Tensile Behavior of Basalt-Fiber-Grid-Reinforced Mortar before and after Exposure to Elevated Temperature

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

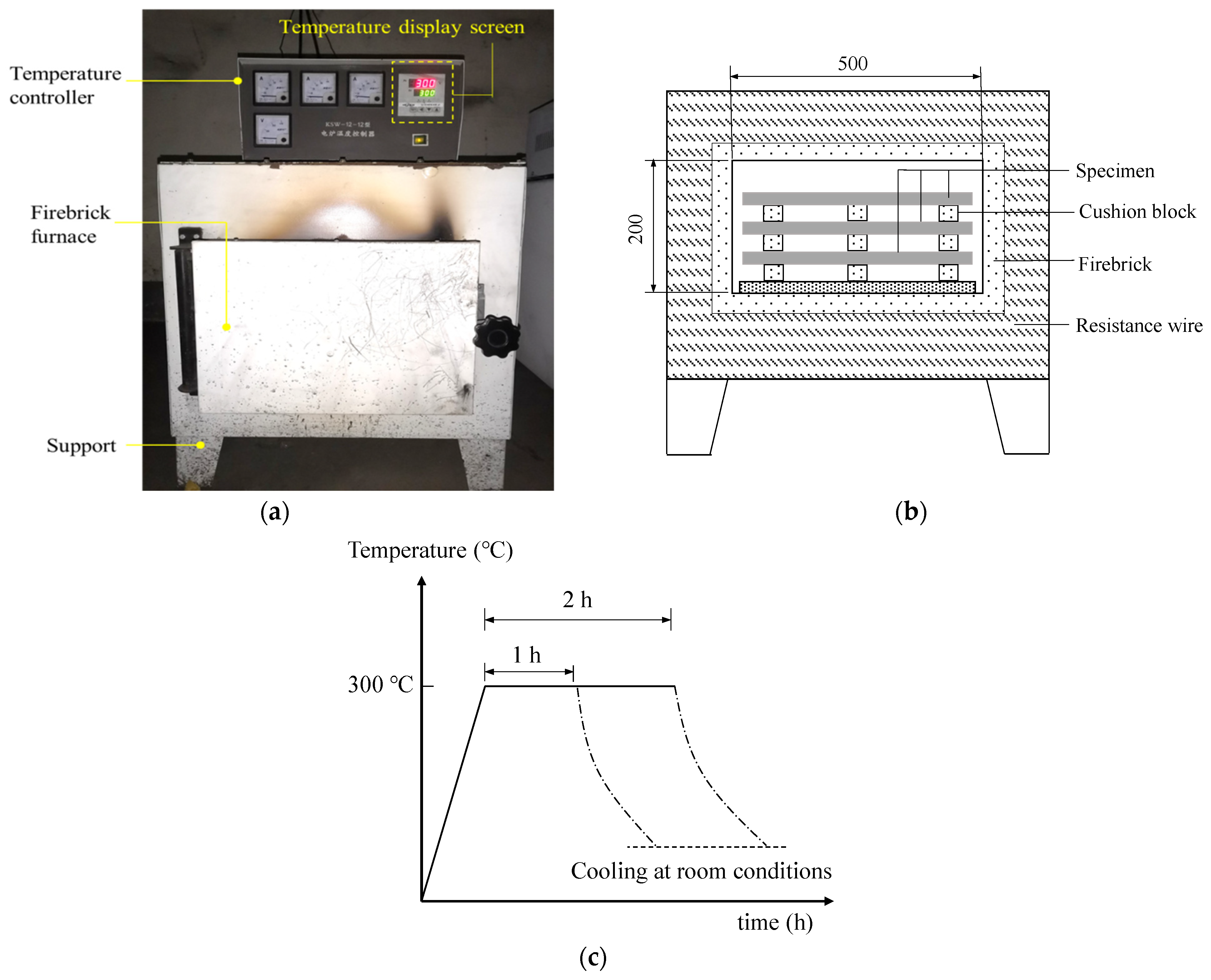

2.2. Specimen Preparation and Test Set-Up

3. Results and Discussions

3.1. Tensile Behavior of BGRM before Exposure to Elevated Temperature

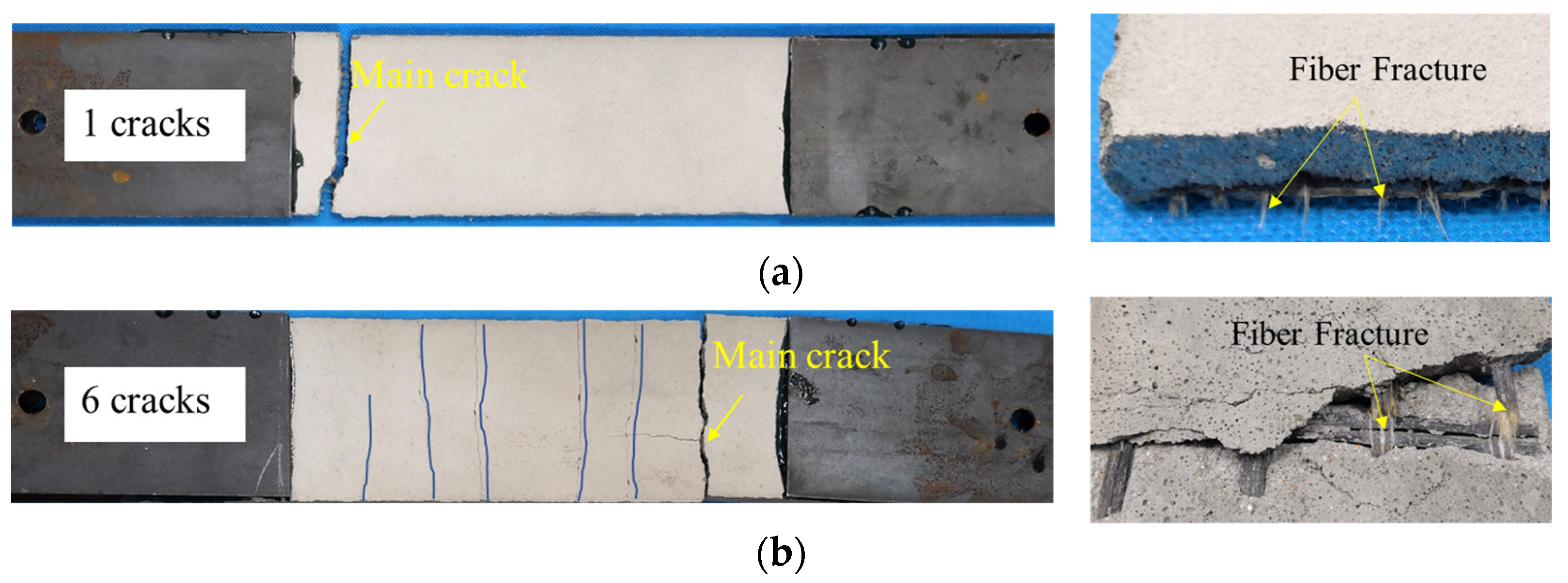

3.1.1. Failure and Cracking Modes

3.1.2. Tensile Stress–Strain Curves

3.1.3. Comparison of the BGRM Reinforced with Different Basalt Fiber Grids

3.2. Tensile Behavior of the BGRM after Exposure to Elevated Temperature

3.2.1. Failure and Cracking Modes

3.2.2. Tensile Stress–Strain Curves

3.2.3. Degradation of Tensile Behavior of the BGRM

3.2.4. Strength Degradation Model

4. Conclusions

- The T25- and G50-reinforced mortar plates at ambient temperature exhibited more cracks and more obvious strain hardening in the post-cracking stage of stress–strain curves. The higher the bearing capacity of the grid, the greater the peak stress of the thin plate. The peak stress for the T25-reinforced plate was 85% and 32% higher than that of the T5- and G50-reinforced plates, respectively. In addition, adding short fibers to the mortar was a good choice to improve the tensile properties of BGRM, where both the cracking and peak stress can be improved.

