Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations

Abstract

:1. Introduction

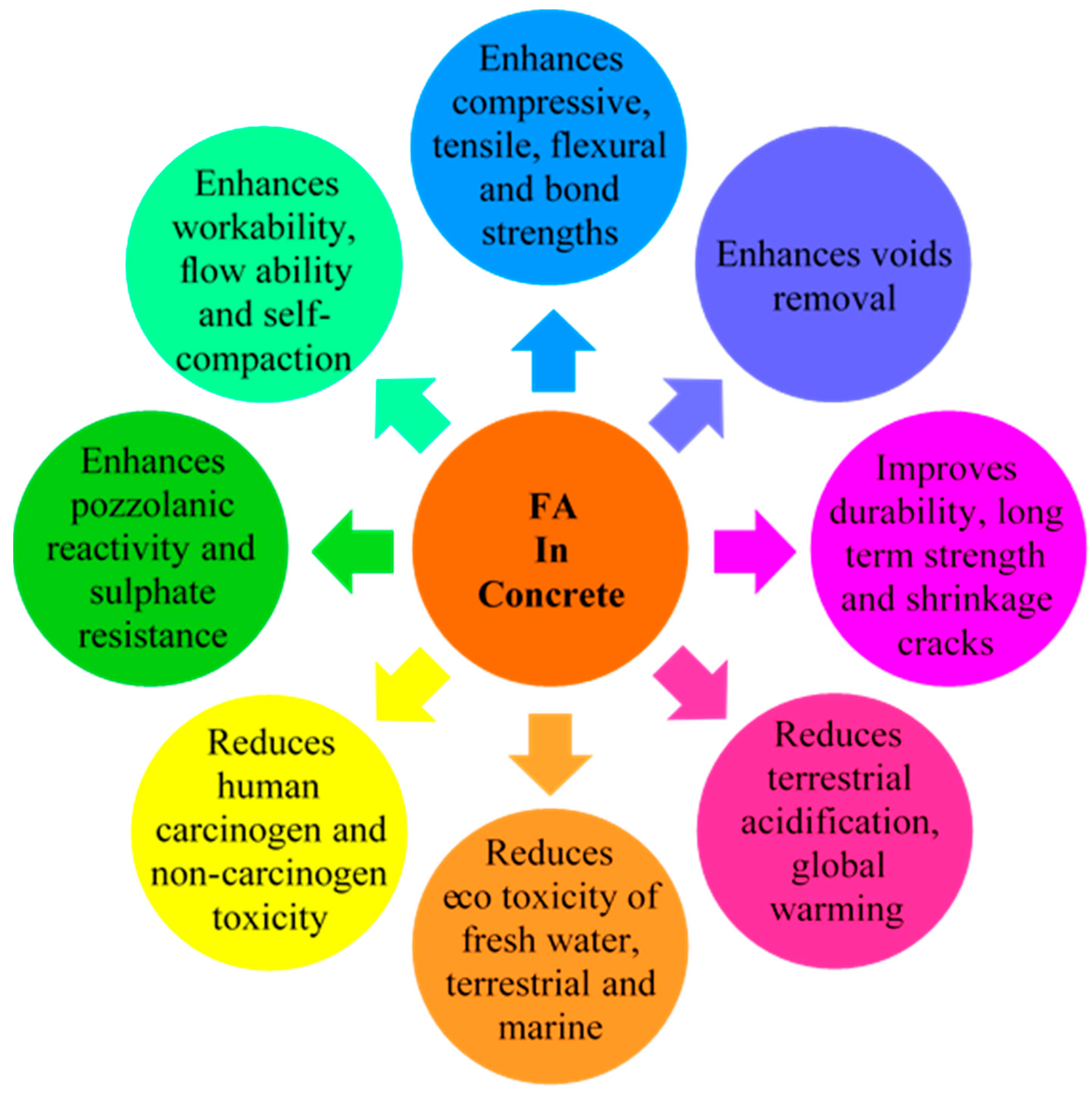

1.1. Fly Ash

1.2. Optimization Method

1.3. Environmental Evaluation

1.4. Research Significance

2. Research Methodology

2.1. Data Collection

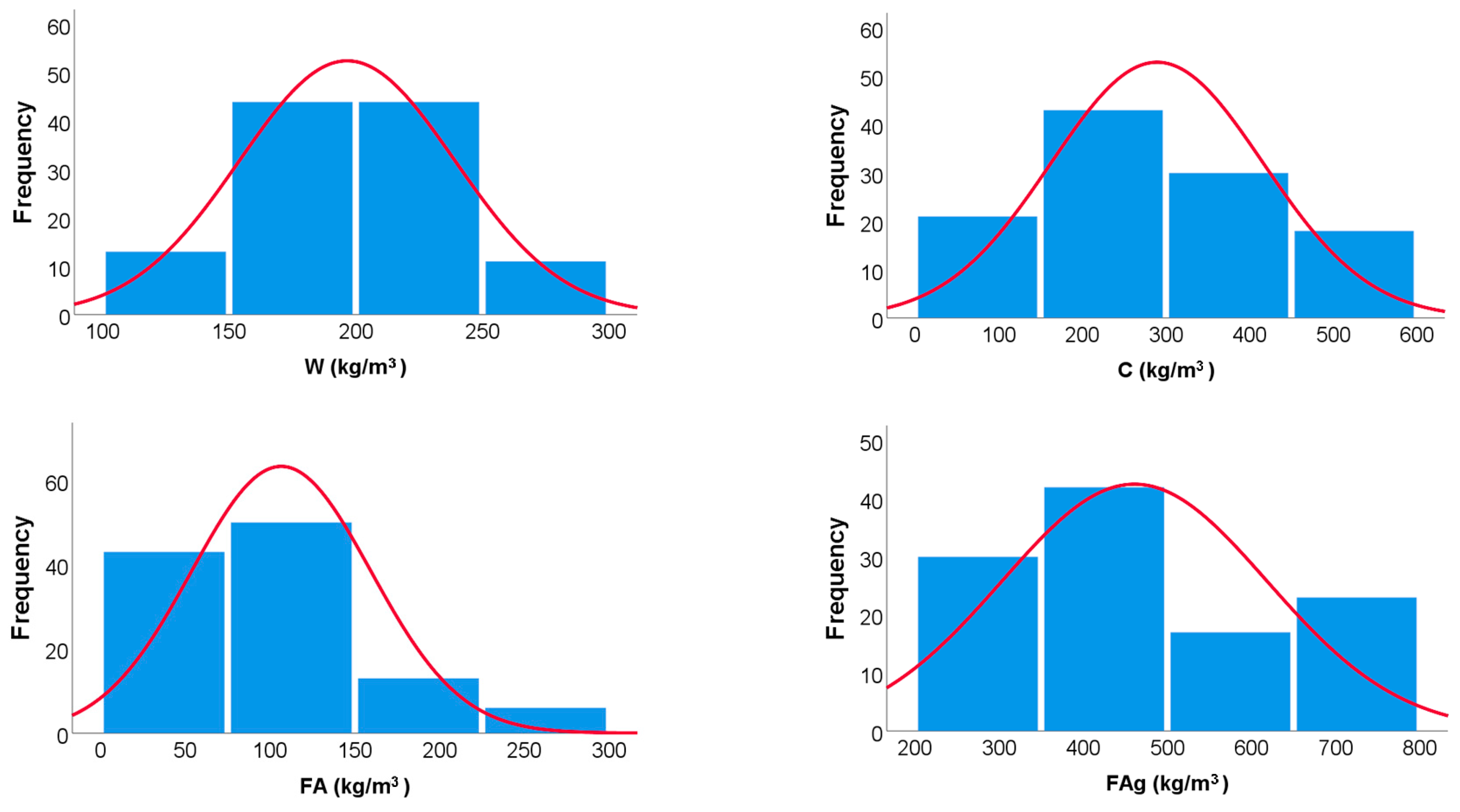

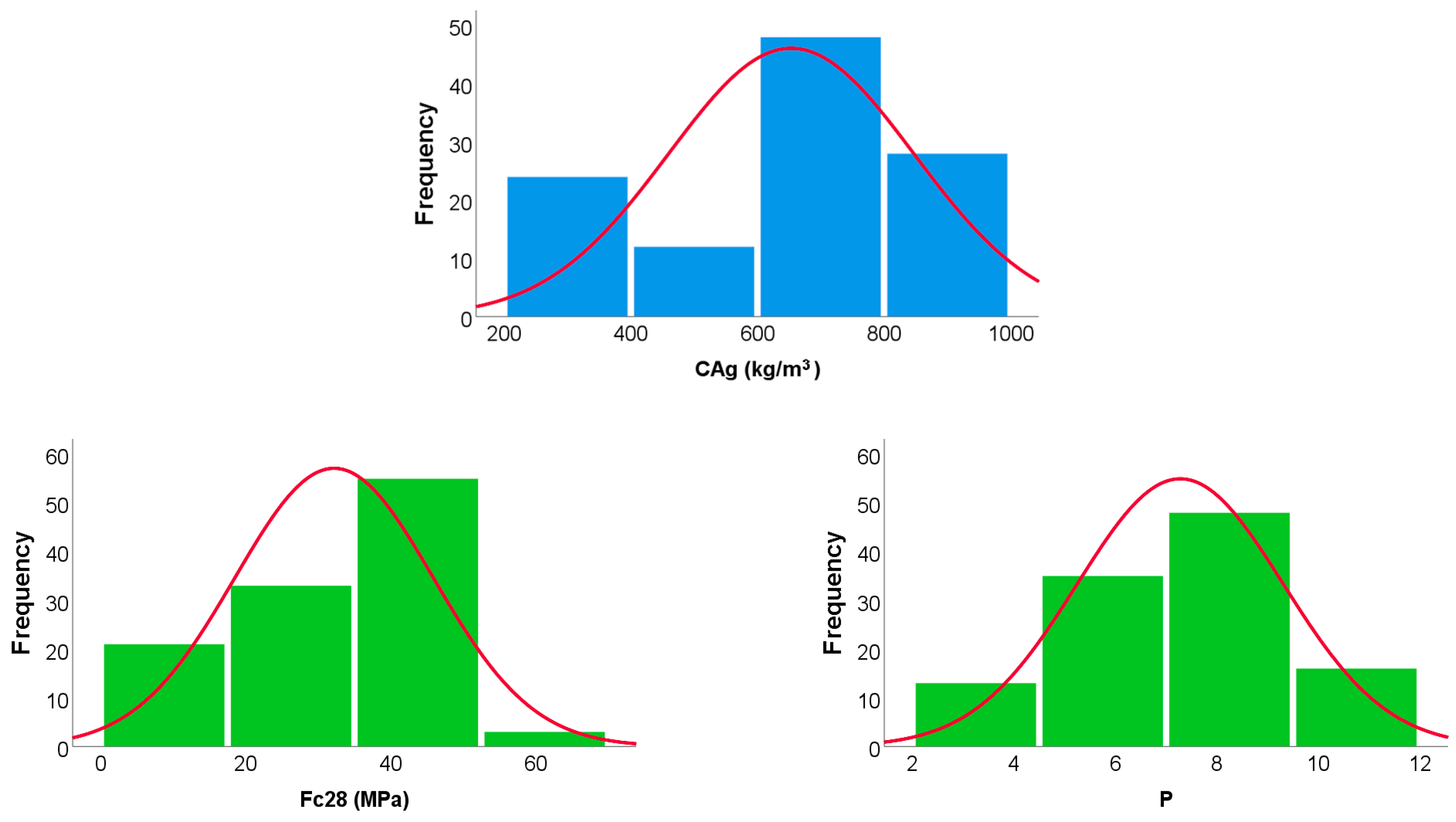

2.2. Collected Database and Statistical Analysis

2.3. Research Program and Modelling Plan

2.3.1. Genetic Algorithm (GA)

2.3.2. Genetic Programming (GP)

2.3.3. Evolutionary Polynomial Regression (EPR)

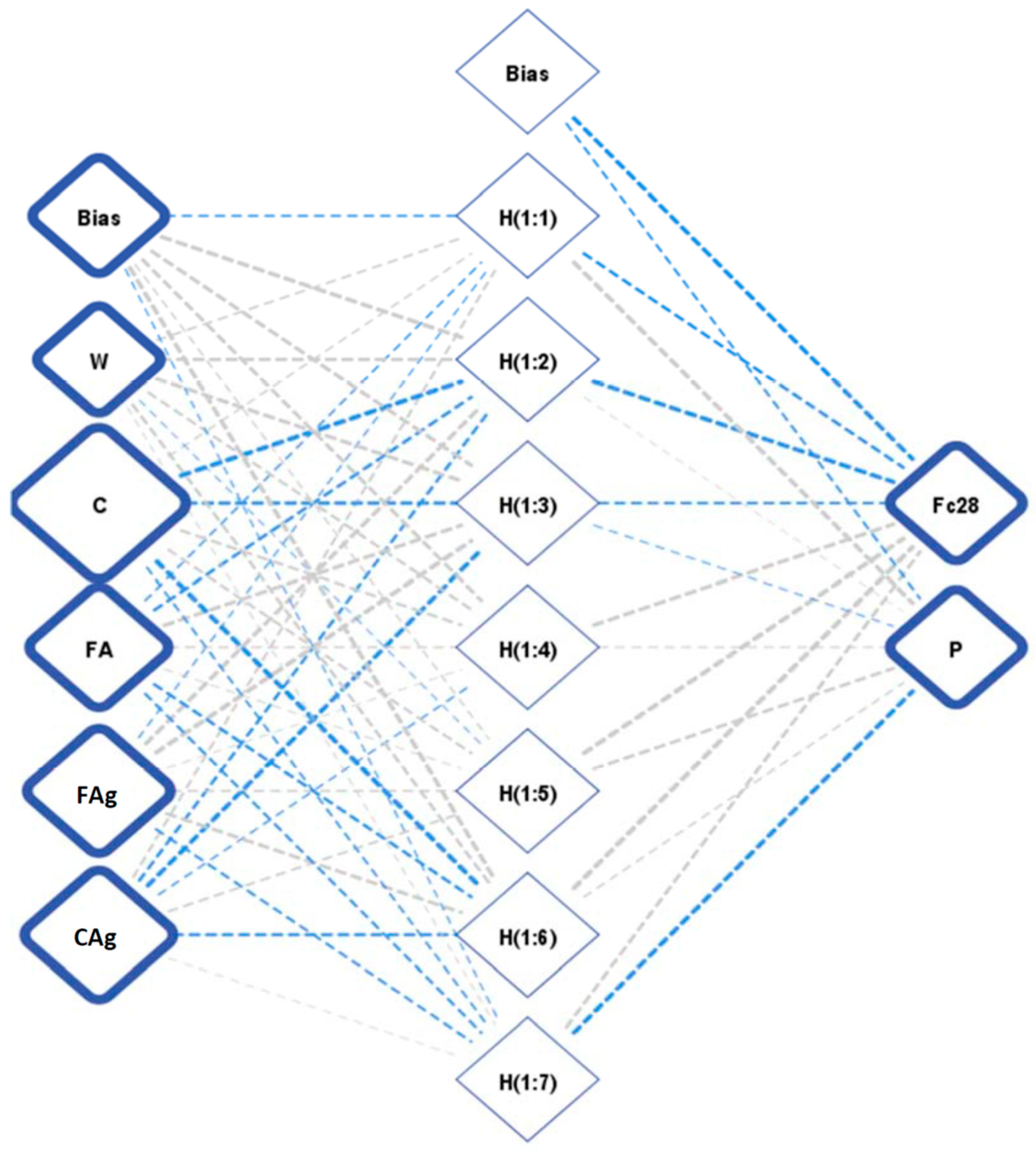

2.3.4. Artificial Neural Network (ANN)

ANN Using “Back Propagation (ANN-BP)”

ANN Using “Gradually Reduced Gradient (ANN-GRG)”

ANN Using “Genetic Algorithm (ANN-GA)”

