Energy Dissipation Between Concrete and Composite Waterproof Sheet Interface

Abstract

1. Introduction

2. Experimental Program

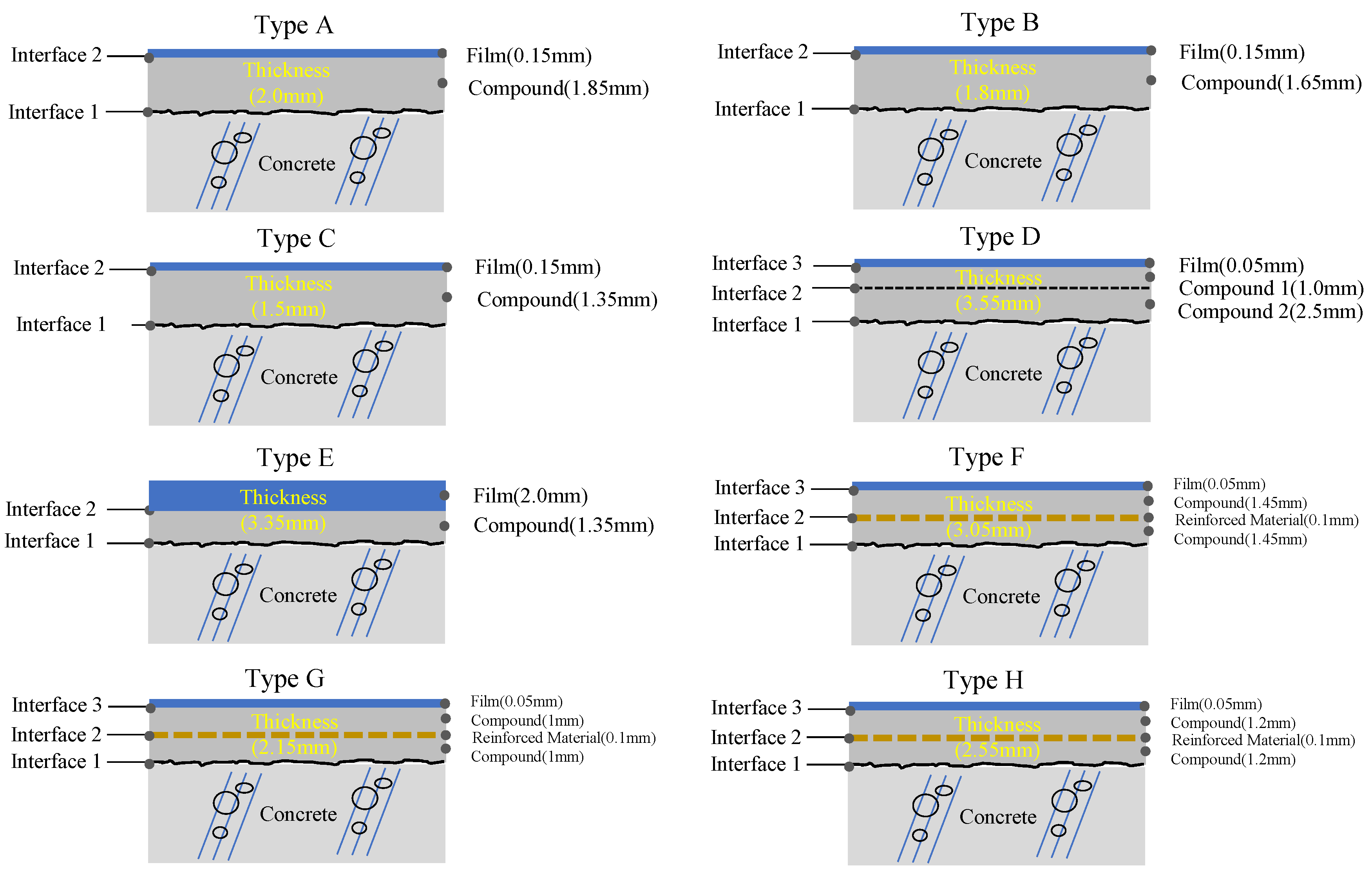

2.1. Waterproofing Materials and Properties

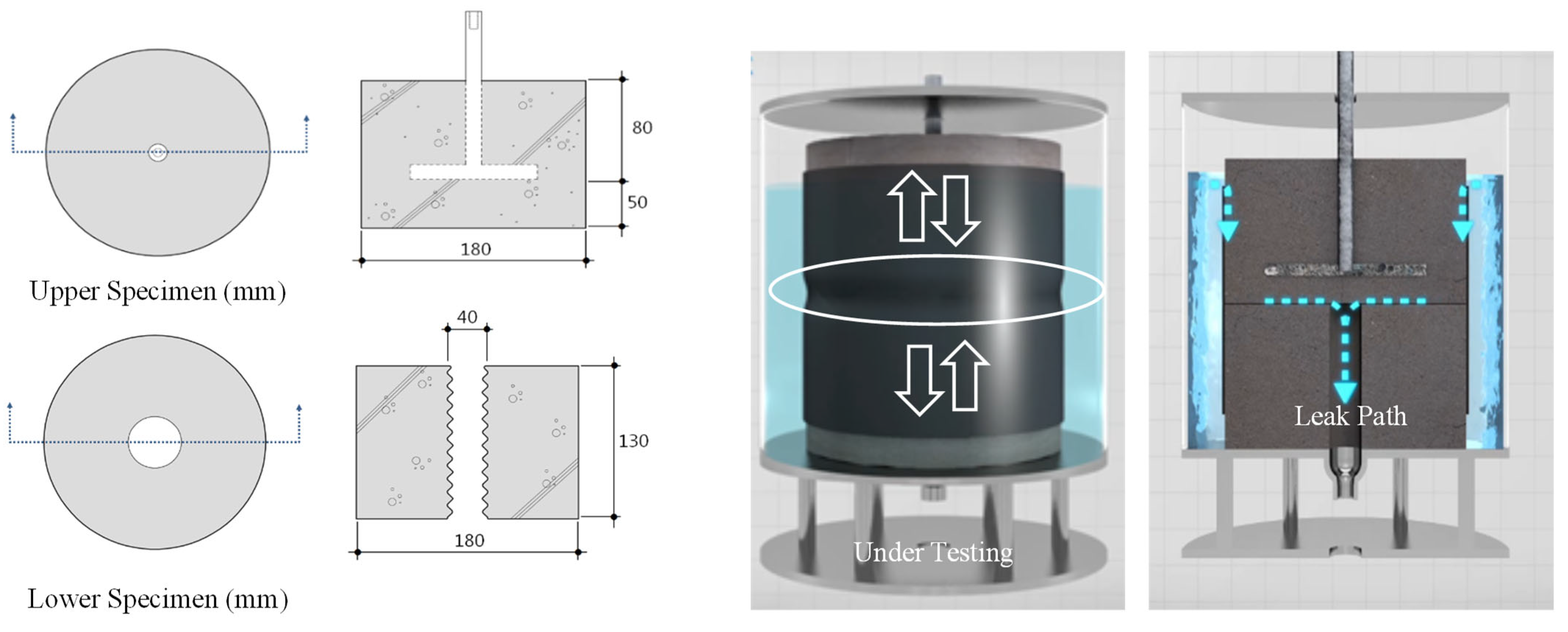

2.2. Test Specimens and Setup

3. Test Results

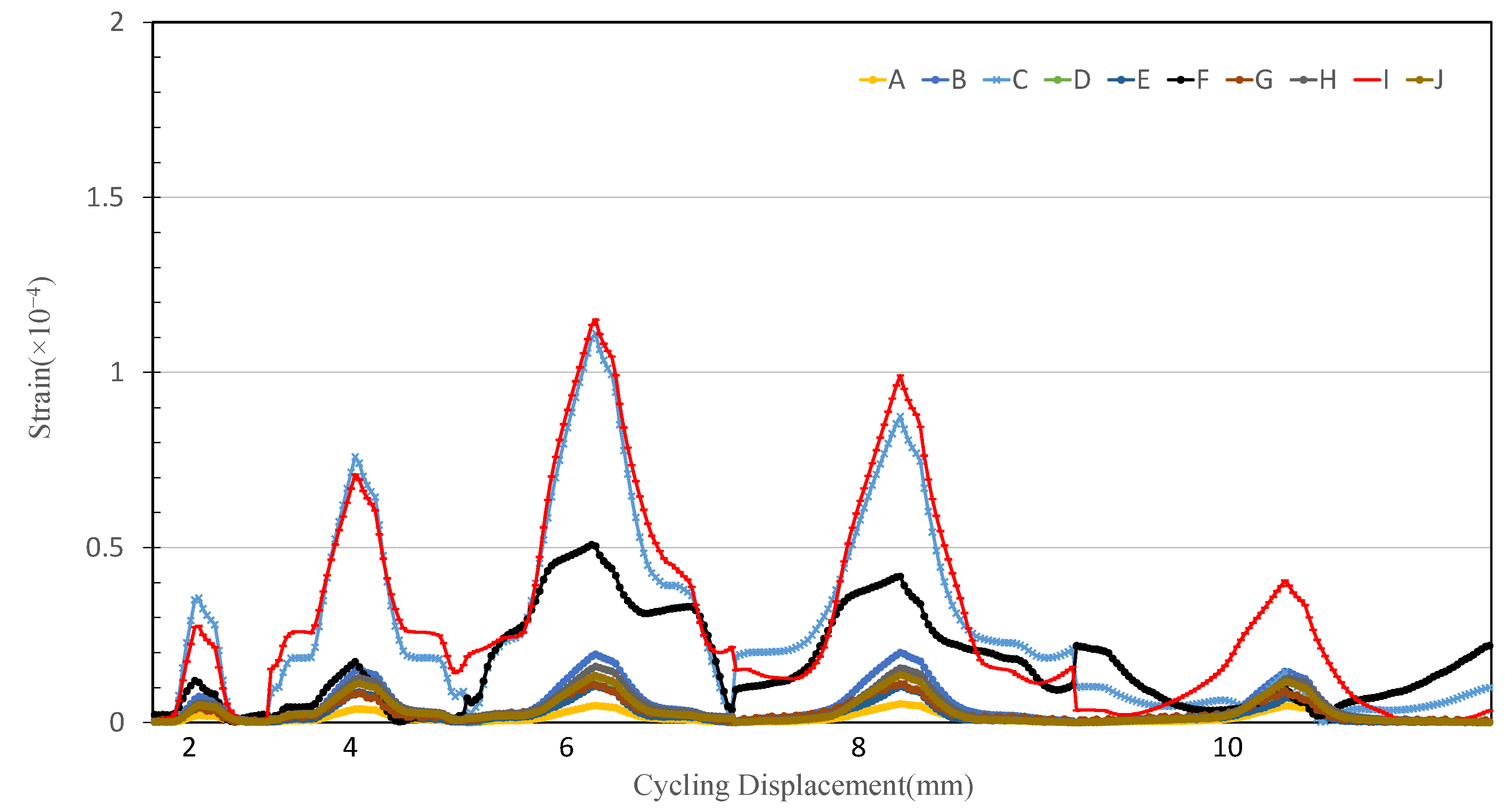

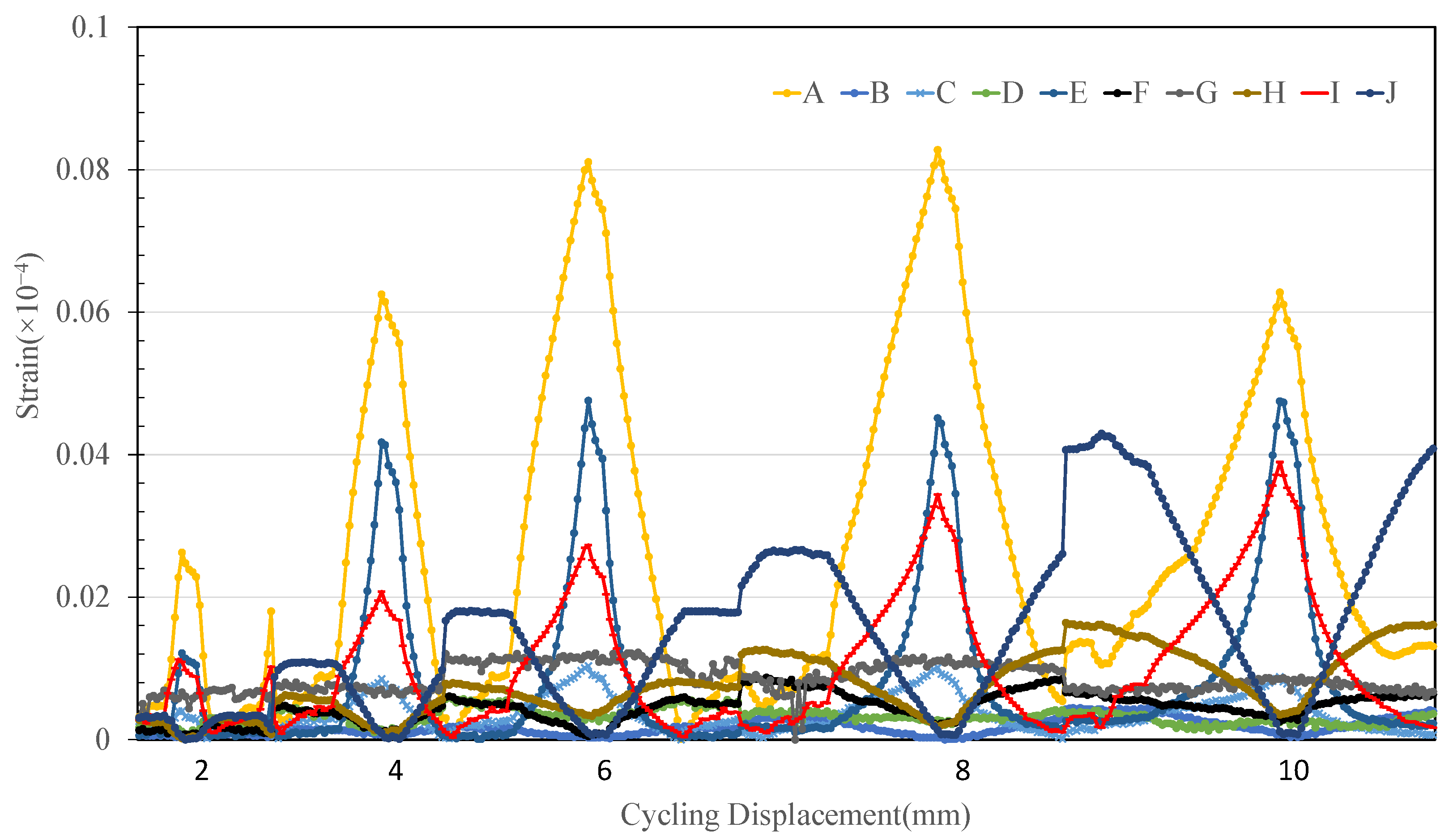

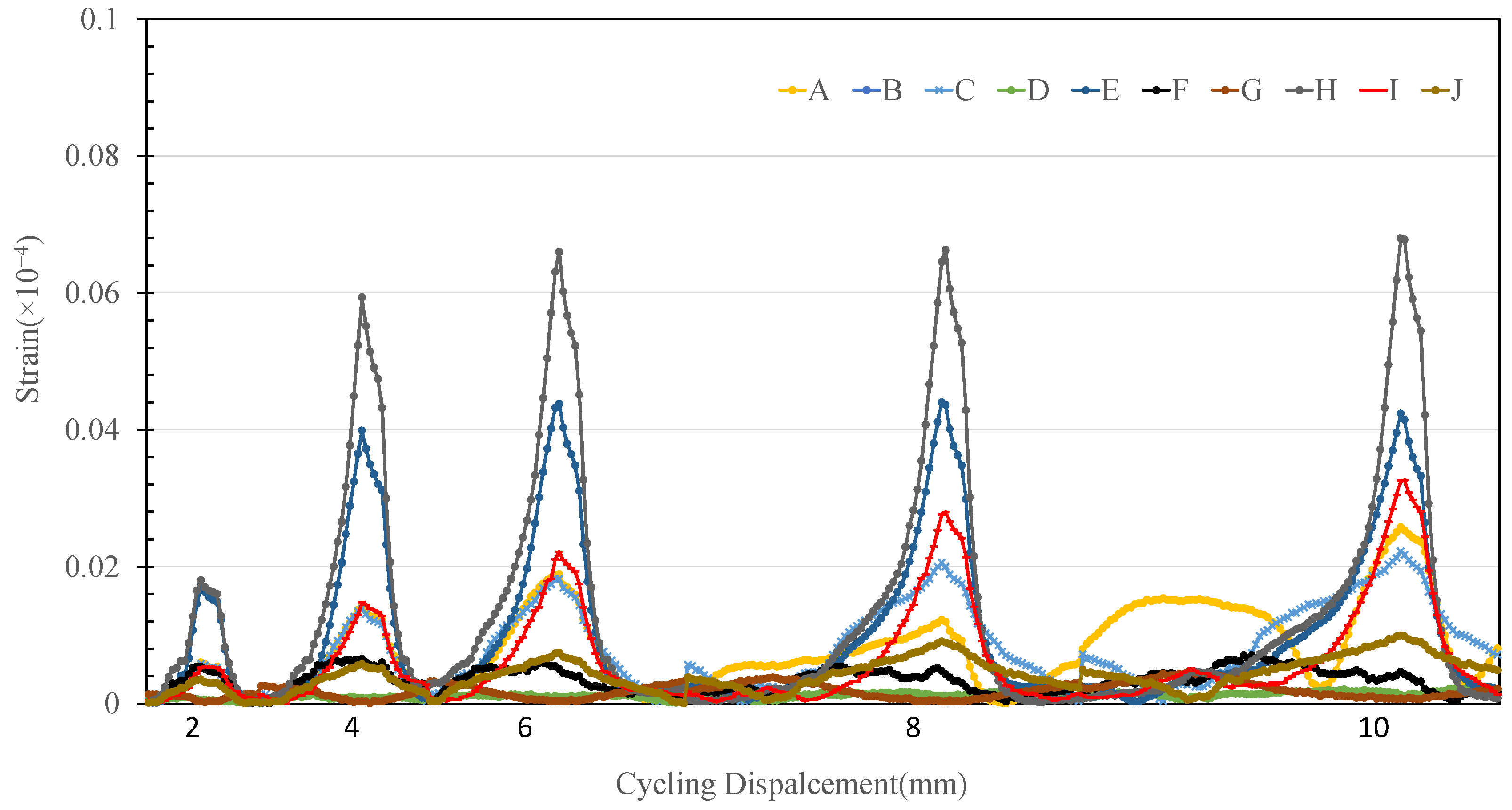

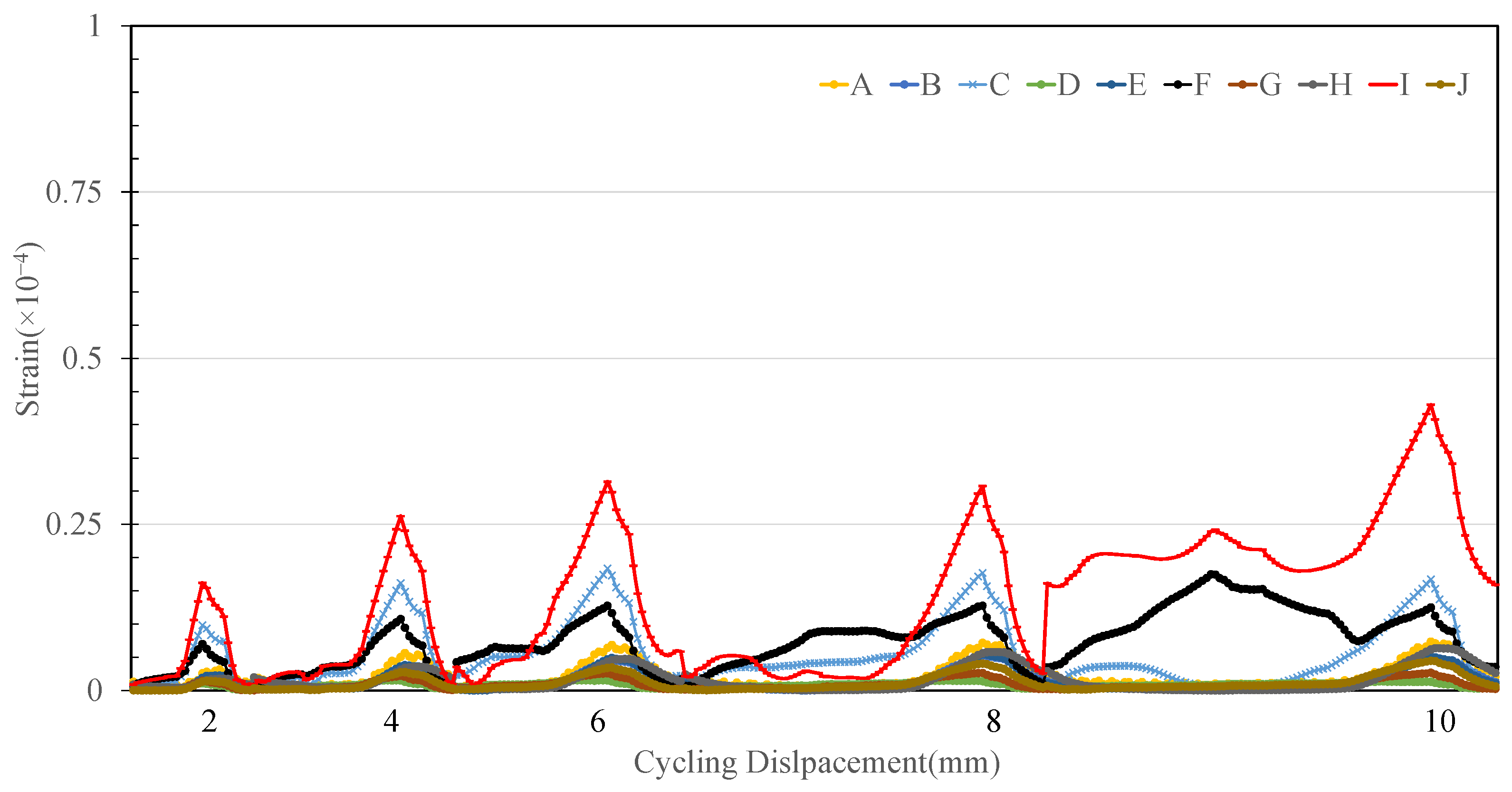

3.1. Relationship Between Cycling Displacement vs. Strains

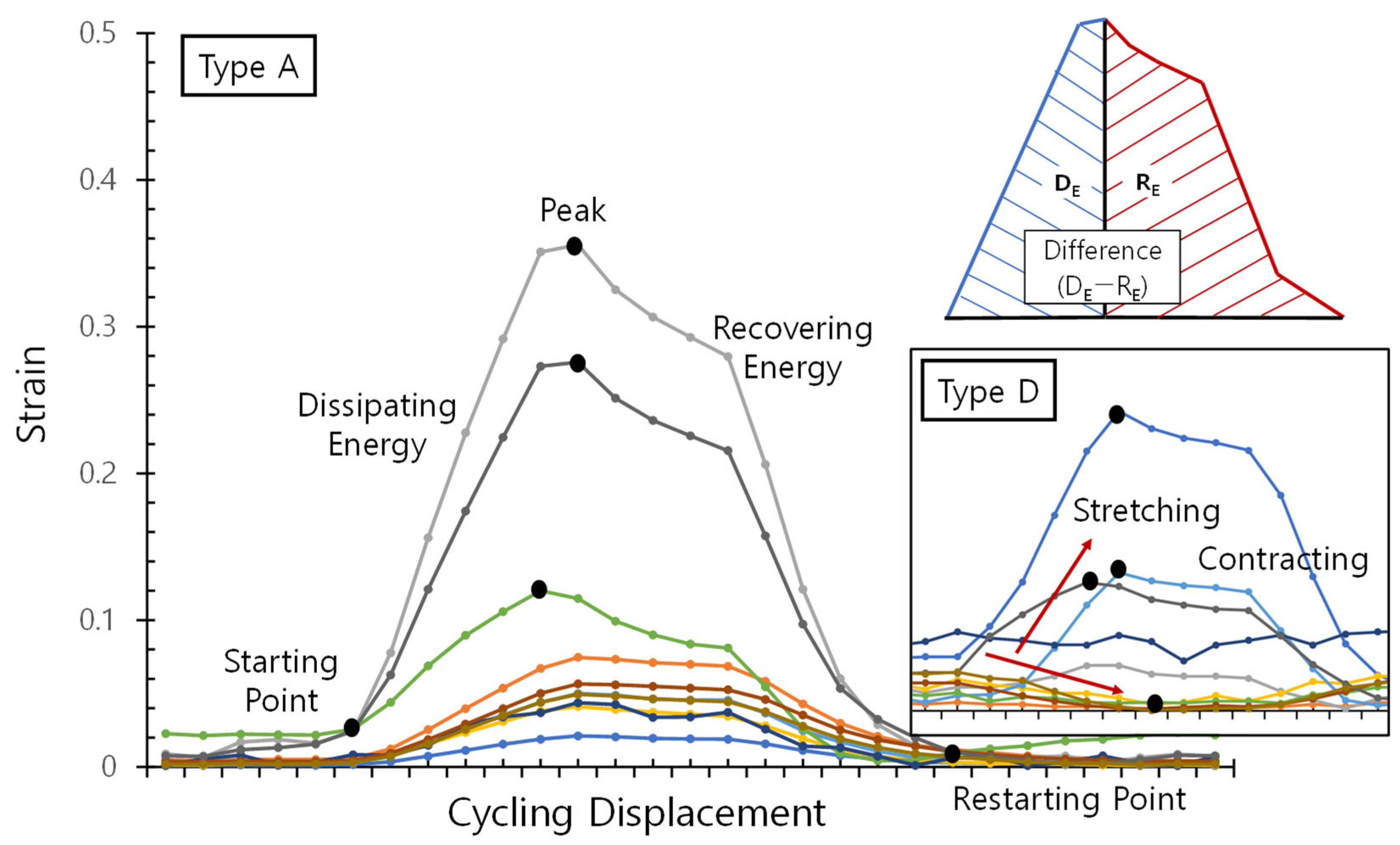

3.2. Dissipating and Recovering Energy

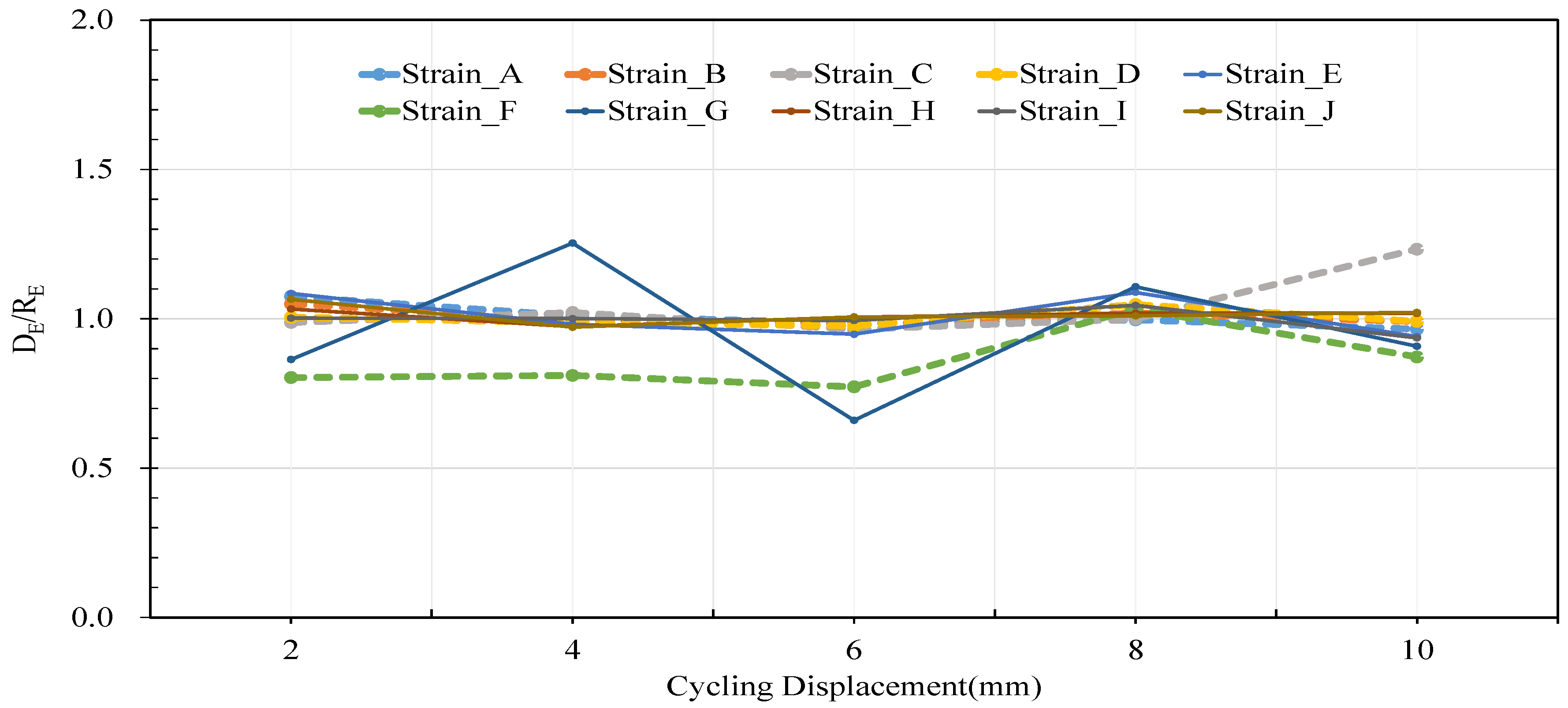

