1. Introduction

In most structures and buildings, fire is considered a serious potential risk [

1]. This is due to the drastic microstructural thermo–physio–chemical degradations that occur in the properties of construction materials under high temperatures, and these materials may never recover their pre-fire properties even after they have cooled to ambient temperature [

2].

As a structural material, concrete is extensively used in building construction because of its considerable advantages, such as durability, strength, and non-combustibility properties [

3]. Concrete may be exposed to heat caused by fire or other reasons. After exposure, its mechanical properties, such as compressive and tensile strength and modulus of elasticity, are significantly decreased [

4]. Concrete undergoes a series of chemical and physical changes, such as the disintegration of hydration products and aggregates, evaporation of water, increased porosity, and microstructure coarsening. These changes will result in the deterioration of the mechanical characteristics of the concrete [

5]. Under high temperatures, the behaviour of concrete as a composite material is highly influenced by its constituents, such as aggregates, water, and binder, including cement and supplementary cementing materials. For decades, SCMs have been used as mineral additives in concrete. These additives improve the physicomechanical properties of concrete [

6]. However, with the increasing use of supplementary cementitious materials (SCMs) in concrete, its high-temperature performance has become more complicated [

7]. Therefore, investigating the influence of concrete constituents at high temperatures is of great significance.

The properties of concrete exposed to high temperatures are typically measured using three test methods: transient, steady-state, and residual tests. In the case of the transient test, the specimens are first loaded (typically 20–40% of ultimate compressive strength). This loading is maintained during heating until the failure of the specimens [

8]. In the steady-state test, the concrete specimens are heated (without a pre-load) until they reach a uniform temperature, and then the specimens are loaded to failure.

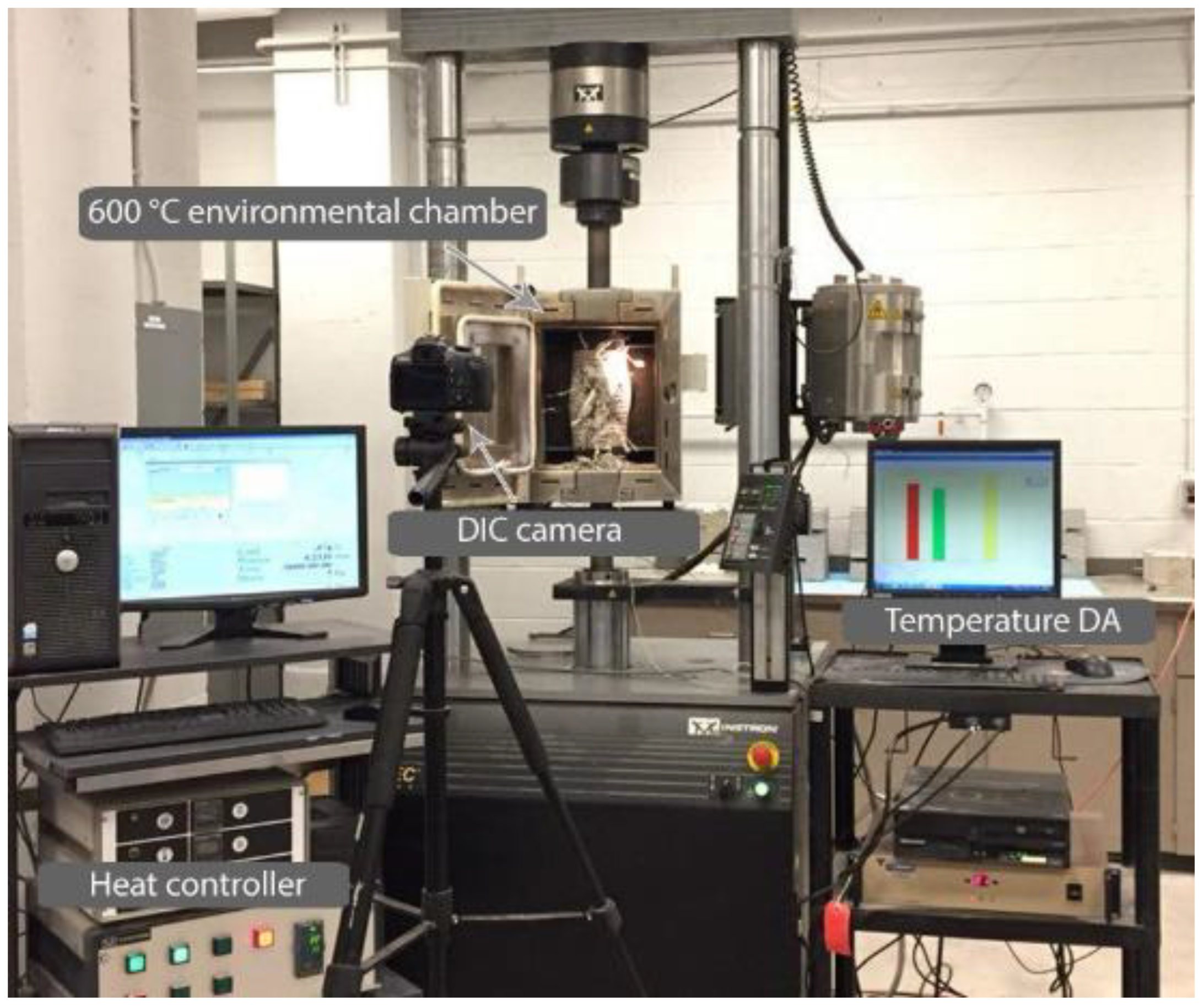

Figure 1 illustrates the test setup for transient and steady-state tests at high temperatures [

9]. The concrete specimens in the residual test method are heated at a constant rate of temperature without a pre-load until specimens reach a thermal steady state. Then the load is applied at the specified rate after the specimens are cooled to room temperature until failure occurs [

8]. Transient and steady-state tests are used to evaluate the properties of concrete during exposure to high temperatures. In contrast, the residual test, which researchers have widely adopted, is excellent for determining post-fire concrete properties [

10].

Due to the complex mechanical properties of concrete at high temperatures and the different high-temperature behaviour of constituent materials, there is a need for a comprehensive review of the available literature on the behaviour of concrete at high temperatures. In previous research conducted by Ma et al. [

5], the mechanical properties of concrete at high temperatures were reviewed, and the authors reported the effects of high temperatures on the mechanical properties of concrete with SCMs. In addition, in another study, Malik et al. [

11] briefly reviewed the thermal and mechanical properties of different types of concrete at high temperatures focusing only on the compressive strength of concrete containing SCM. The present study analytically reviewed existing findings and provided discussions of three important mechanical properties, including residual compressive and tensile strength as well as the modulus of elasticity. This study mainly focuses on the effects of cement replacement with different SCMs and aggregate types on the performance of concrete subjected to high temperatures. In addition, the mechanical behaviour of concrete at room temperature is highlighted for a better understanding of the response of concrete at high temperatures. This study is restricted solely to experimental works conducted to evaluate the residual mechanical characteristics of concrete using the residual test.

2. Supplementary Cementitious Material (SCM)

The primary component of concrete, cement, requires high levels of raw materials extracted from natural resources for its manufacturing process. This produces huge amounts of CO

2 emissions [

12]. Cement is partially replaced with supplementary cementitious materials (SCMs) to reduce cement consumption and lessen the impacts on the environment [

12,

13]. Moreover, using SCMs as the by-product material results in reducing industrial waste. In some cases, this can reduce the cost of the concrete by decreasing the content of cement in the said concrete. Nowadays, silica fume, fly ash, and ground-granulated blast-furnace slag are extensively used in concrete as the materials for partial replacement of cement due to their ability to improve concrete properties and reduce environmental impacts [

14].

Table 1 and

Table 2 summarize the investigations conducted on the effects of SCM on the mechanical characteristics of concrete at room temperature and high temperatures, respectively. The influence of different types of supplementary cementing materials on the mechanical performance of concrete at room and high temperatures is discussed in detail in the following subsections.

2.1. Effect of Silica Fume at Room Temperature

An electric arc furnace produces silica fume as a by-product of smelting silicon and ferrosilicon [

47,

48]. At temperatures up to 2000 °C, high-purity quartz reduction to silicon results in SiO

2 vapours, which oxidize and condense to form tiny particles of amorphous silica in the low-temperature zone. Over 95% of silica fume particles are finer than 1 µm [

48,

49]. The influence of SF in concrete is physicochemical. The physical phase is related to extremely fine particles, which act as a filler, filling the spaces between the particles of cement. In the chemical phase, SF reacts chemically with calcium hydroxide, Ca(OH)

2, leading to calcium silicate hydrate (CSH) formation in concrete.

2.1.1. Compressive Strength

Behnood et al. [

15] studied high-strength concrete (HSC) made with 0%, 6%, and 10% cement replacement with SF at room temperature and after high-temperature exposure. Compared to the mixture without SF, the 28-day strength of concrete containing 6% and 10% SF increased by 19% and 25%, respectively. This can be attributed to the reaction between calcium hydroxide and SF leading to the formation of CSH gel, which increases the strength of concrete. However, the increasing rate of strength is lower at early ages because of the lower calcium hydroxide content. A similar test was conducted by Ghandehari et al. [

16].

Kim et al. [

17] examined the strength of three types of coarse aggregates, including granite, quartzite, and basalt, and the use of 10% SF to replace cement at curing ages of 3, 7, 28, and 56 days. It was observed that the specimens composed of SF and basalt aggregate showed higher strength than those made with quartzite and granite aggregates. This is due to the higher strength of the basalt aggregate in comparison with the other aggregates and the improvement of the interfacial transition zone (ITZ) caused by the filling effect of fine particles of SF.

Mazloom et al. [

18] examined the effect of replacing cement with 0%, 6%, 10%, and 15% SF on high-strength concrete at different ages between 7 and 400 days. Once compared to OPC concrete, it was observed that the presence of SF led to an increase in the strength of concrete for up to 90 days. However, there were no significant changes in the long-term strength of concrete at 400 days. This was due to the formation of a layer that inhibits the further reaction between calcium hydroxide and silica fume at later stages. Similar findings for concrete containing SF up to 20% ranging from 1 day to 5 years were observed in the experimental study conducted by Hooton [

21].

Yogendran et al. [

19] examined the strength of concrete prepared with 0%, 5%, 10%, 15%, 20%, and 25% SF with two water-to-binder ratios (w/b) of 0.28 and 0.34 at the ages of 28, 56, and 91 days. The results revealed that at a w/b ratio of 0.34, the maximum strength of concrete was obtained with 15% silica fume replacement at all ages. According to their findings, the influence of silica fume decreased with increasing SF content and declining w/b ratios.

Bhanja et al. [

20] evaluated the concrete specimens made with 0%, 5%, 10%, 15%, 20%, 25%, and 30% SF as cement substitution, and the water-to-binder (w/b) ratios between 0.26 and 0.42. It was found that the incorporation of silica fume into concrete improved the concrete strength. In addition, it was reported that the optimum replacement level of SF depends on w/b ratios. It was found that the 15% replacement level at w/b of 0.26 yielded the maximum value of compressive strength. Similar observations have been reported by Katkhuda et al. [

50].

