Experimental Investigation on the Mechanical Properties of Geopolymer Recycled Aggregate Concrete Reinforced with Steel-Polypropylene Hybrid Fiber

Abstract

1. Introduction

2. Materials and Methods

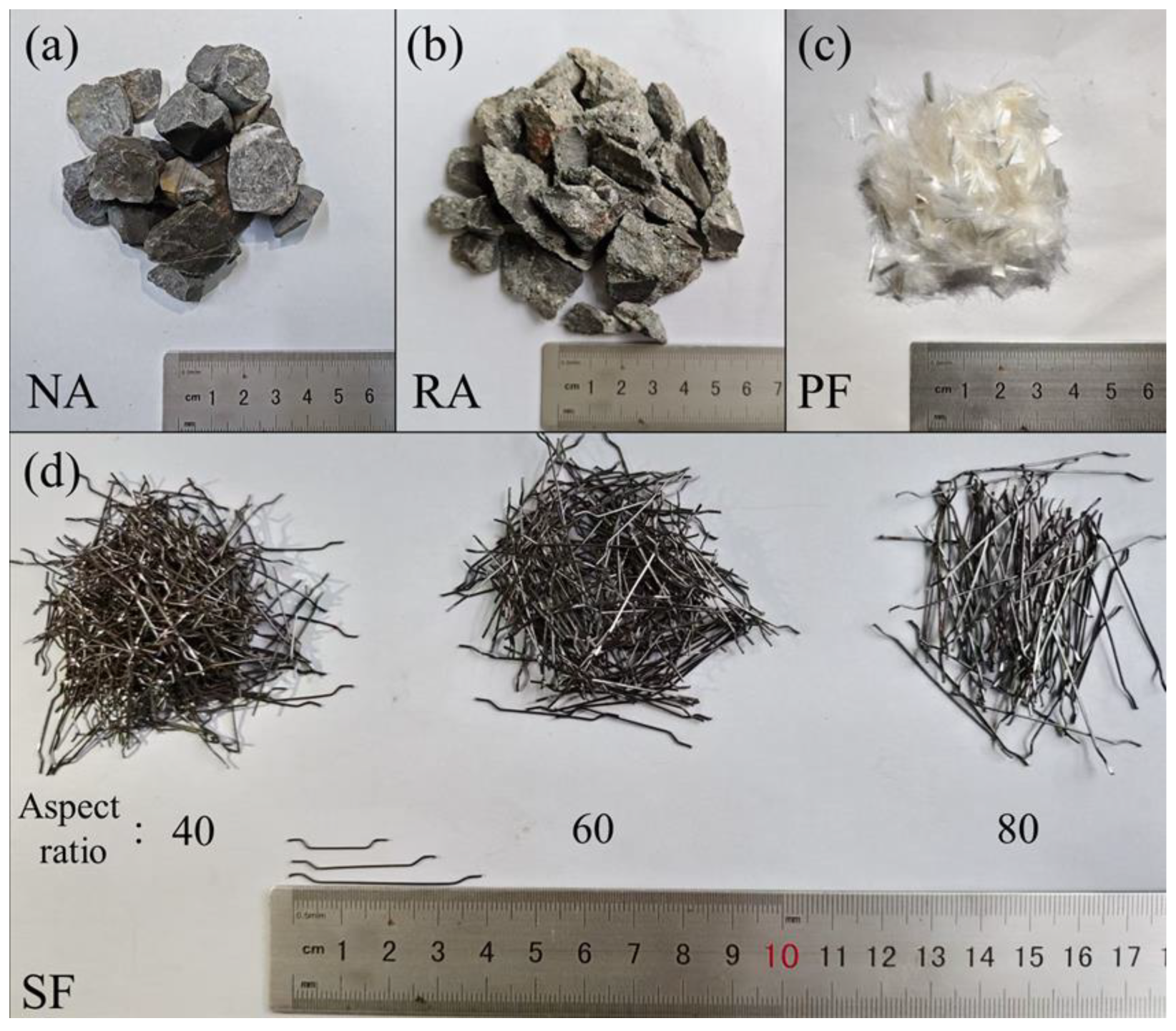

2.1. Materials and Mix Proportions

2.2. Specimen Preparation

2.3. Test Methods

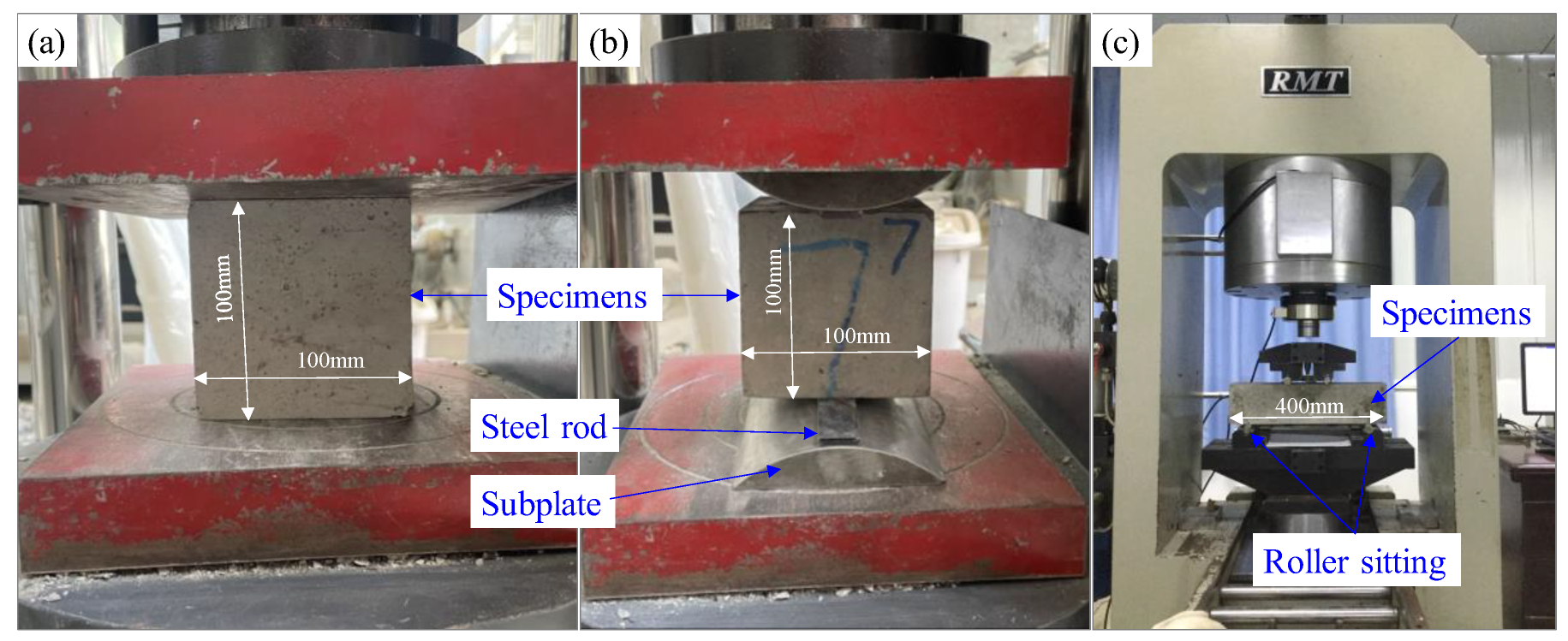

2.3.1. Compressive and Splitting Tensile Strength Test

2.3.2. Four-Point Bending Test

2.3.3. Microstructure Characterization Method