2.3.5. Model Performance Assessment

3. Results and Discussion

3.1. Behavior of the Concrete Mixes and Environmental Impact (EI)

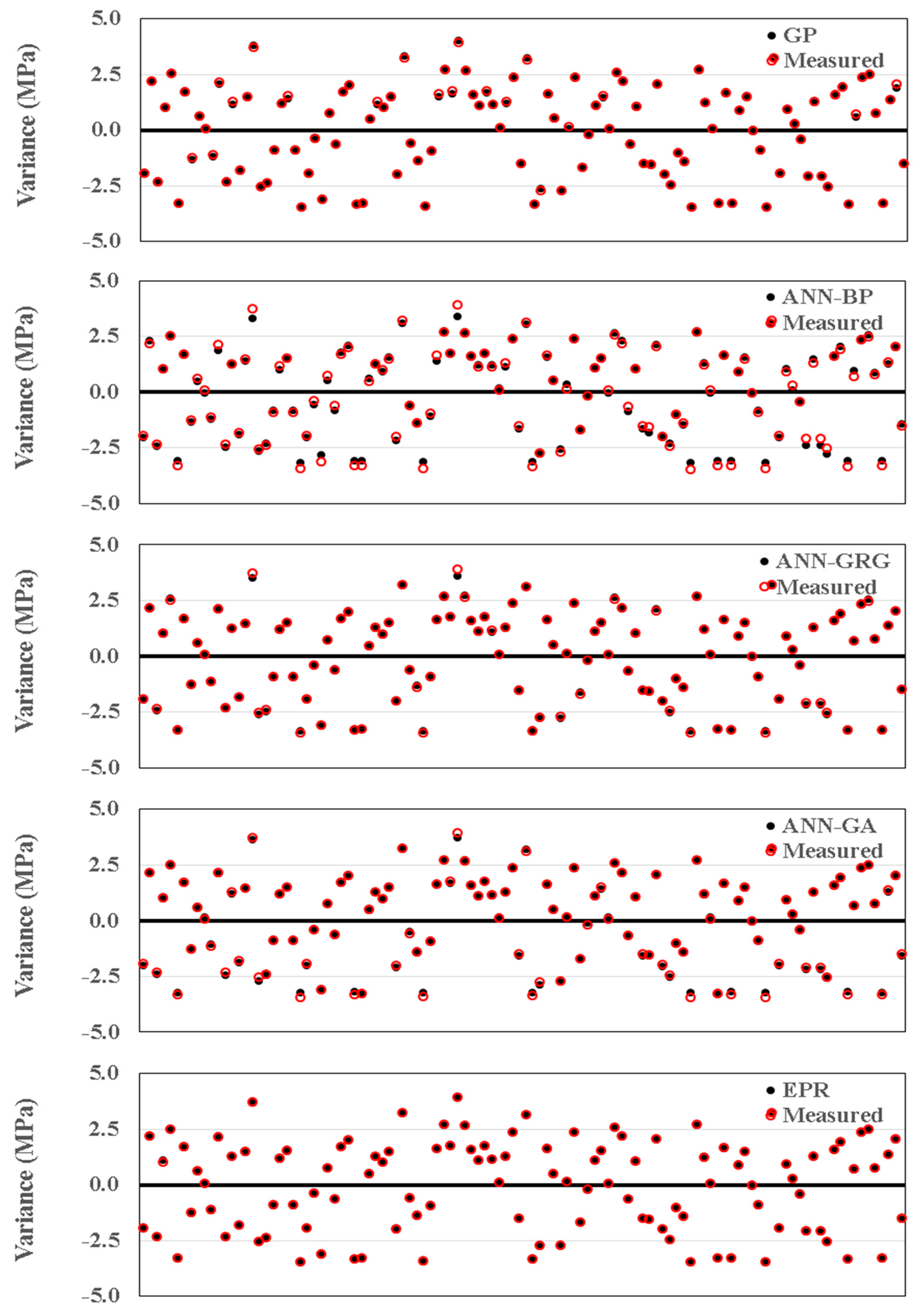

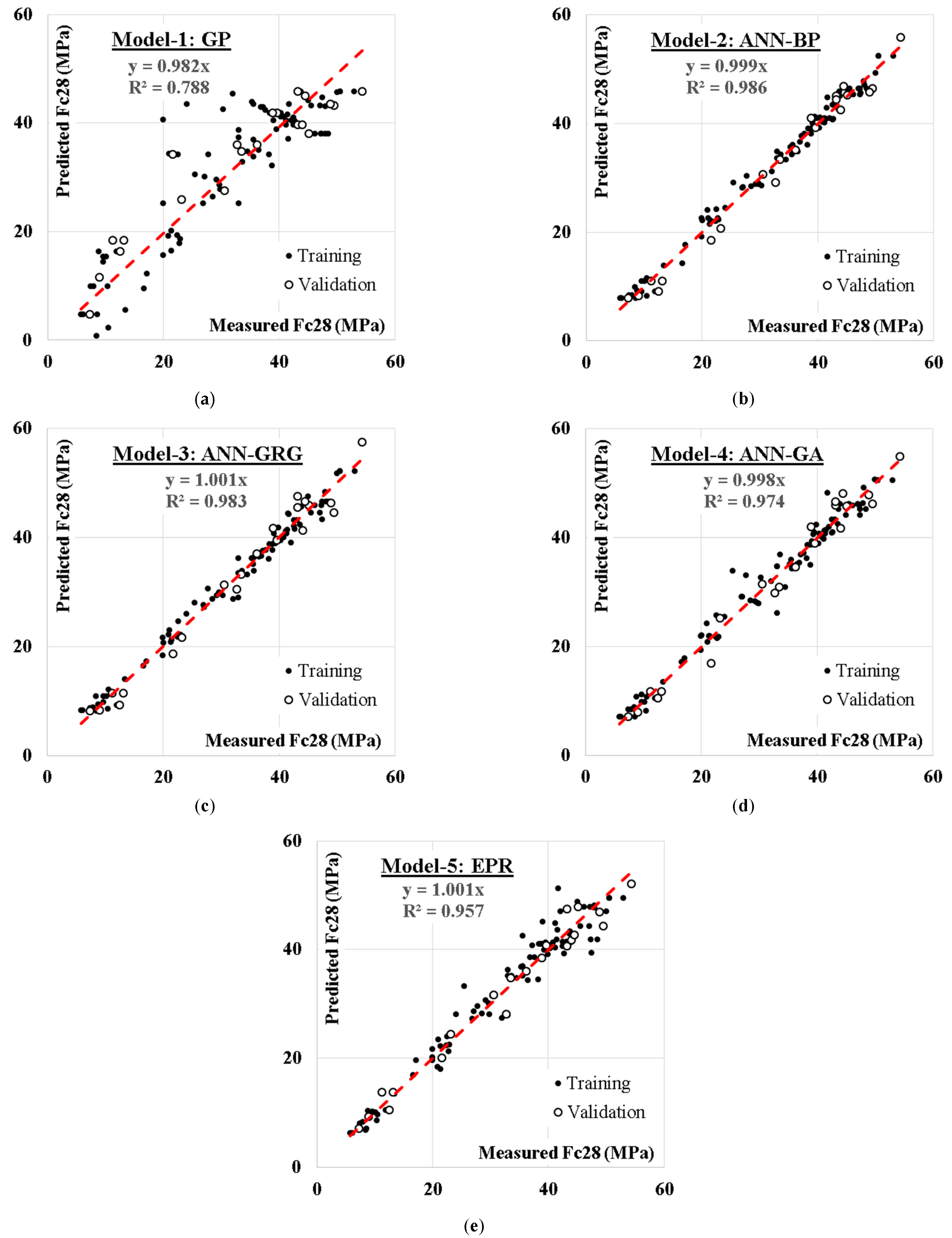

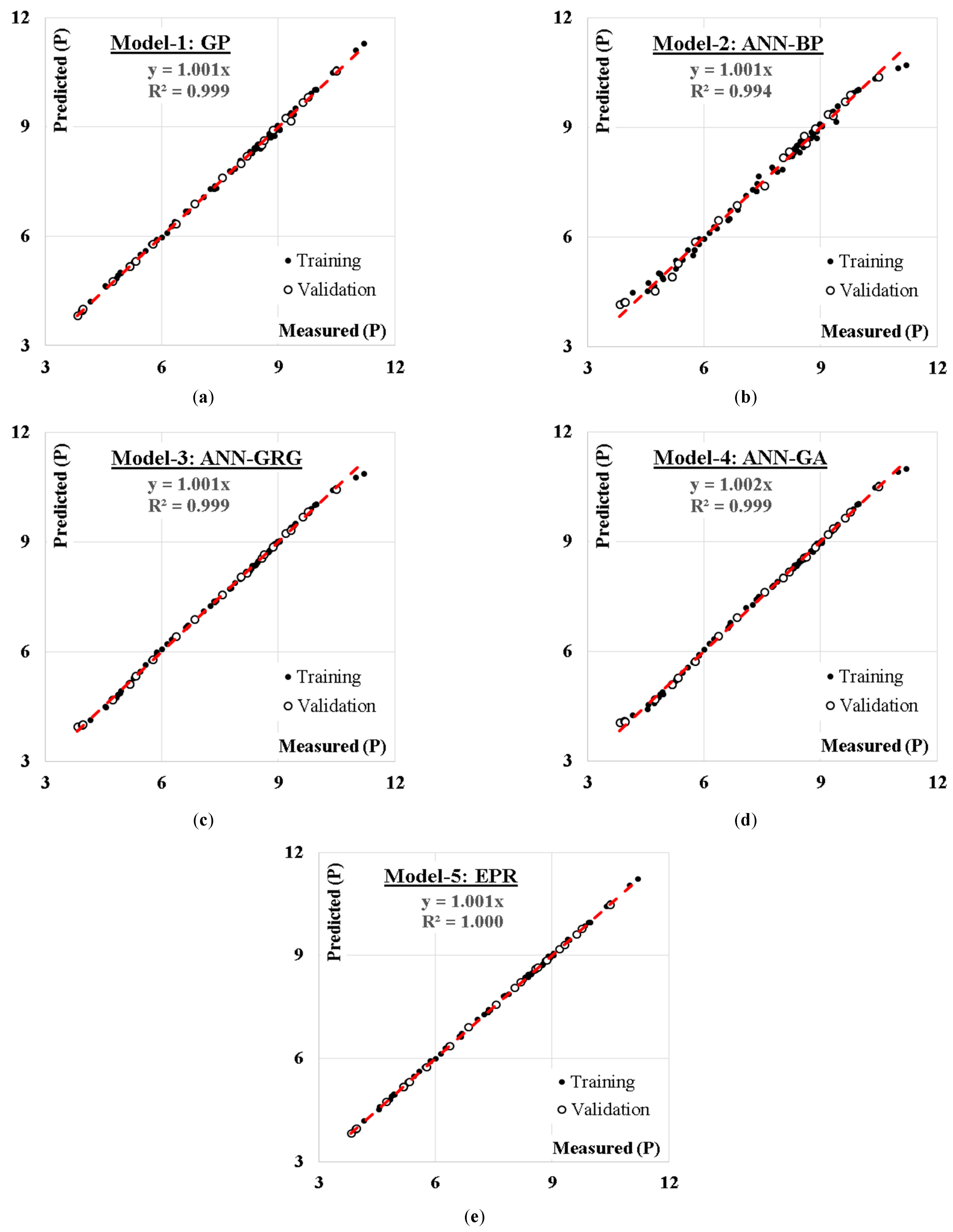

3.2. Prediction of Compressive Strength (Fc) and Environmental Impact (P)

3.2.1. Model (1)—Using the GP Technique

3.2.2. Models (2, 3, and 4)—Using ANN Techniques

3.2.3. Model (5)—Using the EPR Technique

4. Conclusions

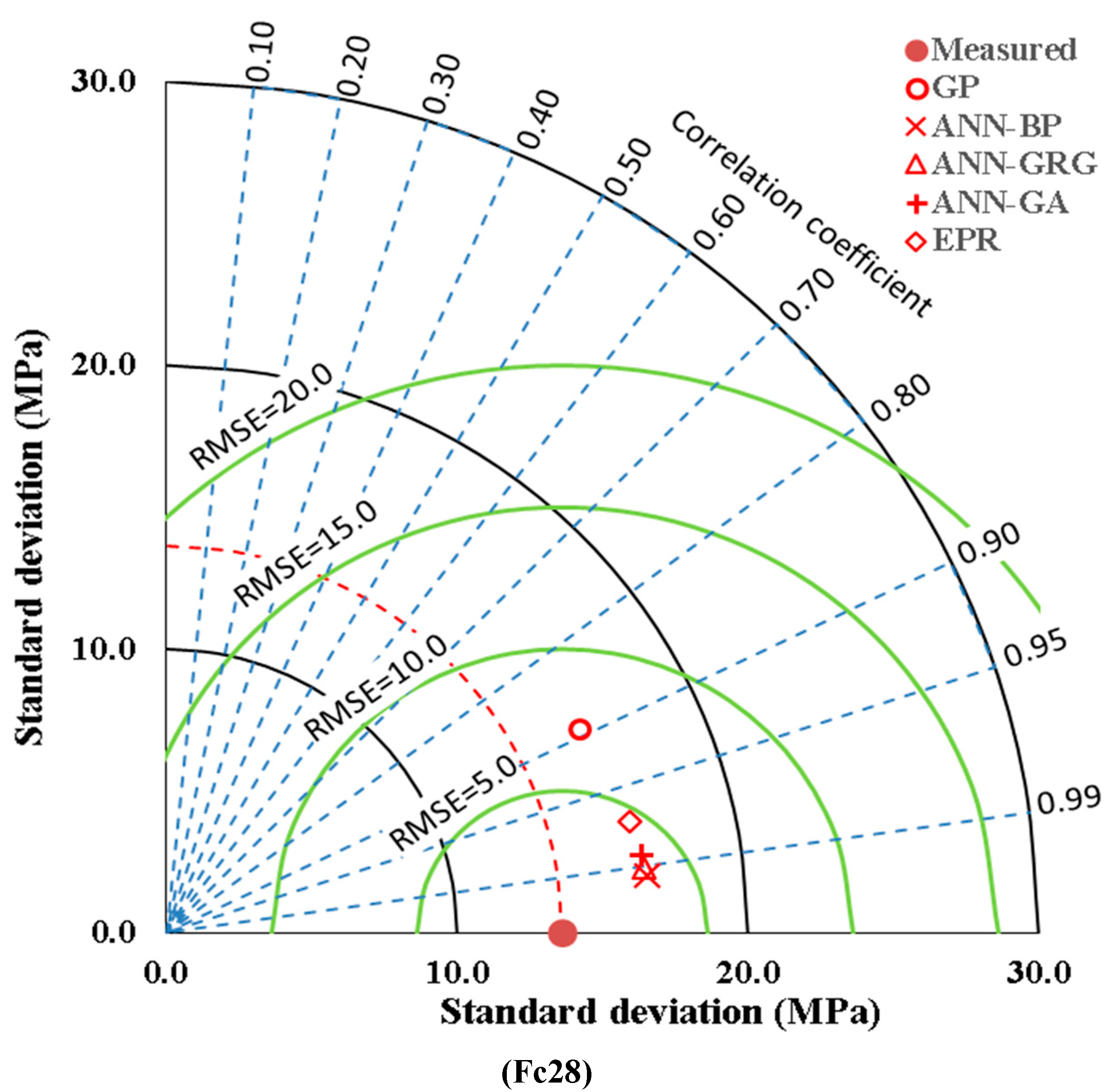

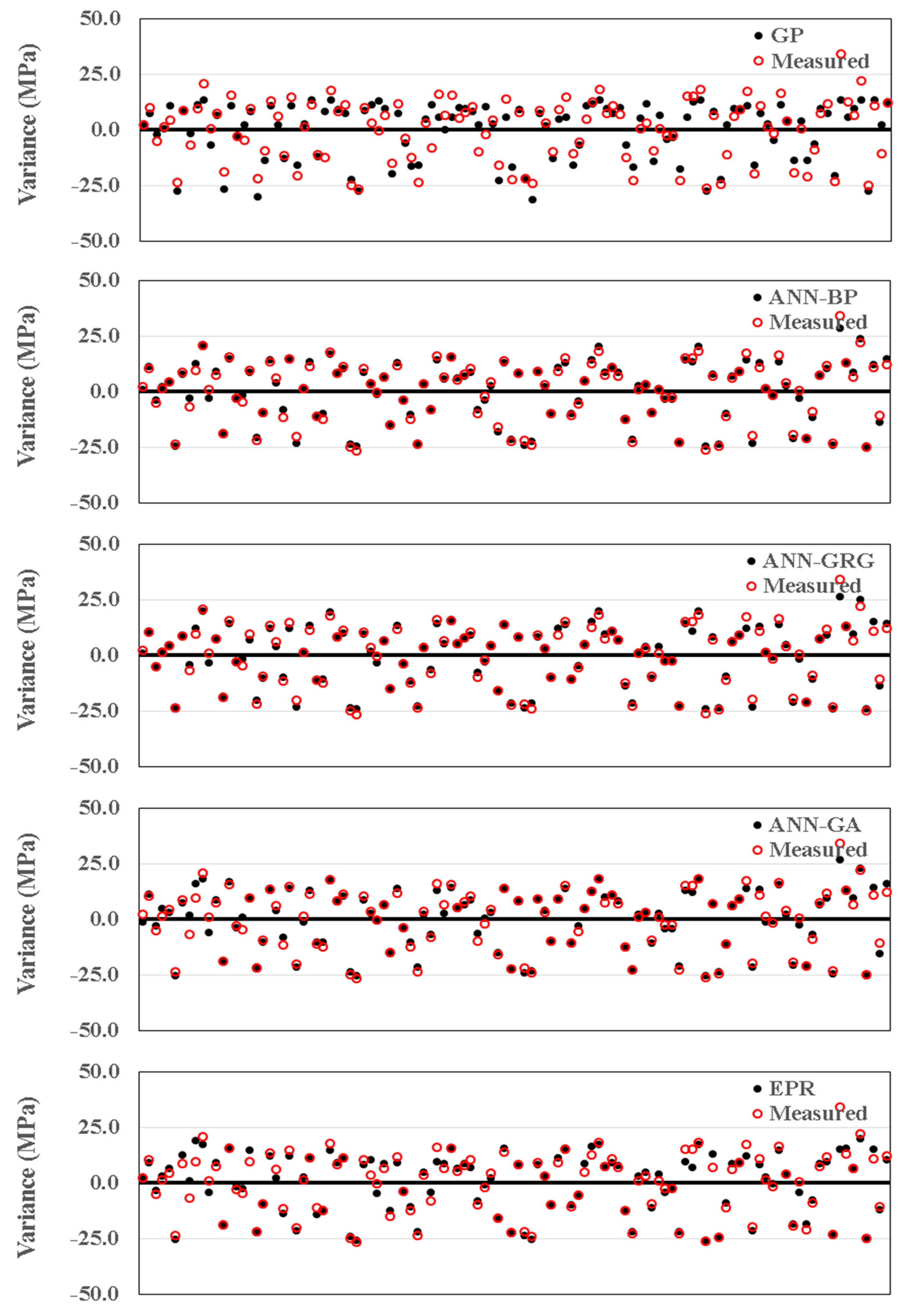

