Optimization of Copper Thermocompression Diffusion Bonding under Vacuum: Microstructural and Mechanical Characteristics

Abstract

:1. Introduction

2. Materials and Methods

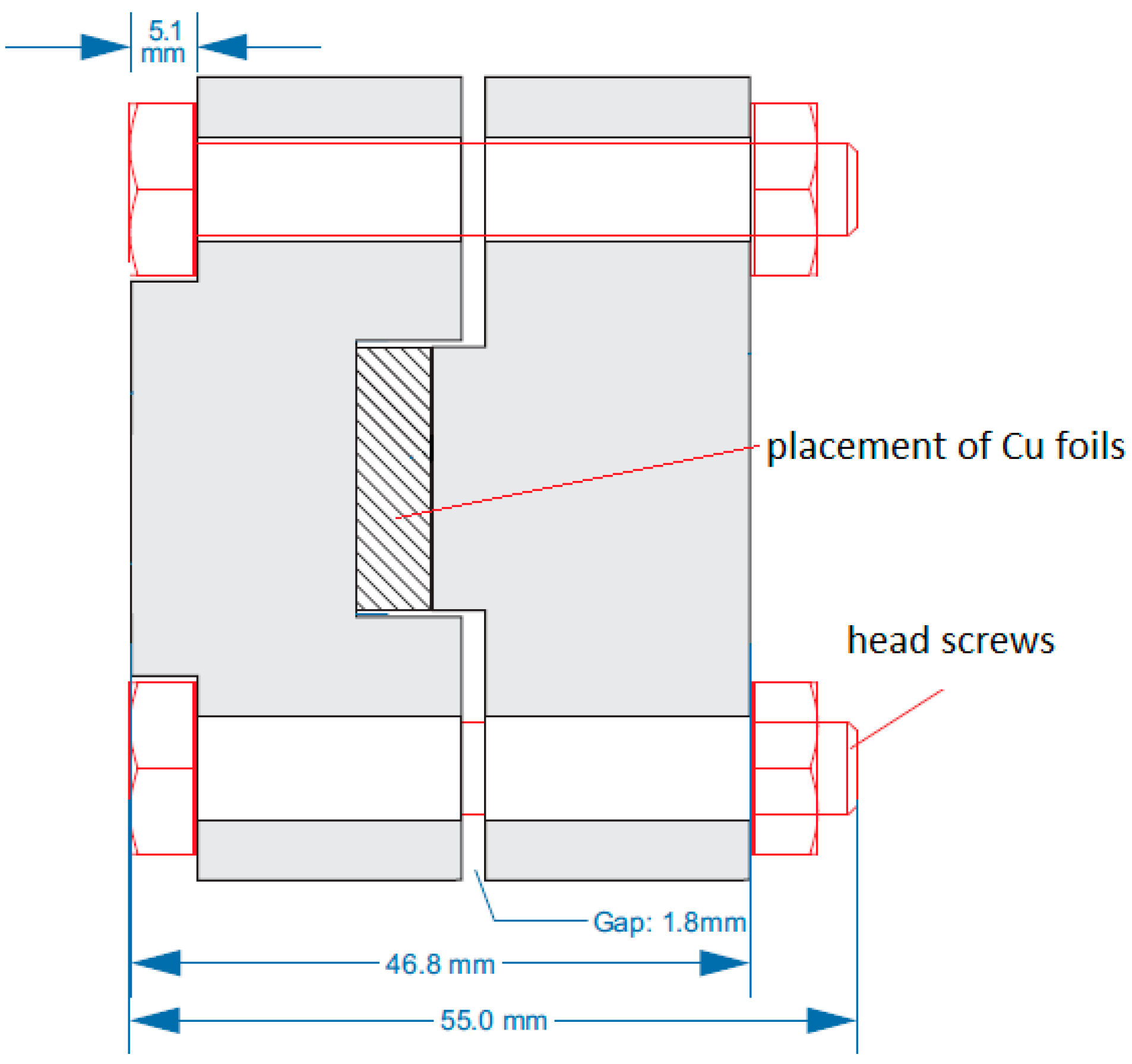

2.1. Cu-Cu Thermocompression Bonding

2.2. Diffusion Bonding Characterization

3. Results and Discussion

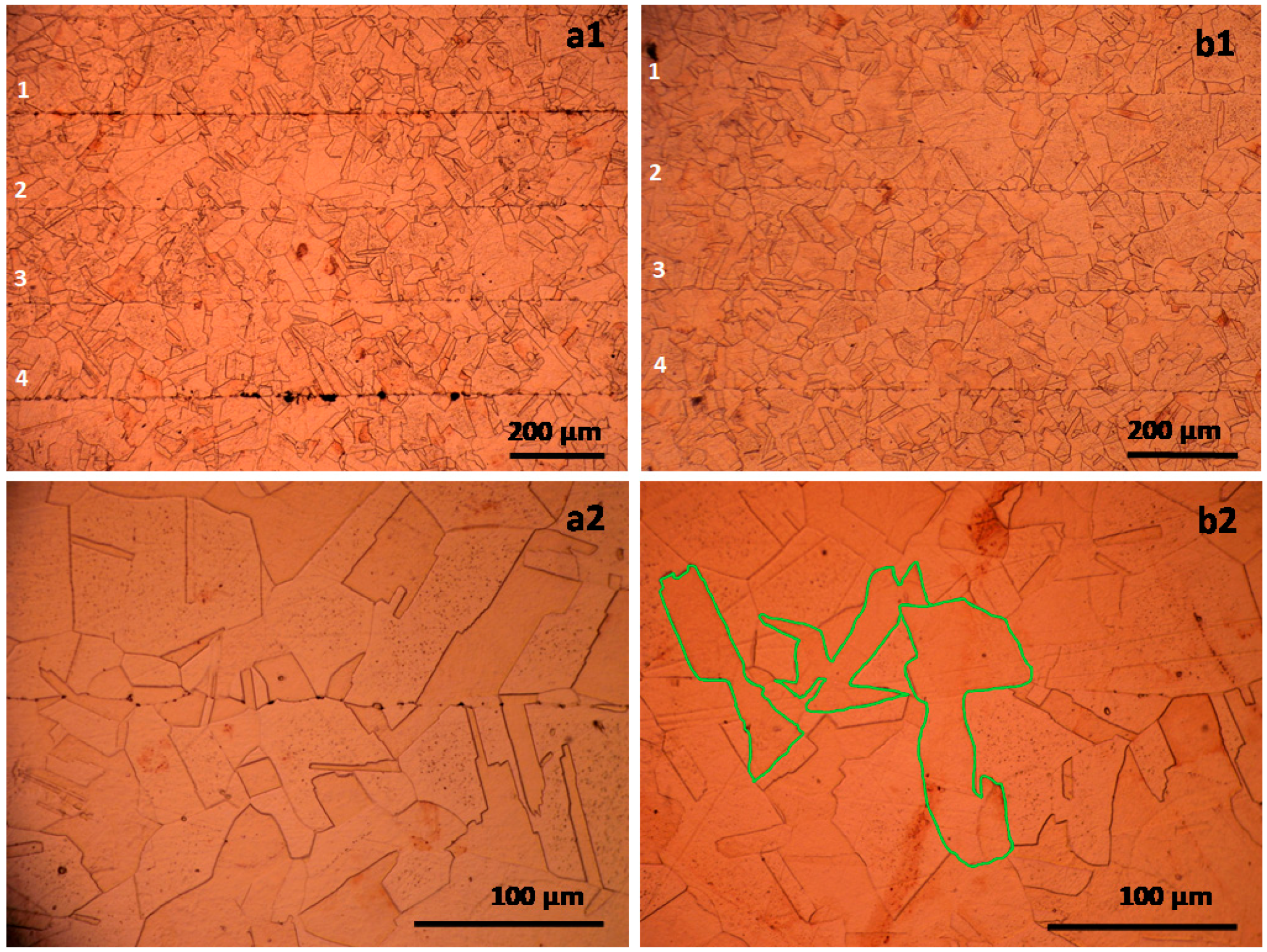

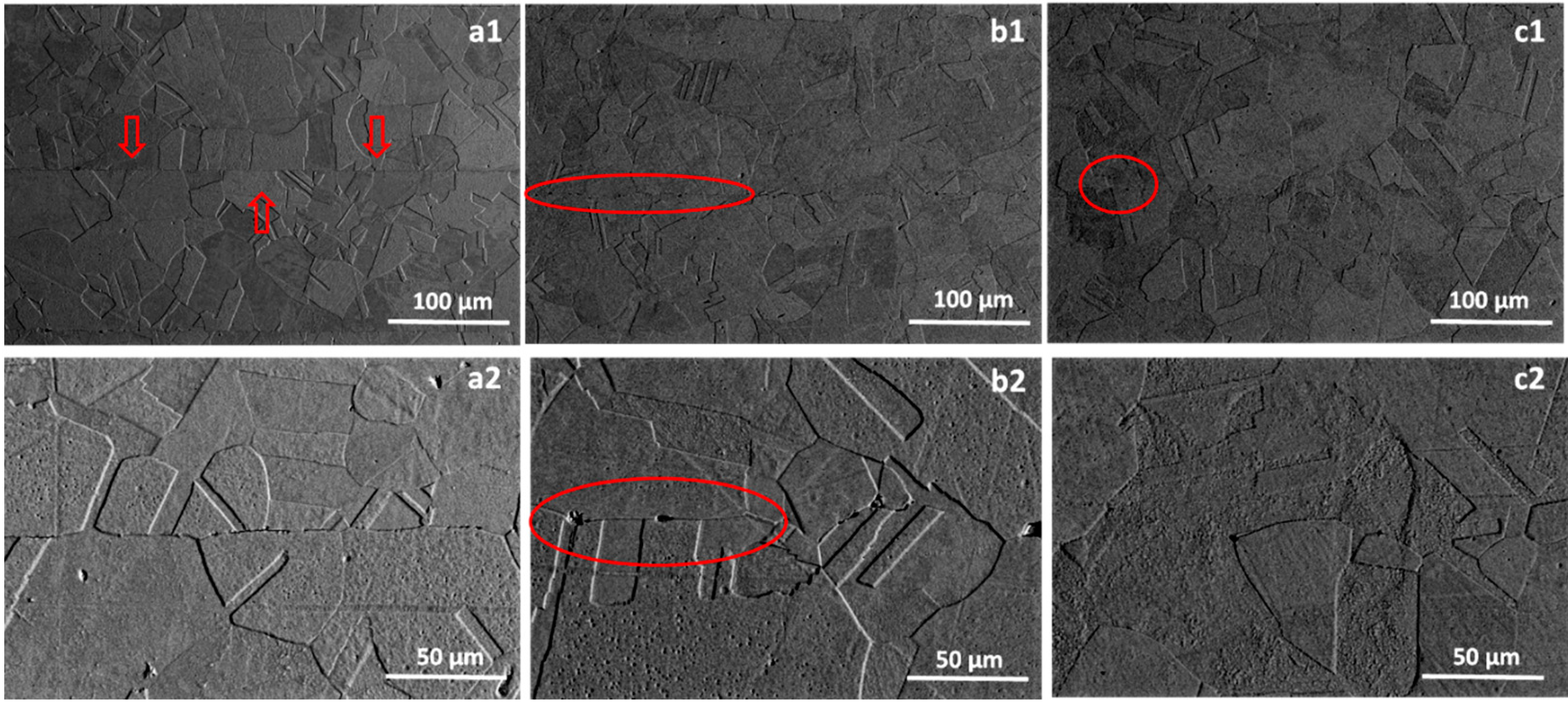

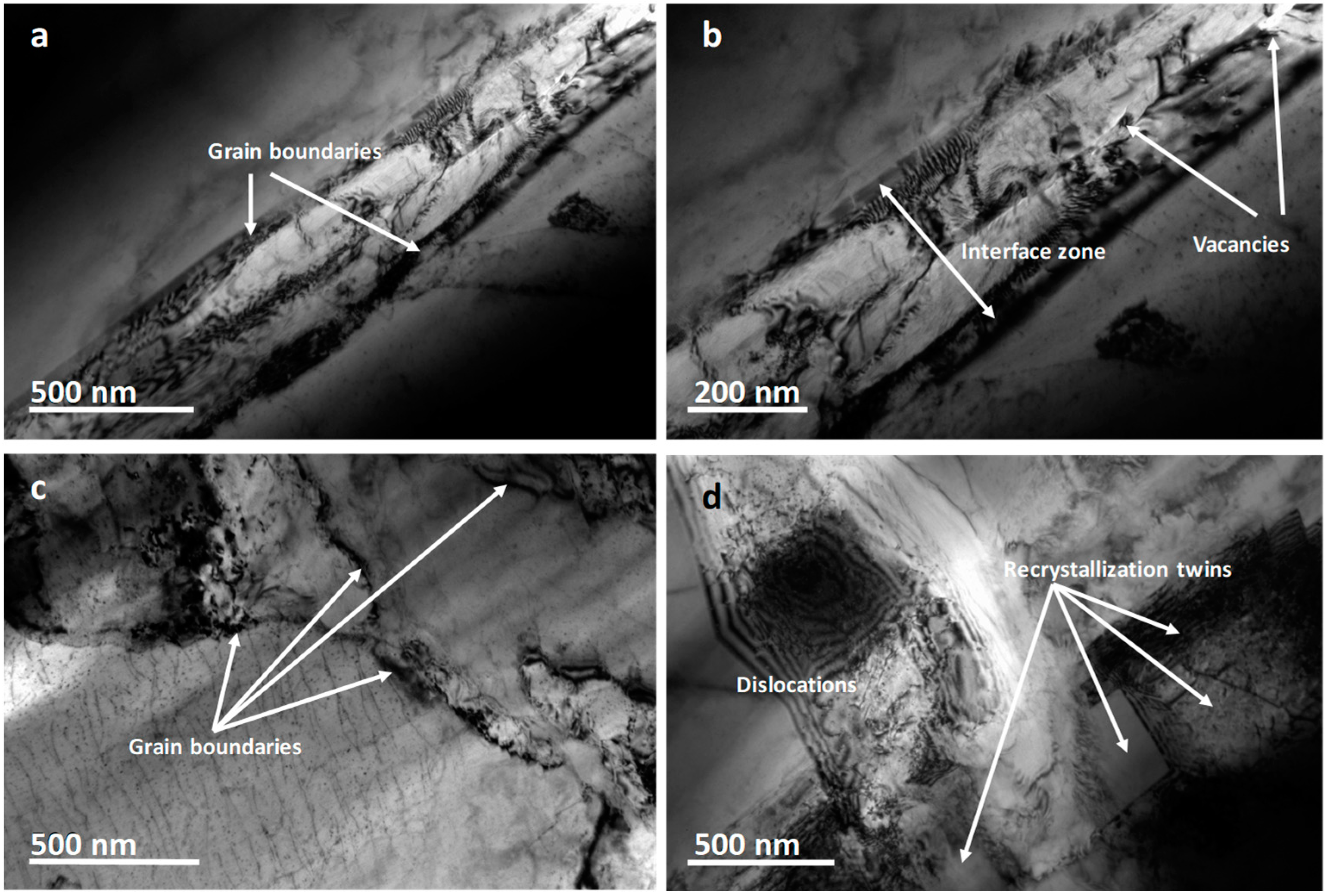

