Compressive Properties of Additively Manufactured Functionally Graded Kagome Lattice Structure

Abstract

1. Introduction

2. Materials and Methods

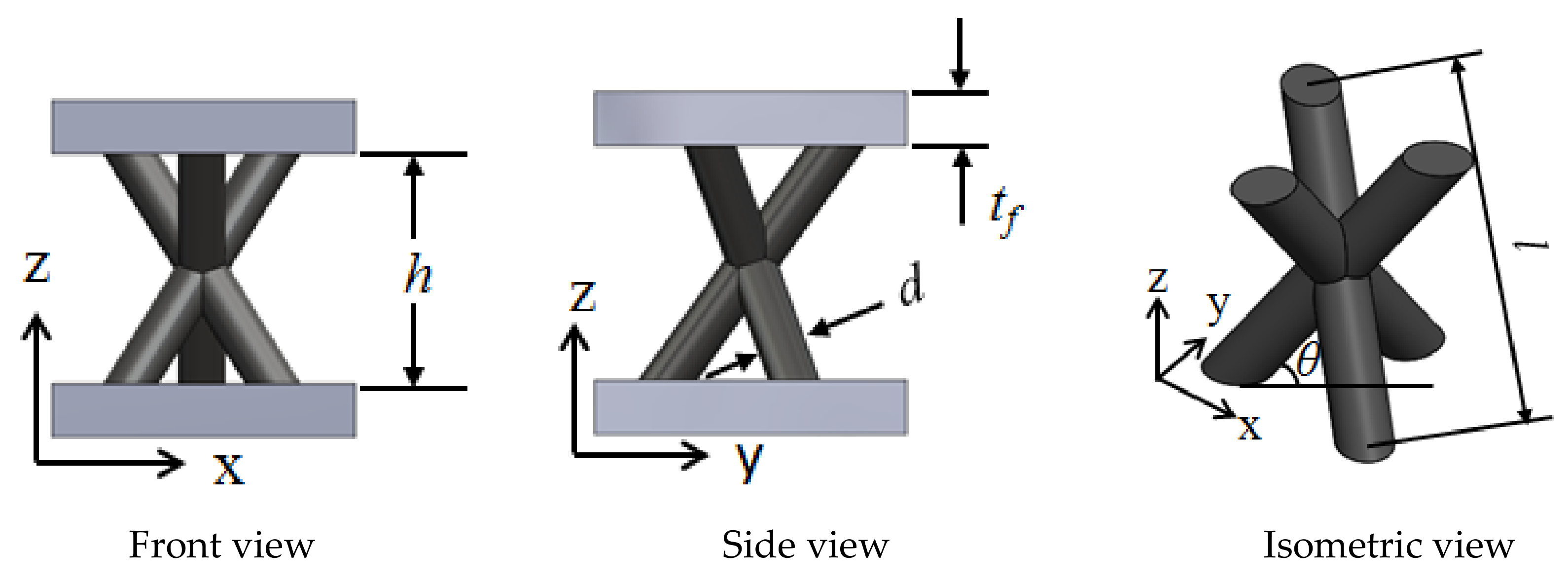

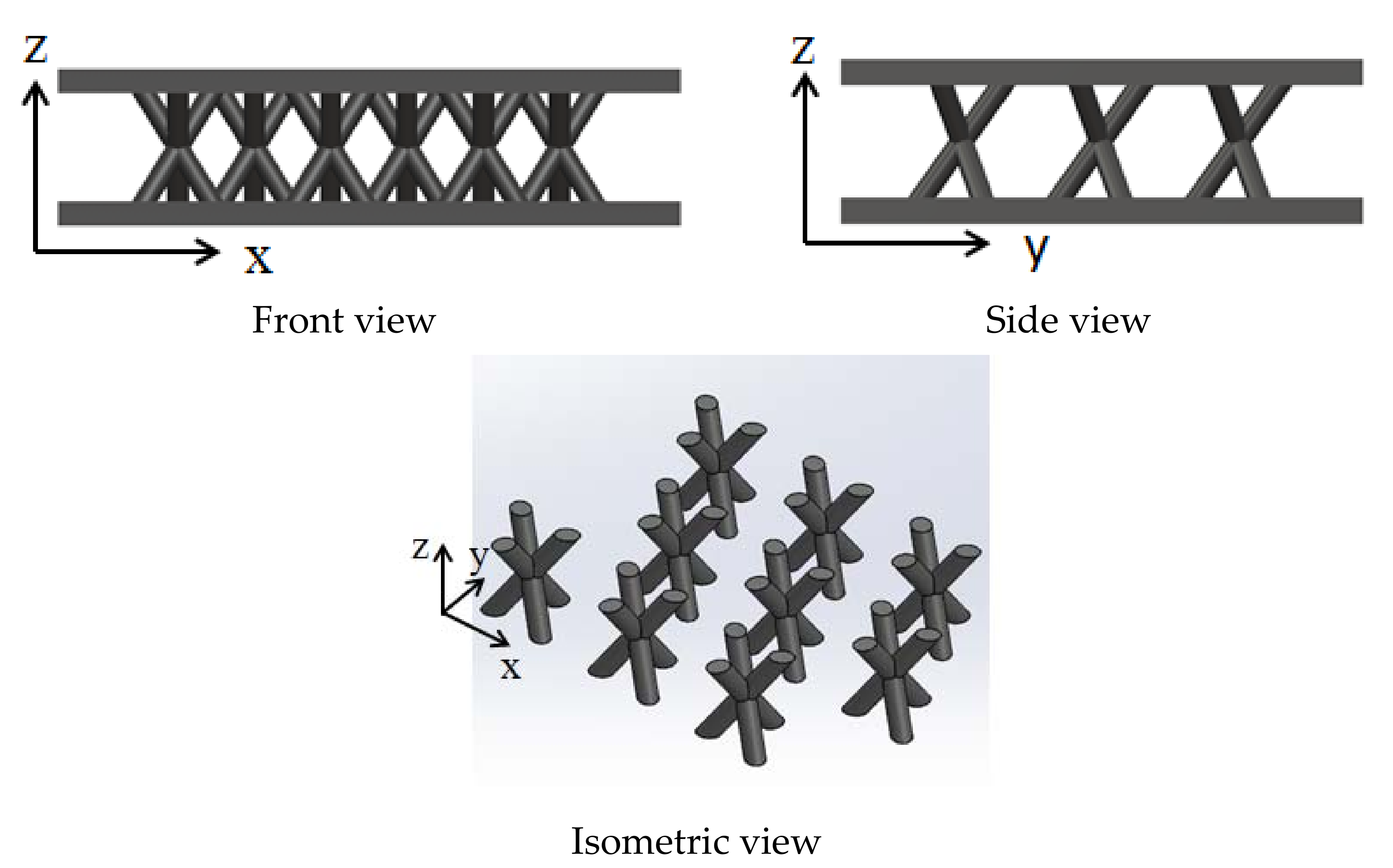

2.1. Design and Fabrication

2.2. Mechanical Testing

3. Results and Discussion

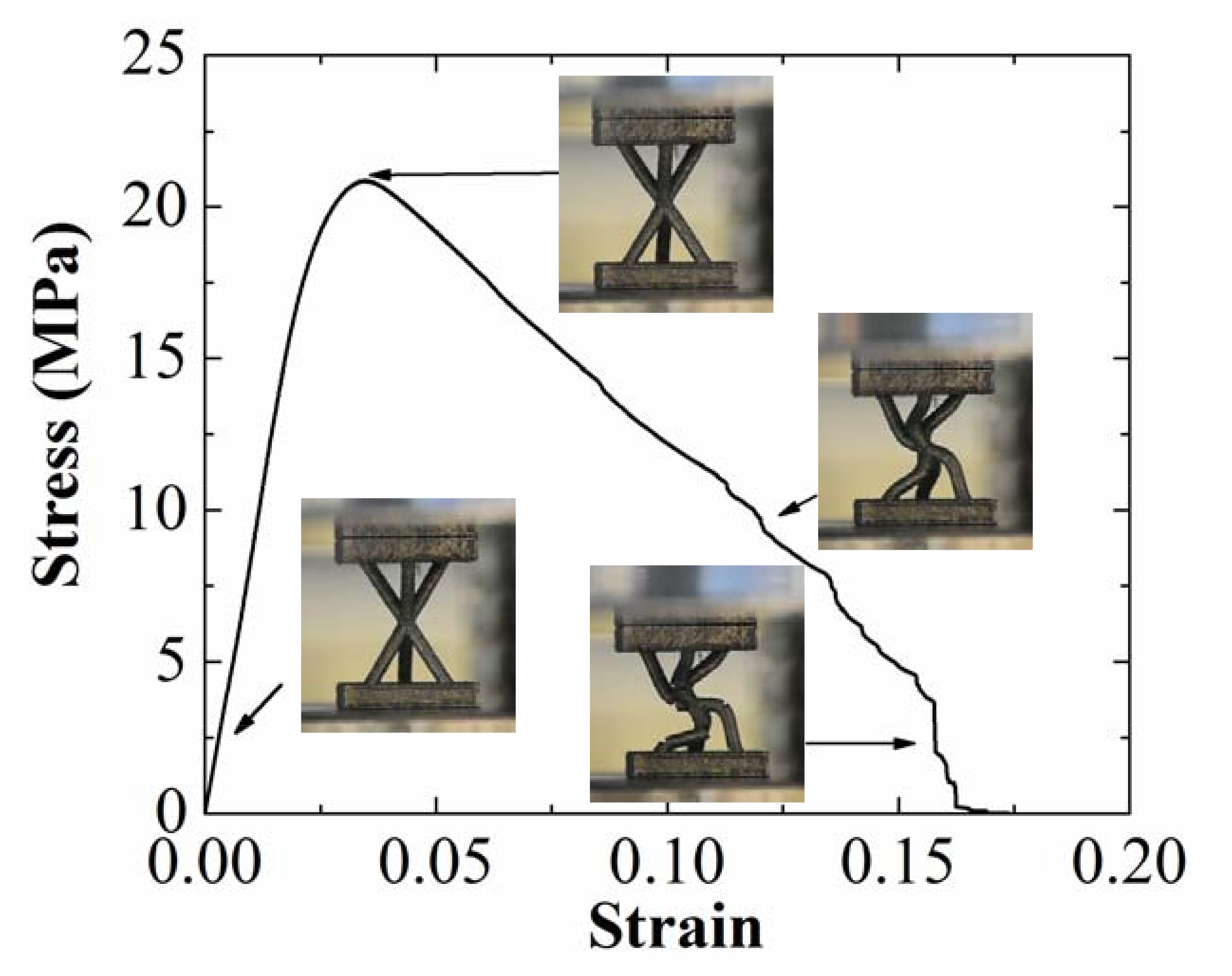

3.1. Compression Properties of Unit Kagome Structure Fabricated by Selective Laser Melting

3.2. Compression Properties of Kagome Structure Fabricated by Fused Deposition Modeling

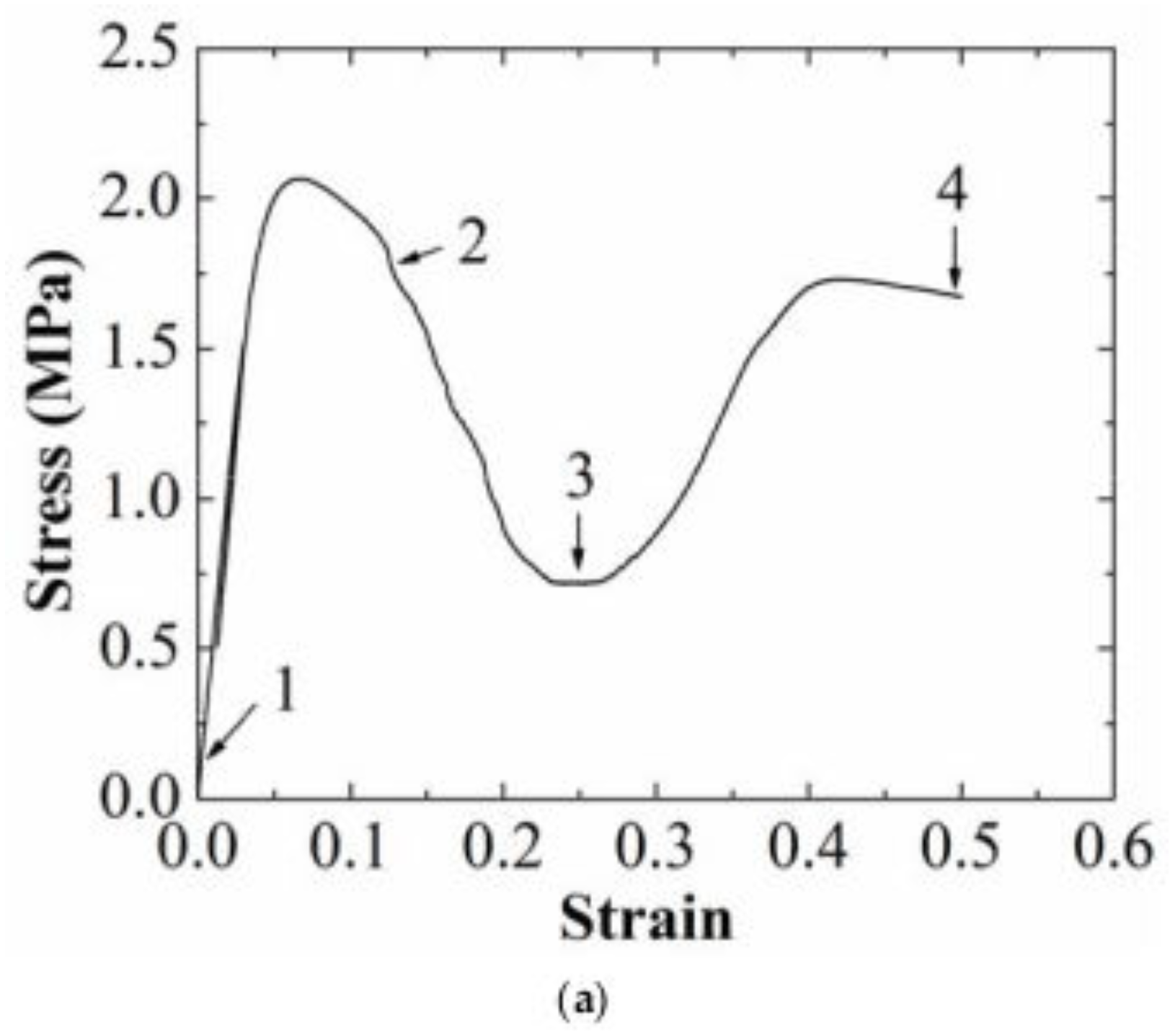

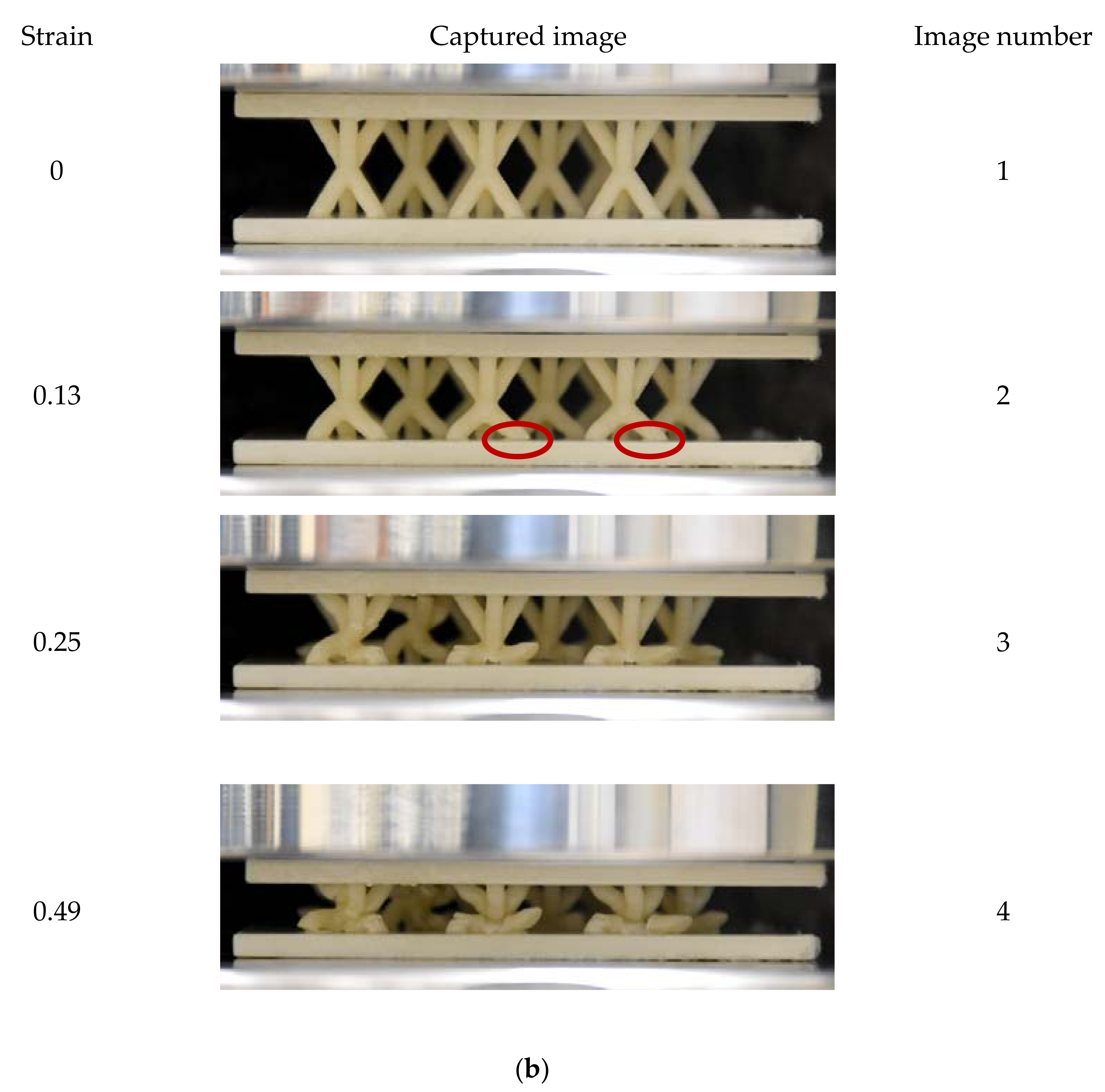

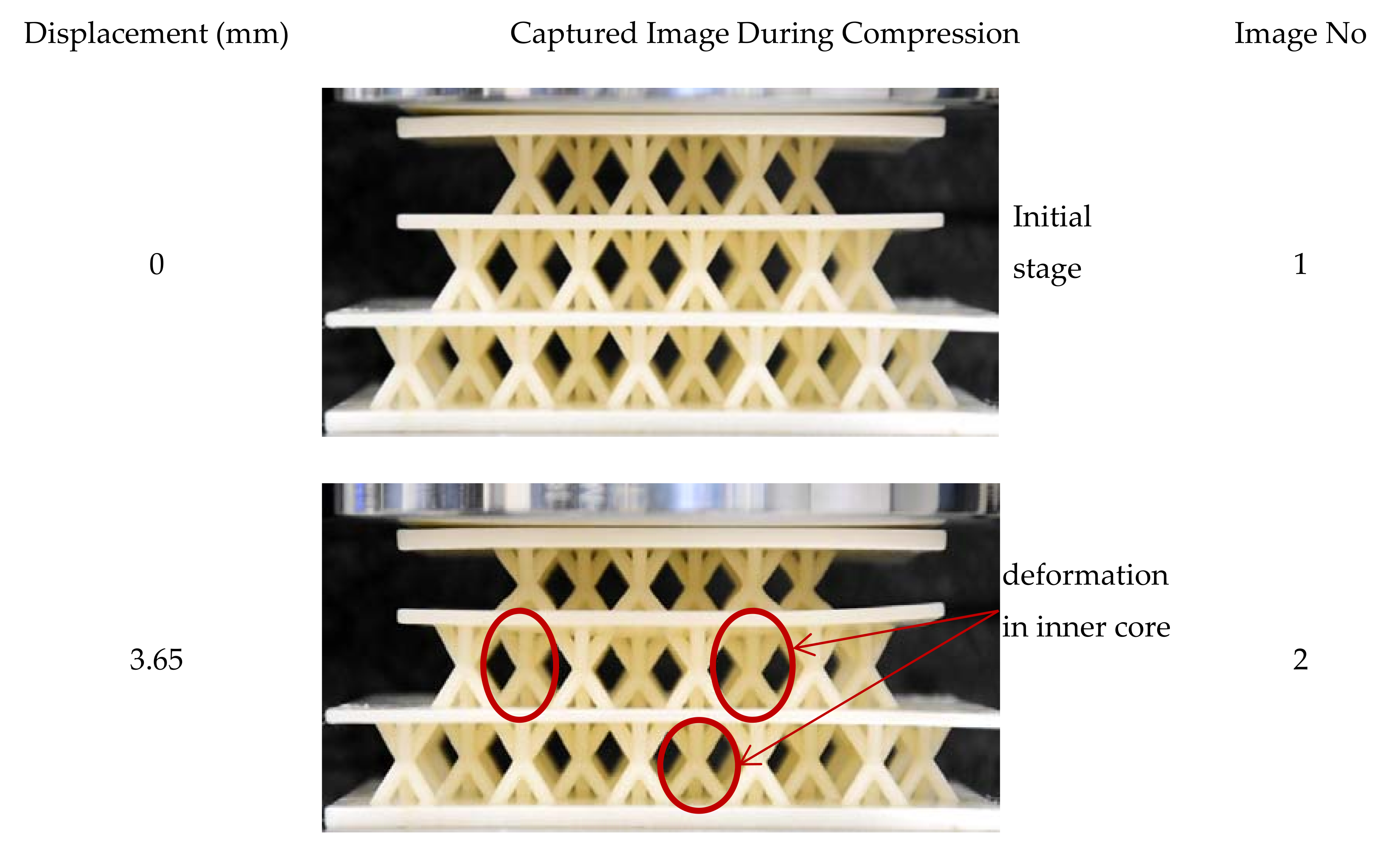

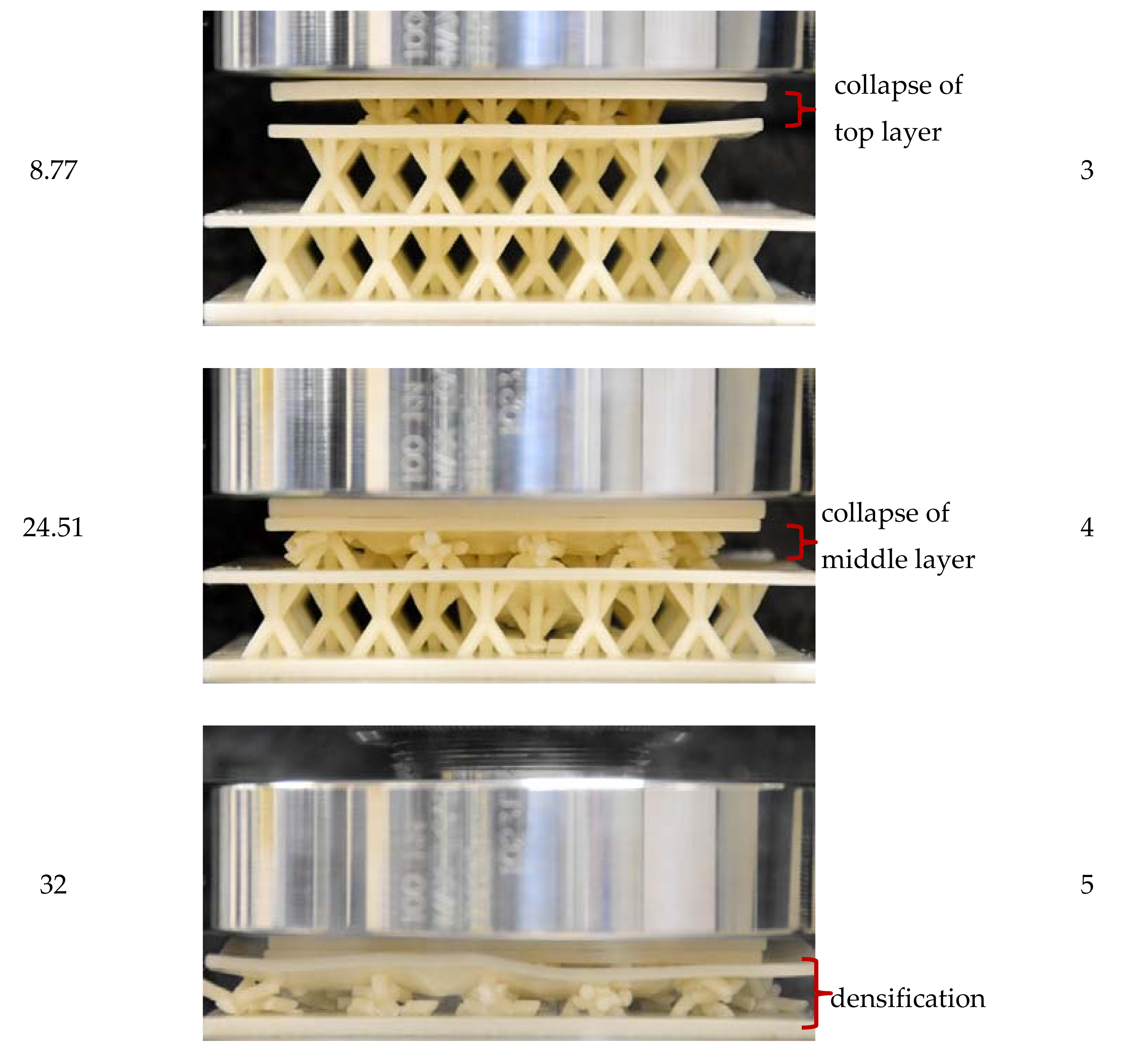

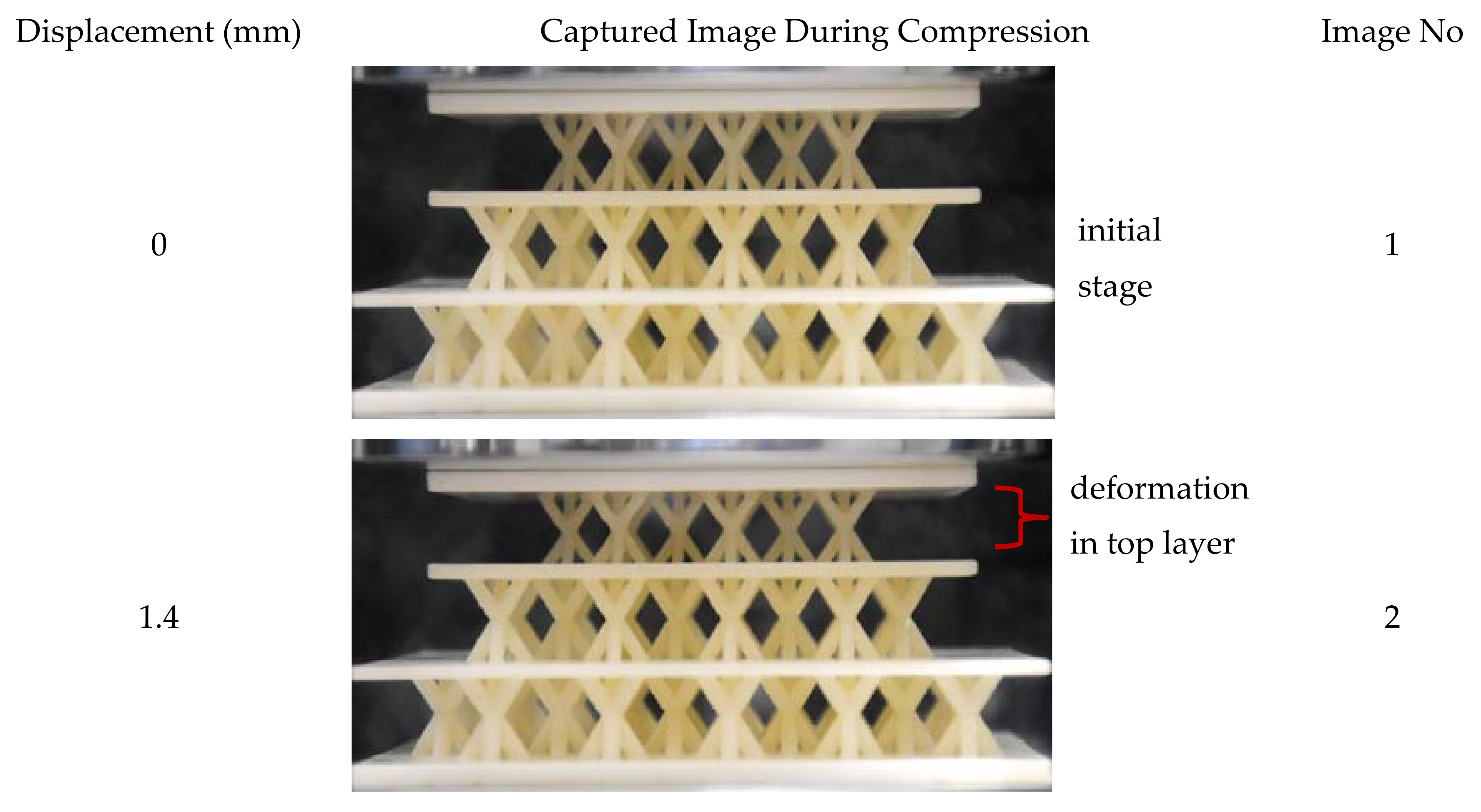

