Interactive Effects of Admixtures on the Compressive Strength Development of Portland Cement Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Sample Preparation

2.2. Central Composite Face-Centered Design (CCFD)

3. Results and Discussion

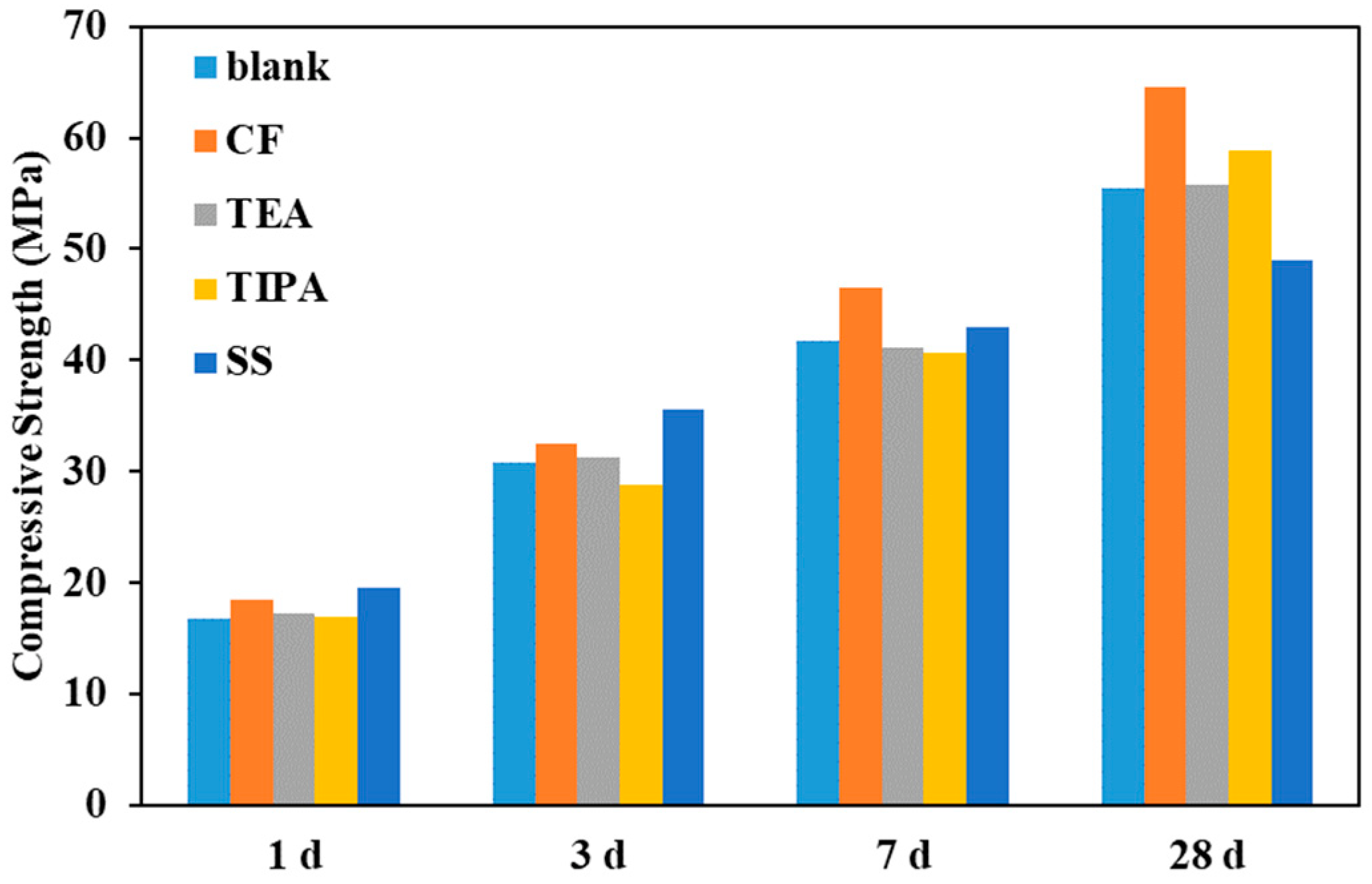

