The Interface Microstructure and Shear Strength of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints under Thermal-Cycle Loading

Abstract

:1. Introduction

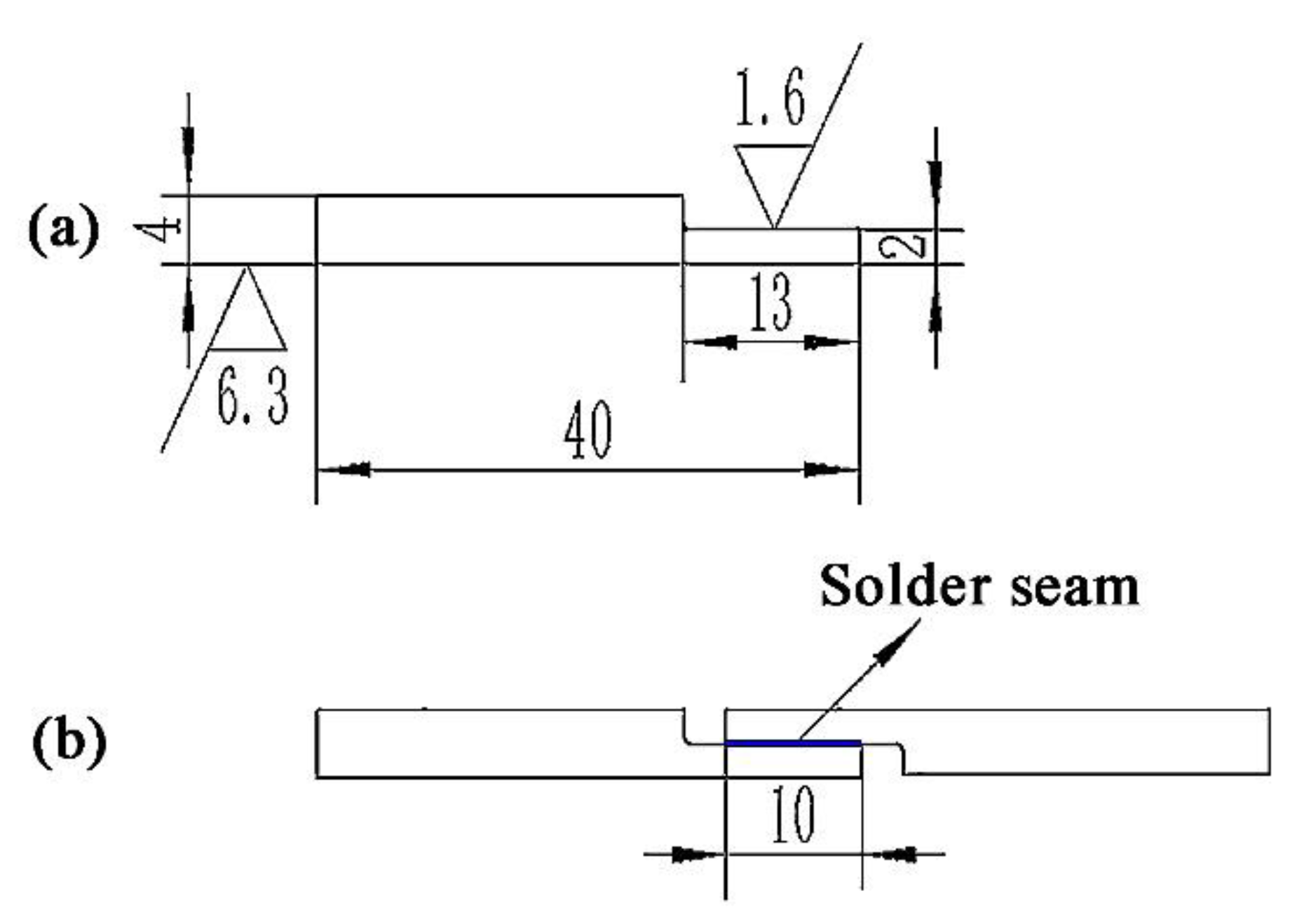

2. Materials and Methods

2.1. Materials

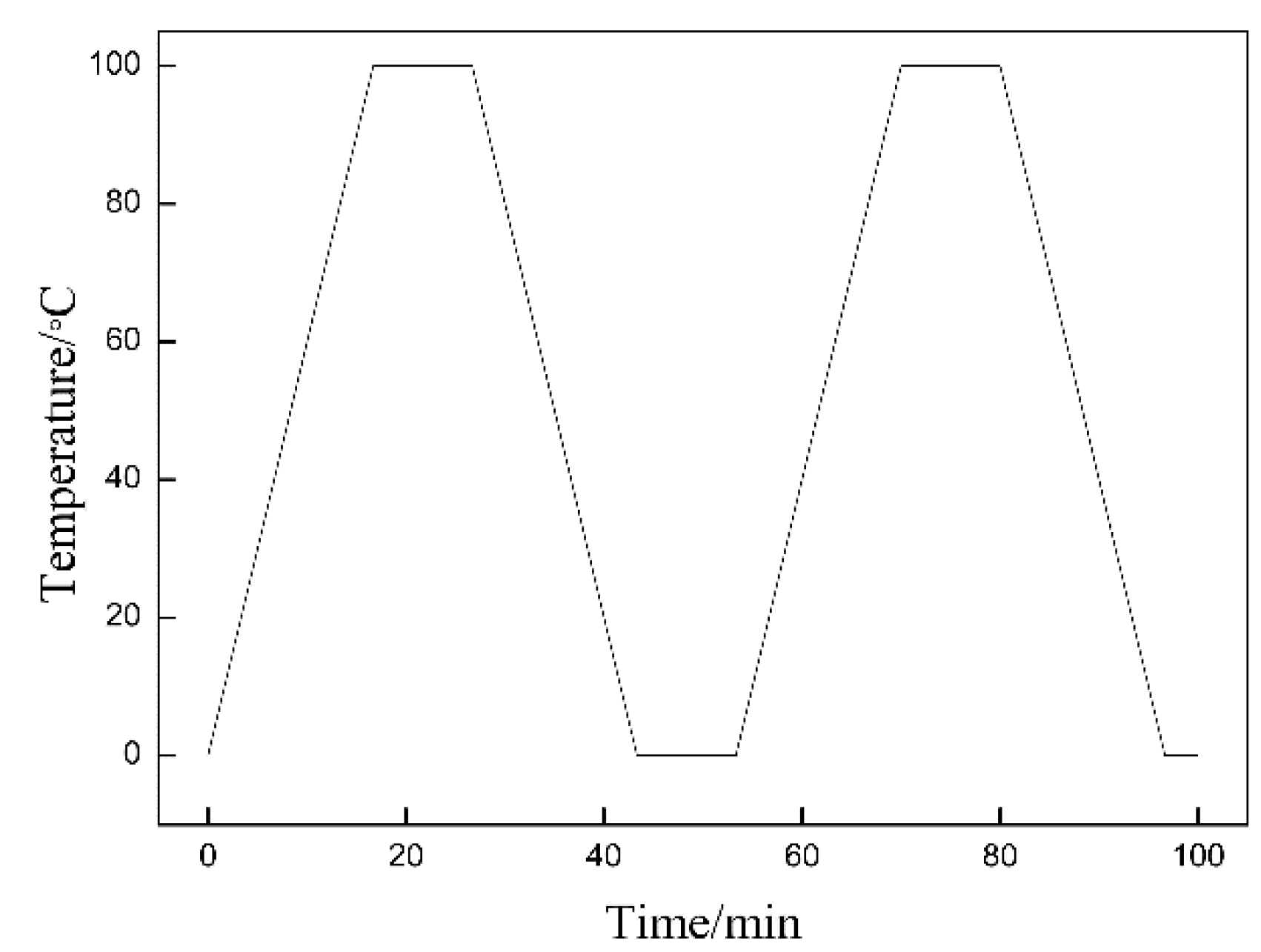

2.2. Methods and Conditions

3. Results and Discussion

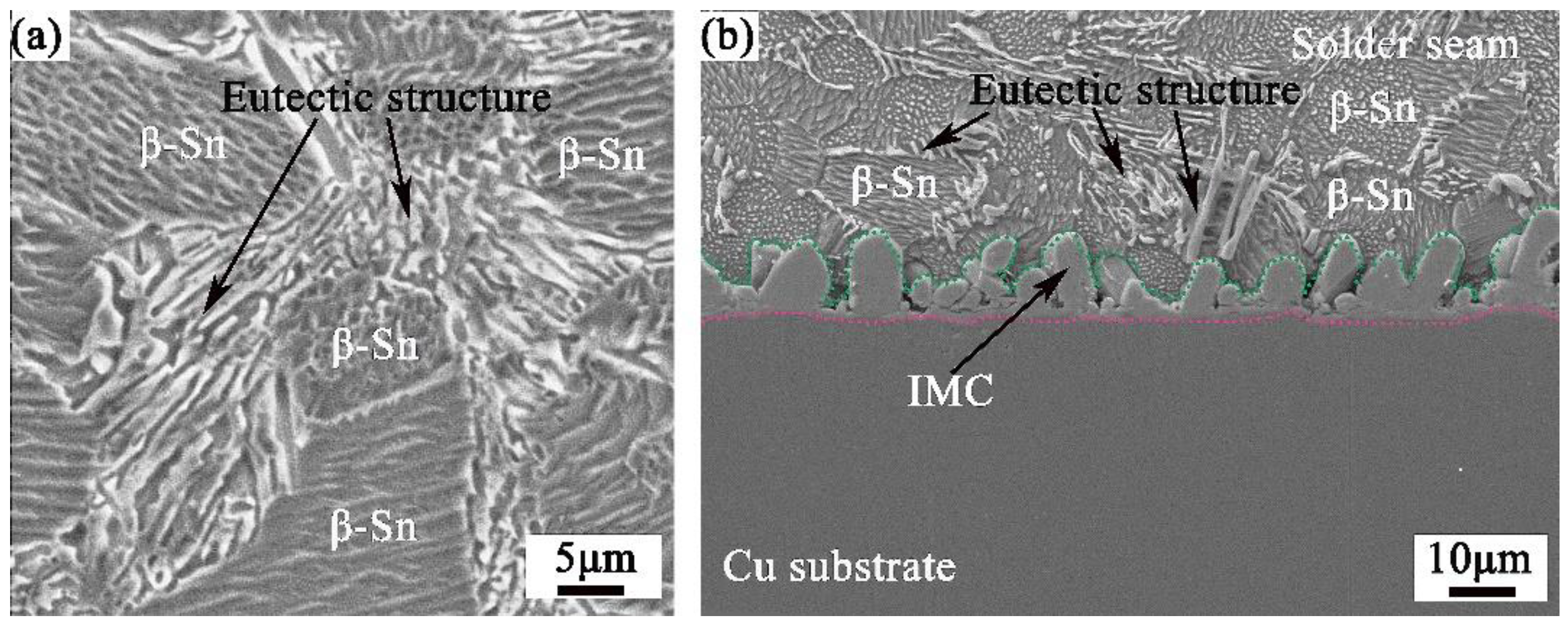

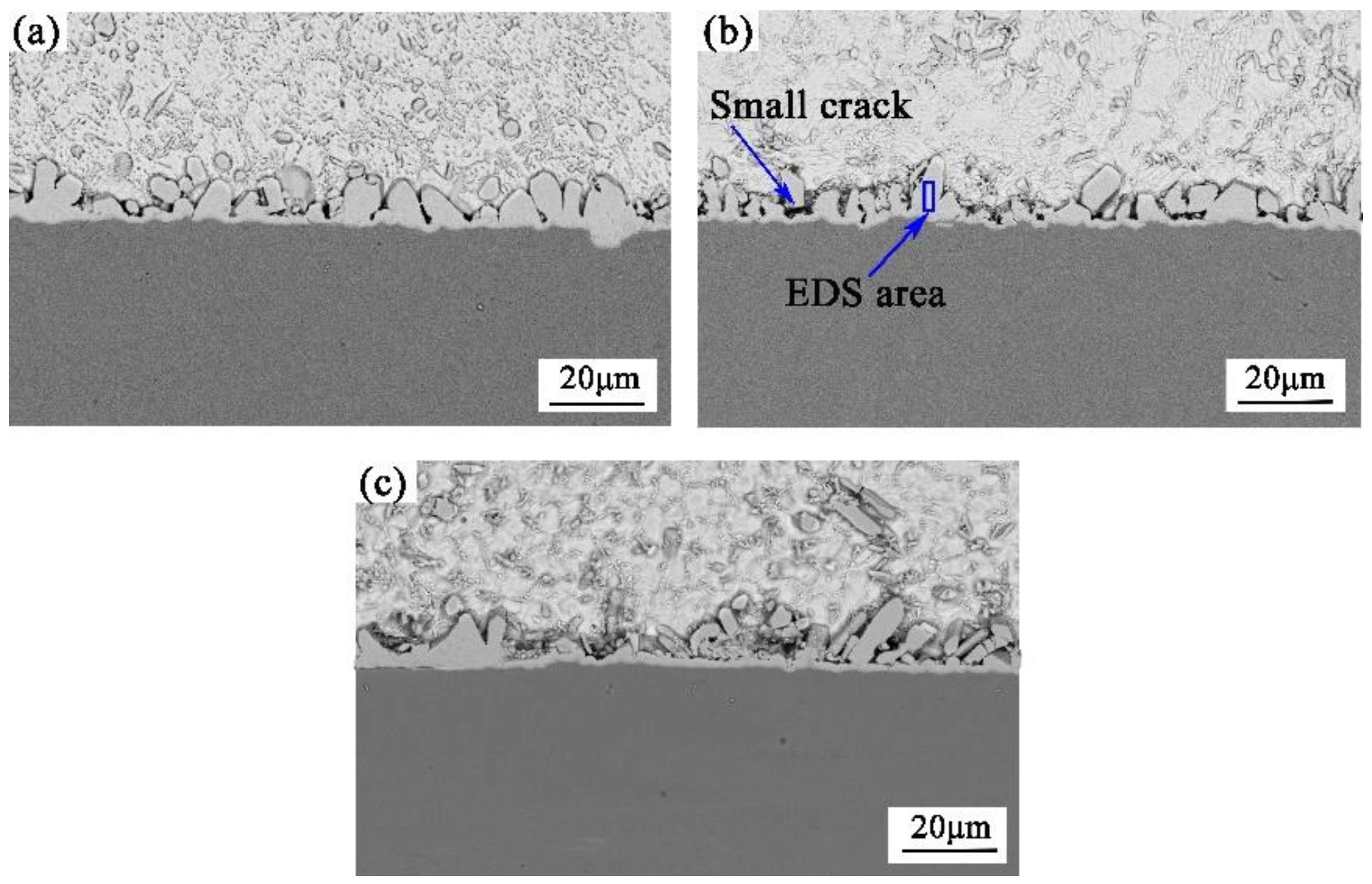

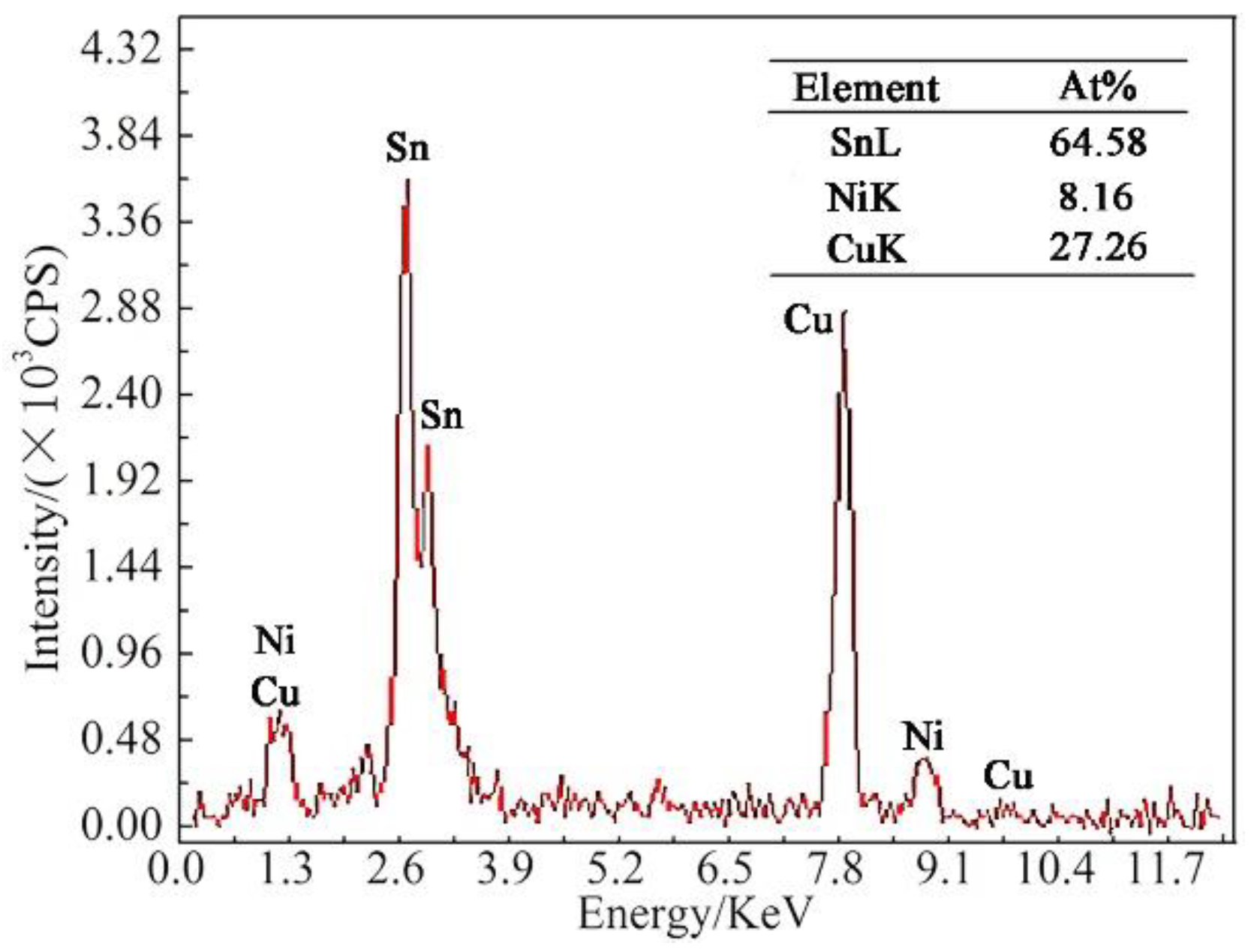

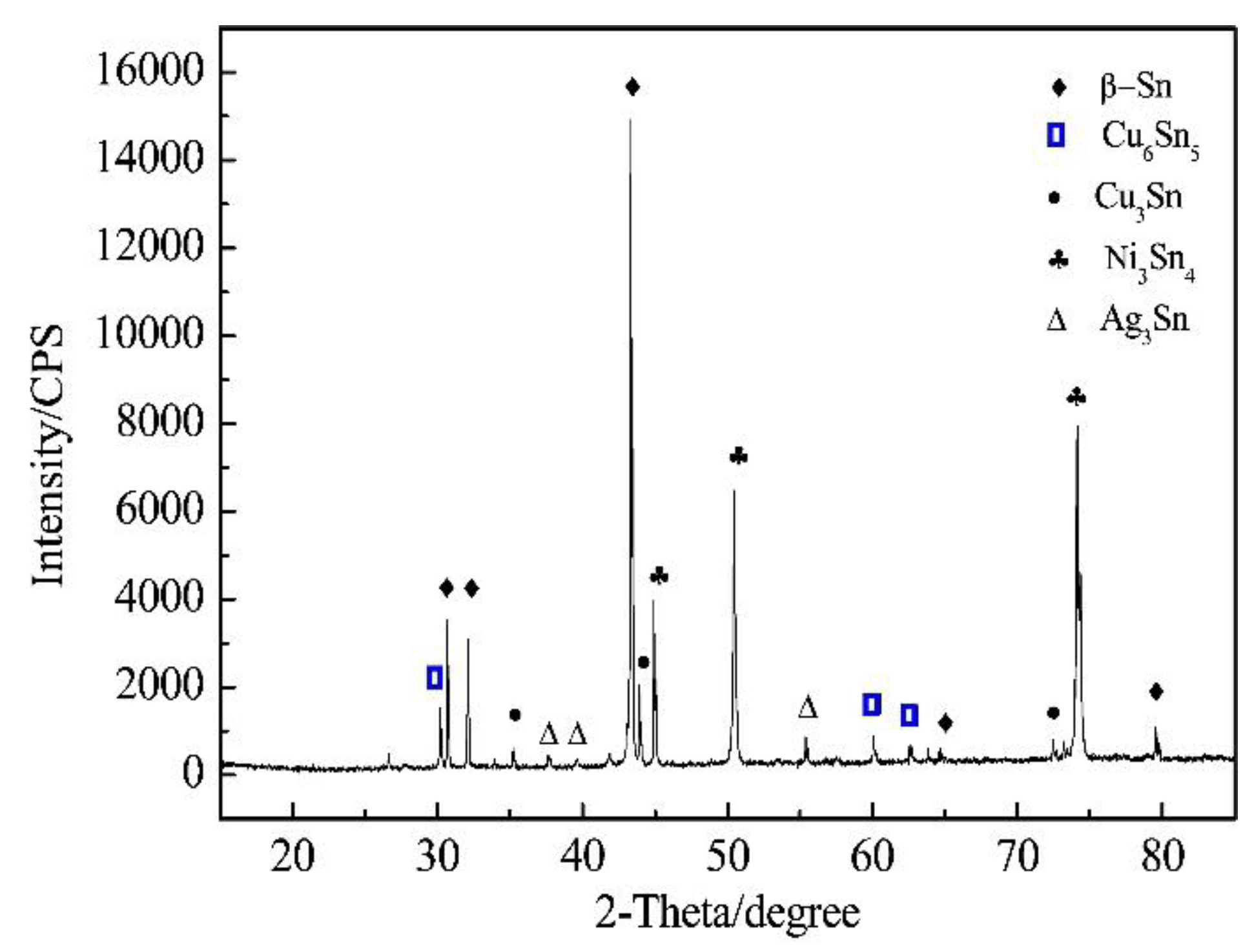

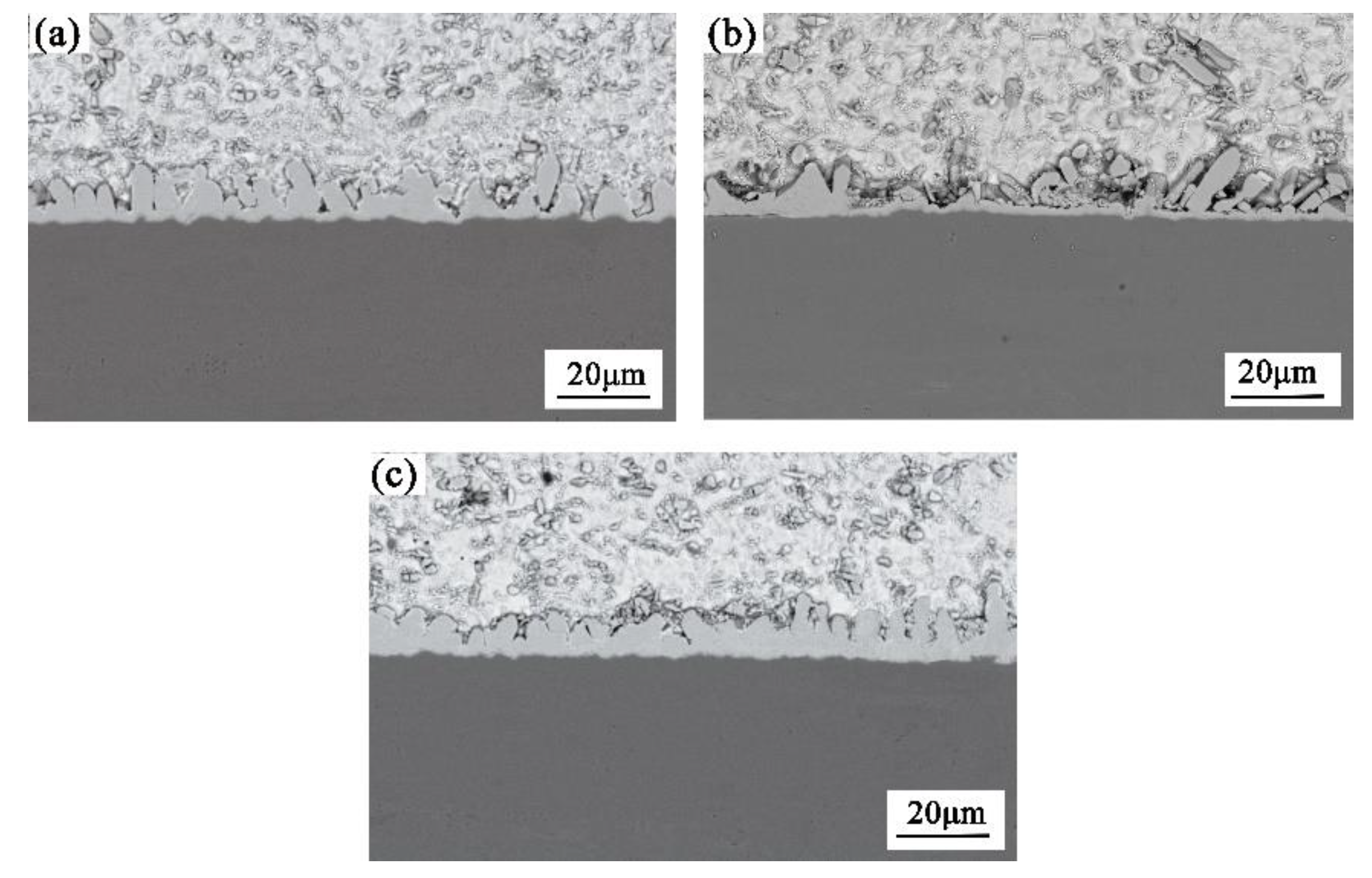

3.1. Microstructure of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints after Thermal-Cycle Loading