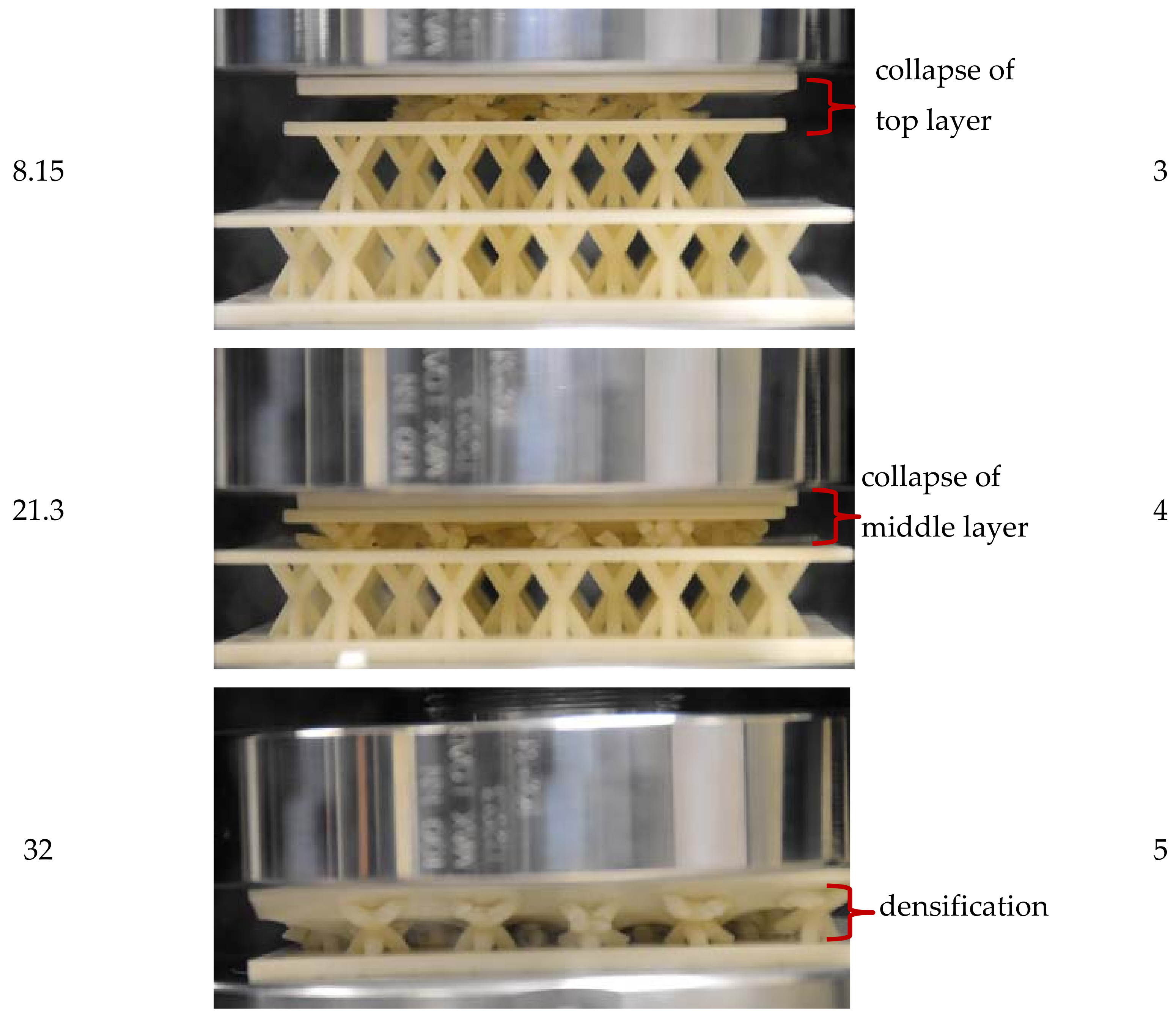

3.2.1. Deformation of Multi-Unit Kagome Structure

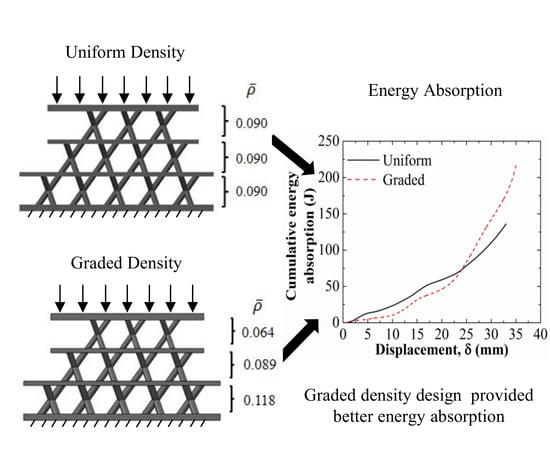

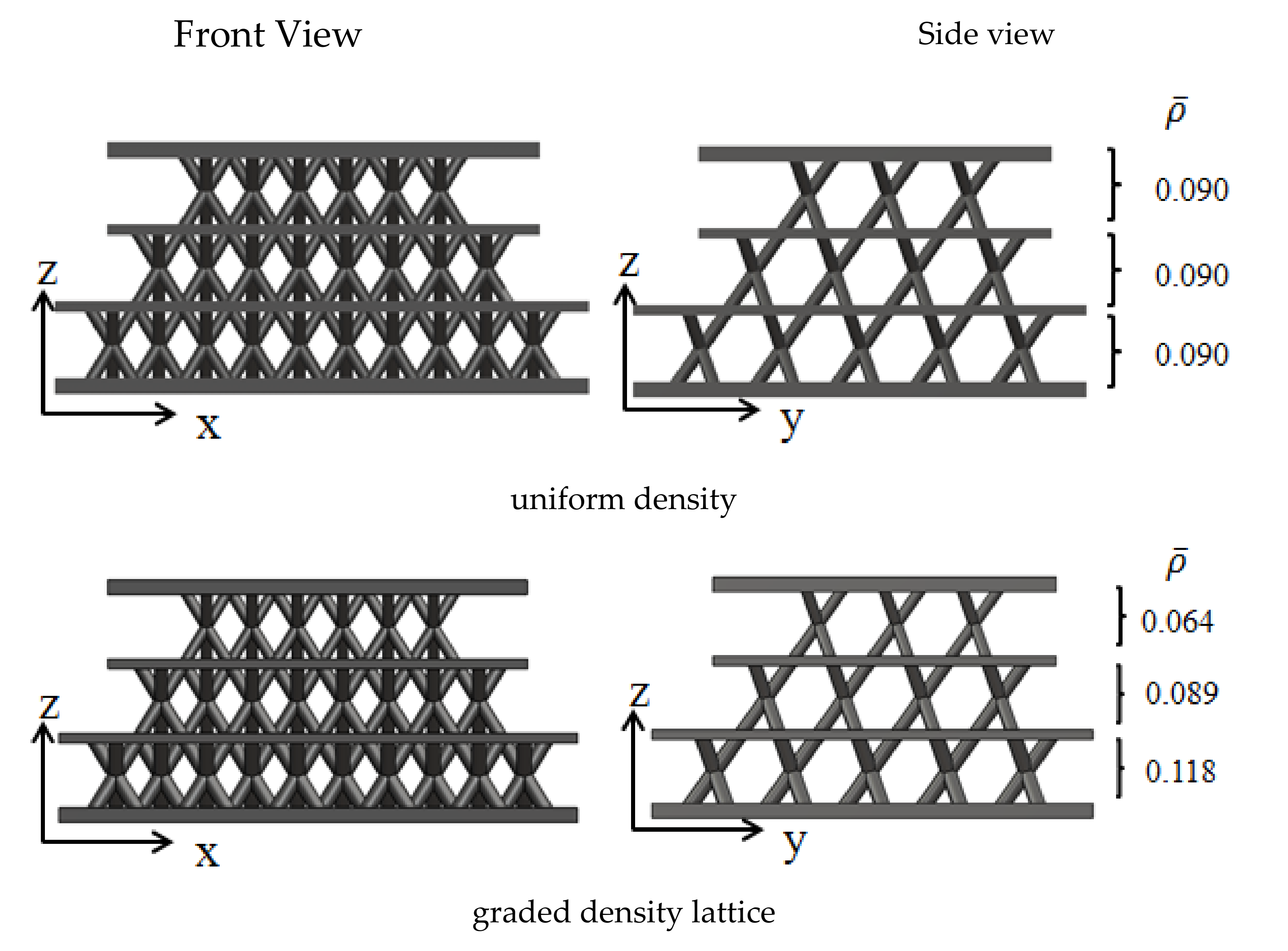

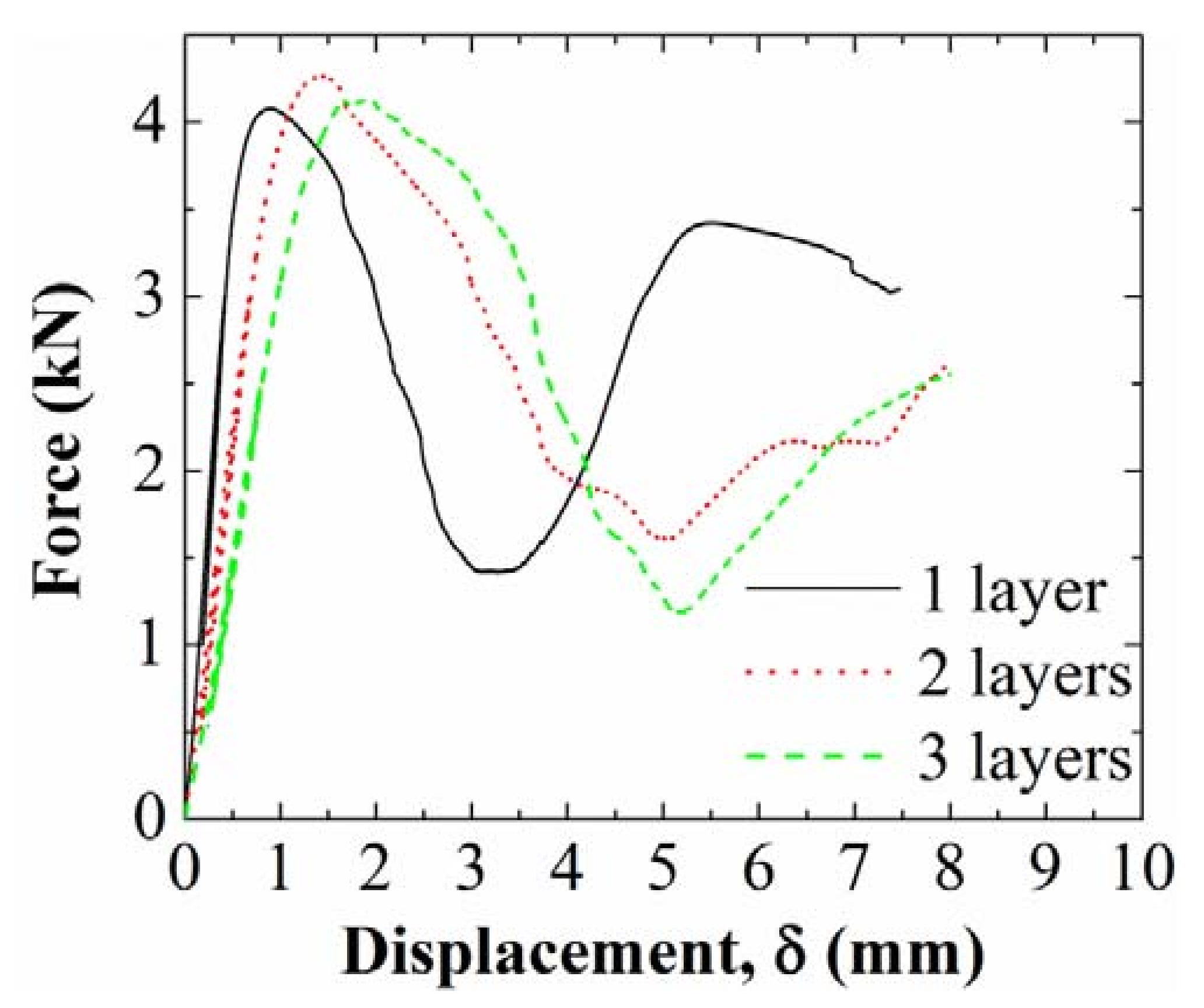

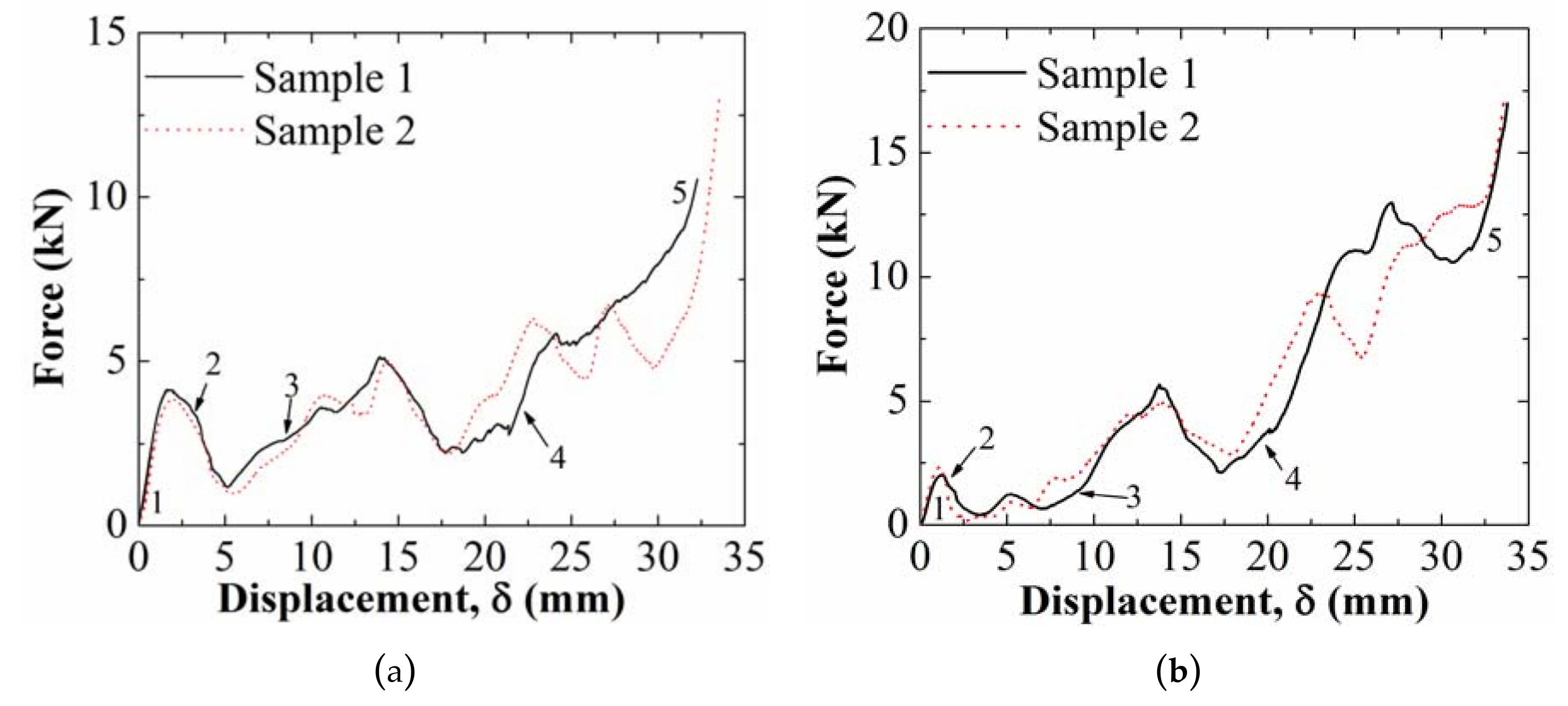

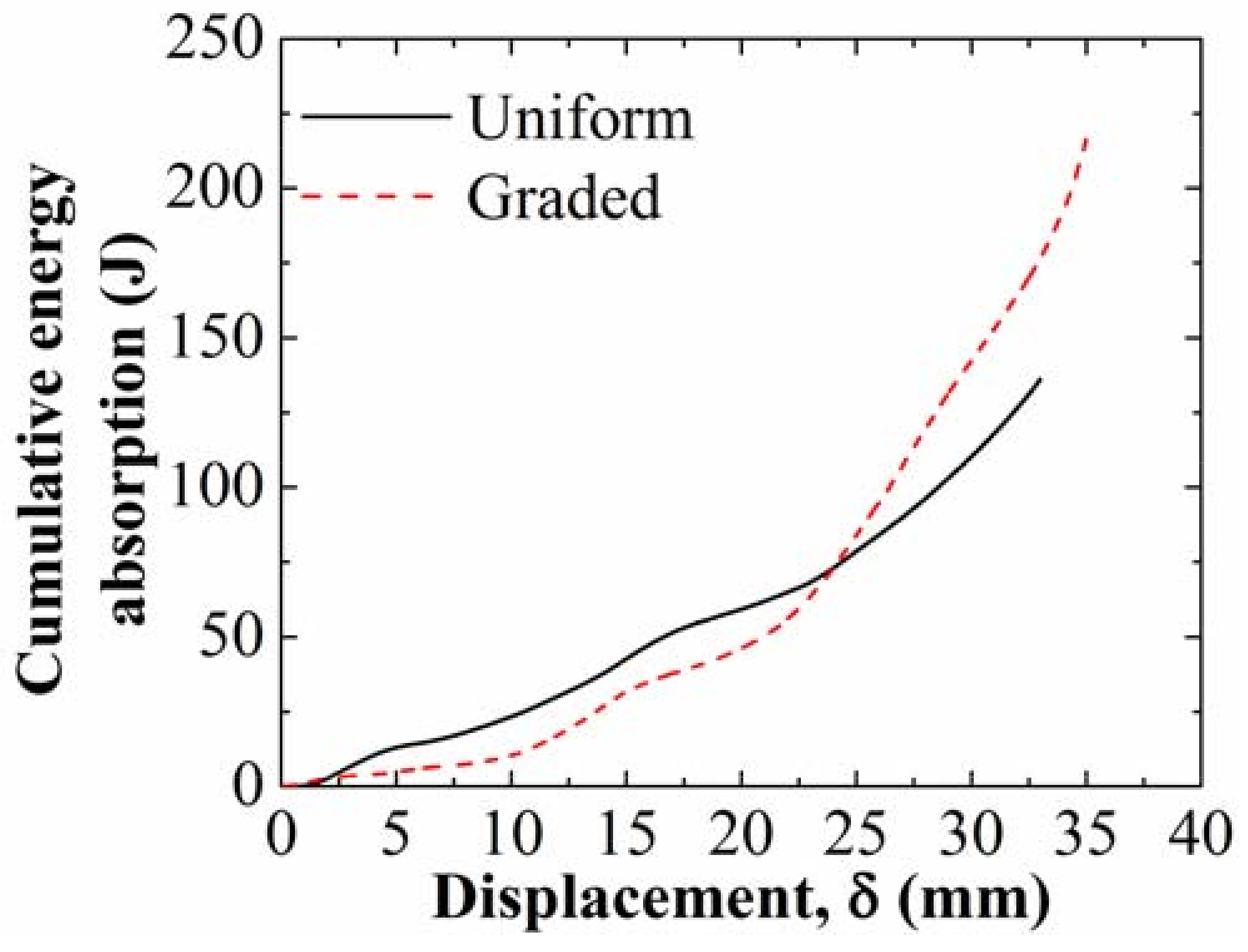

3.2.2 Uniform Density and Graded Density Kagome Structure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wadley, H.N. Multifunctional periodic cellular metals. Philos. Trans. A Math. Phys. Eng. Sci. 2006, 364, 31–68. [Google Scholar] [CrossRef] [PubMed]

- Deshpande, V.S.; Ashby, M.F.; Fleck, N.A. Foam topology: Bending versus stretching dominated architectures. Acta Mater. 2001, 49, 1035–1040. [Google Scholar] [CrossRef]

