1. Introduction

In addition to blockages caused by by-products resulting from side reactions, corrosion is one of the main reasons for the failure of micro process devices due to the low material thickness. Furthermore, micro process devices are often manufactured from a large number of thin, microstructured sheets, which are mainly joined by diffusion bonding. During processing, they are exposed to high temperatures and long dwell times, which is often associated with a decrease of material strength and formation of precipitations at grain boundaries.

Sulfuric acid is widely used in different concentrations in the chemical industry. Depending on the source and ambient condition during manufacturing, it may contain impurities and a water content that varies within certain limits. During chemical conversion, the strong heat of reactions may occur. This can be controlled quite well by micro process devices, which have large surface to volume ratios. For this reason, for a number of years now, various investigations at KIT-IMVT were performed to identify a robust solution for micro-process engineering apparatus in contact with sulfuric acid.

In this paper, two highly molybdenum-alloyed materials, namely Hastelloy B3 and Hastelloy BC-1, were evaluated regarding corrosion resistance in hot 70% sulfuric acid and eligibility to diffusion bonding.

Molybdenum is known to decrease the surface corrosion in non-oxidizing acids such as sulfuric acid and to improve the pitting corrosion resistance [

1,

2,

3,

4,

5]. In an earlier AiF-research project (German Federation of Industrial Research Associations) four different materials were characterized with regard to their corrosion behavior (

Table 1) [

6]. However, the rate of corrosion or material changes were that significant, that the life cycles do not seem to be sufficient enough for micro process devices. In addition, the results were fluctuating and not consistent to different concentrations of sulfuric acid, so that a useful life prediction for micro process devices is not possible.

Even for Alloy 2120 MoN (2.4700) produced by VDM Metals International GmbH, Werdohl, Germany containing comparable high contents of molybdenum, no good results were obtained, despite it showed the lowest corrosion rate in 70% sulfuric acid at 100 °C, especially in the heat-treated condition.

Also coating concepts, such as tantalization, were investigated to improve the corrosion resistance of micro process devices [

7]. However, it has to be stated that any coating solution is susceptible to mechanical damaging in harsh industrial environments.

2. Materials and Design of Experiments

Hastelloy B3 and BC-1 are highly molybdenum-alloyed materials. In

Table 2, physical properties and the composition of these alloys are given, together with values of Alloy 2120 MoN for comparison reasons.

It needs to be mentioned, that all materials reveal a cubic face-centered lattice (fcc). However, due to the high content of molybdenum and according to Grüneisen’s Rule, in contrast to ordinary austenitic stainless steels, the coefficient of thermal expansion is more comparable to that of ferritic steels. While Hastelloy BC-1 has a clearly higher chromium content than Hastelloy B3, B3 contains significantly more molybdenum.

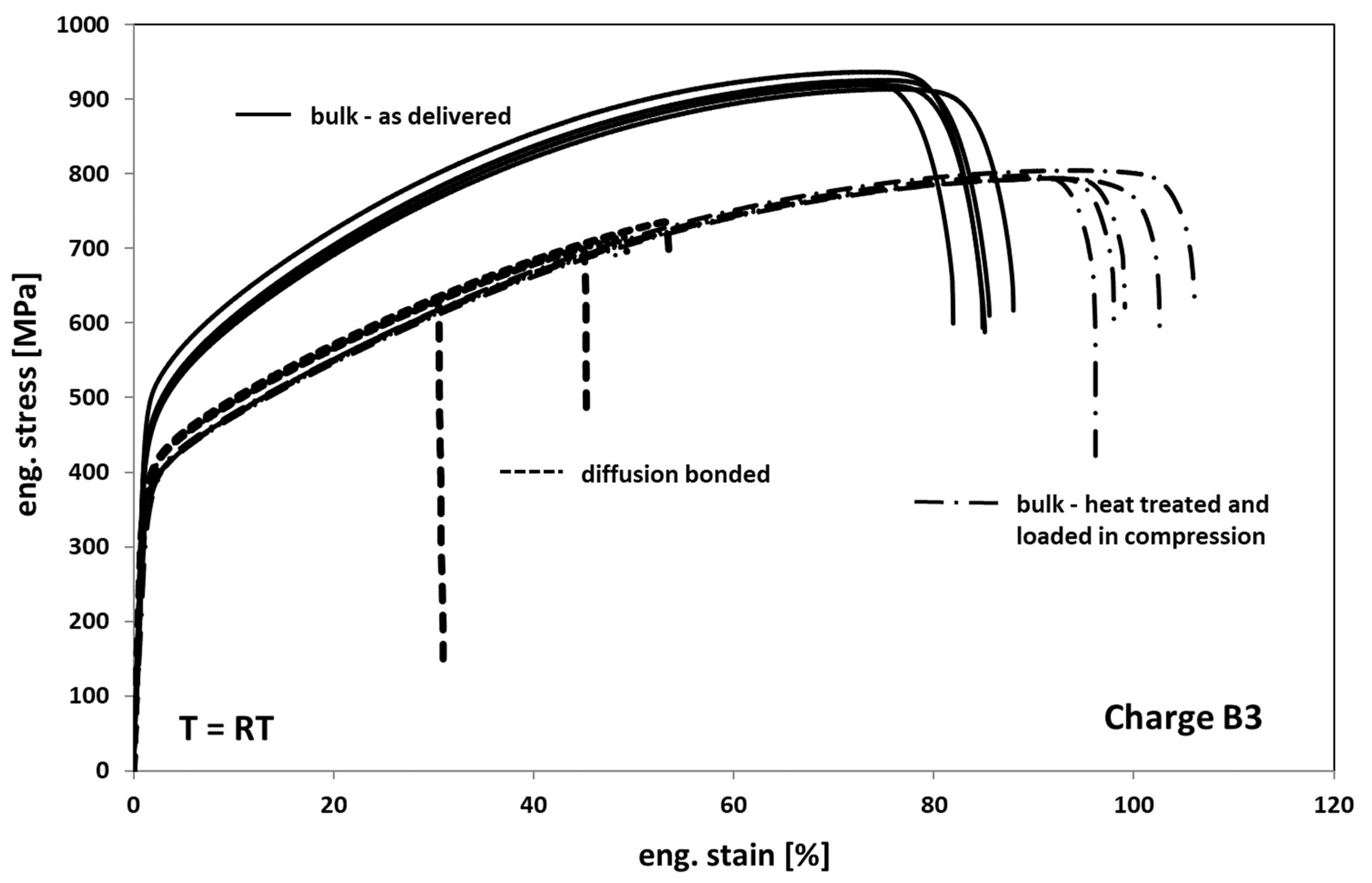

For Hastelloy B3, the yield strength at room temperature in solution annealed condition is ranging from 400 to 421 MPa, depending on form of delivery. The tensile strength is specified with 862–883 MPa, while the elongation at fracture varies between 53% and 58%. For solution annealing, a temperature of 1066 °C is recommended.

For Hastelloy BC-1, the yield strength at room temperature in solution annealed condition ranges from 362 to 405 MPa, depending on the thickness of semi-finished products. The tensile strength varies between 809 and 841 MPa, while the elongation at fracture varies between 61.6 and 70.5%. For solution annealing, a much higher temperature than for Hastelloy B3, namely 1149 °C, is recommended.