3.1. Effect of Each Admixture Alone on Compressive Strength of Mortars

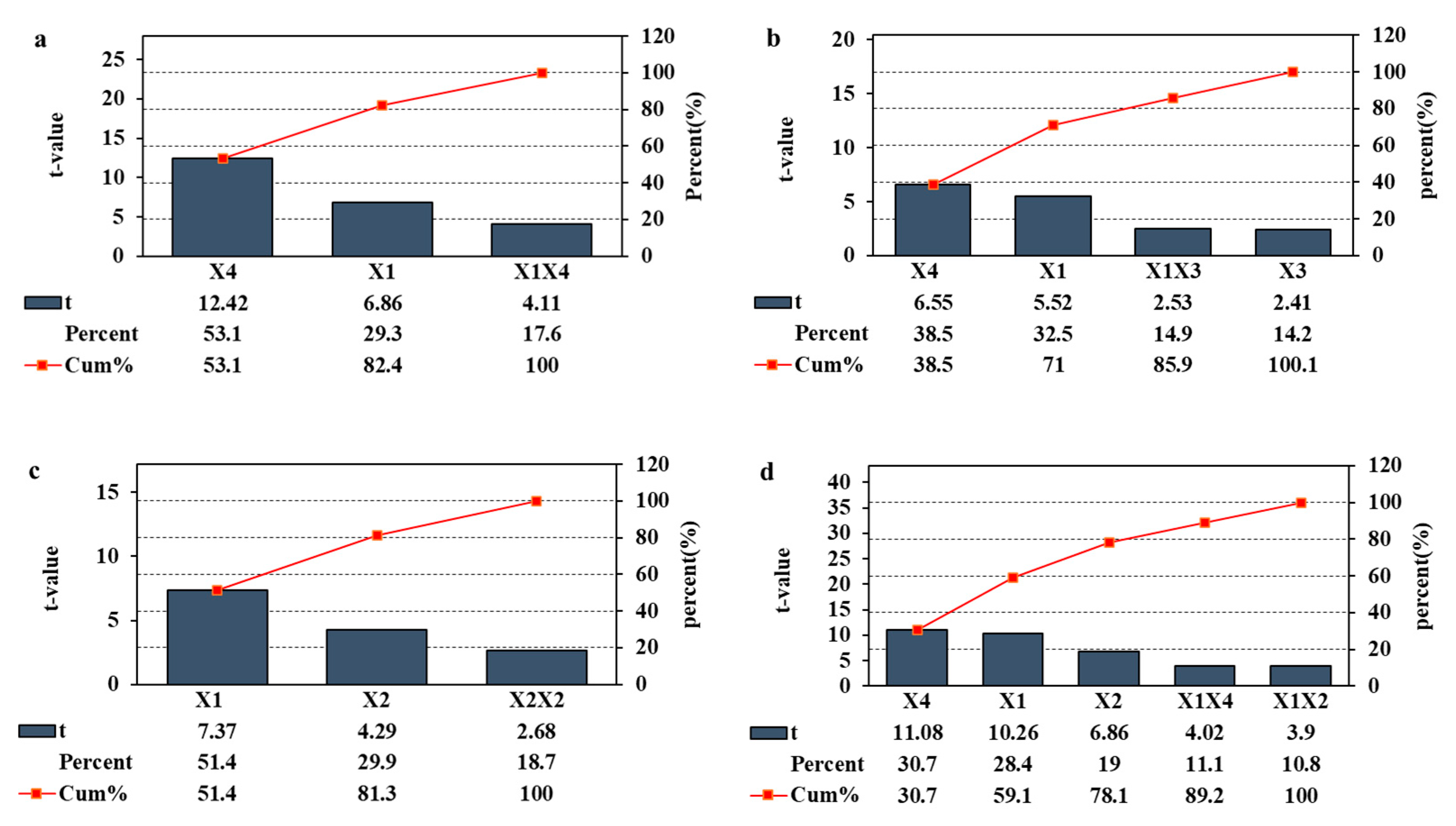

3.2. Statistical Model for Assessing the Interactive Effects of Chemical Admixtures

3.3. Interactive Effect of Chemical Admixtures on Compressive Strength of Mortars

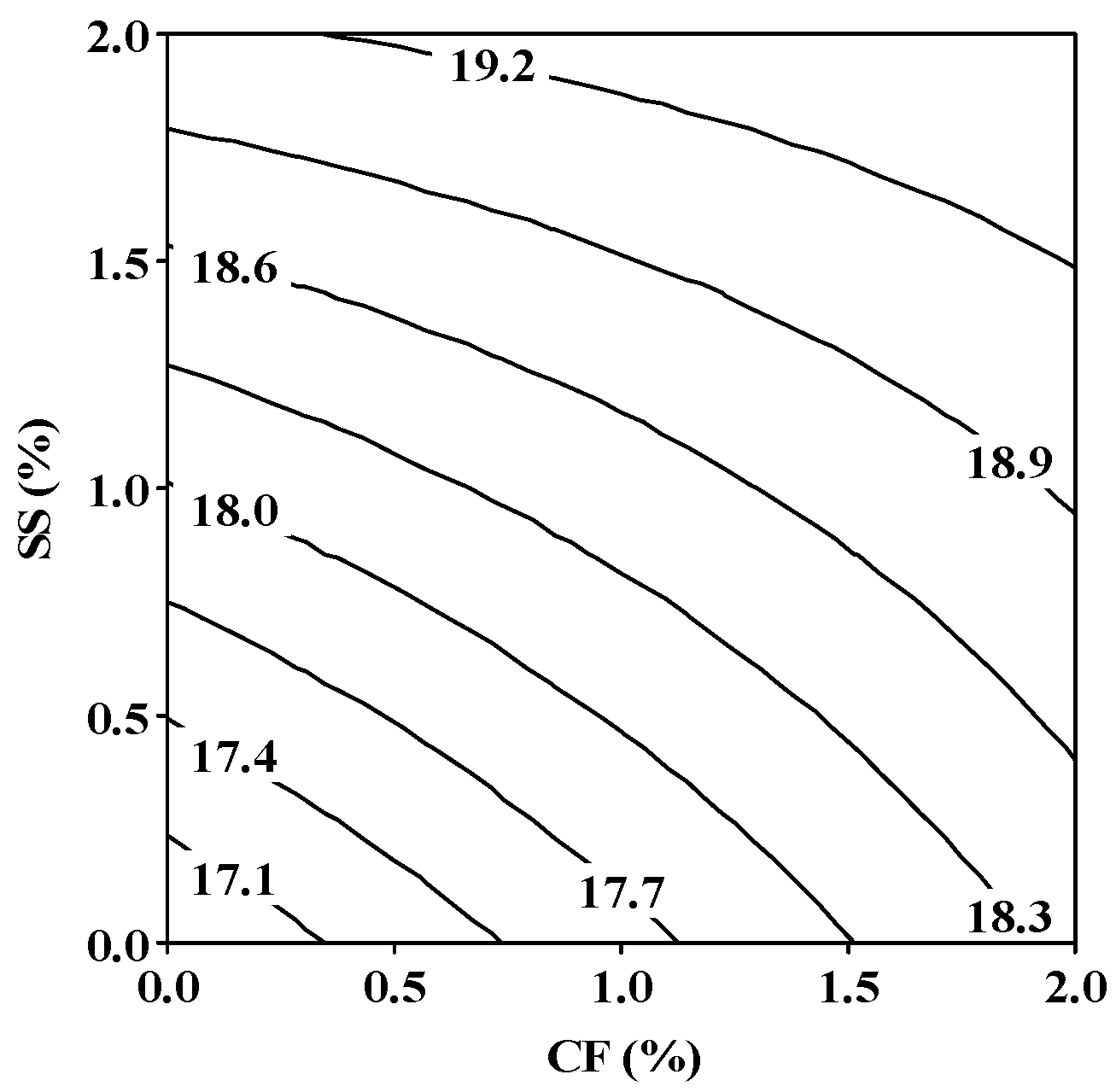

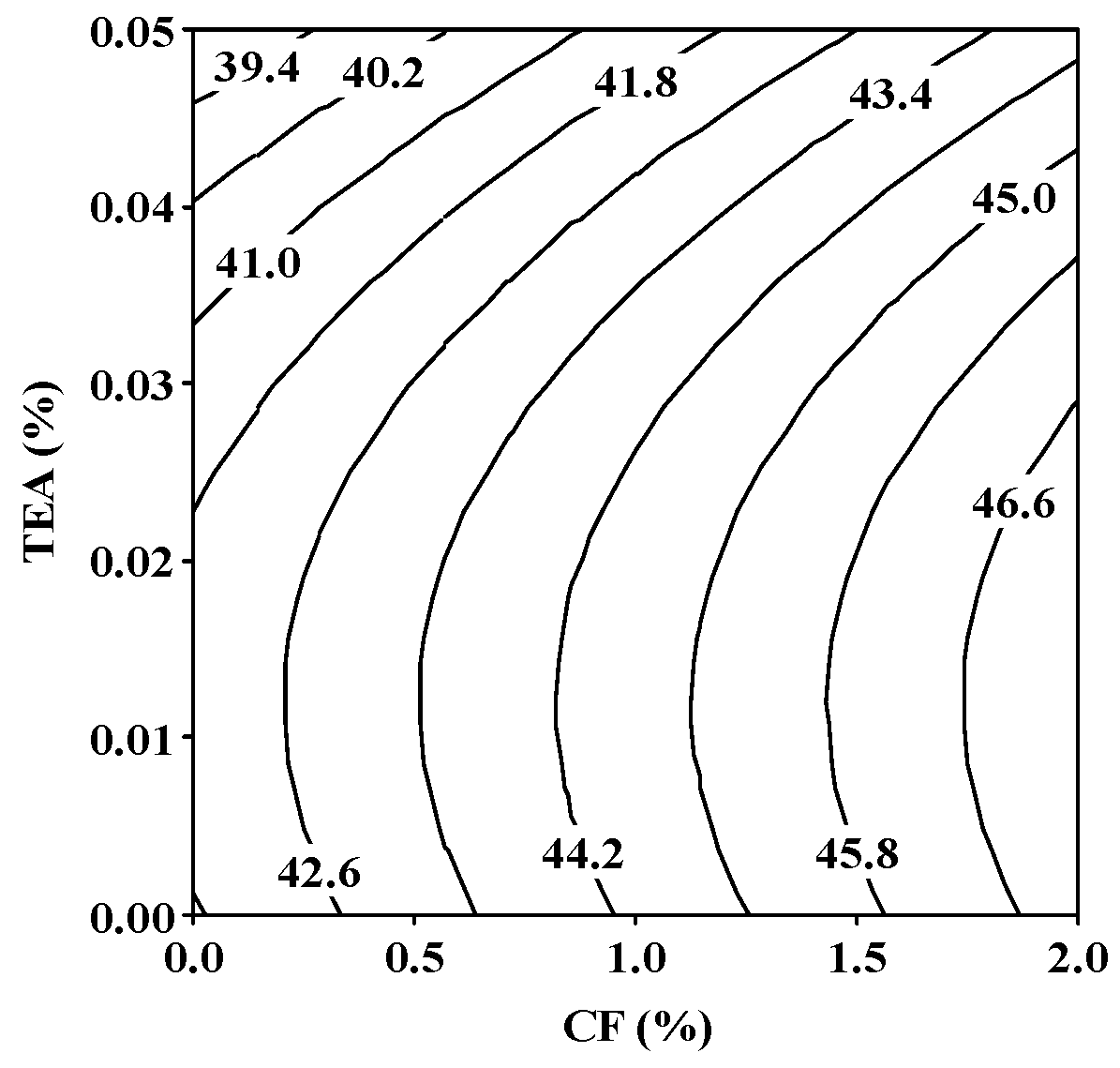