- Regarding Fc28, the GP model was the simplest and the least accurate one (80.9%). Then, EPR had an accuracy of 89.9%, and finally the three ANN models had almost the same accuracy of ≈94.0%;

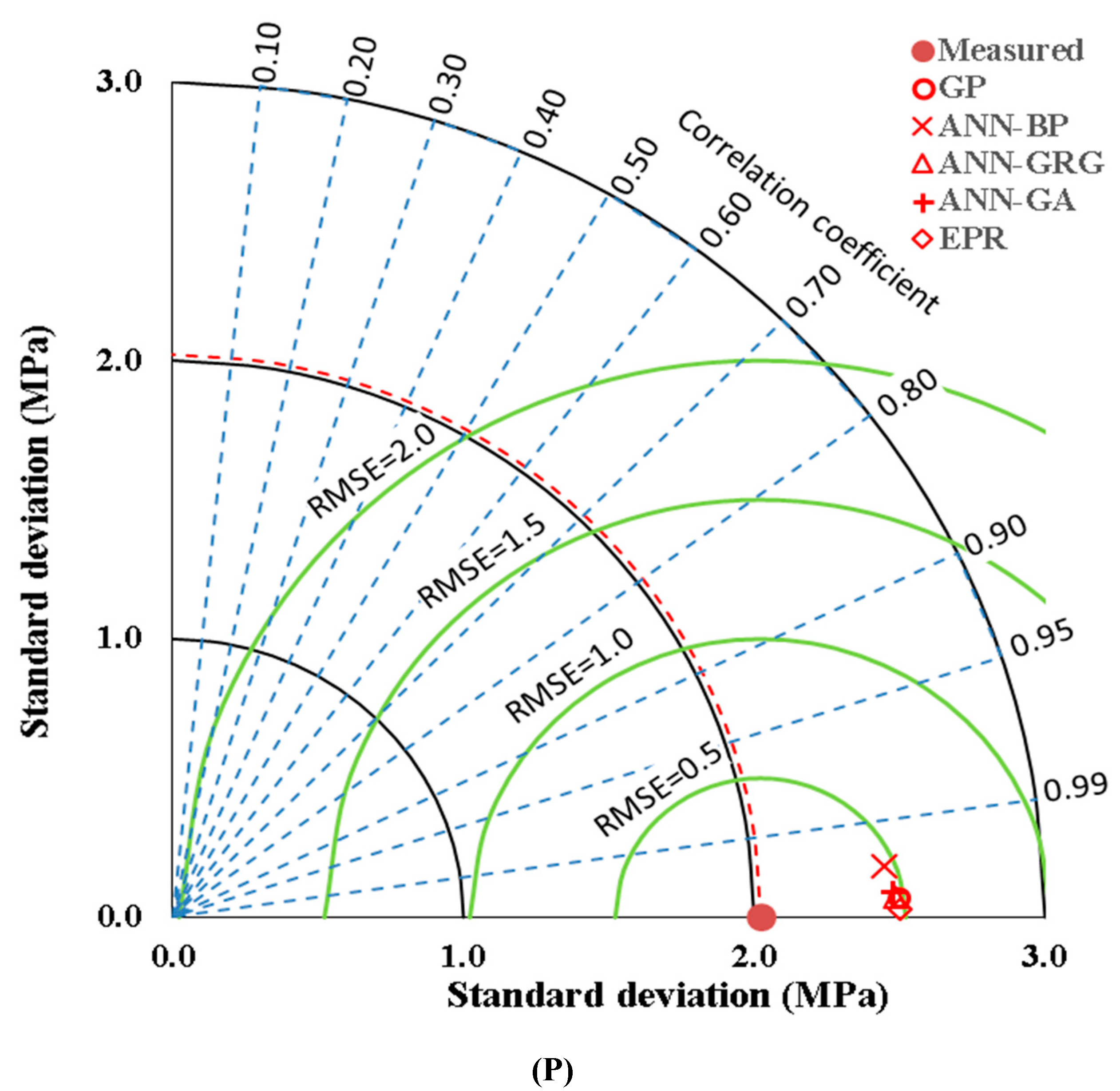

- Regarding P, all five models had almost the same accuracy (99.0%);

- The prediction accuracy of the EPR model was lower than the ANN models, but their outputs were closed-form equations that could be used manually or as software, unlike the ANN output, which cannot be used manually;

- The results indicate that the accuracy of the ANN model was slightly affected by the training algorithm. The back propagation (BP) showed the best level of accuracy (94.9% and 97.8%), gradually reduced gradient (GRG) came in the second with accuracies of 94.2% and 99.2%, and the genetic algorithm (GA) showed the lowest level of accuracy with 93.0% and 99.0% for Fc28 and P, respectively;

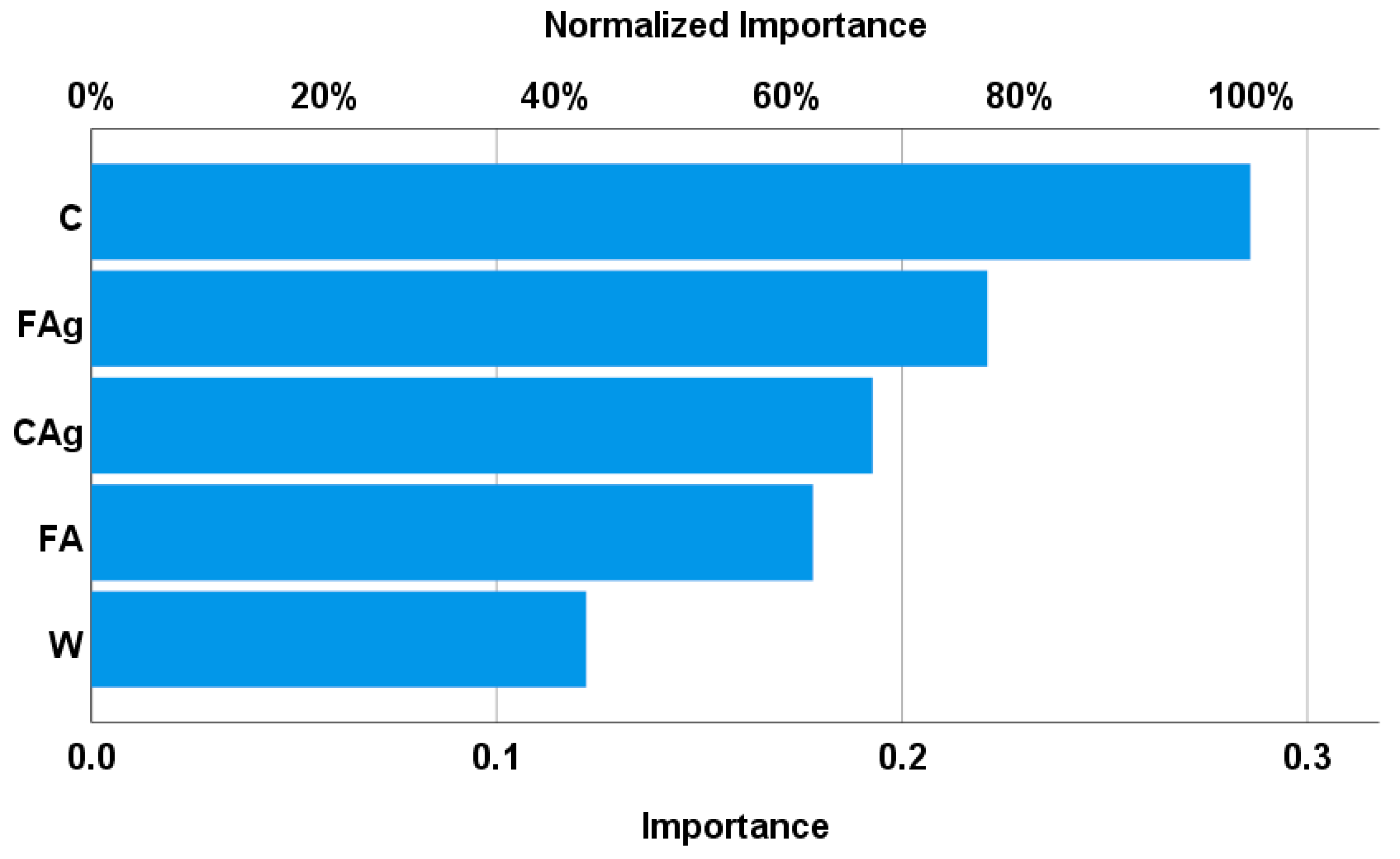

- The summation of the absolute weights of each neuron in the input layer of the developed ANN model indicated that for both Fc28 and P, cement content (C) was the most important factor, and then aggregate content (FAg and CAg). Fly ash and water content came last in the importance ranking;