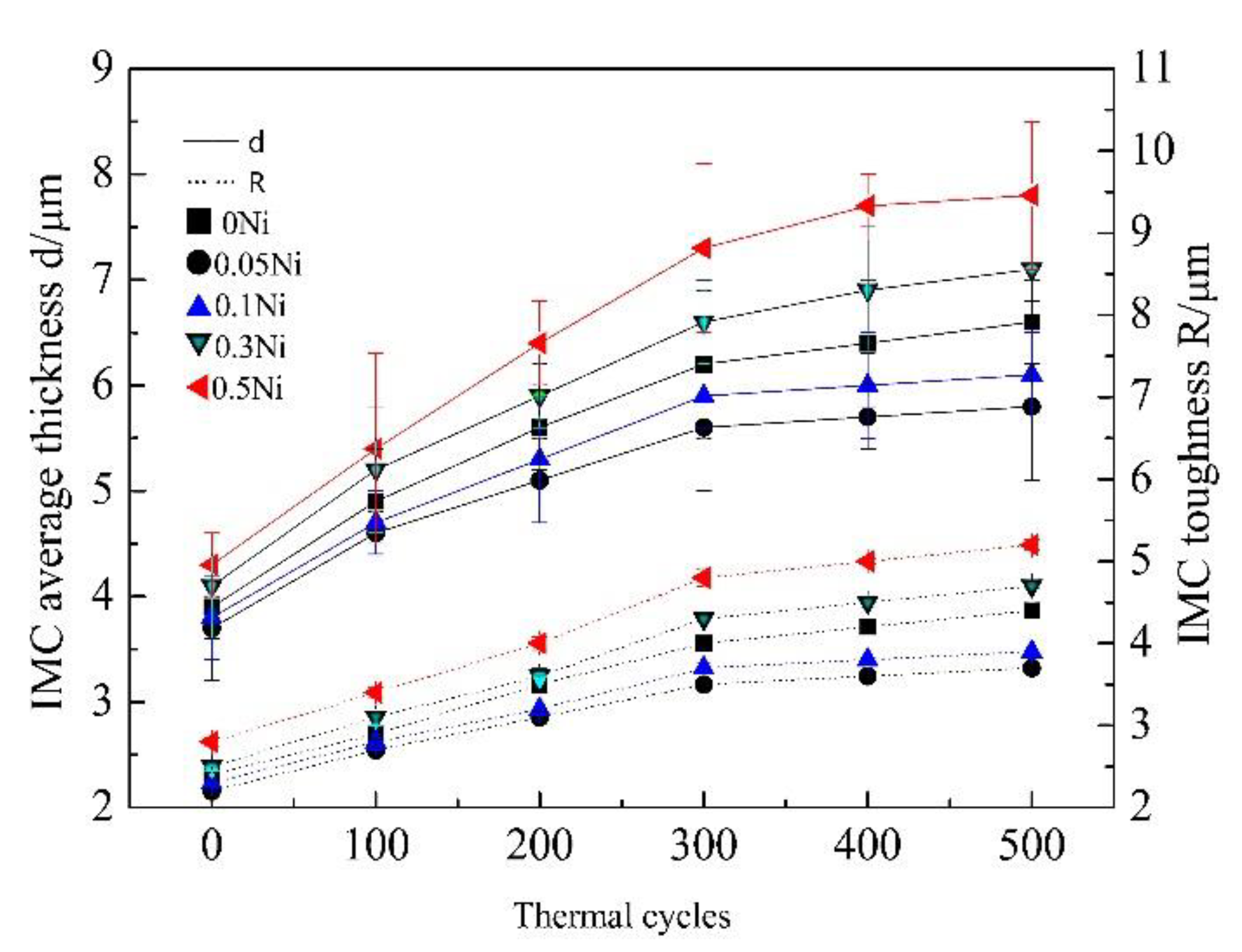

3.1.1. Effect of Thermal-Cycle Loading

3.1.2. Effect of Ni Content

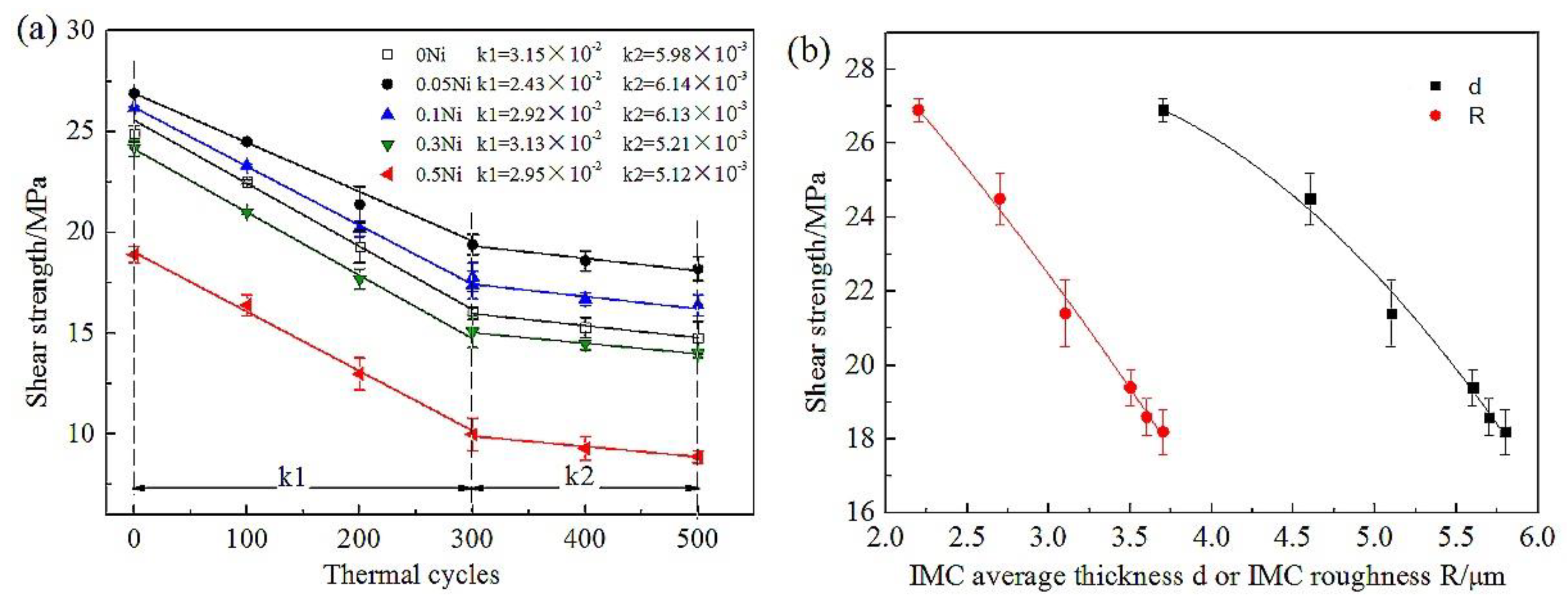

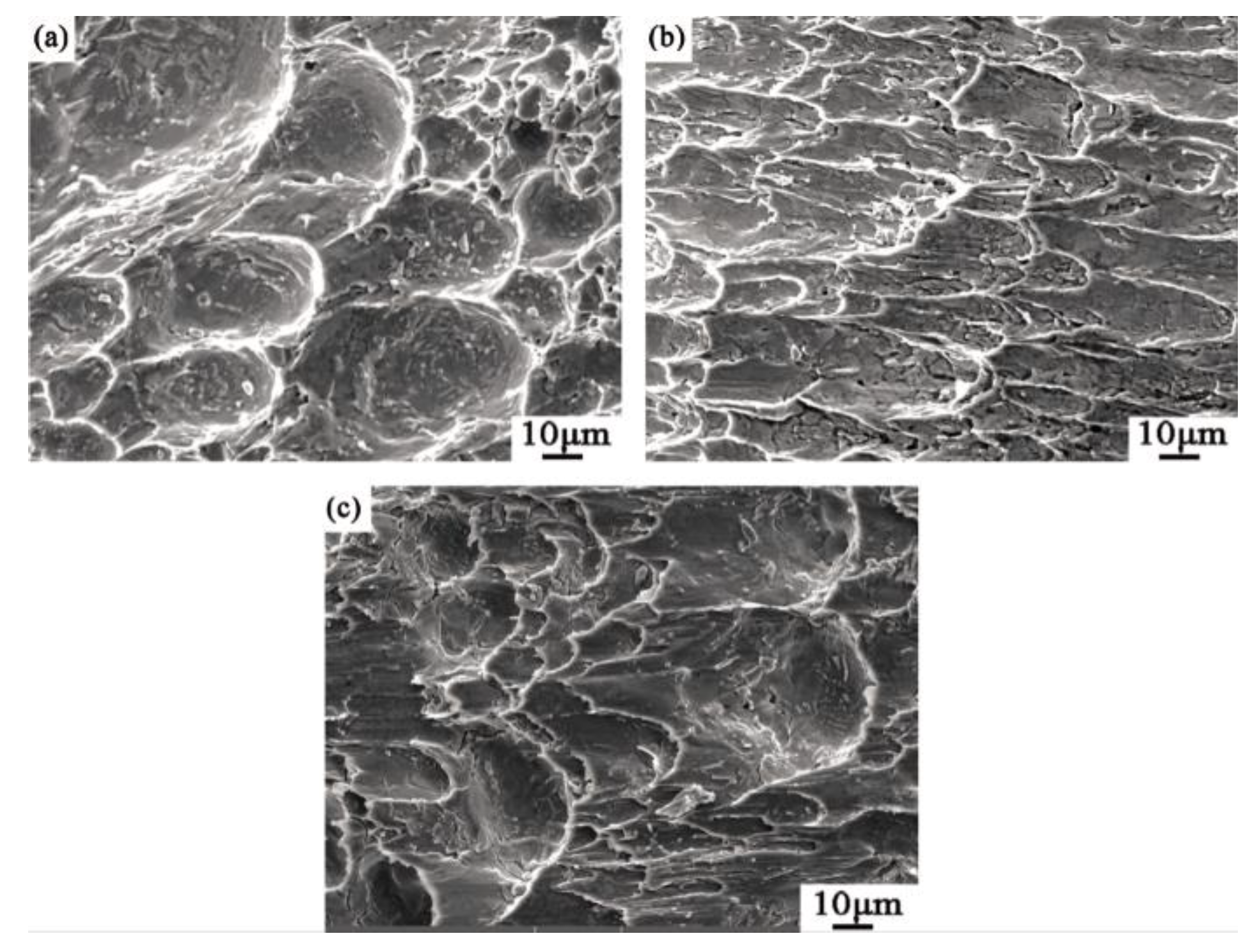

3.2. Shear Strength of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints under Thermal-Cycle Loading

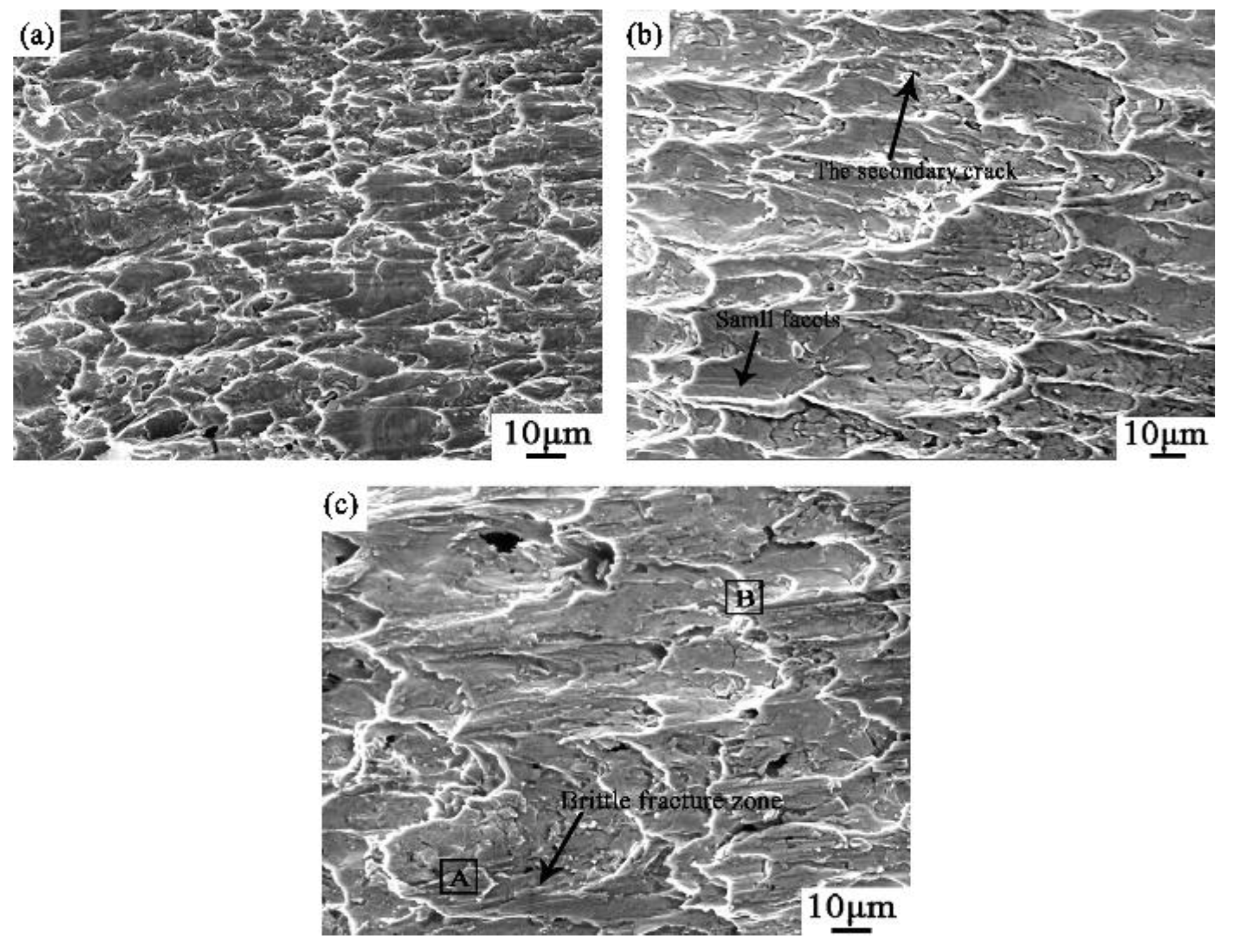

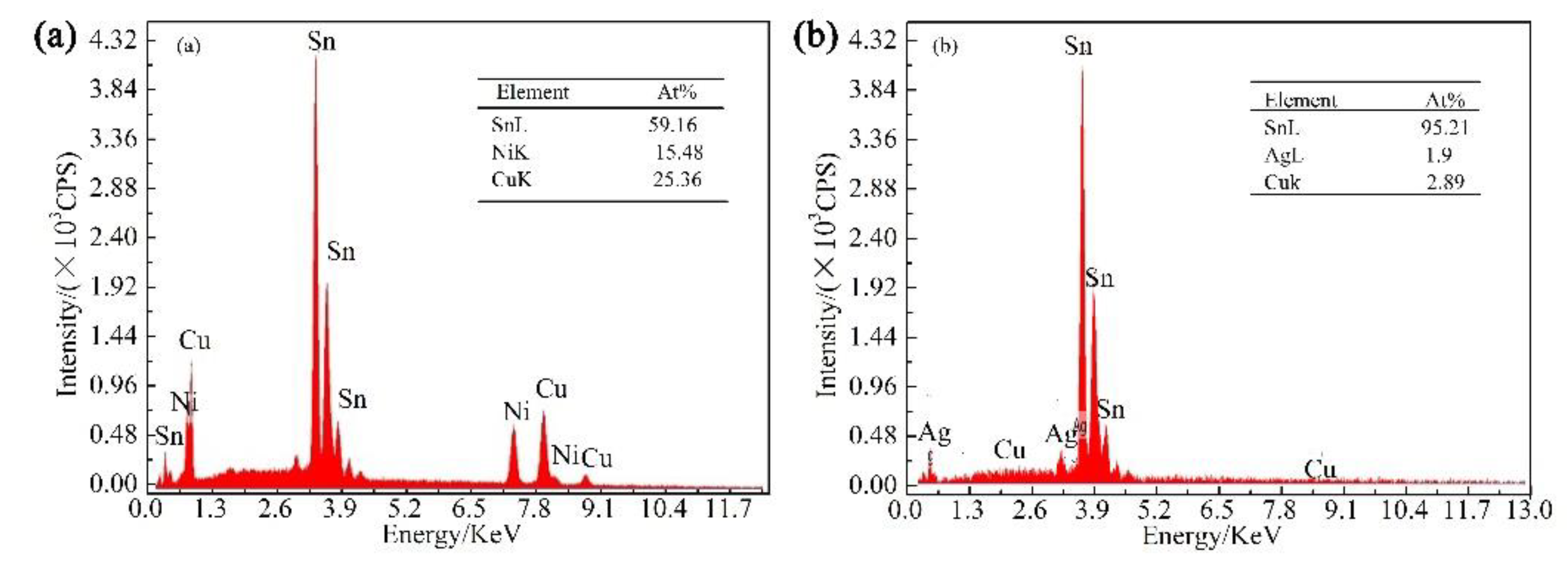

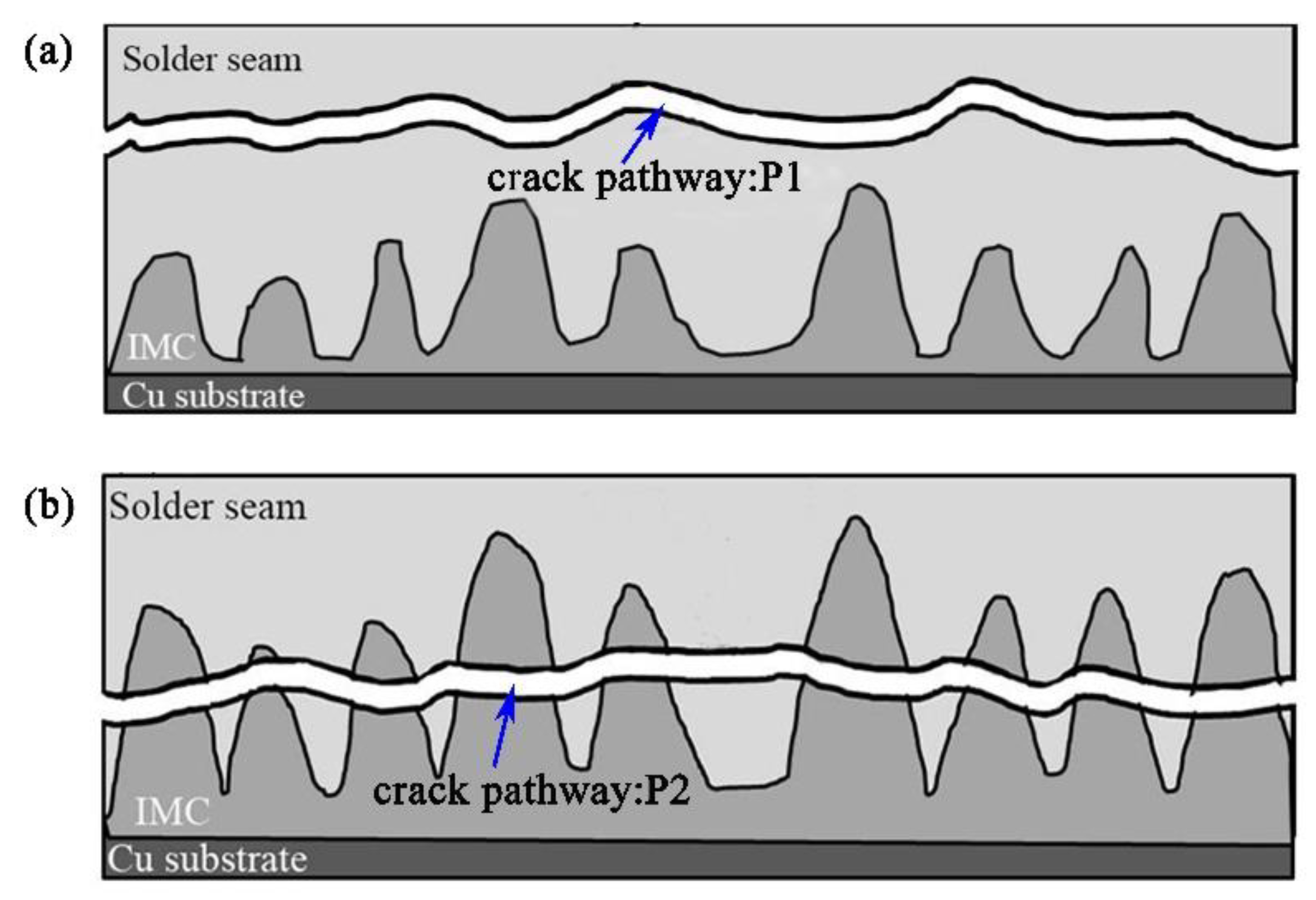

3.3. Analysis and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Gain, A.K.; Zhang, L.; Chan, Y.C. Microstructure, elastic modulus and shear strength of alumina (Al2O3) nanoparticles-doped tin-silver-copper (Sn-Ag-Cu) solders on copper (Cu) and gold/nickel (Au/Ni)-plated Cu substrates. J. Mater. Sci.