For the corrosion experiments, coupons of Hastelloy B3 and BC-1, containing a TIG weld and made of 3 mm thick sheet metal, were provided by HAYNES. Using a disk cutter from ATM Qness GmbH, Mammelzen, Germany, type Brillant 250, pieces with a size of approximately 20 × 80 mm² and 40 g in weight were cut. One set of specimens was investigated in condition as delivered. A second set of specimens was placed inside a diffusion bonding furnace during a run to simulate a heat treatment. For this purpose, a temperature of T = 1100 °C was applied for t = 4 h. Subsequently, the samples were cooled down in diffusion bonding furnace 2.

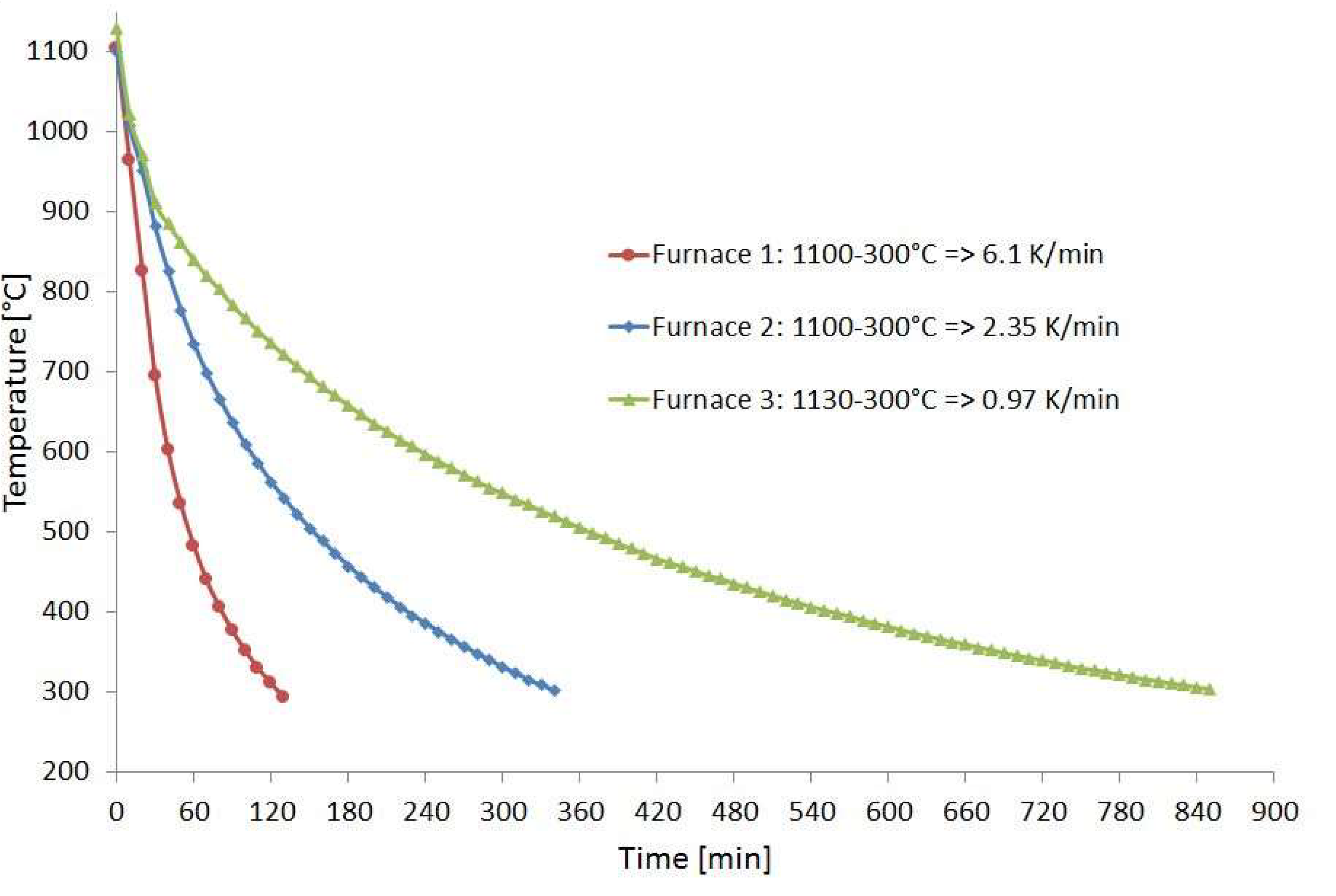

Figure 1 shows the cooling behavior of three diffusion bonding furnaces of different sizes with 20 kN, 200 kN, and 2 MN compressive load, respectively, available at IMVT. It can be seen that the cooling rate of furnace 2 at approx. 600 °C falls below 5 K/min, which is half of the heating rate. This facilitates sensitization, especially with nickel-based alloys, which has an impact on corrosion behavior in aggressive media [

11,

12,

13].

The main point of criticism of the authors with regard to the investigation of intergranular corrosion according to ASTM G-28A-02 (2015) for micro process apparatus is the short alloy-specific test duration and the determination of a specific corrosion medium and temperature [

14]. If we further realize that the criterion for the derivation of the sensitization diagrams is a corrosion attack depth of 50 µm under the above-mentioned conditions, the test does not provide any helpful information on the suitability of a material in micro-process engineering where dimensions below 1 mm wall thickness need to be realized. Significantly longer test periods are required to obtain reliable results. For this reason, a test duration of 1000 h was specified.