3. Experimental Results and Discussion

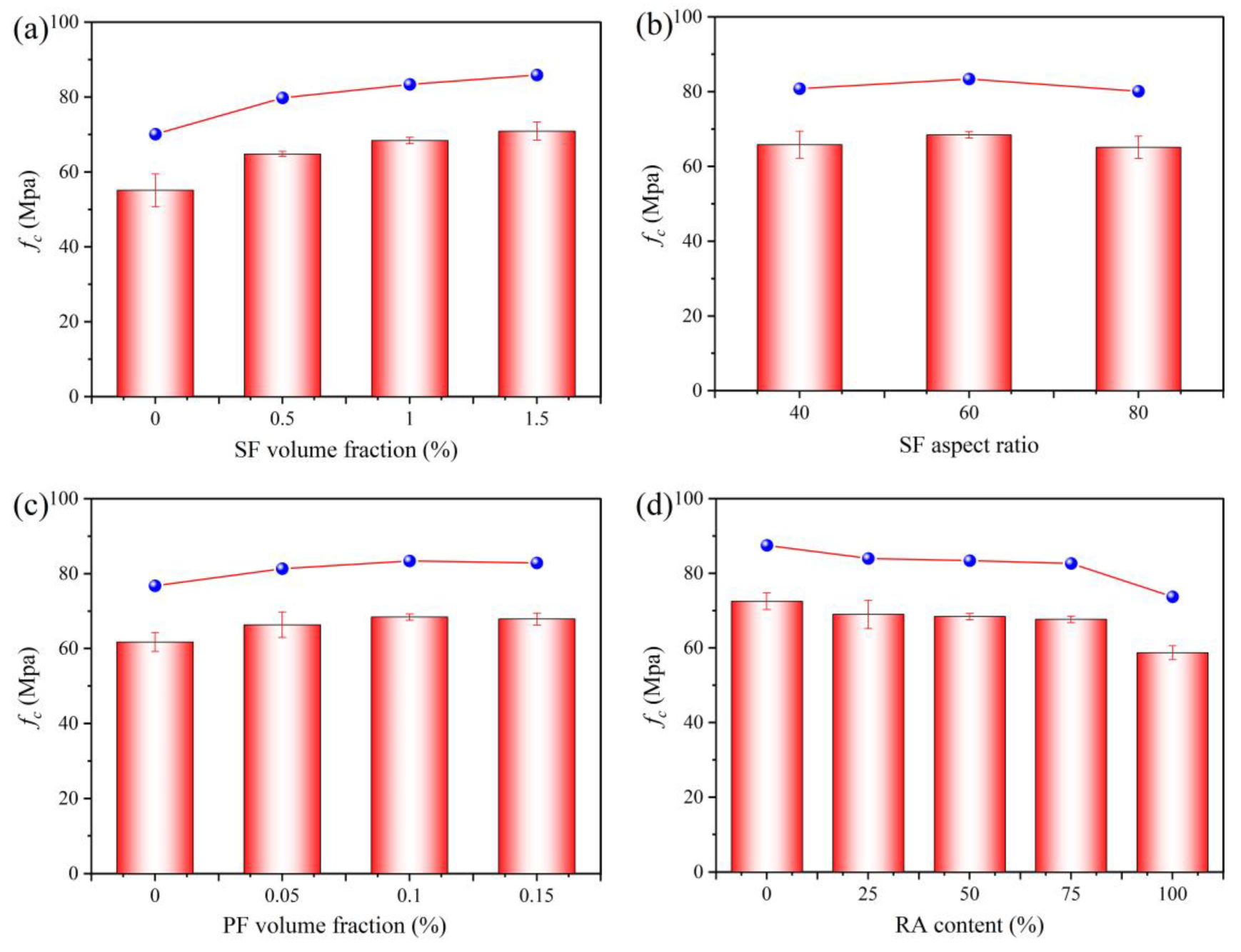

3.1. Compressive Strength

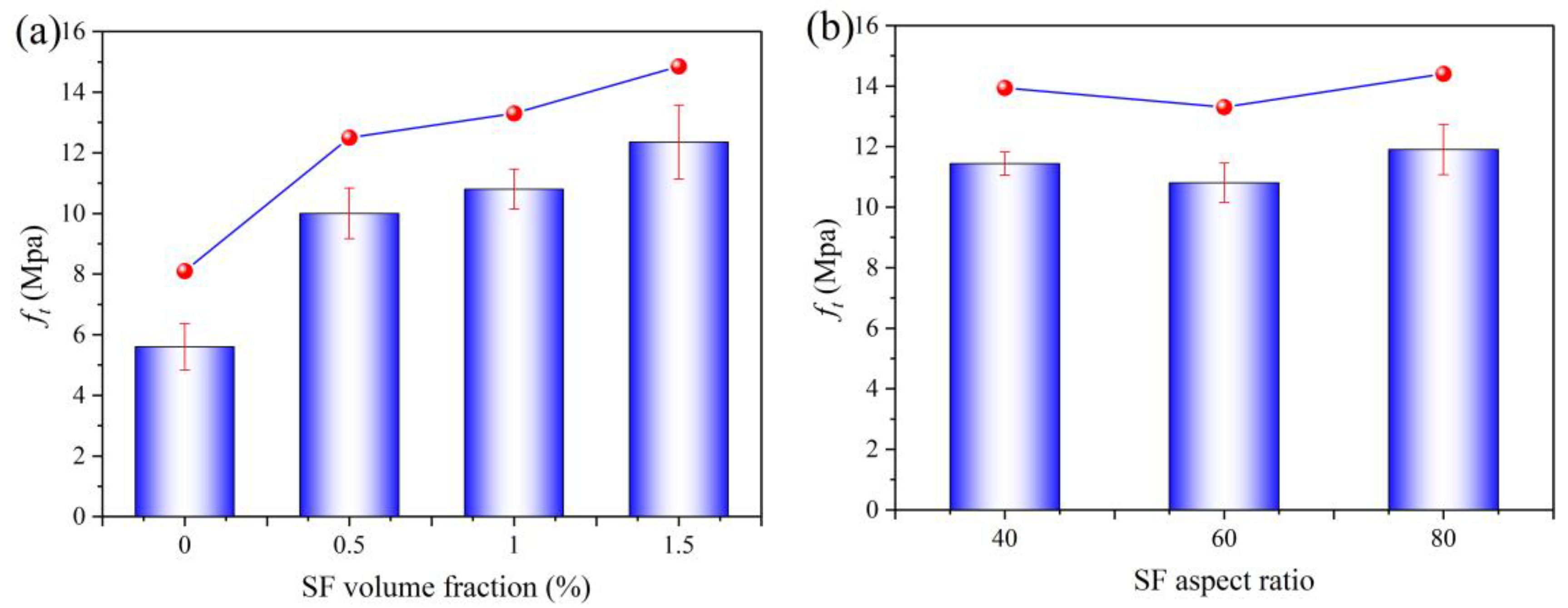

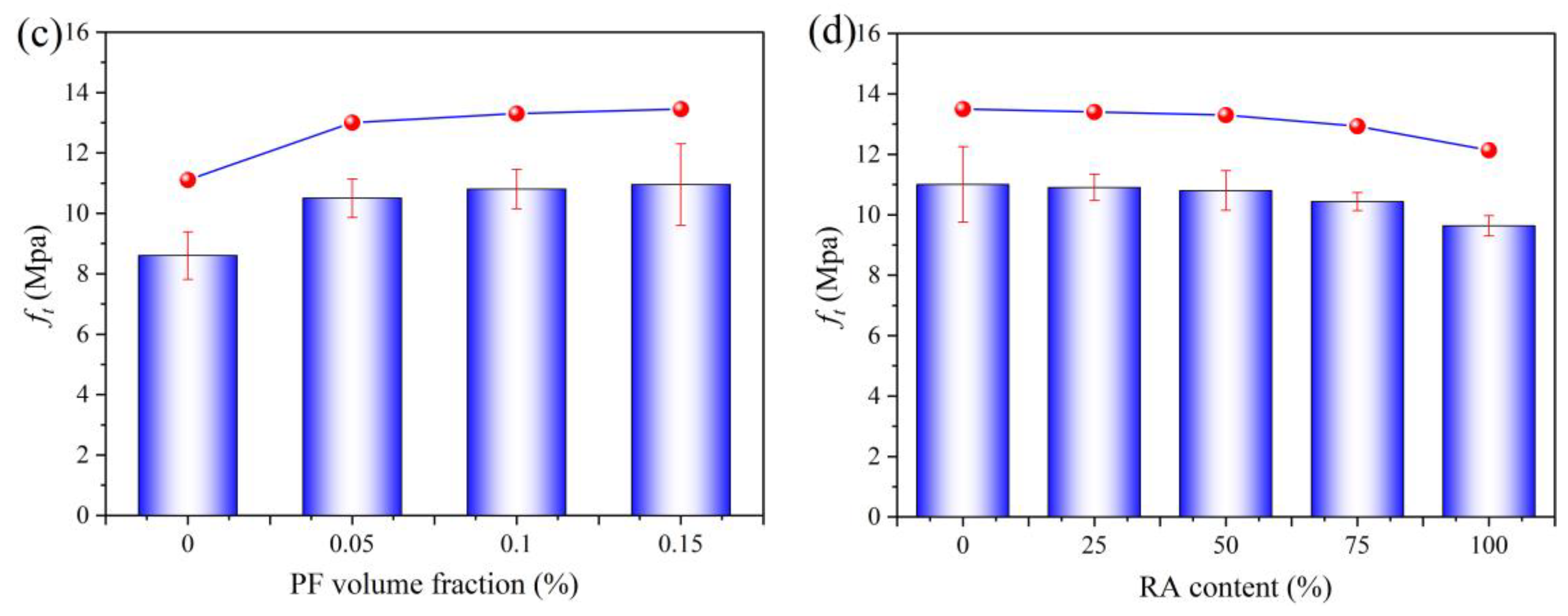

3.2. Splitting Tensile Strength

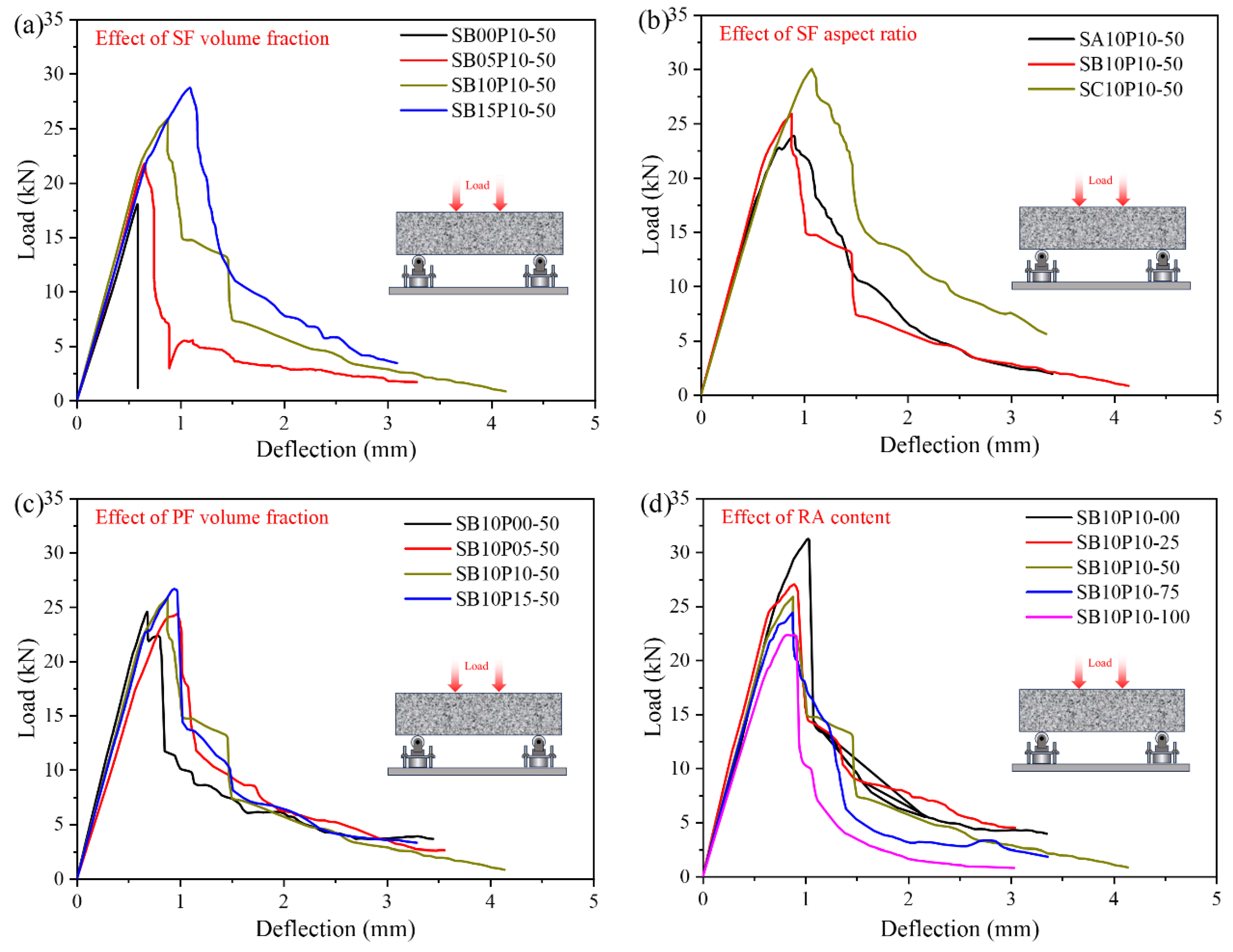

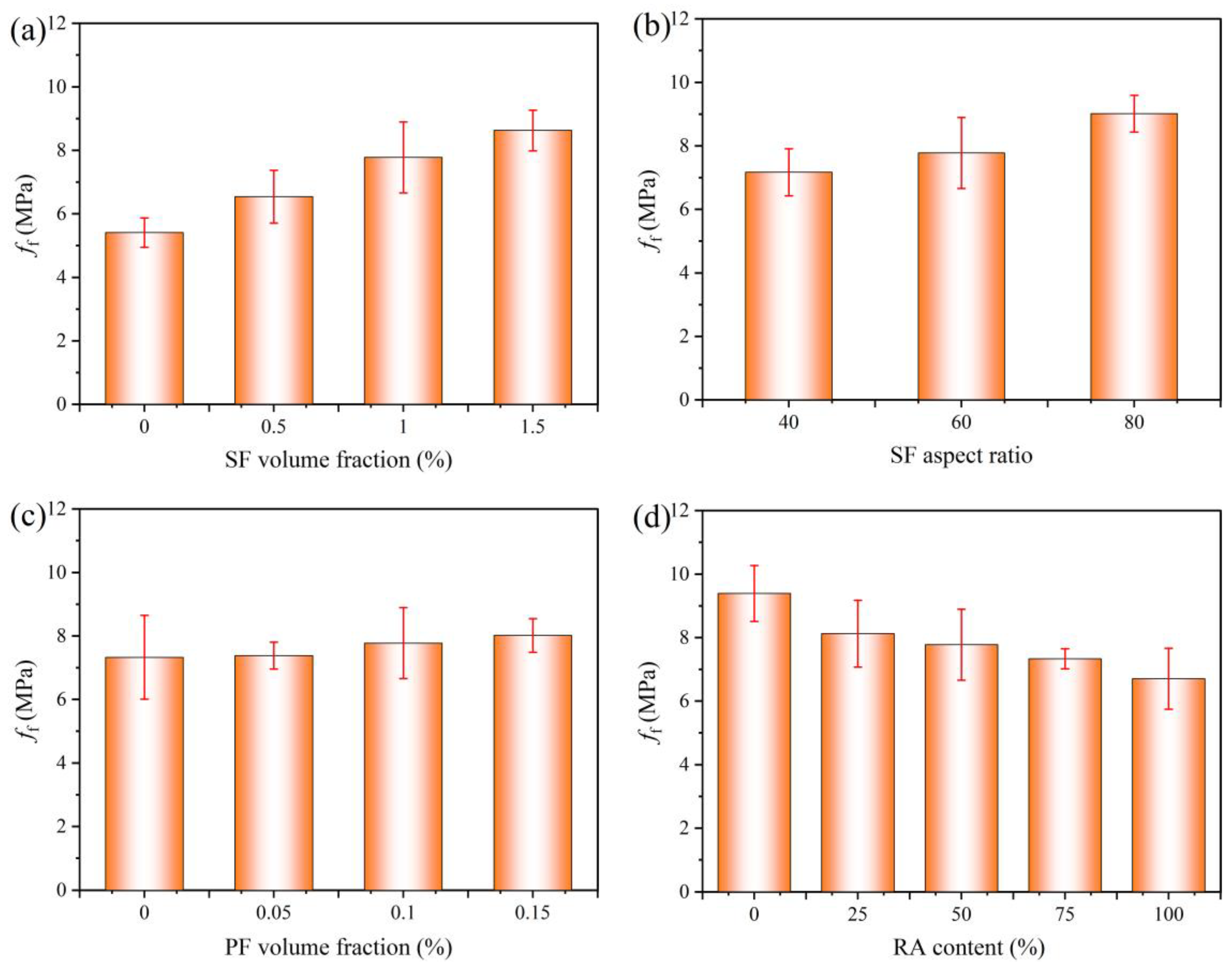

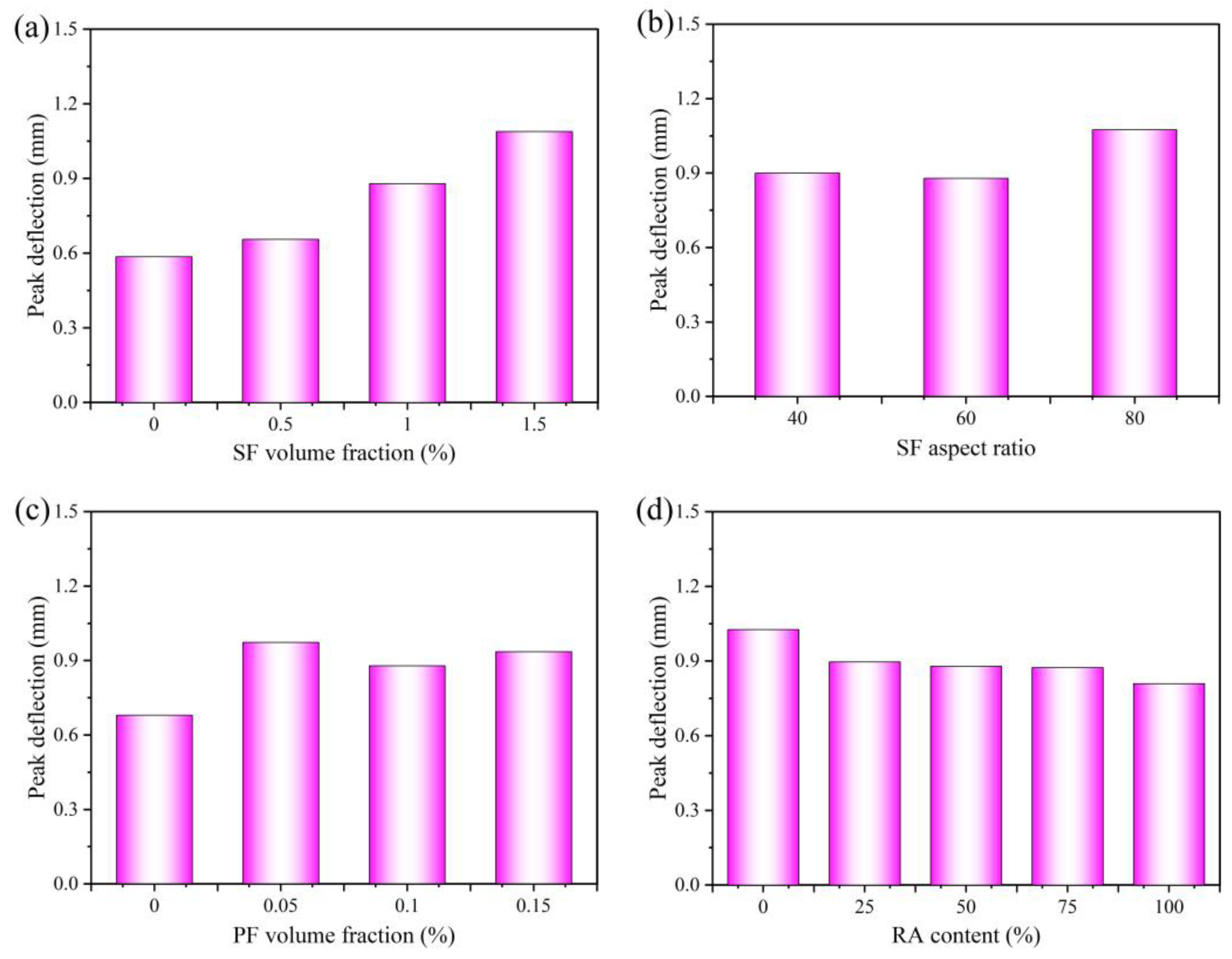

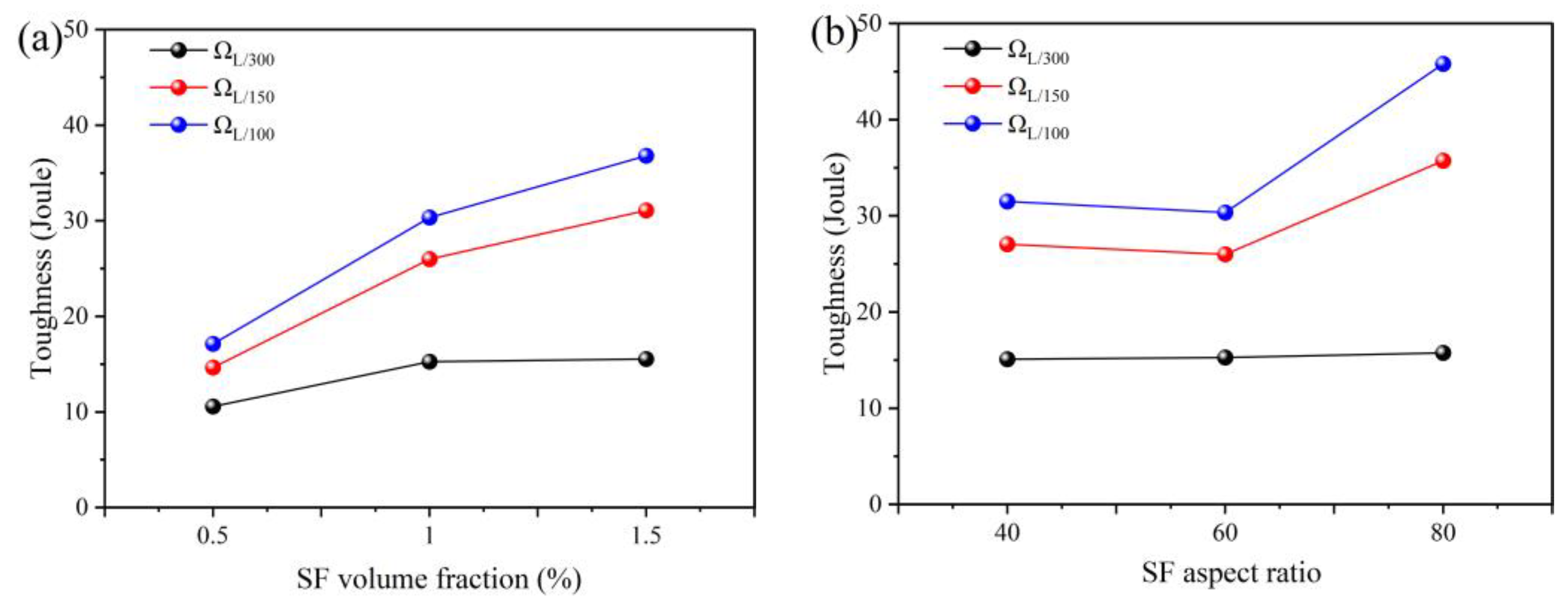

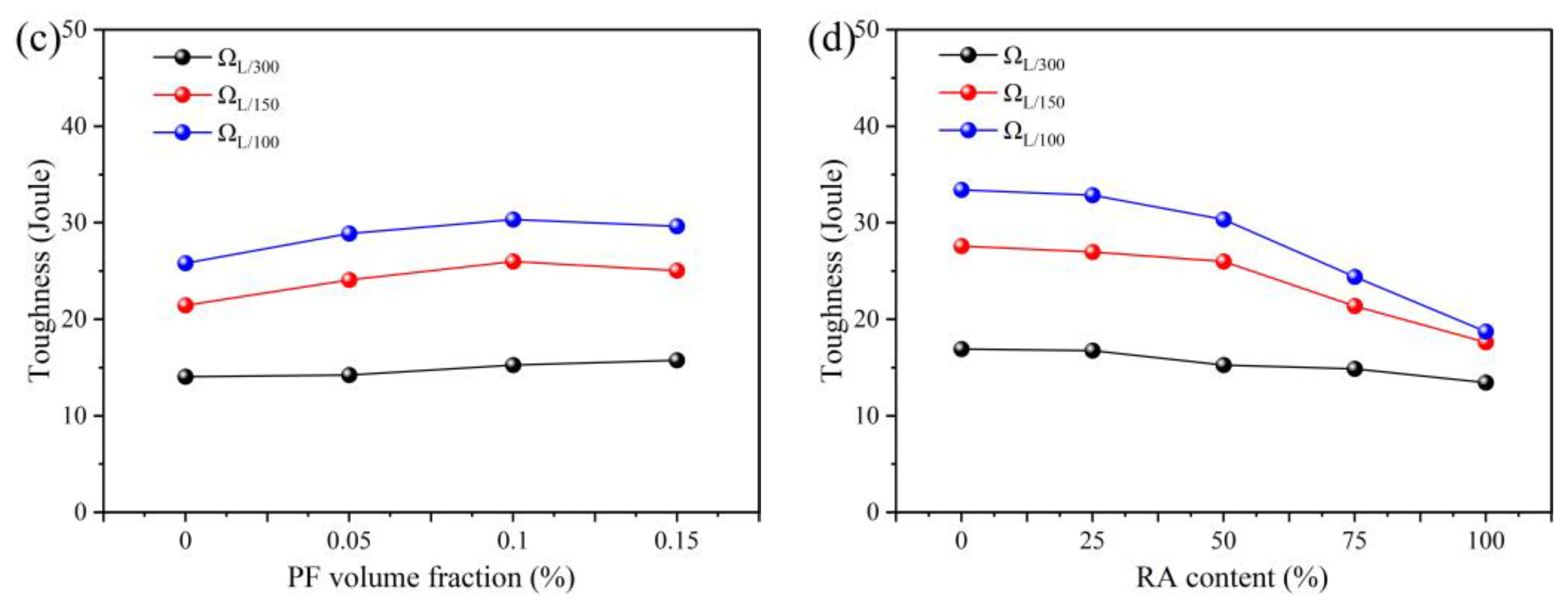

3.3. Flexural Behavior

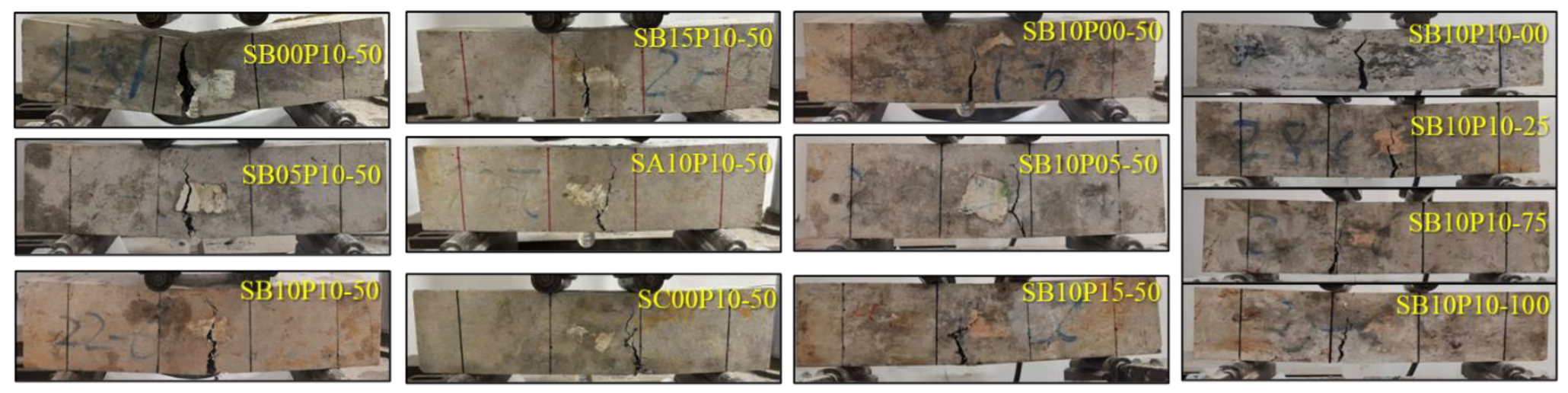