3.3.1. Interactive Effect of Chemical Admixtures on 1 d Strength

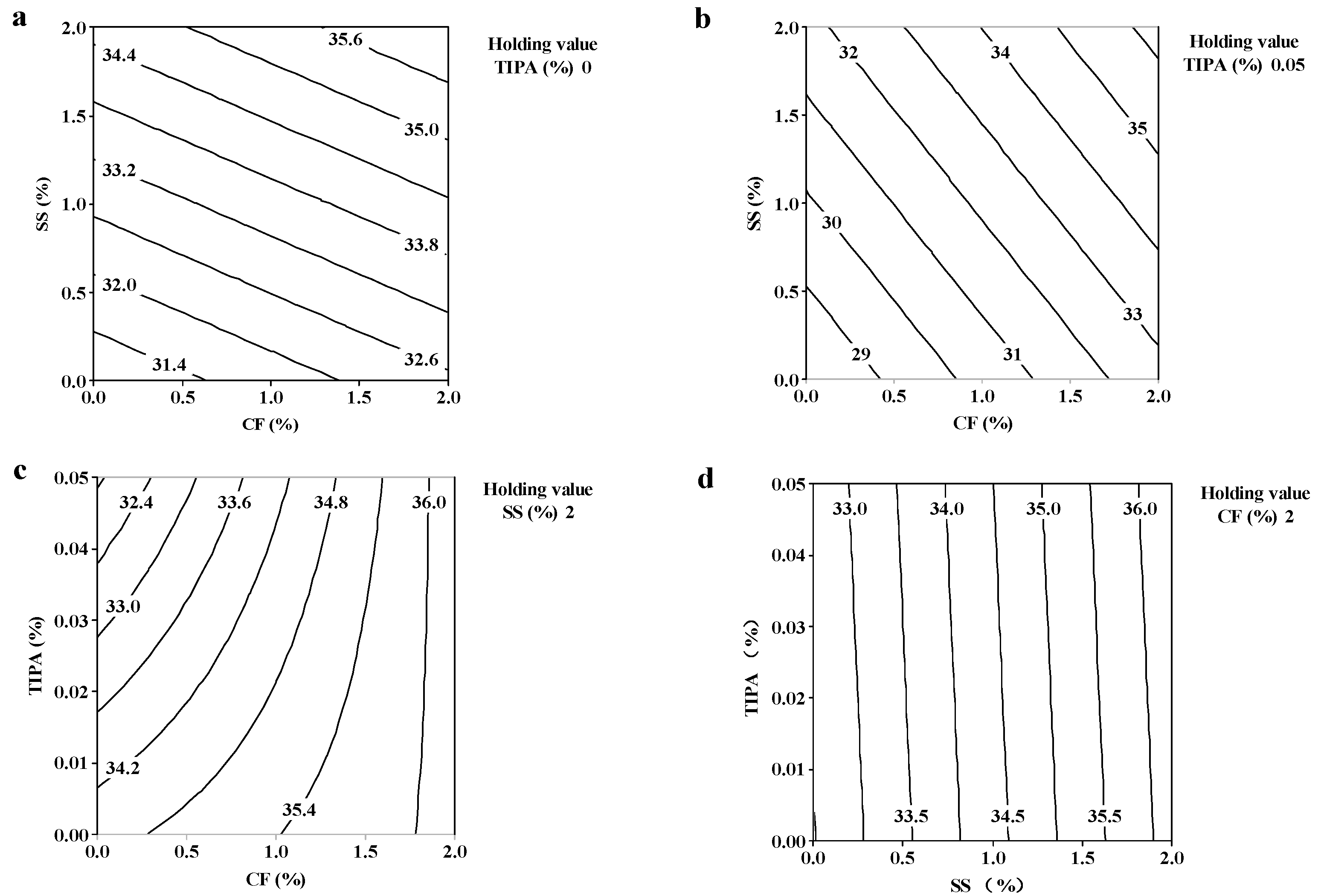

3.3.2. Interactive Effect of Chemical Admixtures on 3 d Strength

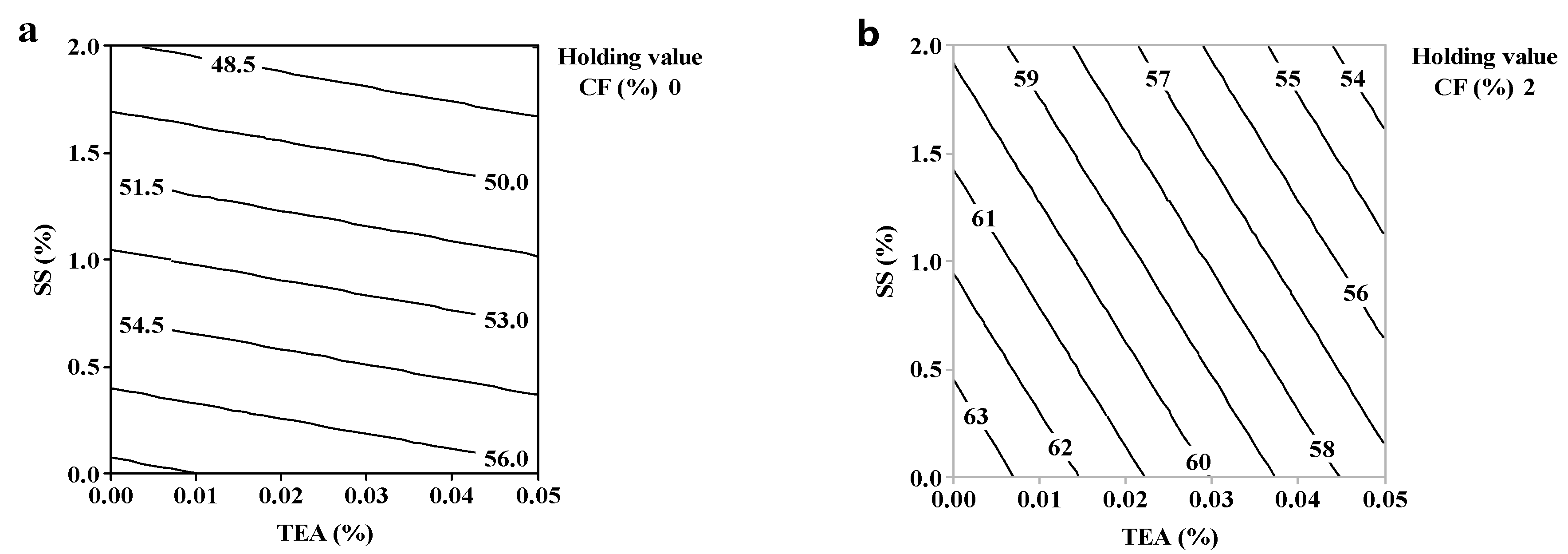

3.3.3. Interactive Effect of Chemical Admixtures on 7 d Strength

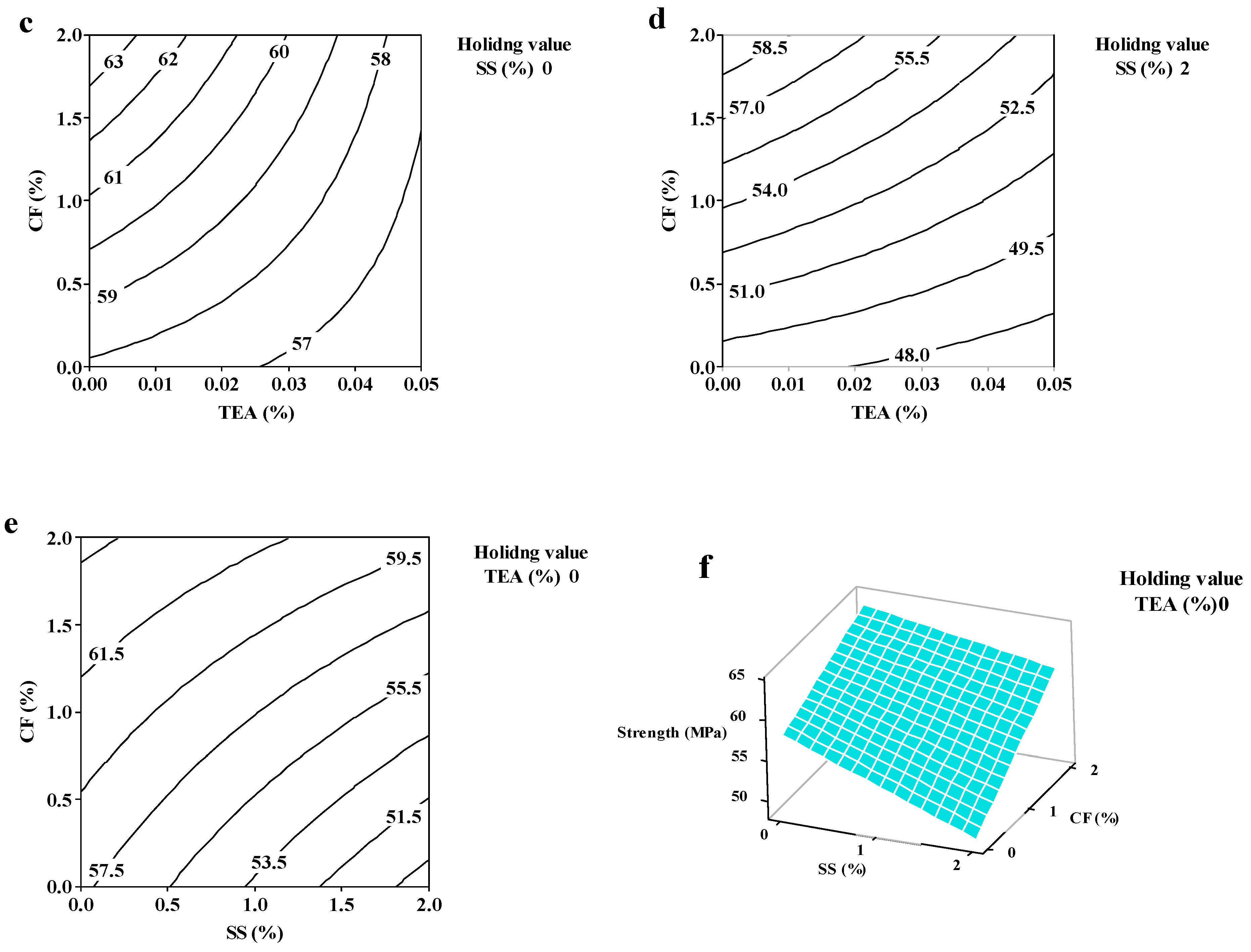

3.3.4. Interactive Effect of Chemical Admixtures on 28 d Strength

4. Conclusions

- (1)

- The addition of CF could enhance the compressive strength of Portland cement mortars at all the curing days. SS contributed significantly to the compressive strength of mortars at early ages of curing (1 d and 3 d) but was not noticeable or even detrimental to concrete strength at the later ages. TIPA could improve the strength development at 1 d but had almost no impact at other curing days. TEA had a positive impact on 1 d and 28 d strength but had no noticeable or even had a small detrimental impact on 3 d and 7 d strength.