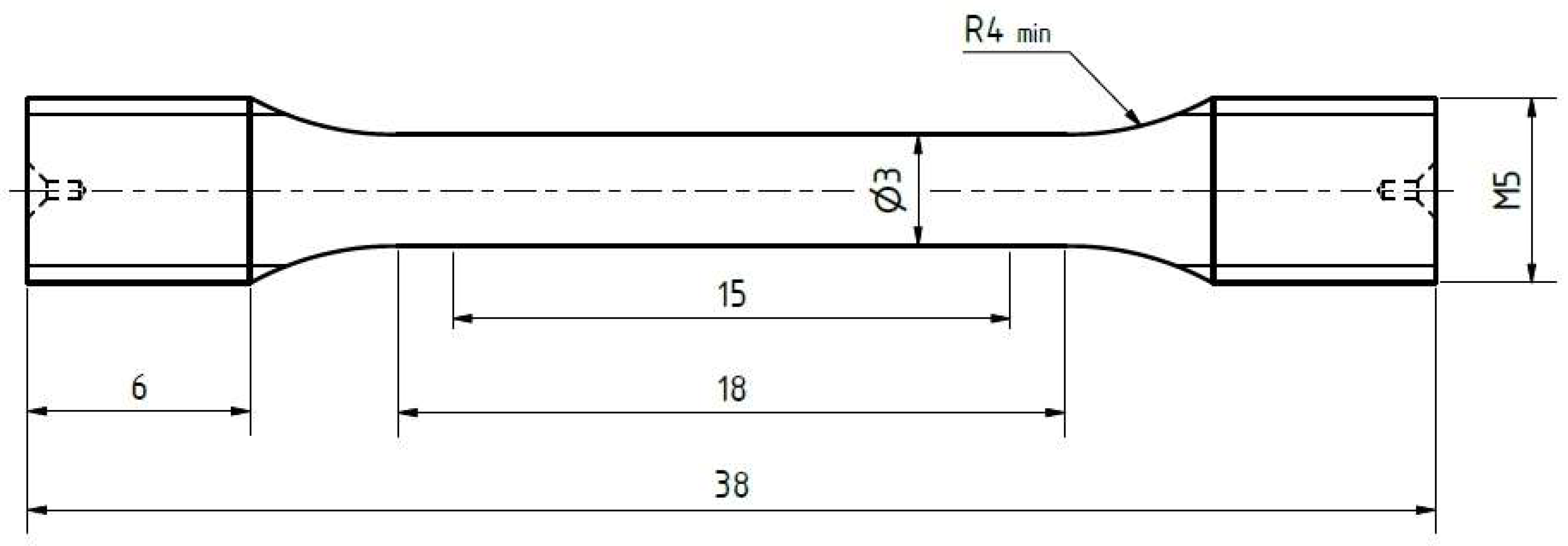

For initial diffusion bonding experiments, sheet material of Hastelloy BC-1 and Hastelloy B3 were supplied by HAYNES, 1.0 mm and 1.6 mm in thickness, respectively. From these sheets, 10 pieces—each 20 × 20 mm² in size—were cut using a TruLaser Cell 3010, combined with a 3 kW TruDisk 3001 (TRUMPF GmbH + Co. KG, Ditzingen, Germany).

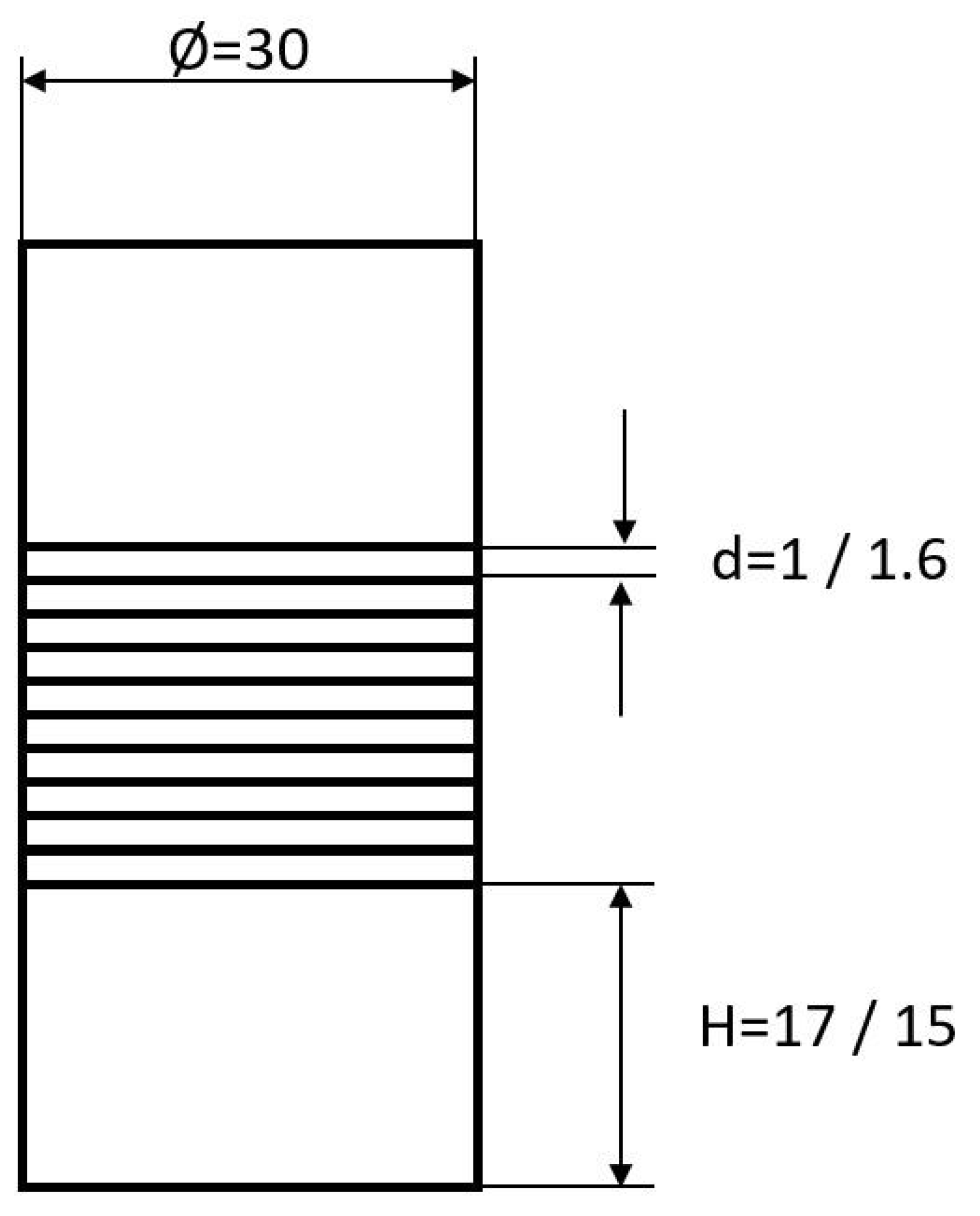

Round stock of different diameters from both alloys was used to produce the initial material with a diameter of 30 mm by wire erosion. Additional, for both materials, ten disks, 30 mm in diameter, were cut by laser from sheet material. To ensure a reasonable initial height of the diffusion bonding specimens related to the preparation of tensile specimens, two pieces of round stock with a height of 15 mm and 17 mm for Hastelloy B3 and Hastelloy BC-1, respectively, were prepared. In between, 10 layers of sheet material were stacked, giving an absolute height of 46 mm and 44 mm, respectively (

Figure 2).