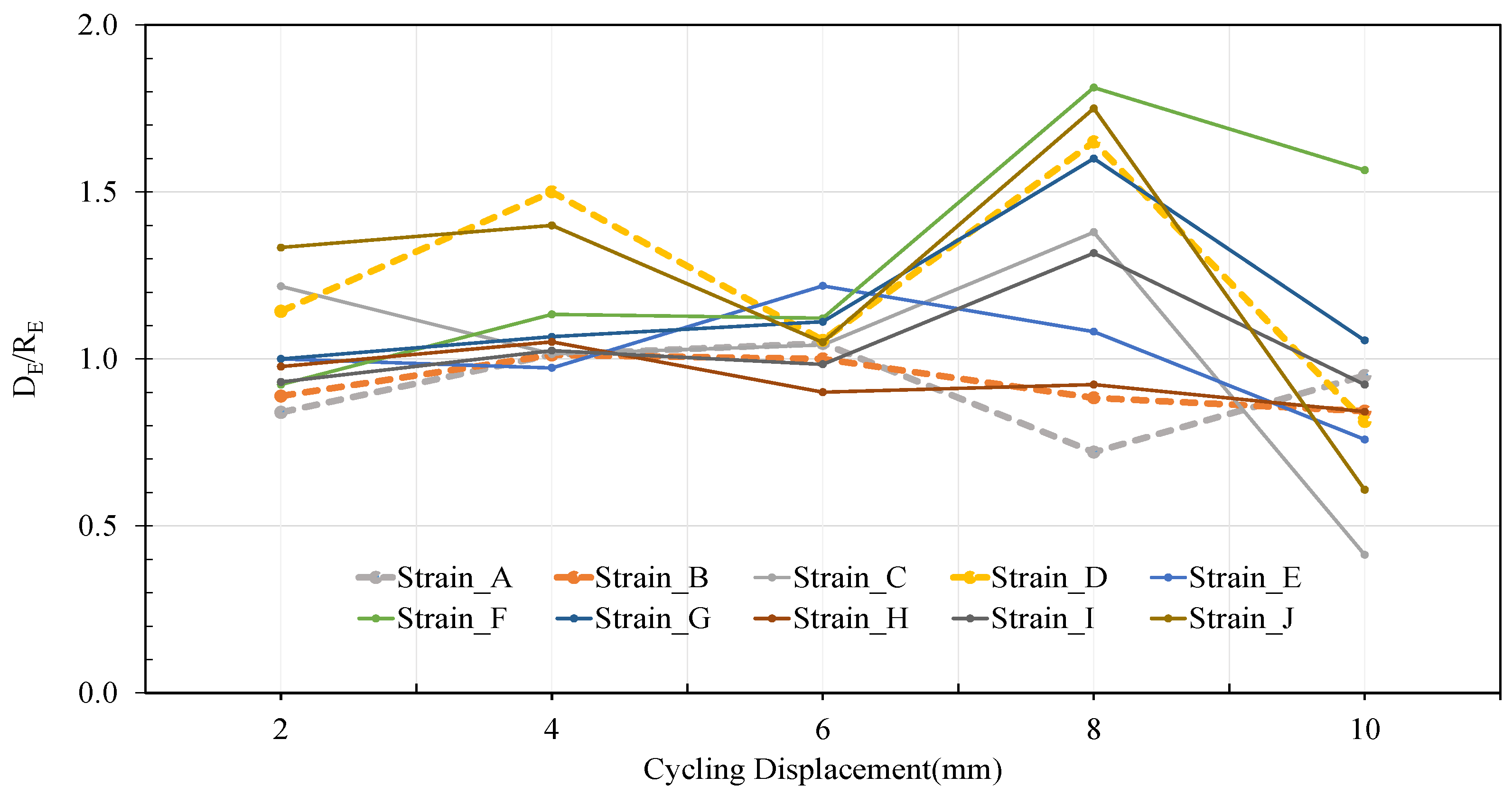

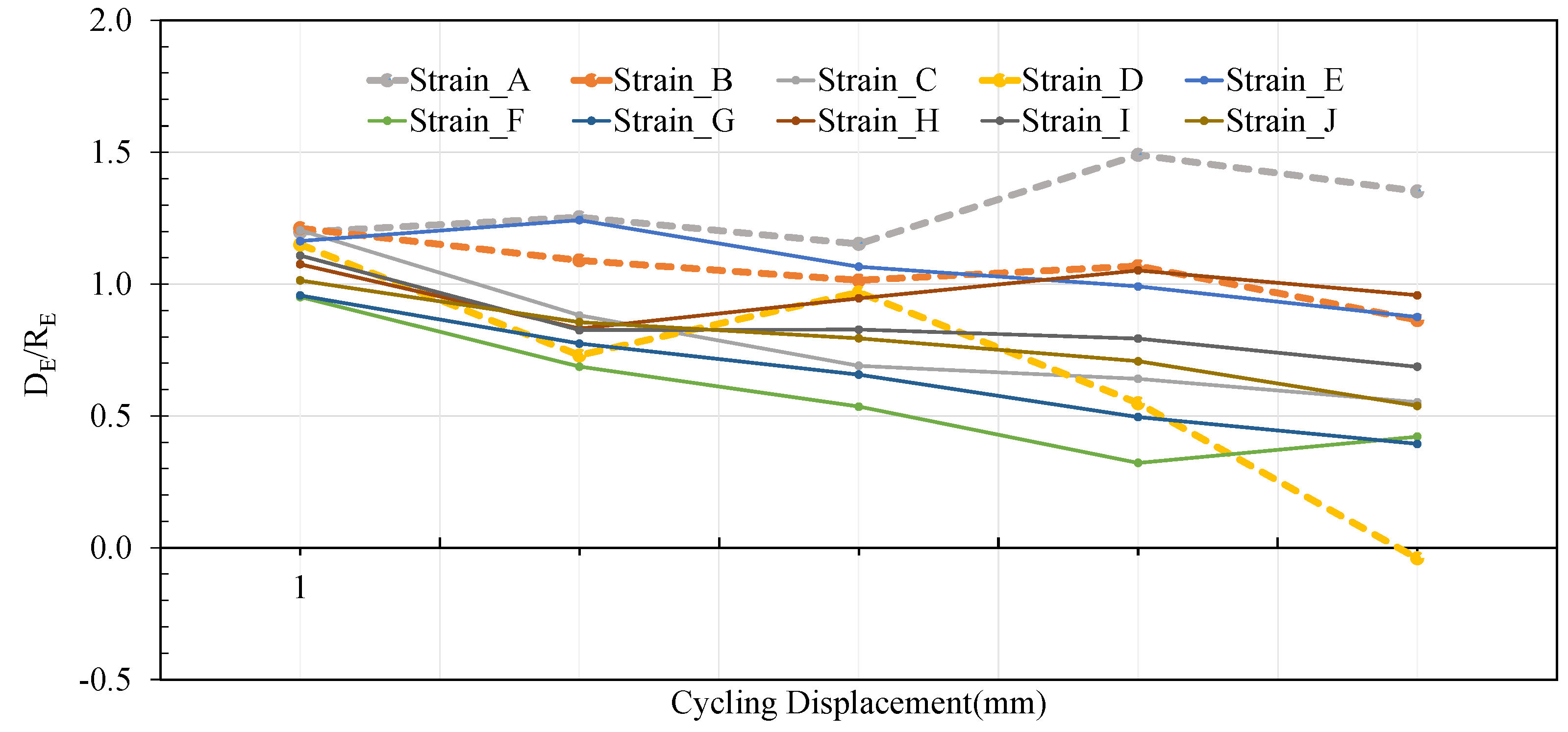

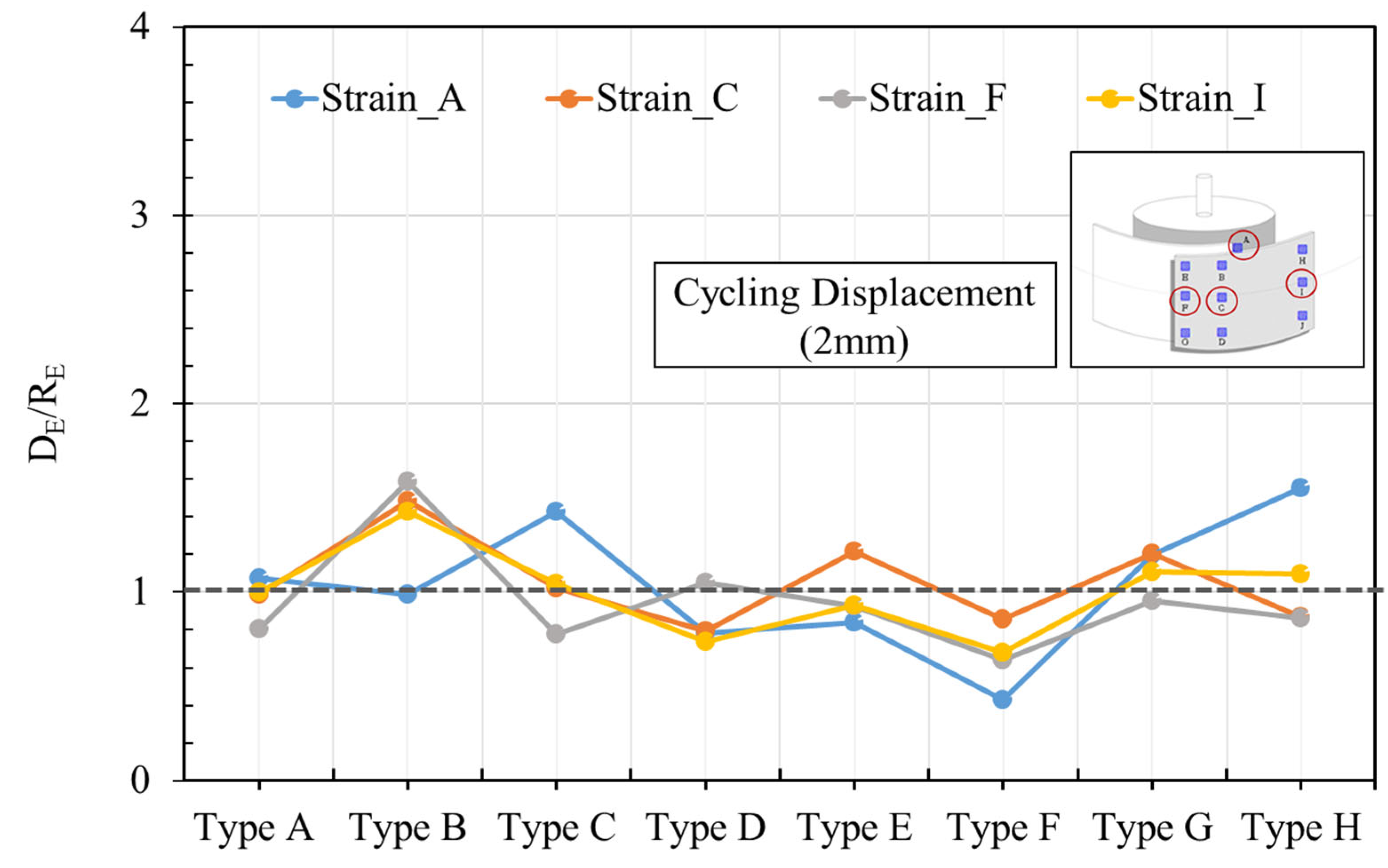

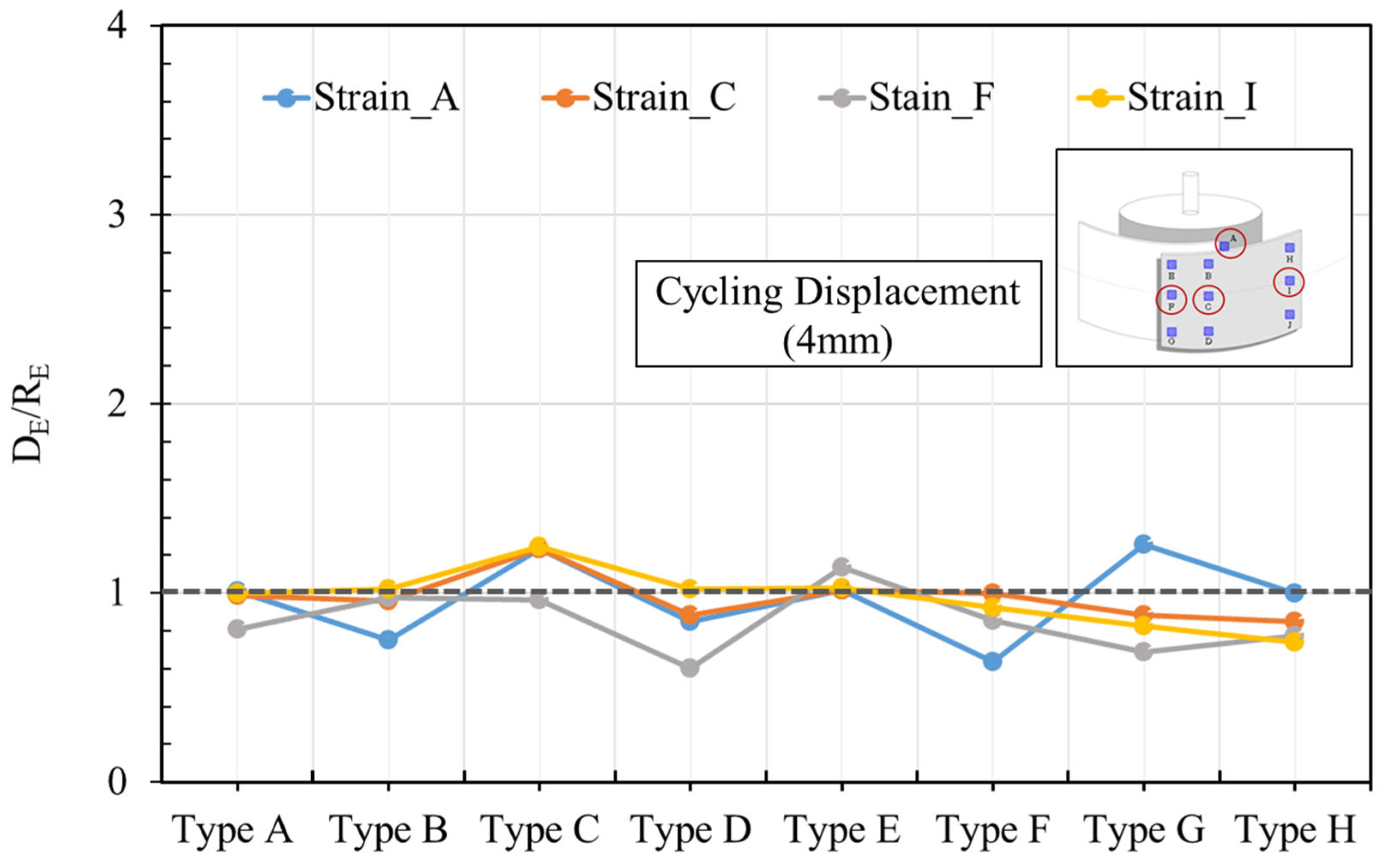

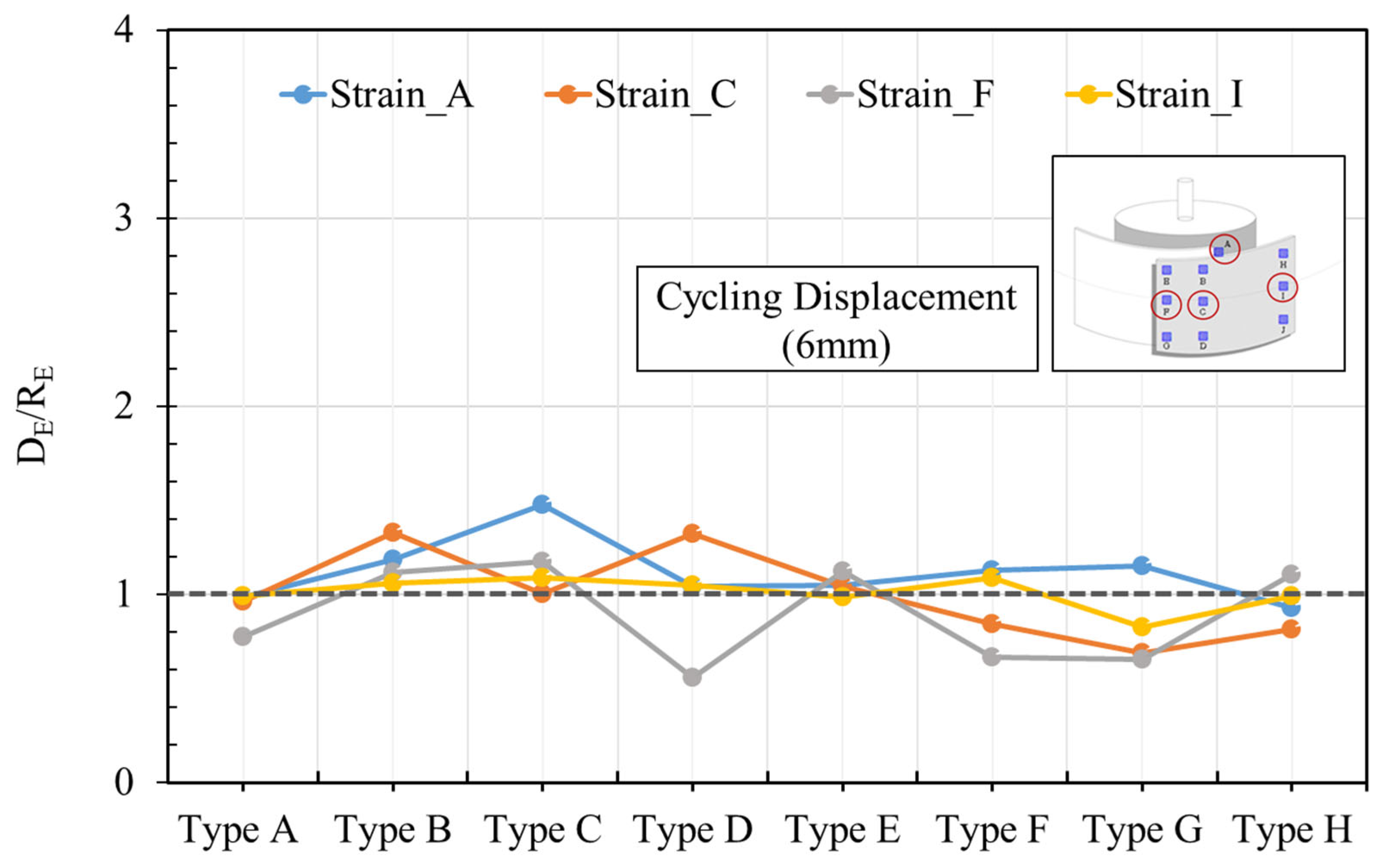

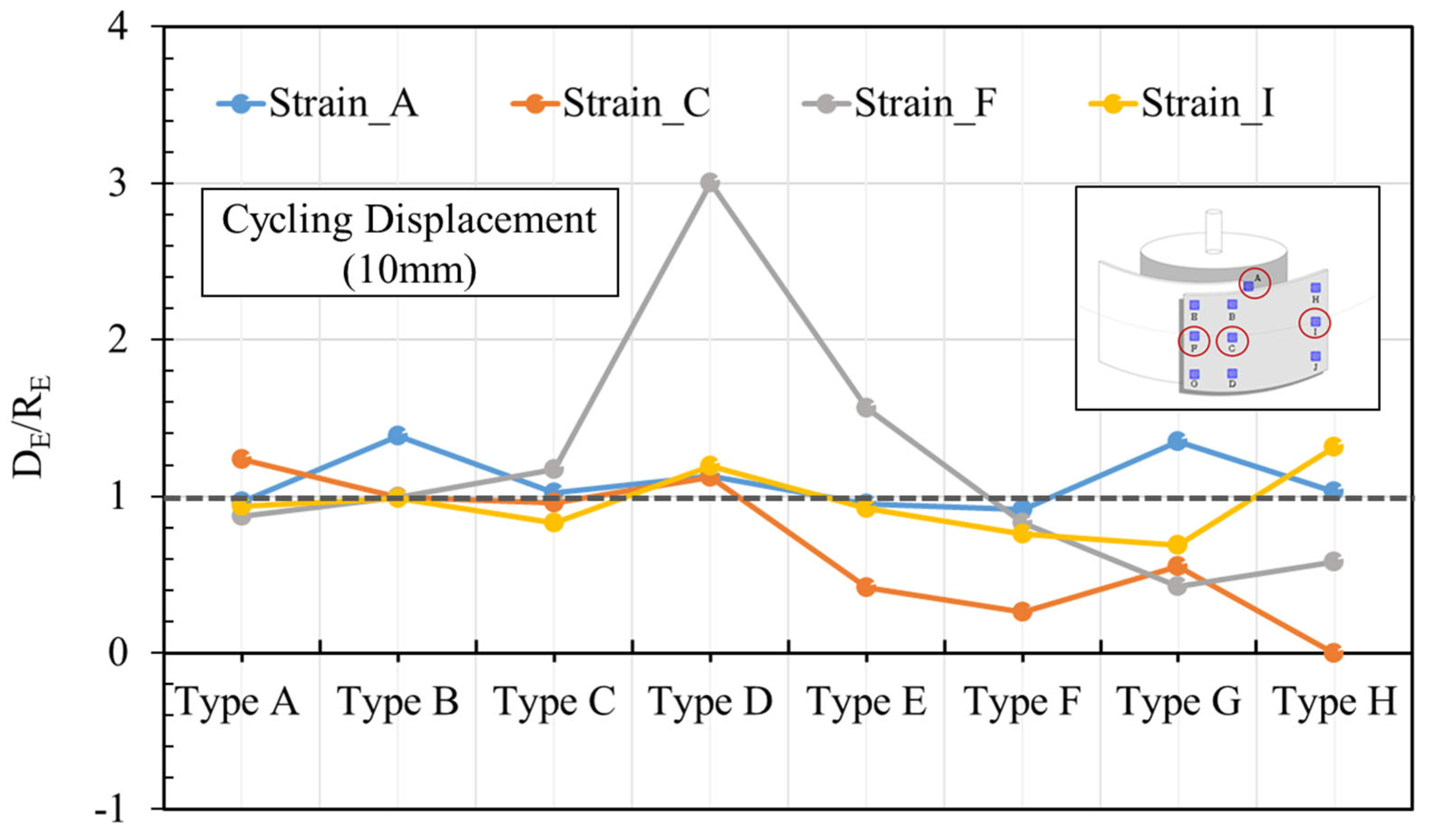

3.3. Dissipating and Recovering Energy Ratio (DE/RE)

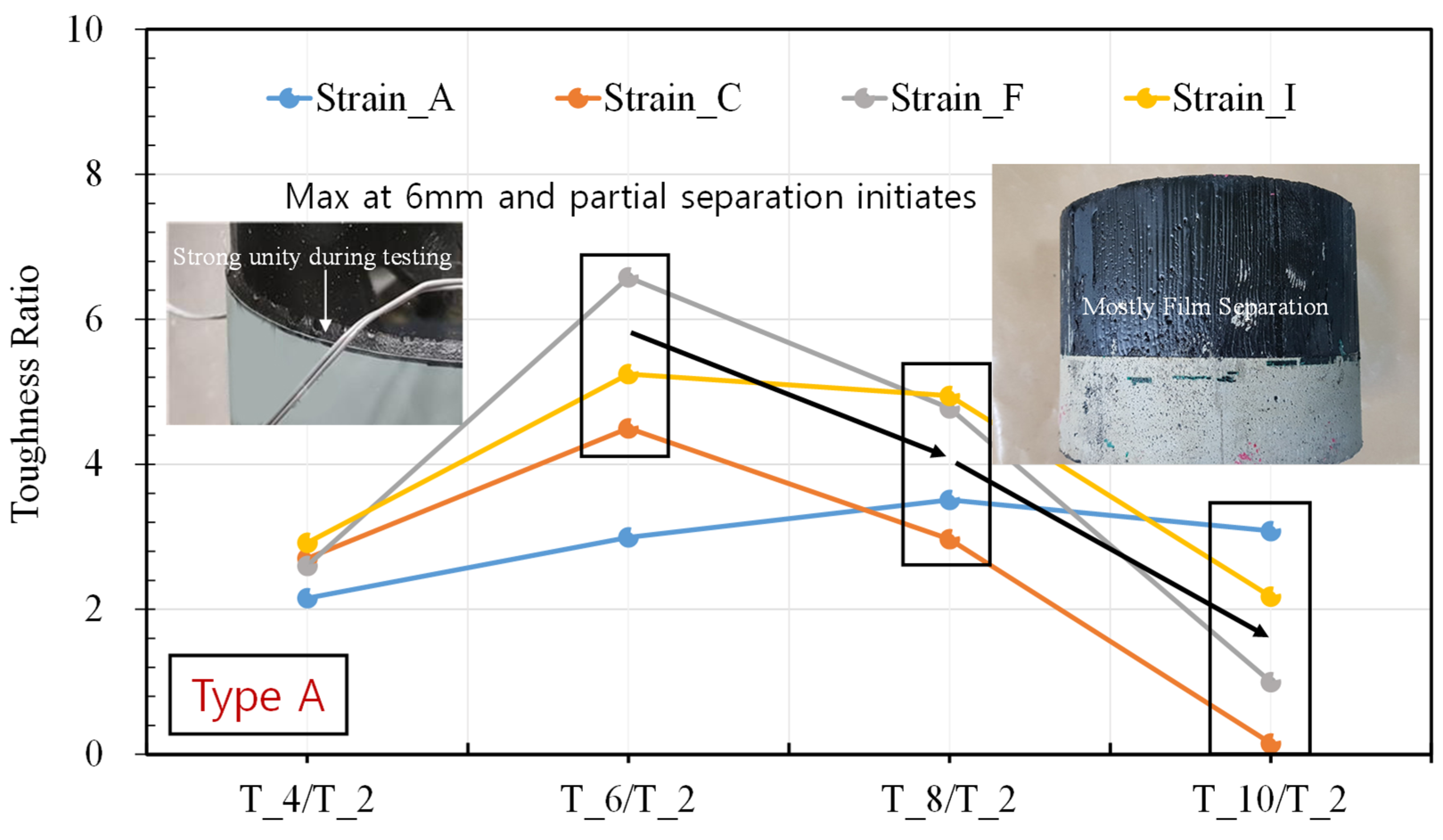

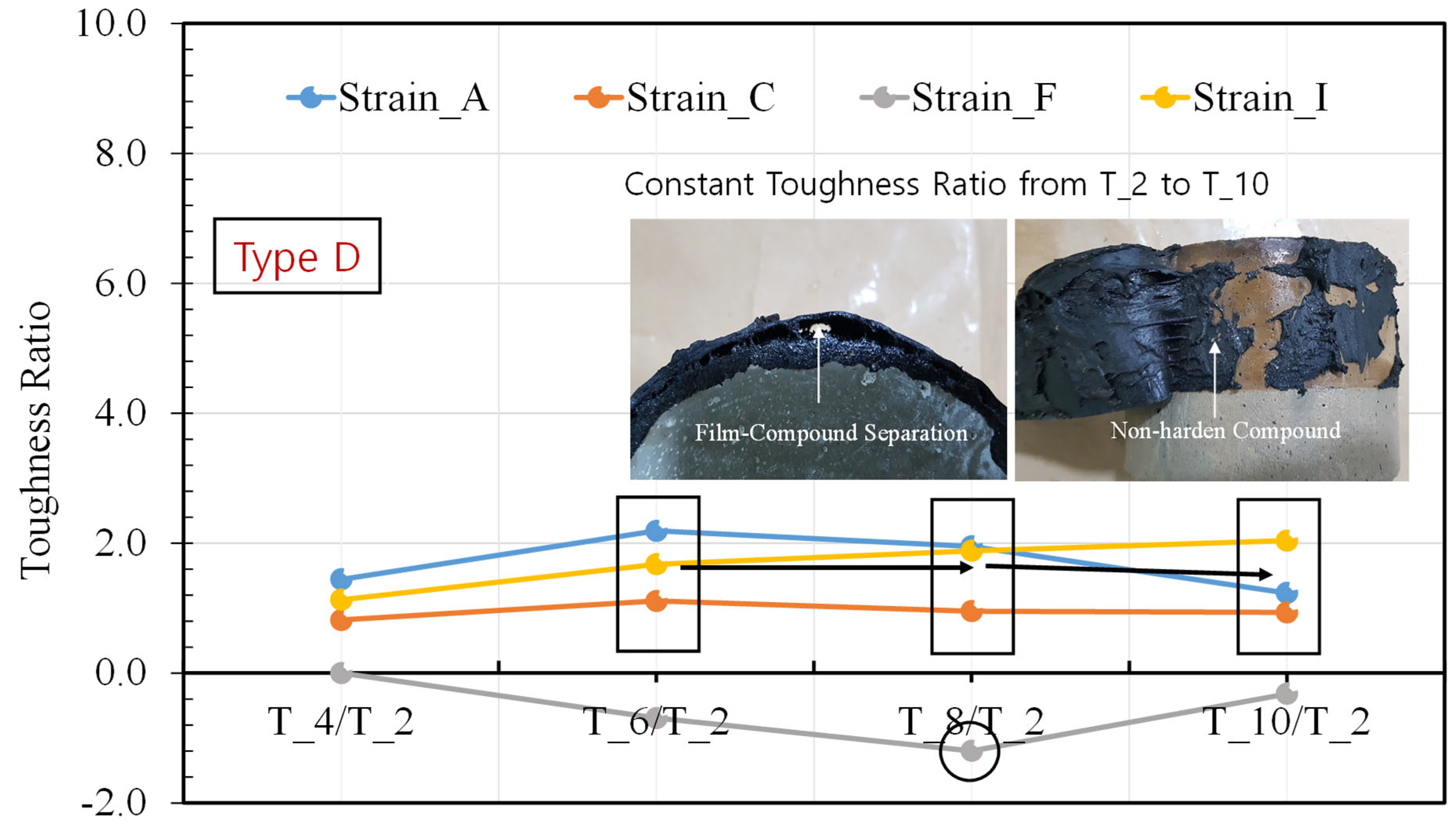

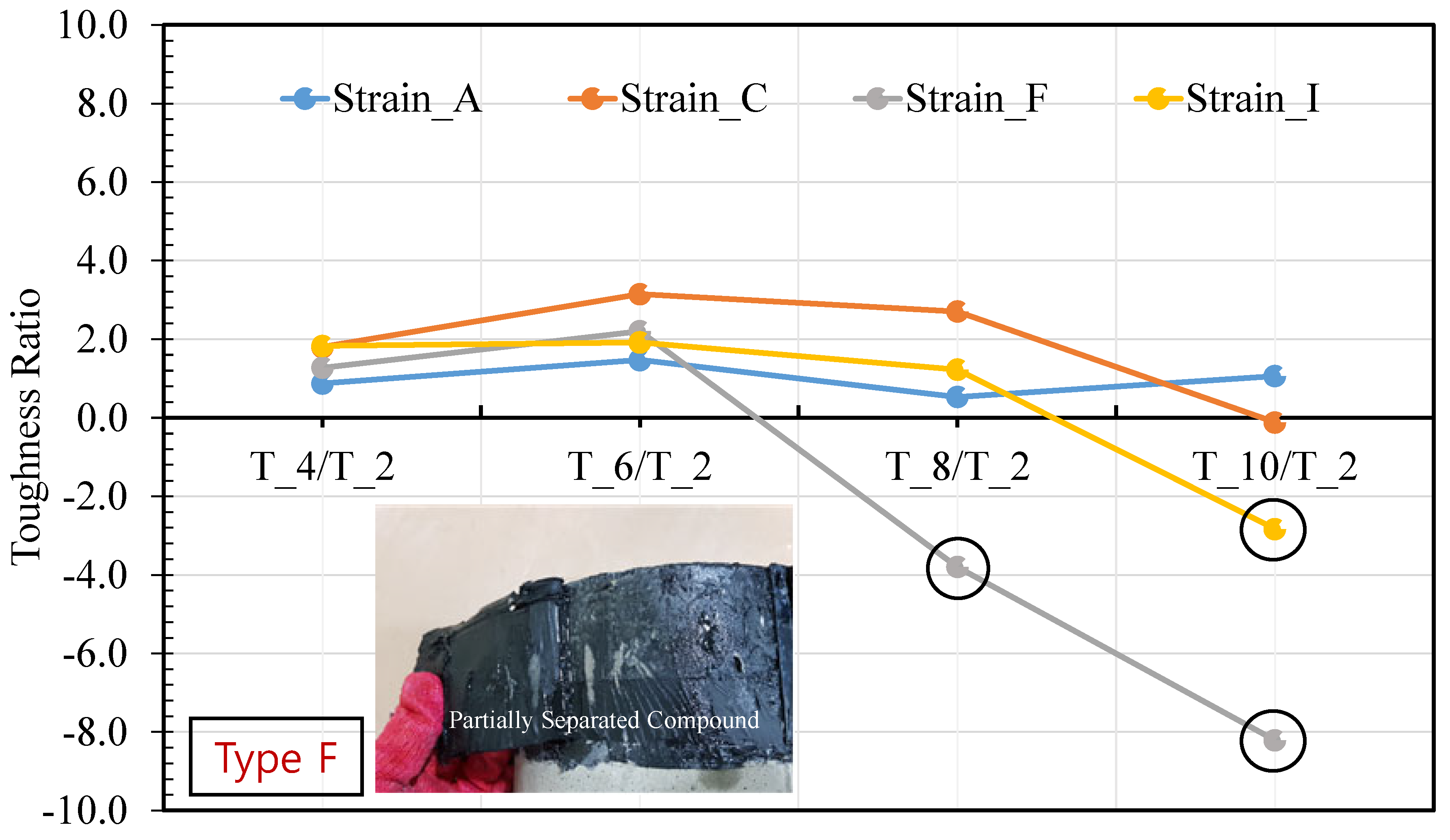

3.4. Toughness Properties

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Y.; Zhao, Z.; Qiang, H.; Wang, X.; Guo, J. Blast resisting responses and upgrading technology for an underground structure subjected to external explosions. Structures 2023, 56, 105055. [Google Scholar] [CrossRef]