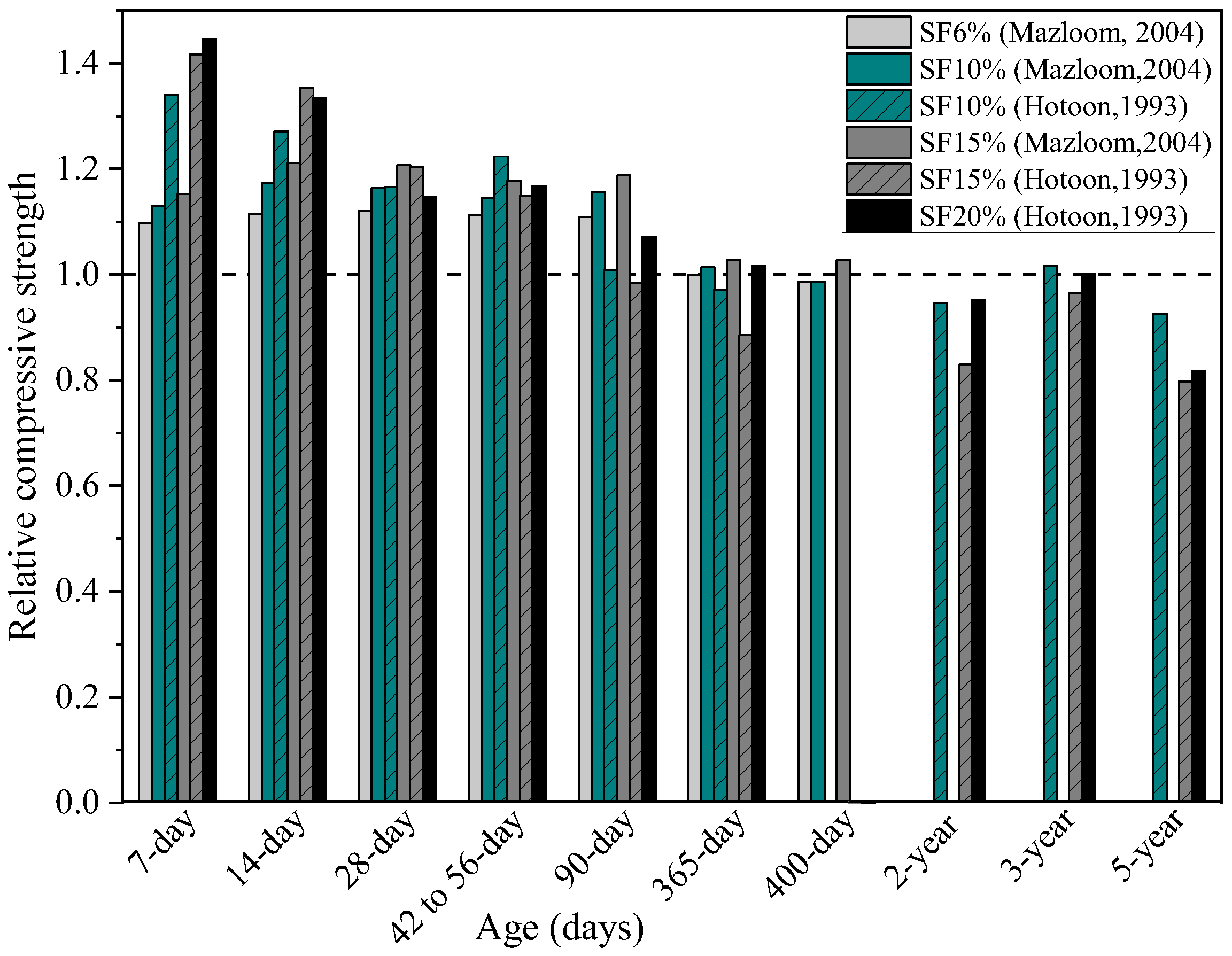

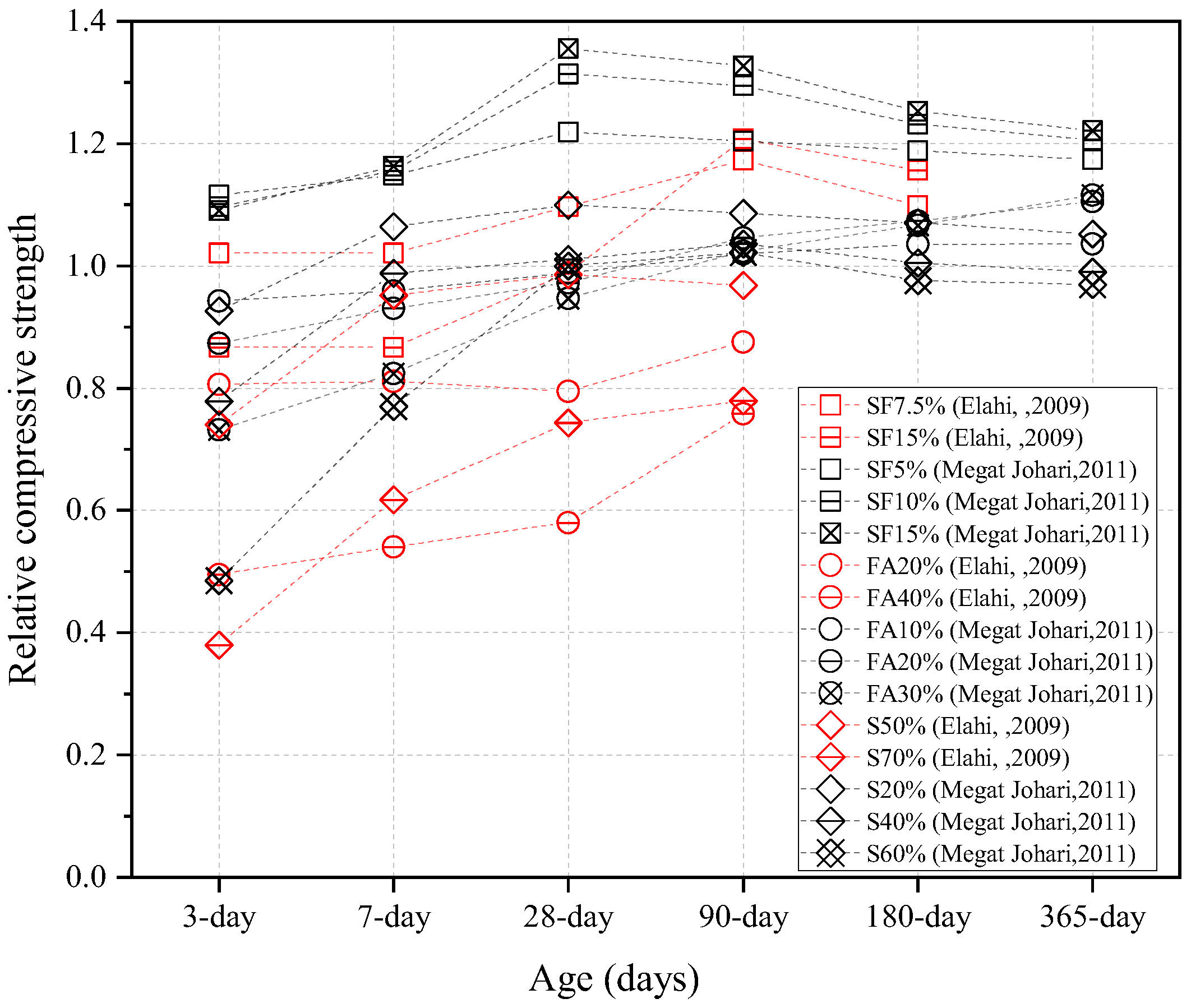

Figure 2 shows the ratio strength of SF concrete to the strength of control concrete without SF versus the curing ages at room temperature reported by Mazloom et al. [

18] and Hooton [

21]. As seen in

Figure 2, replacing cement with SF increases the strength of concrete compared to OPC concrete. This enhancement in strength can be explained by transforming the weak crystals of Ca(OH)

2 into calcium silicate hydrate (CSH) through the pozzolanic reaction. The calcium silicate hydrate as a hydration product improves the strength of concrete [

51]. The substitution of cement with SF mainly influences the short-term strength of concrete. Silica fume concrete has low long-term strength gain compared to concrete without silica fume after one year.

2.1.2. Splitting Tensile Strength

Bhanja et al. [

20] evaluated the splitting tensile strength of concrete incorporating silica fume at 28 days. The mixtures were prepared with 0%, 5%, 10%, 15%, 20%, 25%, and 30% silica fume at w/b ratios of 0.26, 0.30, 0.34, 0.38, and 0.42. The results indicated that the 5–10% replacements of SF caused a significant increase in the tensile strength in comparison to the control concrete for all w/b ratios. In addition, the enhancement of splitting strength for more than 15% replacement of cement with SF was insignificant. In another study, Hooton et al. [

21] investigated the influence of cement replacement with 0%, 10%, 15%, and 20% SF on the splitting tensile strength of concrete at the ages of 28, 91, and 182 days. It was observed that the splitting tensile strength of the SF mixes was not increased except at the age of 28 days. The results demonstrated that the splitting strength of concrete with 10% and 15% SF was approximately equal but greater than concrete without SF at 28 days. However, the concrete with 20% SF exhibited the lowest splitting tensile strength at all ages.

2.1.3. Modulus of Elasticity

Khedr et al. [

22] examined the modulus of elasticity of concrete with 0%, 10%, and 20% silica fume. The results showed that the modulus of elasticity increased with the addition of SF. The most desirable results were achieved with 20% SF. Mazloom et al. [

18] reported similar findings for the secant modulus of elasticity of high-strength concrete with 0%, 6%, 10%, and 15% silica fume up to 400 days.

Hooton [

21] studied the effect of SF on the modulus of elasticity of concrete at the testing ages from 28 to 365 days. The results demonstrated that the elastic modulus of the ordinary Portland cement concrete and SF concrete was approximately equal at 28 days. However, the modulus of elasticity of all specimens increased at later ages until one year.

2.2. Effect of Silica Fume at High Temperatures

2.2.1. Compressive Strength

Behnood et al. [

15] reported how different contents of silica fume affect the residual strength of concrete subjected to temperatures up to 600 °C. Three concrete mixtures with 0%, 6%, and 10% silica fume were prepared with the w/b ratio of 0.30. At 100 °C, the concrete strength decreased significantly in comparison to the strength at room temperature. A slight increase in residual strength was observed between the temperatures of 100 °C and 200 °C for all the concrete mixtures with and without silica fume. However, this strength recovery was higher in OPC concrete in comparison to SF concrete. This can be explained by the filler role of extremely fine particles of SF and their pozzolanic reactions, which caused the microstructure of concrete containing SF to become denser. This, in turn, results in the moisture content of SF concrete being unable to remove freely compared to OPC at 200 °C. At temperatures between 300 °C and 600 °C, the relative strength was considerably reduced for all concrete specimens. It was noticed that the relative strength was lower in SF concrete, especially for that containing 10% SF compared to OPC concrete. This was due to the denser transition zone between paste and aggregates formed in SF concrete. Ghandehari et al. [

16] also reported the same results.

Poon et al. [

35] evaluated the strength of high-strength pozzolanic concrete with SF after exposure to high temperatures up to 800 °C. The SF content as the cement substitution was 0%, 5%, and 10%. The strength of high-strength concrete with SF decreased slightly at temperatures between 20 °C and 200 °C. Between 200 °C and 400 °C, hairline cracks appeared in SF concrete but no spalling. Beyond 400 °C, severe cracking and spalling occurred in SF concrete, and the residual strength of SF concrete was lower than the ordinary Portland cement concrete. This can be attributed to the buildup of vapour pressure caused by the dense structure of SF concrete. In addition, Phan et al. [

37] examined the residual mechanical properties of high-performance concrete (HPC) mixtures with 0% and 10% SF as cement replacement and the w/b ratios of 0.22, 0.33, and 0.57 exposed to 450 °C and below. It was found that the mixtures with SF and a lower w/b ratio demonstrated lower strength loss and were more susceptible to explosive spalling compared to other concrete mixtures.

Tanyildizi et al. [

36] and Sancak et al. [

34] investigated the effects of SF on the strength of lightweight concrete after high-temperature exposure. They reported that lightweight concrete containing SF performed better than lightweight concrete without SF after exposure to high temperatures.

In conclusion, silica fume incorporation increased the relative strength of concrete at temperatures below 200 °C. However, the strength of SF concrete decreased at further temperatures. This was due to the pozzolanic reactions of silica fume and its ultra-fine particles resulting in a very dense aggregate–paste transition zone. Thus, the cement paste contraction and the aggregate expansion led to higher stress levels in the transition zone, resulting in the bonding between cement paste and aggregate being more sensitive in concrete with SF than in OPC concrete [

15]. Moreover, the concrete containing SF with a very dense microstructure was more prone to severe cracking and spalling because of the accumulation of pore pressures produced by chemically and physically bound water evaporation [

35].

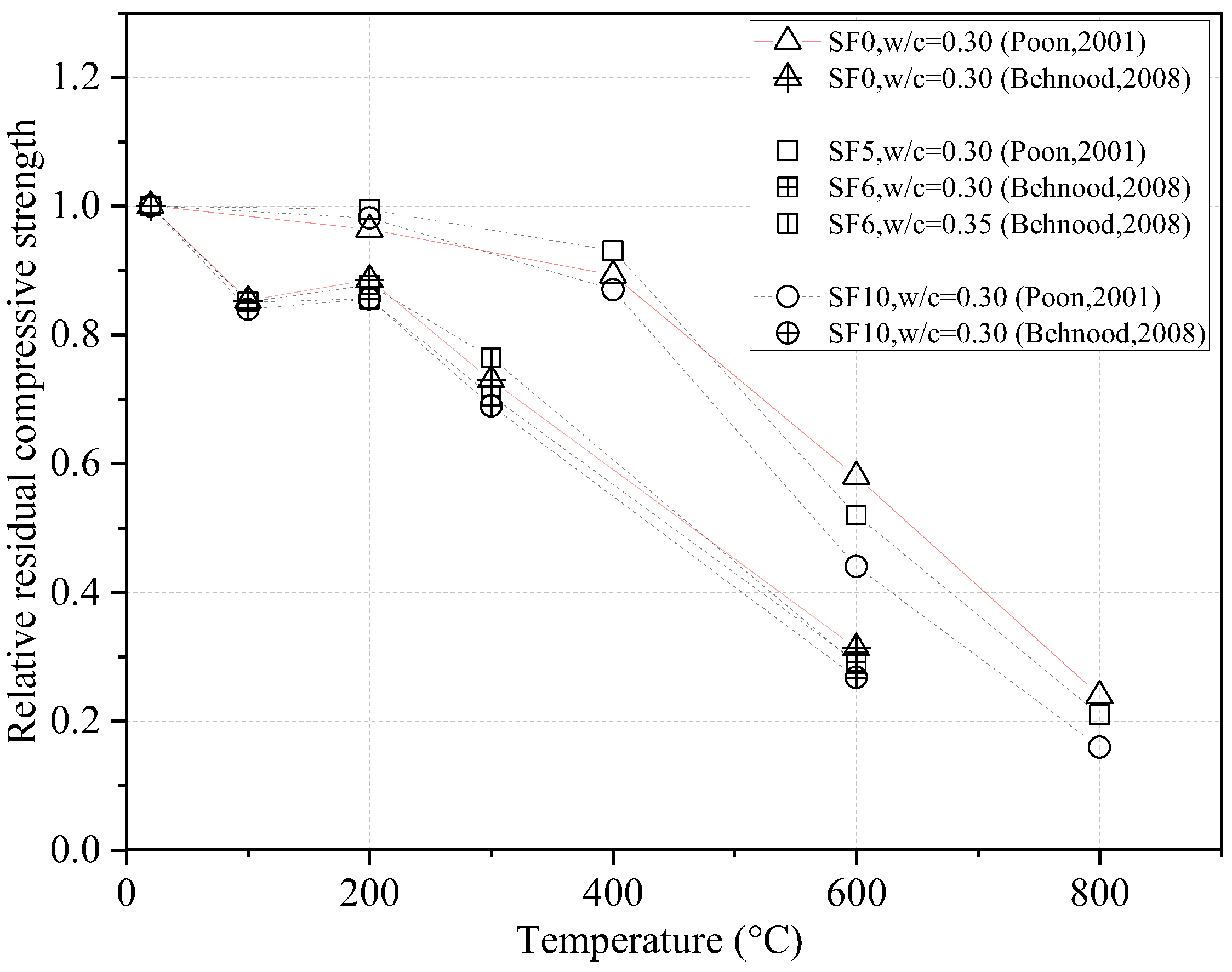

Figure 3 illustrates the relative residual compressive strength (the ratio of concrete strength at a particular temperature to the strength of concrete at room temperature) over temperature variation. While the findings of Behnood et al. [

15] do not show a notable difference between the OPC and the SF-contained specimens, the results of Poon et al. [

35] show that the specimens with higher SF have a slightly higher strength reduction above 400 °C.

