Blockchain Design with Optimal Maintenance Planning

Abstract

1. Introduction

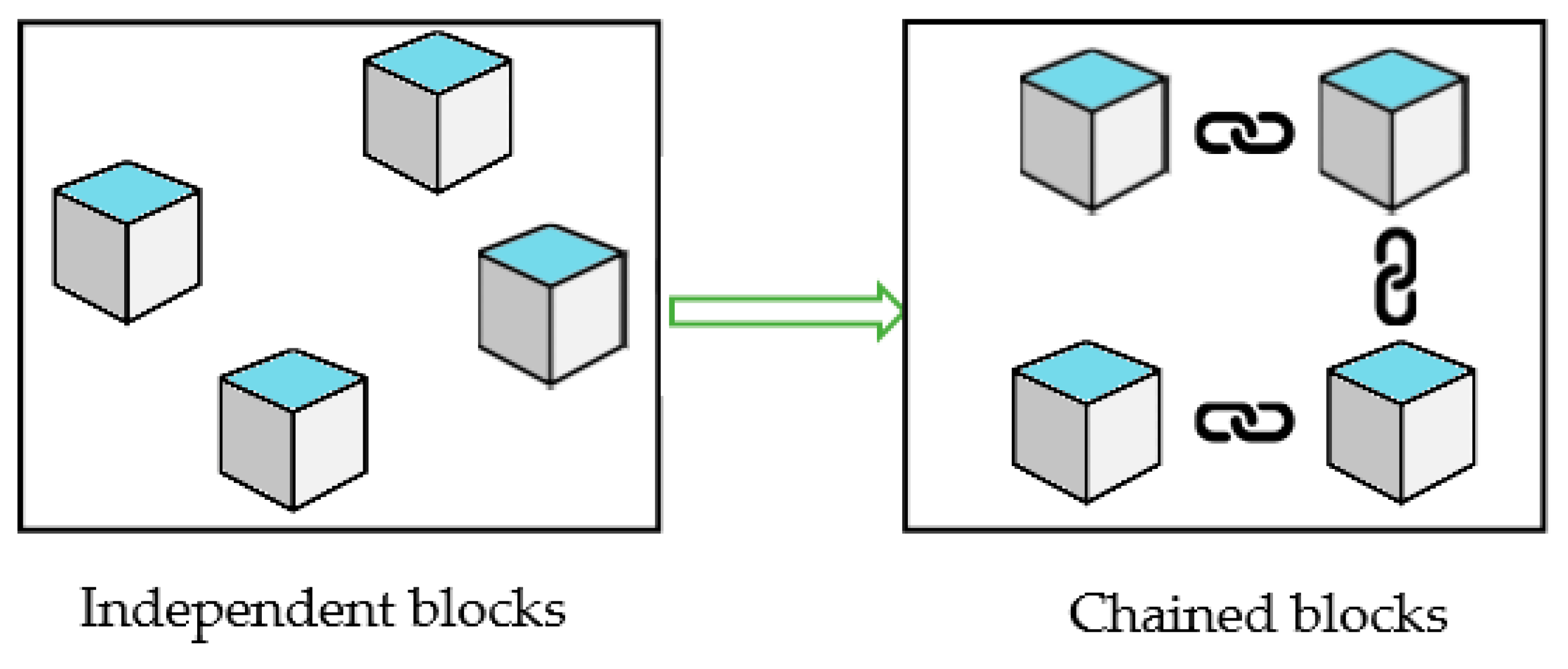

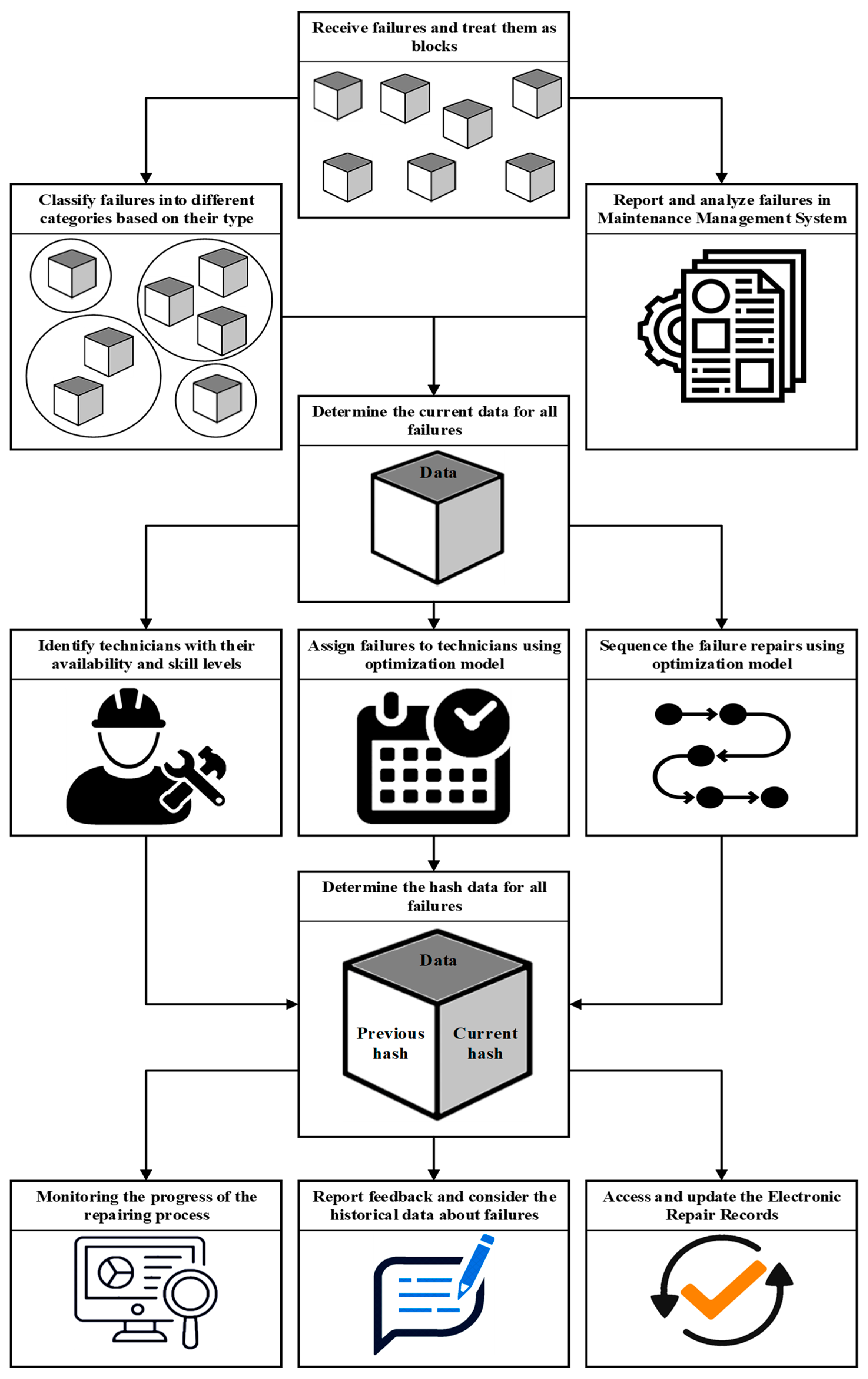

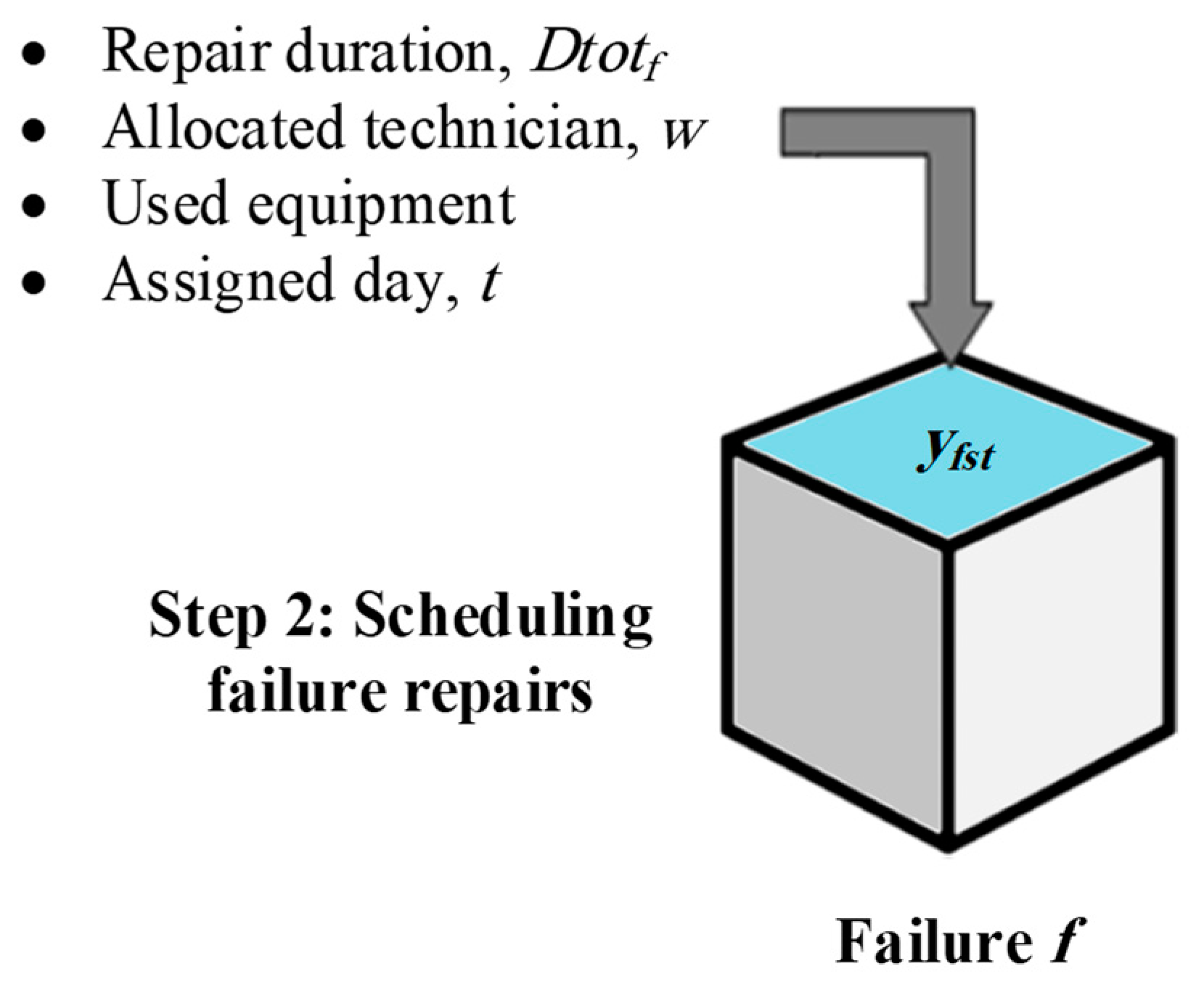

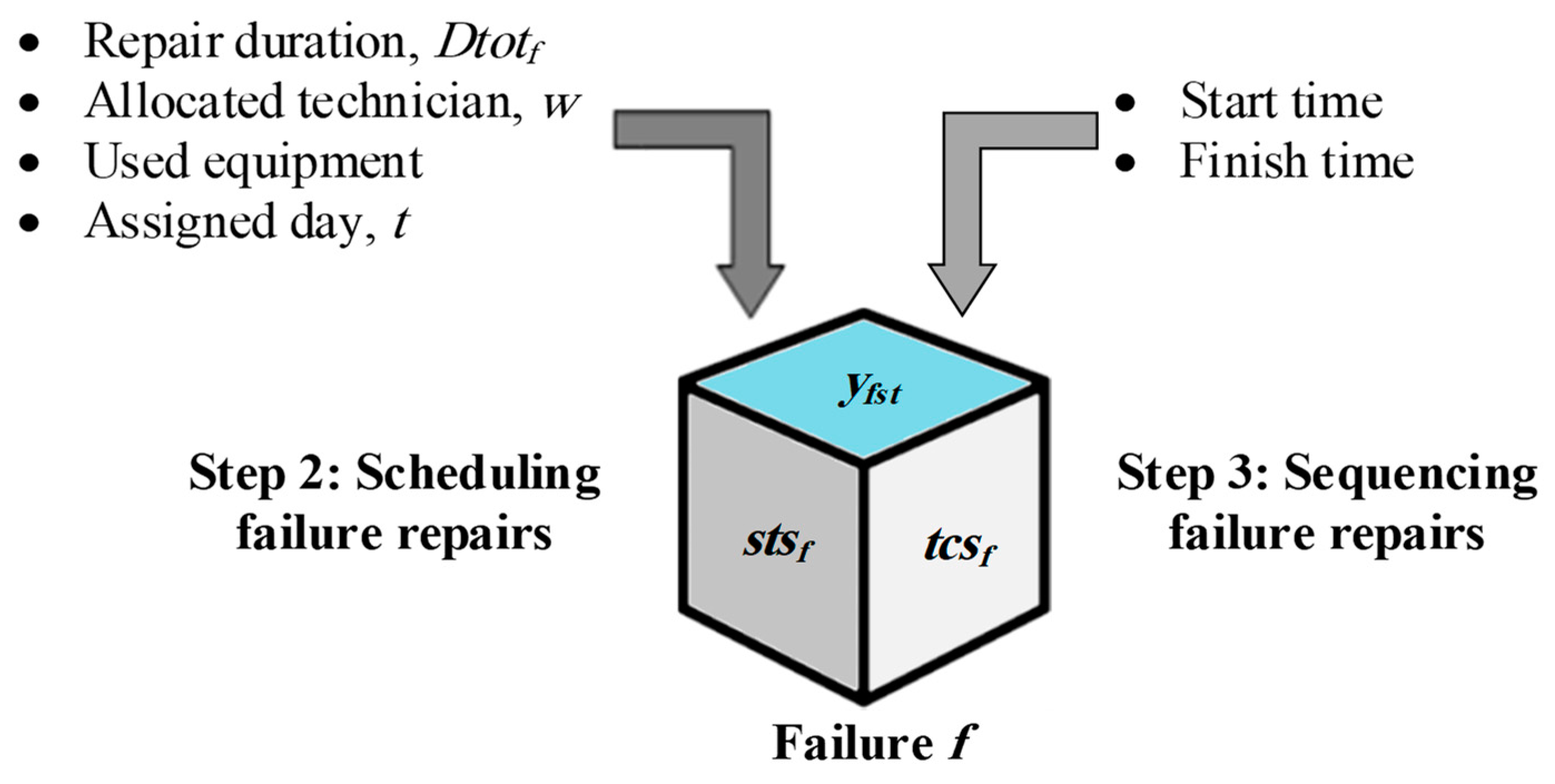

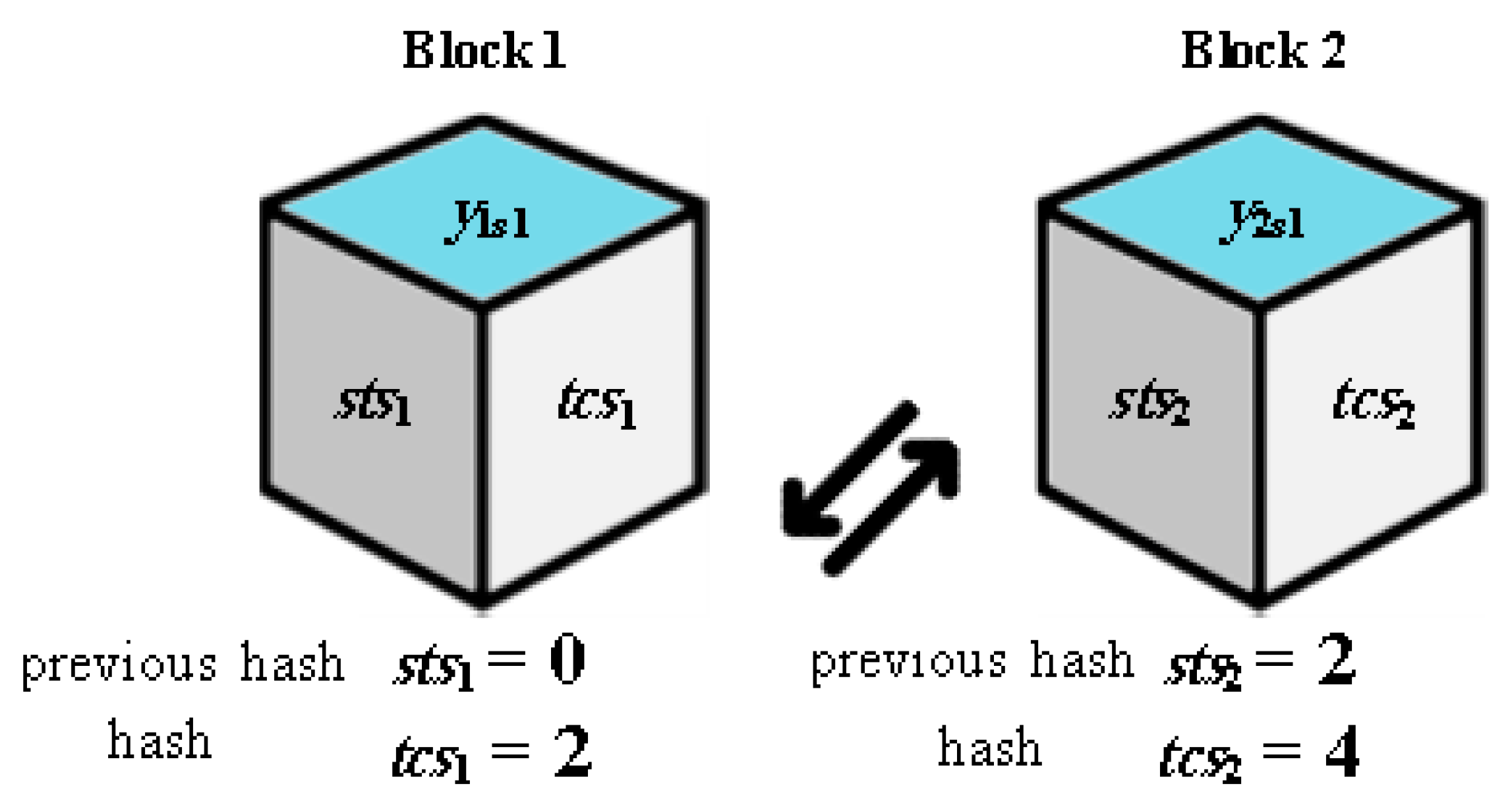