- Cheng, Y.; Pan, D.; Chen, Q.; Huang, Y.; Zhang, D. Shaking table test on underground structure-soil-aboveground structure interaction. Tunn. Undergr. Space Technol. 2023, 140, 105300. [Google Scholar] [CrossRef]

- Li, G.; Zhang, H.; Wang, R.; Dong, Z.Q.; Yu, D.H. Seismic damage characteristics and evaluation of aboveground-underground coupled structures. Eng. Stuctures 2023, 283, 115871. [Google Scholar] [CrossRef]

- Lee, K.J. An analytical study on the patents substance of urban underground space development technology. J. Archit. Inst. Korea Struct. Constr. 2019, 35, 129–138. [Google Scholar]

- Lee, S.M.; Yoon, H.M. Actual Conditions and Utilization of Spill Groundwater in Seoul; The Seoul Institute: Seoul, Republic of Korea, 2019; Volume 275. [Google Scholar]

- Adagunodo, T.A.; Aremu, A.A.; Bayowa, O.G.; Ojoawo, A.I.; Adewoye, A.O.; Olonade, T.E. Assessment and health effects of radon and its relation with some parameters in groundwater sources from shallow aquifers in granitic terrains, southeastern axis of Ibadan, Nigeria. Groundw. Sustain. Dev. 2023, 21, 100930. [Google Scholar] [CrossRef]

- Song, J.Y.; Kwak, K.S.; Oh, S.K. Mechanism of water leakage and need for waterproofing in concrete structure. Archi. Inst. Korea 2012, 24, 18–23. [Google Scholar]