2.2.2. Splitting Tensile Strength

Ghandehari et al. [

16] studied the splitting tensile strength of high-strength concrete containing SF (0%, 6%, and 10%) when subjected to 600 °C and below. The splitting tensile strength of SF concrete decreased with rising temperatures. As the concrete temperature increased from 300 °C to 600 °C, the relative splitting tensile strength of concrete sharply reduced from 71% to 25%. This considerable loss of strength was due to the different expansion of the cement paste and aggregate as well as the decomposition of the hydration products in concrete at high temperatures. It was also found that a higher rate of tensile strength loss was observed compared to compressive strength loss due to the more significant effects of crack coalescence on the tensile strength compared to the compressive strength. In addition, the cracks tend to close when subjected to compressive loads while opening under tensile loads.

Tanyildizi et al. [

36] investigated the splitting tensile strength of lightweight concrete with SF at substitution levels of 0%, 10%, 20%, and 30% after being subjected to 200 °C, 400 °C, and 800 °C. It was found that the tensile strength declined when increasing the temperature. Moreover, lightweight concrete that contained 20% SF exhibited higher strength at all temperatures.

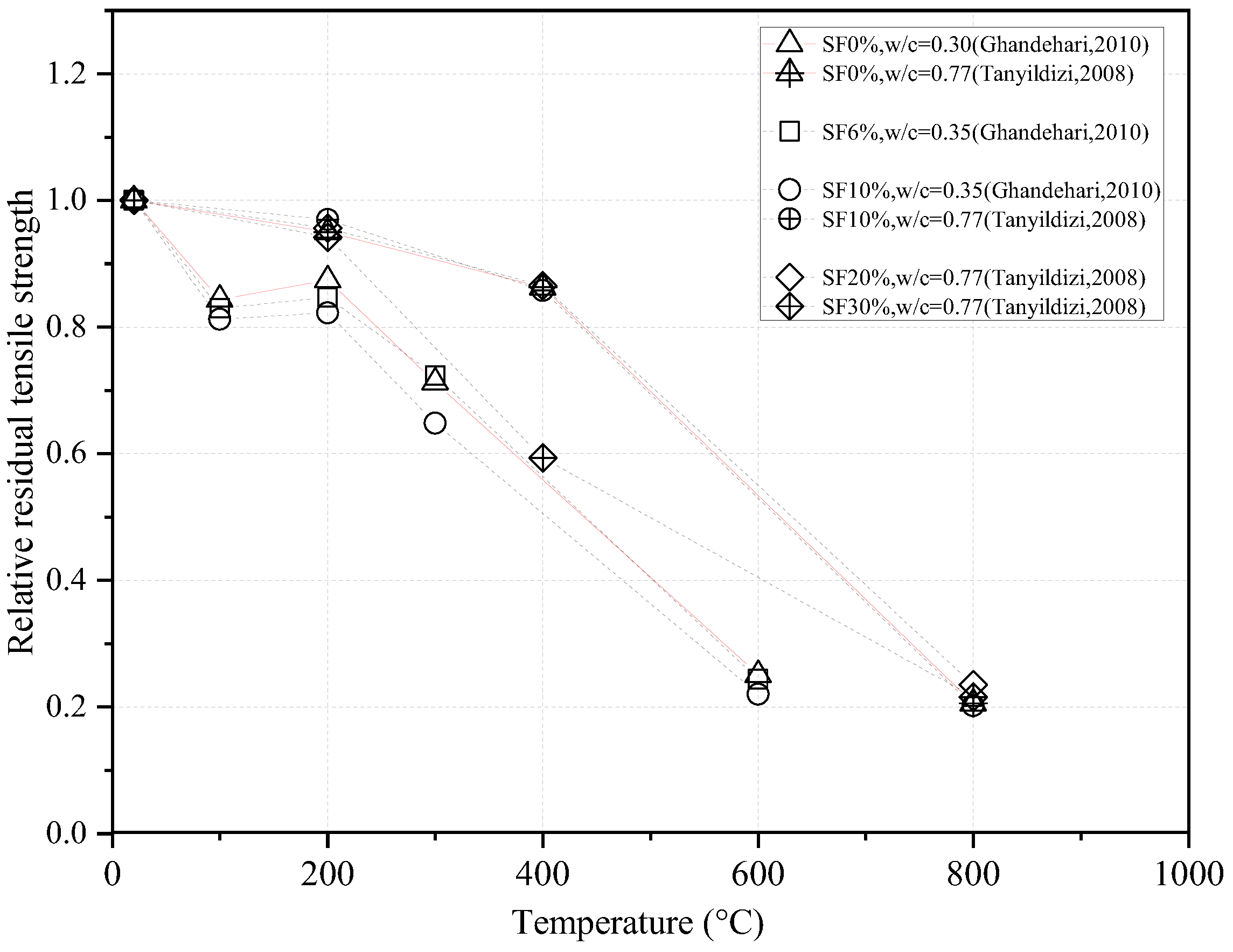

The variation of the relative splitting tensile strength of concrete with temperatures is plotted in

Figure 4. The relative splitting tensile strength of SF concrete decreases beyond 200 °C, and the residual tensile strength of SF concrete at the temperature of 800 °C is almost 20% of its original strength at room temperature.

2.2.3. Modulus of Elasticity

Various techniques of high-temperature deformation measurement, including contact and non-contact approaches, have been developed to determine deformation at high temperatures. Linear position transducer, linear variable differential transformer, compressometer, high-temperature strain gauge, and Fiber-optic sensor are typical contact methods for strain measurement. On the other hand, Laser sensors and Digital image correlation are the two key non-contact optical methods increasingly used to measure high-temperature deformation [

52,

53]. However, there are still difficult technical problems in measuring deformation-related properties, such as the modulus of elasticity, despite the rapid development of various measurement techniques. Due to these difficulties and challenges, there is very limited reliable experimental data in the literature regarding the deformation-related properties, such as the modulus of elasticity of different concrete mixtures.

Phan et al. [

37] examined the influence of high temperatures on the modulus of elasticity of HPC containing 0% and 10% silica fume up to 450 °C. It was observed that the modulus of elasticity of the HPC in this test program decreased for all mixtures with and without silica fume with increasing temperatures. All mixtures demonstrated a 50% reduction in the modulus of elasticity between room temperature and 300 °C. The modulus reduction was slower from 300 °C to 450 °C. However, all mixes lost more than 70% of their initial modulus of elasticity at 450 °C.

2.3. Effect of Fly Ash at Room Temperature

Fly ash (FA), or pulverized fly ash (PFA), is the industrial by-product of electricity-generating plants and is commonly used as a cement replacement in the concrete industry [

54,

55]. Generally, fly ash particles are spherical and mainly glassy, with particle sizes ranging from <1 µm to 150 µm. Fly ash has a specific gravity of 2.1 to 3.0 and a specific surface area between 170 and 1000 m

2/kg [

56]. The primary composition of FA consists of silica (SiO

2), iron oxide (Fe

2O

3), calcium oxide (CaO), and aluminum oxide (Al

2O

3) [

57]. There are two main types of fly ash: low-calcium fly ash (Class F) and high-calcium fly ash (Class C). Calcium hydroxide is required by low-calcium fly ash (Class F) to generate strength-developing products using the pozzolanic reaction. Therefore, it is combined with Portland cement, which produces calcium hydroxide in the hydration process [

58,

59]. However, Class C can significantly alter the hydration processes in cement due to higher reactivity, and more studies are needed to investigate the application of Class C of FA in concrete production [

60]. The reaction of fly ash with calcium hydroxide caused more calcium aluminate hydrate (CAH) and calcium silicate hydrate (CSH), resulting in a denser matrix in concrete [

55,

61]. Moreover, the physical properties of fly ash, including its size and shape, significantly affect the properties of FA concrete. The fly ash concrete made with finner FA has a higher compressive strength [

62].

2.3.1. Compressive Strength

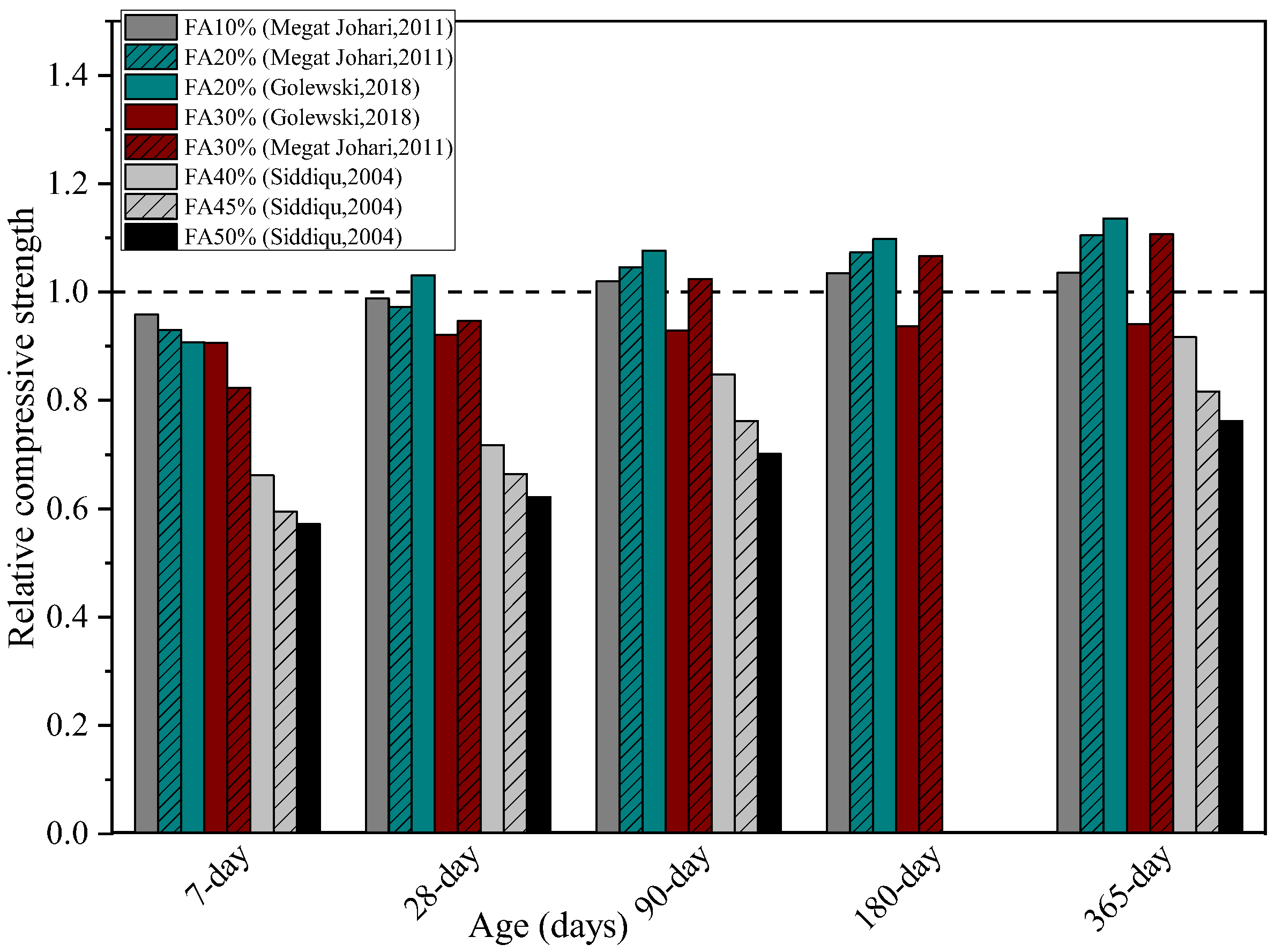

Megat Johari et al. [

26] examined the strength of high-strength concrete that contained fly ash for up to 365 days. The concrete specimens were prepared with 0%, 10%, 20%, and 30% FA. It was found that the strength of FA concrete decreased at early ages. Moreover, a considerable reduction was observed at higher substitution levels of FA. However, at later ages, the relative strength exceeded continuously with increasing curing age. At 90 days, fly ash-containing concrete showed higher strength than OPC concrete. After one year, the relative strength of concrete with 10%, 20%, and 30% fly ash concrete was found as 104%, 111%, and 112%, respectively. Therefore, 30% is the optimum amount of fly ash for high-strength concrete, which results in maximum long-term strength. A similar study was conducted by Golewski [

23]. A lower early-age compressive strength was observed in FA concrete in comparison to control concrete (i.e., 0% FA). However, FA concrete exhibited higher strength compared to concrete without FA at later ages. A greater increase was reported for concrete with 20% fly ash replacement than the control concrete after 28 days and subsequent curing ages. This was due to the sharp rise of products from the pozzolanic reaction at the longer time of curing. The strength of concrete with 30% FA was higher than the control concrete only after 180 and 365 days.

The influences of the inclusion of a high volume of Class F fly ash on compressive, splitting tensile, and the modulus of elasticity of concrete at three ages (28, 91, and 365 days) were investigated by Siddique et al. [

24]. The dosages of replacing cement with FA were 0%, 40%, 45%, and 50%. It was found that there was a reduction in the strength of concrete made with FA compared to the strength of the control concrete at the age of 28 days. However, beyond 28 days, the compressive strength increased gradually in FA concrete because of the pozzolanic reaction of FA.

Abubaker et al. [

25] determined the influence of replacing cement with 10%, 25%, and 50% fly ash on the mechanical characteristics of concrete with a w/b ratio of 0.35 and 0.45 until 90 days of curing. The concrete strength decreased with increasing FA content due to the slow secondary hydration reaction at an early age compared to concrete without fly ash. In FA concrete, the strength increased with age. Moreover, it was found that the concrete with a higher w/b ratio exhibited a lower strength.