- Both the GP and EPR models indicated that the environmental impact factor (P) depended only on the cementitious materials (C and FA);

- The GA technique successfully reduced the 56 and 6 terms of conventional polynomial regression quadrilateral formula to only 28 and 3 terms for Fc28 and P, respectively, without a significant impact on accuracy;

- Similar to any other regression technique, the generated formulas were valid within the considered range of parameter values; beyond this range, the prediction accuracy should be verified.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Malhotra, V. Introduction: Sustainable Development and Concrete Technology. Concr. Int. 2002, 24, 22. [Google Scholar]

- Dabbaghi, F.; Rashidi, M.; Nehdi, M.L.; Sadeghi, H.; Karimaei, M.; Rasekh, H.; Qaderi, F. Experimental and Informational Modeling Study on Flexural Strength of Eco-Friendly Concrete Incorporating Coal Waste. Sustain. 2021, 13, 7506. [Google Scholar] [CrossRef]

- Kafi, M.A.; Sadeghi-Nik, A.; Bahari, A.; Sadeghi-Nik, A.; Mirshafiei, E. Microstructural Characterization and Mechanical Properties of Cementitious Mortar Containing Montmorillonite Nanoparticles. J. Mater. Civ. Eng. 2016, 28, 04016155. [Google Scholar] [CrossRef]

- Sadeghi-Nik, A.; Lotfi-Omran, O.; Khalilpasha, M.H.; Nik, A.S.; Omran, O.L.; Kimiaeifard, K.; Molla, M.A. Properties of Lime-Cement Concrete Containing Various Amounts of Waste Tire Powder under Different Ground Moisture Conditions. Adv. Civ. Archit. Constr. Eng. Manag. 2022, 14, 482. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Fallahnezhad, H.; Nasrollahpour, S.; Dehestani, M.; Yousefpour, H. Evaluation of Fracture Energy, Toughness, Brittleness, and Fracture Process Zone Properties for Lightweight Concrete Exposed to High Temperatures. Theor. Appl. Fract. Mech. 2021, 116, 103088. [Google Scholar] [CrossRef]

- Amiri, H.; Azadi, S.; Karimaei, M.; Sadeghi, H. Farshad Dabbaghi Multi-Objective Optimization of Coal Waste Recycling in Concrete Using Response Surface Methodology. J. Build. Eng. 2022, 45, 103472. [Google Scholar] [CrossRef]

- Dabbaghi, F.; Sadeghi-Nik, A.; Ali Libre, N.; Nasrollahpour, S. Characterizing Fiber Reinforced Concrete Incorporating Zeolite and Metakaolin as Natural Pozzolans. Structures 2021, 34, 2617–2627. [Google Scholar] [CrossRef]

- Bahari, A.; Sadeghi-Nik, A.; Roodbari, M.; Sadeghi-Nik, A.; Mirshafiei, E. Experimental and Theoretical Studies of Ordinary Portland Cement Composites Contains Nano LSCO Perovskite with Fokker-Planck and Chemical Reaction Equations. Constr. Build. Mater. 2018, 163, 247–255. [Google Scholar] [CrossRef]

- Bahari, A.; Sadeghi-Nik, A.; Shaikh, F.U.A.; Sadeghi-Nik, A.; Cerro-Prada, E.; Mirshafiei, E.; Roodbari, M. Experimental Studies on Rheological, Mechanical, and Microstructure Properties of self-compacting Concrete Containing Perovskite Nanomaterial. Struct. Concr. 2021, 23, 564–578. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M. A Review on the Utilization of Fly Ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Sadeghi-Nik, A.; Berenjian, J.; Bahari, A.; Safaei, A.S.; Dehestani, M. Modification of Microstructure and Mechanical Properties of Cement by Nanoparticles through a Sustainable Development Approach. Constr. Build. Mater. 2017, 155, 880–891. [Google Scholar] [CrossRef]

- Bahari, A.; Berenjian, J.; Sadeghi-Nik, A. Modification of Portland Cement with Nano SiC. Proc. Natl. Acad. Sci. India Sect. A Phys. Sci. 2016, 86, 323–331. [Google Scholar] [CrossRef]

- Nonavinakere, S.; Reed, B.E. Fly Ash Enhanced Metal Removal Process. In Proceedings of the Mid-Atlantic Industrial Waste Conference, Bethlehem, PA, USA, 31 December 1995. [Google Scholar]

- González, A.; Navia, R.; Moreno, N. Fly Ashes from Coal and Petroleum Coke Combustion: Current and Innovative Potential Applications. Waste Manag. Res. 2009, 27, 976–987. [Google Scholar] [CrossRef] [PubMed]

- Juenger, M.C.G.; Siddique, R. Recent Advances in Understanding the Role of Supplementary Cementitious Materials in Concrete. Cem. Concr. Res. 2015, 78, 71–80. [Google Scholar] [CrossRef]

- Rashidi, M.; Joshaghani, A.; Ghodrat, M. Towards Eco-Flowable Concrete Production. Sustainability 2020, 12, 1208. [Google Scholar] [CrossRef] [Green Version]

- Saha, A.K.; Sarker, P.K. Sustainable Use of Ferronickel Slag Fine Aggregate and Fly Ash in Structural Concrete: Mechanical Properties and Leaching Study. J. Clean. Prod. 2017, 162, 438–448. [Google Scholar] [CrossRef]

- Berndt, M.L. Properties of Sustainable Concrete Containing Fly Ash, Slag and Recycled Concrete Aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Pellegrino, C.; Gaddo, V. Mechanical and Durability Characteristics of Concrete Containing EAF Slag as Aggregate. Cem. Concr. Compos. 2009, 31, 663–671. [Google Scholar] [CrossRef]

- Li, G.; Zhao, X. Properties of Concrete Incorporating Fly Ash and Ground Granulated Blast-Furnace Slag. Cem. Concr. Compos. 2003, 25, 293–299. [Google Scholar] [CrossRef]

- ACI Committee 211.1-91. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete. In ACI Manual of Concrete Practice: Part 1; American Concrete Institute: Farming Hills, MI, USA, 2000; Volume 38.

- Chindaprasirt, P.; Jaturapitakkul, C.; Chalee, W.; Rattanasak, U. Comparative study on the characteristics of fly ash and bottom ash geopolymers. Waste Manag. 2009, 29, 539–543. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Chotithanorm, C.; Cao, H.T.; Sirivivatnanon, V. Influence of Fly Ash Fineness on the Chloride Penetration of Concrete. Constr. Build. Mater. 2007, 2, 356–361. [Google Scholar] [CrossRef]

- Atiş, C.D.D. High-Volume Fly Ash Concrete with High Strength and Low Drying Shrinkage. J. Mater. Civ. Eng. 2003, 15, 153–156. [Google Scholar] [CrossRef]

- Supit, S.W.M.; Shaikh, F.U.A. Durability Properties of High Volume Fly Ash Concrete Containing Nano-Silica. Mater. Struct. 2014, 48, 2431–2445. [Google Scholar] [CrossRef]

- Ravina, D.; Mehta, P.K. Properties of Fresh Concrete Containing Large Amounts of Fly Ash. Cem. Concr. Res. 1986, 16, 227–238. [Google Scholar] [CrossRef]

- Mardani-Aghabaglou, A.; Andiç-Çakir, Ö.; Ramyar, K. Freeze–Thaw Resistance and Transport Properties of High-Volume Fly Ash Roller Compacted Concrete Designed by Maximum Density Method. Cem. Concr. Compos. 2013, 37, 259–266. [Google Scholar] [CrossRef]

- Gopalan, M.K. Sorptivity of Fly Ash Concretes. Cem. Concr. Res. 1996, 26, 1189–1197. [Google Scholar] [CrossRef]

- Haque, M.N.; Kayali, O. Properties of High-Strength Concrete Using a Fine Fly Ash. Cem. Concr. Res. 1998, 28, 1445–1452. [Google Scholar] [CrossRef]

- Sumer, M. Compressive Strength and Sulfate Resistance Properties of Concretes Containing Class F and Class C Fly Ashes. Constr. Build. Mater. 2012, 34, 531–536. [Google Scholar] [CrossRef]

- Siddique, R. Performance Characteristics of High-Volume Class F Fly Ash Concrete. Cem. Concr. Res. 2004, 34, 487–493. [Google Scholar] [CrossRef]

- Supit, S.W.; Shaikh, F.U.; Sarker, P.K. Effect of ultrafine fly ash on mechanical properties of high volume fly ash mortar. Constr Build Mater. 2014, 51, 278–286. [Google Scholar] [CrossRef]

- Ahn, Y.B.; Jang, J.G.; Lee, H.K. Mechanical Properties of Lightweight Concrete Made with Coal Ashes after Exposure to Elevated Temperatures. Cem. Concr. Compos. 2016, 72, 27–38. [Google Scholar] [CrossRef]

- Wang, S.; Llamazos, E.; Baxter, L.; Fonseca, F. Durability of Biomass Fly Ash Concrete: Freezing and Thawing and Rapid Chloride Permeability Tests. Fuel 2008, 87, 359–364. [Google Scholar] [CrossRef]

- Naik, T.R.; Singh, S.; Ramme, B. Mechanical Properties and Durability of Concrete Made with Blended Fly Ash. Mater. J. 1998, 95, 454–462. [Google Scholar] [CrossRef]

- Malhotra, V.M. Durability of Concrete Incorporating High-Volume of Low-Calcium (ASTM Class F) Fly Ash. Cem. Concr. Compos. 1990, 12, 271–277. [Google Scholar] [CrossRef]

- Kate, G.K.; Nayak, C.B.; Thakare, S.B. Optimization of Sustainable High-Strength–High-Volume Fly Ash Concrete with and without Steel Fiber Using Taguchi Method and Multi-Regression Analysis. Innov. Infrastruct. Solut. 2021, 6, 102. [Google Scholar] [CrossRef]

