Bainitic Transformation in 100Cr6 Steel for Bearing Balls: Effect on Fatigue Endurance

Abstract

1. Introduction

2. Materials and Methods

2.1. Overview

- Determination of the average percentage of residual austenite on 10 new spheres, 5 subjected to standard heat treatment and 5 subjected to bainitic hardening treatment. Measurement was carried out using an X-ray diffraction technique with a diffractometer, according to ASTM E975 standard [19].

- Measurement of the average diameter Dwm1 of each new sphere for a total of 20 spheres; 10 consisted of tempered martensite and 10 consisted of bainite, with an accuracy of 0.1 μm. Detection was carried out using a comparator in a temperature-controlled chamber and following a procedure that minimizes the effects of any thermal expansion on the measurement.

- Tempering of the 20 spheres mentioned above at a temperature of 235 °C ± 2 °C for a period of 4 h in atmospheric air.

- Measurement of the average diameter Dwm2 of each tempered sphere using a procedure completely similar to the one described previously.

- Evaluation of the variation in size of each sphere using the following relationship:

2.2. Materials and Specimens

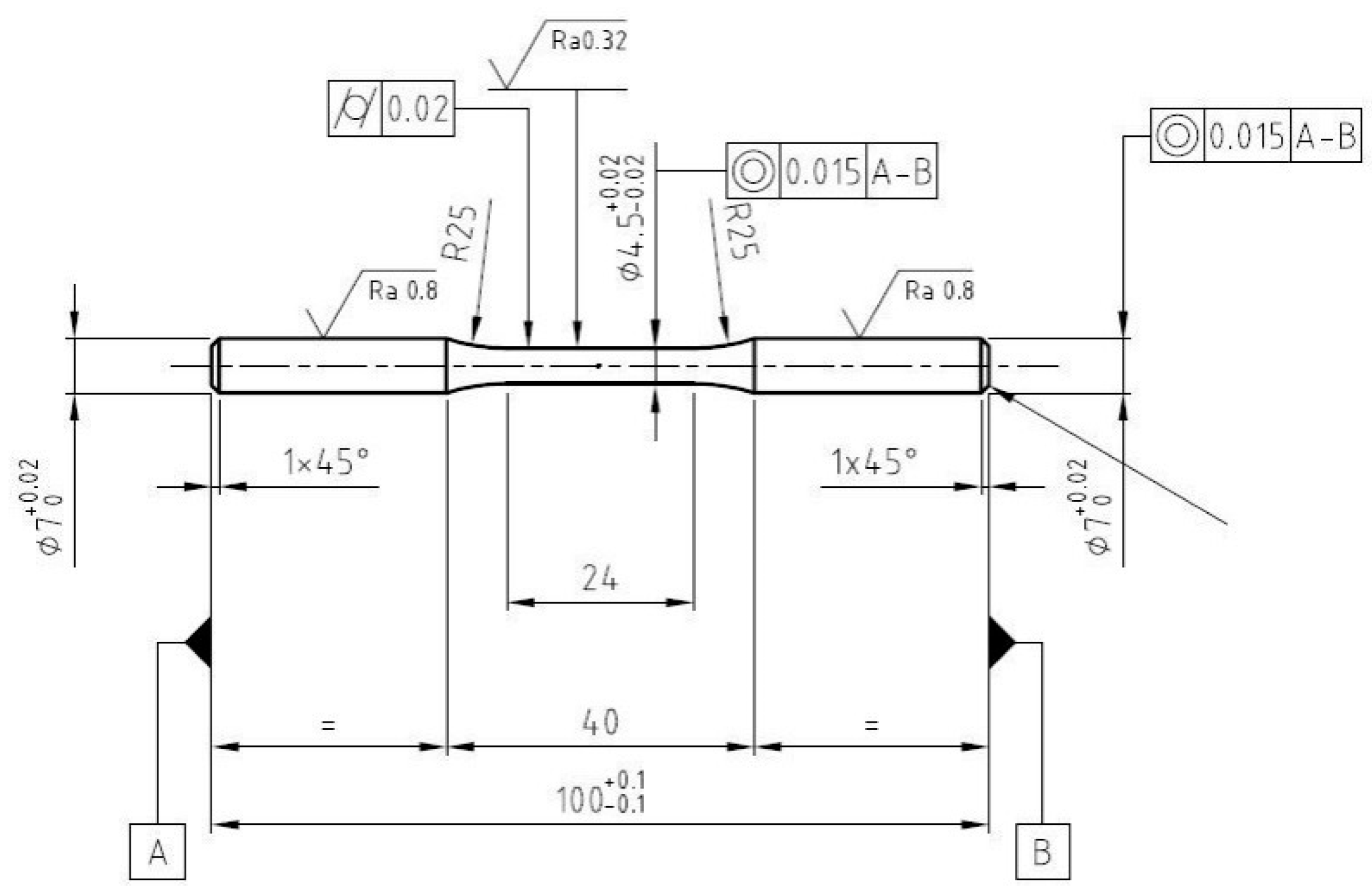

2.3. Mechanical Testing

3. Results and Discussion

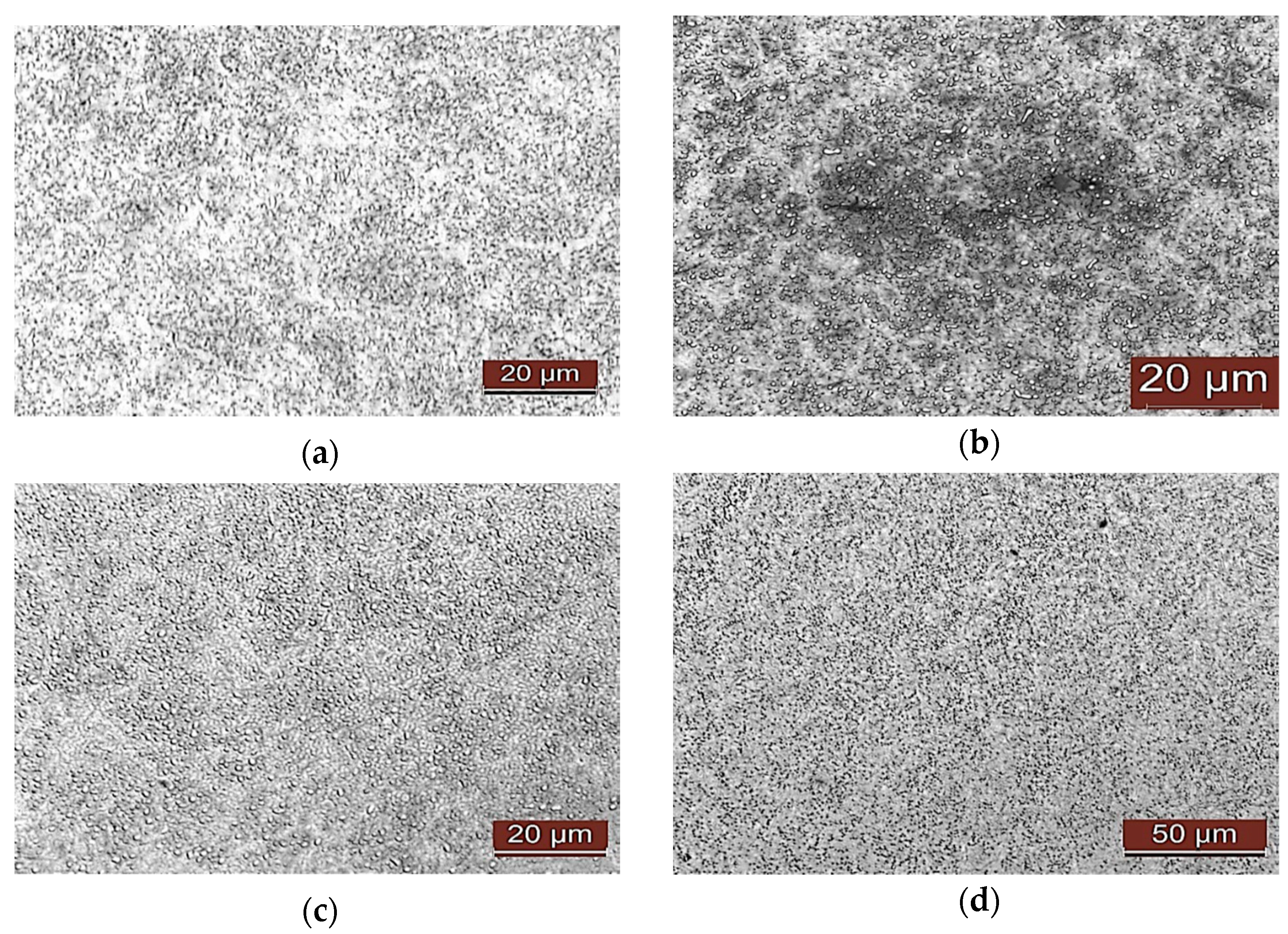

3.1. Microstructure

3.2. Tensile Testing

3.3. Chrapy Tests

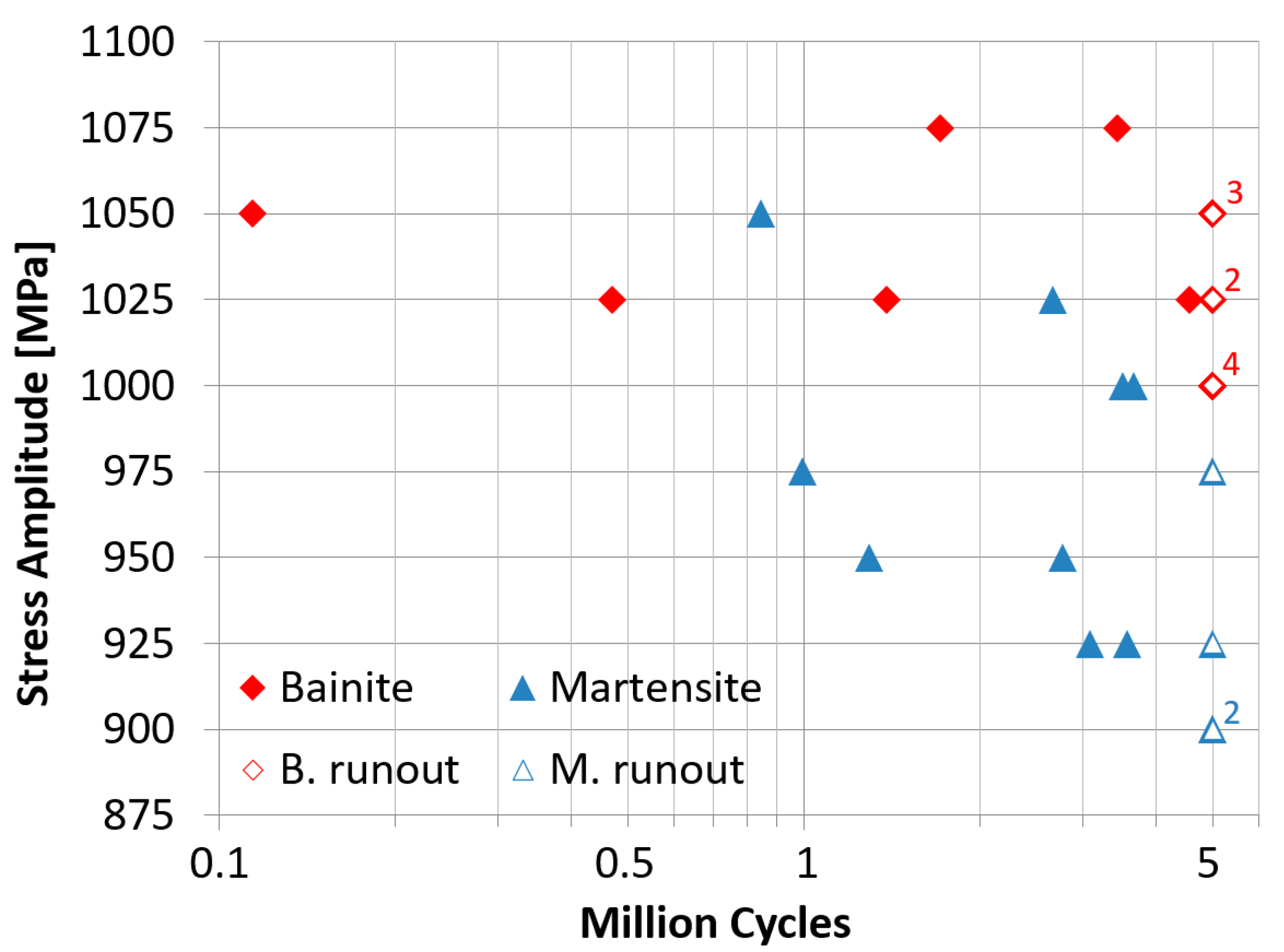

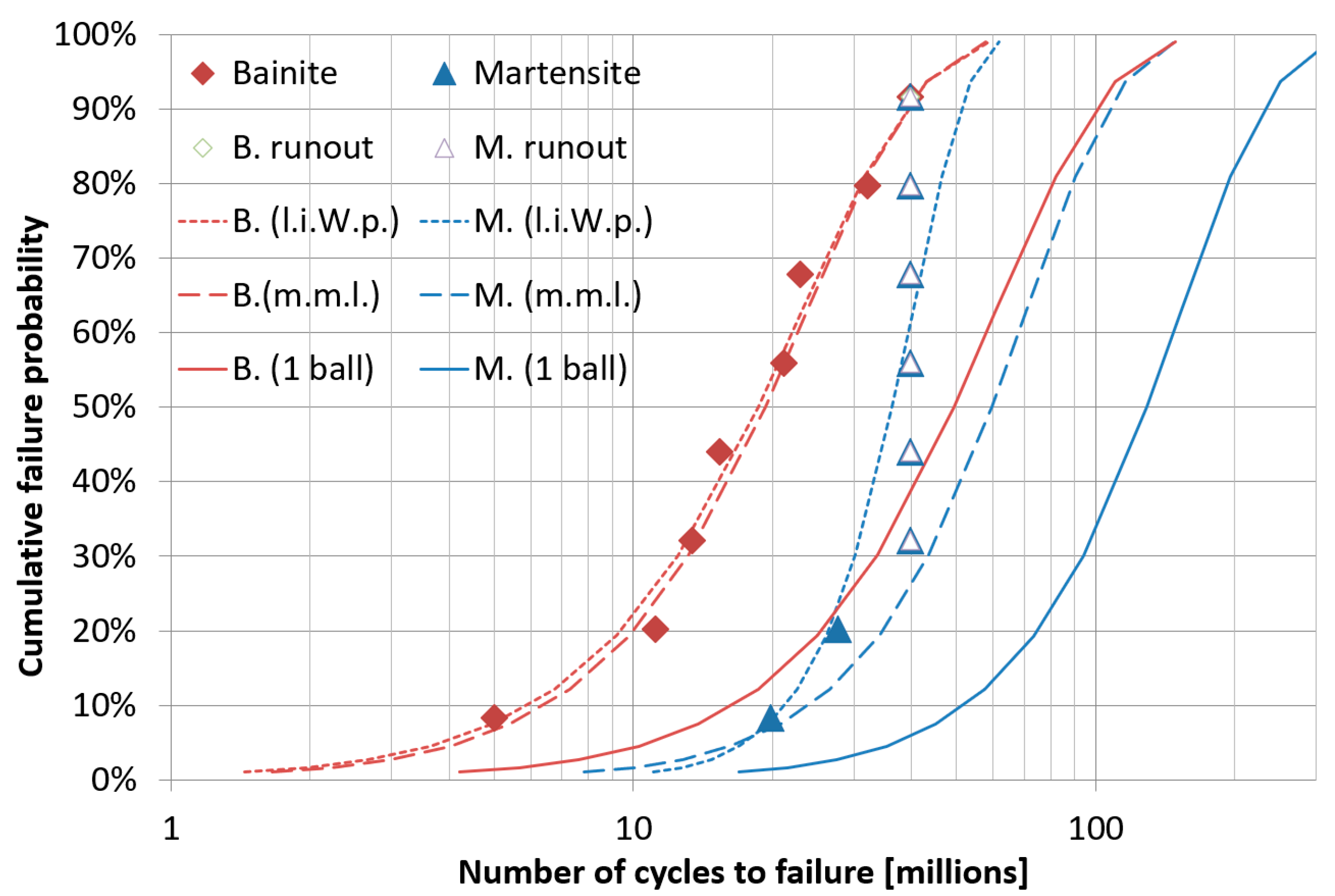

3.4. Rotating Bending Fatigue Tests

3.5. Ball Dimensional Stability

- Phase A, in which ε-carbides are precipitated and the amount of carbon present in the martensitic matrix is reduced. The formation of carbides leads to expansion, while the reduction in the martensitic matrix leads to a contraction of greater amplitude; the overall effect is a contraction in volume.

- Phase B, in which there is decomposition of residual austenite and the formation of cementite carbides to the detriment of ε carbides; in this case, the two processes involve an expansion, and the overall effect is a volume expansion.