Due to the pozzolanic reaction and micro filler effect, FA could improve the properties of cement and concrete [

57]. The content of Al

2O

3 and SiO

2 are major factors that influence the pozzolanic reaction as they react with calcium hydroxide and produce more CSH gel. The variation in the relative strength of FA concrete versus concrete curing age is shown in

Figure 5. It can be seen that FA concrete, particularly concrete with higher FA content, showed lower relative strength at early ages because of the slow rate of the pozzolanic reaction of fly ash and Ca(OH)

2 compared to OPC concrete. However, the strength of FA concrete increased at later ages because of the additional formation of CSH due to the use of unreacted fly ash [

30]. As the percentage of FA increased, the strength of concrete reduced because of the slower rate of hydration with respect to cement [

63]. Fly ash concrete with up to 30% FA substitution showed a higher long-term strength compared to OPC concrete.

2.3.2. Splitting Tensile Strength

Lam et al. [

27] evaluated the splitting tensile strength of FA concrete at 28 and 56 days. The cement was partially substituted with 0%, 15%, 25%, 45%, and 55% fly ash. The results revealed that 15% to 25% fly ash replacement improved tensile strength. However, a higher content of FA replacement caused somewhat lower tensile strength at 28 and 56 days. This can be attributed to the lower concentration of cement hydration products, which required longer curing times to develop interfacial bonds in high-volume FA concrete. A study by Siddique et al. [

24] reported that the cement replacement with fly ash at 0%, 40%, 45%, and 50% caused an enhancement in the concrete tensile strength at 91 and 365 days compared to tensile strength at 28 days. However, increasing the FA content reduced the tensile strength at all ages.

2.3.3. Modulus of Elasticity

Siddique et al. [

24] examined the modulus of elasticity of high-volume FA concrete made with 0% to 50% fly ash at the ages of 28, 91, and 365 days. The results revealed that beyond 28 days, the modulus of elasticity of FA concrete increased with age. They also observed that utilization of the higher content of FA decreased the modulus of elasticity in comparison to the control concrete mix.

2.4. Effect of Fly Ash at High Temperature

2.4.1. Compressive Strength

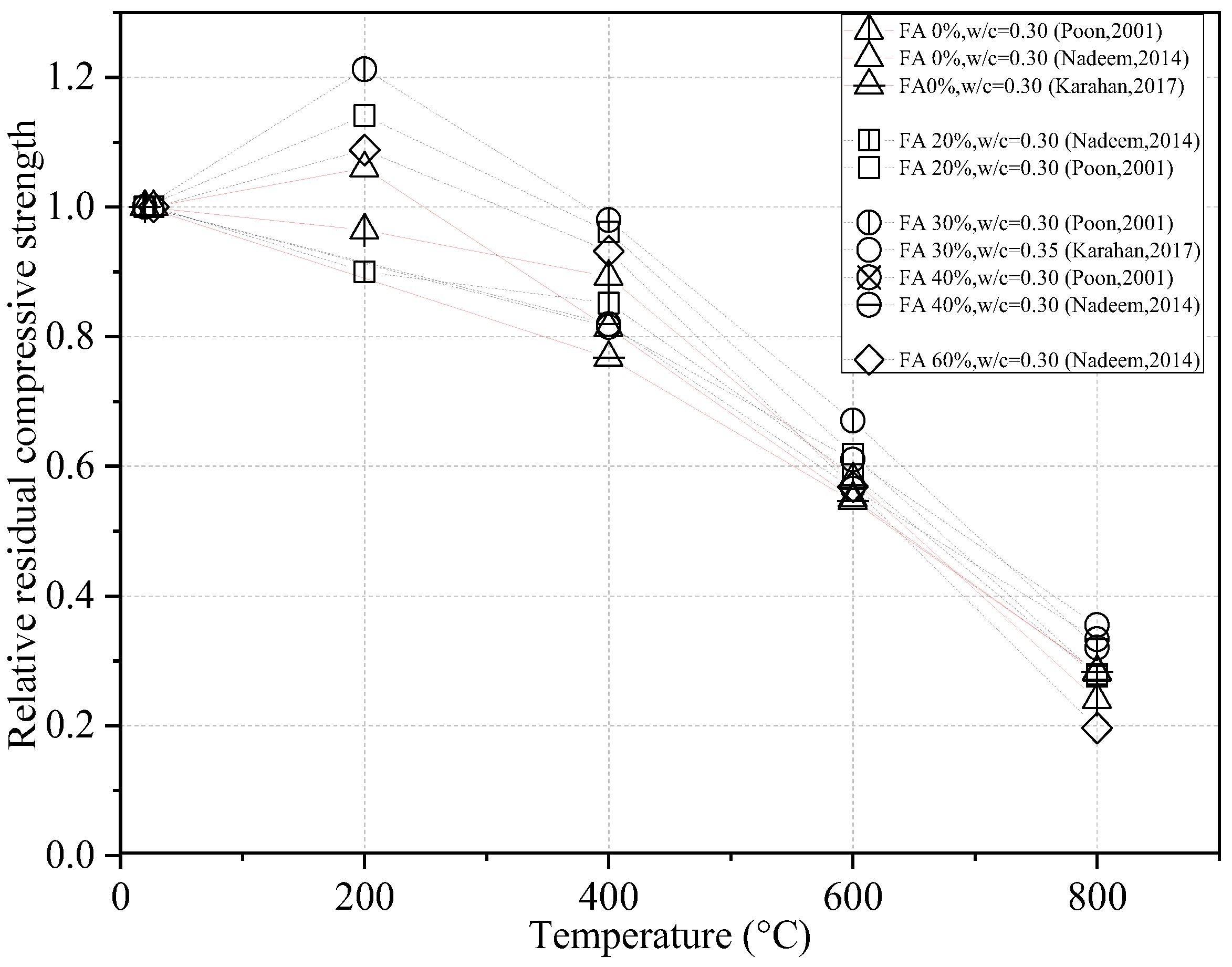

Several studies have been conducted on the effect of FA on the mechanical characteristics of concrete after exposure to high temperatures. Wang et al. [

38] evaluated the influence of heat on the strength of concrete with 30% FA in comparison to control concrete without FA up to the temperature of 550 °C. The results demonstrated that (i) up to the temperature of 250 °C, the strength decreased for all concrete mixtures with and without fly ash; (ii) between 250 °C and 350 °C, the strength was rebounded; and (iii) after 350 °C, the strength of concrete continuously reduced. At the temperature of 550 °C, the strength of the control concrete and fly ash concrete was 6.1% and 26.6% lower than the original strength at room temperature, respectively.

Khan et al. [

64] examined the behaviour of fly ash concrete after heating to temperatures up to 900 °C. In the concrete specimens, cement was replaced with 0%, 40%, 50%, and 60% FA. It was reported that by increasing the test temperature up to 300 °C, the residual strength of the concrete increased. However, the strength of all the mixes decreased with a further increase in temperature. This reduction might be due to moisture evaporation and thermal expansion mismatch between the aggregate and cement paste. Furthermore, for a given temperature, concrete with a higher content of FA exhibited a greater reduction in strength. Similar findings were reported by Karahanet [

39] for concrete made with 0%, 30%, 50%, 70%, and 90% FA after being exposed to 400 °C, 600 °C, and 800 °C. It was observed that the compressive strength of FA concrete was remarkably decreased by increasing the fly ash replacement percentage.

The influence of pulverized fly ash on the cracking and mechanical properties of concrete made with different PFA dosages (0%, 25%, and 55%) after high-temperature exposure up to 800 °C at 90 days was investigated in the study carried out by Xu et al. [

41]. It was found that the presence of PFA improved the relative residual strength compared to OPC concrete and resulted in the generation of a minor network of cracks in PFA concrete.

In another study, Nadeem et al. [

42] reported the behaviour of high-performance concrete containing fly ash from 20% to 60% that was exposed to 800 °C under two types of cooling methods: slow cooling and quick cooling at the age of 180 days. At 200 °C, the strength decreased continuously in mixes containing 20% and 40% fly ash, while a slight increase was observed in the strength of concrete with 60% fly ash and OPC concrete. This slight increase can be attributed to the additional hydration of the unhydrated cement grains. This is due to the steam effect of internal autoclaving, or free water evaporation, which results in greater Van der Waals forces as the layers of cement gel move closer together. After exposure to 400 °C, a major strength loss was observed for all concrete mixtures. They also found that the loss of strength under quick cooling in water was more significant than under slow cooling in water. This was due to the generation of microcracking caused by the difference in temperature between the inner and outer layers of concrete.

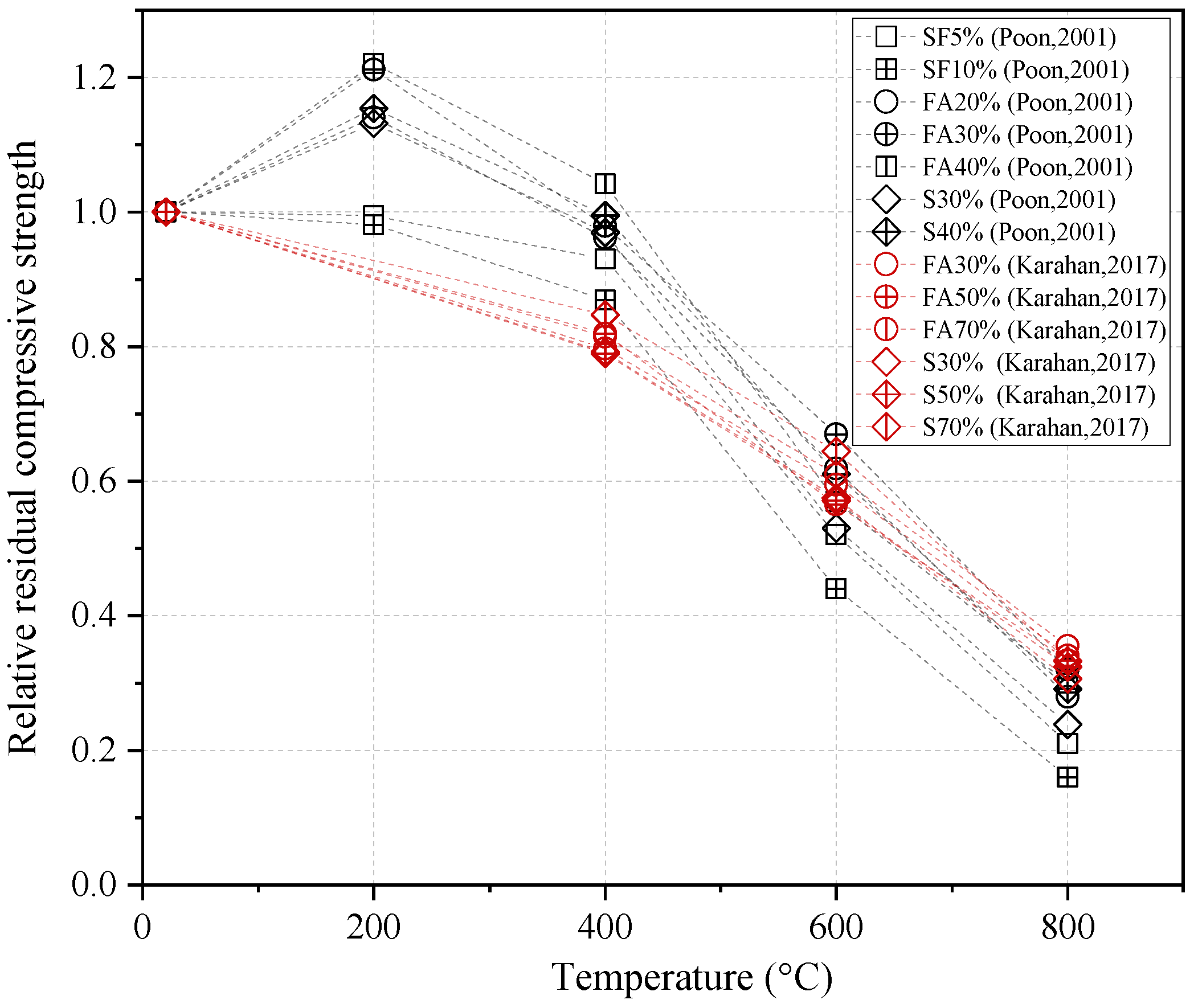

Poon et al. [

35] conducted a comprehensive study on different SCMs and investigated the strength of high-strength concrete (HSC) and normal-strength concrete (NSC) containing SF (5% and 10%), FA (20%, 30%, and 40%), and GGBFS (30% and 40%) exposed to temperatures up to 800 °C at 60 days. The strength of FA and GGBFS concrete increased up to 200 °C. Between 200 °C and 400 °C, high-strength concrete retained its initial strength, while a significant reduction was reported in the strength of NSC. However, both types of concrete lost their strength due to the reduction of Ca(OH)

2 in concrete at temperatures above 400 °C. It was also found that high-strength concrete exhibited higher relative residual strength compared to normal-strength concrete. Fly ash concrete showed the best performance in high-strength concrete, followed by GGBFS, OPC, and SF concrete, and the best performance in NCS was GGBFS, FA, and then OPC. In addition, the maximum relative residual strength was observed in concrete with a 30% FA replacement level in high-strength concrete after heating to high temperatures.

The results from several studies on the effect of high-temperature exposure on the behaviour of FA concrete up to 800 °C are depicted in

Figure 6. The residual compressive strength of FA concrete increases at around 200 °C due to the generation of tobermorite as a product of the lime and FA reaction, which is two to three times stronger than the CSH gel [

35]. However, at temperatures above 200 °C, the relative compressive strength decreases continuously. The further degradation of FA concrete with increasing temperature is because of the loss of bound water, increased porosity, and permeability. At the temperature of 800 °C, severe strength loss occurred because of the decomposition of CSH gel. Previous studies obtained contradictory results when determining the optimum percentage of FA in concrete exposed to high temperatures. However, concrete with FA greater than 30% replacement shows lower compressive strength than OPC concrete.