- The fiber strength utilization efficiency of the grid was affected by the impregnation polymer. The G50 had the highest strength utilization efficiency of 78.3% when tensioned alone, and the T5 had the lowest value of 24.5%. The epoxy resin was recommended as the impregnated polymer for the high-strength utilization of fiber in the grid. Moreover, the strength utilization efficiency of the T25 and G50 decreased when tensioned in the plate, while the strength utilization efficiency of the T5 was improved due to that the twisted yarn was restrained by the mortar.

- High-temperature exposure time was the key factor affecting the tensile properties of BGRM. With the high-temperature exposure time increasing, the reinforcement effect of the fiber grid on the mortar was gradually weakened. The strain hardening in the post-cracking stage of the stress–strain curve gradually became less obvious, and the cracking and peak stress decreased significantly. In addition, owing to the melting of short fibers at high temperature, it is undesirable to improve the tensile properties by adding PVA fiber into the mortar.

- As the high-temperature exposure time increased, the strength degradation coefficient of the BGRM plates decreased rapidly at first and then gradually became gentle. The higher the impregnation polymer content in the fiber grid, the slower the strength degradation of the plate. The slowest strength degradation was observed in the G50-reinforced mortar plate, whose degradation coefficient was 26.2% higher than that of the T5-reinforced plate. Based on the experimental results, an exponential strength degradation model related to the high-temperature exposure time was proposed, which can describe the strength degradation law of the BGRM plates well.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quadflieg, T.; Leimbrink, S.; Gries, T.; Stolyarov, O. Effect of coating type on the mechanical performance of warp-knitted fabrics and cement-based composites. J. Compos. Mater. 2018, 52, 1–14. [Google Scholar] [CrossRef]

- Dvorkin, D.; Poursaee, A.; Peled, A.; Weiss, W.J. Influence of bundle coating on the tensile behavior, bonding, cracking and fluid transport of fabric cement-based composites. Cement Concr. Compos. 2013, 42, 9–19. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Kulas, C.; Gmbh, S. Actual Applications and Potential of Textile-Reinforced Concrete; GRC: Dubai, The United Arab Emirates, 2005. [Google Scholar]

- Rossi, E.; Randl, N.; Harsányi, P.; Mészly, T. Experimental study of fibre-reinforced TRC shear strengthening applications on non-stirrup reinforced concrete T-beams. Eng. Struct. 2022, 256, 113923. [Google Scholar] [CrossRef]

- Mesticou, Z.; Bui, L.; Larbi, A.S. Experimental investigation of tensile fatigue behavior of Textile-Reinforced Concrete (TRC): Effect of fatigue load and strain rate. Compos. Struct. 2017, 160, 1136–1146. [Google Scholar] [CrossRef]

- Zhou, F.; Liu, H.; Du, Y.; Liu, L.; Zhu, D.; Pan, W. Uniaxial Tensile Behavior of Carbon Textile Reinforced Mortar. Materials 2019, 12, 374. [Google Scholar] [CrossRef] [Green Version]

- Younis, A.; Ebead, U.A.; Shrestha, K.C. Tensile characterization of multiply fabric-reinforced cementitious matrix strengthening systems. Struct. Concr. 2020, 21, 713–723. [Google Scholar] [CrossRef]

- Goliath, K.B.; Cardoso, D.C.; Silva, F.A. Flexural behavior of carbon-textile-reinforced concrete I-section beams. Compos. Struct. 2021, 260, 113540. [Google Scholar] [CrossRef]

- Chandrathilaka, E.; Baduge, S.K.; Mendis, P.; Thilakarathna, P. Flexural Performance of Prefabricated Ultra-High-Strength Textile Reinforced Concrete (UHSTRC): An Experimental and Analytical Investigation. Buildings 2020, 10, 68. [Google Scholar] [CrossRef] [Green Version]

- Harri, G.; Gokulnath, N.; Karthick, R. Flexural Strengthening of Reinforced Concrete Beams using Ferrocement by Basalt Reinforcing Mesh. J. Civ. Eng. Environ. Technol. 2015, 2, 668–671. [Google Scholar]

- Jiang, Y.; Wang, X.; Li, B.; Higashi, Y.; Taniguchi, K.; Koga, D.; Ishida, K. Tunnel reinforcement effects by using combined PCM shotcrete and FRP grid technique. In Proceedings of the ISRM International Symposium-8th Asian Rock Mechanics Symposium, Sapporo, Japan, 14–16 October 2014. [Google Scholar]