4. Conclusions and Outlook

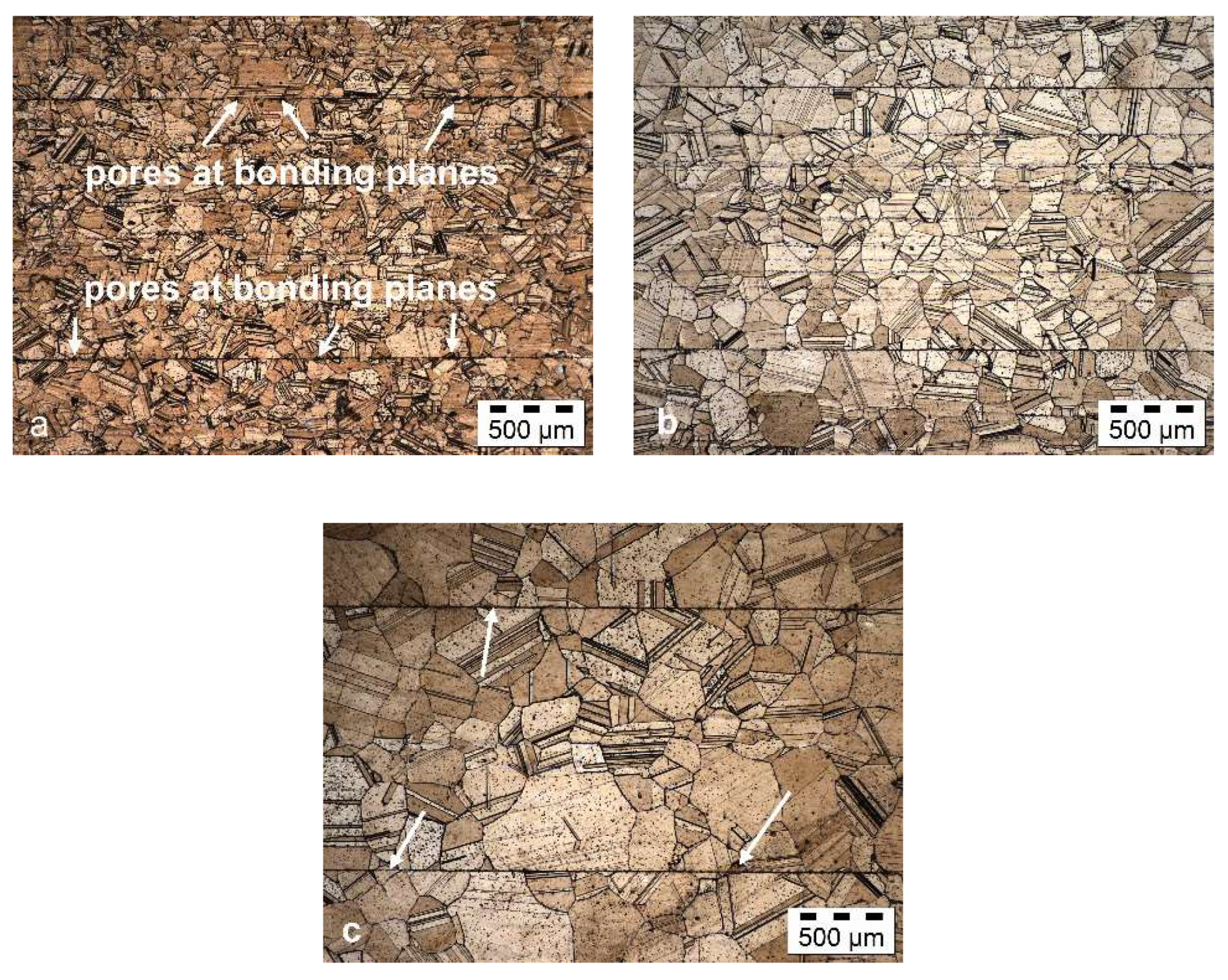

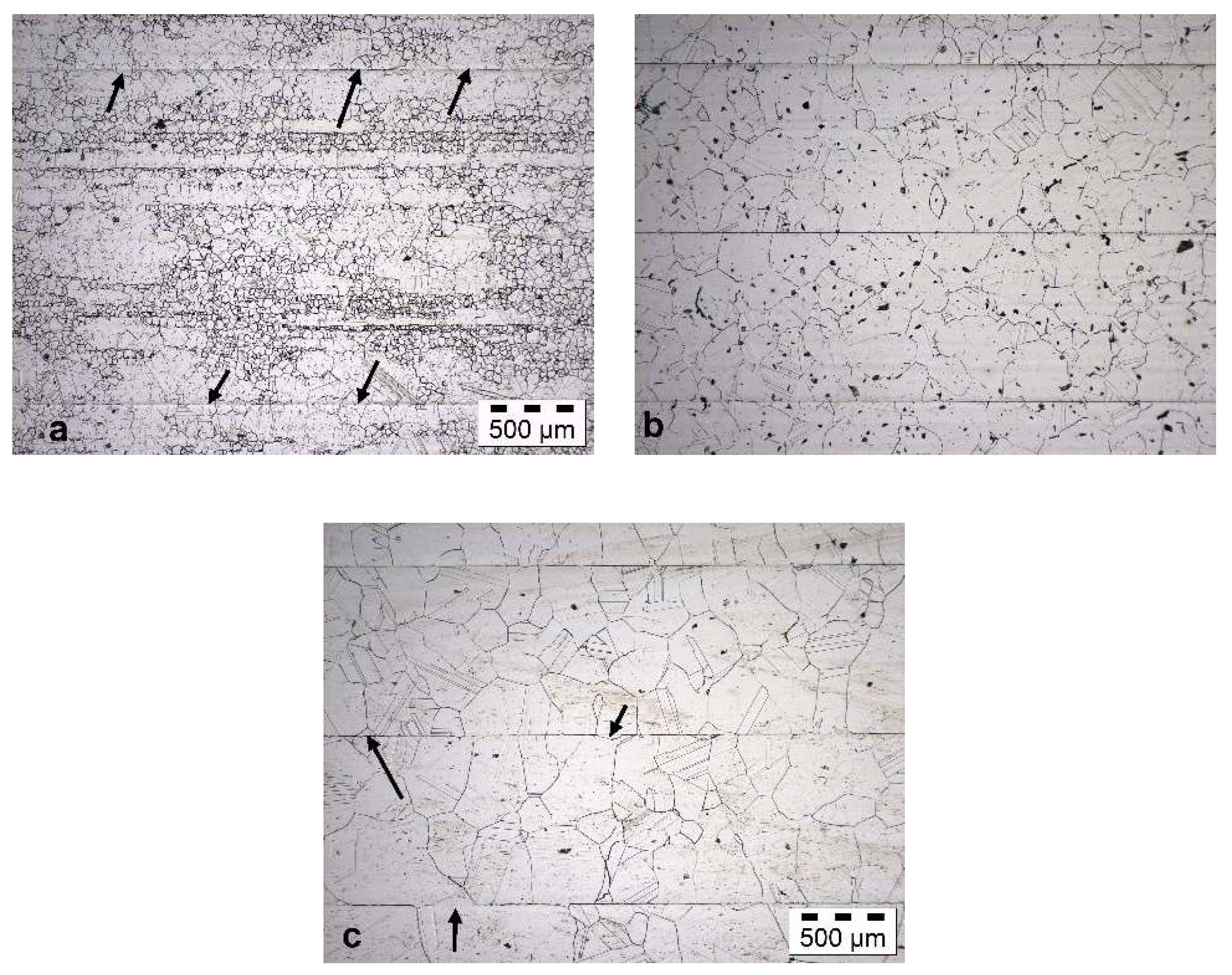

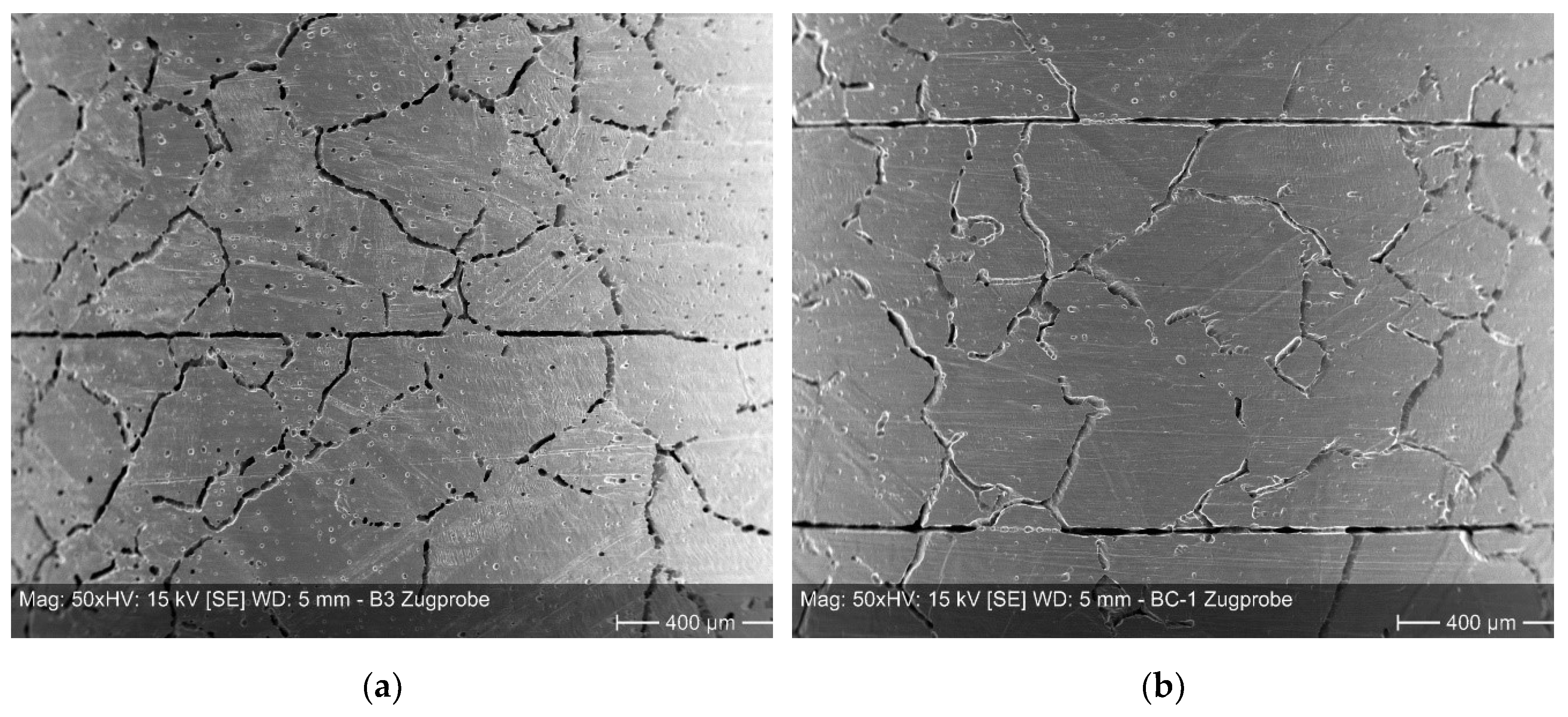

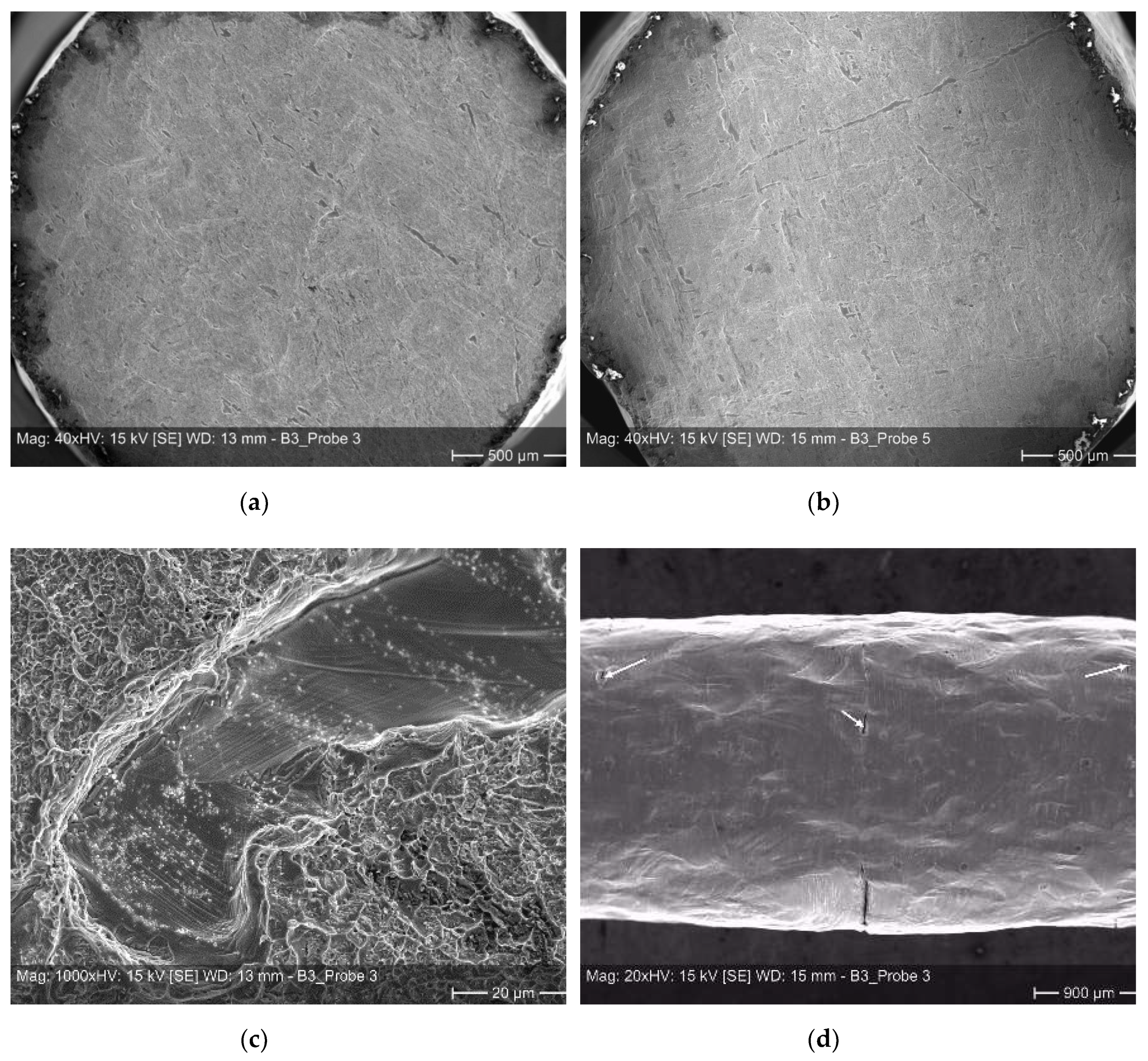