3.3.1. Flexural Process and Failure Modes

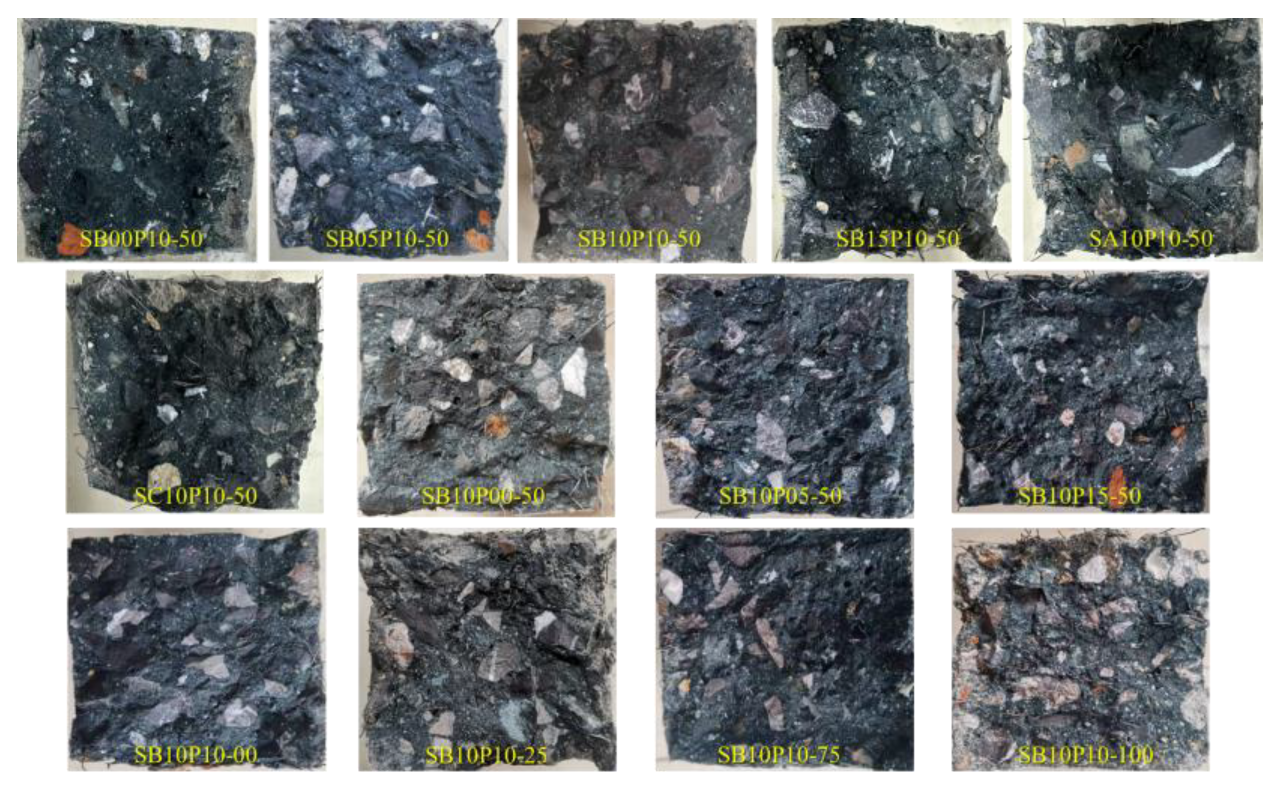

3.3.2. Load–Deflection Curve

3.3.3. Load and Deflection Characteristics

3.3.4. Toughness

3.4. Hybrid Effect Analysis

- (a)

- The compressive strength enhancement coefficient exhibits a positive correlation with SF volume fraction, owing to the fact that the superior stiffness of SF primarily drives the reinforcement effect in single-fiber-reinforced systems. However, under a constant SF dosage, the hybrid effect coefficient decreases by 12–28% with increasing PF content.

- (b)

- SF and PF generally demonstrate a positive synergistic effect on splitting tensile strength, though the intensity of this interaction is highly dependent on fiber proportions. When PF content is below 0.1%, the α value shows a linear decreasing trend with increasing SF content, primarily due to fiber–matrix interfacial competition [37]. When the PF is 0.15%, the α value transitions to a positive correlation with SF content because the crack-bridging capacity of SF effectively suppresses the micro crack propagation caused by PF overdosing.

- (c)

- The flexural strength predominantly demonstrates negative synergy (α < 1), except for the group with 0.5% SF and 0.15% PF, which shows anomalous positive synergy (α = 1.12). This critical point achieves an optimized three-dimensional network structure where SF governs the macroscopic crack propagation path and PF implements synergistic toughening through micro crack inhibition.