-Mater. Electron. 2015, 26, 7039–7048. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Interfacial microstructure, wettability and material properties of nickel (Ni) nanoparticle doped tin-bismuth-silver (Sn-Bi-Ag) solder on copper (Cu) substrate. J. Mater. Sci.-Mater. Electron. 2016, 27, 3982–3994. [Google Scholar] [CrossRef]

- Gnecco, F.; Ricci, E.; Amore, S.; Borzone, G.; Novakovic, R. Wetting behaviour and reactivity of lead free Au–In–Sn and Bi–In–Sn alloys on copper substrates. Int. J. Adhes. Adhes. 2007, 27, 409–416. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L.; Quadir, M.Z. Thermal aging effects on microstructures and mechanical properties of an environmentally friendly eutectic tin-copper solder alloy. Mater. Des. 2016, 110, 275–283. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Howes, P.D.; Mannan, S.H. A review: On the development of low melting temperature Pb-free solders. Microelectron. Reliab. 2014, 54, 1253–1273. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Microstructure, thermal analysis and damping properties of Ag and Ni nano-particles doped Sn-8Zn-3Bi solder on OSP-Cu substrate. J. Alloys Compd. 2014, 617, 779–786. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Growth mechanism of intermetallic compound and mechanical properties of nickel (Ni) nanoparticle doped low melting temperature tin–bismuth (Sn–Bi) solder. J. Mater. Sci.-Mater. Electron. 2016, 27, 781–794. [Google Scholar] [CrossRef]

- Chan, Y.C.; Yang, D. Failure mechanisms of solder interconnects under current stressing in advanced electronic packages. Prog. Mater. Sci. 2010, 55, 428–475. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Microstructure, mechanical and electrical performances of zirconia nanoparticles-doped tin-silver-copper solder alloys. J. Mater. Sci.-Mater. Electron. 2017, 27, 7524–7533. [Google Scholar] [CrossRef]