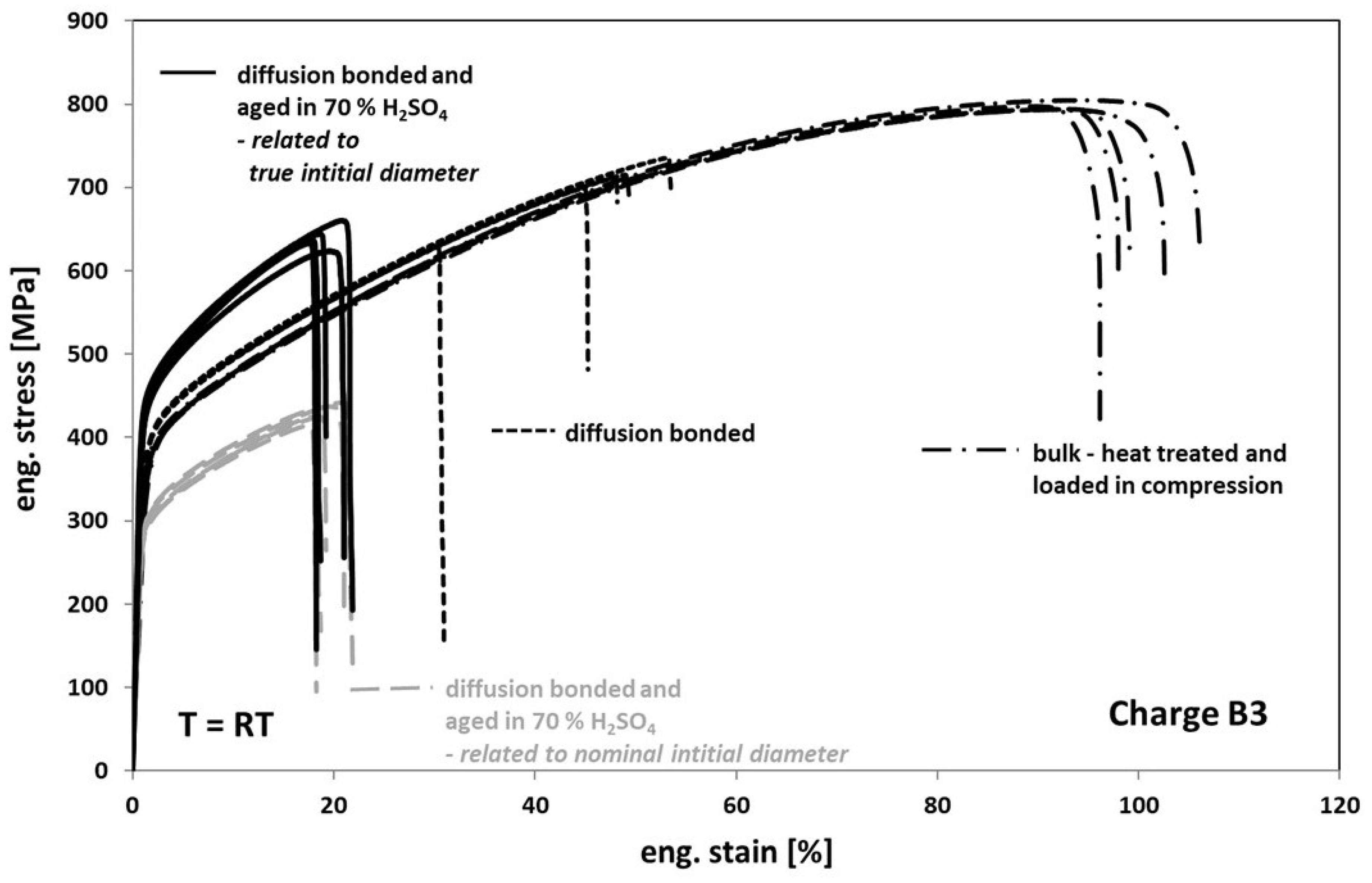

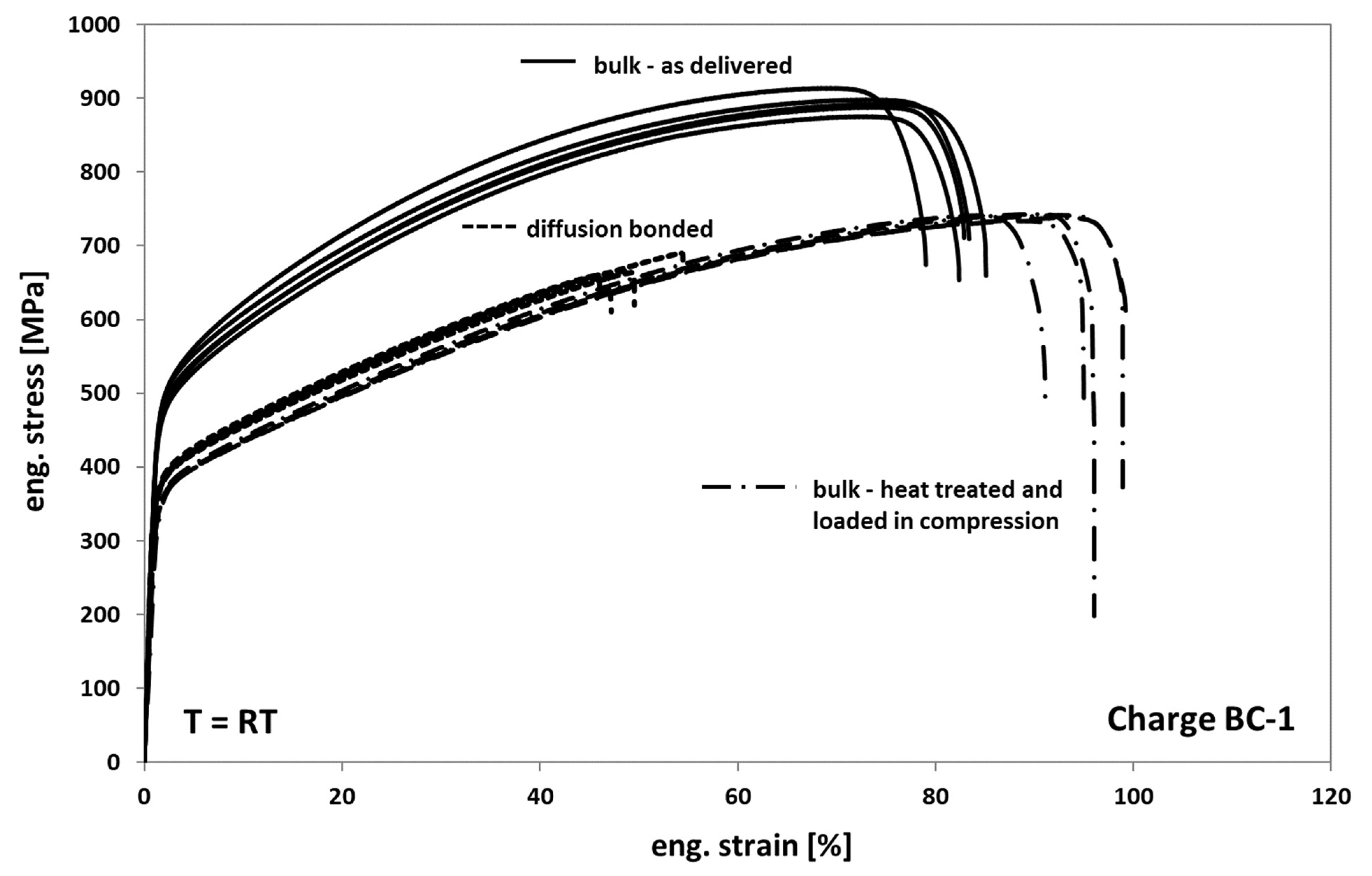

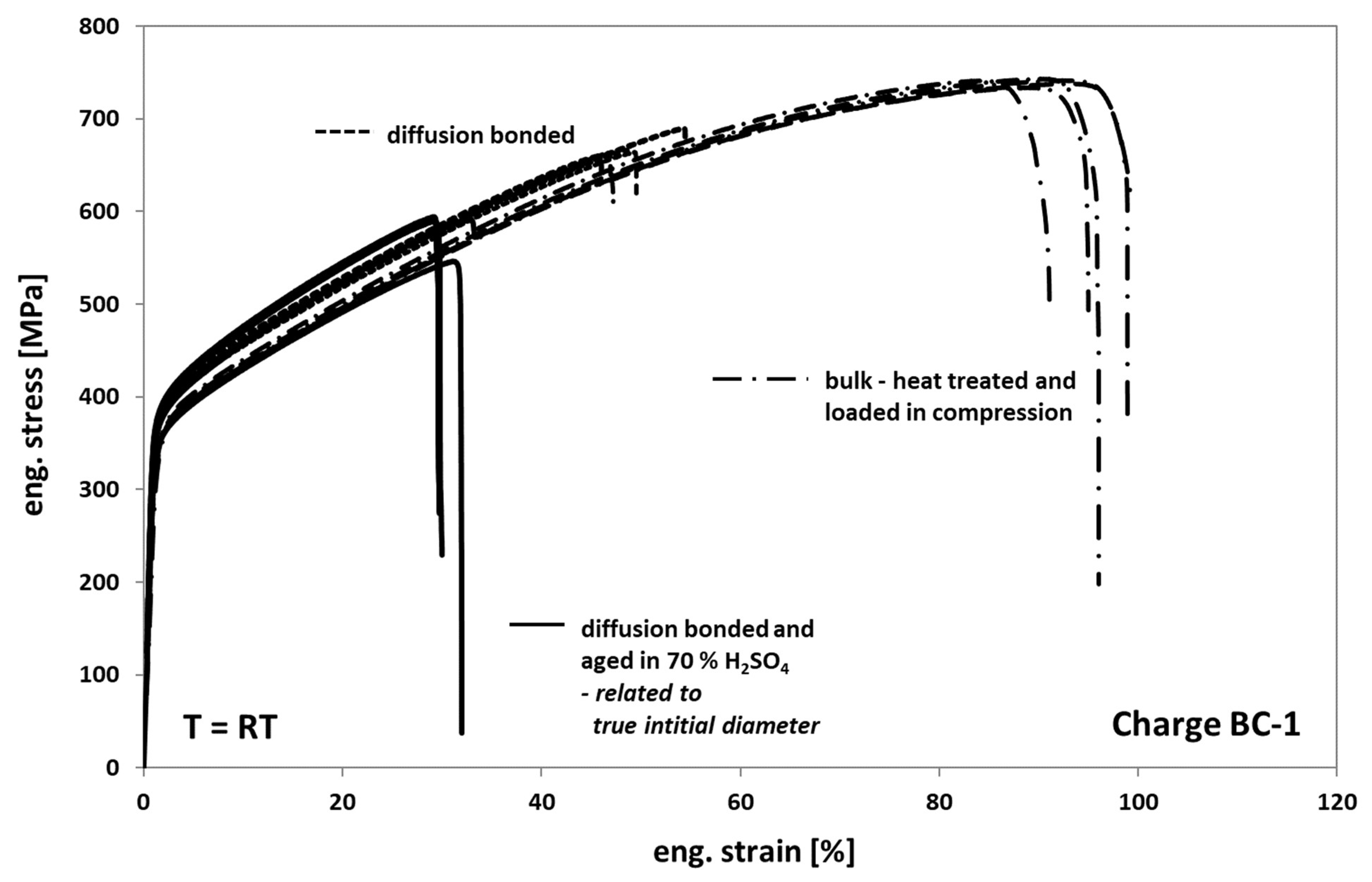

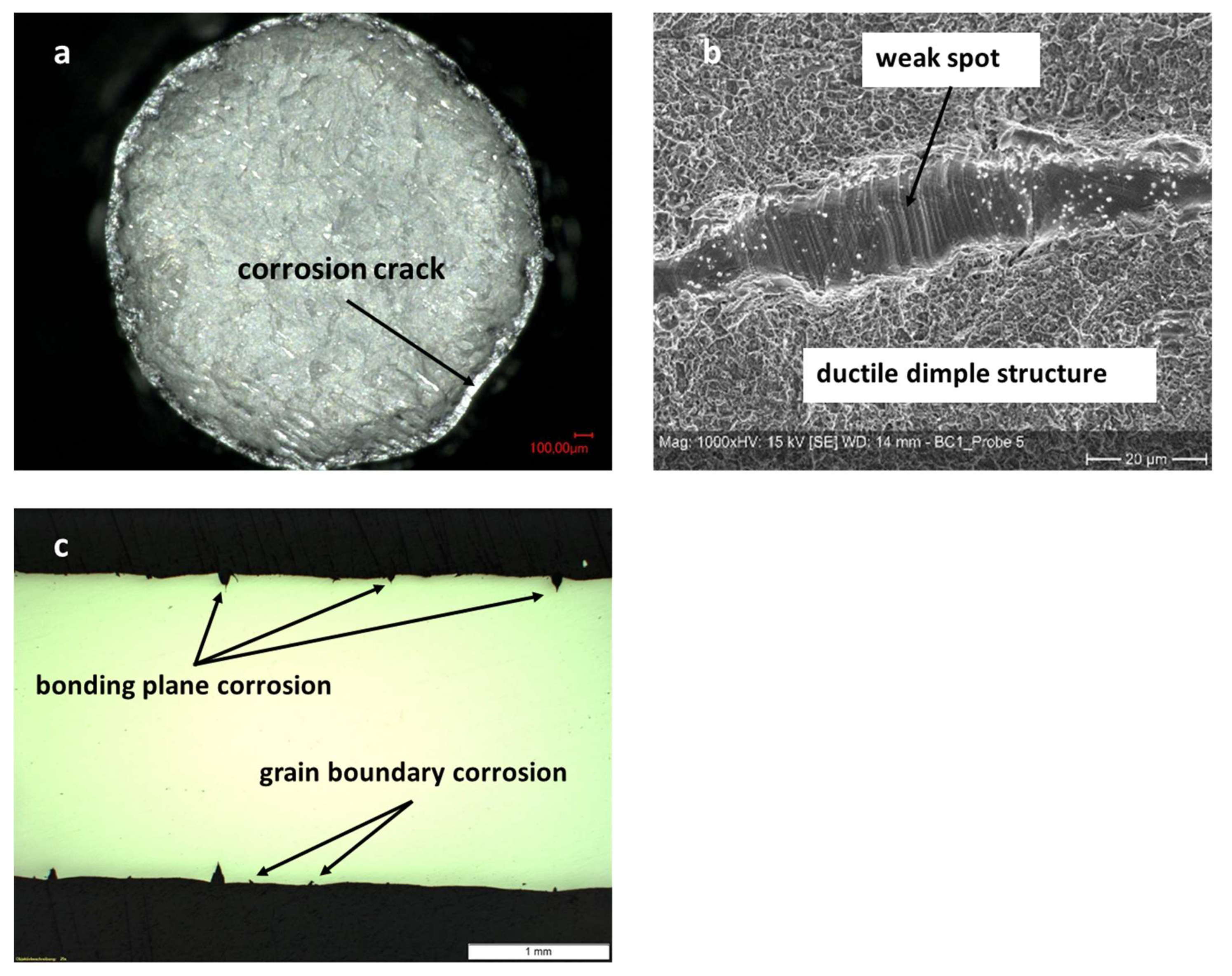

Within this study, both the effect of diffusion bonding process on the mechanical properties, and the corrosion resistance against hot 70% sulfuric acid of Hastelloy B3 and Hastelloy BC-1 was found to be better than previously investigated alloys. Although the grain growth crossing bonding planes during diffusion bonding is not fully satisfactory, both materials achieve sufficiently high elongation at fracture values for engineering applications.