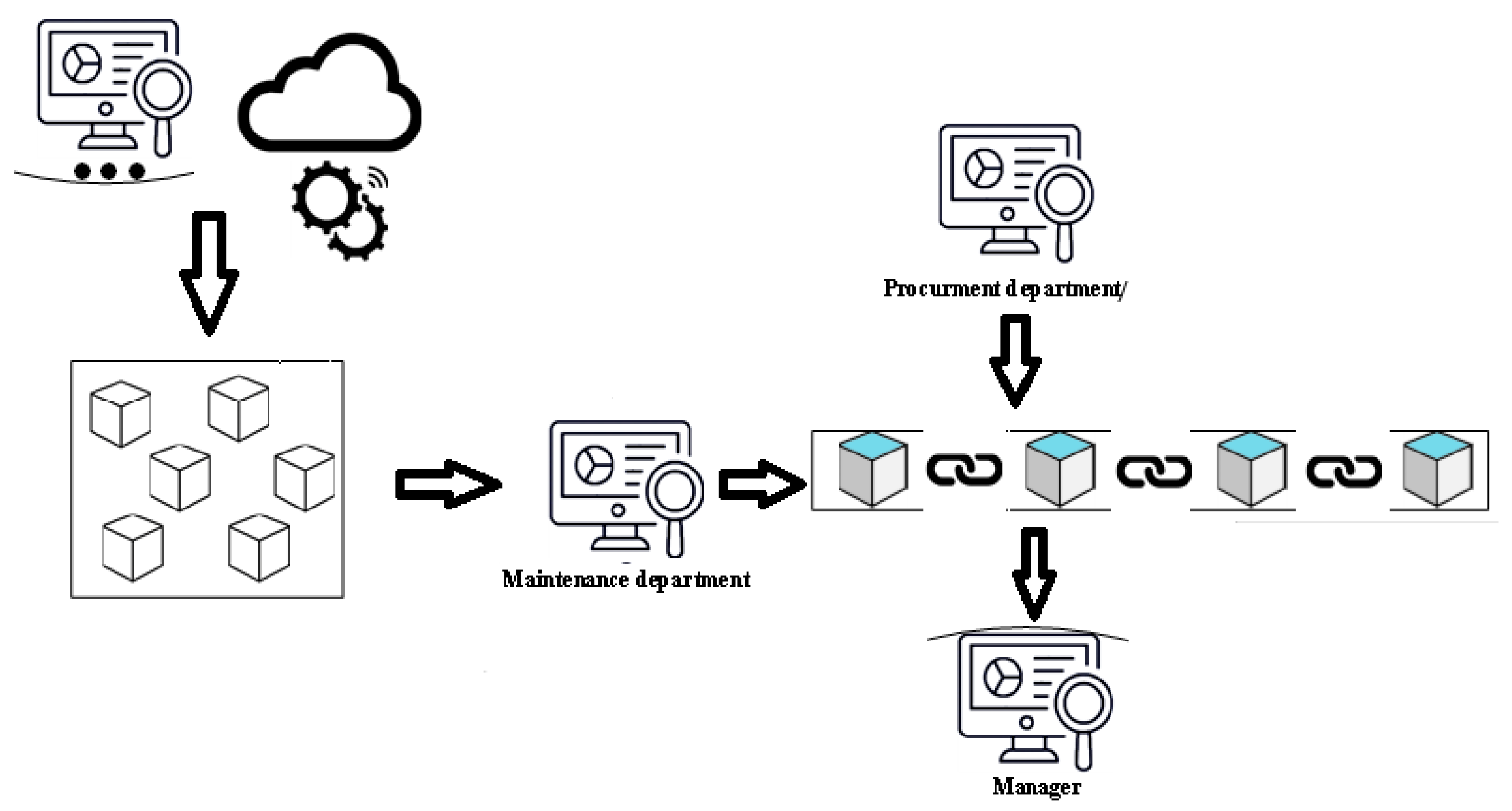

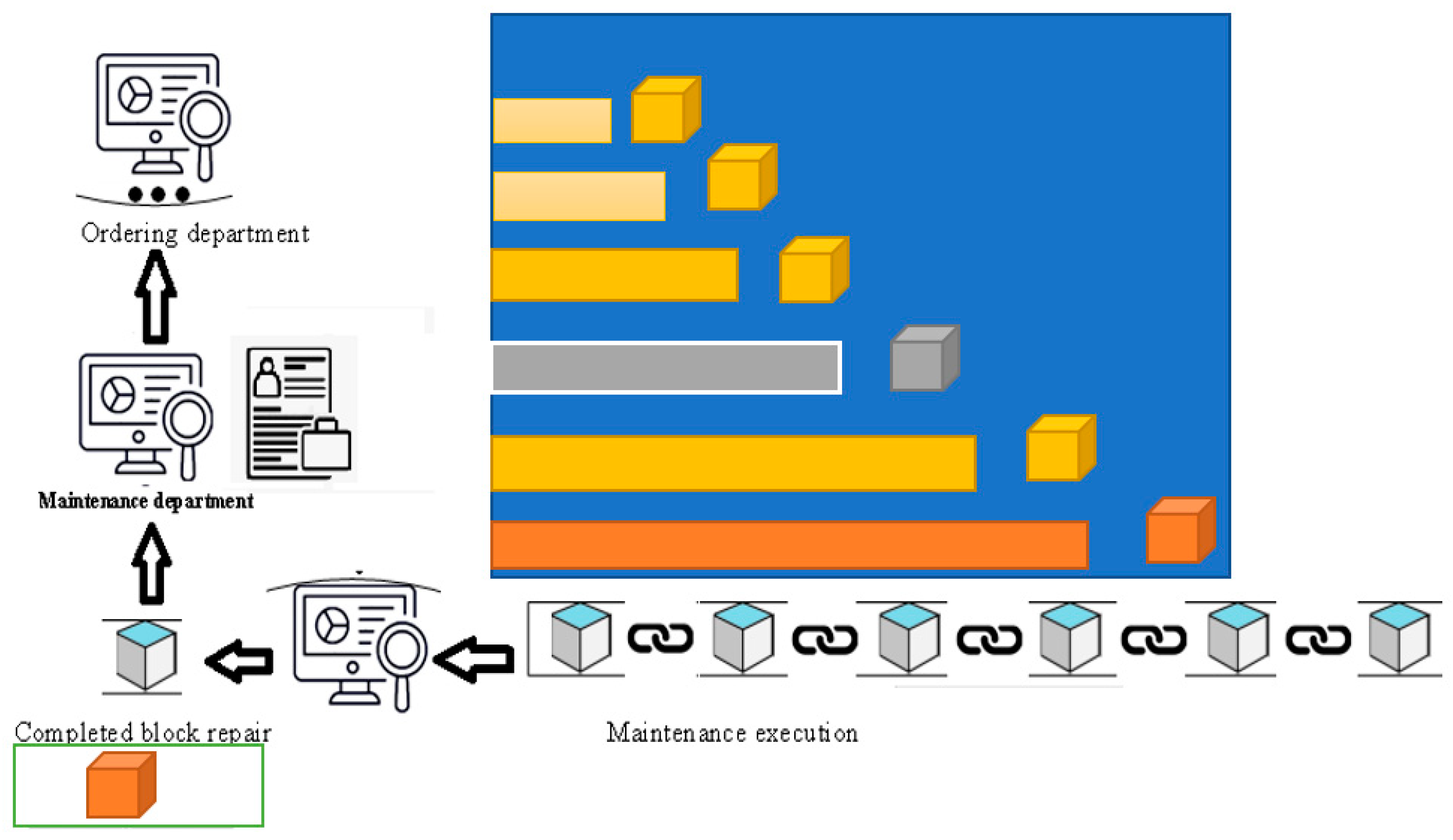

2. Development of the ERR System

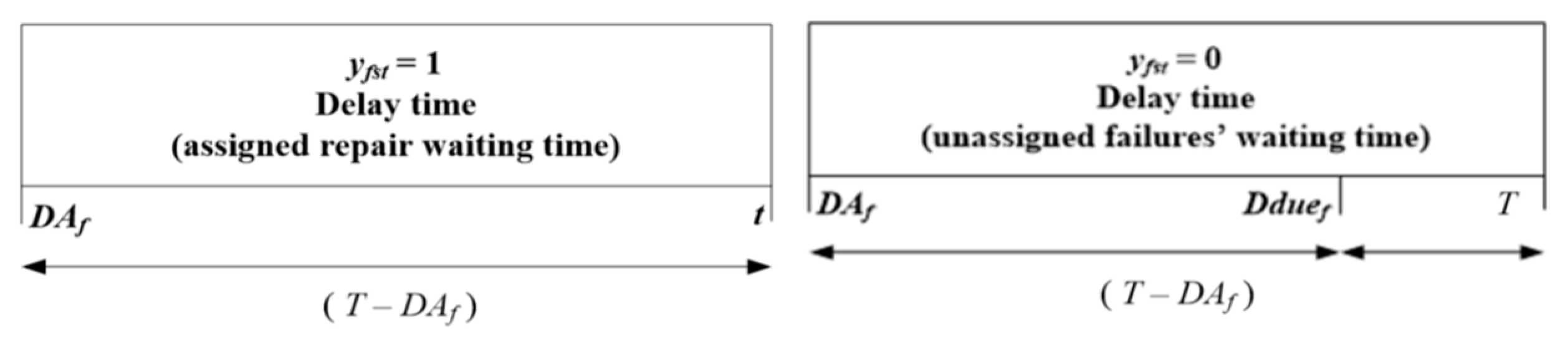

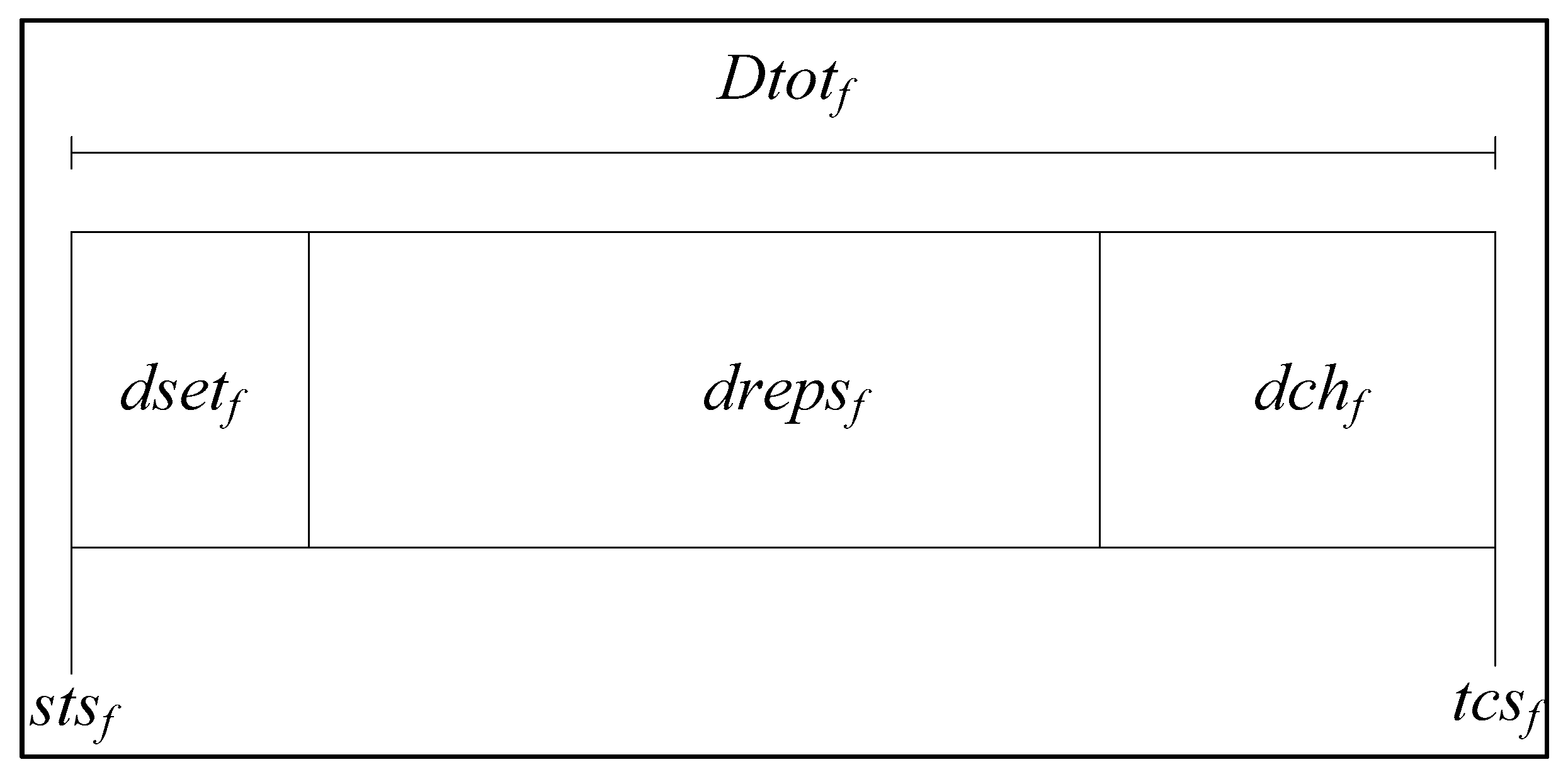

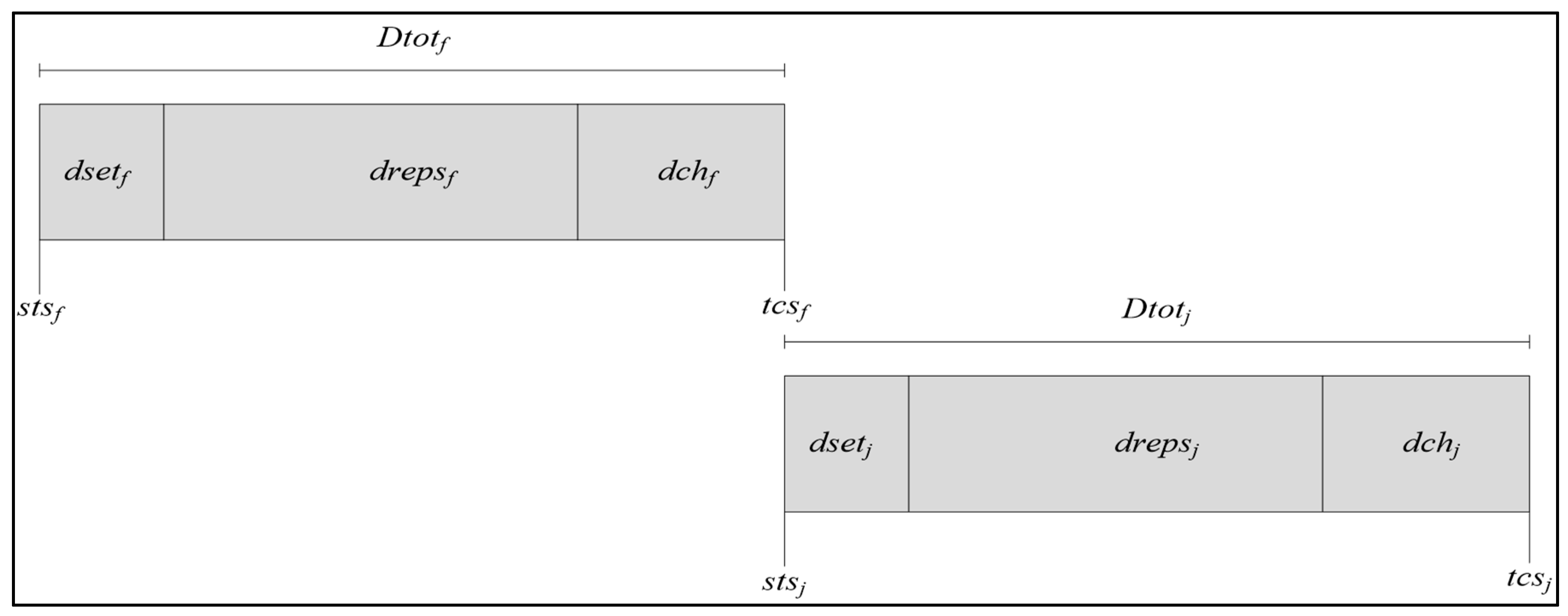