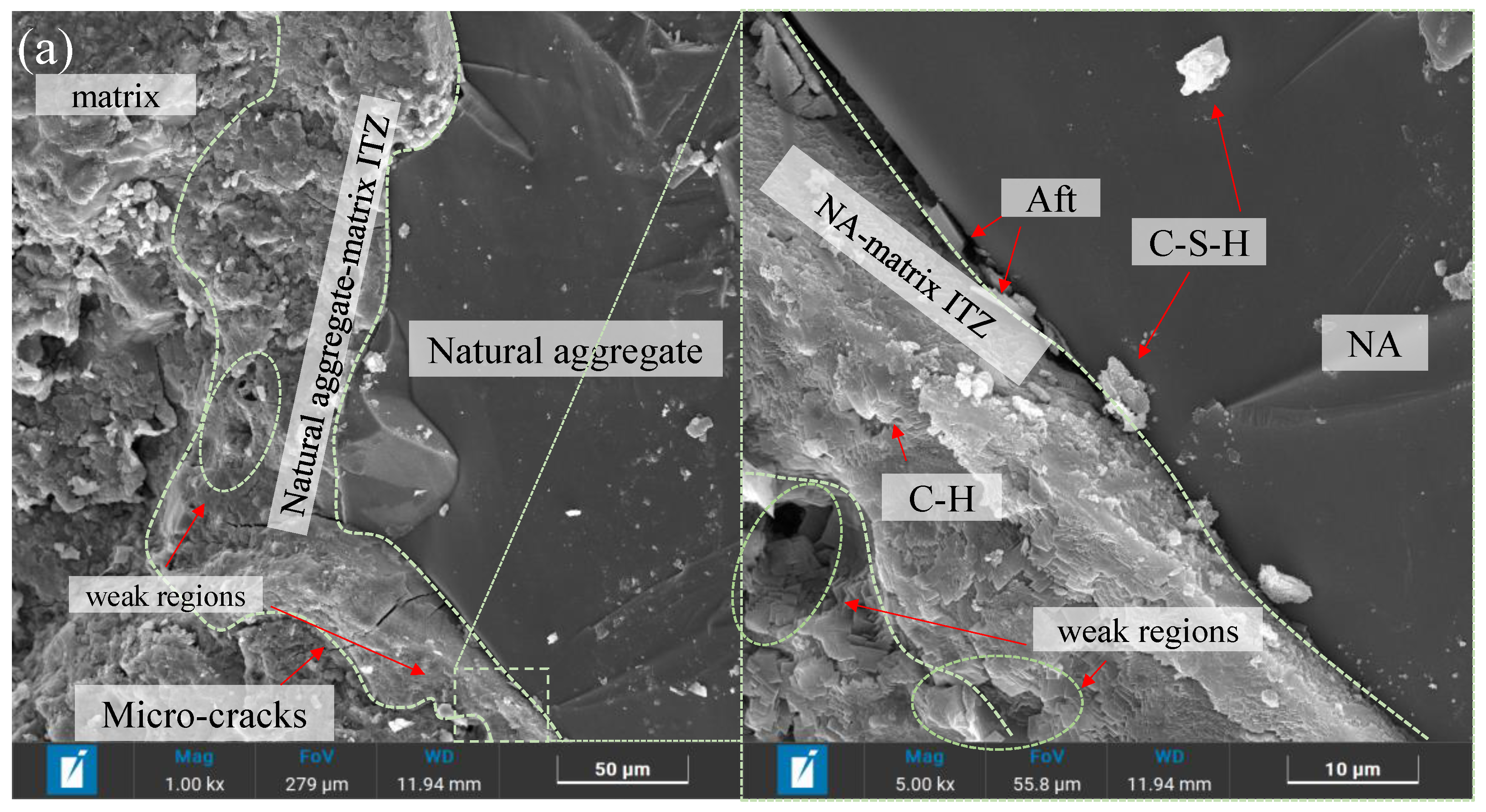

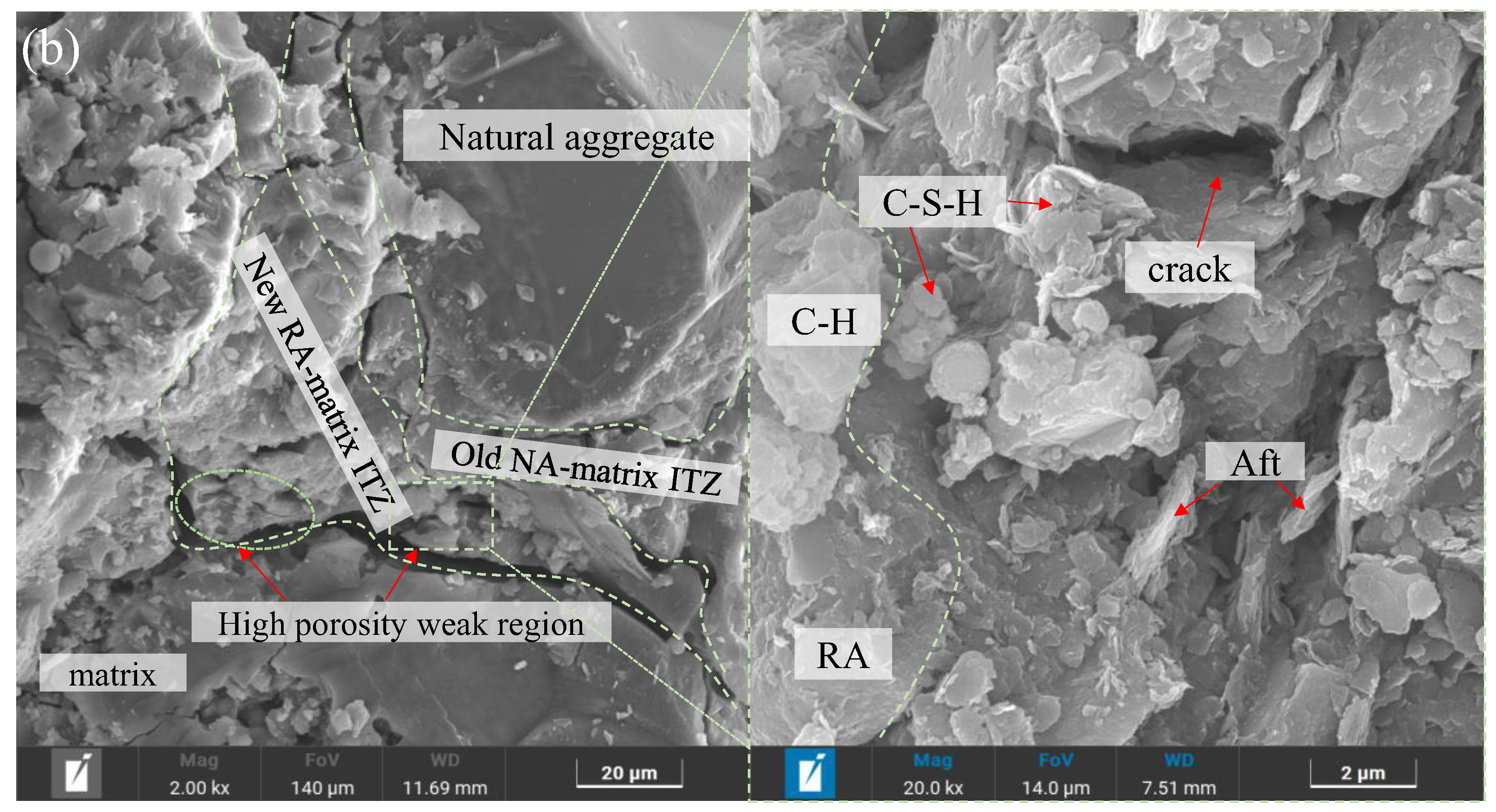

3.5. Microscopic Mechanism

4. Conclusions

- (1)

- The mechanical properties of HFRGRAC are significantly affected by hybrid fiber and RA parameters. Higher RA content negatively impacts compressive and splitting tensile strengths, reducing them by up to 21.21% and 12.61%, respectively. SF and PF enhance mechanical performance, with SF showing notably higher reinforcement efficiency than PF. The aspect ratio of SF has minimal influence.

- (2)

- Incorporating SF changes the flexural failure mode of GRAC from brittle tensile failure to ductile shear failure due to fiber bridging. A higher SF volume fraction deflects crack paths and induces multi-stage cracking. PF and RA preserve the fundamental flexural failure mode but promote crack bifurcation, micro crack density, and zigzag fracture surfaces.

- (3)

- The increase in SF volume content and aspect ratio significantly improves flexural ductility and peak load under flexure through optimized fiber-bridging and energy absorption mechanisms. Low PF content enhances flexural performance through the 3D micro crack constraint, whereas excessive PF would cause performance degradation due to stress concentrations. In addition, RA content exceeding 50% raises interfacial porosity, reducing flexural strength by 28.63% and toughness by 43.35%.

- (4)

- SF and PF exhibit a positive hybrid effect on the mechanical properties of GRAC. The hybrid effect coefficients for compressive and tensile strengths decrease with increasing PF content, which is attributable to dominant SF interfacial competition. However, at a PF content of 0.15%, the α-value for splitting tensile strength shifts to a positive correlation with SF content. In contrast, flexural strength generally shows negative synergy, except for the 0.5% SF and 0.15% PF group.