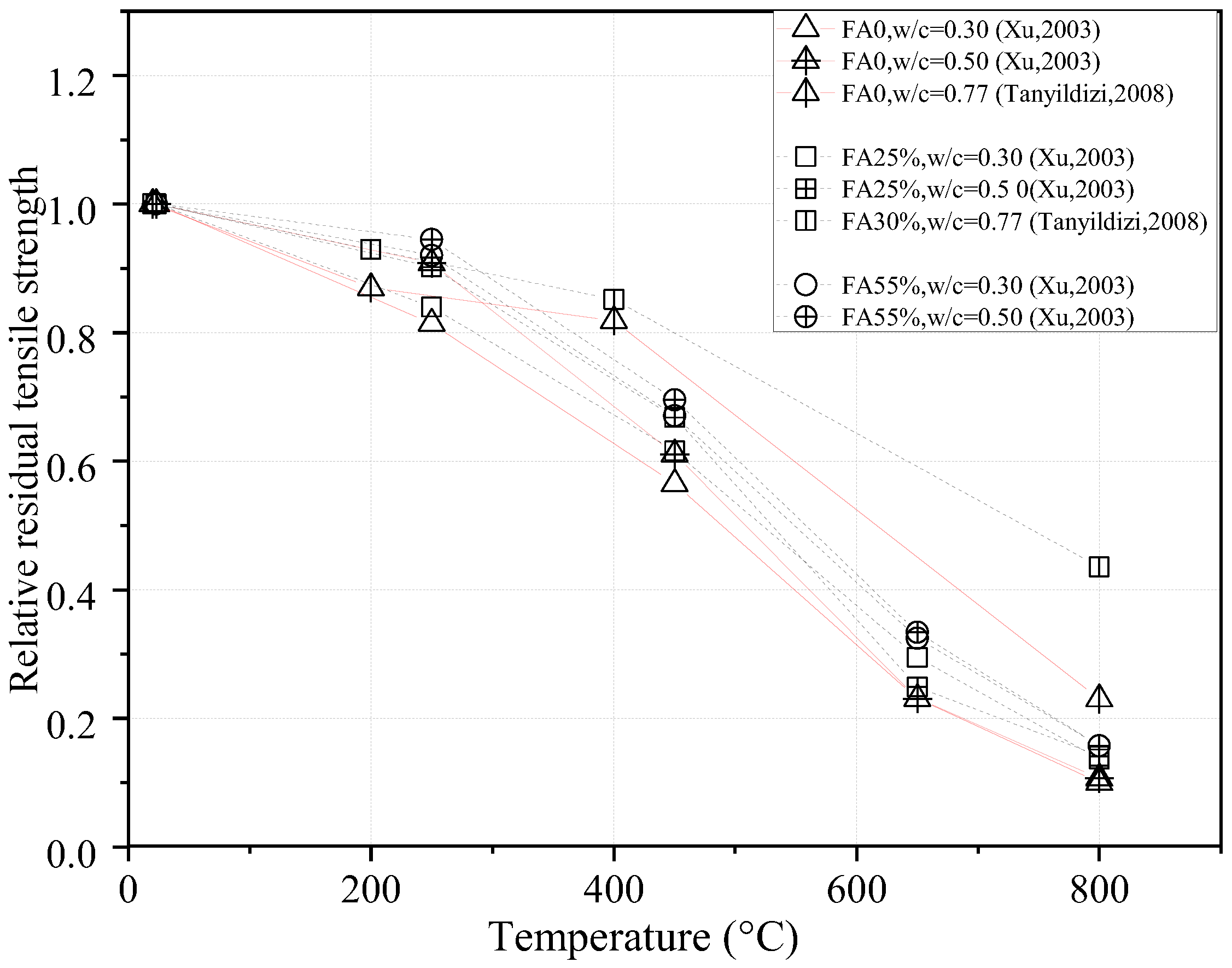

2.4.2. Splitting Tensile Strength

Xu et al. [

41] studied the influence of PFA on tensile strength, and the results revealed that at the temperature of 250 °C, minor cracks were observed in concrete and all the mixtures showed some losses in tensile strength as the temperature increased. However, PFA concrete showed improved performance.

Tanyildizi et al. [

43] studied the splitting tensile strength of lightweight concrete containing between 0% and 30% FA. The splitting tensile strength decreased after exposing the concrete to temperatures of 800 °C, mostly because of micro- and macro-cracks in lightweight structural concrete. It was found that a lower reduction in tensile strength occurred in lightweight FA concrete compared to the control concrete. The highest tensile strength was observed with 30% FA in the concrete specimens.

Khan et al. [

40] investigated the tensile strength of concrete with high-volume FA at replacement levels of 40%, 50%, and 60% exposed to 900 °C and below. The tensile strength of FA concrete increased up to 300 °C. However, above 300 °C, the splitting tensile strength decreased sharply. Moreover, it was found that increasing FA ash content resulted in a reduction in the tensile strength of concrete.

The influence of high temperatures on the splitting tensile strength of FA concrete is plotted in

Figure 7. The decline in the tensile strength of concrete with FA was nearly linear. However, compared to OPC concrete, concrete that contained fly ash exhibited a higher tensile strength.

2.4.3. Modulus of Elasticity

Nasser et al. [

44] examined the modulus of elasticity of concrete made with 25% FA exposed to 232 °C. It was observed that the modulus of elasticity remained constant in the temperature range of 121 °C to 149 °C. However, the modulus of elasticity decreased when the exposure temperature was 232 °C.

2.5. Effect of Slag at Room Temperature

A by-product of the blast furnace in steel manufacturing industries is blast-furnace slag [

65]. The mixture of limestone and iron ore is fed into blast furnaces and heated to a temperature of around 1500 °C, producing molten slag and iron [

66,

67]. The molten slag is quenched quickly in a pond or using powerful water jets, leading to the formation of the fine and glassy form known as granulated slag [

67]. Ground-granulated blast-furnace slag (GGBFS) is typically composed of CaO (30–50%), SiO

2 (28–38%), MgO (1–18%), and Al

2O

3 (8–24%) [

68]. Using ground-granulated blast-furnace slag in concrete has attracted considerable attention because it improves the properties of the concrete and decreases negative environmental effects [

45]. GGBFS with latent hydraulic properties is hydrated with calcium hydroxide and water. This secondary pozzolanic reaction results in a denser microstructure due to the consumption of Ca(OH)

2 coupled with the CSH formation in concrete [

28].

2.5.1. Compressive Strength

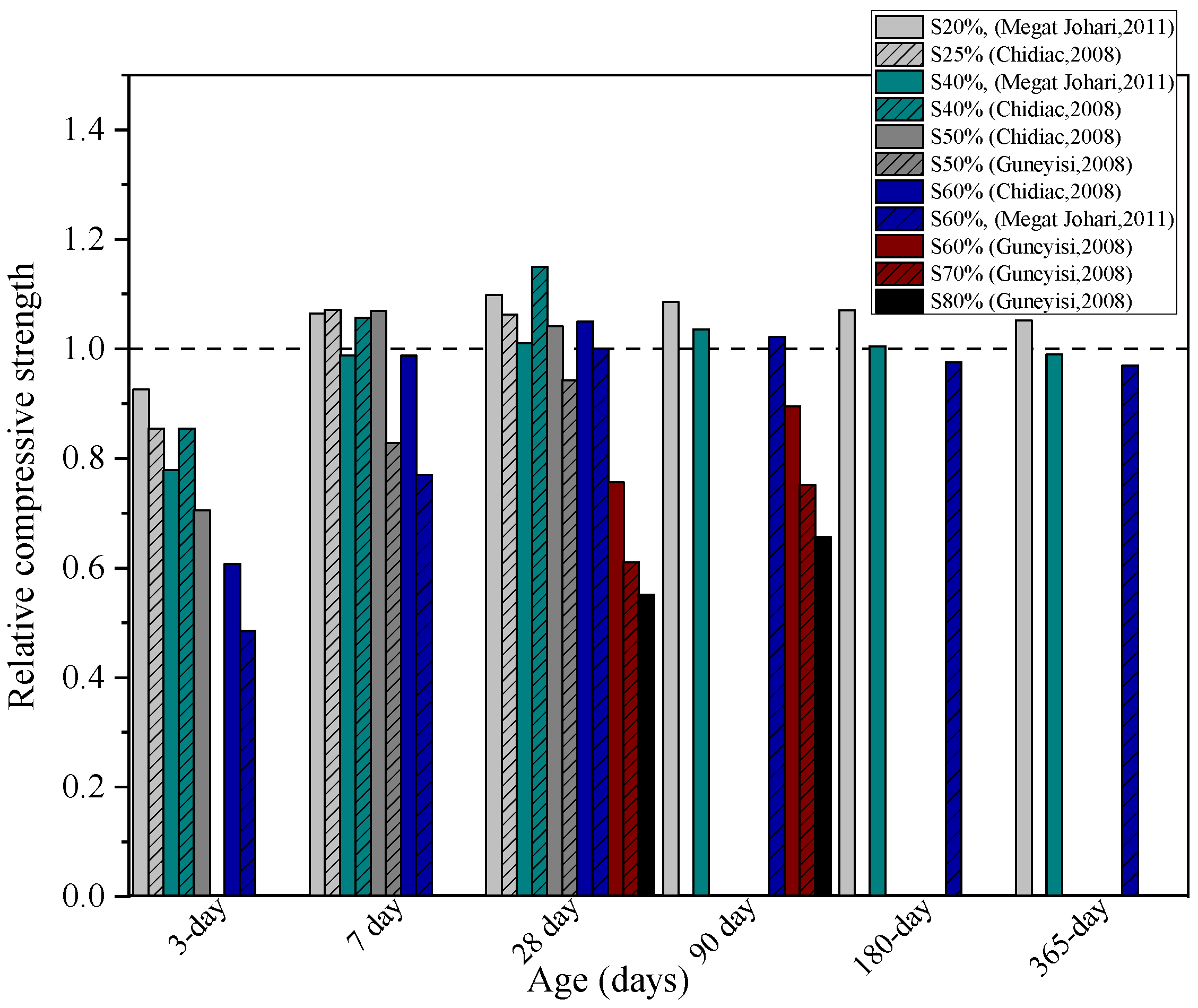

Chidiac et al. [

28] investigated the strength of concrete with GGBFS as the cement replacement (0%, 25%, 40%, 50%, and 60%) and two different w/b ratios (0.31 and 0.38) at 1, 3, 7, and 28 days at room temperature. The concrete with GGBFS displayed a lower strength at early ages than OPC due to the relatively slower initial hydration rate, while a higher strength was observed for GGBFS concrete between 7 and 28 days with the formation of a denser microstructure in concrete. The results also indicated that the strength of GGBFS concrete improved with increasing the w/b ratio because of a higher degree of hydration.

The properties of HSC made with 0%, 20%, 40%, and 60% GGBFS at the ages of 1, 3, 7, 14, 28, 90, 180, and 365 days were investigated by Megat Johari et al. [

26]. The incorporation of GGBFS in concrete decreased the initial-age strength of the concrete compared to OPC concrete, mainly at the higher replacement ratios. This was due to the slower GGBFS reactivity as well as the diluting effect since part of the cement was substituted by GGBFS. The strength of GGBFS concrete increased at advanced ages up to one year. However, the later-age strength of the HSC decreased gradually with the addition of GGBFS content, and a higher long-term strength was observed for the replacement ratio of 20% compared to 40% and 60% GGBFS.

Khatib et al. [

30] investigated the strength of concrete by replacing cement with different ratios of GGBFS between 0% and 80% up to 90 days of curing. Strength declined as the content of GGBFS increased at an early age. Between 28 and 90 days, concrete containing 40% and 60% GGBFS showed higher strength compared to concrete without GGBFS. A considerable strength loss of GGBFS concrete was observed at the replacement level of 80% at all ages. In another study, Güneyisi et al. [

29] examined the effects of different methods of curing (air and wet curing) on the characteristics of high-performance concrete made with high levels of (e.g., 0%, 50%, 60%, 70%, and 80%) cement with blast-furnace slag at the ages of 28 and 90 days. The results revealed that the strength of concrete reduced gradually with increasing the slag content, particularly in air-cured specimens. However, for concrete containing slag up to 60%, the strength increased at 90 days under wet curing conditions.

The relative compressive strength of GGBFS concrete with varying replacement ratios of GGBFS at different curing ages is presented in

Figure 8. It can be seen that the strength of the concrete containing GGBFS is highly affected by curing age. The inclusion of GGBFS in concrete decreases the relative compressive strength at early stages but increases the strength at later ages. The strength of GGBFS concrete increased compared to OPC concrete up to 90 days. This can be attributed to the pozzolanic reaction of GGBFS that occurs gradually over time [

69]. Moreover, the relative strength of the GGBFS concrete is inversely proportional to the GGBFS content at a replacement ratio greater than 40%. This can be explained by the dilution effect caused by replacing higher amounts of GGBFS, resulting in a higher amount of silica ready to react with alkali, which leads to the alkali–silica reaction [

70]. However, there is little difference in the long-term strength of concrete containing 20%, 40%, and 60% slag substitution.

2.5.2. Splitting Tensile Strength

Güneyisi et al. [

29] evaluated the splitting strength of HPC with 50–80% slag replacement at the ages of 28 and 90 days using two types of curing: air and wet curing. They observed that the tensile strength decreased with the augmentation of slag content except for concrete specimens with 50% and 60% slag exposed to wet curing conditions at 90 days.

Aldea et al. [

31] examined the effect of replacing cement with 25%, 50%, and 75% slag on the splitting tensile strength in comparison to a concrete mix without slag at two types of curing: steam curing and normal curing. The results demonstrated that the tensile strength improved for 25% and 50% slag replacement in concrete compared to the concrete without slag. In addition, it was found that cement replacement with a higher content of slag (i.e., 75% slag) decreased the tensile strength of concrete regardless of the type of curing. The reduction in tensile strength of concrete containing a higher slag content is caused by alkali–silica reactivity, causing expansion and cracks in the concrete [

69].