- Laxman, K.C.; Tabassum, N.; Ai, L.; Cole, C.; Ziehl, P. Automated crack detection and crack depth prediction for reinforced concrete structures using deep learning. Constr. Build. Mater. 2023, 370, 130709. [Google Scholar] [CrossRef]

- Deng, H.S.; Fu, H.L.; Chen, W.; Zhao, Y.B.; Yi, H.D. Study on deterioration, cracking mechanism and treatment measures of plain concrete lining with cold joints in high-speed railroad tunnel. Case Stud. Constr. Mater. 2023, 18, e01895. [Google Scholar] [CrossRef]

- Zhan, X.; Zhang, H.; Wang, P.; Ren, Q.; Zhang, D.; Yan, L.; Zhu, X. Flow-field fitting method applied to the detection of leakages in the concrete gravity. J. Appl. Geophys. 2023, 208, 104896. [Google Scholar]

- Song, X.F.; Wei, J.F.; He, T.S.H. A method to repair concrete leakage through cracks by synthesizing super-absorbent resin in situ. Constr. Build. Mater. 2009, 23, 386–391. [Google Scholar] [CrossRef]

- Lee, J.H.; Song, J.Y.; Oh, S.K. Leakage situation and main leakage areas of domestic residential building underground parking lots. J. Korean Recycl. Constr. Resour. Inst. 2016, 4, 496–503. [Google Scholar]

- Han, Y.J.; Oh, K.W.; Kim, S.R.; Kim, B.I.; Oh, S.K. Consumer awareness analysis of residential building underground structure leakage prevention measurements. J. Korean Recycl. Constr. Resour. Inst. 2016, 4, 379–387. [Google Scholar] [CrossRef]