- Li, C.; Xian, G. Experimental investigation of the microstructures and tensile properties of polyacrylonitrile-based carbon fibers exposed to elevated temperatures in air. J. Eng. Fiber. Fabr. 2019, 14, 155892501985001. [Google Scholar] [CrossRef]

- Feih, S.; Mouritz, A.P. Tensile properties of carbon fibers and carbon fiber–polymer composites in fire. Compos. Part A—Appl. Sci. Manuf. 2012, 43, 765–772. [Google Scholar] [CrossRef] [Green Version]

- Ombres, L.; Mazzuca, P.; Verre, S. Effects of Thermal Conditioning at High Temperatures on the Response of Concrete Elements Confined with a PBO-FRCM Composite System. J. Mater. Civ. Eng. 2022, 34, 04021413. [Google Scholar] [CrossRef]

- Nanni, A. FRCM strengthening—A new tool in the concrete and masonry repair toolbox. Concr. Int. Des. Constr. 2012, 34, 43–49. [Google Scholar]

- Estevan, L.; Varona, F.B.; Baeza, F.J.; Torres, B.; Bru, D. Textile Reinforced Mortars (TRM) tensile behavior after high temperature exposure. Constr. Build. Mater. 2022, 328, 127116. [Google Scholar] [CrossRef]

- Xu, S.; Shen, L.; Wang, J. The high-temperature resistance performance of TRC thin-plates with different cementitious materials: Experimental study. Constr. Build. Mater. 2016, 115, 506–519. [Google Scholar] [CrossRef]

- Ferretti, F.; Tilocca, A.R.; Incerti, A.; Mazzotti, C.; Savoia, M. Effects of Thermal Variations on the Tensile Behavior of FRCM Strengthening Systems. J. Compos. Constr. 2022, 26, 4022067. [Google Scholar] [CrossRef]

- Rambo, D.S.; Silva, F.A.; Filho, R.T.; Gomes, O.M. Effect of elevated temperatures on the mechanical behavior of basalt textile reinforced refractory concrete. Mater. Des. 2015, 65, 24–33. [Google Scholar] [CrossRef]

- Rambo, D.S.; Yao, Y.; Silva, F.A.; Filho, R.T.; Mobasher, B. Experimental investigation and modelling of the temperature effects on the tensile behavior of textile reinforced refractory concretes. Cement Concr. Compos. 2017, 75, 51–61. [Google Scholar] [CrossRef]

- Dinh, N.H.; Park, S.; Choi, K. Effect of dispersed micro-fibers on tensile behavior of uncoated carbon textile-reinforced cementitious mortar after high-temperature exposure. Cement Concr. Compos. 2021, 118, 103949. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Vu, X.H.; Larbi, A.S.; Ferrier, E. Experimental study of the effect of simultaneous mechanical and high-temperature loadings on the behavior of textile-reinforced concrete (TRC). Constr. Build. Mater. 2016, 125, 253–270. [Google Scholar] [CrossRef]

- Rambo, D.S.; Silva, F.A.; Filho, R.T.; Ukrainczyk, N.; Koenders, E. Tensile strength of a calcium-aluminate cementitious composite reinforced with basalt textile in a high-temperature environment. Cement Concr. Compos. 2016, 70, 183–193. [Google Scholar] [CrossRef]

- Homoro, O.; Vu, X.H.; Ferrier, E. Experimental and analytical study of the thermo-mechanical behavior of textile-reinforced concrete (TRC) at elevated temperatures: Role of discontinuous short glass fibers. Constr. Build. Mater. 2018, 190, 645–663. [Google Scholar] [CrossRef]

- Tlaiji, T.V.; Vu, X.; Ferrier, E.; Larbi, A.S. Thermomechanical behavior and residual properties of textile reinforced concrete (TRC) subjected to elevated and high temperature loading Experimental and comparative study. Compos. B Eng. 2018, 144, 99–110. [Google Scholar] [CrossRef]

- Hulin, T.; Lauridsen, D.H.; Hodicky, K.; Schmidt, J.W.; Stang, H. Influence of Basalt FRP Mesh Reinforcement on High-Performance Concrete Thin Plates at High Temperatures. J. Compos. Constr. 2015, 20, 04015034. [Google Scholar] [CrossRef]

- EN 1991-1-2; Eurocode 1: Actions on Structures—Part 1–2: General Actions-Actions on Structures Exposed to Fire. European Committee for Standardization: Brussels, Belgium, 2002.