- Naseri, H.; Jahanbakhsh, H.; Khezri, K.; Shirzadi Javid, A.A. Toward Sustainability in Optimizing the Fly Ash Concrete Mixture Ingredients by Introducing a New Prediction Algorithm. Environ. Dev. Sustain. 2021, 24, 2767–2803. [Google Scholar] [CrossRef]

- International Organization for Standardization. Environmental Management—Life Cycle Assessment—Principles and Framework; ISO: Geneva, Switzerland, 2006. [Google Scholar]

- Dabbaghi, F.; Nasrollahpour, S.; Dehestani, M.; Yousefpour, H. Optimization of Concrete Mixtures Containing Lightweight Expanded Clay Aggregates Based on Mechanical, Economical, Fire-Resistance, and Environmental Considerations. J. Mater. Civ. Eng. 2021, 34, 04021445. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Petek Gursel, A.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical Properties, Durability, and Life-Cycle Assessment of Self-Consolidating Concrete Mixtures Made with Blended Portland Cements Containing Fly Ash and Limestone Powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef] [Green Version]

- Huntzinger, D.N.; Eatmon, T.D. A Life-Cycle Assessment of Portland Cement Manufacturing: Comparing the Traditional Process with Alternative Technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Chen, C.; Habert, G.; Bouzidi, Y.; Jullien, A.; Ventura, A. LCA Allocation Procedure Used as an Incitative Method for Waste Recycling: An Application to Mineral Additions in Concrete. Resour. Conserv. Recycl. 2010, 54, 1231–1240. [Google Scholar] [CrossRef] [Green Version]

- Collins, F. Inclusion of Carbonation during the Life Cycle of Built and Recycled Concrete: Influence on Their Carbon Footprint. Int. J. Life Cycle Assess. 2010, 15, 549–556. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life Cycle Greenhouse Gas Emissions of Blended Cement Concrete Including Carbonation and Durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Shi, C.; Jiménez, A.F.; Palomo, A. New Cements for the 21st Century: The Pursuit of an Alternative to Portland Cement. Cem. Concr. Res. 2011, 7, 750–763. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Ménaché, J.; O’Moore, L.M. Impact of Fly Ash Content and Fly Ash Transportation Distance on Embodied Greenhouse Gas Emissions and Water Consumption in Concrete. Int. J. Life Cycle Assess. 2009, 7, 621–629. [Google Scholar] [CrossRef] [Green Version]

- Iftikhar, B.; Alih, S.C.; Vafaei, M.; Elkotb, M.A.; Shutaywi, M.; Javed, M.F.; Deebani, W.; Khan, M.I.; Aslam, F. Predictive Modeling of Compressive Strength of Sustainable Rice Husk Ash Concrete: Ensemble Learner Optimization and Comparison. J. Clean. Prod. 2022, 348, 131285. [Google Scholar] [CrossRef]

- Pradhan, S.; Chang Boon Poh, A.; Qian, S. Impact of Service Life and System Boundaries on Life Cycle Assessment of Sustainable Concrete Mixes. J. Clean. Prod. 2022, 342, 130847. [Google Scholar] [CrossRef]

- Rehan, R.; Nehdi, M. Carbon Dioxide Emissions and Climate Change: Policy Implications for the Cement Industry. Environ. Sci. Policy 2005, 8, 105–114. [Google Scholar] [CrossRef]

- Liu, Z.; Takasu, K.; Koyamada, H.; Suyama, H. A Study on Engineering Properties and Environmental Impact of Sustainable Concrete with Fly Ash or GGBS. Constr. Build. Mater. 2022, 316, 125776. [Google Scholar] [CrossRef]

- Colaço, R. Reduce the Environmental Impact of Cement. Constr. Mag. 2019, 90, 12–14. [Google Scholar]

- Rahla, K.M.; Mateus, R.; Bragança, L. Comparative Sustainability Assessment of Binary Blended Concretes Using Supplementary Cementitious Materials (SCMs) and Ordinary Portland Cement (OPC). J. Clean. Prod. 2019, 220, 445–459. [Google Scholar] [CrossRef]

- Schorcht, F.; Kourti, I.; Scalet, B.M.; Roudier, S.; Sancho, L.D. Best Available Techniques (BAT) Reference Document for the Production of Cement, Lime and Magnesium Oxide; European Commission Joint Research Centre Institute for Prospective Technological Studies: Luxembourg, 2013. [Google Scholar]

- Supino, S.; Malandrino, O.; Testa, M.; Sica, D. Sustainability in the EU Cement Industry: The Italian and German Experiences. J. Clean. Prod. 2016, 112, 430–442. [Google Scholar] [CrossRef]

- Tang, P.; Chen, W.; Xuan, D.; Zuo, Y.; Poon, C.S. Investigation of Cementitious Properties of Different Constituents in Municipal Solid Waste Incineration Bottom Ash as Supplementary Cementitious Materials. J. Clean. Prod. 2020, 258, 120675. [Google Scholar] [CrossRef]

- He, Z.-H.; Zhu, H.-N.; Zhang, M.-Y.; Shi, J.-Y.; Du, S.-G.; Liu, B. Autogenous Shrinkage and Nano-Mechanical Properties of UHPC Containing Waste Brick Powder Derived from Construction and Demolition Waste. Constr. Build. Mater. 2021, 306, 124869. [Google Scholar] [CrossRef]

- Aprianti, S.E. A Huge Number of Artificial Waste Material Can Be Supplementary Cementitious Material (SCM) for Concrete Production—A Review Part II. J. Clean. Prod. 2017, 142, 4178–4194. [Google Scholar] [CrossRef]

- Wang, N.; Sun, X.; Zhao, Q.; Yang, Y.; Wang, P. Leachability and Adverse Effects of Coal Fly Ash: A Review. J. Hazard. Mater. 2020, 396, 122725. [Google Scholar] [CrossRef]

- Heidrich, C.; Feuerborn, H.; Weir, A. Coal Combustion Products: A Global Perspective. In Proceedings of the World of Coal Ash (WOCA) Conference, Lexington, KY, USA, 22 April 2013. [Google Scholar]

- National Development and Reform Commission. Annual Report on Comprehensive Utilization of Resources in China; National Development and Reform Commission: Beijing, China, 2014.

- Central Electricity Authority. Report On, Fly Ash Generation at Coal/Lignite Based Thermal Power Stations and its Utilization in the Country for The Year 2014–2015; Central Electricity Authority (CEA): New Delhi, India, 2016.

- American Coal Ash Association. 2013 Coal Combustion Product (CCP) Production & Use Survey Report; American Coal Ash Association (ACAA): Farmington Hills, MI, USA, 2013. [Google Scholar]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995; Volume 4. [Google Scholar]

- Rafieizonooz, M.; Khankhaje, E.; Rezania, S. Assessment of Environmental and Chemical Properties of Coal Ashes Including Fly Ash and Bottom Ash, and Coal Ash Concrete. J. Build. Eng. 2022, 49, 104040. [Google Scholar] [CrossRef]

- Chindaprasirt, P.; Jaturapitakkul, C.; Sinsiri, T. Effect of fly ash fineness on compressive strength and pore size of blended cement paste. Cem. Concr. Compos. 2005, 27, 425–428. [Google Scholar] [CrossRef]

- Moffatt, E.G.; Thomas, M.D.A.; Fahim, A. Performance of High-Volume Fly Ash Concrete in Marine Environment. Cem. Concr. Res. 2017, 102, 127–135. [Google Scholar] [CrossRef]

- Hussain, S.; Bhunia, D.; Singh, S.B. Comparative Study of Accelerated Carbonation of Plain Cement and Fly-Ash Concrete. J. Build. Eng. 2017, 10, 26–31. [Google Scholar] [CrossRef]

- Hefni, Y.; El Zaher, Y.A.; Wahab, M.A. Influence of Activation of Fly Ash on the Mechanical Properties of Concrete. Constr. Build. Mater. 2018, 172, 728–734. [Google Scholar] [CrossRef]

- Kara De Maeijer, P.; Craeye, B.; Snellings, R.; Kazemi-Kamyab, H.; Loots, M.; Janssens, K.; Nuyts, G. Effect of Ultra-Fine Fly Ash on Concrete Performance and Durability. Constr. Build. Mater. 2020, 263, 120493. [Google Scholar] [CrossRef]

- Garg, C.; Namdeo, A.; Singhal, A.; Singh, P.; Shaw, R.N.N.; Ghosh, A. Adaptive Fuzzy Logic Models for the Prediction of Compressive Strength of Sustainable Concrete; Springer: Singapore, 2022; pp. 593–605. [Google Scholar]

- Zhao, H.; Sun, W.; Wu, X.; Gao, B. Sustainable Self-Compacting Concrete Containing High-Amount Industrial by-Product Fly Ash as Supplementary Cementitious Materials. Environ. Sci. Pollut. Res. 2022, 29, 3616–3628. [Google Scholar] [CrossRef] [PubMed]

- Khursheed, S.; Jagan, J.; Samui, P.; Kumar, S. Compressive Strength Prediction of Fly Ash Concrete by Using Machine Learning Techniques. Innov. Infrastruct. Solut. 2021, 6, 149. [Google Scholar] [CrossRef]

- Hansen, T.C. Long-Term Strength of High Fly Ash Concretes. Cem. Concr. Res. 1990, 20, 193–196. [Google Scholar] [CrossRef]

- Mehta, P.K.; Gjørv, O.E. Properties of Portland Cement Concrete Containing Fly Ash and Condensed Silica-Fume. Cem. Concr. Res. 1982, 12, 587–595. [Google Scholar] [CrossRef]

- Ravina, D.; Mehta, P.K. Compressive Strength of Low Cement/High Fly Ash Concrete. Cem. Concr. Res. 1988, 18, 571–583. [Google Scholar] [CrossRef]

- Thomas, M.D.A.; Matthews, J.D. Carbonation of Fly Ash Concrete. Mag. Concr. Res. 1992, 44, 217–228. [Google Scholar] [CrossRef]

- Lam, L.; Wong, Y.L.; Poon, C.S. Effect of Fly Ash and Silica Fume on Compressive and Fracture Behaviors of Concrete. Cem. Concr. Res. 1998, 28, 271–283. [Google Scholar] [CrossRef]

- Atiş, C.D. Heat Evolution of High-Volume Fly Ash Concrete. Cem. Concr. Res. 2002, 32, 751–756. [Google Scholar] [CrossRef]

- Oner, A.; Akyuz, S.; Yildiz, R. An Experimental Study on Strength Development of Concrete Containing Fly Ash and Optimum Usage of Fly Ash in Concrete. Cem. Concr. Res. 2005, 35, 1165–1171. [Google Scholar] [CrossRef]

- Chalee, W.; Ausapanit, P.; Jaturapitakkul, C. Utilization of Fly Ash Concrete in Marine Environment for Long Term Design Life Analysis. Mater. Des. 2010, 31, 1242–1249. [Google Scholar] [CrossRef]