2.5.3. Modulus of Elasticity

Siddique et al. [

32] observed that the modulus of elasticity of concrete made with GGBFS (0%, 20%, 40%, and 60%) was lower than the OPC concrete at room temperature. Concrete containing 20%, 40%, and 60% GGBFS had the modulus of elasticity values that were 22.5%, 39.98%, and 41.7% less than control concrete, respectively. Furthermore, the results revealed that the increase in GGBFS content reduced the modulus of elasticity at room temperature for 28 days.

Swamy et al. [

33] studied the modulus of elasticity of concrete specimens prepared with 50% and 65% slag under air and wet curing conditions. It was found that there is a slight difference in the modulus of elasticity of slag concrete and OPC concrete when the concrete is exposed to wet curing conditions. Nevertheless, a considerable reduction in the elastic modulus was observed under air curing.

Khatib et al. [

30] examined the modulus of elasticity of GGBFS concrete up to 90 days of curing. The results revealed that the modulus of elasticity decreased up to 28 days. However, above 28 days, the modulus of elasticity of concrete with 40% and 60% GGBFS increased slightly. It was also found that, compared with the differences in compressive strength, there are little differences in the modulus of elasticity values for all concrete mixtures.

2.6. Effect of Slag at High Temperature

2.6.1. Compressive Strength

Siddique et al. [

32] studied concrete with 0%, 20%, 40%, and 60% GGBFS when subjected to temperatures up to 350 °C. At 100 °C, the strength of concrete containing 0% and 20% GGBFS was reduced. Then, the strength increased with increasing temperature. However, no significant change occurred in the residual strength for the GGBFS concrete at replacement ratios of 40% and 50% with the increase in this temperature. It was also found that the strength decreased as the GGBFS replacement ratio increased at 350 °C.

Shumuye et al. [

46] investigated the strength of concrete containing 30%, 50%, and 70% GGBFS when exposed to 200–800 °C. The strength of concrete with 30% and 50% slag replacement decreased at 200 °C and then increased at 400 °C. However, after heating to 400 °C, the strength continuously decreased for all specimens. The most rapid strength loss was observed for concrete made with 70% slag. However, concrete with 30% slag exhibited better performance in comparison to the other concrete mixes.

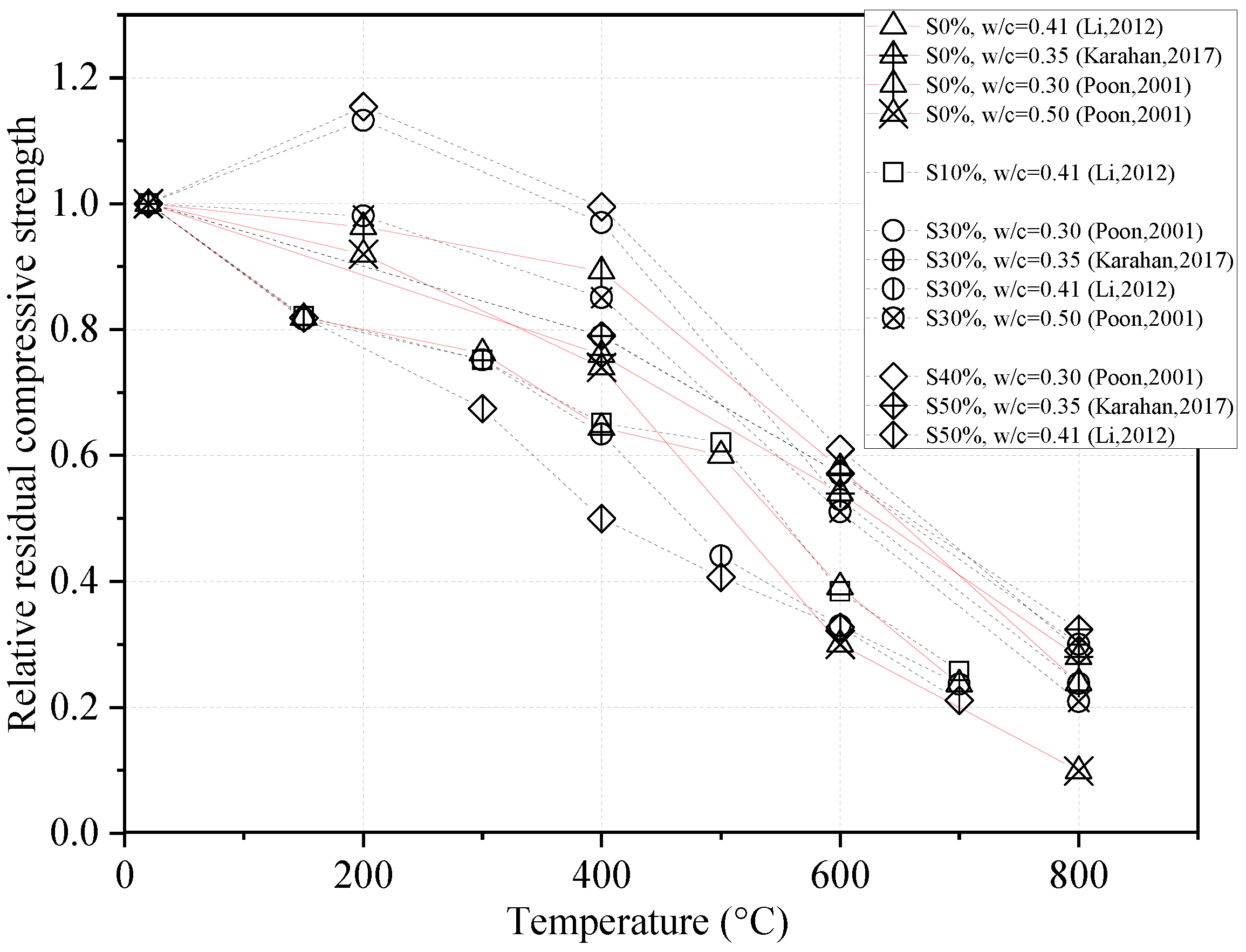

Li et al. [

45] examined the properties of concrete incorporating GGBFS after exposure to 700 °C and below. The cement was replaced with three percentages of 0%, 10%, 30%, and 50% of GGBFS. The strength decreased with the temperature rise from 150 °C to 700 °C. The obtained amount of relative strength with 10% GGBFS replacement was similar to OPC concrete. However, concrete containing 30% and 50% GGBFS exhibited lower remaining strength at temperatures between 300 °C and 700 °C.

Karahan [

39] studied the strength of concrete prepared with the replacement of cement with 0%, 30%, 50%, 70%, and 90% GGBFS exposed to 200 °C, 400 °C, and 800 °C. The results showed that the strength declined with increasing temperatures for all concrete mixtures. The concrete containing slag up to 70% showed lower or similar strength compared to the control mix. It was also observed that the optimum amount of slag as a cement replacement was 50–70%. In the study carried out by Poon et al. [

35] on GGBFS concrete, the maximum relative residual strength was observed in concrete with 40% slag replacement after exposure to high temperatures. The relative residual strength of concrete containing slag at high temperatures reported by multiple researchers is illustrated

Figure 9. It can be seen above that 50% of the initial compressive strength at room temperature was retained up to 400 °C, and the relative compressive strength significantly decreased beyond this temperature. The results indicate that the slag concrete exhibited residual strength close to or higher than the OPC concrete below 400 °C. However, the optimum content of slag as cement replacement has been reported inconsistently by different researchers [

35,

39,

46].

2.6.2. Splitting Tensile Strength

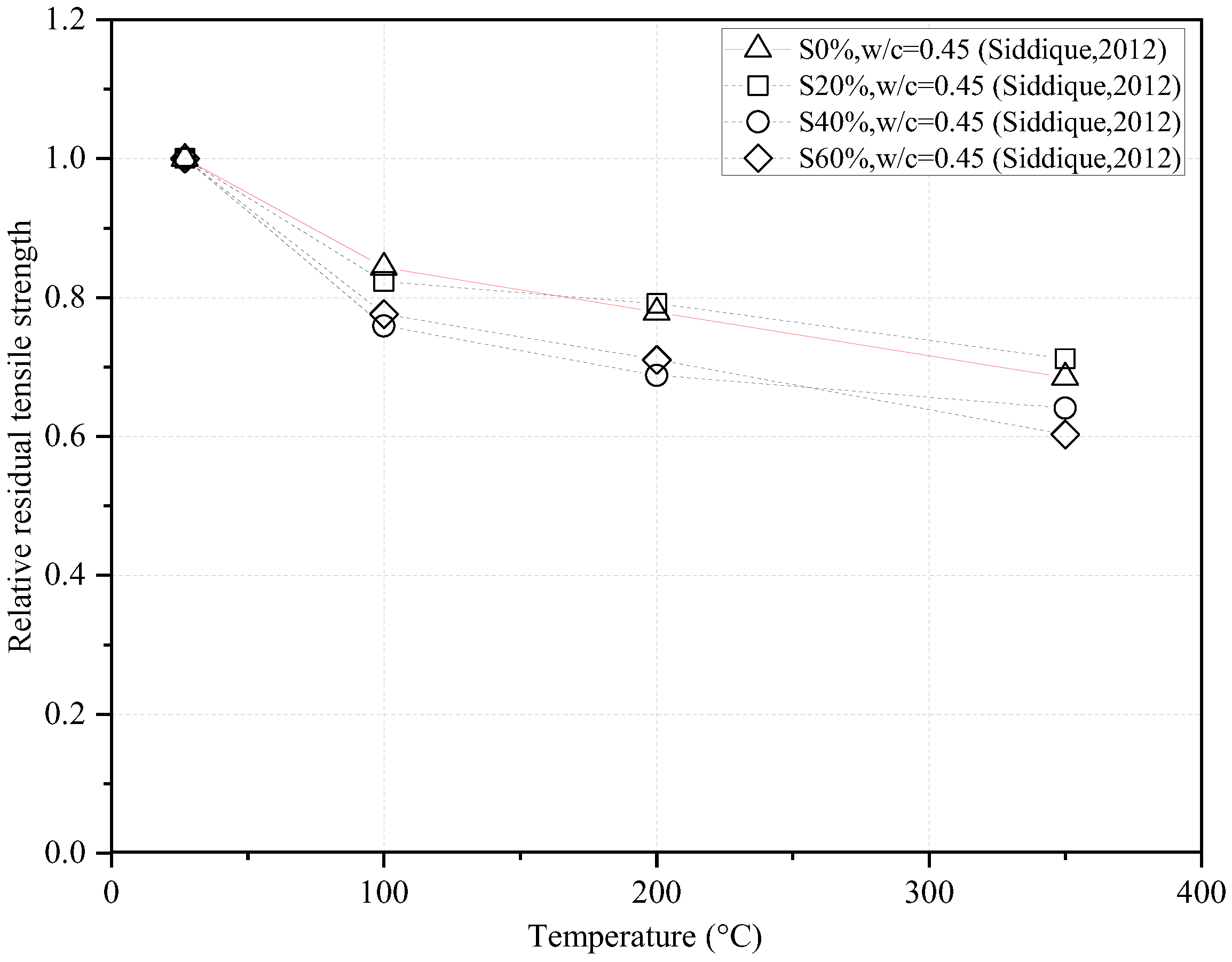

This literature review demonstrated that limited research had been carried out to study the tensile strength of slag concrete. Siddique et al. [

32] evaluated the influence of GGBFS on the splitting tensile strength of concrete at high temperatures up to 350 °C. It was observed that the splitting tensile strength decreased as the temperature was raised from 100 °C to 350 °C for all replacement levels of GGBFS. They also reported that there is a very pronounced loss in splitting tensile strength, which contrasts with the gradual decline in compressive strength. This was because tensile strength was more susceptible to micro- and macro-cracks induced by high temperatures. The results of this study are presented in

Figure 10.

2.6.3. Modulus of Elasticity

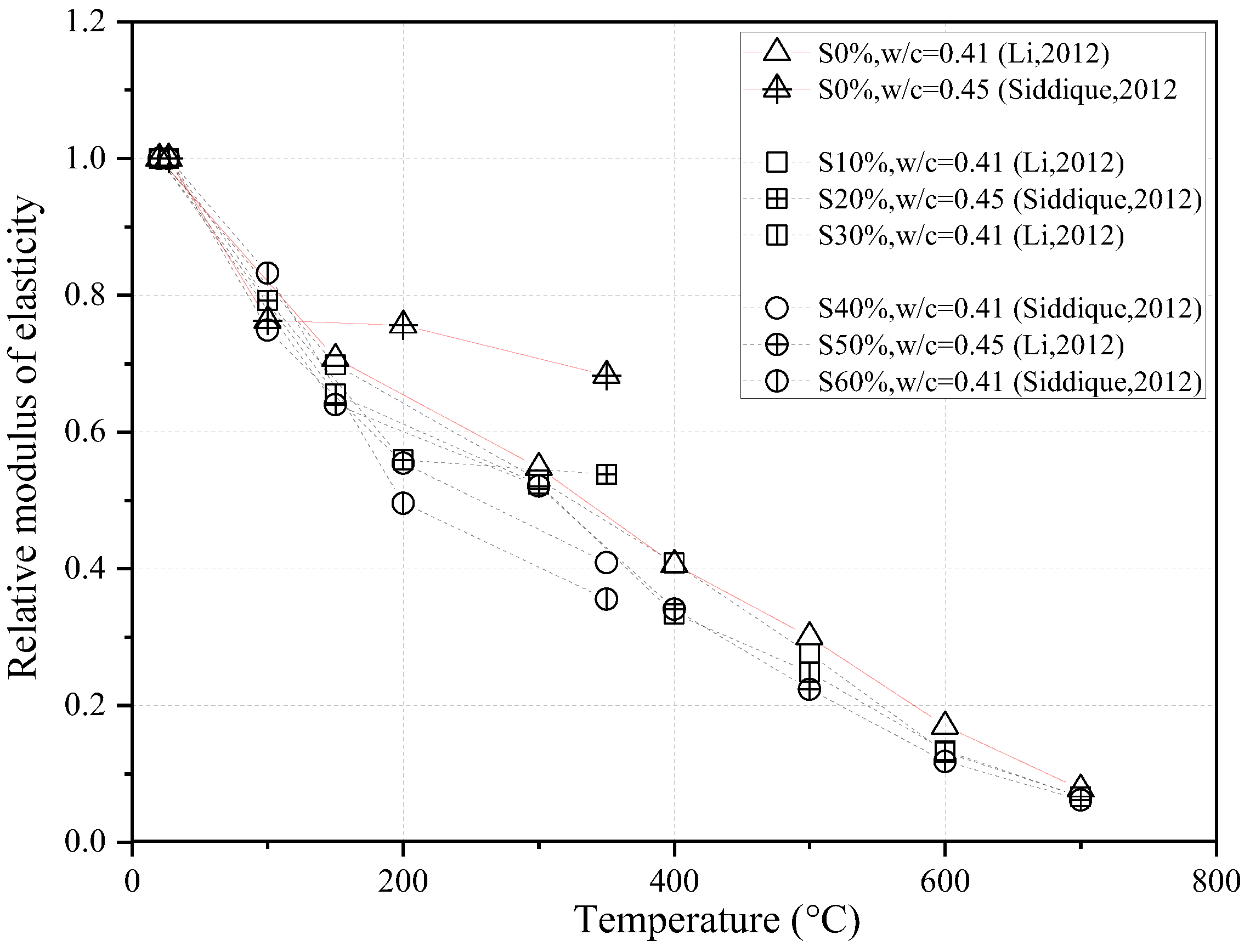

Li et al. [

45] studied the properties of GGBFS concrete with replacement levels of 10%, 30%, and 50% at temperatures up to 700 °C. The results indicated that when concrete was exposed to elevated temperatures, the modulus of elasticity decreased with increasing GGBFS content. Siddique et al. [