- Lopresto, V.; Leone, C.; Iorio, D.I. Mechanical characterization of basalt fiber reinforced plastic. Compos. B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Sim, J.; Park, C.; Moon, D.Y. Characteristic of basalt fiber as strengthening material for concrete structures. Compos. B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Elmesalami, N.; Abed, F.; Refai, A.E. Concrete Columns Reinforced with GFRP and BFRP Bars under Concentric and Eccentric Loads: Experimental Testing and Analytical Investigation. J. Compos. Constr. 2021, 25, 04021003. [Google Scholar] [CrossRef]

- ISO 10618; Carbon Fiber—Determination of Tensile Properties of Resin-Impregnated Yarn. ISO: Geneva, Switzerland, 2004.

- GB 50016; Code for Design of Building Fire Protection. Ministry of Construction of the PRC: Beijing, China, 2014.

- Zhang, X.; Wang, X.; Peng, Z.; Zhu, Z.; Wu, Z. Parametric study on mechanical properties of basalt leno textile applied as concrete reinforcement. Adv. Struct. Eng. 2022, 25, 48–62. [Google Scholar] [CrossRef]

- Tian, L.; Zhang, J.; Dong, S.; Yuan, G.; Zhang, Q. Study on mechanical properties of cementitious composites reinforced with PVA fibers after exposure to high temperatures. Concrete 2011, 28, 31–33. [Google Scholar]

- Lion, M.; Skoczylas, F.; Lafhaj, Z.; Sersar, M. Experimental study on a mortar. Temperature effects on porosity and permeability. Residual properties or direct measurements under temperature. Cement Concr. Res. 2005, 35, 1937–1942. [Google Scholar] [CrossRef]

- Hager, I. Behavior of cement concrete at high temperature. Bull. Pol. Acad. 2013, 61, 145–154. [Google Scholar]

- Silva, F.A.; Butler, M.; Hempel, S.; Filho, R.T.; Mechtcherine, V. Effects of elevated temperatures on the interface properties of carbon textile-reinforced concrete. Cement Concr. Compos. 2014, 48, 26–34. [Google Scholar] [CrossRef]

| Basalt Fiber Grid | Mesh Size (mm) | Cross-Sectional Area of Fibers in the Grid (mm2) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Ultimate Strain (%) |

|---|---|---|---|---|---|

| T5 | 5 × 5 | 3.98 | 694 (21.4) | 32.6 (1.7) | 2.7 (0.31) |

| T25 | 25 × 25 | 6.04 | 1647 (126.4) | 74.6 (5.2) | 2.4 (0.08) |

| G50 | 50 × 50 | 2.72 | 2217 (150.3) | 93.4 (7.8) | 2.3 (0.12) |

| BGRM Plate Series | Specimen Number | Grid Type | Reinforcement Ratio (%) | Short PVA Fiber (%) | Temperature T (°C) | Exposure Time t (h) |

|---|---|---|---|---|---|---|

| BT5 | BT5-CT | T5 | 0.398 | 20 | ||

| BT5-300-1h | 300 | 1 | ||||

| BT5-300-2h | 300 | 2 | ||||

| BT25 | BT25-CT | T25 | 0.604 | 20 | ||

| BT25-300-1h | 300 | 1 | ||||

| BT25-300-2h | 300 | 2 | ||||

| BG50 | BG50-CT | G50 | 0.272 | 20 | ||

| BG50-300-1h | 300 | 1 | ||||

| BG50-300-2h | 300 | 2 | ||||

| BG50F | BG50F-CT | G50 | 0.272 | 1.0 | 20 | |

| BG50F-300-1h | 300 | 1 | ||||

| BG50F-300-2h | 300 | 2 |

| Specimen Number | Cracking Load Pcr (N) | Cracking Stress σcr (MPa) | Cracking Strain εcr (%) | Peak Load Pu (N) | Peak Stress σu (MPa) | Peak Strain εu (%) |