- (2)

- As the 1 d strength model shows, only CF and SS had a significant effect on the compressive strength of mortar at 1 d. Although the interaction of CF and SS would hinder their respective positive effect on the strength of mortars, the 1 d strength of cement mortar still increased with the increasing content of both CF and SS.

- (3)

- There was a negative effect of TIPA and a positive interactive effect between TIPA and CF on the compressive strength at 3 d. If the dosage of CF exceeded 2%, the positive interactive effect of TIPA and CF was sufficient to offset the negative effect of TIPA on the strength of mortars at 3 d.

- (4)

- The effects of SS and TIPA disappeared at 7 d and the effect of TEA and square term (TEA2) appeared in the quadratic 7 d strength model. TIPA had a positive influence on 7 d strength until a turning point was reached, and the optimum dosage was approximately 0.013%.

- (5)

- The 28 d strength model indicated that the interactive effects of CF with TEA and SS occurred. TEA itself and the interaction between TEA and CF both had negative effects on the strength of mortar at 28 d. In addition, SS itself had a significant negative effect on the 28 d strength. Thus, although SS could strengthen the effect of CF, the 28 d strength enhancement only depended on the dosage of CF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Igliński, B.; Buczkowski, R. Development of Cement Industry in Poland—History, Current State, Ecological Aspects. A Review. J. Clean. Prod. 2017, 141, 702–720. [Google Scholar] [CrossRef]

- Xu, D.; Cui, Y.; Li, H.; Yang, K.; Xu, W.; Chen, Y. On the Future of Chinese Cement Industry. Cem. Concr. Res. 2015, 78, 2–13. [Google Scholar] [CrossRef]

- Scrivener, K.; Ouzia, A.; Juilland, P.; Mohamed, A.K. Advances in Understanding Cement Hydration Mechanisms. Cem. Concr. Res. 2019, 124, 105823. [Google Scholar] [CrossRef]

- Dodson, V.H. Concrete Admixture; Springer Science & Business Media: Berlin, Germany, 2013. [Google Scholar]

- Wang, D.; Shi, C.; Wu, Z.; Xiao, J.; Huang, Z.; Fang, Z. A Review on Ultra High Performance Concrete: Part II. Hydration, Microstructure and Properties. Constr. Build. Mater. 2015, 96, 368–377. [Google Scholar] [CrossRef]

- Dorn, T.; Blask, O.; Stephan, D. Acceleration of Cement Hydration—A Review of the Working Mechanisms, Effects on Setting Time, and Compressive Strength Development of Accelerating Admixtures. Constr. Build. Mater. 2022, 323, 126554. [Google Scholar] [CrossRef]

- Heikal, M. Effect of Calcium Formate as an Accelerator on the Physicochemical and Mechanical Properties of Pozzolanic Cement Pastes. Cem. Concr. Res. 2004, 34, 1051–1056. [Google Scholar] [CrossRef]

- Zhang, F.; Bai, Y.; Cai, Y. Effect of Calcium Formate on Early Hydration of Cement at 5 °C. Cailiao Daobao/Mater. Rep. 2021, 35, 1–8. Available online: http://www.mater-rep.com/EN/10.11896/cldb.20020138 (accessed on 29 March 2022).

- Ben, X.; Jiang, L.; Guo, M.Z.; Meng, Y.; Chen, L.; Jin, W.; Wang, F. Chloride Erosion Resistance of Calcium Formate Incorporated Cement Mortar under Chloride Attack. Constr. Build. Mater. 2022, 314, 125611. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, J.; Cao, Q.; Gao, X. Effect of Calcium Formate on the Compressive Strength, and Hydration Process of Cement Composite Containing Fly Ash and Slag. J. Build. Eng. 2022, 50, 104133. [Google Scholar] [CrossRef]

- Here, Z.; Olmez, H. The Influence of Ethanolamines on the Hydration and Mechanical Properties of Portland Cement. Cem. Concr. Res. 1996, 26, 701–705. [Google Scholar] [CrossRef]

- Here, Z.; Olmez, H. The Influence of Ethanolamines on the Surface Properties of Portland Cement Pastes. Cem. Concr. Res. 1997, 27, 805–809. [Google Scholar] [CrossRef]

- Gartner, E.; Myers, D. Influence of Tertiary Alkanolamines on Portland Cement Hydration. J. Am. Ceram. Soc. 1993, 76, 1521–1530. [Google Scholar] [CrossRef]

- Dodson, V.H. Concrete Admixture; Van Nostrand Reinhold: New York, NY, USA, 1990. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford: London, UK, 1997. [Google Scholar]

- Sandberg, P.J.; Doncaster, F. On the Mechanism of Strength Enhancement of Cement Paste and Mortar with Triisopropanolamine. Cem. Concr. Res. 2004, 34, 973–976. [Google Scholar] [CrossRef]

- Zhang, T.; Sun, Z.; Yang, H.; Ji, Y.; Yan, Z. Enhancement of Triisopropanolamine on the Compressive Strength Development of Cement Paste Incorporated with High Content of Wasted Clay Brick Powder and Its Working Mechanism. Constr. Build. Mater. 2021, 302, 124052. [Google Scholar] [CrossRef]