- Moon, S.K.; Tan, Y.E.; Hwang, J.; Yoon, Y.-J. Application of 3D printing technology for designing light-weight unmanned aerial vehicle wing structures. Int. J. Precis. Eng. Manuf. Green Technol. 2014, 1, 223–228. [Google Scholar] [CrossRef]

- Hyun, S.; Karlsson, A.M.; Torquato, S.; Evans, A.G. Simulated properties of Kagome and tetragonal truss core panels. Int. J. Solids Struct. 2003, 40, 6989–6998. [Google Scholar] [CrossRef]

- Wang, J.; Evans, A.G.; Dharmasena, K.; Wadley, H.N.G. On the performance of truss panels with Kagome cores. Int. J. Solids Struct. 2003, 40, 6981–6988. [Google Scholar] [CrossRef]

- Lee, B.-K.; Kang, K.-J. A parametric study on compressive characteristics of wire-woven bulk Kagome truss cores. Compos. Struct. 2010, 92, 445–453. [Google Scholar] [CrossRef]

- Ullah, I.; Elambasseril, J.; Brandt, M.; Feih, S. Performance of bio-inspired Kagome truss core structures under compression and shear loading. Compos. Struct. 2014, 118, 294–302. [Google Scholar] [CrossRef]

- Ullah, I.; Brandt, M.; Feih, S. Failure and energy absorption characteristics of advanced 3D truss core structures. Mater. Des. 2016, 92, 937–948. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S. Performance of strut-reinforced Kagome truss core structure under compression fabricated by selective laser melting. Mater. Des. 2019, 164, 107541. [Google Scholar] [CrossRef]

- Qian, X.; Dutta, D. Design of heterogeneous turbine blade. Comput. Aided Des. 2003, 35, 319–329. [Google Scholar] [CrossRef]

