7322.90 | 34,507 | 49.36 | 45.53 | 1.16 | 88.46 | 56.53 | 10,721.46 |

| 2015 | 7345.20 | 35,994 | 51.67 | 43.64 | 1.17 | 88.83 | 56.58 | 9126.17 |

| 2016 | 7374.99 | 38,688 | 53.87 | 43.31 | 1.11 | 87.33 | 57.09 | 9898.58 |

| 2017 | 7409.14 | 41,451 | 55.74 | 41.70 | 1.05 | 86.05 | 60.05 | 9125.50 |

| 2018 | 7426.37 | 43,808 | 57.33 | 39.71 | 0.99 | 83.61 | 63.72 | 9554.30 |

| 2019 | 7446.56 | 47,036 | 58.77 | 38.29 | 0.93 | 81.96 | 64.98 | 10,527.39 |

| 2020 | 7463.84 | 48,564 | 60.07 | 37.55 | 0.91 | 80.51 | 65.93 | 11,859.97 |

| 2021 | 7448.00 | 54,172 | 61.14 | 40.49 | 0.81 | 76.58 | 64.53 | 11,354.63 |

| 2022 | 7420.00 | 56,995 | 61.65 | 40.24 | 0.77 | 73.44 | 65.61 | 10,033.94 |

| 2023 | 7393.00 | 59,332 | 62.77 | 37.40 | 0.75 | 70.20 | 65.00 | 10,130.59 |

| Model | R | R2 | Adjusted R2 | Standard Estimate Error | |||

|---|---|---|---|---|---|---|---|

| 1.000a* | 0.999 | 0.998 | 0.00598 | ||||

| Unstandardized Coefficients | Standardization Coefficient | t | sig. | Collinearity Statistics | |||

| B | Standard Error | Beta | Tolerance | VIF | |||

| constant | −3.761 | 2.748 | - | −1.462 | 0.178 | - | - |

| lnP | −0.107 | 0.294 | −0.021 | −0.365 | 0.724 | 0.008 | 131.702 |

| lnA | −0.060 | 0.051 | −0.18 | −1.17 | 0.272 | 0.001 | 926.886 |

| lnU | 0.089 | 0.090 | 0.098 | 0.988 | 0.349 | 0.003 | 385.681 |

| lnIS | 0.061 | 0.060 | 0.036 | 1.013 | 0.337 | 0.020 | 48.915 |

| lnT | −0.042 | 0.068 | −0.092 | −0.615 | 0.554 | 0.001 | 873.358 |

| lnES | 0.093 | 0.069 | 0.042 | 1.342 | 0.212 | 0.026 | 38.454 |

| lnCS | 0.930 | 0.031 | 0.490 | 29.84 | 0.000 | 0.094 | 10.583 |

| lnB | 1.009 | 0.010 | 1.074 | 104.045 | 0.000 | 0.239 | 4.159 |

| Variable | Unstandardized Coefficients | Standardization Coefficient | t | P | R2 | Adjusted R2 | F | |

|---|---|---|---|---|---|---|---|---|

| B | Standard Error | Beta | ||||||

| constant | 0.242 | 0.282 | - | 0.859 | 0.043 | 0.993 | 0.977 | F = 61.94 P = 0.003 |

| lnP | 0.178 | 0.028 | 0.178 | 6.14 | 0.008 | |||

| lnA | 0.205 | 0.033 | 0.211 | 5.97 | 0.009 | |||

| lnU | 0.135 | 0.056 | 0.033 | 0.626 | 0.035 | |||

| lnIS | 0.113 | 0.029 | 0.107 | 3.897 | 0.029 | |||

| lnT | −0.056 | 0.042 | −0.003 | −0.081 | 0.094 | |||

| lnES | 0.126 | 0.031 | 0.121 | 4.039 | 0.027 | |||

| lnCS | 0.109 | 0.030 | 0.104 | 3.592 | 0.036 | |||

| lnB | 0.234 | 0.035 | 0.237 | 6.568 | 0.007 | |||

| Dependent variable: lnI | ||||||||

| Factor | Limestone | Clay | Sandstone | Iron Ore | Gypsum | Slag | Fly Ash | Coal | Electricity |

|---|---|---|---|---|---|---|---|---|---|

| Sensitivity coefficient | 0.6220 | 0.0009 | 0.0021 | 0.0019 | 0.0125 | 0.0053 | 0.0047 | 0.2935 | 0.0539 |

| Emission Stage | Raw Material Mining | Raw Material Transportation | Process Emissions | Fuel Combustion | Power Consumption | Total Emissions |

|---|---|---|---|---|---|---|

| Uncertainty | 8.02% | 5.52% | 11.18% | 11.18% | 11.18% | 7.44% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, W.; Yang, W.; Guo, L.; Wang, R. Analysis of Carbon Emission Characteristics and Influencing Factors of Cement Industry in Hebei Province. Buildings 2025, 15, 1808. https://doi.org/10.3390/buildings15111808

Zheng W, Yang W, Guo L, Wang R. Analysis of Carbon Emission Characteristics and Influencing Factors of Cement Industry in Hebei Province. Buildings. 2025; 15(11):1808. https://doi.org/10.3390/buildings15111808

Chicago/Turabian StyleZheng, Wen, Weihua Yang, Liying Guo, and Ruyan Wang. 2025. "Analysis of Carbon Emission Characteristics and Influencing Factors of Cement Industry in Hebei Province" Buildings 15, no. 11: 1808. https://doi.org/10.3390/buildings15111808

APA StyleZheng, W., Yang, W., Guo, L., & Wang, R. (2025). Analysis of Carbon Emission Characteristics and Influencing Factors of Cement Industry in Hebei Province. Buildings, 15(11), 1808. https://doi.org/10.3390/buildings15111808