- Zhang, L.; Tu, K.N. Structure and properties of lead-free solders bearing micro and nano particles. Mater. Sci. Eng. R. 2014, 82, 1–32. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Harsh service environment effects on the microstructure and mechanical properties of Sn-Ag-Cu-1 wt% nano-Al solder alloy. J. Mater. Sci.-Mater. Electron. 2016, 27, 11273–11283. [Google Scholar] [CrossRef]

- Zhang, L.; Xue, S.B.; Zeng, G.; Gao, L.L.; Ye, H. Interface reaction between SnAgCu/SnAgCuCe solders and Cu substrate subjected to thermal cycling and isothermal aging. J. Alloys Compd. 2012, 510, 38–45. [Google Scholar] [CrossRef]

- Zhang, L.; Fan, X.Y.; Guo, Y.H.; He, C.W. Properties enhancement of SnAgCu solders containing rare earth Yb. Mater. Des. 2014, 57, 646–651. [Google Scholar] [CrossRef]

- Li, G.; Shi, Y.; Hao, H.; Xia, Z.; Lei, Y. Effect of rare earth addition on shear strength of SnAgCu lead-free solder joints. J. Mater. Sci.-Mater. Electron. 2009, 20, 186–192. [Google Scholar] [CrossRef]

- Zhang, K.K.; Zhang, X.J.; Qiu, R.F.; Shi, H.X.; Liu, Y.J. The combined effects of ultrasonic wave and electric field on the microstructure and properties of Sn2.5Ag0.7Cu0.1RE/Cu soldered joints. J. Mater. Sci.-Mater. Electron. 2014, 25, 1681–1686. [Google Scholar] [CrossRef]