- Liu, M.H.; Wang, Y.F. Prediction of the Strength Development of Fly Ash Concrete. Adv. Mater. Res. 2010, 150–151, 1026–1033. [Google Scholar] [CrossRef]

- Pitroda, D.J. Prediction of Strength for Fly Ash Cement Concrete through Soft Computing Approaches. Int. J. Adv. Res. Eng. Sci. Manag. 2020, 1, 1766–2394. [Google Scholar]

- Chopra, P.; Sharma, R.K.; Kumar, M. Prediction of Compressive Strength of Concrete Using Artificial Neural Network and Genetic Programming. Adv. Mater. Sci. Eng. 2016, 2016, 7648467. [Google Scholar] [CrossRef] [Green Version]

- Ebid, A.M. 35 Years of (AI) in Geotechnical Engineering: State of the Art. Geotech. Geol. Eng. 2021, 39, 637–690. [Google Scholar] [CrossRef]

| W | C | FA | Fag | Cag | Fc28 | P |

|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | MPa | - |

| Training dataset | ||||||

| 171.58 | 199.19 | 85.79 | 388.65 | 835.47 | 34.5 | 5.3 |

| 202.16 | 459.46 | 68.92 | 326.13 | 713.03 | 42.5 | 9.5 |

| 220.48 | 237.29 | 34.60 | 770.12 | 352.57 | 27.1 | 4.9 |

| 252.37 | 283.79 | 167.24 | 667.68 | 305.88 | 33.6 | 8.3 |

| 233.76 | 477.06 | 71.56 | 383.18 | 585.98 | 36.9 | 9.8 |

| 150.14 | 101.71 | 101.71 | 542.80 | 754.80 | 8.5 | 4.0 |

| 196.07 | 435.71 | 65.36 | 295.71 | 771.13 | 41.1 | 9.0 |

| 155.22 | 168.32 | 147.16 | 357.72 | 879.94 | 25.4 | 6.0 |

| 161.46 | 322.92 | 107.64 | 376.63 | 785.04 | 41.7 | 7.9 |

| 172.12 | 278.58 | 119.39 | 335.14 | 828.50 | 53.0 | 7.4 |

| 160.62 | 160.62 | 160.62 | 364.24 | 860.37 | 33.0 | 6.1 |

| 258.82 | 324.80 | 187.77 | 637.66 | 292.24 | 39.5 | 9.4 |

| 154.59 | 107.41 | 146.56 | 386.88 | 884.30 | 13.4 | 5.0 |

| 162.20 | 226.28 | 226.28 | 320.43 | 831.12 | 48.0 | 8.5 |

| 223.88 | 238.81 | 59.70 | 756.47 | 346.29 | 29.2 | 5.5 |

| 146.40 | 385.27 | 96.32 | 216.44 | 952.93 | 27.7 | 8.8 |

| 242.48 | 538.85 | 80.83 | 365.71 | 549.76 | 42.0 | 11.0 |

| 154.46 | 94.28 | 146.44 | 395.32 | 882.93 | 10.5 | 4.7 |

| 220.25 | 199.32 | 64.78 | 773.17 | 354.07 | 22.9 | 4.9 |

| 171.55 | 239.98 | 103.13 | 372.31 | 820.54 | 45.5 | 6.4 |

| 161.67 | 425.45 | 47.27 | 212.46 | 935.37 | 38.2 | 8.5 |

| 257.16 | 234.58 | 234.58 | 390.51 | 581.41 | 20.9 | 8.8 |

| 171.55 | 239.98 | 103.13 | 372.31 | 820.54 | 47.0 | 6.4 |

| 150.94 | 131.47 | 68.17 | 545.71 | 752.41 | 11.9 | 3.8 |

| 171.58 | 199.19 | 85.79 | 388.65 | 835.47 | 33.5 | 5.3 |

| 173.01 | 286.71 | 88.98 | 518.31 | 645.04 | 43.7 | 6.9 |

| 213.26 | 197.47 | 29.62 | 794.88 | 363.82 | 21.3 | 4.2 |

| 290.79 | 379.62 | 67.32 | 372.02 | 554.49 | 19.9 | 8.0 |

| 178.50 | 311.39 | 54.54 | 348.25 | 821.22 | 50.0 | 6.7 |

| 200.55 | 435.97 | 65.40 | 333.89 | 722.64 | 40.7 | 9.0 |

| 198.28 | 450.64 | 67.60 | 319.87 | 732.08 | 43.6 | 9.3 |

| 150.99 | 116.89 | 87.67 | 545.87 | 749.42 | 7.4 | 4.0 |

| 150.70 | 102.09 | 102.09 | 544.84 | 751.22 | 5.8 | 4.0 |

| 244.25 | 321.65 | 105.54 | 685.94 | 313.97 | 42.5 | 7.8 |

| 125.31 | 250.63 | 205.06 | 379.92 | 830.85 | 35.6 | 8.6 |

| 252.27 | 390.92 | 69.33 | 383.09 | 602.78 | 32.0 | 8.3 |

| 199.96 | 425.45 | 63.82 | 339.08 | 724.87 | 38.9 | 8.8 |

| 154.76 | 125.62 | 146.72 | 377.93 | 883.29 | 17.1 | 5.3 |

| 225.86 | 513.31 | 77.00 | 338.79 | 623.73 | 43.9 | 10.5 |

| 237.33 | 241.35 | 120.68 | 717.57 | 328.73 | 28.5 | 6.7 |

| 232.81 | 200.70 | 115.40 | 739.77 | 338.63 | 20.0 | 5.9 |

| 151.80 | 132.21 | 68.55 | 545.76 | 750.22 | 8.8 | 3.9 |

| 231.42 | 279.30 | 69.82 | 729.15 | 333.97 | 35.6 | 6.3 |

| 105.59 | 211.17 | 258.10 | 381.99 | 855.63 | 24.0 | 8.9 |

| 203.96 | 485.63 | 72.84 | 317.49 | 702.32 | 48.4 | 10.0 |

| 216.33 | 240.48 | 240.48 | 400.33 | 635.89 | 38.8 | 9.0 |

| 230.38 | 548.51 | 82.28 | 324.45 | 608.54 | 47.9 | 11.2 |

| 232.71 | 484.81 | 72.72 | 380.34 | 585.88 | 37.7 | 9.9 |

| 202.29 | 430.41 | 64.56 | 334.99 | 721.96 | 40.3 | 8.9 |

| 249.55 | 323.31 | 136.39 | 668.08 | 305.58 | 42.7 | 8.4 |

| 130.56 | 343.57 | 147.24 | 220.58 | 971.16 | 22.5 | 9.0 |

| 253.69 | 347.61 | 115.22 | 385.24 | 596.58 | 30.3 | 8.4 |

| 241.52 | 281.77 | 120.76 | 698.01 | 319.65 | 36.5 | 7.4 |

| 297.03 | 228.26 | 228.26 | 379.99 | 529.80 | 16.6 | 8.6 |

| 196.93 | 468.88 | 70.33 | 286.11 | 758.61 | 46.1 | 9.7 |

| 138.68 | 118.87 | 178.30 | 496.49 | 771.89 | 10.1 | 5.8 |

| 234.12 | 508.97 | 76.35 | 370.78 | 578.11 | 40.3 | 10.4 |

| 149.86 | 116.02 | 87.01 | 544.79 | 753.39 | 10.4 | 3.9 |

| 154.36 | 83.19 | 146.34 | 401.91 | 882.33 | 8.4 | 4.5 |

| 254.63 | 324.62 | 162.31 | 651.85 | 298.78 | 41.2 | 8.9 |

| 247.22 | 282.53 | 141.27 | 683.56 | 313.19 | 35.5 | 7.8 |

| 217.32 | 198.47 | 49.62 | 782.23 | 358.46 | 22.4 | 4.6 |

| 161.60 | 195.52 | 195.52 | 358.39 | 826.09 | 41.5 | 7.4 |

| 196.93 | 468.88 | 70.33 | 286.11 | 758.61 | 47.3 | 9.7 |

| 229.22 | 200.20 | 100.10 | 749.77 | 343.07 | 21.4 | 5.6 |

| 242.07 | 242.07 | 141.21 | 704.62 | 322.38 | 26.9 | 7.1 |

| 198.88 | 405.87 | 60.88 | 346.21 | 731.71 | 37.2 | 8.4 |

| 214.66 | 310.50 | 166.73 | 397.23 | 644.16 | 45.0 | 8.8 |

| 172.12 | 278.58 | 119.39 | 335.14 | 828.50 | 50.5 | 7.4 |

| 225.59 | 479.99 | 72.00 | 349.67 | 633.94 | 39.9 | 9.9 |

| 202.16 | 459.46 | 68.92 | 326.13 | 713.03 | 43.1 | 9.5 |

| 235.58 | 318.08 | 49.70 | 717.32 | 328.87 | 39.3 | 6.6 |

| 294.42 | 294.42 | 158.10 | 376.65 | 540.14 | 19.9 | 8.3 |

| 138.68 | 118.87 | 178.30 | 496.49 | 771.89 | 9.6 | 5.8 |

| 227.80 | 277.32 | 39.62 | 744.96 | 341.42 | 33.0 | 5.7 |

| 231.63 | 454.17 | 68.13 | 393.07 | 593.85 | 35.2 | 9.3 |

| 223.69 | 199.72 | 84.88 | 761.67 | 348.85 | 22.7 | 5.3 |

| 178.19 | 222.50 | 39.38 | 400.28 | 824.38 | 33.0 | 4.8 |

| 231.14 | 240.15 | 100.06 | 732.67 | 335.68 | 29.8 | 6.3 |

| 227.94 | 239.94 | 79.98 | 743.87 | 340.67 | 29.6 | 5.9 |

| 155.62 | 131.30 | 68.08 | 542.01 | 748.28 | 9.6 | 3.8 |

| 203.96 | 485.63 | 72.84 | 317.49 | 702.32 | 47.3 | 10.0 |

| 212.44 | 401.17 | 71.14 | 393.13 | 655.13 | 47.4 | 8.5 |

| 172.12 | 278.58 | 119.39 | 335.14 | 828.50 | 50.5 | 7.4 |

| 150.70 | 102.09 | 102.09 | 544.84 | 751.22 | 6.1 | 4.0 |

| 195.08 | 433.52 | 65.03 | 296.92 | 772.97 | 39.0 | 8.9 |

| 151.27 | 117.11 | 87.84 | 543.86 | 750.84 | 7.9 | 4.0 |

| 292.59 | 337.75 | 111.96 | 374.32 | 547.36 | 21.0 | 8.2 |

| 199.96 | 425.45 | 63.82 | 339.08 | 724.87 | 38.4 | 8.8 |

| 240.49 | 320.65 | 80.16 | 700.02 | 320.27 | 41.4 | 7.3 |

| Validation dataset | ||||||

| 171.55 | 239.98 | 103.13 | 372.31 | 820.54 | 49.5 | 6.4 |

| 150.94 | 131.47 | 68.17 | 545.71 | 752.41 | 12.5 | 3.8 |