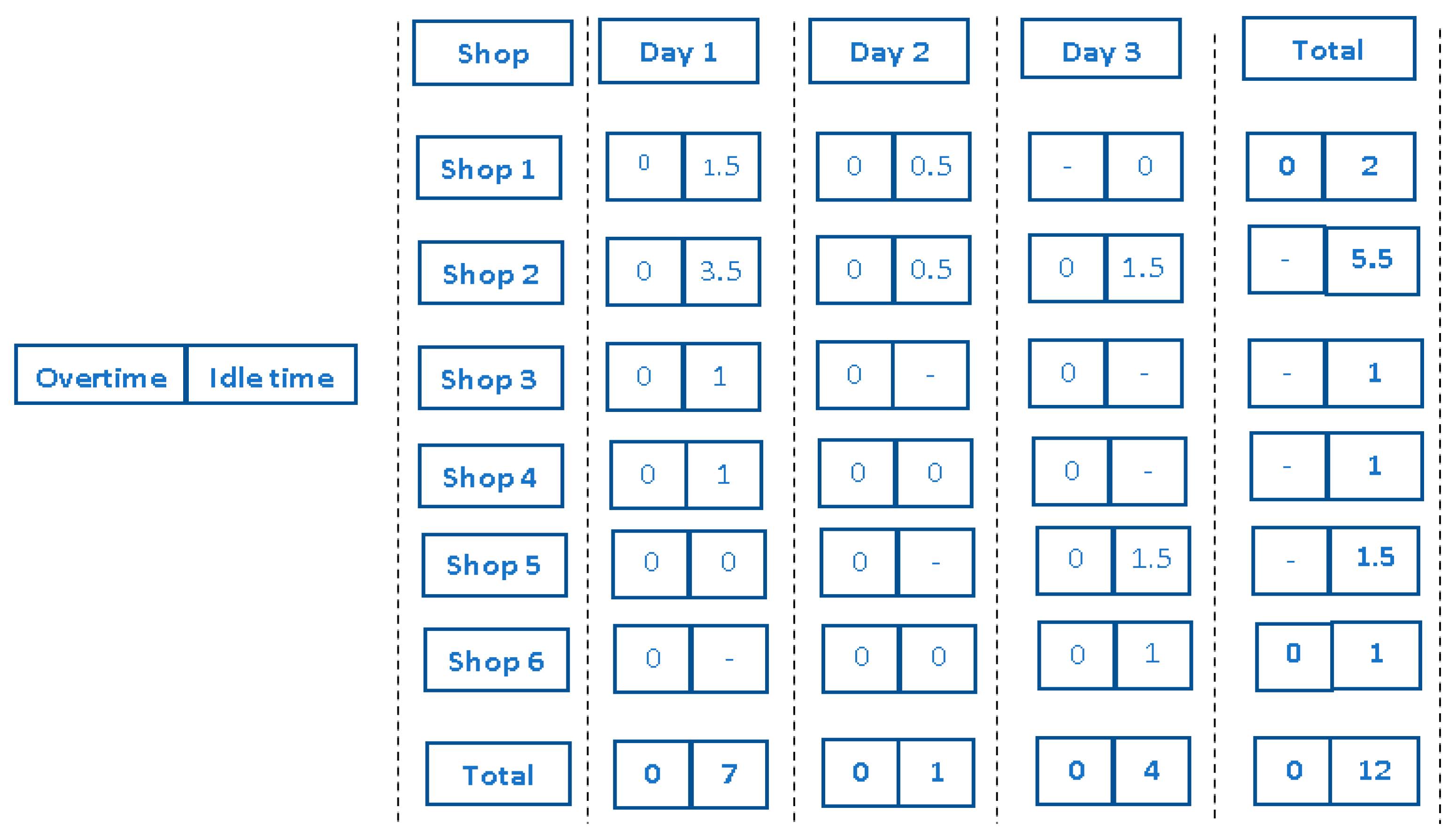

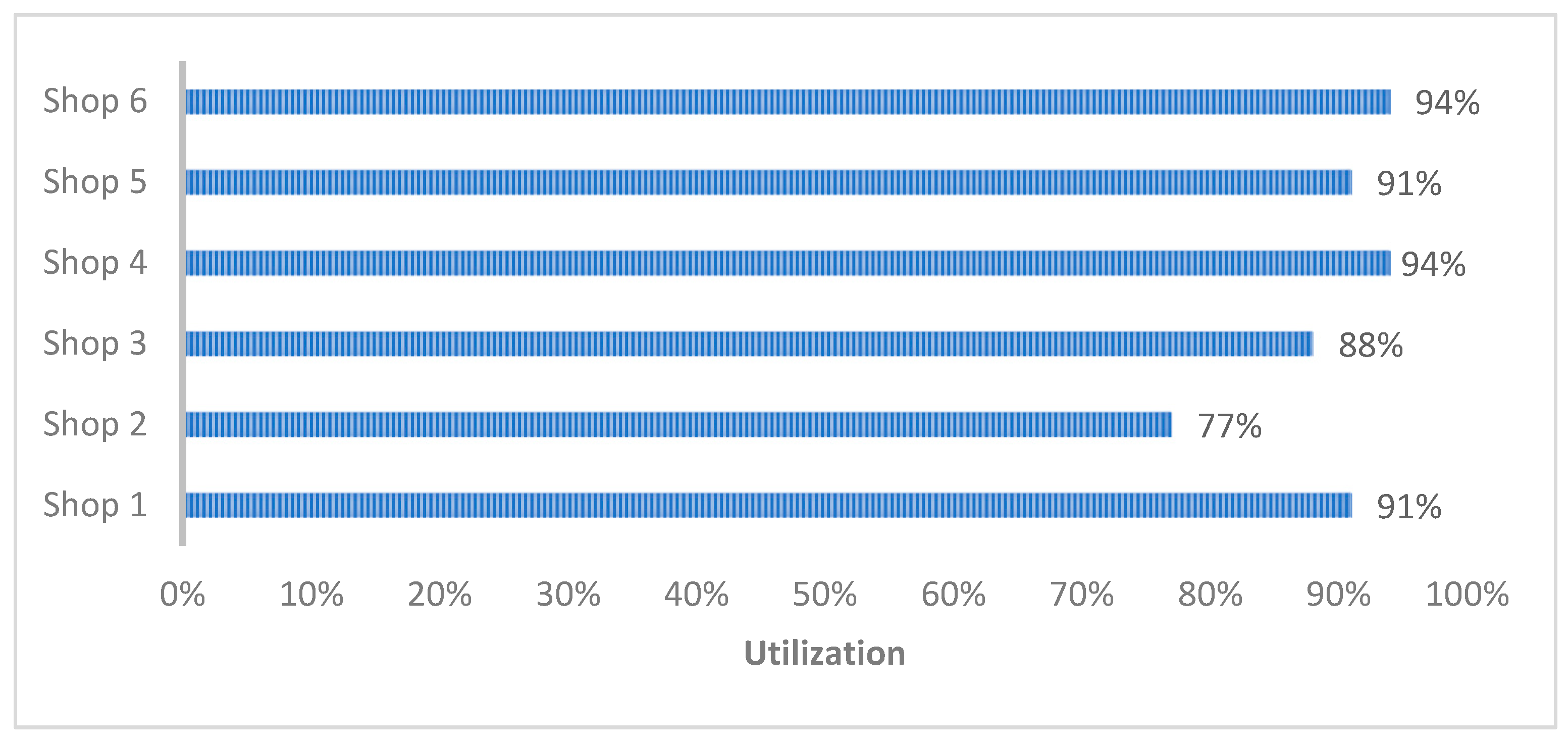

- For shop s on day t, the idle time, Ist, t is always positive and equal to the difference between regular time hours and the summation of the duration of all performed repairs. Let Nst denote the regular time of shop s on day t (hours) and αst specifies whether shop s is working on day t or not. The total duration of repair, Dtotf, is the time reserved for a given repair procedure, including the time required for setup, dsetf, repairing, drepsf, and changeover, dchf.