- El-Daly, A.A.; El-Taher, A.M. Evolution of thermal property and creep resistance of Ni and Zn-doped Sn-2.0Ag-0.5Cu lead-free solders. Mater. Des. 2013, 51, 789–796. [Google Scholar] [CrossRef]

- Tao, Q.B.; Benabou, L.; Le, V.N.; Wang, H.; Lu, D.B. Viscoplastic characterization and post-rupture microanalysis of a novel lead-free solder with small additions of Bi, Sb and Ni. J. Alloys Compd. 2016, 694, 892–904. [Google Scholar] [CrossRef]

- Park, Y.; Bang, J.H.; Oh, C.M.; Hong, W.S.; Kang, N. Effect of eutectic structure on creep properties of Sn-3.0Ag-0.5Cu and Sn-8.0Sb-3.0Ag solders. Metals 2017, 7, 540. [Google Scholar] [CrossRef]

- Li, S.; Yan, Y.F. Intermetallic growth study at Sn-3.0Ag-0.5Cu/Cu solder joint interface during different thermal conditions. J. Mater. Sci.-Mater. Electron 2015, 26, 9470–9477. [Google Scholar] [CrossRef]

- Zhang, K.K.; Li, C.Y.; Qiu, R.F.; Shi, H.X.; Wang, Y.L. Effect of Ni on growing of intermetallic compound in interface of Sn2.5Ag0.7Cu0.1RE/Cu solder joint during aging. Mater. Sci. Technol. 2012, 28, 760–765. [Google Scholar] [CrossRef]

- Xiao, H.; Li, X.Y.; Hu, Y.; Guo, F.; Shi, Y.W. Damage behavior of SnAgCu/Cu solder joints subjected to thermomechanical cycling. J. Alloys Compd. 2013, 578, 110–117. [Google Scholar] [CrossRef]

- Han, Y.D.; Jing, H.Y.; Nai, S.M.L.; Xu, L.Y.; Tan, C.M. Interfacial reaction and shear strength of Ni-coated carbon nanotubes reinforced Sn-Ag-Cu solder joints during thermal cycling. Intermetallics 2012, 3, 72–78. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhou, B.; Lee, T.K.; Bieler, T. Microstructural evolution of SAC305 solder joints in wafer level chip-scale packaging (WLCSP) with continuous and interrupted accelerated thermal cycling. J. Electron. Mater. 2016, 45, 3013–3024. [Google Scholar] [CrossRef]

- Bang, J.; Yu, D.Y.; Yang, M.; Ko, Y.H.; Yoon, J.W.; Nishikawa, H.; Lee, C.W. Improvement in thermomechanical reliability of low cost Sn-Based BGA interconnects by Cr Addition. Metals 2018, 8, 586. [Google Scholar] [CrossRef]

- IPC-9701. Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments; IPC: Northbrook, IL, USA, 2002. [Google Scholar]

- Yu, D.Q.; Wang, L. The growth and roughness evolution of intermetallic compounds of Sn-Ag-Cu/Cu interface during soldering reaction. J. Alloys Compd. 2008, 458, 542–547. [Google Scholar] [CrossRef]

- Zhao, D.; Zhang, K.; Cui, J.; Ma, N.; Pan, Y.; Yin, C. Effect of ultrasonic vibration on the interfacial IMC three-dimensional morphology and mechanical properties of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu halogen free solder joints. J. Mater. Sci.-Mater. Electron. 2018, 29, 18828–18839. [Google Scholar] [CrossRef]

- Li, C.Y.; Zhang, K.K.; Wang, Y.L.; Zhao, K.; Du, Y.L. Effect of Ni on interfacial IMC and mechanical properties of Sn2.5Ag0.7Cu0.1RE/Cu solder joints. Trans. China Weld. Inst. 2012, 33, 39–42. (In Chinese) [Google Scholar]

- Cui, J.G.; Zhang, K.K.; Zhao, D.; Ma, N.; Cao, C.C.; Pan, Y.B. Microstructure and properties of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu solder joints obtained by external energy assisted soldering. Rare Metal. Mat. Eng. 2018, 47, 2800–2806. (In Chinese) [Google Scholar]

- Guo, X.D.; Zhang, K.K.; Qiu, R.F.; Shi, H.X.; Wang, Y.L.; Ma, N. Effect on interface and property of Sn2.5Ag0.7Cu0.1RExNi/Cu solder joints in severe thermal cycling. Chin. J. Nonferrous. Met. 2016, 26, 2573–2579. (In Chinese) [Google Scholar]

- Zhang, K.K.; Guo, X.D.; Wang, H.G. Interfacial microstructure and mechanical properties of Sn2.5Ag0.7Cu0.1RE0.05Ni/Cu solder joint under thermal shock. Rare Metal. Mat. Eng. 2017, 46, 1353–1358. (In Chinese) [Google Scholar]

- Shen, J.; Zhao, M.; He, P.; Pu, Y. Growth behaviors of intermetallic compounds at Sn-3Ag-0.5Cu/Cu interface during isothermal and non-isothermal aging. J. Alloys Compd. 2013, 574, 451–458. [Google Scholar] [CrossRef]

- Yang, D.; Cai, J.; Wang, Q.; Li, J.; Hu, Y. IMC growth and shear strength of Sn-Ag-Cu/Co-P ball grid array solder joints under thermal cycling. J. Mater. Sci.-Mater. Electron. 2015, 26, 962–969. [Google Scholar] [CrossRef]

- Zeng, G.; Mcdonald, S.D.; Mu, D.; Terada, Y.; Yasuda, H. The influence of ageing on the stabilisation of interfacial (Cu,Ni)6(Sn,Zn)5,and(Cu,Au,Ni)6Sn5, intermetallics in Pb-free Ball Grid Array (BGA) solder joints. J. Alloys Compd. 2016, 685, 471–482. [Google Scholar] [CrossRef]

- Yang, S.T.; Chung, Y.; Kim, Y.H.; Hong, B.H. Intermetallic growth between Sn-Ag-(Cu) solder and Ni. Proceed. Adv. Electron. Mater. Pack. 2001, 19–22, 219–224. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cao, C.; Zhang, K.; Shi, B.; Wang, H.; Zhao, D.; Sun, M.; Zhang, C. The Interface Microstructure and Shear Strength of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints under Thermal-Cycle Loading. Metals 2019, 9, 518. https://doi.org/10.3390/met9050518

Cao C, Zhang K, Shi B, Wang H, Zhao D, Sun M, Zhang C. The Interface Microstructure and Shear Strength of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints under Thermal-Cycle Loading. Metals. 2019; 9(5):518. https://doi.org/10.3390/met9050518

Chicago/Turabian StyleCao, Congcong, Keke Zhang, Baojin Shi, Huigai Wang, Di Zhao, Mengmeng Sun, and Chao Zhang. 2019. "The Interface Microstructure and Shear Strength of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints under Thermal-Cycle Loading" Metals 9, no. 5: 518. https://doi.org/10.3390/met9050518

APA StyleCao, C., Zhang, K., Shi, B., Wang, H., Zhao, D., Sun, M., & Zhang, C. (2019). The Interface Microstructure and Shear Strength of Sn2.5Ag0.7Cu0.1RExNi/Cu Solder Joints under Thermal-Cycle Loading. Metals, 9(5), 518. https://doi.org/10.3390/met9050518