- (5)

- SF’s hydrophilicity induces localized Ca2⁺ depletion, whereas PF’s hydrophobicity inhibits surface hydration, resulting in a heterogeneous distribution of hydration products and the subsequent formation of micro cracks and porous structures. Although alkali activation partially at the old mortar layers fills the pores in RA, insufficient hydration in the ITZ persists due to the higher water absorption of RA, leading to weaker interfaces compared to those of NA.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Chinnu, S.N.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Clean. Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Nanyakkara, O.; Gunasekara, C.; Sandanayake, M.; Law, D.W.; Nguyen, K.; Xia, J.; Setunge, S. Alkali activated slag concrete incorporating recycled aggregate concrete: Long term performance and sustainability aspect. Constr. Build. Mater. 2021, 271, 121512. [Google Scholar] [CrossRef]

- Shi, X.S.; Collins, F.G.; Zhao, X.L.; Wang, Q.Y. Mechanical properties and microstructures analysis of fly ash geopolymeric recycled concrete. J. Hazard. Mater. 2012, 237–238, 20–29. [Google Scholar] [CrossRef]

- Li, B.; Jiang, G.; Hu, J.; Li, Y.; Wu, F.; Qin, Z.; Wang, S. Specimen size effect on compressive and splitting tensile strengths of sustainable geopolymeric recycled aggregate concrete: Experimental and theoretical analysis. J. Clean. Prod. 2024, 434, 140154. [Google Scholar] [CrossRef]

- Zheng, Y.; Du, J.; Zheng, L.; Wang, C. Compressive behavior of geopolymer recycled brick aggregate concrete confined by steel tubes. J. Build. Eng. 2023, 70, 106350. [Google Scholar] [CrossRef]

- Kan, L.; Wang, F.; Zhang, Z.; Kabala, W.; Zhao, Y. Mechanical properties of high ductile alkali-activated fiber reinforced composites with different curing ages. Constr. Build. Mater. 2021, 306, 124833. [Google Scholar] [CrossRef]

- Wang, C.; Zhang, Y.; Ma, Z.; Wang, D. Hysteresis deteriorating behaviors of fiber-reinforced recycled aggregate concrete composites subjected to cyclic compressive loadings. J. Build. Eng. 2022, 49, 104087. [Google Scholar] [CrossRef]

- Nis, A.; Eren, N.Q.; Cevik, A. Effects of nanosilica and steel fibers on the impact resistance of slag based self-compacting alkali-activated concrete. Ceram. Int. 2021, 47, 23905–23918. [Google Scholar] [CrossRef]

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H.; Lee, Y.Y. Fiber-reinforced alkali-activated concrete: A review. J. Build. Eng. 2022, 45, 103638. [Google Scholar] [CrossRef]

- Nazir, K.; Canpolat, O.; Uysal, M. Durability properties of steel, polyamide, and polyethylene fiber-reinforced geopolymer mortar made with recycled concrete aggregate and glass powder as fillers. J. Build. Eng. 2023, 76, 107313. [Google Scholar] [CrossRef]

- Shaikh, F.U.A. Mechanical and durability properties of fly ash geopolymer concrete containing recycled coarse aggregates. Int. J. Sustain. Built. Environ. 2016, 5, 277–287. [Google Scholar] [CrossRef]

- Moulya, H.V.; Chandrashekha, A. Experimental investigation of effect of recycled coarse aggregate properties on the mechanical and durability characteristics of geopolymer concrete. Mater. Today Proc. 2022, 59, 1700–1707. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the engineering and durability properties of alkali activated slag concrete. Constr. Build. Mater. 2017, 133, 65–72. [Google Scholar]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- Pawluczuk, E.; Wichrowska, K.K.; Jimenez, J.R.; Rodríguez, J.M.F.; Morales, D.S. Geopolymer concrete with treated recycled aggregates: Macro and microstructural behavior. J. Build. Eng. 2021, 44, 103317. [Google Scholar] [CrossRef]

- Fang, G.; Chen, J.; Dong, B.; Liu, B. Microstructure and micromechanical properties of interfacial transition zone in green recycled aggregate concrete. J. Build. Eng. 2023, 66, 105860. [Google Scholar] [CrossRef]

- Pradhan, P.; Panda, S.; Parhi, S.K.; Panigrahi, S.K. Variation in fresh and mechanical properties of GGBS based self-compacting geopolymer concrete in the presence of NCA and RCA. Mater. Today Proc. 2022, 62, 6348–6358. [Google Scholar] [CrossRef]

- Kathirvel, P.; Kaliyaperumal, S.R.M. Influence of recycled concrete aggregates on the flexural properties of reinforced alkali activated slag concrete. Constr. Build. Mater. 2016, 102, 51–58. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Zhang, B.; Fang, C.; Li, L. Physicochemical properties of alkali activated GGBS and fly ash geopolymeric recycled concrete. Constr. Build. Mater. 2019, 204, 384–398. [Google Scholar] [CrossRef]

- Sedaghatdoost, A.; Behfarnia, K.; Bayati, M.; Vaezi, M. Influence of recycled concrete aggregates on alkali-activated slag mortar exposed to elevated temperatures. J. Build. Eng. 2019, 26, 100871. [Google Scholar] [CrossRef]

- Li, B.; Wu, F.; Xia, D.; Li, Y.; Cui, K.; Wu, F.; Yu, J. Compressive and flexural behavior of alkali-activated slag-based concrete: Effect of recycled aggregate content. J. Build. Eng. 2023, 67, 105993. [Google Scholar] [CrossRef]

- Bernal, S.; Gutierrez, R.; Delvasto, S.; Rodriguez, E. Performance of an alkali-activated slag concrete reinforced with steel fibers. Constr. Build. Mater. 2010, 24, 208–214. [Google Scholar] [CrossRef]

- Hammad, N.; EI-Nemr, A.; Hasan, H.E.D. The performance of fiber GGBS based alkali-activated concrete. J. Build. Eng. 2021, 42, 102464. [Google Scholar] [CrossRef]

- Hammad, N.; EI-Nemr, A.; Hasan, H.E.D. Flexural performance of reinforced Alkali-activated concrete beams incorporating steel and structural Macro synthetic polypropylene fiber. Constr. Build. Mater. 2022, 324, 126634. [Google Scholar] [CrossRef]

- El-Hassan, H.; Elkholy, S. Enhancing the performance of Alkali-activated slag-fly ash blended concrete through hybrid steel fiber reinforcement. Constr. Build. Mater. 2021, 311, 125313. [Google Scholar] [CrossRef]

- Zhou, M.; He, X.; Wang, H.; Wu, C.; He, J.; Wei, B. Mechanical properties and microstructure of ITZs in steel and polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2024, 415, 135119. [Google Scholar] [CrossRef]

- Zhao, Q.; Wang, Y.; Xie, M.; Huang, B. Experimental study on mechanical behavior of steel fiber reinforced geopolymeric recycled aggregate concrete. Constr. Build. Mater. 2022, 356, 129267. [Google Scholar] [CrossRef]

- Li, B.; Yu, S.; Gao, B.; Li, Y.; Wu, F.; Xia, D.; Chi, Y.; Wang, S. Effect of recycled aggregate and steel fiber contents on the mechanical properties and sustainability aspects of alkali-activated slag-based concrete. J. Build. Eng. 2023, 66, 105939. [Google Scholar] [CrossRef]

- Tang, Z.; Hu, Y.; Tam, V.W.Y.; Li, W. Uniaxial compressive behaviors of fly ash/slag-based geopolymeric concrete with recycled aggregates. Cem. Concr. Comp. 2019, 104, 103375. [Google Scholar] [CrossRef]

- Zhao, Q.; Dong, S.; Xie, M. Experiments on stress-strain curve of steel fiber reinforced geopolymer recycled concrete under uniaxial compression. J. Build. Struct. 2022, 43, 255–265. (In Chinese) [Google Scholar]

- Li, B.; Wang, C.; Yu, S.; Yu, J.; Wang, S. Compressive constitutive behavior of steel fiber reinforced geopolymeric recycled aggregate concrete: Experimental investigation and analytical model. Structures 2023, 58, 105531. [Google Scholar] [CrossRef]

- Fang, G.; Ho, W.K.; Tu, W.; Zhang, M. Workability and mechanical properties of alkali-activated fly ash-slag concrete cured at ambient temperature. Construct. Build. Mater. 2018, 172, 476–487. [Google Scholar] [CrossRef]

- Li, B.; Xu, L.; Shi, Y.; Chi, Y.; Liu, Q.; Li, C. Effects of fiber type, volume fraction and aspect ratio on the flexural and acoustic emission behaviors of steel fiber reinforced concrete. Constr. Build. Mater. 2018, 181, 474–486. [Google Scholar] [CrossRef]

- Chachar, K.H.; Oad, M.; Memon, B.A.; Siyal, Z.A.; Siyal, K.F. Workability and Flexural Strength of Recycled Aggregate Concrete with Steel Fibers. Eng. Technol. Appl. Sci. 2023, 13, 11051–11057. [Google Scholar] [CrossRef]

- GB/T 50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2019. (In Chinese)

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- Xu, L.; Deng, F.; Chi, Y. Nano-mechanical behavior of the interfacial transition zone between steel-polypropylene fiber and cement paste. Constr. Build. Mater. 2017, 145, 619–638. [Google Scholar] [CrossRef]

- Yurt, U. An experimental study on fracture energy of alkali activated slag composites incorporated different fibers. J. Build. Eng. 2020, 32, 101519. [Google Scholar] [CrossRef]

- ASTM/C1609M-2012; Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete. ASTM: West Conshohocken, PA, USA, 2012.