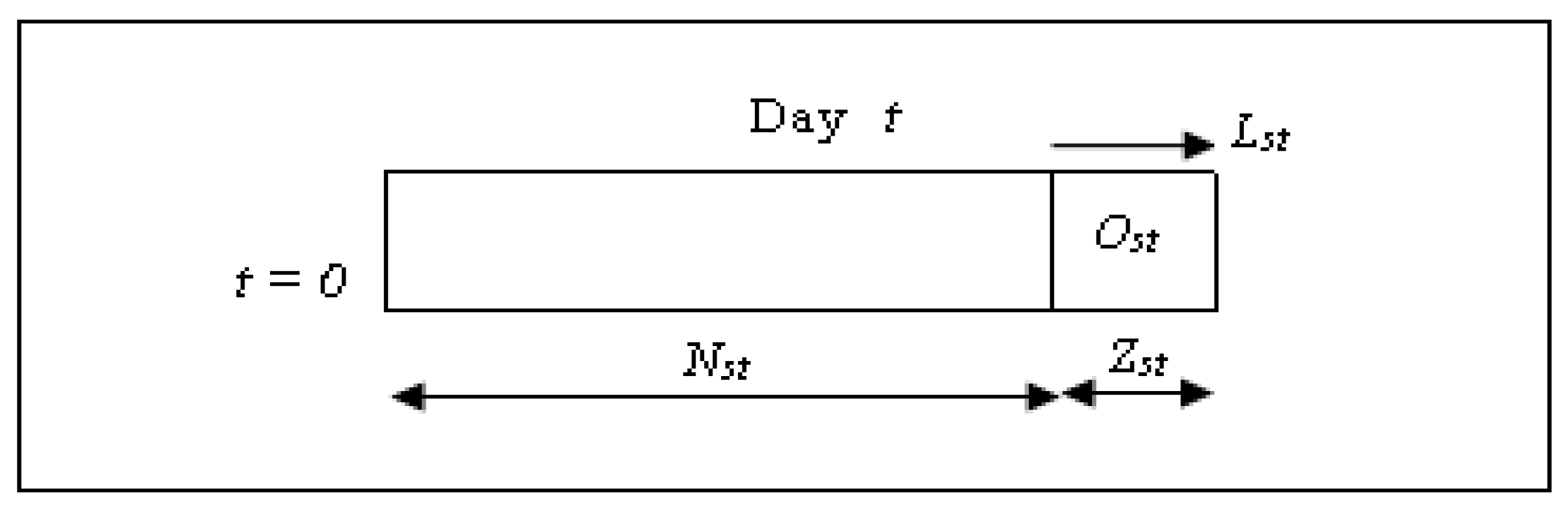

- Then, the overtime, Ost, for shop s on day t is always positive and equal to the summation of the duration of repairs of F failures performed outside regular hours of that shop, or mathematically:

- The total of repair durations of F failures on day t in shop s can exceed regular hours by the maximum allowed overtime for this shop on day t. Let Zst denote the maximum overtime allowed in shop s on day t. Then, the overtime repair duration must not exceed Zst, as expressed in Equation (10).

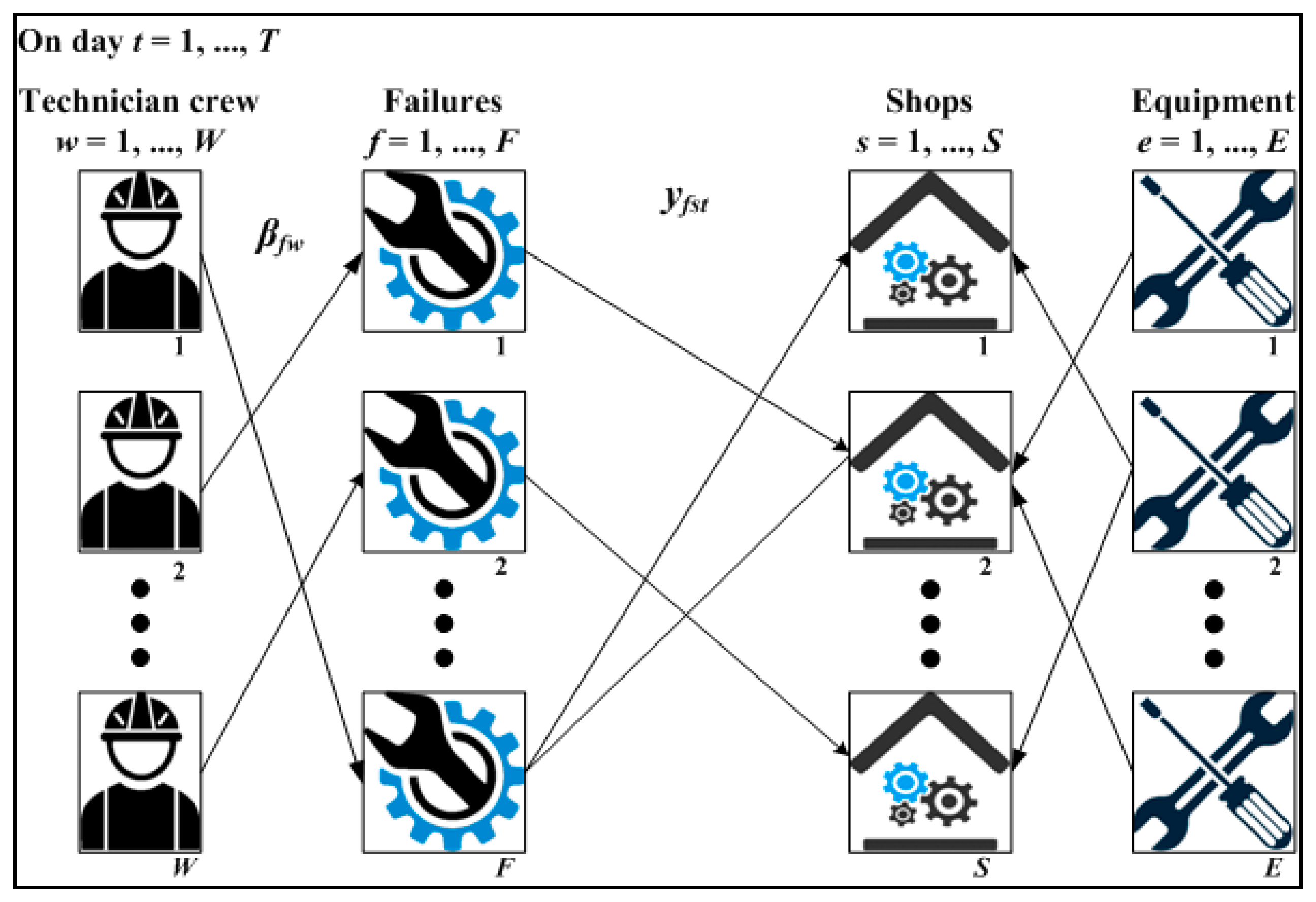

- Let λwt and βfw be binary variables that identify whether technician crew w is available on day t and the repair assignment of failure f to technician crew w, respectively. It should be emphasized that the repair assignment of failure f to technician crew w depends on this failure’s category and skill level of this crew. In addition, the total repair duration of F failures in S shops by the technician crew w on day t should not exceed the maximum working time, Gwt, on this day. Mathematically,

- Let the binary variable, τfst, denote the availability of the needed equipment to repair failure f in shop s on day t. To assign a failure repair to shop s on day t, shop s, skilled crew w, and equipment should be available, and their assignment should be applicable as expressed in Equation (12):

- The failure’s repair due date, Dduef, should be respected and a failure repair should be assigned at most once in S shops, or

- Integrality of the variables should be assured by introducing Equation (15):

- Failure repairs are assigned based on the duration of a failure’s repair as well as a failure’s severity and seriousness. A failure that requires a repair duration of less than or equal to a half hour will be assigned first in shop s, as given by Equation (16).

- Let RPNf denote the risk priority number of failure f, which indicates the failure’s severity and seriousness. Then, the repair of a failure with RPNf is equal to or greater than the selected criteria of the failure severity and seriousness, CRT, shall be assigned only once in shop s, as stated in Equations (17) and (18).

- However, if the risk priority number of failure f, RPNf, is less than CRT, then it should be postponed to the next scheduling period, T2, and assigned once at most in shop s, as expressed in Equations (19) and (20).

- 1.

- The closing time, Lst, for shop s on day t cannot be before the completion of regular hours, Nst, and the maximum allowed overtime is Zst, as illustrated in Figure 7, where the closing time, Lst, constraints are expressed mathematically as follows:

- 2.