| 224.52 | 510.27 | 76.54 | 339.96 | 626.77 | 43.2 | 10.5 |

| 171.58 | 199.19 | 85.79 | 388.65 | 835.47 | 33.5 | 5.3 |

| 122.64 | 126.87 | 296.02 | 394.96 | 837.80 | 30.6 | 8.2 |

| 178.12 | 356.23 | 62.86 | 374.87 | 764.13 | 48.9 | 7.6 |

| 236.72 | 280.86 | 95.29 | 713.23 | 326.56 | 36.2 | 6.9 |

| 146.87 | 132.18 | 137.08 | 506.00 | 762.97 | 13.1 | 5.2 |

| 255.12 | 302.83 | 162.61 | 387.42 | 590.31 | 32.7 | 8.6 |

| 146.87 | 132.18 | 137.08 | 506.00 | 762.97 | 11.2 | 5.2 |

| 196.98 | 198.87 | 56.82 | 574.90 | 609.75 | 23.2 | 4.7 |

| 202.29 | 430.41 | 64.56 | 334.99 | 721.96 | 39.6 | 8.9 |

| 196.57 | 446.75 | 67.01 | 331.02 | 725.75 | 44.0 | 9.2 |

| 145.75 | 116.60 | 87.45 | 547.51 | 757.15 | 9.0 | 4.0 |

| 126.32 | 210.53 | 210.53 | 393.26 | 834.18 | 66.5 | 8.0 |

| 196.57 | 468.03 | 70.20 | 285.59 | 760.33 | 45.1 | 9.6 |

| 223.52 | 475.57 | 71.34 | 352.37 | 637.53 | 38.9 | 9.8 |

| 170.60 | 293.59 | 142.83 | 450.21 | 687.75 | 54.3 | 8.1 |

| 150.14 | 101.71 | 101.71 | 542.80 | 754.80 | 7.3 | 4.0 |

| 213.58 | 356.64 | 118.22 | 395.25 | 649.47 | 43.2 | 8.6 |

| 114.09 | 300.23 | 200.15 | 224.89 | 990.10 | 21.6 | 9.3 |

| 177.96 | 267.93 | 47.46 | 390.90 | 805.02 | 44.5 | 5.8 |

| W | C | FA | FAg | CAg | Fc28 | P | |

|---|---|---|---|---|---|---|---|

| kg/m3 | kg/m3 | kg/m3 | kg/m3 | kg/m3 | MPa | - | |

| Training set | |||||||

| Min. | 105.6 | 83.2 | 29.6 | 212.5 | 292.2 | 5.8 | 3.8 |

| Max. | 297.0 | 548.5 | 258.1 | 794.9 | 971.2 | 53.0 | 11.2 |

| Avg. | 201.1 | 292.7 | 105.2 | 469.7 | 635.1 | 31.7 | 7.3 |

| SD | 42.2 | 125.5 | 50.8 | 165.3 | 202.0 | 13.0 | 2.0 |

| VAR | 0.2 | 0.4 | 0.5 | 0.4 | 0.3 | 0.4 | 0.3 |

| Validation set | |||||||

| Min. | 114.1 | 101.7 | 47.5 | 224.9 | 326.6 | 7.3 | 3.8 |

| Max. | 255.1 | 510.3 | 296.0 | 713.2 | 990.1 | 66.5 | 10.5 |

| Avg. | 178.1 | 276.3 | 111.9 | 425.1 | 727.9 | 34.0 | 7.2 |

| SD | 37.5 | 127.4 | 59.7 | 109.5 | 125.3 | 15.9 | 2.1 |

| VAR | 0.2 | 0.5 | 0.5 | 0.3 | 0.2 | 0.5 | 0.3 |

| W | C | FA | FAg | CAg | Fc28 | P | |

|---|---|---|---|---|---|---|---|

| W | 1.00 | ||||||

| C | 0.47 | 1.00 | |||||

| FA | −0.19 | −0.36 | 1.00 | ||||

| FAg | 0.29 | −0.44 | −0.11 | 1.00 | |||

| CAg | −0.78 | −0.11 | 0.15 | −0.80 | 1.00 | ||

| Fc28 | 0.23 | 0.68 | −0.10 | −0.34 | −0.03 | 1.00 | |

| P | 0.40 | 0.88 | 0.12 | −0.54 | −0.03 | 0.68 | 1.00 |

| Hidden Layer | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| (1–1) | (1–2) | (1–3) | (1–4) | (1–5) | (1–6) | (1–7) | |||

| Input Layer | (Bias) | −0.20 | 1.95 | 1.47 | 1.09 | 0.14 | 1.86 | −0.11 | |

| W | 0.22 | 1.09 | 1.48 | 0.44 | −0.05 | 0.63 | 0.05 | ||

| C | 0.15 | −3.86 | −1.37 | 0.45 | 0.38 | −3.43 | −0.20 | ||

| FA | −0.16 | -0.80 | 1.58 | 0.18 | 0.10 | -0.68 | −0.32 | ||

| FAg | −0.12 | 1.79 | 3.03 | 0.07 | 0.24 | 1.15 | −0.31 | ||

| CAg | 0.30 | −0.59 | −2.40 | −0.14 | 0.27 | −1.01 | 0.02 | ||

| Hidden Layer | |||||||||

| (1–1) | (1–2) | (1–3) | (1–4) | (1–5) | (1–6) | (1–7) | (Bias) | ||

| Output Layer | Fc28 | −0.83 | −2.73 | −0.37 | 1.67 | 3.25 | 3.56 | 1.04 | −2.04 |

| P | 2.15 | 0.01 | −0.11 | 0.13 | 1.05 | 0.15 | -2.47 | −0.25 | |

| Hidden Layer | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| (1–1) | (1–2) | (1–3) | (1–4) | (1–5) | (1–6) | (1–7) | |||

| Input Layer | (Bias) | 0.96 | 0.88 | 1.05 | 2.79 | −0.95 | 0.74 | −2.50 | |

| W | 2.00 | −0.89 | 0.17 | −0.28 | −1.25 | 0.15 | 1.32 | ||

| C | −6.73 | 0.18 | −0.76 | 1.52 | 6.05 | 0.44 | −0.97 | ||

| FA | −2.04 | −0.44 | −0.49 | 1.09 | 1.81 | 0.09 | 1.41 | ||

| FAg | 3.24 | −0.08 | 0.29 | −0.84 | −2.77 | −0.56 | 2.17 | ||

| CAg | −0.95 | 0.93 | 0.34 | −0.88 | 1.17 | −0.47 | −2.07 | ||

| Hidden Layer | |||||||||

| (1–1) | (1–2) | (1–3) | (1–4) | (1–5) | (1–6) | (1–7) | (Bias) | ||

| Output Layer | Fc28 | −3.70 | 2.16 | −0.60 | −0.43 | −4.52 | 4.12 | 0.89 | −2.63 |

| P | −0.08 | -0.03 | −3.29 | 3.18 | -0.08 | -0.02 | −0.02 | −0.33 | |

| Hidden Layer | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| (1–1) | (1–2) | (1–3) | (1–4) | (1–5) | (1–6) | (1–7) | |||

| Input Layer | (Bias) | 1.77 | 0.32 | 0.61 | −0.57 | 0.61 | −1.43 | 1.87 | |

| W | 0.89 | −0.18 | 2.78 | −2.57 | 1.11 | −4.93 | 4.45 | ||

| C | −2.52 | 2.07 | −2.30 | 3.37 | 6.53 | 6.68 | −7.43 | ||

| FA | −1.62 | 1.38 | −1.34 | 1.46 | 1.08 | 0.61 | −0.87 | ||

| FAg | 1.42 | −0.14 | −1.13 | 0.80 | −1.50 | -3.41 | 4.18 | ||

| CAg | 1.67 | −0.20 | 1.19 | −1.25 | −0.27 | 1.31 | −1.03 | ||

| Hidden Layer | |||||||||

| (1–1) | (1–2) | (1–3) | (1–4) | (1–5) | (1–6) | (1–7) | (Bias) | ||

| Output Layer | Fc28 | −0.07 | −1.84 | 2.73 | 2.55 | 2.63 | 3.93 | 4.33 | −2.41 |

| P | −3.10 | 3.27 | −0.08 | −0.11 | 0.30 | −0.07 | −0.09 | −0.18 | |

| Item | Technique | Model | SSE | Avg. Error % | R2 |

|---|---|---|---|---|---|

| Fc28 | GP | Equation (1) | 4238 | 19.1 | 0.788 |

| ANN-BP | Figure 3, Table 3 | 306 | 5.1 | 0.986 | |

| ANN-GRG | Figure 3, Table 4 | 392 | 5.8 | 0.983 | |

| ANN-GA | Figure 3, Table 5 | 568 | 7.0 | 0.974 | |

| EPR | Equation (3) | 1195 | 10.1 | 0.957 | |

| P | GP | Equation (2) | 0 | 0.8 | 0.999 |

| ANN-BP | Figure 3, Table 3 | 3 | 2.2 | 0.994 | |

| ANN-GRG | Figure 3, Table 4 | 0 | 0.8 | 0.999 | |

| ANN-GA | Figure 3, Table 5 | 1 | 1.0 | 0.999 | |

| EPR | Equation (4) | 0 | 0.4 | 1.000 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Onyelowe, K.C.; Kontoni, D.-P.N.; Ebid, A.M.; Dabbaghi, F.; Soleymani, A.; Jahangir, H.; Nehdi, M.L. Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings 2022, 12, 948. https://doi.org/10.3390/buildings12070948

Onyelowe KC, Kontoni D-PN, Ebid AM, Dabbaghi F, Soleymani A, Jahangir H, Nehdi ML. Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings. 2022; 12(7):948. https://doi.org/10.3390/buildings12070948

Chicago/Turabian StyleOnyelowe, Kennedy C., Denise-Penelope N. Kontoni, Ahmed M. Ebid, Farshad Dabbaghi, Atefeh Soleymani, Hashem Jahangir, and Moncef L. Nehdi. 2022. "Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations" Buildings 12, no. 7: 948. https://doi.org/10.3390/buildings12070948

APA StyleOnyelowe, K. C., Kontoni, D.-P. N., Ebid, A. M., Dabbaghi, F., Soleymani, A., Jahangir, H., & Nehdi, M. L. (2022). Multi-Objective Optimization of Sustainable Concrete Containing Fly Ash Based on Environmental and Mechanical Considerations. Buildings, 12(7), 948. https://doi.org/10.3390/buildings12070948