|---|---|---|---|---|---|---|

| BT5-CT | 4154.3 (4.4) | 4.15 (4.4) | 0.46 (6.7) | 3505.8 (7.3) | 3.51 (7.3) | 0.84 (1.1) |

| BT25-CT | 3961.4 (17) | 3.96 (17) | 0.41 (7.9) | 6503.5 (1.6) | 6.50 (1.6) | 3.54 (6.7) |

| BG50-CT | 3487.1 (8.7) | 3.49 (8.7) | 0.46 (22) | 4936.5 (5.2) | 4.94 (5.2) | 3.31 (10) |

| BG50F-CT | 4640.2 (13) | 4.64 (13) | 0.37 (3.3) | 5702.3 (0.9) | 5.70 (0.9) | 1.88 (9.8) |

| Specimen Number | Cracking Load Pcr (N) | Cracking Stress σcr (MPa) | Cracking Strain εcr (%) | Peak Load Pu (N) | Peak Stress σu (MPa) | Peak Strain εu (%) | Degradation Coefficient |

|---|---|---|---|---|---|---|---|

| BT5-300-1h | 2293.1 (16) | 2.29 (16) | 0.28 (16) | 2591.7 (9.4) | 2.59 (9.4) | 1.09 (20) | 0.74 |

| BT5-300-2h | 1642.7 (13) | 1.64 (13) | 0.19 (14) | 2148.5 (3.9) | 2.15 (3.9) | 0.51 (27) | 0.61 |

| BT25-300-1h | 2660.9 (13) | 2.66 (13) | 0.25 (7.2) | 5409.5 (13) | 5.4 (13) | 2.50 (15) | 0.83 |

| BT25-300-2h | 1942.2 (15) | 1.94 (15) | 0.30 (5.3) | 4916.0 (15) | 4.92 (15) | 2.34 (11) | 0.75 |

| BG50-300-1h | 1982.2 (7.5) | 1.98 (7.5) | 0.46 (2.7) | 4478.2 (11) | 4.48 (11) | 2.21 (9.2) | 0.91 |

| BG50-300-2h | 1897.3 (1.0) | 1.90 (1.0) | 0.18 (24) | 3818.2 (13) | 3.82 (13) | 1.52 (16) | 0.77 |

| BG50F-300-1h | 3050.8 (11) | 3.05 (11) | 0.24 (18) | 4404.2 (12) | 4.40 (12) | 2.27 (8.9) | 0.89 |

| BG50F-300-2h | 2348.1 (6.1) | 2.35 (6.1) | 0.23 (17) | 3990.3 (3.4) | 3.99 (3.4) | 1.12 (1.5) | 0.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; He, W.; Zhang, Y.; Chen, C.; Wu, X. Tensile Behavior of Basalt-Fiber-Grid-Reinforced Mortar before and after Exposure to Elevated Temperature. Buildings 2022, 12, 2269. https://doi.org/10.3390/buildings12122269

Zhang X, He W, Zhang Y, Chen C, Wu X. Tensile Behavior of Basalt-Fiber-Grid-Reinforced Mortar before and after Exposure to Elevated Temperature. Buildings. 2022; 12(12):2269. https://doi.org/10.3390/buildings12122269

Chicago/Turabian StyleZhang, Xiaofei, Weidong He, Yongwang Zhang, Cheng Chen, and Xun Wu. 2022. "Tensile Behavior of Basalt-Fiber-Grid-Reinforced Mortar before and after Exposure to Elevated Temperature" Buildings 12, no. 12: 2269. https://doi.org/10.3390/buildings12122269

APA StyleZhang, X., He, W., Zhang, Y., Chen, C., & Wu, X. (2022). Tensile Behavior of Basalt-Fiber-Grid-Reinforced Mortar before and after Exposure to Elevated Temperature. Buildings, 12(12), 2269. https://doi.org/10.3390/buildings12122269