- Sang, Y.C. Groundwater obstruction and countermeasures for groundwater discharge from subway in Seoul, Korea. J. Geol. Soc. Korea 2010, 46, 61–72. [Google Scholar]

- Mossberg, A.; Nilsson, D.; Frantzich, H. Evaluating new evacuation systems related to human behavior using a situational awareness approach- A study of the implementation of evacuation elevators in an underground facility. Fire Saf. J. 2022, 134, 103693. [Google Scholar] [CrossRef]

- Sun, W.; Iiu, H.; Zhang, W.; Iiu, S.; Han, L. Determination of groundwater buoyancy reduction coefficient in clay: Model tests, numerical simulations and machine learning methods. Undergr. Space 2023, 13, 228–240. [Google Scholar] [CrossRef]

- Matias, S.R.; Ferreira, P.A. The role of railway traffic and extreme weather on slab track long-term performance. Constr. Build. Mater. 2022, 322, 126445. [Google Scholar] [CrossRef]

- Song, J.Y.; Oh, K.W.; Kim, B.; Oh, S.K. Performance evaluation of waterproofing membrane systems subject to the concrete joint load behavior of below-grade concrete structures. Appl. Sci. 2017, 7, 1147. [Google Scholar] [CrossRef]

- Kim, D.B.; Choi, S.Y.; Park, J.S.; He, X.Y.; Oh, S.K. Oil Leakage evaluation for selection of emulsion-based non-curable synthetic polymer eubberized gel (ENC-SPRG) as waterproofing material in underground structures. Materials 2019, 12, 3816. [Google Scholar] [CrossRef]

- Kim, S.Y.; Oh, S.K.; Kim, B. Artificial-crack-behavior test evaluation of the water-leakage repair materials used for the repair of water-leakage cracks in concrete Structures. Appl. Sci. 2016, 6, 253. [Google Scholar] [CrossRef]

- Chung, C.P.; Choi, S.Y.; Kim, D.B.; Park, W.G.; Kim, B.; Oh, S.K. Evaluation of sheet-coated composite waterproofing joint types by analysis of tensile strength change and concrete displacement resistance testing under environmental degradation. Materials 2020, 13, 2120. [Google Scholar] [CrossRef]

- Cho, B.H.; Nam, B.H.; Seo, S.; Kim, J.; An, J.; Youn, H. Waterproofing performance of waterstop with adhesive bonding used at joints of underground concrete structures. Constr. Build. Mater. 2019, 221, 491–500. [Google Scholar] [CrossRef]

- Zhang, H.; Gao, P.; Zhang, Z.; Pan, Y. Experimental study of the performance of a stress-absorbing waterproof layer for use in asphalt pavements on bridge decks. Constr. Build. Mater. 2020, 254, 119290. [Google Scholar] [CrossRef]

- Pelz, U.; Karlovsek, J. Spray-applied waterproofing membranes in tunneling: Application and research directions in Australia. Tunn. Undergr. Space Technol. 2022, 122, 104364. [Google Scholar] [CrossRef]

- Xia, H.; Lu, C.; Yang, H.; Song, L.; Geng, J.; Cui, Z.; Niu, Y.; Sun, Y. Preparation and performance of durable waterproof adhesive layer for steel bridge deck based on self-stratification effect. Constr. Build. Mater. 2023, 366, 130133. [Google Scholar] [CrossRef]

- Muhammad, N.Z.; Keyvanfar, A.; Majid, M.Z.A.; Shafaghat, A.; Mirza, J. Waterproof performance of concrete: A critical review on implemented approaches. Constr. Build. Mater. 2015, 101 Pt 1, 80–90. [Google Scholar] [CrossRef]

- Kim, S.Y.; Kim, M.G.; Oh, S.K. A study on the seismic performance design of waterproofing materials applied single-side walls on underground structures. Korea Inst. Struct. Maint. Insp. 2020, 24, 43–50. [Google Scholar]

- Oh, S.K.; Lee, J.Y.; Choi, S.M. An experimental study on the highly adhesive composite waterproofing sheet using reclaimed rubber. J. Archit. Inst. Korea 2014, 16, 279–284. [Google Scholar]

- Kim, M.G.; Lee, S.W.; Kim, S.Y.; Oh, S.K. Construction verification evaluation for securing the field quality of composite membrane waterproofing material. Korea Inst. Build. Constr. 2021, 21, 87–95. [Google Scholar]

- Kim, S.Y.; Park, J.S.; Oh, S.K. Verification and improvement of structural behavior response performance evaluation method for the standard establishment of adhesive composite waterproofing sheets. Korea Inst. Struct. Maint. Insp. 2021, 21, 377–386. [Google Scholar]

- Julie Anne, B. dos Santos; Renata Monte. Evaluation of the creak bridging ability of waterproofing membranes using indirect tensile test and digital image correlation. J. Build. Eng. 2022, 45, 103667. [Google Scholar]

- Wee, J.W.; Chudnvsky, A.; Choi, B.H. Crack layer modeling of overload-induced slow crack growth retardation of high-density polyethylene. Inter. J. Mech. Sci. 2023, 257, 108546. [Google Scholar] [CrossRef]

- Lourmpas, N.; Bailas, K.; Papanikos, P.; Lekkas, D.F.; Kyriakakis, E.C.; Efthimiadou, E.K.; Alexopoulos, N.D. Assessing the weathering-induced degradation on the structural integrity of high-density polyethylene. Mater. Today Proc. 2023, 93, 844–849. [Google Scholar] [CrossRef]

- Shi, R.; Ma, J.; Song, X.; Zhan, B.; Xu, X.; Zhao, S.; He, J. Composition effects on thermodynamic properties and interfacial structure in styrene-butadiene rubber: A combined experimental and simulation study. Chem. Eng. Sci. 2023, 275, 118750. [Google Scholar] [CrossRef]

- Yao, H.; Wang, Q.; Zhang, Z.; Zhou, X.; Cao, Y. Effect of styrene-butadiene-styrene triblock copolymer structure on the rheological properties of high content SBS polymer modified asphalts. Constr. Build. Mater. 2023, 400, 132738. [Google Scholar] [CrossRef]

- Wei, K.; Cao, X.; Wu, Y.; Cheng, Z.; Tang, B.; Shan, B. Dynamic chemistry approach for self-healing of polymer-modified asphalt: A state-of-the-art review. Constr. Build. Mater. 2023, 403, 133128. [Google Scholar] [CrossRef]

| Type | Composition | Materials Property | Adhesive Strength (N/mm2) | Tensile Performance (N/mm2, %) | ||

|---|---|---|---|---|---|---|

| A | Film (0.15 mm) + Compound (1.85 mm) | -Film: high-density polyethylene (HDPE) -Compound: high-adhesion asphalt containing butyl and latex, etc. | 0.75 | Tensile strength | 6.2 | |

| Elongation | 643 | |||||

| B | Film (0.15 mm) + Compound (1.65 mm) | 1.80 | Tensile strength | 6.2 | ||

| Elongation | 597 | |||||

| C | Film (0.15 mm) + Compound (1.35 mm) | 1.65 | Tensile strength | 5.3 | ||

| Elongation | 576 | |||||

| D | Film (0.05 mm) + Compound (1.0 mm) +Compound (2.5 mm) | -Film: polyethylene (PE) -Improved asphalt waterproofing sheet + high-viscosity sealing materials (compound) | 1.00 | Tensile strength | 13.4 | |

| Elongation | 220 | |||||

| E | Film (2.0 mm) + Compound (1.35 mm) | -Film: polyethylene (PE) -Improved asphalt waterproofing sheet + non-hardening seal (compound) |  | 0.10 | Tensile strength | 14.1 |

| Elongation | 429 | |||||

| F | Film (0.05 mm) + Compound (1.45 mm) + Reinforced Material (0.1 mm) +Compound (1.45 mm) | -Film: polyethylene (PE) -Compound: high-adhesion asphalt containing butyl and latex, etc. -Reinforced materials: polypropylene connecting and reinforcing two compound layers -Attachment: with a torch | 2.20 | Tensile strength | 17.3 | |

| Elongation | 576 | |||||

| G | Film (0.05 mm) + Compound (1.0 mm) +Reinforced Material (0.1 mm) +Compound (1.0 mm) | 1.60 | Tensile strength | 14.1 | ||

| Elongation | 429 | |||||

| H | Film (0.05 mm) + Compound (1.2 mm) +Reinforced Material (0.1 mm) +Compound (1.2 mm) | 1.80 | Tensile strength | 16.8 | ||

| Elongation | 839 | |||||

| Cycling Displacement | DE-RE (×10−4) | Specimen Types | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | ||

| 2 | 0.052 | 0.118 | −0.137 | 0.007 | 0.144 | −0.700 | −0.379 | 0.059 | 0.02 | 0.105 | Type A |

| 4 | 0.015 | −0.039 | 0.619 | −0.046 | −0.070 | −1.749 | 0.797 | −0.132 | 0.023 | −0.124 | |

| 6 | −0.034 | −0.170 | −1.774 | −0.119 | −0.255 | −5.425 | −2.674 | 0.034 | −0.238 | 0.034 | |

| 8 | −0.009 | 0.178 | −0.027 | 0.232 | 0.437 | 0.5 | 0.571 | 0.134 | 1.829 | 0.062 | |

| 10 | −0.078 | −0.065 | 0.352 | −0.034 | −0.194 | −0.437 | −0.406 | 0.102 | −1.213 | 0.115 | |

| 2 | −0.001 | 0.121 | 1.123 | 0.146 | 0.096 | 0.686 | 0.107 | 0.03 | 0.979 | 0.077 | Type B |

| 4 | −0.047 | −0.142 | −0.228 | 0.043 | −0.031 | −0.064 | −0.017 | 0.01 | 0.138 | −0.024 | |

| 6 | 0.053 | 0.198 | 1.427 | 0.154 | 0.089 | 0.28 | 0.078 | 0.024 | 0.43 | −0.003 | |

| 8 | 0.052 | 0.087 | 0.12 | −0.033 | −0.001 | −0.334 | −0.010 | 0.015 | −0.134 | 0.001 | |

| 10 | 0.147 | 0.08 | −0.022 | 0.021 | −0.013 | −0.024 | −0.033 | 0.006 | −0.067 | −0.021 | |

| 2 | 0.041 | 0.027 | 0.041 | 0.022 | −0.006 | −0.174 | 0.008 | 0.026 | 0.115 | 0.028 | Type C |

| 4 | 0.03 | 0.089 | 0.478 | 0.069 | 0.041 | −0.032 | 0.027 | 0.062 | 0.79 | 0.045 | |

| 6 | 0.113 | 0.021 | 0.013 | 0.049 | 0.013 | 0.467 | −0.004 | 0.04 | 0.655 | 0.063 | |

| 8 | −0.010 | 0.002 | −0.314 | 0.015 | −0.031 | 0.071 | −0.047 | 0.012 | 0.518 | 0.021 | |

| 10 | 0.006 | 0.09 | −0.117 | 0.078 | 0.056 | 0.491 | 0.096 | 0.089 | −4.394 | 0.08 | |

| 2 | −0.056 | 0.004 | −0.013 | 0.013 | −0.027 | 0.002 | 0.002 | 0.02 | −0.031 | 0.007 | Type D |

| 4 | −0.055 | −0.028 | −0.006 | −0.094 | −0.002 | 0.018 | 0.016 | −0.042 | 0.002 | −0.055 | |