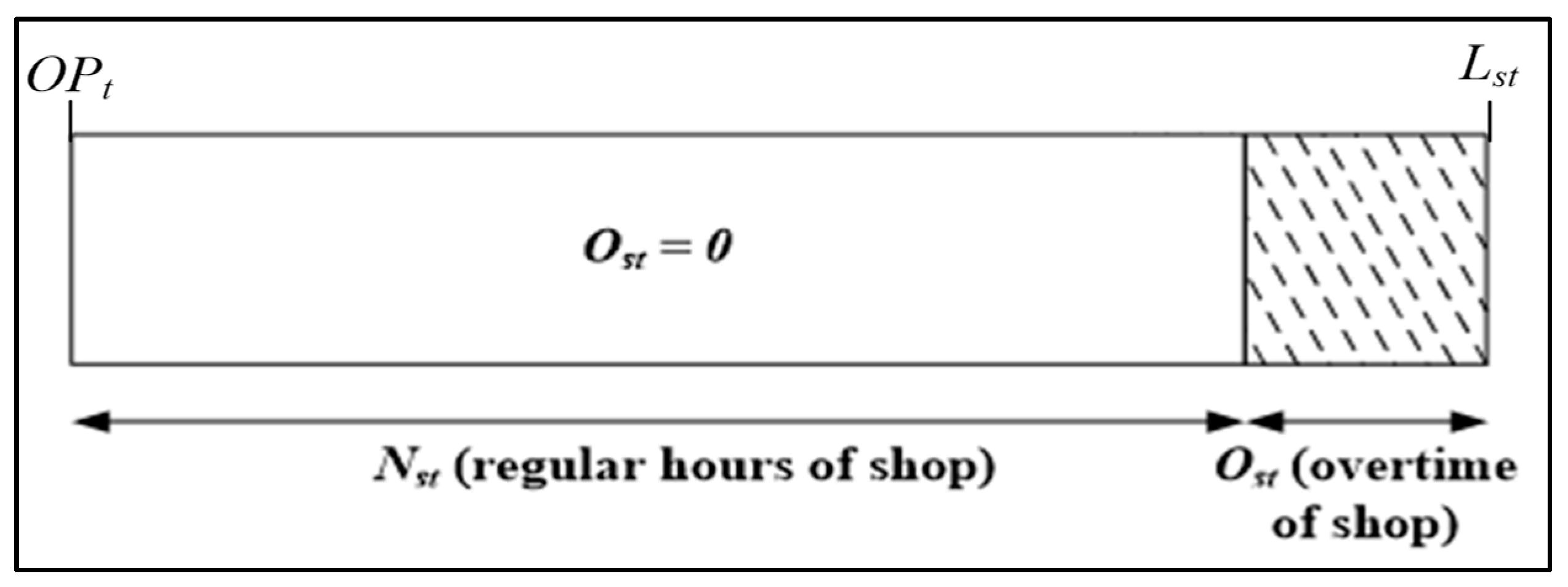

- Let OPt denote the time of the shop opening on day t. Then, the overtime, Ost, of shop s on day t is the difference between the closing time, Lst, and regular hours, Nst, as illustrated in Figure 9 and expressed in Equation (25).

- 3.

- The overtime, Ost, for shop s on day t should not exceed the maximum overtime of that shop, Zst. That is,

- 4.

- All repairs should be performed after the opening of the shop, OPt. Then, all failure repairs start times, stsf, should begin after shop opening, as stated in Equation (28).

- 5.

- The technician crew should operate during the interval of regular hours, Nst. Let Bwt denote the start of the working time of crew w on day t and Gwt denote the corresponding maximum working time of crew w on day t. The repair of failure f performed by crew w on day t should be completed before Gwt, as given in Equation (29).

- 6.

- If the repairs of distinct failures f and j are assigned to the same crew w (βfw = βjw = 1) in the same shop s on the same day t, the stsf of failure j is scheduled after the repair of failure j is completed, as expressed by Equation (31).

- 7.

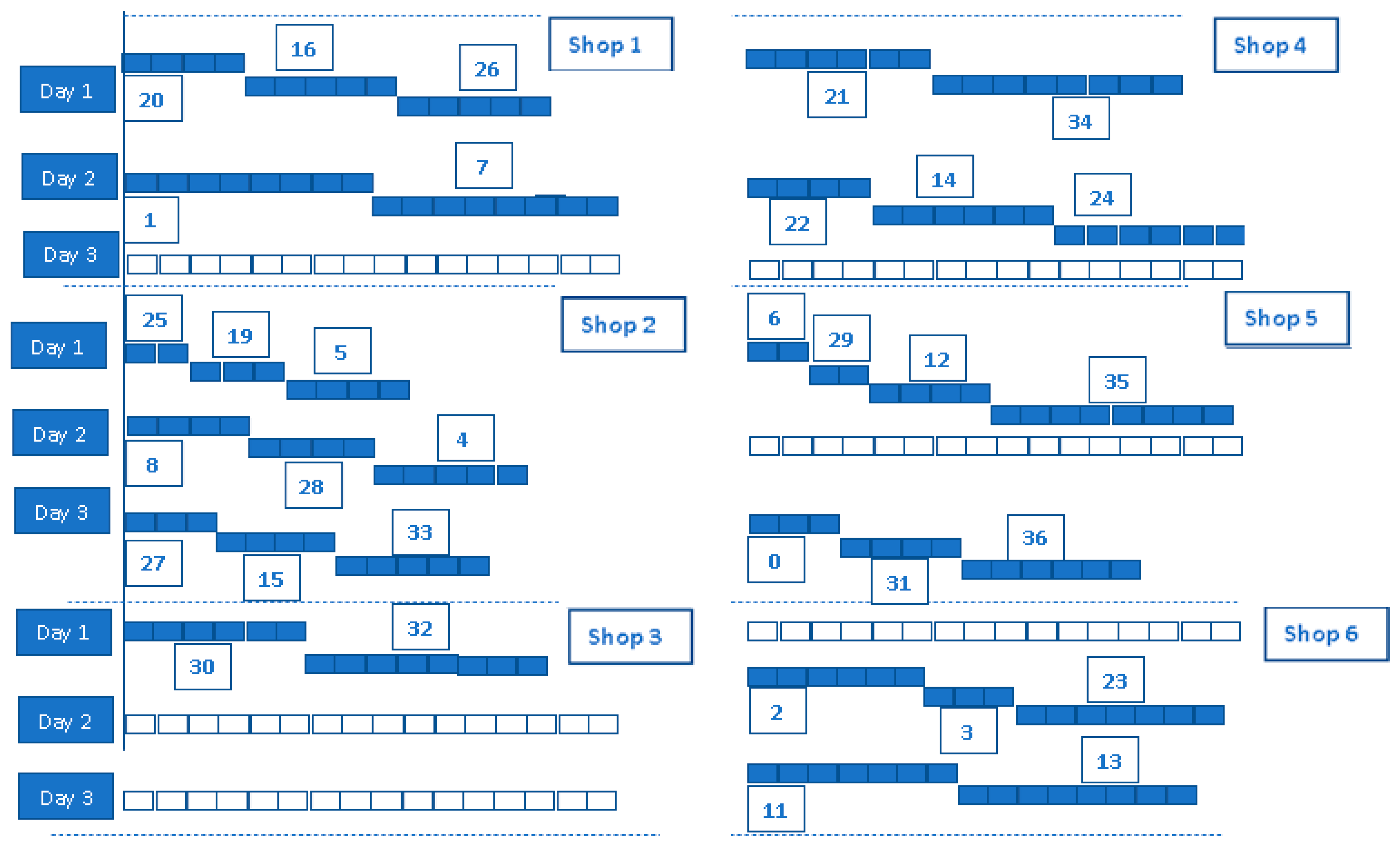

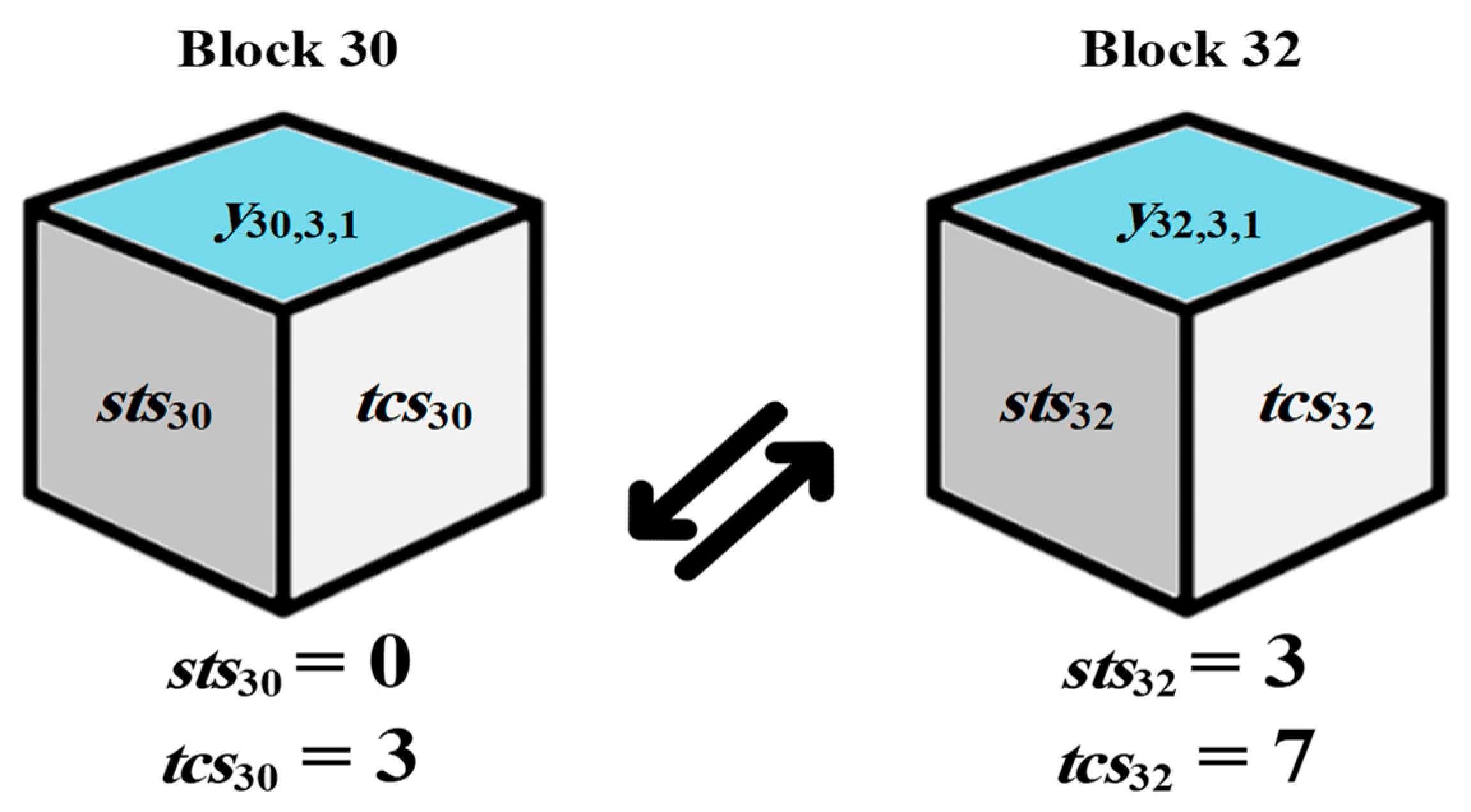

- If failures f and j are assigned to the same shop (yfst = yjst = 1) and failure f will be repaired before failure j, χfjt = 1, on the same day, as shown in Figure 10, then the start time of failure j, stsj, should be equal to or greater than the entire time required in shop s for the repair of failure f. That is,

- 8.