32] examined the modulus of elasticity of concrete with 0%, 20%, 40%, and 60% GGBFS at temperatures up to 350 °C at the ages of 28 and 56 days. At 28 days, the modulus of elasticity of concrete decreased as the exposure temperature increased for all GGBFS replacement levels. Furthermore, it was observed that the modulus elasticity of GGBFS concrete is lower than control concrete at all temperatures. Test results at 56 days demonstrated a similar trend. The variation in the modulus of elasticity as a function of temperature for slag-contained concrete is illustrated in

Figure 11.

3. Concrete Aggregates and High Temperatures

Aggregates make up 60–75% of the volume of concrete. Therefore, the aggregate has a critical role in concrete behaviour at room and high temperatures. The coarse aggregate used in concrete can be classified into three groups according to its chemical composition and mineralogical nature: siliceous (Si) aggregate (e.g., quartzite, sandstone, and granite), calcareous (Ca) aggregate (e.g., limestone, dolomite, basalt, and diabase), and lightweight aggregate (LWA) (e.g., diatomite, pumice, scoria, clay ash, slate, perlite, and shale). The mechanical properties of concrete with three different types of aggregates at high temperatures are investigated in the following sections.

Table 3 summarizes the effects of aggregate type on the mechanical properties of concrete after exposure to high temperatures.

3.1. Effect of Calcareous and Siliceous Aggregate at High Temperature

3.1.1. Compressive Strength

Arioz et al. [

4] examined the influence of high temperatures on the strength of four concrete mixes prepared with two aggregate types (river gravel aggregate and limestone aggregate) and three water-to-cement ratios (w/c) ratios of 0.4, 0.5, and 0.6. The relative strength of concrete reduced as high temperatures increased between 200 °C and 1200 °C. It was found that the strength loss was more significant for concrete with siliceous river gravel aggregate than crushed limestone aggregate. The relative strength of river gravel concrete decreased gradually but substantially as temperature increased. In the limestone concrete mixture, relative strength was slightly reduced up to 600 °C. However, the relative strength sharply decreased at temperatures above 600 °C.

Savva et al. [

71] studied the residual compressive strength of concrete containing different pozzolans, two lignite fly ashes, and one natural pozzolan as cement replacements when concrete was subjected to 100 °C, 300 °C, 600 °C, and 750 °C. Two series of concrete specimens were made with limestone and siliceous aggregate. An increase in the strength of siliceous concrete was observed. This can be attributed to the higher cement–aggregate bond in siliceous aggregate concrete observed at 300 °C. Between 300 °C and 600 °C, strength decreased in both aggregate types, which was more significant for siliceous concrete. At temperatures above 600 °C, strength deterioration was observed in all concrete mixtures. However, limestone concrete showed a slightly higher strength reduction due to the decarbonization of limestone at these temperatures.

Tufail et al. [

72] investigated the mechanical properties of three different concrete mixtures with granite, quartzite, and limestone aggregates exposed to high temperatures up to 650 °C and below. Granite concrete showed the lowest strength loss value, followed by quartzite and limestone concrete. This was due to the high temperature-induced partial decomposition of calcite and inner fractures and cracks of mineral particles in limestone aggregates. In contrast, Masood et al. [

73] found that concrete containing quartzite aggregate exhibited higher residual strength than granite and basalt at temperatures ranging from 200 °C to 600 °C.

Xing et al. [

74] evaluated the influence of the three types of aggregate (calcareous, siliceous, and semi-crushed silico-calcareous) on the mechanical properties of normal strength and high-performance concrete at 150 °C, 300 °C, 450 °C, 600 °C, and 750 °C. Similar behaviour was observed for normal concrete with the three different aggregate types up to 300 °C. After heating to 300 °C, normal-strength concrete with the calcareous aggregate presented a lower strength loss compared to normal-strength concrete with silico-calcareous and siliceous aggregates. This finding is partially adapted to the Eurocode [

80] predictions. Nevertheless, high-performance siliceous aggregate concrete exhibited better performance than the other aggregate types, which was inconsistent with that predicted in the Eurocode.

Contrary to the studies discussed above, Santos et al. [

75] carried out an experimental study on the mechanical properties of two types of concrete with calcareous and granite aggregates under two loading levels (0.3 fʹ

c and 0.7 fʹ

c) and different cooling methods (cooling in air and water jet) exposed to 300 °C, 500 °C, and 800 °C. For the loading level of 0.3 fʹ

c, the strength of calcareous-aggregate concrete decreased significantly in comparison to granite-aggregate concrete, regardless of the cooling process. A similar trend was found for 0.7 fʹ

c with loading conditions up to 300 °C. However, above 300 °C, calcareous-aggregate concrete exhibited higher strength than granite-aggregate concrete. Furthermore, for both types of concrete, cooling by water jet induced a greater reduction in strength at temperatures between 20 °C and 800 °C.

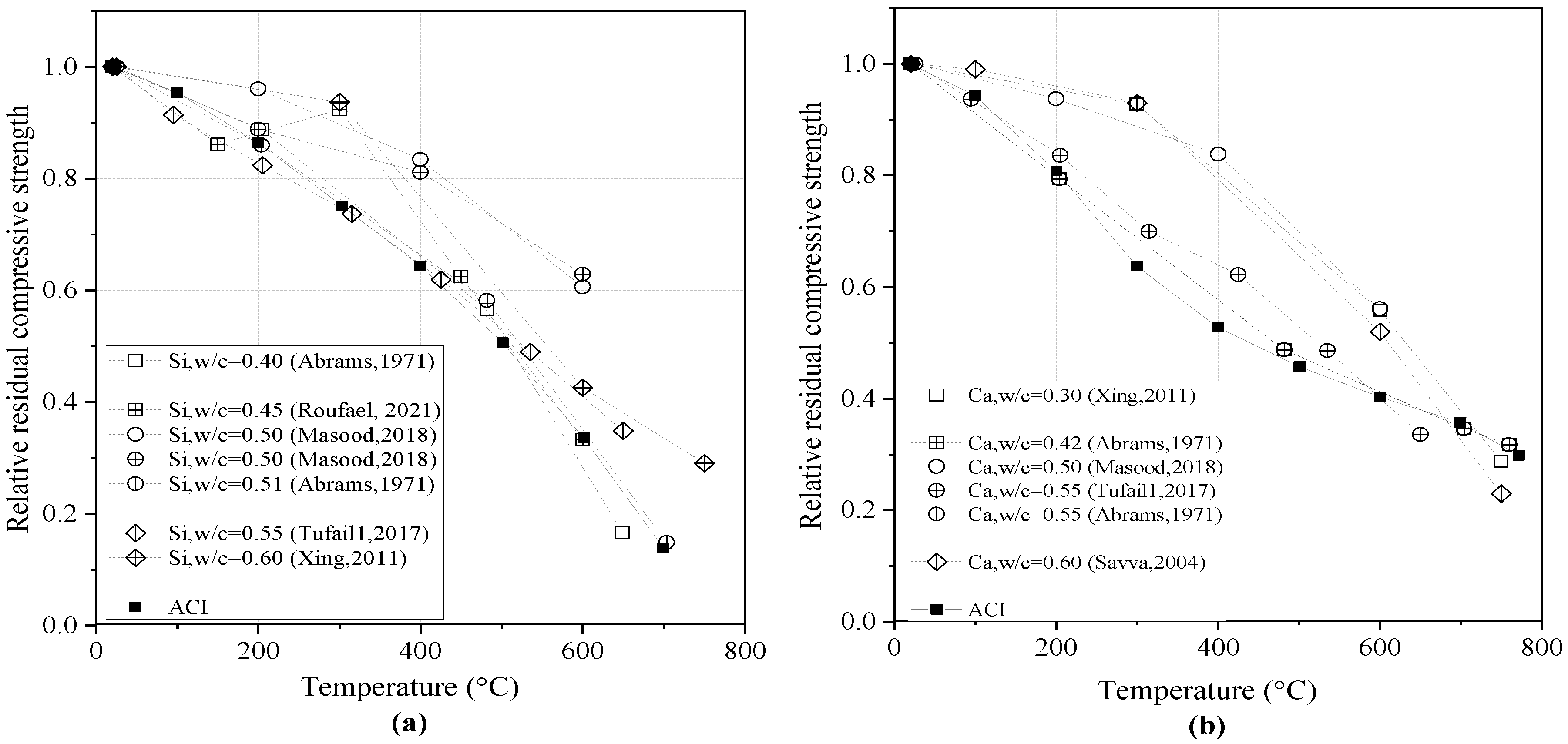

The residual strength curves of siliceous- and calcareous-aggregate concrete are shown with ACI 216.1 [

81] curves in

Figure 12. Overall, there seems to be a close agreement between the curves, particularly beyond 400 °C. The ACI 216.1 [

81] curves provide a conservative lower bound for the residual strength of concrete. Contrary to the Eurocode [

82], the findings of some research in the literature indicated that the performance of siliceous aggregate is slightly better than calcareous concrete. It can be seen in

Figure 12a,b that siliceous concrete performed better than calcareous concrete up to 500 °C. However, above this temperature, the degradation of residual strength of calcareous concrete becomes slower than siliceous concrete. It is worth noting that the Eurocode curves are produced from transient and steady-state tests and are not presented in

Figure 12.

3.1.2. Splitting Tensile Strength

Santos et al. [

75] studied the tensile strength of granite-aggregate concrete and calcareous-aggregate concrete with different cooling approaches, including in the air and with a water jet. It was found that both granite-aggregate concrete and calcareous aggregate showed similar behaviour up to 300 °C. However, above 300 °C, granite-aggregate concrete displayed lower residual splitting tensile strength compared to calcareous concrete.

Xing et al. [

74] indicated that the concrete with calcareous aggregates showed better residual tensile strength than silico-calcareous and siliceous aggregates up to 600 °C. However, due to the dissociation of calcium carbonate, the reduction in tensile strength of calcareous aggregates became more considerable at temperatures above 600 °C.

Tufail et al. [

72] investigated the tensile strength of three concrete mixes containing limestone, quartzite, and granite aggregates up to 650 °C. It was found that the tensile strength reduced as the exposure temperature increased. The granite-aggregate concrete showed the highest tensile strength at all temperatures compared to the two other concrete mixes.

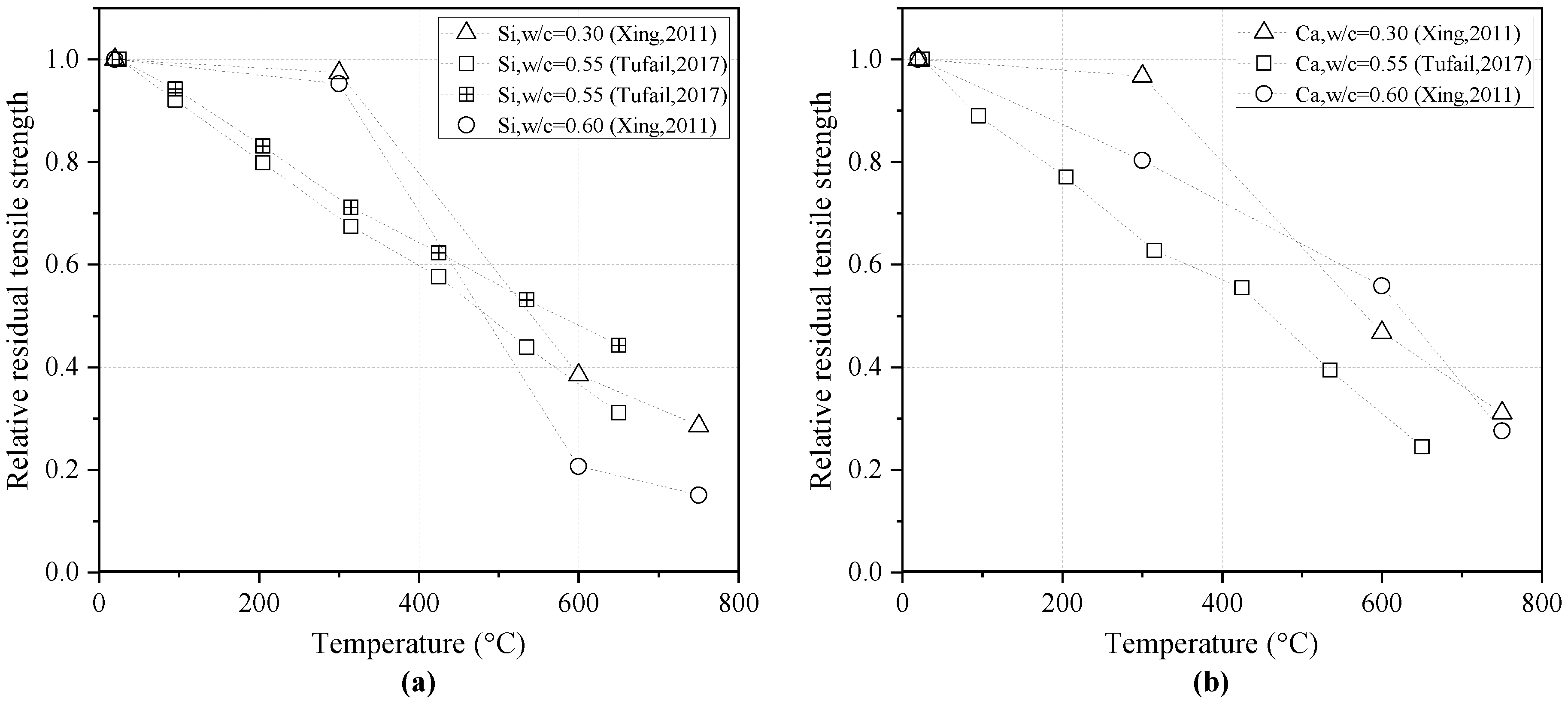

The residual tensile strength of siliceous and calcareous concrete is presented in

Figure 13. The degradation in splitting tensile strength at high temperatures seems quite linear despite the results captured at 300 °C by Xing et al. [

74]. Tufail et al. [

72] tested specimens with closer temperature intervals and verified a continuous degradation in splitting strength at high temperatures. While the results of Xing et al. [

74] show better performance of concrete with calcareous aggregate, the results of Tufail et al. [

72] showed quite similar tensile strength behaviour at high temperatures for both aggregate types.