- Ocylok, S.; Weisheit, A.; Kelbassa, I. Functionally graded multi-layers by laser cladding for increased wear and corrosion protection. Phys. Procedia 2010, 5, 359–367. [Google Scholar] [CrossRef]

- Choy, S.Y.; Sun, C.-N.; Leong, K.F.; Wei, J. Compressive properties of functionally graded lattice structures manufactured by selective laser melting. Mater. Des. 2017, 131, 112–120. [Google Scholar] [CrossRef]

- Maskery, I.; Hussey, A.; Panesar, A.; Aremu, A.; Tuck, C.; Ashcroft, I.; Hague, R. An investigation into reinforced and functionally graded lattice structures. J. Cell. Plast. 2017, 53, 151–165. [Google Scholar] [CrossRef]

- Maskery, I.; Aboulkhair, N.; Aremu, A.; Tuck, C.; Ashcroft, I.; Wildman, R.D.; Hague, R.J. A mechanical property evaluation of graded density Al-Si10-Mg lattice structures manufactured by selective laser melting. Mater. Sci. Eng. A 2016, 670, 264–274. [Google Scholar] [CrossRef]

- Gautam, R.; Idapalapati, S.; Feih, S. Printing and characterisation of Kagome lattice structures by fused deposition modelling. Mater. Des. 2018, 137, 266–275. [Google Scholar] [CrossRef]

- Ravari, M.R.K.; Kadkhodaei, M.; Badrossamay, M.; Rezaei, R. Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int. J. Mech. Sci. 2014, 88, 154–161. [Google Scholar] [CrossRef]

| Properties | Predicted | Experimental |

|---|---|---|

| Average Effective Modulus (MPa) | 1293.11 | 909.70 ± 6.18 |

| Average Peak Strength (MPa) | 18.12 | 20.01 ± 0.63 |

| Designed Strut Diameter (mm) | Measured Strut Diameter (mm) | Difference (%) |

|---|---|---|