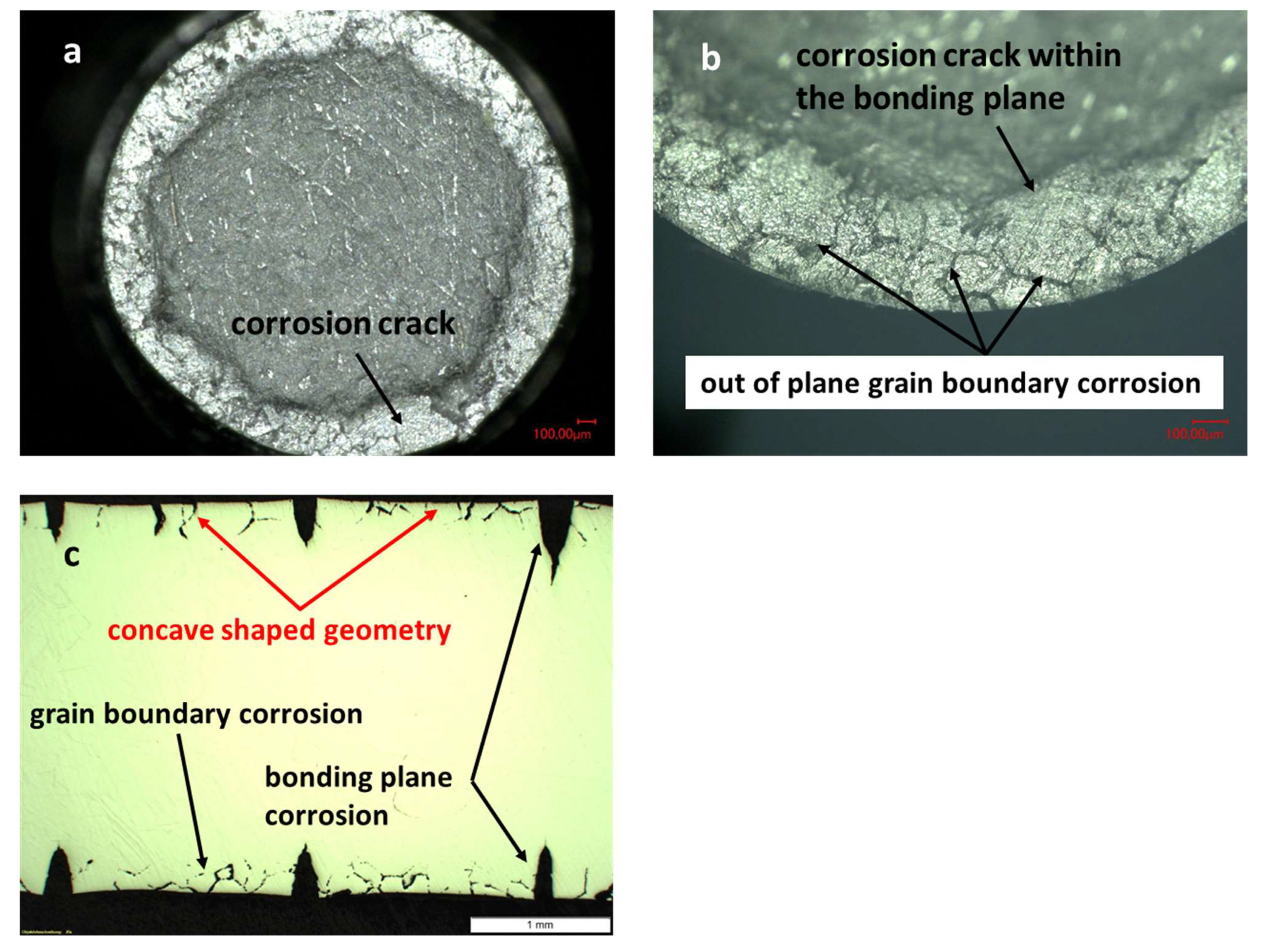

The deformation of about 2% achieved at diffusion bonding of samples for tensile tests is not yet sufficient for eliminating all surface defects. Defects promote crack formation and propagation. The deformation until fracture decreases. Recently, the elongation at fracture values of diffusion bonded samples for both materials are significantly reduced. Depending on the design of devices, bonding parameters—mainly bearing pressure and bonding temperature—should be optimized to obtain a slightly increased deformation.

Diffusion bonded tensile test samples of both alloys aged in 70% sulfuric acid at 100 °C for 1000 h, show only a low corrosion attack compared to other materials investigated so far, especially Hastelloy C-22. For Hastelloy B3 (2.4600), however, the corrosion attack is more pronounced than for Hastelloy BC-1 (2.4708) despite its higher molybdenum content. This is in accordance with the results from the beaker tests (

Table 4). Therefore, only Hastelloy BC-1 represents an interesting solution for use in micro process devices for hot diluted sulfuric acid.

Obviously, the higher chromium content of Hastelloy BC-1 leads to higher corrosion resistance. It is not understood why in earlier investigations the material Alloy 2120 MoN (2.4700), which has a very similar composition to Hastelloy BC-1, did not perform comparably well, especially after aging in 70% sulfuric acid in heat-treated condition (

Table 1).

In comparison to solely diffusion bonded condition, the elongation at fracture of samples aged in 70% sulfuric acid at 100 °C for six weeks decreased to 20% and 30% for Hastelloy B3 and Hastelloy BC-1, respectively. These values are still sufficient for use of these materials in micro process apparatuses. However, it shows that the impact of corrosion in micro process technology may not be neglected for long-term use. Standardized corrosion tests such as ASTM G28-A with special electrolytes and short test duration do not provide sufficient information concerning corrosion for micro process devices.

In contrast to the findings in this study, corrosion data from the data sheets of Hastelloy B3 and Hastelloy BC-1 for sulfuric acid of different concentrations suggested that Hastelloy B3 should be more resistant to corrosion. This is surprising so far as the joining temperature of 1200 °C for both materials is above the recommended solution annealing temperatures. Sensitization therefore was only expected during the cooling phase in high vacuum.

Both Ni-base alloys, due to their high content of molybdenum, have a low coefficient of thermal expansion, which is close to that of ferritic steels. Therefore, they may be considered as an alternative to ferritic stainless steels, in particular for combining with zirconium oxide, used as a diffusion or thermal barrier layer, if improved corrosion resistance of the matrix material is required.