- The failure with RPNf greater than the selected criteria of failure severity and seriousness, CRT, shall be repaired first. That is,

- 9.

- If the RPN for failures f and j are equal on the same day in shop s, the failure with an earlier arrival time, DA, shall be assigned first, as expressed by Equation (35).

- 10.

- The binary decision variables are written as:

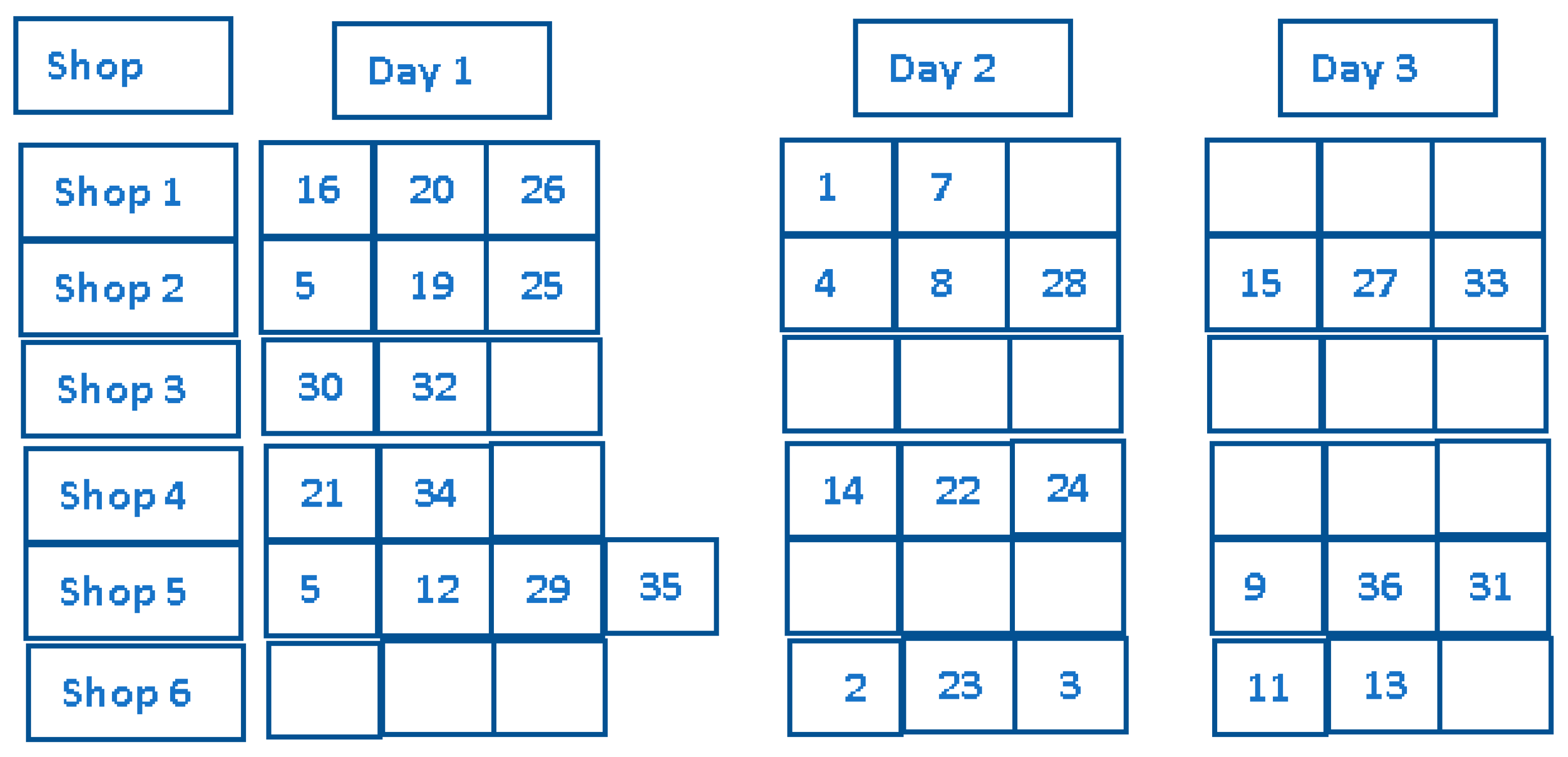

3. Application of Electronic Repair Records

4. Research Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Christodoulou, P.; Christodoulou, K.; Andreou, A. A decentralised application for logistics: Using blockchain in real-world applications. Cyprus Rev. 2018, 30, 181–193. [Google Scholar]

- Swan, M. Blockchain Blueprint for a New Economy; O’Reilly Media Inc.: Sebastopol, CA, USA, 2015. [Google Scholar]

- Issaoui, Y.; Khiat, A.; Bahnasse, A.; Ouajji, H. Smart logistics: Study of the application of blockchain technology. Procedia Comput. Sci. 2019, 160, 266–271. [Google Scholar] [CrossRef]

- Lee, J.; Azamfar, M.; Singh, J. A blockchain enabled Cyber-Physical System architecture for Industry 4.0 manufacturing systems. Manuf. Lett. 2019, 20, 34–39. [Google Scholar] [CrossRef]

- Singh, M. Blockchain Technology for Data Management in Industry 4.0. In Blockchain Technology for Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2020; pp. 59–72. [Google Scholar] [CrossRef]

- Ullah, F.; Al-Turjman, F. A conceptual framework for blockchain smart contract adoption to manage real estate deals in smart cities. Neural Comput. Appl. 2021, 1–22. [Google Scholar] [CrossRef]

- Kawaguchi, N. Application of blockchain to supply chain: Flexible blockchain technology. Procedia Comput. Sci. 2019, 164, 143–148. [Google Scholar] [CrossRef]

- Zheng, Z.; Xie, S.; Dai, H.; Chen, X.; Wang, H. An Overview of Blockchain Technology: Architecture, Consensus, and Future Trends. In Proceedings of the 2017 IEEE International Congress on Big Data, Boston, MA, USA, 11–14 December 2017; pp. 557–564. [Google Scholar] [CrossRef]

- Song, J.M.; Sung, J.; Park, T. Applications of blockchain to improve supply chain traceability. Procedia Comput. Sci. 2019, 162, 119–122. [Google Scholar] [CrossRef]

- Lohmer, J.; Lasch, R. Blockchain in operations management and manufacturing: Potential and barriers. Comput. Ind. Eng. 2020, 149, 106789. [Google Scholar] [CrossRef]

- Zhong, P.; Zhong, Q.; Mi, H.; Zhang, S.; Xiang, Y. Privacy-Protected Blockchain System. In Proceedings of the 2019 20th IEEE International Conference on Mobile Data Management, Hong Kong, China, 10–13 June 2019; pp. 457–461. [Google Scholar] [CrossRef]

- Guo, Y.; Liang, C. Blockchain application and outlook in the banking industry. Financ. Innov. 2016, 2, 24. [Google Scholar] [CrossRef]

- Muzylyov, D.; Shramenko, N. Blockchain technology in transportation as a part of the efficiency in Industry 4.0 strategy. In Proceedings of the Grabchenko’s International Conference on Advanced Manufacturing Processes 2019, Odessa, Ukraine, 10–13 September 2019; pp. 216–225. [Google Scholar] [CrossRef]

- Zhu, Q.; Bai, C.; Sarkis, J. Blockchain technology and supply chains: The paradox of the atheoretical research discourse. Transp. Res. Part E Logist. Transp. Rev. 2022, 164, 102824. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, S.; Lopez, C.; Lu, H.; Elgueta, S.; Chen, H.; Boshkoska, B.M. Blockchain technology in agri-food value chain management: A synthesis of applications, challenges, and future research directions. Comput. Ind. 2019, 109, 83–99. [Google Scholar] [CrossRef]

- Tanwar, S.; Parekh, K.; Evans, R. Blockchain-based electronic healthcare record system for healthcare 4.0 applications. J. Inf. Secur. Appl. 2020, 50, 102407. [Google Scholar] [CrossRef]

- Hartmann, S.; Thomas, S. Applying blockchain to the Australian carbon market. Econ. Pap. J. Appl. Econ. Policy 2020, 39, 133–151. [Google Scholar] [CrossRef]

- Olawumi, T.O.; Chan, D.W.; Ojo, S.; Yam, M.C. Automating the modular construction process: A review of digital technologies and future directions with blockchain technology. J. Build. Eng. 2021, 46, 103720. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.H.; Masoud, N.; Krishnan, M.S.; Li, V.C. Integrated digital twin and blockchain framework to support accountable information sharing in construction projects. Autom. Constr. 2021, 127, 103688. [Google Scholar] [CrossRef]

- Sun, H.; Tang, W.; Duffield, C.F.; Zhang, L.; Hui, F.K.P. How to get international construction projects delivered on time: From Chinese contractors’ perspective. J. Civ. Eng. Manag. 2022, 28, 134–149. [Google Scholar] [CrossRef]

- Celik, Y.; Petri, I.; Barati, M. Blockchain supported BIM data provenance for construction projects. Comput. Ind. 2022, 144, 103768. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Lepkova, N.; Camlibel, M.E. The Relationships between the Pillars of TPM and TQM and Manufacturing Performance Using Structural Equation Modeling. Sustainability 2022, 14, 1497. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Al-Hawadi, A. Optimal fuzzy repairs’ scheduling and sequencing of failure types over multiple periods. J. Ambient Intell. Humaniz. Comput. 2022, 13, 201–217. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Almowas, H. Multi-objective maintenance planning under preventive maintenance. J. Qual. Maint. Eng. 2021. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Al-Shalaldeh, H.; Lepkova, N. Proposed procedure for optimal maintenance scheduling under emergent failures. J. Civ. Eng. Manag. 2020, 26, 396–409. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Abedalqader, H. Optimal berth scheduling and sequencing under unexpected events. J. Oper. Res. Soc. 2022, 73, 430–444. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Qapaja, A.; Al-Hawadi, A. Optimal Fuzzy Scheduling and Sequencing of Work-Intensive Multiple Projects Under Normal and Unexpected Events. Int. J. Inf. Technol. Proj. Manag. IJITPM 2021, 12, 64–89. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Al-Hawadi, A.; Fraij, S. Optimization models for clustering of solid waste collection process. Eng. Optim. 2021, 53, 2056–2069. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Judeh, M.; Chen, T. Optimal multiple-period scheduling and sequencing of operating room and intensive care unit. Oper. Res. 2018, 18, 645–670. [Google Scholar] [CrossRef]