- Wang, L.; Hou, D.; Shang, H.; Zhao, T. Molecular Dynamics Study on the Tri-Calcium Silicate Hydration in Sodium Sulfate Solution: Interface Structure, Dynamics and Dissolution Mechanism. Constr. Build. Mater. 2018, 170, 402–417. [Google Scholar] [CrossRef]

- Ma, C.; Zhao, B.; Wang, L.; Long, G.; Xie, Y. Clean and Low-Alkalinity One-Part Geopolymeric Cement: Effects of Sodium Sulfate on Microstructure and Properties. J. Clean. Prod. 2020, 252, 119279. [Google Scholar] [CrossRef]

- Tan, H.; Deng, X.; He, X.; Zhang, J.; Zhang, X.; Su, Y.; Yang, J. Compressive Strength and Hydration Process of Wet-Grinded Granulated Blast-Furnace Slag Activated by Sodium Sulfate and Sodium Carbonate. Cem. Concr. Compos. 2019, 97, 387–398. [Google Scholar] [CrossRef]

- Zhao, Y.; Qiu, J.; Zhang, S.; Guo, Z.; Ma, Z.; Sun, X.; Xing, J. Effect of Sodium Sulfate on the Hydration and Mechanical Properties of Lime-Slag Based Eco-Friendly Binders. Constr. Build. Mater. 2020, 250, 118603. [Google Scholar] [CrossRef]

- Chakchouk, A.; Trifi, L.; Samet, B.; Bouaziz, S. Formulation of Blended Cement: Effect of Process Variables on Clay Pozzolanic Activity. Constr. Build. Mater. 2009, 23, 1365–1373. [Google Scholar] [CrossRef]

- Huang, H.; Shen, X.; Zheng, J. Modeling, Analysis of Interaction Effects of Several Chemical Additives on the Strength Development of Silicate Cement. Constr. Build. Mater. 2010, 24, 1937–1943. [Google Scholar] [CrossRef]

- Pareto Chart. Available online: http://en.wikipedia.org/wiki/Pareto_chart (accessed on 30 January 2022).

- Contour Plot. Available online: http://en.wikipedia.org/wiki/Contour_line (accessed on 2 March 2022).

- GB/T 17671, Test Method of Cement Mortar Strength (ISO Method), China. 1999. Available online: http://std.samr.gov.cn/gb/search/gbDetailed?id=71F772D798CCD3A7E05397BE0A0AB82A (accessed on 31 May 2021).

- Shi, Z. Effects of Triisopropanol Amine, Sodium Chloride and Limestone on the Compressive Strength and Hydration of Portland Cement. Constr. Build. Mater. 2016, 125, 210–218. [Google Scholar] [CrossRef]

- Kamoun, A.; Samet, B.; Bouaziz, J.; Châabouni, M. Application of a Rotatable Orthogonal Central Composite Design to the Optimization of the Formulation and Utilization of an Useful Plasticizer for Cement. Analusis 1999, 27, 91–96. [Google Scholar] [CrossRef]

- Tang, S.W.; Cai, X.H.; He, Z.; Shao, H.Y.; Li, Z.J.; Chen, E. Hydration Process of Fly Ash Blended Cement Pastes by Impedance Measurement. Constr. Build. Mater. 2016, 113, 939–950. [Google Scholar] [CrossRef]

- Zhu, J.; Li, Z.; Yang, R.; Zhang, Y. Organic Additive Implantation onto Cement Hydration Products. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2014, 29, 527–533. [Google Scholar] [CrossRef]

| Compound | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Loss |

|---|---|---|---|---|---|---|---|

| wt.% | 65.74 | 22.35 | 4.61 | 3.62 | 2.08 | 0.32 | 1.28 |

| Admixture | Symbol | Low Level | Intermediate Level | High Level | |||

|---|---|---|---|---|---|---|---|

| Coded | Actual (%) | Coded | Actual (%) | Coded | Actual (%) | ||

| CF | x1 | −1 | 0 | 0 | 1 | 1 | 2 |

| TEA | x2 | 0 | 0.025 | 0.05 | |||

| TIPA | x3 | 0 | 0.025 | 0.05 | |||

| Na2SO4 | x4 | 0 | 1 | 2 | |||

| Chemical Additives (Coded Number) | Compressive Strengths (MPa) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Standard No. | Run No | CF (x1) | TEA (x1) | TIPA (x1) | SS (x1) | 1 d | 3 d | 7 d | 28 d |