- Banthia, N.; Majdzadeh, F.; Wu, J.; Bindiganavile, V. Fiber synergy in hybrid fiber reinforced concrete (HyFRC) in flexure and direct shear. Cem. Concr. Compos. 2014, 48, 91–97. [Google Scholar] [CrossRef]

- Huang, L.; Chi, Y.; Xu, L.; Chen, P.; Zhang, A. Local bond performance of rebar embedded in steel-polypropylene hybrid fiber reinforced concrete under monotonic and cyclic loading. Constr. Build. Mater. 2016, 103, 77–92. [Google Scholar] [CrossRef]

- Hasnaoui, A.; Ghorbel, E.; Wardeh, G. Performance of metakaolin/slag-based geopolymer concrete made with recycled fine and coarse aggregates. J. Build. Eng. 2021, 42, 102813. [Google Scholar] [CrossRef]

| Binders | Composition (%) | Density (g/cm3) | Specific Surface Area (m2/kg4) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | MgO | SO3 | K2O | Na2O | MnO | Fe2O3 | TiO2 | |||

| Slag | 36.82 | 26.75 | 19.66 | 11.1 | 2.65 | 0.29 | 0.84 | 0.37 | 0.32 | 0.94 | 2.8 | 455 |

| FA | 5.6 | 45.1 | 24.2 | 1.21 | 2.1 | 1.41 | 0.85 | 0.26 | 0.85 | 0.14 | 2.2 | 330 |

| CA Type | Size (mm) | Bulk Density (kg/m3) | Crushing Value (%) | Impact Value (%) | Specific Gravity (kg/m3) | Fineness Modulus | Water Absorption (%) |

|---|---|---|---|---|---|---|---|

| NA | 5–20 | 1431 | 9.7 | 13 | 2873 | 2.7 | 1.68 |

| RA | 5–20 | 1366 | 15.3 | 28 | 2655 | 2.6 | 5.85 |

| Fiber Type | Characteristic | Length, l (mm) | Diameter, d (mm) | Aspect Ratio, l/d | Elastic Modulus (GPa) | Density (kg/m3) | Tensile Strength (MPa) |

|---|---|---|---|---|---|---|---|

| SF | Hooked-end | 20/30/40 | 0.5 | 40/60/80 | 190 | 7850 | 1200 |

| PF | Monofilament | 9 | 0.0327 | 275 | 40.23 | 0.91 | 396 |

| Specimen | Materials (kg·m−3) | fc/MPa | ft/MPa | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SF | PF | GGBS | FA | River Sand | NA | RA | Sodium Silicate | NaOH | Water | Water Reducer | |||

| SB00P10-50 | - | 0.032 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 55.10 | 5.60 |

| SB05P10-50 | 1.36 | 0.032 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 64.78 | 10.01 |

| SB10P10-50 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 68.38 | 10.80 |

| SB15P10-50 | 4.08 | 0.032 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 70.88 | 12.41 |

| SA10P10-50 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 65.80 | 11.41 |

| SC10P10-50 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 65.08 | 11.90 |

| SB10P00-50 | 2.72 | - | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 61.74 | 8.60 |

| SB10P05-50 | 2.72 | 0.016 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 66.33 | 10.71 |

| SB10P15-50 | 2.72 | 0.047 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 67.87 | 11.52 |

| SB10P10-00 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | 37.63 | - | 37.63 | 3.077 | 0.593 | 3.885 | 74.48 | 11.02 |

| SB10P10-25 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | 28.22 | 9.41 | 37.63 | 3.077 | 0.593 | 3.885 | 68.97 | 10.90 |

| SB10P10-75 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | 9.41 | 28.22 | 37.63 | 3.077 | 0.593 | 3.885 | 67.63 | 10.40 |

| SB10P10-100 | 2.72 | 0.032 | 11.56 | 2.89 | 25.1 | - | 37.63 | 37.63 | 3.077 | 0.593 | 3.885 | 58.68 | 9.63 |

| SB00P00-50 | - | - | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 53.97 | 6.97 |

| SB05P00-50 | 1.36 | - | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 59.28 | 7.50 |

| SB15P00-50 | 4.08 | - | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 65.22 | 9.93 |

| SB00P05-50 | - | 0.016 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 51.95 | 5.30 |

| SB00P15-50 | - | 0.047 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 58.80 | 5.71 |

| SB05P15-50 | 1.36 | 0.047 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 62.15 | 9.63 |

| SB15P05-50 | 4.08 | 0.016 | 11.56 | 2.89 | 25.1 | 18.81 | 18.81 | 37.63 | 3.077 | 0.593 | 3.885 | 72.32 | 11.87 |

| Specimen | Peak Point | Residual Load (kN) | Flexural Toughness (Joule) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| δpeak (mm) | Ppeak (kN) | fpeak (MPa) | PL300 | PL150 | PL100 | Ω300 | ΩL150 | ΩL100 | |

| SB00P10-50 | 0.585 | 18.031 | 5.407 | - | - | - | - | - | - |

| SB05P10-50 | 0.651 | 21.790 | 6.538 | 5.311 | 2.964 | 1.762 | 10.586 | 14.651 | 17.122 |

| SB10P10-50 | 0.879 | 25.921 | 7.775 | 16.707 | 5.796 | 2.865 | 15.263 | 25.990 | 30.339 |

| SB15P10-50 | 1.091 | 28.748 | 8.625 | 27.724 | 8.896 | 3.690 | 15.541 | 31.084 | 36.801 |

| SA10P10-50 | 0.899 | 23.892 | 7.167 | 21.972 | 7.076 | 1.628 | 15.086 | 27.043 | 31.484 |

| SC10P10-50 | 1.074 | 30.051 | 9.015 | 29.038 | 12.692 | 7.581 | 15.743 | 35.723 | 45.797 |

| SB10P00-50 | 0.680 | 24.420 | 7.326 | 10.135 | 6.042 | 3.699 | 14.058 | 21.451 | 25.817 |

| SB10P05-50 | 0.972 | 24.602 | 7.381 | 23.436 | 6.198 | 3.567 | 14.238 | 24.090 | 28.888 |

| SB10P15-50 | 0.938 | 26.718 | 8.014 | 17.308 | 7.034 | 3.121 | 15.763 | 25.046 | 29.649 |

| SB10P10-00 | 1.027 | 31.309 | 9.391 | 31.017 | 6.126 | 2.369 | 16.928 | 27.587 | 33.047 |

| SB10P10-25 | 0.901 | 27.082 | 8.124 | 16.323 | 7.747 | 4.576 | 16.769 | 26.972 | 32.854 |

| SB10P10-75 | 0.874 | 24.441 | 7.331 | 17.807 | 3.416 | 2.526 | 14.868 | 21.383 | 24.403 |

| SB10P10-100 | 0.810 | 22.342 | 6.702 | 10.283 | 1.662 | 0.704 | 13.453 | 17.629 | 18.722 |

| SF Content (%) | PF Content (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Compressive Strength | Splitting Tensile Strength | Flexural Strength | |||||||

| 0.05 | 0.1 | 0.15 | 0.05 | 0.1 | 0.15 | 0.05 | 0.1 | 0.15 | |

| 0 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| 0.5 | - | 1.070 | 0.962 | - | 1.195 | 1.132 | - | 0.975 | 1.015 |

| 1.0 | 1.116 | 1.085 | 1.009 | 1.178 | 1.167 | 1.178 | 0.848 | 0.853 | 0.851 |

| 1.5 | 1.152 | 1.064 | - | 1.128 | 1.110 | - | 0.824 | 0.799 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, L.; Zhen, C.; Zeng, Q.; Li, B. Experimental Investigation on the Mechanical Properties of Geopolymer Recycled Aggregate Concrete Reinforced with Steel-Polypropylene Hybrid Fiber. Buildings 2025, 15, 1723. https://doi.org/10.3390/buildings15101723

Ma L, Zhen C, Zeng Q, Li B. Experimental Investigation on the Mechanical Properties of Geopolymer Recycled Aggregate Concrete Reinforced with Steel-Polypropylene Hybrid Fiber. Buildings. 2025; 15(10):1723. https://doi.org/10.3390/buildings15101723

Chicago/Turabian StyleMa, Lili, Cheng Zhen, Qingxin Zeng, and Biao Li. 2025. "Experimental Investigation on the Mechanical Properties of Geopolymer Recycled Aggregate Concrete Reinforced with Steel-Polypropylene Hybrid Fiber" Buildings 15, no. 10: 1723. https://doi.org/10.3390/buildings15101723

APA StyleMa, L., Zhen, C., Zeng, Q., & Li, B. (2025). Experimental Investigation on the Mechanical Properties of Geopolymer Recycled Aggregate Concrete Reinforced with Steel-Polypropylene Hybrid Fiber. Buildings, 15(10), 1723. https://doi.org/10.3390/buildings15101723