- Al-Refaie, A.; Chen, T.; Judeh, M. Optimal operating room scheduling for normal and unexpected events in a smart hospital. Oper. Res. 2018, 18, 579–602. [Google Scholar] [CrossRef]

- El-Sharkh, M.Y.; El-Keib, A.A. Maintenance scheduling of generation and transmission systems using fuzzy evolutionary programming. IEEE Trans. Power Syst. 2003, 18, 862–866. [Google Scholar] [CrossRef]

- Ruiz, R.; García-Díaz, J.C.; Maroto, C. Considering scheduling and preventive maintenance in the flow-shop sequencing problem. Comput. Oper. Res. 2007, 34, 3314–3330. [Google Scholar] [CrossRef]

- Squires, R.R.; Hoffman, K.L. A military maintenance planning and scheduling problem. Optim. Lett. 2015, 9, 1675–1688. [Google Scholar] [CrossRef]

- Xiao, L.; Song, S.; Chen, X.; Coit, D.W. Joint optimization of production scheduling and machine group preventive maintenance. Reliab. Eng. Syst. Saf. 2016, 146, 68–78. [Google Scholar] [CrossRef]

- Irawan, C.A.; Ouelhadj, D.; Jones, D.; Stålhane, M.; Sperstad, I.B. Optimization of maintenance routing and scheduling for offshore wind farms. Eur. J. Oper. Res. 2017, 256, 76–89. [Google Scholar] [CrossRef]

- Liao, W.; Zhang, X.; Jiang, M. Multi-objective group scheduling optimization integrated with preventive maintenance. Eng. Optim. 2017, 49, 1890–1904. [Google Scholar] [CrossRef]

- Gholami, P.; Hafezalkotob, A. Maintenance scheduling using data mining techniques and time series models. Int. J. Manag. Sci. Eng. Manag. 2018, 13, 100–107. [Google Scholar] [CrossRef]

- Kiefer, A.; Schilde, M.; Doerner, K.F. Scheduling of maintenance work of a large-scale tramway network. Eur. J. Oper. Res. 2018, 270, 1158–1170. [Google Scholar] [CrossRef]

- Alayo, H.; Paucar, E. A MILP model for maintenance scheduling in transmission systems and an example application to the Peruvian system. IEEE Lat. Am. Trans. 2018, 16, 1099–1104. [Google Scholar] [CrossRef]

- Su, Z.; De Schutter, B. Optimal scheduling of track maintenance activities for railway networks. IFAC-PapersOnLine 2018, 51, 386–391. [Google Scholar] [CrossRef]

- Samadi, M.; Seifi, H.; Haghifam, M.R. Midterm system level maintenance scheduling of transmission equipment using inspection-based model. Int. J. Electr. Power Energy Syst. 2019, 110, 467–476. [Google Scholar] [CrossRef]

- Chansombat, S.; Pongcharoen, P.; Hicks, C. A mixed-integer linear programming model for integrated production and preventive maintenance scheduling in the capital goods industry. Int. J. Prod. Res. 2019, 57, 61–82. [Google Scholar] [CrossRef]

- Yeardley, A.S.; Ejeh, J.O.; Allen, L.; Brown, S.F.; Cordiner, J. Integrating machine learning techniques into optimal maintenance scheduling. Comput. Chem. Eng. 2022, 166, 107958. [Google Scholar] [CrossRef]

- Hu, J.; Wang, Y.; Pang, Y.; Liu, Y. Optimal maintenance scheduling under uncertainties using Linear Programming-enhanced Reinforcement Learning. Eng. Appl. Artif. Intell. 2022, 109, 104655. [Google Scholar] [CrossRef]

- Chou, S.Y.; Yu, T.H.K. Developing an exhaustive optimal maintenance schedule for offshore wind turbines based on risk-assessment, technical factors and cost-effective evaluation. Energy 2022, 249, 123613. [Google Scholar] [CrossRef]

- Urbani, M.; Brunelli, M.; Punkka, A. An approach for bi-objective maintenance scheduling on a networked system with limited resources. Eur. J. Oper. Res. 2022, 305, 101–113. [Google Scholar] [CrossRef]

| Maintenance Shop, s | Maintenance Category |

|---|---|

| 1, 3, 5 | General failures |

| 2 | Electrical failures |

| 4 | Mechanical failures |

| 6 | Welding processes |

| f | Failure-Related Variables | f | Failure-Related Variables | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DAf | dsetf | drepsf | dchf | Dtotf | Dduef | RPNf | DAf | dsetf | drepsf | dchf | Dtotf | Dduef | RPNf | ||

| 1 | 2 | 1 | 2 | 1 | 4 | 2 | 0.9 | 19 | 1 | 0.2 | 0.8 | 0.5 | 1.5 | 1 | 0.1 |

| 2 | 1 | 0.5 | 1.5 | 1 | 3 | 1 | 0.75 | 20 | 1 | 0.2 | 0.5 | 0.3 | 2 | 2 | 0.1 |

| 3 | −1 | 0.25 | 0.75 | 0.5 | 1.5 | 1 | 0.95 | 21 | 1 | 1 | 1 | 1 | 3 | 1 | 0.4 |

| 4 | −2 | 1 | 1.5 | 1 | 3.5 | 1 | 0.1 | 22 | 2 | 0.2 | 0.8 | 1 | 2 | 2 | 0.3 |

| 5 | 1 | 0.5 | 1 | 0.5 | 2 | 1 | 0.5 | 23 | 2 | 1 | 1.5 | 1 | 3.5 | 3 | 0.5 |

| 6 | 1 | 0.25 | 0.5 | 0.25 | 1 | 3 | 0.3 | 24 | 1 | 1 | 1.3 | 0.7 | 3 | 1 | 0.05 |

| 7 | 2 | 0.5 | 2 | 1 | 3.5 | 2 | 0.02 | 25 | 1 | 0.3 | 0.3 | 0.4 | 1 | 1 | 0.01 |

| 8 | 2 | 0.25 | 1.25 | 0.5 | 2 | 3 | 0.05 | 26 | 0 | 0.5 | 1 | 1 | 2.5 | 2 | 0.3 |

| 9 | 1 | 0.25 | 1 | 0.25 | 1.5 | 1 | 0.3 | 27 | 3 | 0.25 | 1 | 0.25 | 1.5 | 3 | 0.5 |

| 10 | 3 | 1 | 1 | 1 | 3 | 3 | 0.08 | 28 | 2 | 0.5 | 1 | 0.5 | 2 | 2 | 0.2 |

| 11 | 3 | 1.25 | 1.5 | 0.25 | 3 | 3 | 0.2 | 29 | 1 | 0.25 | 0.5 | 0.25 | 1 | 1 | 0.1 |

| 12 | 1 | 1 | 1 | 0 | 2 | 2 | 0.09 | 30 | 1 | 0.75 | 1.5 | 0.75 | 3 | 1 | 0.09 |

| 13 | 2 | 1 | 2 | 1 | 4 | 2 | 0.3 | 31 | 2 | 0.5 | 1.25 | 0.25 | 2 | 2 | 0.02 |

| 14 | 1 | 1 | 1 | 1 | 3 | 1 | 0.2 | 32 | 1 | 1 | 2 | 1 | 4 | 3 | 0.01 |

| 15 | 1 | 0.5 | 0.5 | 1 | 2 | 2 | 0.01 | 33 | 3 | 0.25 | 1.75 | 1 | 3 | 3 | 0.3 |

| 16 | 1 | 0.5 | 1 | 1 | 2.5 | 2 | 0.7 | 34 | 1 | 1.5 | 2 | 0.5 | 4 | 1 | 0.06 |

| 17 | 3 | 0.5 | 0.5 | 0.5 | 1.5 | 3 | 0.4 | 35 | 1 | 1 | 1.5 | 1.5 | 4 | 2 | 0.24 |

| 18 | 3 | 0.5 | 1 | 1.5 | 3 | 3 | 0.3 | 36 | 2 | 1 | 1 | 1 | 3 | 2 | 0.35 |

| Technician Crew (w) | Day (t) | Technician Crew (w) | Day (t) | ||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 1 | 2 | 3 | ||

| 1 | 0 | 0 | 1 | 7 | 1 | 1 | 1 |

| 2 | 0 | 0 | 0 | 8 | 1 | 1 | 1 |

| 3 | 1 | 1 | 1 | 9 | 1 | 1 | 1 |

| 4 | 1 | 1 | 1 | 10 | 1 | 1 | 1 |

| 5 | 1 | 1 | 1 | 11 | 1 | 1 | 1 |

| 6 | 1 | 1 | 1 | 12 | 0 | 1 | 0 |

| Shop (s) | Day (t) | ||

|---|---|---|---|

| 1 | 2 | 3 | |

| 1 | 1 | 1 | 0 |

| 2 | 1 | 1 | 1 |

| 3 | 1 | 0 | 0 |

| 4 | 1 | 1 | 0 |

| 5 | 1 | 0 | 1 |

| 6 | 1 | 1 | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Refaie, A.; Al-Hawadi, A.; Lepkova, N. Blockchain Design with Optimal Maintenance Planning. Buildings 2022, 12, 1902. https://doi.org/10.3390/buildings12111902

Al-Refaie A, Al-Hawadi A, Lepkova N. Blockchain Design with Optimal Maintenance Planning. Buildings. 2022; 12(11):1902. https://doi.org/10.3390/buildings12111902

Chicago/Turabian StyleAl-Refaie, Abbas, Ahmad Al-Hawadi, and Natalija Lepkova. 2022. "Blockchain Design with Optimal Maintenance Planning" Buildings 12, no. 11: 1902. https://doi.org/10.3390/buildings12111902

APA StyleAl-Refaie, A., Al-Hawadi, A., & Lepkova, N. (2022). Blockchain Design with Optimal Maintenance Planning. Buildings, 12(11), 1902. https://doi.org/10.3390/buildings12111902