| 29 | 1 | 0 | 0 | 0 | 0 | 18.5 | 34.2 | 46.1 | 56.5 |

| 1 | 2 | −1 | −1 | −1 | −1 | 16.7 | 30.8 | 44.8 | 56.4 |

| 2 | 3 | −1 | −1 | −1 | 1 | 19.6 | 34.9 | 43.0 | 49.0 |

| 15 | 4 | 1 | 1 | 1 | −1 | 18.2 | 32.4 | 44.5 | 56.0 |

| 5 | 5 | −1 | 1 | −1 | −1 | 16.8 | 30.6 | 43.9 | 55.7 |

| 27 | 6 | 0 | 0 | 0 | 0 | 18.9 | 33.4 | 44.6 | 55.9 |

| 12 | 7 | 1 | −1 | 1 | 1 | 19.3 | 39.0 | 53.0 | 57.8 |

| 7 | 8 | 1 | 1 | −1 | −1 | 18.2 | 32.0 | 46.5 | 56.5 |

| 17 | 9 | 0 | 0 | 0 | −1 | 17.2 | 30.3 | 43.3 | 59.8 |

| 10 | 10 | −1 | −1 | 1 | 1 | 18.8 | 33.4 | 42.9 | 48.6 |

| 30 | 11 | 0 | 0 | 0 | 0 | 19.2 | 31.0 | 43.5 | 54.8 |

| 28 | 12 | 0 | 0 | 0 | 0 | 18.8 | 31.3 | 44.8 | 54.0 |

| 16 | 13 | 1 | 1 | 1 | 1 | 19.2 | 36.4 | 43.5 | 54.0 |

| 14 | 14 | −1 | 1 | 1 | 1 | 18.9 | 31.3 | 37.8 | 44.2 |

| 8 | 15 | 1 | 1 | −1 | 1 | 19.2 | 36.0 | 44.2 | 53.7 |

| 13 | 16 | −1 | 1 | 1 | −1 | 16.5 | 29.4 | 39.5 | 56.7 |

| 4 | 17 | 1 | −1 | −1 | 1 | 19.7 | 34.8 | 48.5 | 60.1 |

| 19 | 18 | −1 | 0 | 0 | 0 | 17.6 | 30.9 | 43.3 | 54.4 |

| 23 | 19 | 0 | 0 | −1 | 0 | 18.2 | 34.7 | 42.2 | 53.8 |

| 26 | 20 | 0 | 0 | 0 | 0 | 18.4 | 32.4 | 42.5 | 56.7 |

| 3 | 21 | 1 | −1 | −1 | −1 | 18.9 | 31.8 | 46.6 | 64.6 |

| 6 | 22 | −1 | 1 | −1 | 1 | 19 | 33.5 | 36.7 | 47.8 |

| 22 | 23 | 0 | 1 | 0 | 0 | 18.8 | 32.3 | 41.2 | 54.8 |

| 31 | 24 | 0 | 0 | 0 | 0 | 18.6 | 31.3 | 43.4 | 54.3 |

| 21 | 25 | 0 | −1 | 0 | 0 | 18.2 | 31.0 | 41.4 | 58.4 |

| 18 | 26 | 0 | 0 | 0 | 1 | 19.4 | 35.7 | 44.7 | 52.2 |

| 20 | 27 | 1 | 0 | 0 | 0 | 19.1 | 35.4 | 46.8 | 59.8 |

| 9 | 28 | −1 | −1 | 1 | −1 | 16.9 | 29.2 | 40.7 | 58.9 |

| 24 | 29 | 0 | 0 | 1 | 0 | 18.7 | 33.3 | 45.8 | 56.2 |

| 11 | 30 | 1 | −1 | 1 | −1 | 18.3 | 35.3 | 44.8 | 64.4 |

| 25 | 31 | 0 | 0 | 0 | 0 | 18.6 | 32.2 | 45.7 | 54.7 |

| 1 d Strength | 3 d Strength | 7 d Strength | 28 d Strength | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Term | Coef. | t | p | Term | Coef. | t | p | Term | Coef. | t | p | Term | Coef. | t | p |

| Const. | 16.830 | 351.65 | 0 | Const. | 30.889 | 153.04 | 0 | Const. | 41.728 | 106.47 | 0 | Const. | 57.84 | 242.45 | 0 |

| x1 | 0.772 | 6.86 | 0 | x1 | 0.799 | 5.52 | 0 | x1 | 2.606 | 7.37 | 0 | x1 | 3.046 | 10.26 | 0 |

| x4 | 1.156 | 12.42 | 0 | x3 | −57.4 | −2.41 | 0.024 | x2 | 56.2 | 4.29 | 0 | x2 | −32.7 | −6.86 | 0 |

| x1x4 | −0.3 | −4.11 | 0 | x4 | 1.844 | 6.55 | 0 | x2x2 | −2336 | −2.68 | 0.013 | x4 | −4.609 | −11.08 | 0 |

| x1x3 | 30.3 | 2.53 | 0.018 | x1x4 | 1.281 | 4.02 | 0 | ||||||||

| x1x2 | −49.8 | −3.9 | 0.001 | ||||||||||||

| LoF | 0.199 | LoF | 0.794 | LoF | 0.5 | LoF | 0.322 | ||||||||

| R2 | 88.99% | R2 | 76.69% | R2 | 74.75% | R2 | 92.46% | ||||||||

| Linear | 0 | Linear | 0 | Linear | 0 | Linear | 0 | ||||||||

| Square | 0 | Square | 0 | Square | 0.013 | Square | 0 | ||||||||

| Interaction | 0 | Interaction | 0.018 | Interaction | 0 | Interaction | 0 | ||||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jia, J.; Wang, Y. Interactive Effects of Admixtures on the Compressive Strength Development of Portland Cement Mortars. Buildings 2022, 12, 422. https://doi.org/10.3390/buildings12040422

Jia J, Wang Y. Interactive Effects of Admixtures on the Compressive Strength Development of Portland Cement Mortars. Buildings. 2022; 12(4):422. https://doi.org/10.3390/buildings12040422

Chicago/Turabian StyleJia, Jinqing, and Yimu Wang. 2022. "Interactive Effects of Admixtures on the Compressive Strength Development of Portland Cement Mortars" Buildings 12, no. 4: 422. https://doi.org/10.3390/buildings12040422

APA StyleJia, J., & Wang, Y. (2022). Interactive Effects of Admixtures on the Compressive Strength Development of Portland Cement Mortars. Buildings, 12(4), 422. https://doi.org/10.3390/buildings12040422