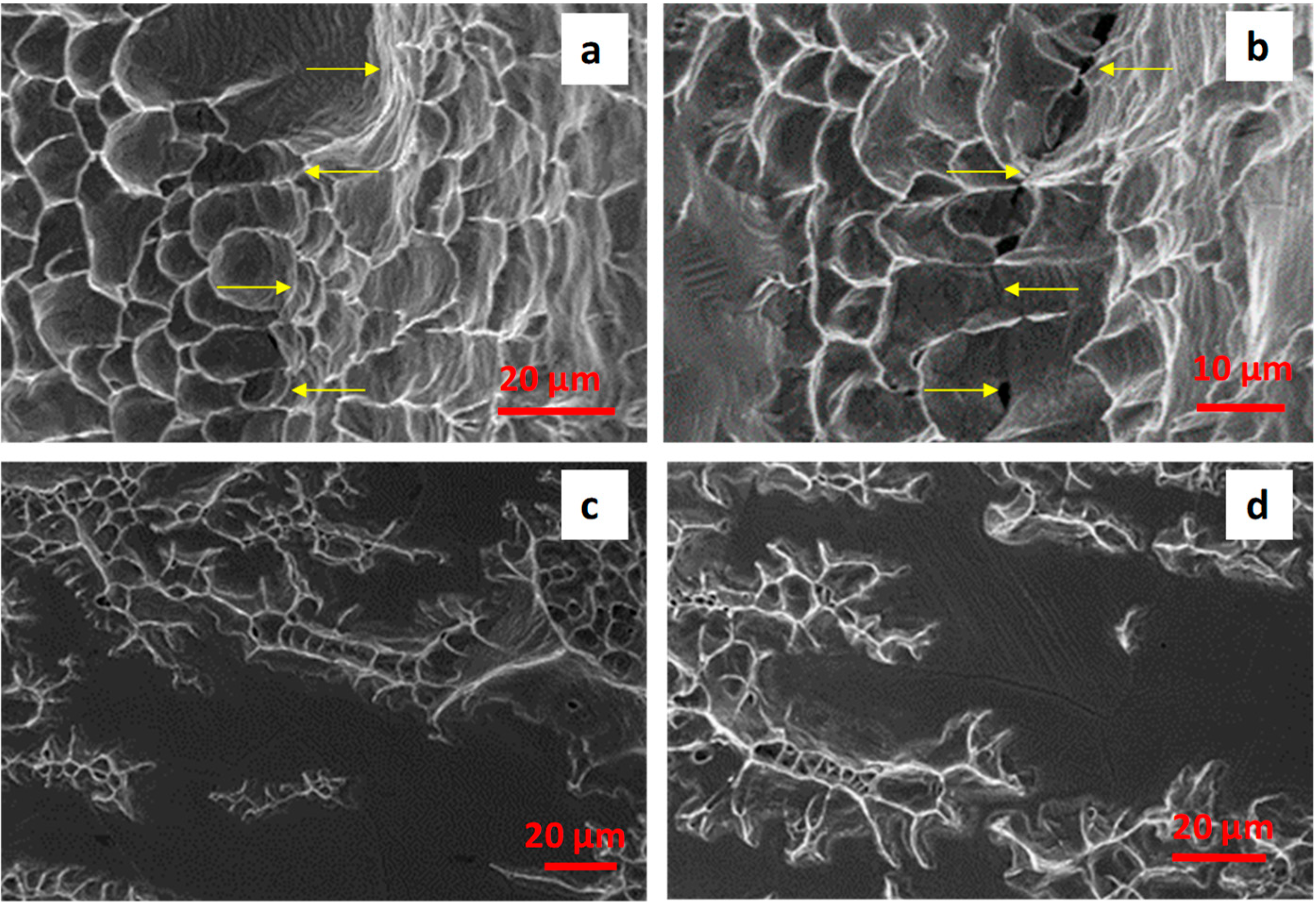

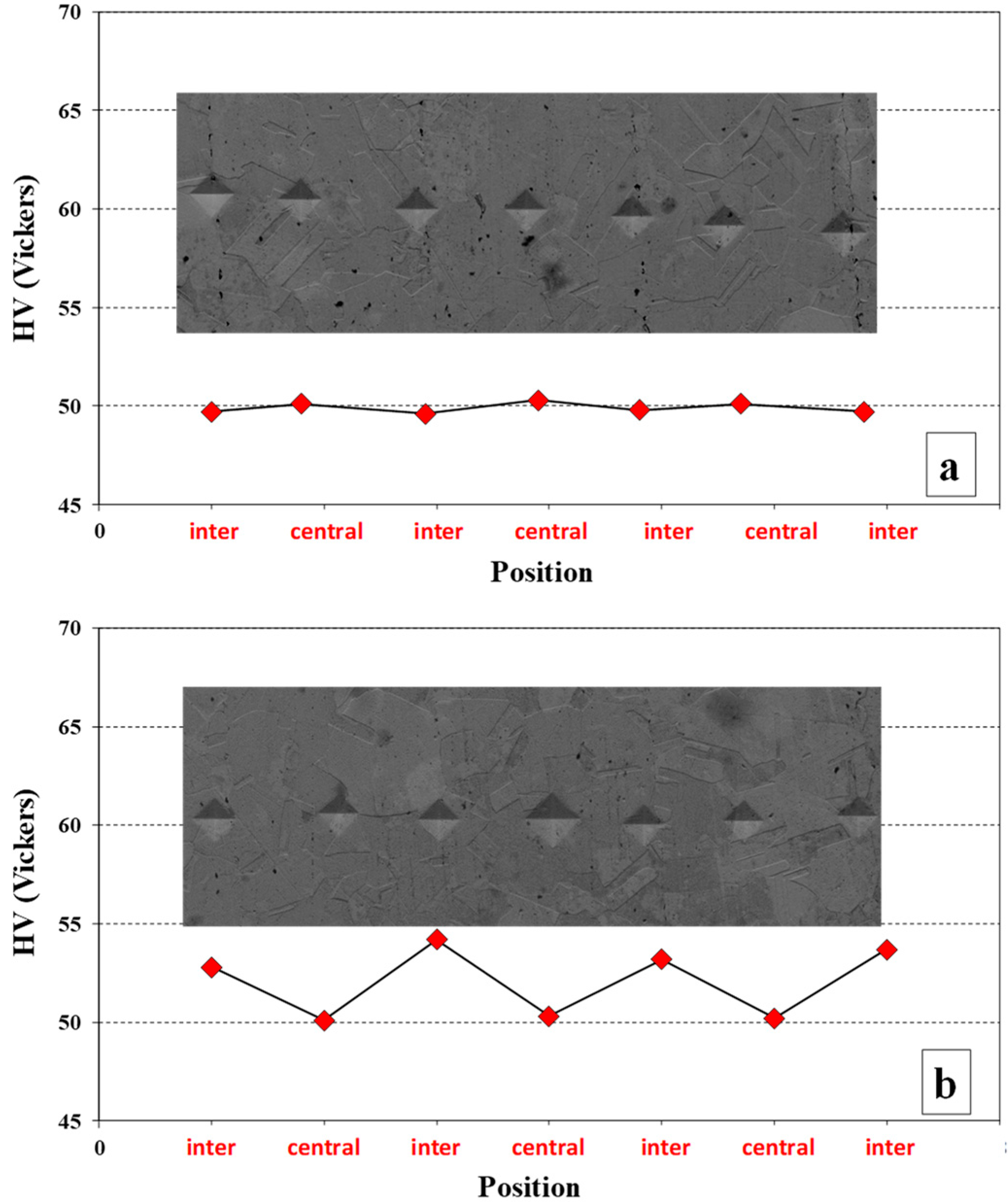

3.1. Microstructural Investigation

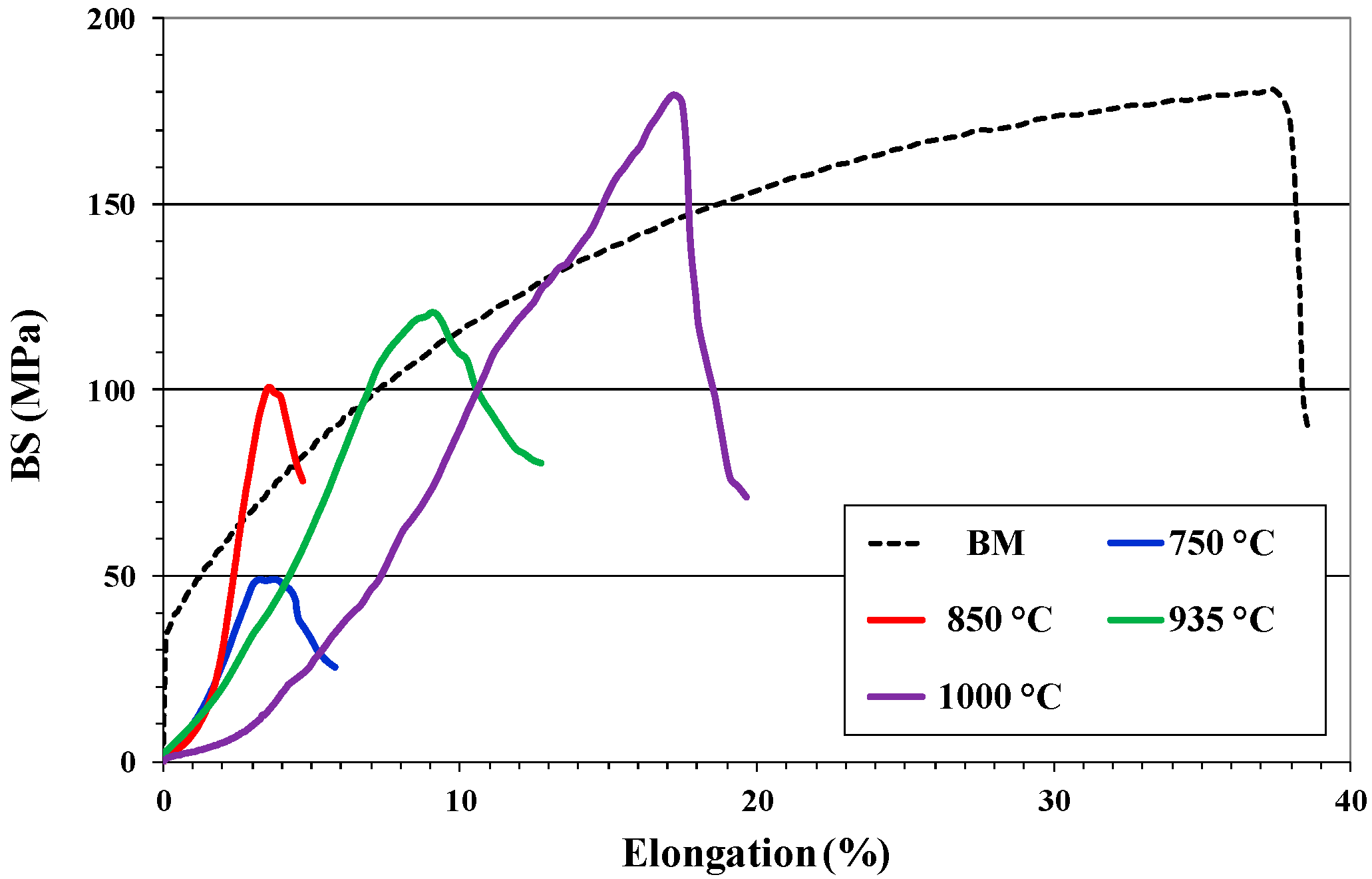

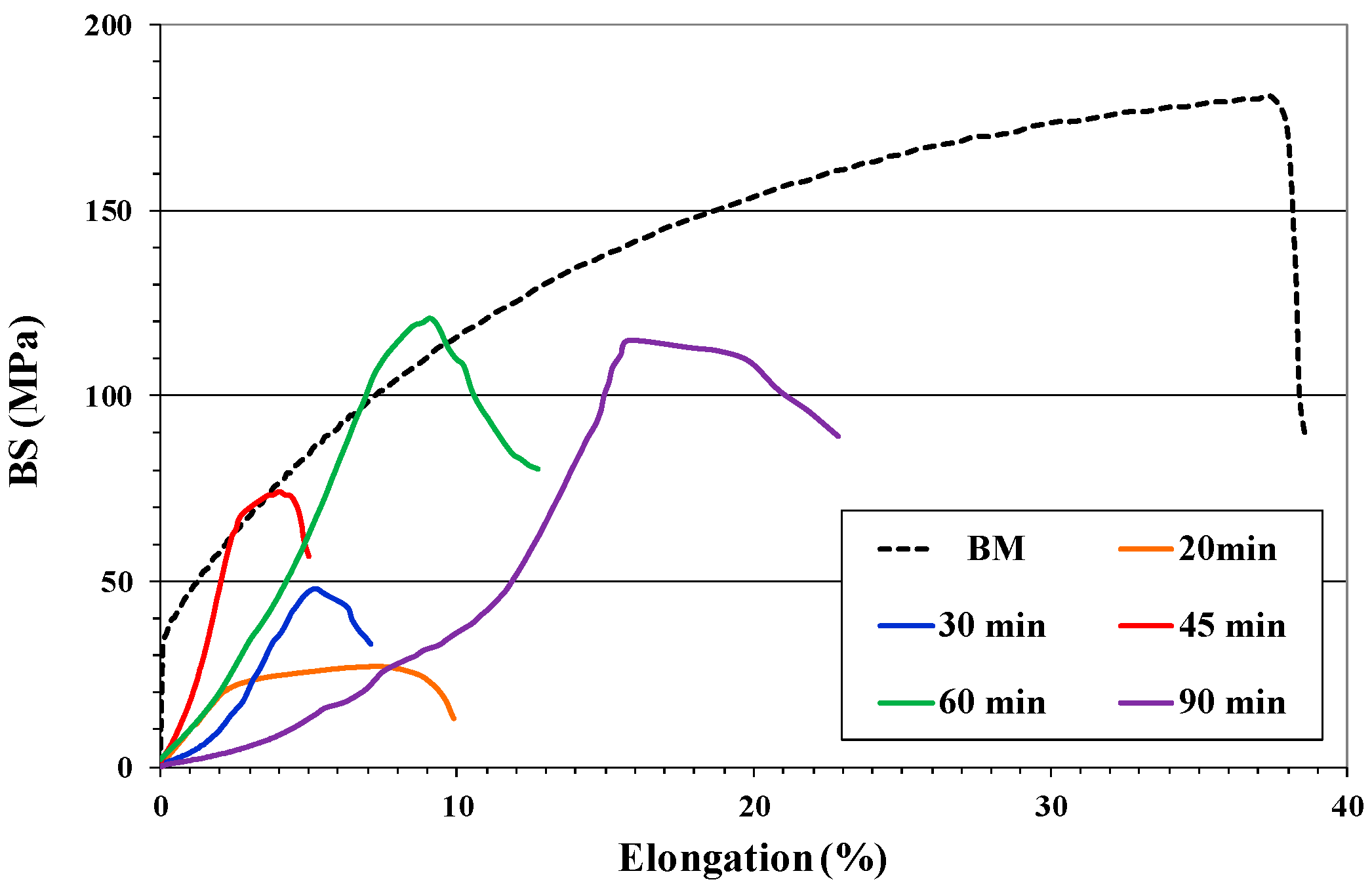

3.2. Mechanical Properties

4. Conclusions

- Cu-Cu bonds with advanced mechanical properties were successfully formatted through a thermocompression process under vacuum. Commercial copper foils with 200 μm thickness were used for the bonding tests, while a pressure of 10 MPa was applied.