| 6 | 0.022 | −0.014 | 0.017 | 0.022 | −0.024 | 0.014 | −0.083 | −0.030 | 0.008 | 0.005 | |

| 8 | −0.002 | −0.006 | 0.003 | 0.001 | 0.013 | −0.004 | 0.051 | −0.003 | 0.005 | 0.008 | |

| 10 | 0.035 | −0.002 | 0.006 | −0.008 | −0.017 | −0.012 | 0 | 0.006 | 0.036 | −0.019 | |

| 2 | −0.005 | −0.008 | 0.007 | 0.001 | 0 | −0.003 | 0 | −0.003 | −0.003 | 0.005 | Type E |

| 4 | 0.001 | 0.003 | 0.001 | 0.003 | −0.006 | 0.004 | 0.001 | 0.017 | 0.002 | 0.01 | |

| 6 | 0.005 | 0 | 0.004 | 0.001 | 0.042 | 0.005 | 0.002 | −0.037 | −0.002 | 0.002 | |

| 8 | −0.034 | −0.051 | 0.048 | 0.015 | 0.022 | 0.03 | 0.014 | −0.034 | 0.052 | 0.031 | |

| 10 | −0.007 | −0.053 | −0.050 | −0.003 | −0.054 | 0.013 | 0.001 | −0.060 | −0.013 | −0.009 | |

| 2 | −0.141 | 0.05 | −0.078 | 0.045 | −0.001 | −0.059 | 0.012 | 0.068 | −0.109 | −0.001 | Type F |

| 4 | −0.069 | −0.008 | −0.003 | 0.012 | −0.004 | −0.027 | 0 | 0.062 | −0.042 | −0.005 | |

| 6 | 0.031 | −0.001 | −0.266 | −0.016 | −0.008 | −0.118 | −0.003 | 0.088 | 0.046 | 0.004 | |

| 8 | −0.010 | −0.015 | 0.033 | −0.003 | 0 | 0.261 | 0.002 | −0.018 | −0.176 | 0.015 | |

| 10 | −0.016 | −0.024 | 0.07 | −0.053 | −0.026 | 0.203 | −0.037 | −0.010 | 0.219 | 0.005 | |

| 2 | 0.037 | 0.019 | 0.105 | 0.008 | 0.02 | −0.020 | −0.004 | 0.005 | 0.1 | 0.001 | Type G |

| 4 | 0.053 | 0.013 | −0.098 | −0.019 | 0.039 | −0.173 | −0.028 | −0.016 | −0.255 | −0.020 | |

| 6 | 0.039 | 0.003 | −0.251 | −0.002 | 0.013 | −0.270 | −0.039 | −0.008 | −0.219 | −0.032 | |

| 8 | 0.103 | 0.013 | −0.305 | −0.028 | −0.002 | −0.412 | −0.059 | 0.009 | −0.276 | −0.053 | |

| 10 | 0.093 | −0.028 | −0.400 | −0.053 | −0.027 | −0.291 | −0.080 | −0.008 | −0.450 | −0.096 | |

| 2 | 0.026 | 0.059 | −0.058 | 0.028 | 0.031 | −0.051 | 0.001 | −0.031 | 0.054 | 0.001 | Type H |

| 4 | 0 | −0.026 | −0.086 | −0.014 | 0.02 | −0.104 | −0.034 | 0.017 | −0.184 | 0.016 | |

| 6 | −0.018 | −0.009 | −0.115 | −0.011 | −0.007 | −0.075 | 0.01 | −0.020 | −0.004 | −0.016 | |

| 8 | 0.032 | 0.045 | −0.227 | −0.060 | 0.002 | −0.230 | −0.053 | 0.051 | −0.172 | 0.003 | |

| 10 | 0.005 | 0.01 | 0 | −0.084 | −0.008 | −0.095 | −0.042 | −0.087 | 0.109 | −0.045 | |

| Cycling Displacement | DE/RE (×10−4) | Specimen Types | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | ||

| 2 | 1.07 | 1.05 | 0.99 | 1.00 | 1.08 | 0.80 | 0.86 | 1.03 | 1.00 | 1.07 | Type A |

| 4 | 1.01 | 0.99 | 1.02 | 0.99 | 0.98 | 0.81 | 1.25 | 0.97 | 1.00 | 0.97 | |

| 6 | 0.98 | 0.98 | 0.97 | 0.98 | 0.95 | 0.77 | 0.66 | 1.01 | 0.99 | 1.01 | |

| 8 | 1.00 | 1.02 | 1.00 | 1.05 | 1.09 | 1.03 | 1.11 | 1.02 | 1.04 | 1.01 | |

| 10 | 0.97 | 0.99 | 1.23 | 0.99 | 0.94 | 0.87 | 0.91 | 1.02 | 0.94 | 1.02 | |

| 2 | 0.99 | 1.35 | 1.49 | 1.35 | 1.32 | 1.59 | 1.47 | 1.10 | 1.43 | 1.19 | Type B |

| 4 | 0.75 | 0.79 | 0.96 | 1.05 | 0.95 | 0.98 | 0.97 | 1.02 | 1.02 | 0.97 | |

| 6 | 1.19 | 1.28 | 1.33 | 1.18 | 1.15 | 1.12 | 1.14 | 1.04 | 1.06 | 1.00 | |

| 8 | 1.12 | 1.08 | 1.01 | 0.97 | 1.00 | 0.91 | 0.99 | 1.02 | 0.99 | 1.00 | |

| 10 | 1.38 | 1.07 | 1.00 | 1.02 | 0.98 | 1.00 | 0.94 | 1.01 | 0.99 | 0.97 | |

| 2 | 1.43 | 1.06 | 1.02 | 1.08 | 0.98 | 0.78 | 1.03 | 1.06 | 1.05 | 1.09 | Type C |

| 4 | 1.24 | 1.19 | 1.23 | 1.21 | 1.11 | 0.96 | 1.09 | 1.13 | 1.25 | 1.13 | |

| 6 | 1.48 | 1.02 | 1.00 | 1.07 | 1.02 | 1.17 | 0.99 | 1.05 | 1.09 | 1.10 | |

| 8 | 0.96 | 1.00 | 0.91 | 1.02 | 0.95 | 1.03 | 0.92 | 1.01 | 1.07 | 1.03 | |

| 10 | 1.02 | 1.12 | 0.96 | 1.12 | 1.10 | 1.17 | 1.21 | 1.12 | 0.83 | 1.13 | |

| 2 | 0.78 | 1.40 | 0.79 | 1.27 | 0.81 | 1.05 | 1.03 | 1.79 | 0.74 | 1.25 | Type D |

| 4 | 0.85 | 0.07 | 0.88 | 0.09 | 0.99 | 0.60 | −3.67 | 0.14 | 1.02 | −5.00 | |

| 6 | 1.05 | −0.10 | 1.33 | −0.31 | 0.94 | 0.56 | 0.59 | 2.77 | 1.05 | 0.95 | |

| 8 | 1.00 | 1.43 | 1.06 | 0.98 | 1.05 | 1.10 | −2.62 | 1.05 | 1.03 | 0.95 | |

| 10 | 1.13 | 1.13 | 1.12 | 0.00 | 0.93 | 3.00 | 1.00 | 0.92 | 1.19 | 1.10 | |

| 2 | 0.84 | 0.89 | 1.22 | 1.14 | 1.00 | 0.92 | 1.00 | 0.98 | 0.93 | 1.33 | Type E |

| 4 | 1.01 | 1.01 | 1.01 | 1.50 | 0.97 | 1.13 | 1.07 | 1.05 | 1.03 | 1.40 | |

| 6 | 1.05 | 1.00 | 1.04 | 1.06 | 1.22 | 1.12 | 1.11 | 0.90 | 0.98 | 1.05 | |

| 8 | 0.72 | 0.88 | 1.38 | 1.65 | 1.08 | 1.81 | 1.60 | 0.92 | 1.32 | 1.75 | |

| 10 | 0.95 | 0.84 | 0.41 | 0.81 | 0.76 | 1.57 | 1.06 | 0.84 | 0.92 | 0.61 | |

| 2 | 0.43 | 1.74 | 0.86 | 1.35 | 0.98 | 0.64 | 1.09 | 1.40 | 0.68 | 0.98 | Type F |

| 4 | 0.63 | 0.97 | 1.00 | 1.04 | 0.97 | 0.86 | 1.00 | 1.30 | 0.92 | 0.96 | |

| 6 | 1.13 | 1.00 | 0.85 | 0.95 | 0.95 | 0.67 | 0.99 | 1.14 | 1.09 | 1.03 | |

| 8 | 0.90 | 0.95 | 1.02 | 0.99 | 1.00 | 0.59 | 1.01 | 0.94 | 0.60 | 1.10 | |

| 10 | 0.92 | 0.87 | 0.26 | 0.83 | 0.74 | 0.83 | 0.85 | 0.97 | 0.76 | 1.04 | |

| 2 | 1.20 | 1.21 | 1.20 | 1.15 | 1.16 | 0.95 | 0.96 | 1.08 | 1.11 | 1.01 | Type G |

| 4 | 1.25 | 1.09 | 0.88 | 0.73 | 1.24 | 0.69 | 0.77 | 0.83 | 0.83 | 0.86 | |

| 6 | 1.15 | 1.01 | 0.69 | 0.97 | 1.07 | 0.54 | 0.66 | 0.95 | 0.83 | 0.79 | |

| 8 | 1.49 | 1.07 | 0.64 | 0.55 | 0.99 | 0.32 | 0.50 | 1.05 | 0.79 | 0.71 | |

| 10 | 1.35 | 0.86 | 0.55 | −0.04 | 0.88 | 0.42 | 0.39 | 0.96 | 0.69 | 0.54 | |

| 2 | 1.56 | 1.49 | 0.87 | 1.27 | 1.38 | 0.87 | 1.01 | 0.81 | 1.09 | 1.01 | Type H |

| 4 | 1.00 | 0.92 | 0.85 | 0.93 | 1.08 | 0.78 | 0.74 | 1.10 | 0.74 | 1.11 | |

| 6 | 0.93 | 0.98 | 0.81 | 0.95 | 0.98 | 0.86 | 1.11 | 0.92 | 0.99 | 0.92 | |

| 8 | 1.14 | 1.10 | 0.52 | 0.74 | 1.01 | 0.44 | 0.63 | 1.20 | 0.74 | 1.02 | |

| 10 | 1.03 | 1.03 | 0.00 | 0.58 | 0.96 | 0.58 | 0.66 | 0.68 | 1.31 | 0.77 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.; Kim, B. Energy Dissipation Between Concrete and Composite Waterproof Sheet Interface. Buildings 2025, 15, 1724. https://doi.org/10.3390/buildings15101724

Park J, Kim B. Energy Dissipation Between Concrete and Composite Waterproof Sheet Interface. Buildings. 2025; 15(10):1724. https://doi.org/10.3390/buildings15101724

Chicago/Turabian StylePark, Jongsun, and Byoungil Kim. 2025. "Energy Dissipation Between Concrete and Composite Waterproof Sheet Interface" Buildings 15, no. 10: 1724. https://doi.org/10.3390/buildings15101724

APA StylePark, J., & Kim, B. (2025). Energy Dissipation Between Concrete and Composite Waterproof Sheet Interface. Buildings, 15(10), 1724. https://doi.org/10.3390/buildings15101724