3.1.3. Modulus of Elasticity

Santos et al. [

75] observed that the reduction in the residual modulus of elasticity was similar for calcareous and granite concrete up to 400 °C. However, above 400 °C, a greater reduction was observed for granite concrete compared to calcareous concrete. The results also indicated that cooling methods have no notable effects on the residual modulus of elasticity of both calcareous and granite concrete.

Savva et al. [

71] examined the modulus of elasticity of limestone and siliceous concrete after exposure to 300 °C to 750 °C. The modulus of elasticity continuously decreased for both aggregate types. However, the results indicated that this reduction was more substantial for limestone concrete.

Cheng et al. [

76] examined the modulus of elasticity of two types of high-strength concrete prepared with carbonate and siliceous aggregate at high temperatures of up to 800 °C. It was noticed that the modulus of elasticity decreased with increasing temperature. It was also found that the type of aggregate has a moderate influence on reducing the modulus of elasticity.

3.2. Effect of Lightweight Aggregate at High Temperature

3.2.1. Compressive Strength

Hossain et al. [

77] evaluated the residual compressive strength of lightweight volcanic pumice concrete (VPC) compared to normal-weight concrete (NWC) with gravel aggregate up to 800 °C for different heating durations of 0, 0.5, 1, and 2 h. As the temperature increased, the results indicated that the residual strength was reduced in lightweight and normal-weight concrete. However, lower strength loss was observed in VPC compared to NWC at a constant temperature for different durations or constant duration at different temperatures. This was due to the less dense pore structure in VPC in comparison to that in NWC. The denser pore structure in NWC results in water vapour buildup, leading to thermal crack formation, thus causing higher strength reductions at high temperatures compared to VPC.

Abrams [

78] investigated the residual strength of three types of concrete made with carbonate, siliceous, and lightweight aggregates after being subjected to nearly 660 °C. The results indicated that lightweight-aggregate and carbonate-aggregate concrete exhibited similar behaviour with higher strength retention than siliceous-aggregate concrete. Moreover, the original strength of concrete did not significantly affect its residual strength at high temperatures.

Roufael et al. [

79] examined three different types of lightweight-aggregate concrete in comparison to normal-weight concrete at temperatures up to 600 °C. It was observed that a slight reduction occurred in residual strength at 150 °C, and then an increase was observed at 300 °C for all mixtures. However, the strength decreased sharply for all concrete mixtures above this temperature. The lightweight-aggregate concrete showed moderate strength loss compared to normal-weight concrete. This can be attributed to the more resistant paste–aggregate bond with porous lightweight aggregates and better thermal deformation compatibility between the lightweight aggregate and the cementitious matrix. This better paste–aggregate bond was due to the paste penetration into the aggregate, causing interlocking sites.

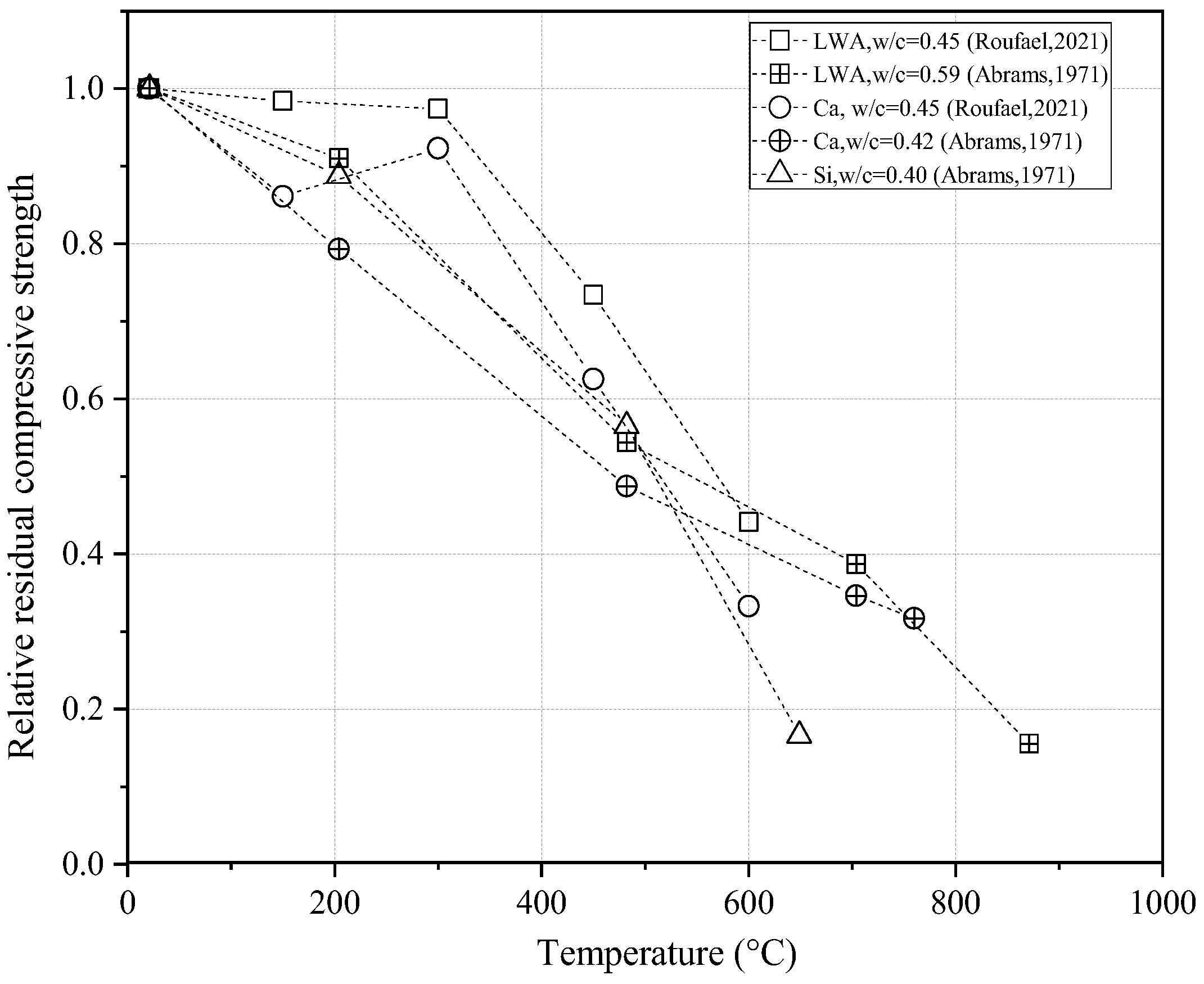

The effect of different aggregates on the residual strength of concrete at high temperatures is plotted

Figure 14. The strength degradation is less in lightweight concrete than in calcareous and siliceous concrete. This can be explained by the porous structure of LWA, which allows excess pressure induced by water evaporation to be relieved faster, resulting in less crack formation [

83].

3.2.2. Splitting Tensile Strength

Roufael [

79] observed that the lightweight-aggregate concrete showed a lower reduction in tensile strength with temperature increase compared to normal-weight-calcareous concrete. Tensile strength loss was due to the aggregate expansion, the dehydration of the cement, and the portlandite decomposition, which resulted in weak ITZ at higher temperatures.

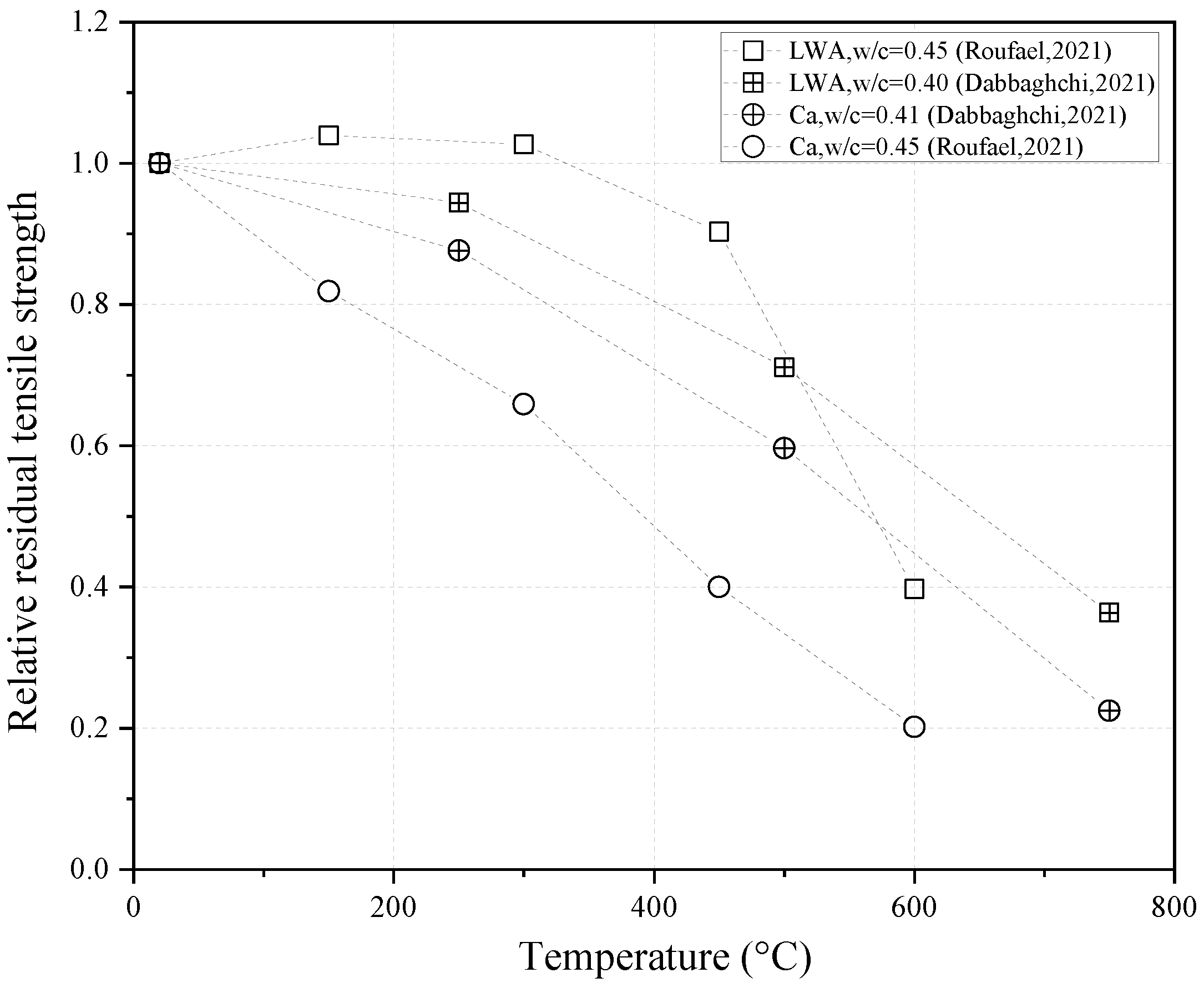

Dabbaghi et al. [

83] studied the residual tensile strength of concrete containing expanded clay compared to calcareous-aggregate concrete when exposed to high temperatures up to 750 °C. They observed that the LWC demonstrated better strength retention due to the generation of fewer cracks induced by thermal stress. The residual tensile strength of concrete containing lightweight aggregate and calcareous aggregate is shown in

Figure 15.

3.2.3. Modulus of Elasticity

Roufael et al. [

79] examined the modulus of elasticity of LWC exposed to 600 °C compared to NWC made with calcareous aggregate. The lightweight-aggregate concrete displayed a lower elastic modulus reduction than normal-weight-calcareous concrete, particularly between 150 °C and 450 °C. It was also found that, contrary to tensile and compressive strength, the modulus of elasticity decreased more linearly at high temperatures.

5. Conclusions

This study provides a review of the residual mechanical properties of concrete after exposure to high temperatures. The effects of supplementary cementitious materials (SCMs), including silica fume (SF), fly ash (FA), and slag (S), as well as different types of aggregates (siliceous, calcareous, and lightweight aggregate) on the mechanical properties of concrete, were discussed at ambient and high temperatures. The following conclusions are presented: