Application of PCM in a Zero-Energy Building and Using a CCHP System Based on Geothermal Energy in Canada and the UAE

Abstract

1. Introduction

2. Research Innovation

- Choosing the two cities of Dubai and Vancouver as hot and cold climates.

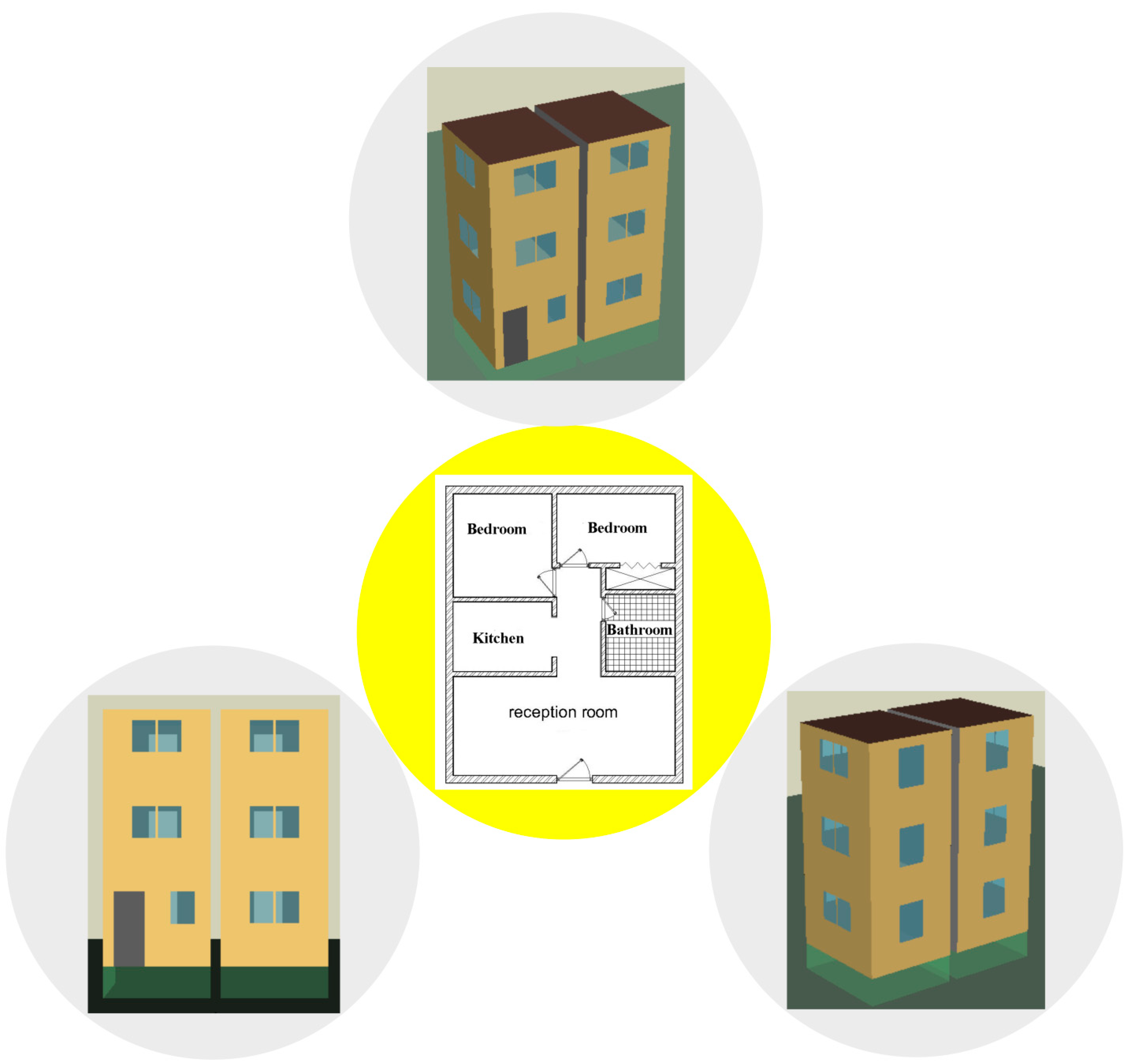

- Simulation of a six-unit residential complex with an area of 120 m2 in Dubai and Vancouver.

- Using BEopt to analyze residential complexes in the two study cities.

- Analysis of the use of PCM in residential complexes in the two study cities.

- Analysis of the use of different materials in the construction of residential complexes in the two study cities.

- Calculation of electricity load and heating and cooling requirements of residential complexes in the two study cities.

- Optimizing residential complexes in Dubai and Vancouver to save energy and reduce pollution.

- Use of a multi-generation system to supply the required load of the residential complex.

- Investigating the environmental performance of the geothermal system of multiple energy production.

3. Residential Complex Design

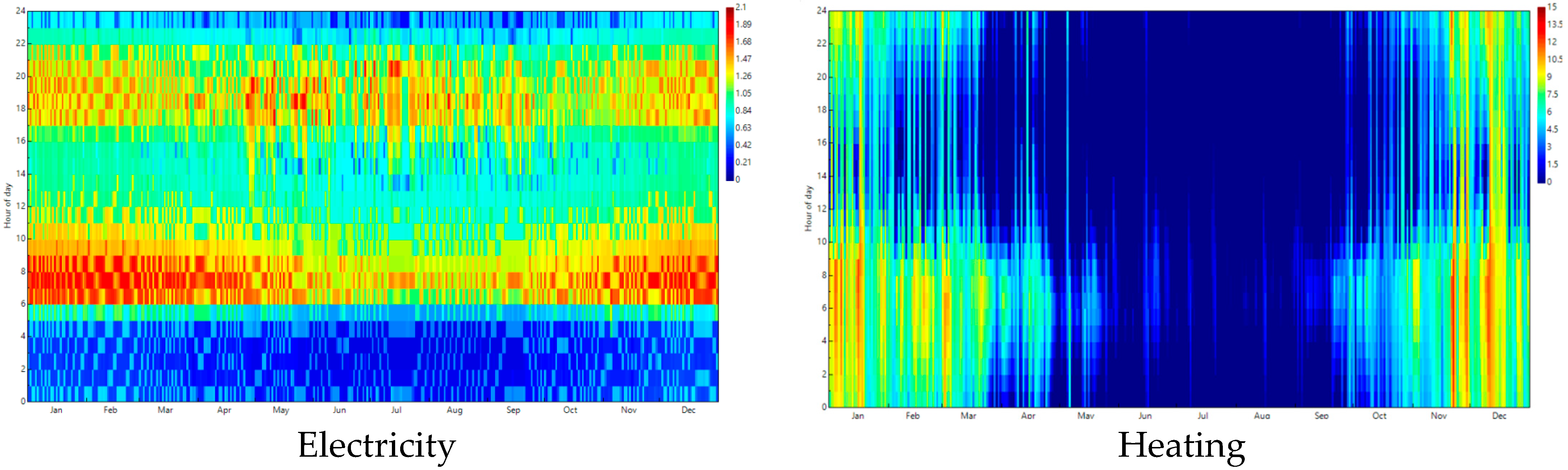

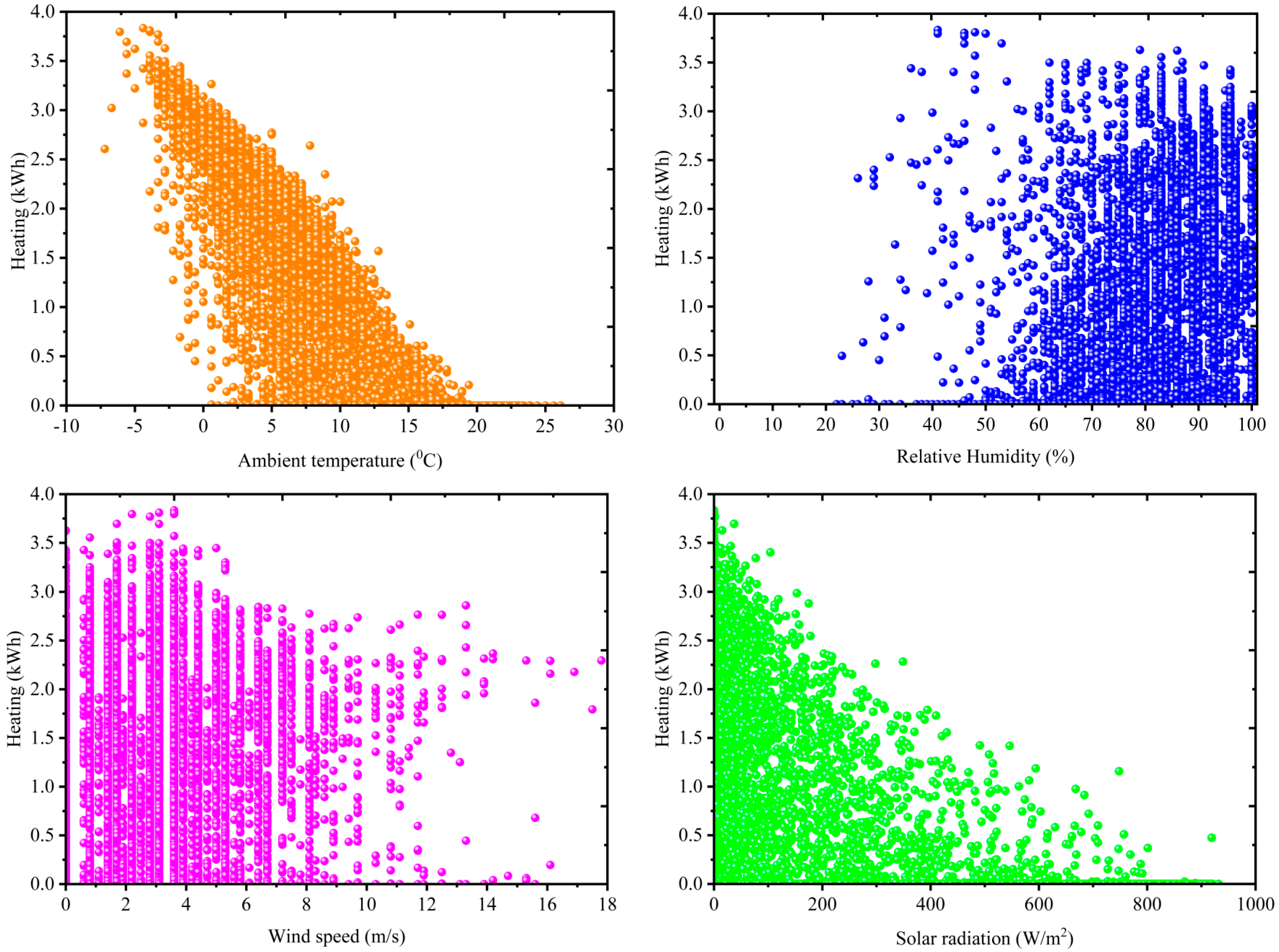

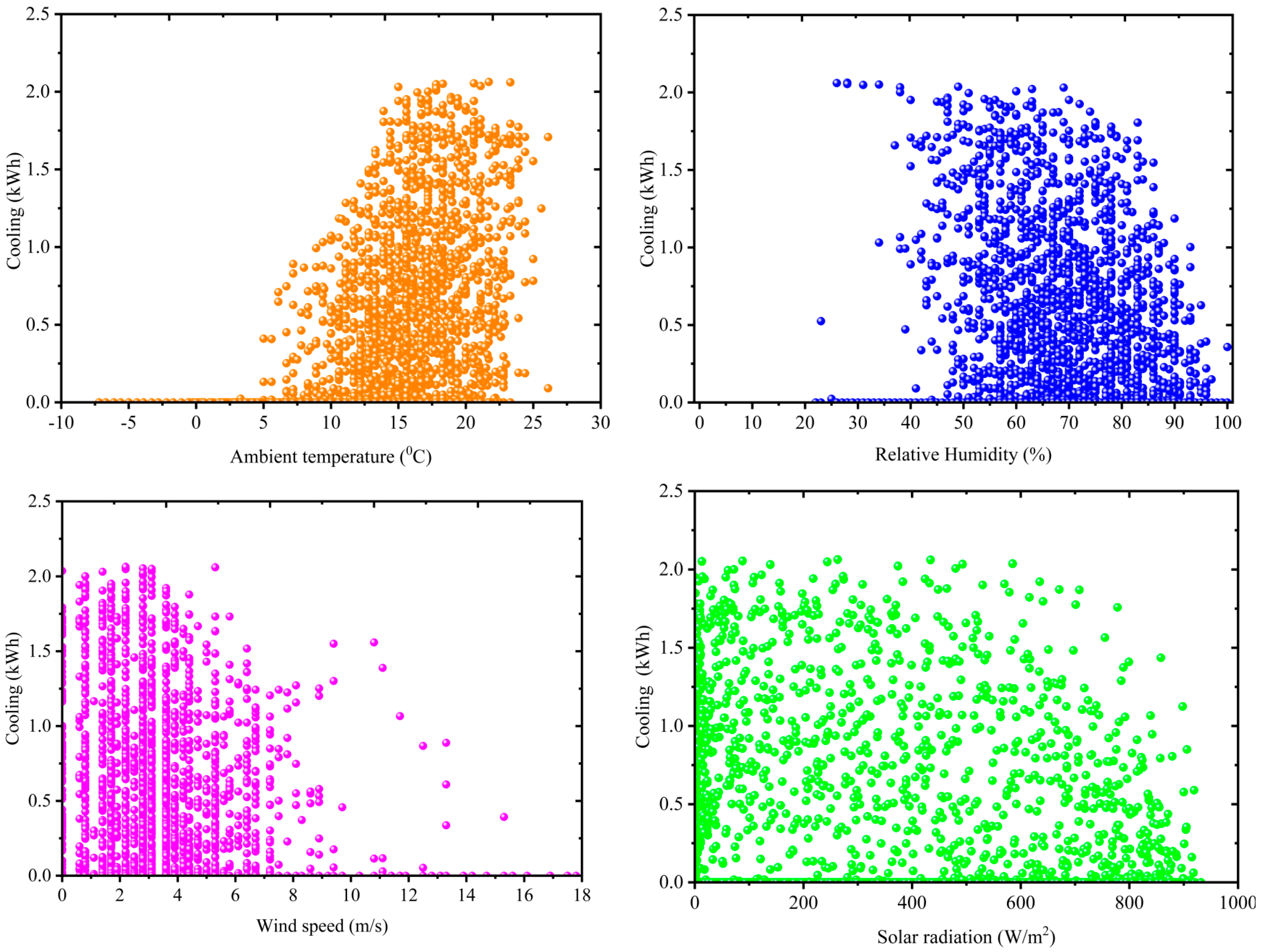

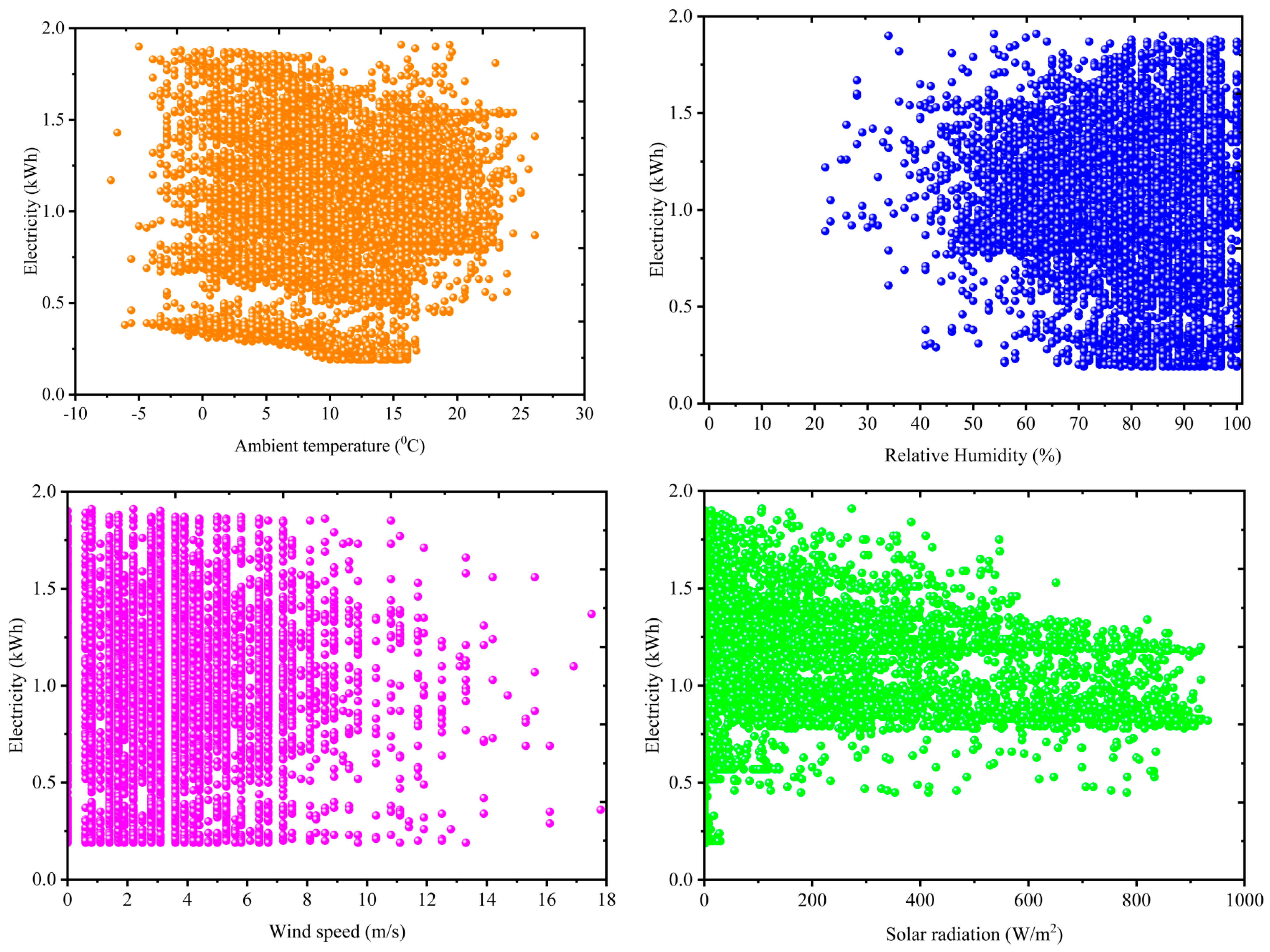

Analysis of Residential Complex Results

4. Optimum Building Analysis in the Best Study City

5. Analysis Geothermal System

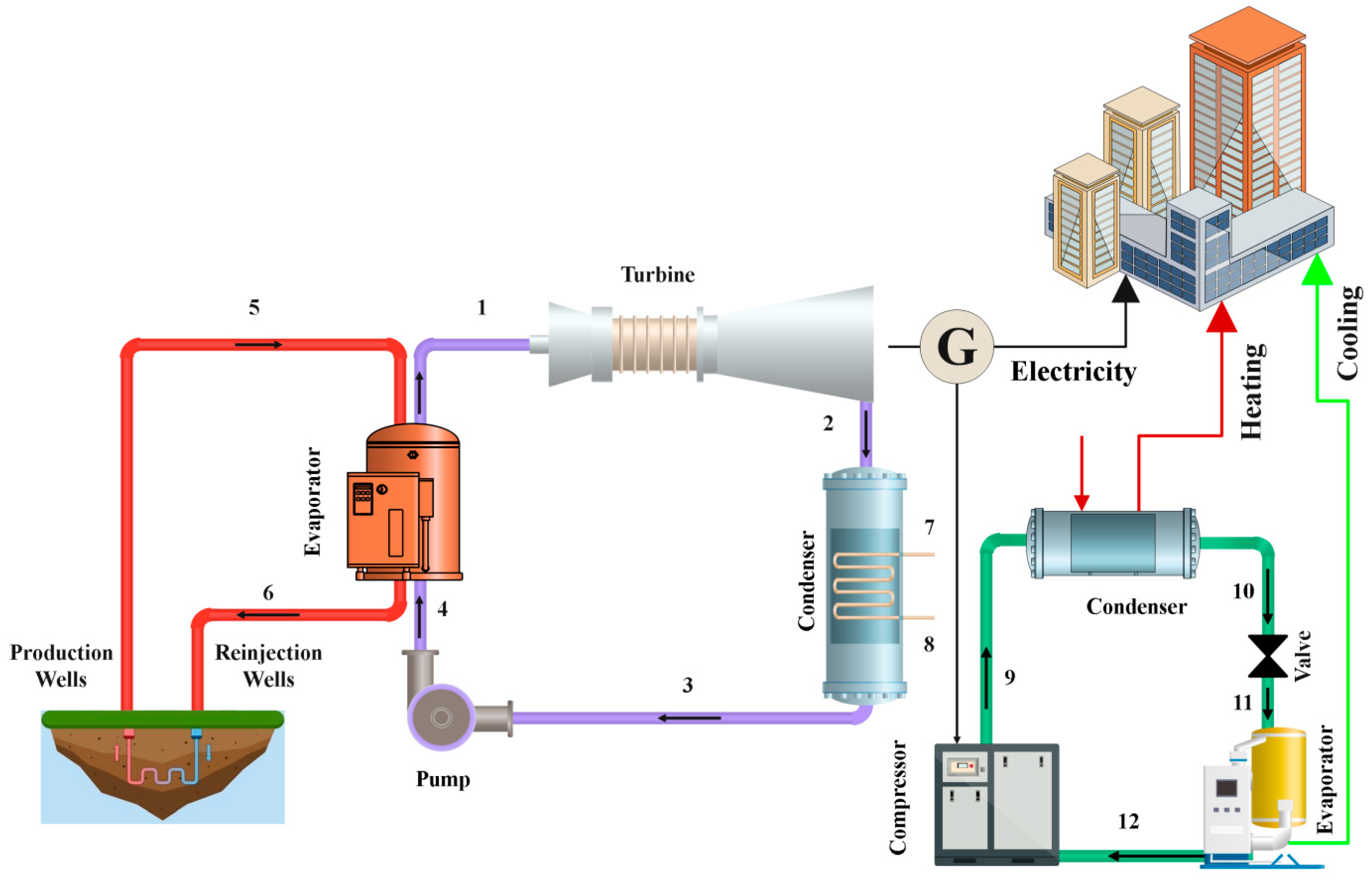

5.1. System Description

- System modeling is carried out using EES software 10.2.

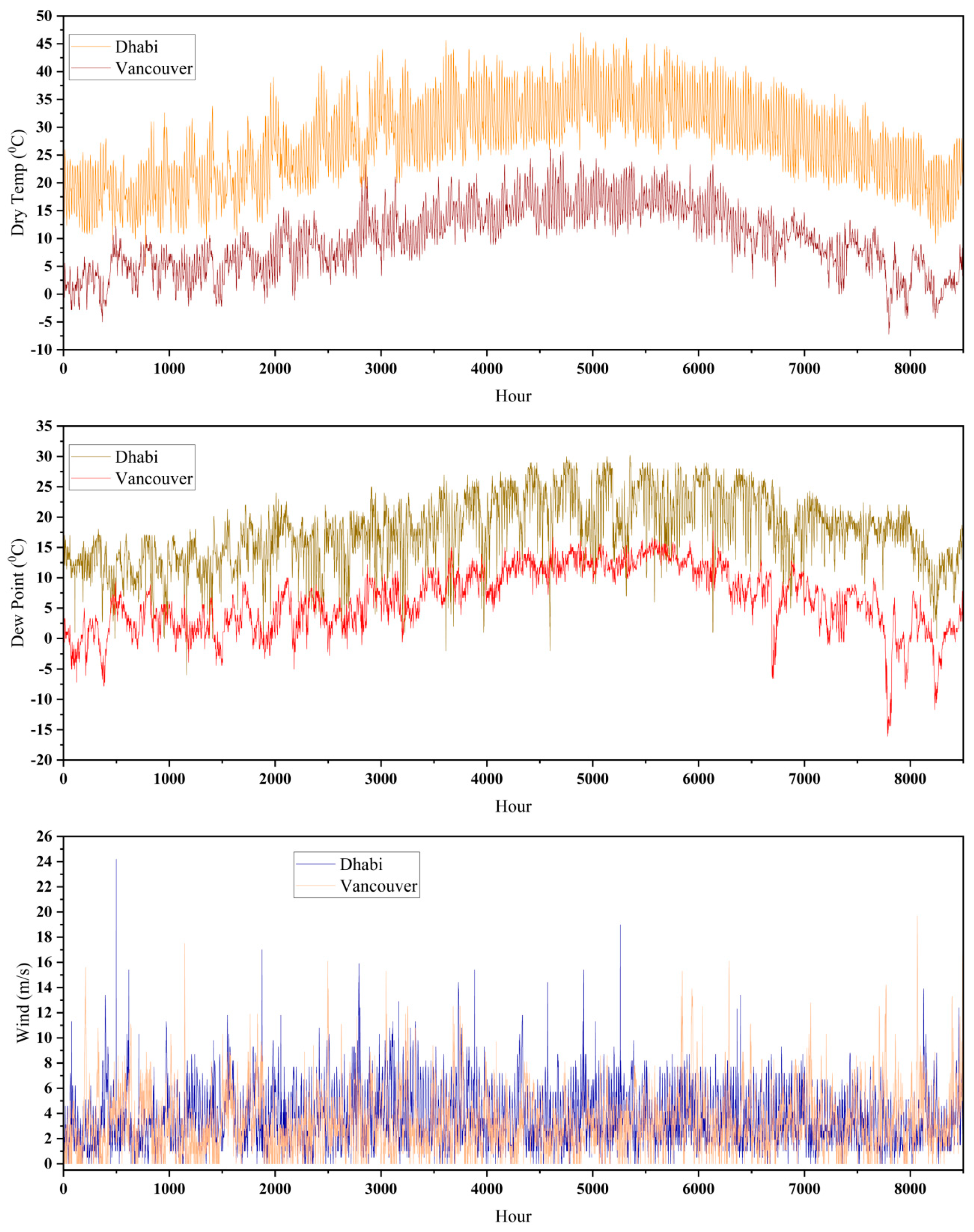

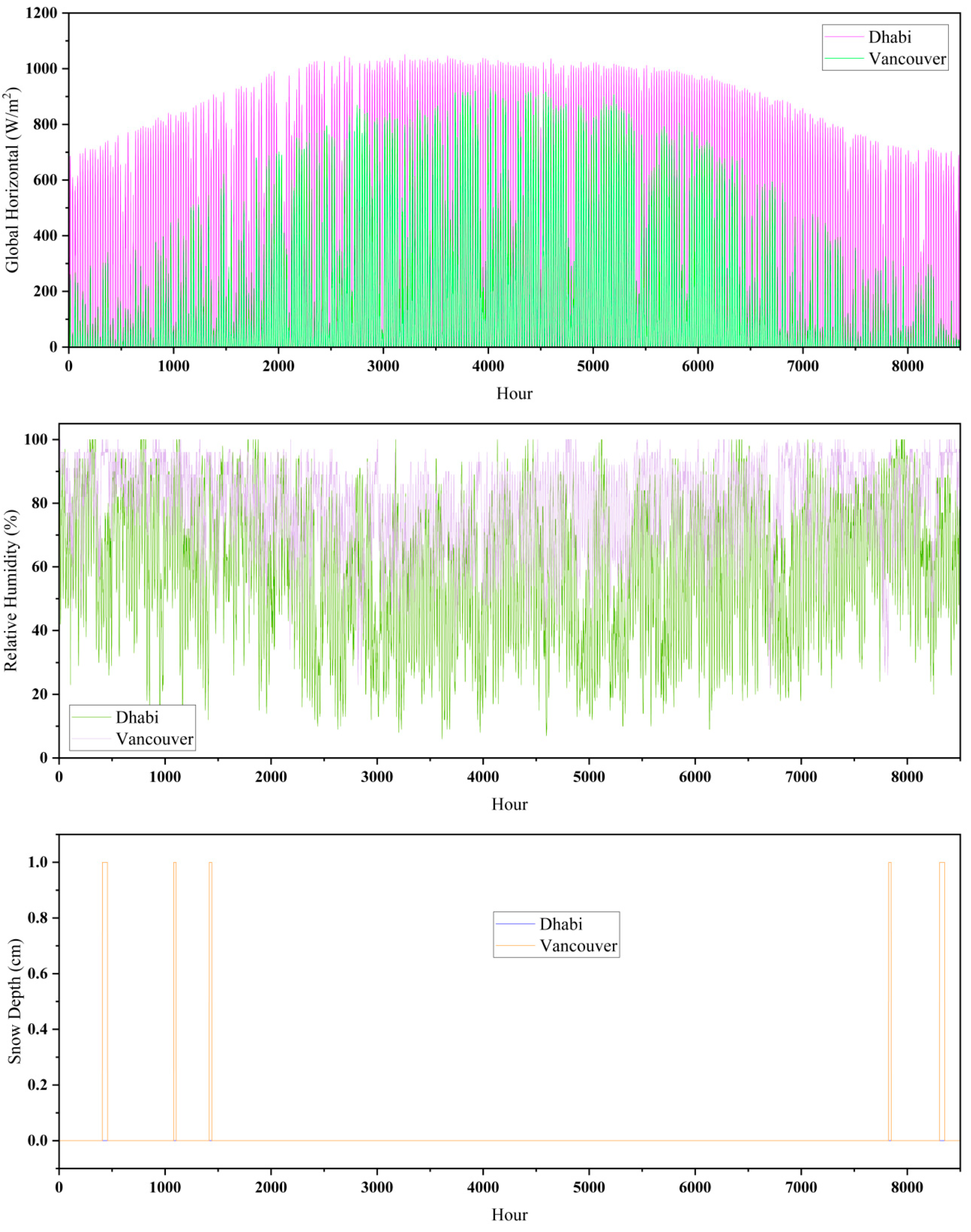

- Choosing the city of Vancouver in Canada for the study system case study.

- Extraction of weather information for Vancouver from Meteonorm software 8.

- Environmental analysis of the geothermal system.

5.2. System Balance

5.3. Case Study (Vancouver)

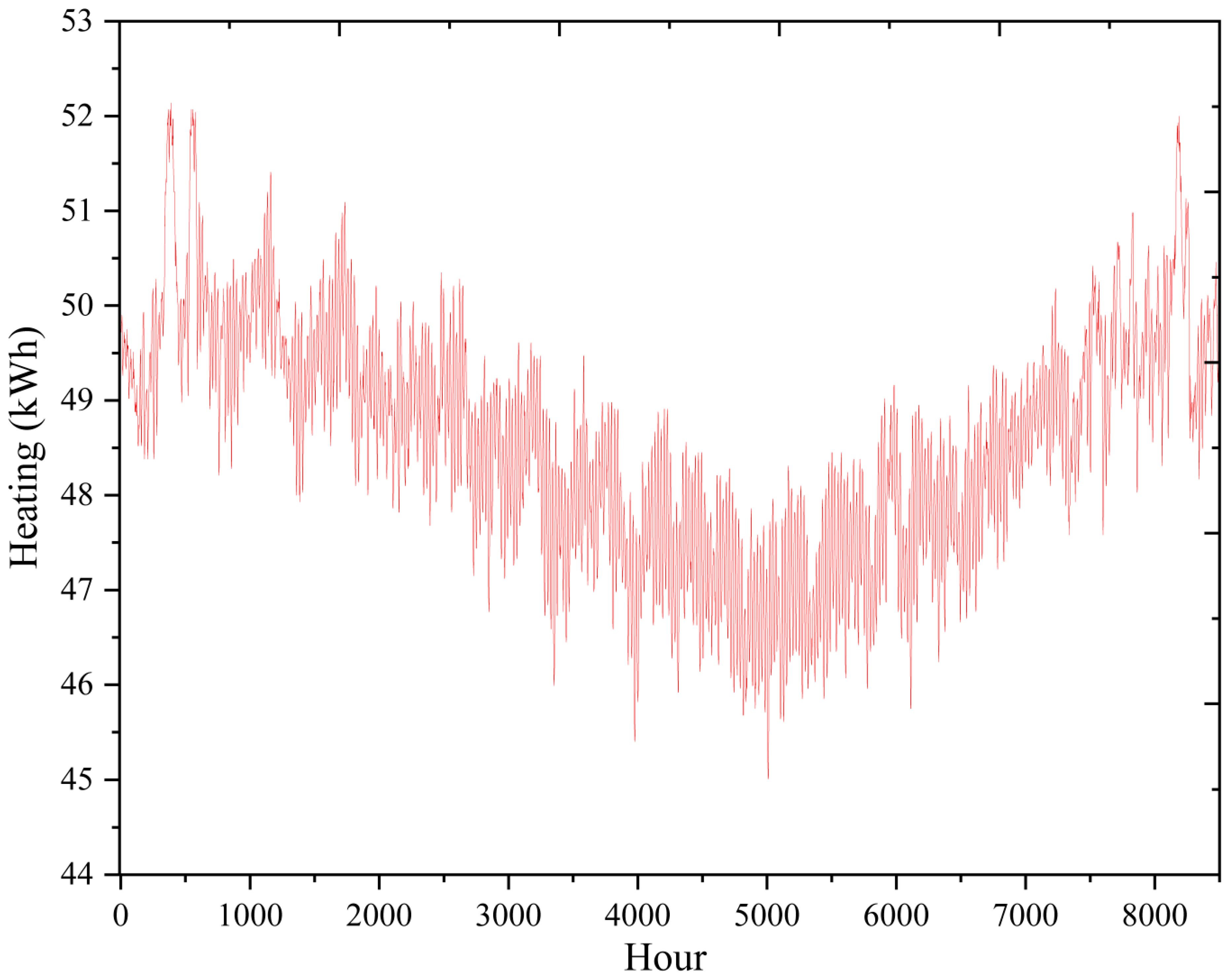

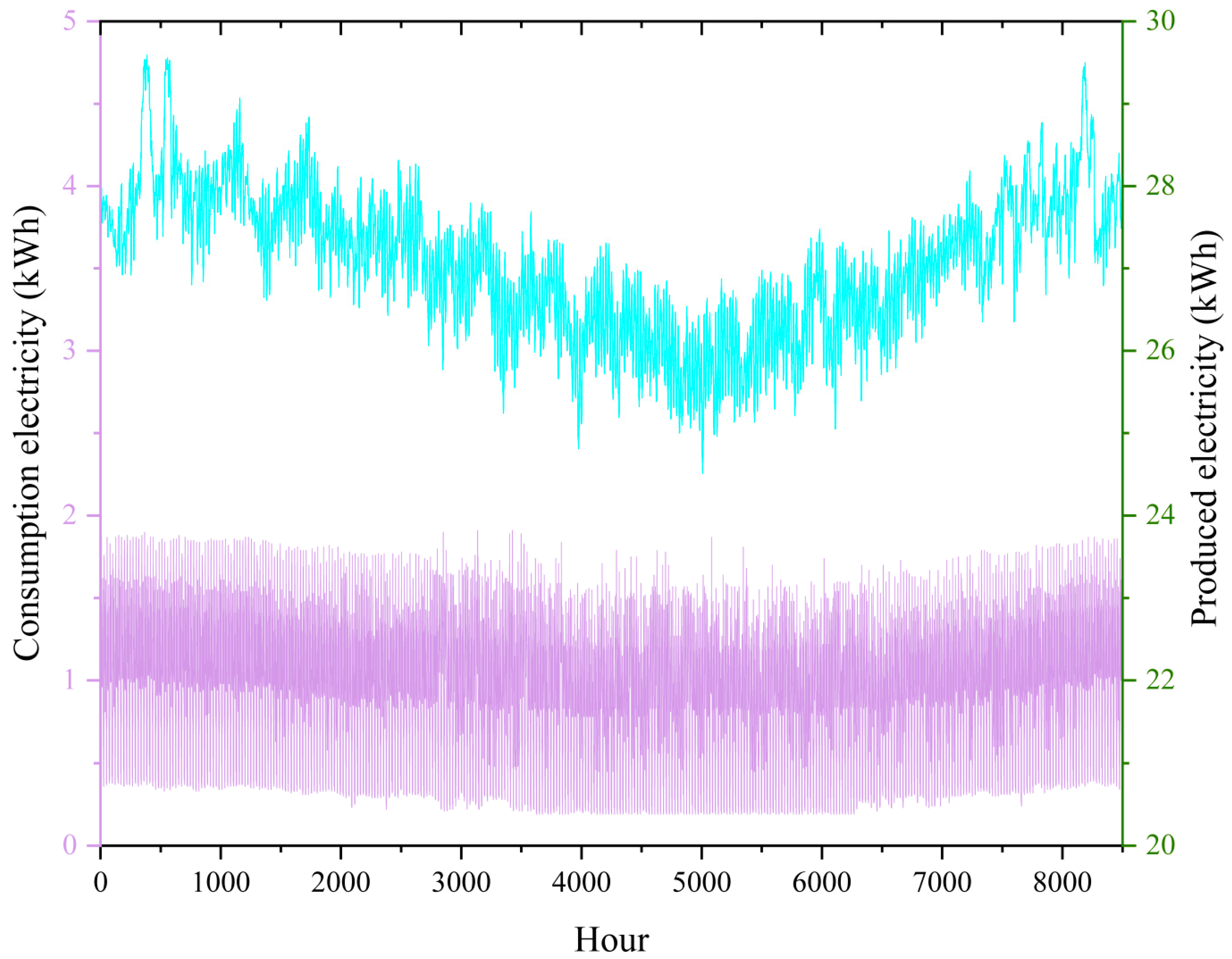

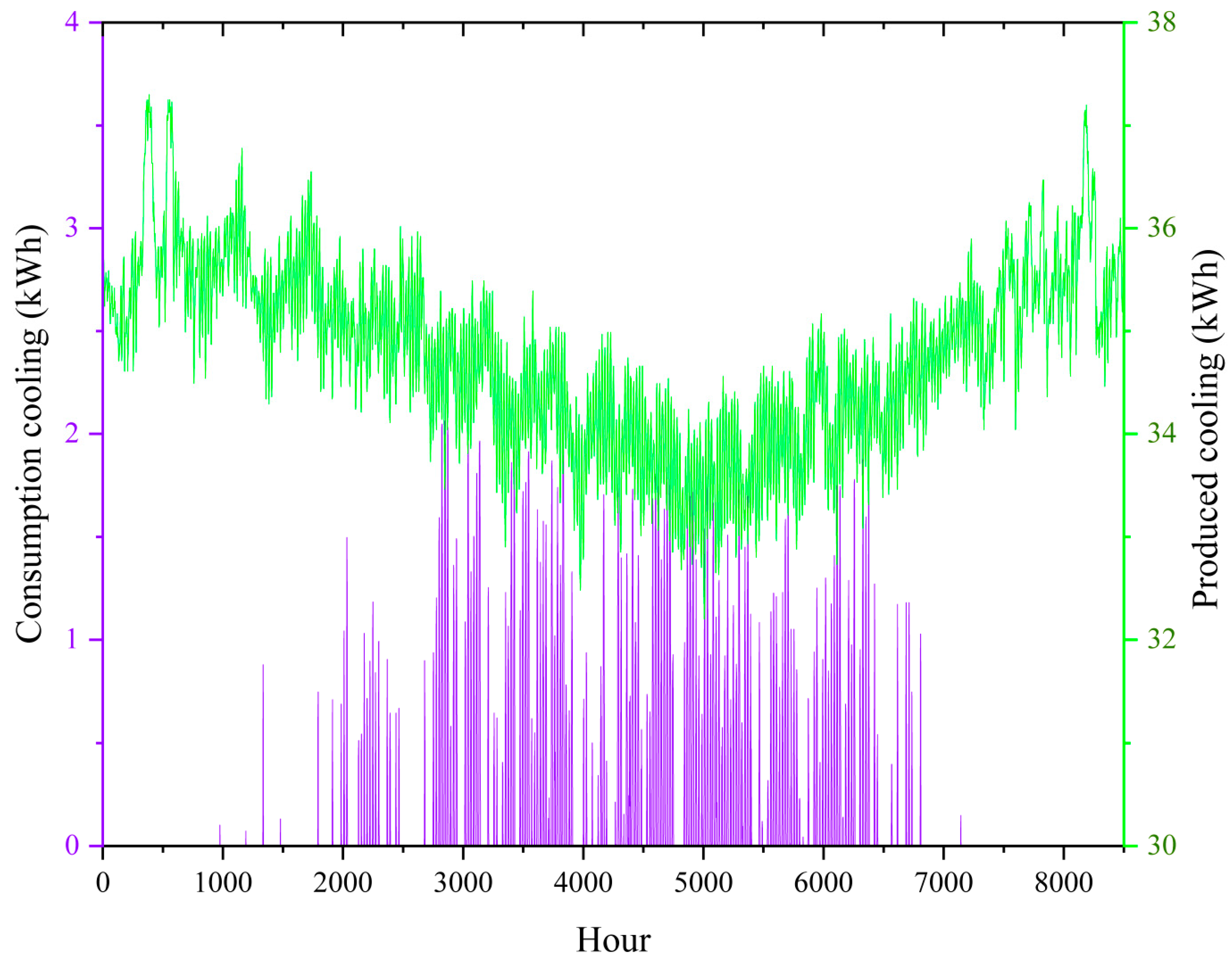

6. Analysis of the Performance of the System in Providing the Energy Consumption of the Building

7. Conclusions

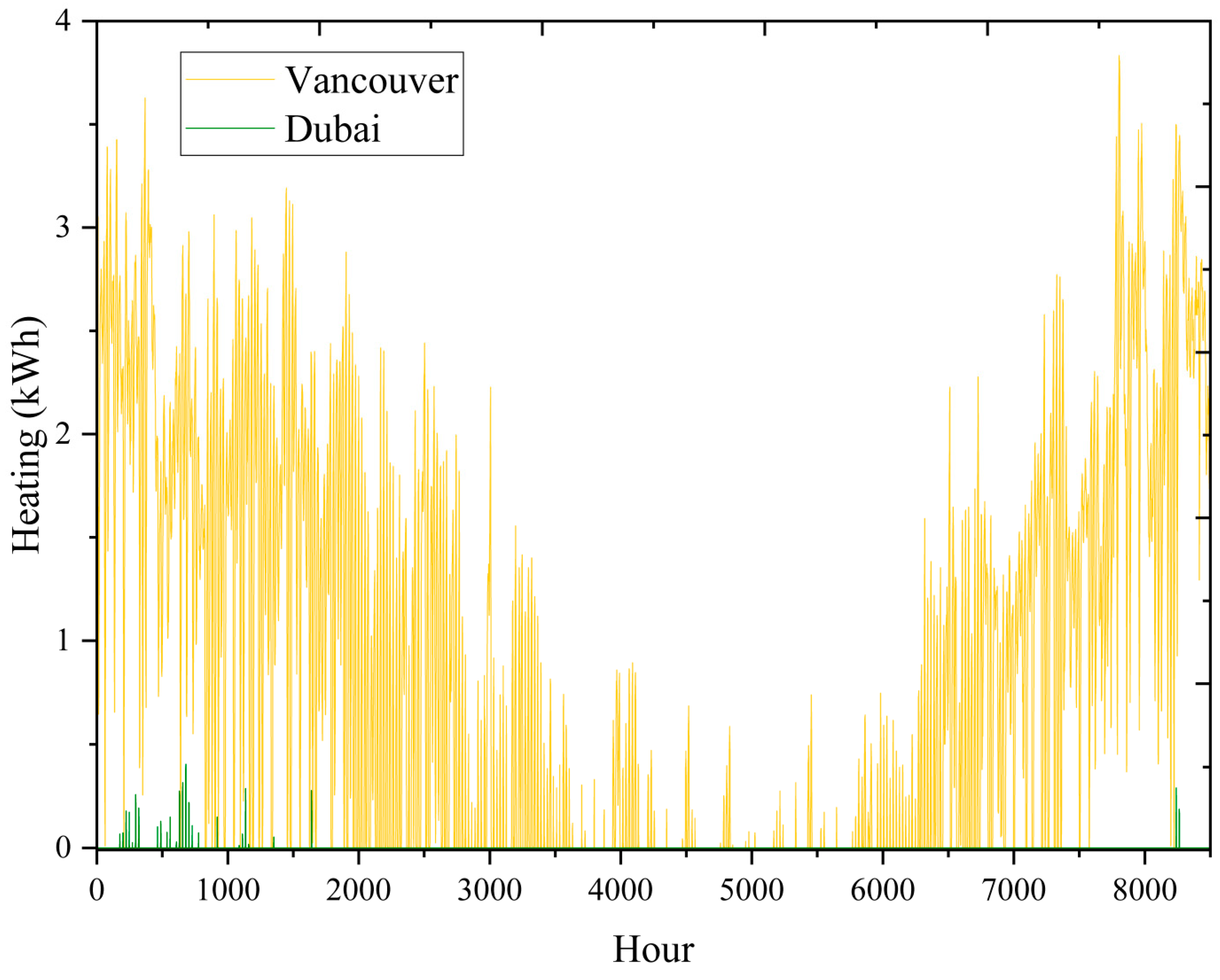

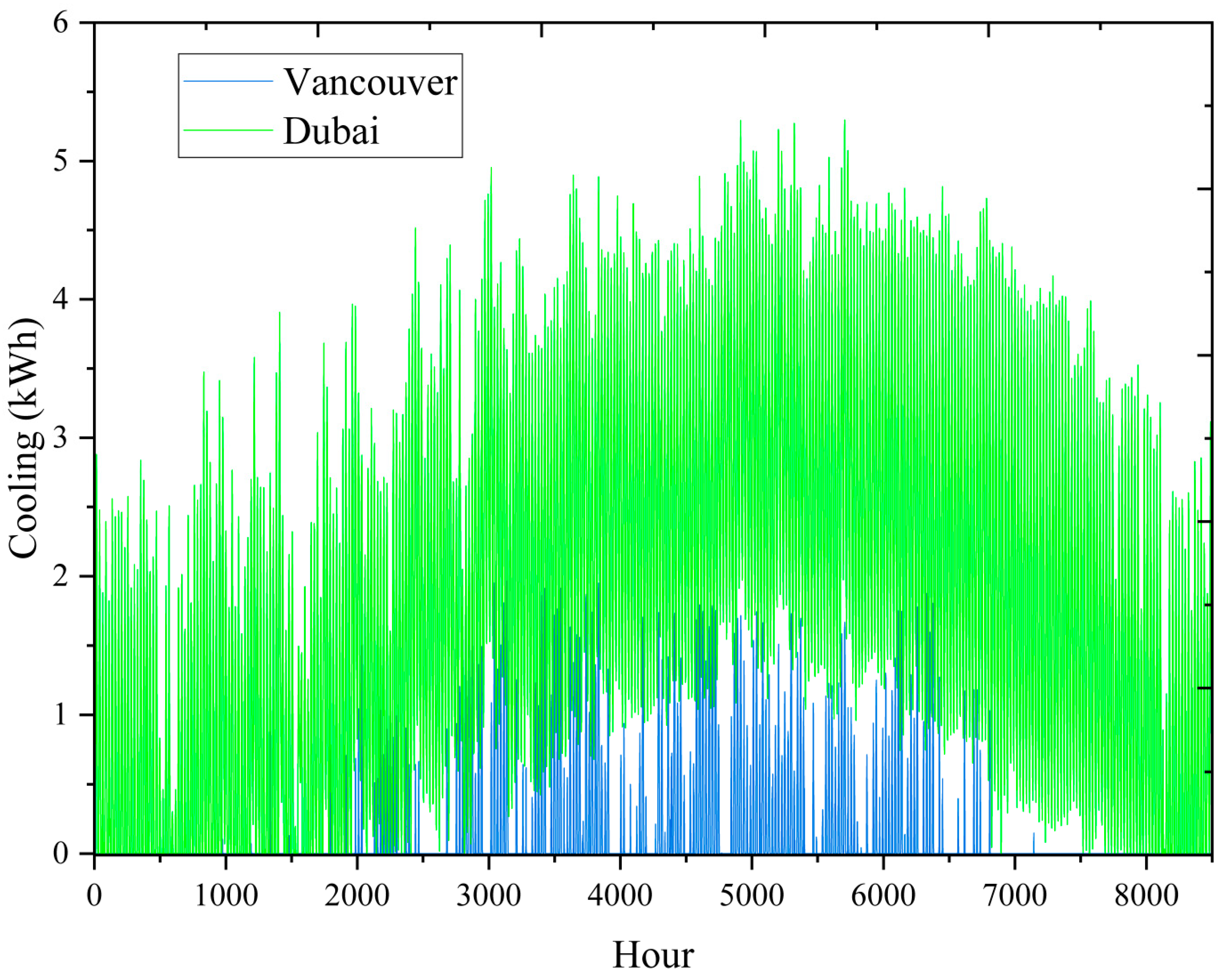

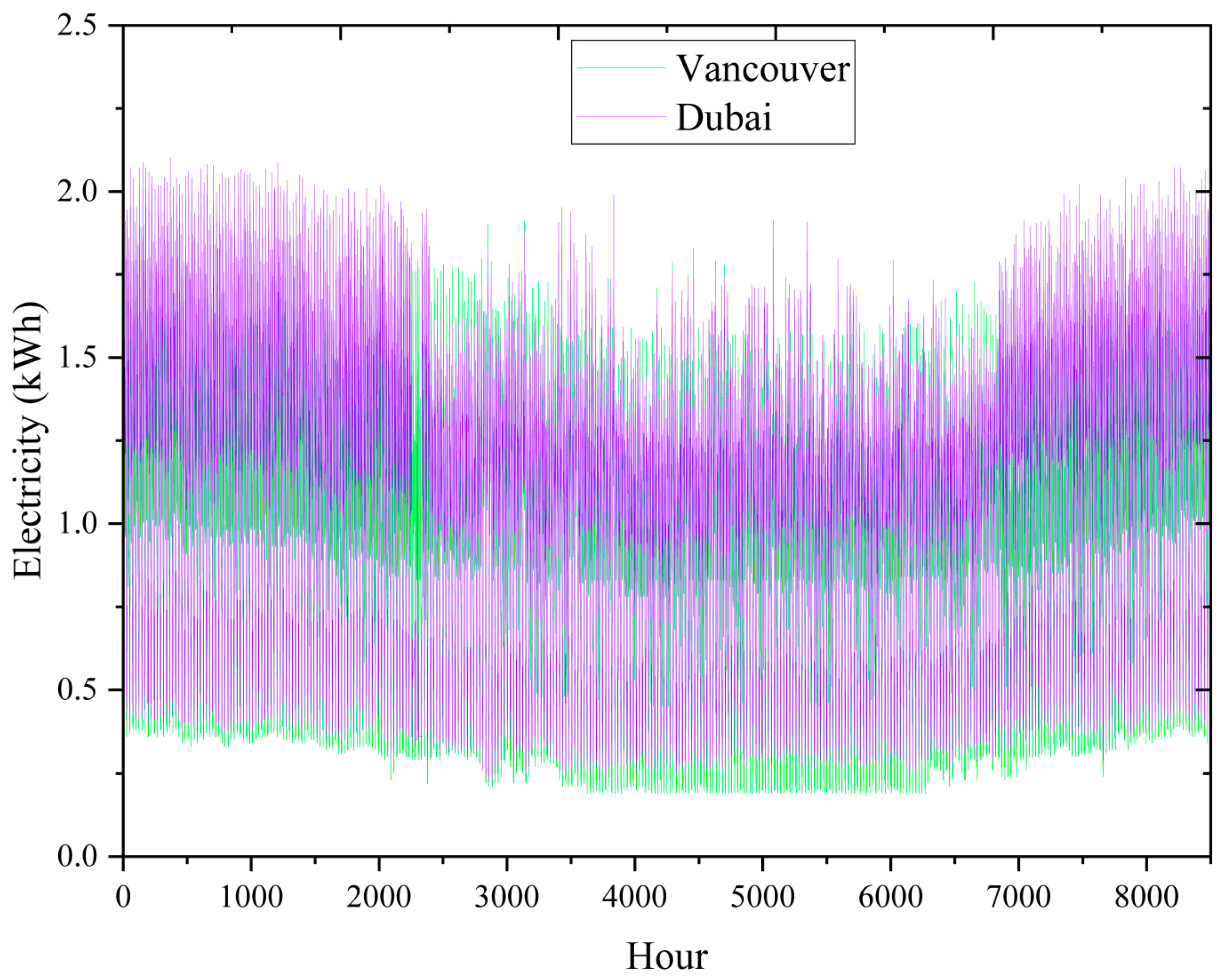

- The consumption of electricity, heating, and cooling of the residential complex during the year in the city of Vancouver is 8493.55, 7899.1, and 1083.97 kWh, respectively.

- The consumption of electricity, heating, and cooling of the buildings during the year in Dubai is 9572.1, 8.99, and 18,845.44 kWh, respectively.

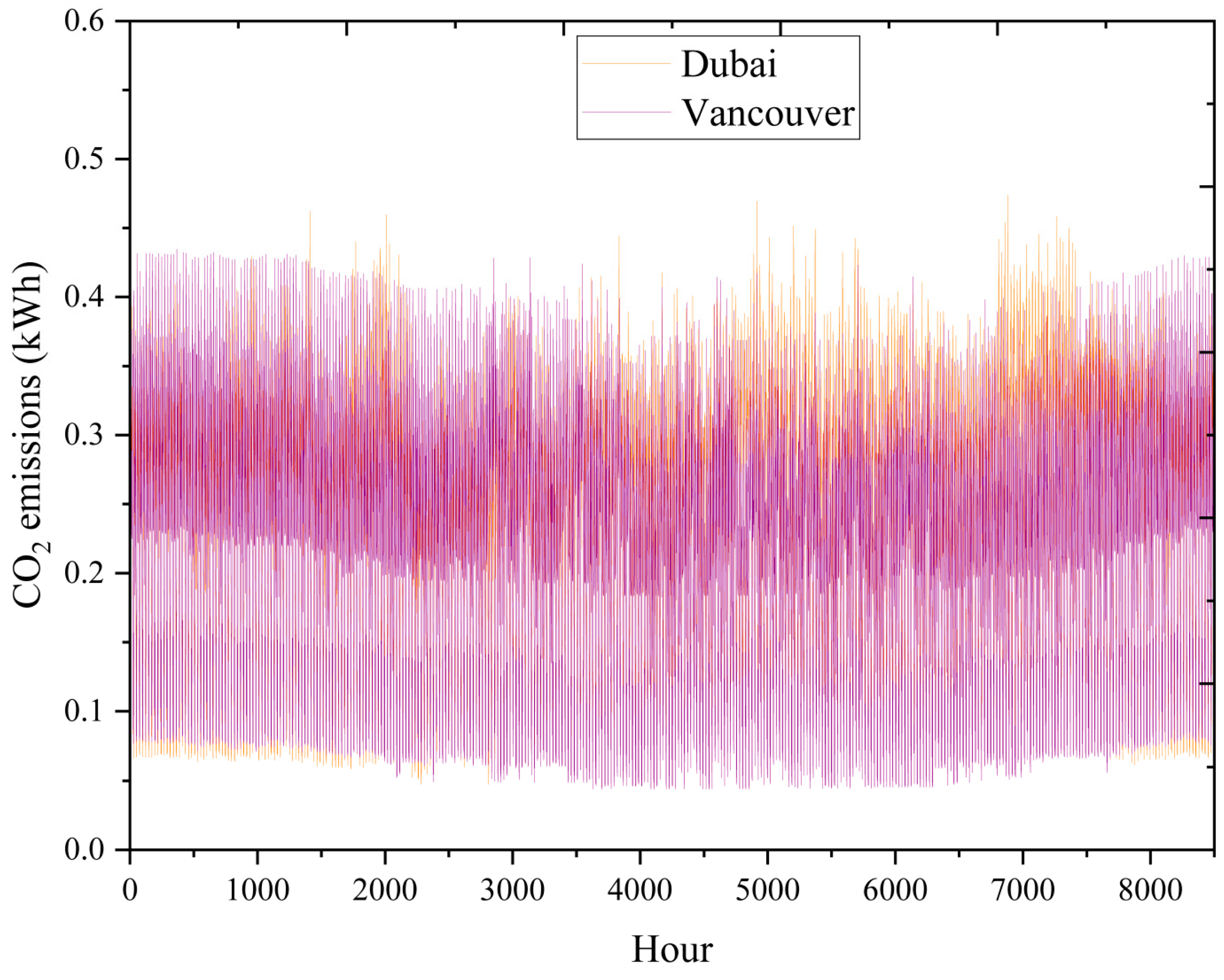

- By optimizing the energy consumption of buildings in Vancouver and Dubai, CO2 emissions can be reduced by 2129.7 and 2773.2 kg/year, respectively.

- The city of Vancouver, Canada, was chosen as the most suitable city for the study due to having more suitable weather conditions, reducing building energy consumption and carbon dioxide emissions.

- The multiple production system was proposed to meet the energy consumption of a six-unit zero-energy residential building with 120 m2 and two bedrooms in Vancouver, Canada.

- The study system can produce 237,364.6 kWh of electricity, 425,959.4 kWh of heating, and 304,732.8 kWh of cooling in one year.

- The results showed that 229,465.5 kWh of electricity was sold to the electricity distribution network during the year and that 417,465.8 kWh of heating and 303,648.8 kWh of cooling were saved throughout the year to compensate for the costs of the system.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Jaysawal, R.K.; Chakraborty, S.; Elangovan, D.; Padmanaban, S. Concept of net zero energy buildings (NZEB)—A literature review. Clean. Eng. Technol. 2022, 11, 100582. [Google Scholar] [CrossRef]

- Lo, K.-Y.; Yeoh, J.H.; Hsieh, I.-Y.L. Towards Nearly Zero-Energy Buildings: Smart Energy Management of Vehicle-to-Building (V2B) Strategy and Renewable Energy Sources. Sustain. Cities Soc. 2023, 99, 104941. [Google Scholar] [CrossRef]

- Lyu, W.; Wang, Z.; Li, X.; Yu, Z.; Yang, Y.; Li, J.; Wang, Z.; Sun, X.; Sun, G.; Han, L.; et al. Energy-efficient fresh air system with pressure-independent dampers for nearly zero energy buildings. Appl. Therm. Eng. 2023, 234, 121240. [Google Scholar] [CrossRef]

- Mohammed, B.U.; Wiysahnyuy, Y.S.; Ashraf, N.; Mempouo, B.; Mengata, G.M. Pathways for efficient transition into net zero energy buildings (nZEB) in Sub-Sahara Africa. Case study: Cameroon, Senegal, and Côte d’Ivoire. Energy Build. 2023, 296, 113422. [Google Scholar] [CrossRef]

- Shirinbakhsh, M.; Harvey, L.D. Feasibility of achieving net-zero energy performance in high-rise buildings using solar energy. Energy Built Environ. 2023; in press. [Google Scholar] [CrossRef]

- Amini, M.H.M.; Temiz, A.; Zuraik, M.A.; Hermawan, A.; Sulaiman, N.S. Shape stabilized phase change material by pine wood absorption. Mater. Today Proc. 2023; in press. [Google Scholar]

- Mohammed, M.A.; Ali, B.M.; Yassin, K.F.; Ali, O.M.; Alomar, O.R. Comparative study of different phase change materials on the thermal performance of photovoltaic cells in Iraq’s climate conditions. Energy Rep. 2024, 11, 18–27. [Google Scholar] [CrossRef]

- Elenga, R.G.; Zhu, L.; Defilla, S. Performance evaluation of different building envelopes integrated with phase change materials in tropical climates. Energy Built Environ. 2023; in press. [Google Scholar] [CrossRef]

- Paul, J.; Jacob, J.; Pandey, A.; Vaka, M.; Samykano, M.; Kadirgama, K.; Rahim, N.A.; Selvaraj, J. Meta data analysis on building thermal management using phase change materials. J. Energy Storage 2024, 76, 109760. [Google Scholar] [CrossRef]

- Tan, Q.; Liu, H.; Shi, Y.; Zhang, M.; Yu, B.; Zhang, Y. Lauric acid/stearic acid/nano-particles composite phase change materials for energy storage in buildings. J. Energy Storage 2024, 76, 109664. [Google Scholar] [CrossRef]

- Vega, M.; Marín, P.E.; Ushak, S.; Shire, S. Research trends and gaps in experimental applications of phase change materials integrated in buildings. J. Energy Storage 2024, 75, 109746. [Google Scholar] [CrossRef]

- Zhan, H.; Mahyuddin, N.; Sulaiman, R.; Khayatian, F. Phase change material (PCM) integrations into buildings in hot climates with simulation access for energy performance and thermal comfort: A review. Constr. Build. Mater. 2023, 397, 132312. [Google Scholar] [CrossRef]

- Sharma, R.K.; Kumar, A.; Rakshit, D. A phase change material (PCM) based novel retrofitting approach in the air conditioning system to reduce building energy demand. Appl. Therm. Eng. 2024, 238, 121872. [Google Scholar] [CrossRef]

- Assareh, E.; Riaz, A.; Ahmadinejad, M.; Hoseinzadeh, S.; Abdehvand, M.Z.; Keykhah, S.; Jafarinejad, T.; Moltames, R.; Lee, M. Enhancing solar thermal collector systems for hot water production through machine learning-driven multi-objective optimization with phase change material (PCM). J. Energy Storage 2023, 73, 108990. [Google Scholar] [CrossRef]

- Abbassi, Y.; Baniasadi, E.; Ahmadikia, H. Transient energy storage in phase change materials, development and simulation of a new TRNSYS component. J. Build. Eng. 2022, 50, 104188. [Google Scholar] [CrossRef]

- Ebrahimi-Moghadam, A.; Ildarabadi, P.; Aliakbari, K.; Arabkoohsar, A.; Fadaee, F. Performance analysis of light shelves in providing visual and thermal comfort and energy savings in residential buildings. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 484. [Google Scholar] [CrossRef]

- Behzadi, A.; Arabkoohsar, A. Feasibility study of a smart building energy system comprising solar PV/T panels and a heat storage unit. Energy 2020, 210, 118528. [Google Scholar] [CrossRef]

- Arabkoohsar, A.; Behzadi, A.; Alsagri, A.S. Techno-economic analysis and multi-objective optimization of a novel solar-based building energy system; An effort to reach the true meaning of zero-energy buildings. Energy Convers. Manag. 2021, 232, 113858. [Google Scholar] [CrossRef]

- Ang, Y.Q.; Polly, A.; Kulkarni, A.; Chambi, G.B.; Hernandez, M.; Haji, M.N. Multi-objective optimization of hybrid renewable energy systems with urban building energy modeling for a prototypical coastal community. Renew. Energy 2022, 201, 72–84. [Google Scholar] [CrossRef]

- Lü, X.; Lu, T.; Karirinne, S.; Mäkiranta, A.; Clements-Croome, D. Renewable energy resources and multi-energy hybrid systems for urban buildings in Nordic climate. Energy Build. 2023, 282, 112789. [Google Scholar] [CrossRef]

- Zhong, C.; Xu, T.; Yuan, Y.; Feng, B.; Yu, H. The feasibility of clean power generation from a novel dual-vertical-well enhanced geothermal system (EGS): A case study in the Gonghe Basin, China. J. Clean. Prod. 2022, 344, 131109. [Google Scholar] [CrossRef]

- Jiansheng, W.; Lide, S.; Qiang, Z.; Jintao, N. Numerical investigation on power generation performance of enhanced geothermal system with horizontal well. Appl. Energy 2022, 325, 119865. [Google Scholar] [CrossRef]

- Dezhdar, A.; Assareh, E.; Agarwal, N.; Bedakhanian, A.; Keykhah, S.; Fard, G.Y.; Zadsar, N.; Aghajari, M.; Lee, M. Transient optimization of a new solar-wind multi-generation system for hydrogen production, desalination, clean electricity, heating, cooling, and energy storage using TRNSYS. Renew. Energy 2023, 208, 512–537. [Google Scholar] [CrossRef]

- Nizovtsev, M.I.; Sterlyagov, A.N. Effect of phase change material (PCM) on thermal inertia of walls in lightweight buildings. J. Build. Eng. 2024, 82, 107912. [Google Scholar] [CrossRef]

- Dezhdar, A.; Assareh, E.; Agarwal, N.; Baheri, A.; Ahmadinejad, M.; Zadsar, N.; Fard, G.Y.; Bedakhanian, A.; Aghajari, M.; Ghodrat, M.; et al. Modeling, optimization, and economic analysis of a comprehensive CCHP system with fuel cells, reverse osmosis, batteries, and hydrogen storage subsystems Powered by renewable energy sources. Renew. Energy 2024, 220, 119695. [Google Scholar] [CrossRef]

- Biswas, K.; Abhari, R. Low-cost phase change material as an energy storage medium in building envelopes: Experimental and numerical analyses. Energy Convers. Manag. 2014, 88, 1020–1031. [Google Scholar] [CrossRef]

- Biswas, K.; Lu, J.; Soroushian, P.; Shrestha, S. Combined experimental and numerical evaluation of a prototype nano-PCM enhanced wallboard. Appl. Energy 2014, 131, 517–529. [Google Scholar] [CrossRef]

- Dezhdar, A.; Assareh, E.; Keykhah, S.; Bedakhanian, A.; Lee, M. A transient model for clean electricity generation using Solar energy and ocean thermal energy conversion (OTEC)—Case study: Karkheh dam—Southwest Iran. Energy Nexus 2023, 9, 100176. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Raeesi, M.; Pourfayaz, F.; Delpisheh, M. Investigation of a hybrid solar thermochemical water-splitting hydrogen production cycle and coal-fueled molten carbonate fuel cell power plant. Sustain. Energy Technol. Assess. 2021, 47, 101458. [Google Scholar] [CrossRef]

- Delpisheh, M.; Haghghi, M.A.; Athari, H.; Mehrpooya, M. Desalinated water and hydrogen generation from seawater via a desalination unit and a low temperature electrolysis using a novel solar-based setup. Int. J. Hydrogen Energy 2021, 46, 7211–7229. [Google Scholar] [CrossRef]

- Dincer, I.; Rosen, M.A.; Ahmadi, P. Optimization of Energy Systems; John Wiley & Sons, Ltd.: Chichester, UK, 2017. [Google Scholar]

- Bedakhanian, A.; Assareh, E.; Agarwal, N.; Lee, M. Thermoeconomical, wind assessments and environmental analysis of compressed air energy storage (CAES) integrated with a wind farm by using RSM as a machine learning optimization technique—Case study—Denmark. J. Energy Storage 2024, 78, 110059. [Google Scholar] [CrossRef]

- Razmi, A.R.; Janbaz, M. Exergoeconomic assessment with reliability consideration of a green cogeneration system based on compressed air energy storage (CAES). Energy Convers. Manag. 2020, 204, 112320. [Google Scholar] [CrossRef]

| Information | Value | Description |

|---|---|---|

| The infrastructure of each floor | 120 m2 | - |

| The infrastructure of every building | 360 m2 | - |

| The infrastructure of all residential complexes | 720 m2 | - |

| Number of buildings | 2 buildings | - |

| Number of floors | 3 floors | In addition to the foundation of the building |

| Number of units per floor | 1 | - |

| The total unit number | 6 | - |

| The type of foundation of the residential complex | Pier beam | The foundation is the lowest part of any building that has direct contact with the soil and supports the entire weight of the structure and transfers it to the ground. Foundation beam bases are long and narrow structures of different materials that sink into the ground and transfer the weight of the building into the ground. |

| Number of inhabitants | 4 people per unit | A total of 24 people |

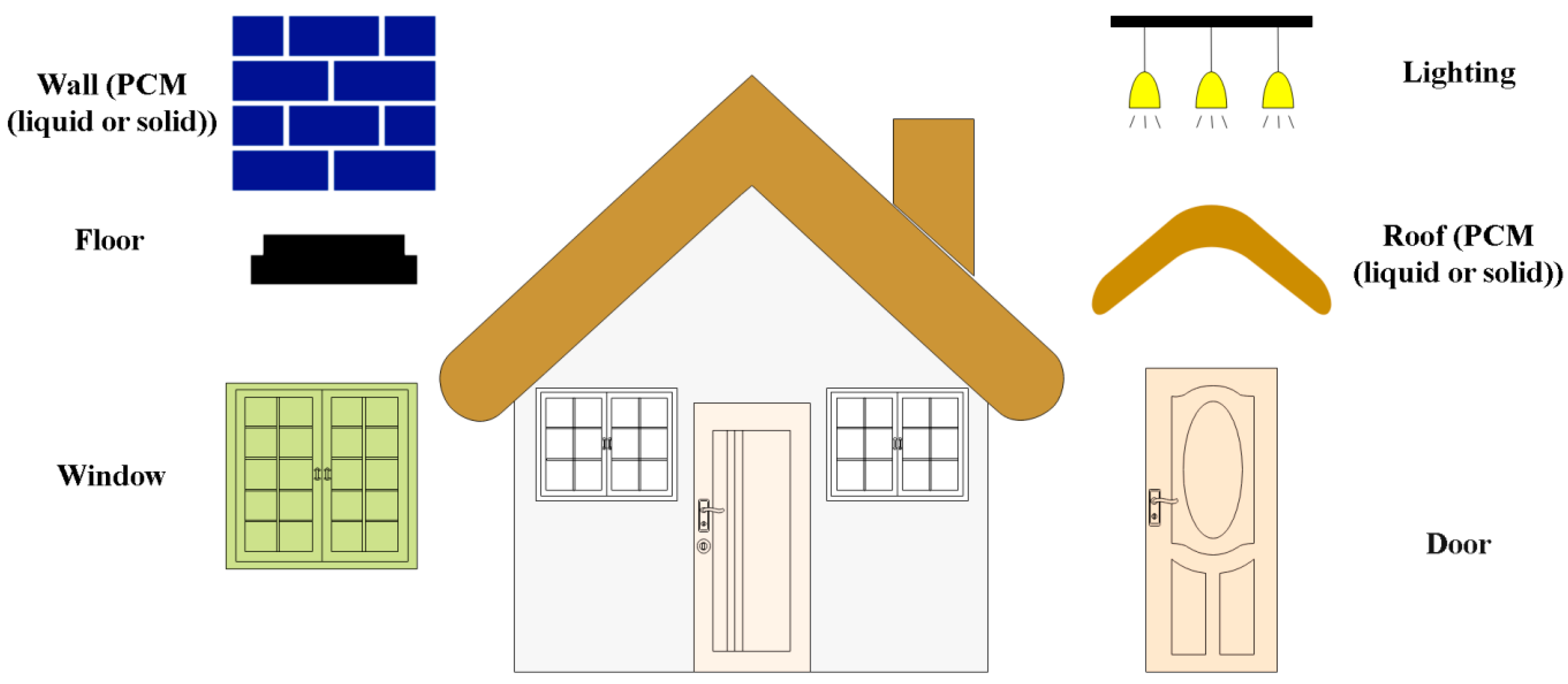

| Option | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Windows | Clear, double, non-metal, air, H-gain | Low-E, triple, insulated, Arg, L-gain | Low-E, triple, Insulated, Arg, M-gain | Low-E, triple, non-metal, Arg, H-gain | Back windows = High-SHGC | Low-E, double, non-metal, air, L-gain |

| Window areas | F18 B15 L15 R15 | F15 B15 L0 R0 | 18% F25 B25 L25 R25 | 15% F25 B25 L25 R25 | F15 B15 L15 R15 | 50 sqft, all facades |

| Door | Wood | Steel | Fiberglass | - | - | - |

| Door Areas | 10 ft2 | 20 ft2 | 30 ft2 | 40 ft2 | - | - |

| Option | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Wall sheathing | OSB | R-15XPS | R-6 Polyiso | R-5XPS | OSB, R-15*PS | OSB, R-12 Polyiso |

| Exterior finish | Stucco, medium/dark | Brick, light | Wood, light | Aluminum, light | Vinyl, light | Fiber–cement, medium/dark |

| Interzonal walls | PCM (liquid) | PCM (solid) | - | - | - | - |

| Wood stud | R-13 fiberglass batt, 2*4, 16 in o.c. | Uninsulated, 2*6, 24 in o.c. | Uninsulated, 2*6, 16 in o.c. | R-13 cellulose, 2*4, 16 in o.c. | R-13 opened cell spray foam, 2*4, 16 in o.c. | R-15 fiberglass batt, 2*4, 16 in o.c. |

| Double wood stud | R-33 fiberglass batt, Gr-1, 2*4 centered, 24 in o.c. | R-33 fiberglass batt, Gr-1, 2*4 staggered, 24 in o.c. | R-45 fiberglass batt, Gr-1, 2*4 staggered, 24 in o.c. | R-39 cellulose, Gr-1, 2*4 staggered, 24 in o.c. | R-45 Cellulose, Gr-1, 2*4 staggered, 24 in o.c. | R-39 fiberglass batt, Gr-1, 2*4 centered, 24 in o.c. |

| Steel stud | Uninsulated, 2*6, 24 in o.c. | R-11 fiberglass batt, 2*4, 24 in o.c. | R-19 fiberglass batt, 2*6, 24 in o.c. | R-25 fiberglass batt, 2*8, 24 in o.c. | R-19 cellulose, 2*4, 16 in o.c., grade 3 | R-30 fiberglass batt, 2*6, 24 in o.c. |

| Option | 1 | 2 | 3 | 4 | 5 | 6 |

|---|---|---|---|---|---|---|

| Interior shading | Summer = 0.7, winter = 0.7 | Summer = 0.5, winter = 0.95 | Summer = 0.7, winter = 0.95 | Summer = 0.6, winter = 0.7 | Summer = 0.5, winter = 0.7 | - |

| Eaves | 1 ft. | 2 ft. | 3 ft. | 4 ft. | - | - |

| Overhangs | 2 ft., all stories, all windows | 2 ft., first story, all windows | 2 ft., first story, back windows | 2 ft., first story, left windows | 2 ft., first story, right windows | - |

| Floor mass | Wood surface | 2 in. gypsum concrete | - | - | - | - |

| Exterior wall mass | 2*1.2 in. drywall | 5.8 in. drywall | 1.2 in. drywall | 2*5.8 in. drywall | - | - |

| Partition wall mass | 2*1.2 in. drywall | 5.8 in. drywall | 1.2 in. drywall | 2*5.8 in. drywall | - | - |

| Ceiling mass | 2*5.8 in. drywall | 5.8 in. drywall | 1.2 in. drywall | 2*1.2 in. drywall | - | - |

| Carpet | 20% | 40% | 60% | 80% | 100% | - |

| Finished roof | R-13 fiberglass batt, 2*4 | R-30+R-19 fiberglass batt | R-38 fiberglass batt, 2*10 | R-47.5 SIPs | R-37.5 SIPs | R-30C fiberglass batt, 2*10 |

| Roof Material | PCM (liquid) | PCM (solid) | - | - | - | - |

| Option | 1 | 2 | 3 | 4 | 5 | 6 | 7 |

|---|---|---|---|---|---|---|---|

| Lighting | 100% incandescent | 40% CLF | 60% CLF | 80% CLF | 60% LED | 80% LED | 40% LED |

| Pier and Beam | Ceiling R-38 fiberglass Batt | Ceiling R-19 fiberglass Batt | Ceiling R-13 fiberglass Batt | Ceiling R-38 opened cell spray foam | Ceiling R-13 closed cell spray foam | Ceiling R-19 opened cell spray foam | Ceiling R-30 closed cell spray foam |

| PCM | Thermal Conductivity (W/m·K) | Specific Heat (kJ/kg·K) | U-Value (W/m2·K) | Density (kg/m3) | Latent Heat (kJ/kg) |

|---|---|---|---|---|---|

| Solid | 0.3 | 2.75 | 46.9 | 878 | 100 |

| Liquid | 0.1 | 1.848 | 15.6 | 898 | 100 |

| Parameter | Dubai | Vancouver |

|---|---|---|

| Time to solve | 14 h 45 m 39 s | 14 h 23 m 12 s |

| Number of repetitions | 81 | 81 |

| Software version | BEopt 3-0-1 | BEopt 3-0-1 |

| Optimal Choice | Building (Vancouver) | Building (Dubai) |

|---|---|---|

| Orientation | North | North |

| Wood stud | R-13 fiberglass batt, 2*4, 16 in o.c. | R-13 opened cell spray foam, 2*4, 16 in o.c. |

| Wall sheathing | OSB | Vinyl, medium/dark |

| Exterior finish | Stucco, medium/dark | Vinyl, light |

| Interzonal walls | PCM (solid) | PCM (solid) |

| Finished roof | R-13 fiberglass, 2*4 | R-37.5 SIPs |

| Roof material | PCM (liquid) | PCM (solid) |

| Pier and beam | Ceiling R-19 fiberglass batt | Ceiling R-38 open cell spray foam |

| Carpet | 20% carpet | 100% carpet |

| Floor mass | Wood surface | Wood surface |

| Exterior wall mass | 2*1/2 in. drywall | 2*5.8 in. drywall |

| Partition wall mass | 2*1/2 in. drywall | 2*5/8 in. drywall |

| Ceiling mass | 2*1/2 in. drywall | 2*5.8 in. drywall |

| Window areas | F15 B15 L15 R15 | F15 B15 L15 R15 |

| Windows | Clear, double, non-metal, air | Low-E, double, non-metal, air, L-gain |

| Interior shading | Summer = 0.7, winter = 0.7 | Summer = 0.5, winter = 0.95 |

| Door area | 30 ft2 | 30 ft2 |

| Doors | Wood | Steel |

| Eaves | 1 ft. | 2 ft. |

| Overhangs | 2 ft., all stories, all windows | 2 ft., first story, back windows |

| Lighting | 40% LED | 60% LED |

| Double wood stud | R-33 fiberglass batt, Gr-1, 2*4 centered, 24 in o.c. | R-33 fiberglass batt, Gr-1, 2*4 centered, 24 in o.c. |

| Steel stud | R-11 fiberglass natt, 2*4, 24 in o.c. | Uninsulated, 2*6, 24 in o.c. |

| City | Electricity (kWh) | CO2 Emissions (kg) | Cooling (kWh) | Heating (kWh) |

|---|---|---|---|---|

| Vancouver | 8493.55 | 2129.78 | 1083.97 | 7899.11 |

| Dubai | 9572.1 | 2773.26 | 18,845.4 | 8.99473 |

| Option | Electricity (kWh) | CO2 Emissions (kg) | Cooling (kWh) | Heating (kWh) |

|---|---|---|---|---|

| Optimal choice 1 | 8493.55 | 2129.78 | 1083.97 | 7899.11 |

| Min cost | 7362.2 | 2016.1 | 958.1 | 7215.14 |

| Max savings | 8155.39 | 2076.34 | 1009.51 | 7641.29 |

| Optimal Point | Target | Value (Vancouver) |

|---|---|---|

| A | Source energy savings (%/yr) | 0.01 |

| Energy-related costs, annualized (USD/yr) | 1634.06 | |

| B | Source energy savings (%/yr) | 0.01 |

| Energy-related costs, net present value (USD) | 2393.81 | |

| C | Source energy savings (%/yr) | 0.01 |

| Energy-related costs, lifecycle cost (USD) | 59,513.3 | |

| D | Site energy consumption (MBtu/yr) | 61.71 |

| Energy-related costs, annualized (USD/yr) | 1634.06 | |

| E | CO2 emissions (Lbs/yr) | 9224.43 |

| Energy-related costs, annualized (USD/yr) | 1634.06 | |

| F | CO2 savings (Lbs/yr) | 5.72 |

| Energy-related costs, annualized (USD/yr) | 1634.06 |

| Relations | Basic Relations |

|---|---|

| Law of survival of crime | |

| Law of the conservation of energy | |

| Exergy balance | |

| Physical exergy | |

| Cost rate | |

| Capital recovery factor |

| Energy | Electricity (kWh) | Cooling (kWh) | Heating (kWh) |

|---|---|---|---|

| Production | 237,365 | 304,733 | 425,959 |

| Consumption | 8493.55 | 1083.97 | 7899.11 |

| Stored | 229,466 | 303,649 | 417,466 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Assareh, E.; Keykhah, A.; Hoseinzadeh, S.; Astiaso Garcia, D. Application of PCM in a Zero-Energy Building and Using a CCHP System Based on Geothermal Energy in Canada and the UAE. Buildings 2024, 14, 477. https://doi.org/10.3390/buildings14020477

Assareh E, Keykhah A, Hoseinzadeh S, Astiaso Garcia D. Application of PCM in a Zero-Energy Building and Using a CCHP System Based on Geothermal Energy in Canada and the UAE. Buildings. 2024; 14(2):477. https://doi.org/10.3390/buildings14020477

Chicago/Turabian StyleAssareh, Ehsanolah, Abolfazl Keykhah, Siamak Hoseinzadeh, and Davide Astiaso Garcia. 2024. "Application of PCM in a Zero-Energy Building and Using a CCHP System Based on Geothermal Energy in Canada and the UAE" Buildings 14, no. 2: 477. https://doi.org/10.3390/buildings14020477

APA StyleAssareh, E., Keykhah, A., Hoseinzadeh, S., & Astiaso Garcia, D. (2024). Application of PCM in a Zero-Energy Building and Using a CCHP System Based on Geothermal Energy in Canada and the UAE. Buildings, 14(2), 477. https://doi.org/10.3390/buildings14020477