- The increase of the bonding temperature, from 750 to 1000 °C, and the duration, from 20 to 90 min, significantly improved the bonding strength of the copper bonds. The highest ultimate BS (180 MPa) approached the respective value of the base material, and was achieved at 1000 °C for 90 min. The transverse microhardness of the bond reached 55 HV, slightly higher in comparison to the respective value of the base material.

- Electron backscatter diffraction (EBSD) investigation, of the optimum bonded specimen, reveals a satisfactory interdiffusion growth in regions with finer grains. Transmission electron microscopy revealed the formation of small equiaxed recrystallized twin crystals in the bonding zone with a size ranging from 200 to 400 nm.

- The above mechanical and microstructural data indicated that the developed copper-bonded structure could be successfully used in devices that are submitted to intense mechanical stress (i.e., bar-wound stators in vehicles).

Author Contributions

Funding

Conflicts of Interest

References

- Messler, R.W. Joining of Materials and Structures. From Pragmatic Process to Enabling Technology, 1st ed.; Elsevier: Burlington, MA, USA, 2004. [Google Scholar]

- Peng, L.; Lim, D.F.; Zhang, L.; Li, H.Y.; Tan, C.S. Effect of prebonding anneal on the microstructure evolution and Cu–Cu diffusion bonding quality for three-dimensional integration. J. Electron. Mater. 2012, 41, 2567–2572. [Google Scholar] [CrossRef]

- Tian, Y.; Wang, C.; Lum, I.; Mayer, M.; Jung, J.P.; Zhou, Y. Investigation of ultrasonic copper wire wedge bonding on Au/Ni plated Cu substrates at ambient temperature. J. Mater. Process. Technol. 2008, 208, 179–186. [Google Scholar] [CrossRef]

- Sahin, M. Joining of aluminium and copper materials with friction welding. Int. J. Adv. Manuf. Technol. 2010, 49, 527–534. [Google Scholar] [CrossRef]

- Ebberta, C.; Schmidt, H.C.; Rodmanc, D.; Nürnbergerc, F.; Hombergb, W.; Maierc, H.J.; Grundmeier, G. Joining with electrochemical support (ECUF): Cold pressure welding of copper. J. Mater. Process. Technol. 2014, 214, 2179–2187. [Google Scholar] [CrossRef]

- Chen, S.Y.; Wu, Z.W.; Liu, K.X.; Li, X.J.; Luo, N.; Lu, G.X. Atomic diffusion behavior in Cu-Al explosive welding process. J. Appl. Phys. 2013, 113, 044901. [Google Scholar] [CrossRef]