| 2.20 | 1.914 ± 0.042 | 13.00 |

| 2.60 | 2.445 ± 0.013 | 5.96 |

| 2.62 | 2.506 ± 0.027 | 4.35 |

| 3.00 | 2.883 ± 0.034 | 3.90 |

| Young’s Modulus (MPa) | 2% Offset Yield Strength (MPa) |

|---|---|

| 1498.53 ± 102.67 | 28.51 ± 0.39 |

| Properties | Predicted | Experimental |

|---|---|---|

| Average Effective modulus (MPa) | 55.17 | 54.49 ± 1.78 |

| Average Peak strength (MPa) | 1.58 | 2.11 ± 0.05 |

| Specimens | First Peak Load (kN) | Displacement at Densification, δ (mm) | Total Energy Absorbed to Densification (J) |

|---|---|---|---|

| Uniform density | 3.99 ± 0.14 | 31.55 ± 0.05 | 121.24 ± 1.02 |

| Graded density | 2.16 ± 0.16 | 32.26 ± 0.26 | 164.25 ± 0.09 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gautam, R.; Idapalapati, S. Compressive Properties of Additively Manufactured Functionally Graded Kagome Lattice Structure. Metals 2019, 9, 517. https://doi.org/10.3390/met9050517

Gautam R, Idapalapati S. Compressive Properties of Additively Manufactured Functionally Graded Kagome Lattice Structure. Metals. 2019; 9(5):517. https://doi.org/10.3390/met9050517

Chicago/Turabian StyleGautam, Rinoj, and Sridhar Idapalapati. 2019. "Compressive Properties of Additively Manufactured Functionally Graded Kagome Lattice Structure" Metals 9, no. 5: 517. https://doi.org/10.3390/met9050517

APA StyleGautam, R., & Idapalapati, S. (2019). Compressive Properties of Additively Manufactured Functionally Graded Kagome Lattice Structure. Metals, 9(5), 517. https://doi.org/10.3390/met9050517