- Panigrahy, A.K.; Chen, K.N. Low temperature Cu–Cu bonding technology in three-dimensional integration: An extensive review. J. Electron. Packag. 2018, 140, 010801. [Google Scholar] [CrossRef]

- Liu, C.M.; Lin, H.W.; Chu, Y.C.; Chen, C.; Lyu, D.R.; Chen, K.N.; Tu, K.N. Low-temperature direct copper-to-copper bonding enabled by creep on highly (111)-oriented Cu surfaces. Scr. Mater. 2014, 12, 65–68. [Google Scholar] [CrossRef]

- Yang, W.; Shintani, H.; Akaike, M.; Suga, T. Low Temperature Cu-Cu Direct Bonding Using Formic Acid Vapor Pretreatment. In Proceedings of the IEEE 61st Electronic Components and Technology Conference, Lake Buena Vista, FL, USA, 31 May–3 June 2011. [Google Scholar]

- Chen, K.N.; Chang, S.M.; Shen, L.C.; Reif, R. Investigations of strength of copper-bonded wafers with several quantitative and qualitative tests. J. Electron. Mater. 2006, 35, 1082–1086. [Google Scholar] [CrossRef]

- Utsumi, J.; Ichiyanagi, Y. Cu-Cu Direct Bonding Achieved by Surface Method at Room Temperature. In Proceedings of the Irago Conference, Tahara, Japan, 24–25 October 2013. [Google Scholar]

- Tanaka, K.; Wang, W.S.; Baum, M.; Froemel, J.; Hirano, H.; Tanaka, S.; Wiemer, M.; Otto, T. Investigation of surface pre-treatment methods for wafer-level Cu-Cu thermo-compression bonding. Micromachines 2016, 7, 234. [Google Scholar] [CrossRef] [PubMed]

- Koteswararao, B.; Suresh, Y.; Ravi, D. Analysis of quality in solid state welding (copper-copper) by using NDT and DT by altering physical properties at constant time. Mater. Today Proc. 2017, 4, 7351–7356. [Google Scholar]

- Kumar, A.S.; Mohan, T.; Kumar, S.S.; Ravisankar, B. Destructive and Non-Destructive Evaluation of Cu/Cu Diffusion Bonding with Interlayer Aluminum. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012045. [Google Scholar] [CrossRef]

- Agapiou, J.S.; Perry, T.A. Resistance mash welding for joining of copper conductors for electric motors. J. Manuf. Processes 2013, 1, 549–557. [Google Scholar] [CrossRef]

- Serge, M. RFQ vacuum brazing at CERN. In Proceedings of the EPAC08 Conference, Genoa, Italy, 23–27 June 2008. [Google Scholar]

- Singh, R.; Pant, K.K.; Lal, S.; Yadav, D.P.; Garg, S.R.; Raghuvanshi, V.K.; Mundra, G. Vacuum brazing of accelerator components. IOP J. Phys. Conf. Ser. 2012, 390, 012025. [Google Scholar] [CrossRef]

- Zotti, L.A.; Teobaldi, G.; Palotás, K.; Ji, W.; Gao, H.J.; Hofer, W.A. Adsorption of benzene, fluorobenzene and meta-di-fluorobenzene on Cu(110): A computational study. J. Comput. Chem. 2008, 29, 1589–1595. [Google Scholar] [CrossRef] [PubMed]

- Copper. Available online: https://www.kupferinstitut.de/en/materials/material-properties/copper.html (accessed on 11 August 2019).

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samouhos, M.; Peppas, A.; Angelopoulos, P.; Taxiarchou, M.; Tsakiridis, P. Optimization of Copper Thermocompression Diffusion Bonding under Vacuum: Microstructural and Mechanical Characteristics. Metals 2019, 9, 1044. https://doi.org/10.3390/met9101044

Samouhos M, Peppas A, Angelopoulos P, Taxiarchou M, Tsakiridis P. Optimization of Copper Thermocompression Diffusion Bonding under Vacuum: Microstructural and Mechanical Characteristics. Metals. 2019; 9(10):1044. https://doi.org/10.3390/met9101044

Chicago/Turabian StyleSamouhos, Michail, Antonis Peppas, Panagiotis Angelopoulos, Maria Taxiarchou, and Petros Tsakiridis. 2019. "Optimization of Copper Thermocompression Diffusion Bonding under Vacuum: Microstructural and Mechanical Characteristics" Metals 9, no. 10: 1044. https://doi.org/10.3390/met9101044

APA StyleSamouhos, M., Peppas, A., Angelopoulos, P., Taxiarchou, M., & Tsakiridis, P. (2019). Optimization of Copper Thermocompression Diffusion Bonding under Vacuum: Microstructural and Mechanical Characteristics. Metals, 9(10), 1044. https://doi.org/10.3390/met9101044