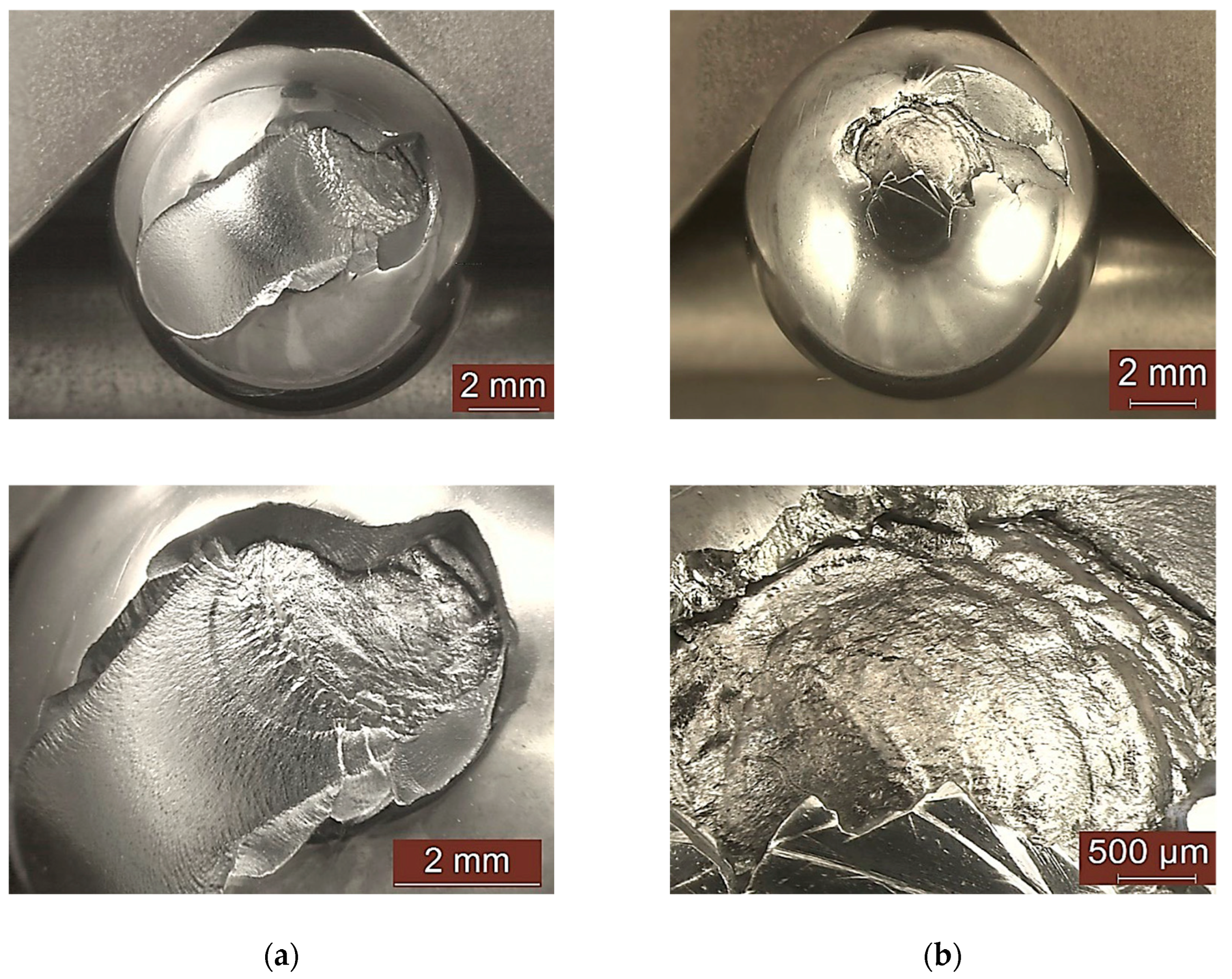

3.6. Rolling Contact Fatigue

4. Conclusions

- Lower strength (approximately 2300 vs. 2600 MPa) and hardness (approximately 680 vs. 750 HV);

- Near-equal tensile elongation (approximately 5%) and higher Charpy V impact energy (approximately 5 vs. 3 J with subsized specimens).

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zaretsky, E.V. Rolling Bearing Life Prediction, Theory, and Application; NASA/TP—2013-215305; NASA: Washington, DC, USA, 1 March 2013. [Google Scholar]

- Ioannides, T.A.; Harris, E.; Ragen, M. Endurance of aircraft gas turbine mainshaft ball bearings—Analysis using improved fatigue life theory: Part I—Application to a Long-Life Bearing. J. Tribol. 1990, 112, 304–308. [Google Scholar] [CrossRef]

- Raj, K.K.; Kumar, S.; Kumar, R.R. Systematic Review of Bearing Component Failure: Strategies for Diagnosis and Prognosis in Rotating Machinery. Arab. J. Sci. Eng. 2025, 50, 5353–5375. [Google Scholar] [CrossRef]

- Sun, D.; Zhao, J.; Zhang, M.; Fang, Q.; Long, X.; Zhang, F.; Yang, Z. In-situ observation of phase transformation during heat treatment process of high-carbon bainitic bearing steel. J. Mater. Res. Technol. 2022, 19, 3713–3723. [Google Scholar] [CrossRef]

- Yu, X.F.; Wei, Y.H.; Zheng, D.Y.; Shen, X.Y.; Su, Y.; Xia, Y.Z.; Liu, Y.B. Effect of nano-bainite microstructure and residual stress on friction properties of M50 bearing steel. Tribol. Int. 2022, 165, 107285. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, B.; Pan, Q.; Zhao, J.; Zhao, X.; Sun, H.; Xu, D.; Yang, Z. Effect of Austempering on Mechanical Properties of Nb/V Microalloyed Bainitic Bearing Steel. Crystals 2022, 12, 1001. [Google Scholar] [CrossRef]

- Hua, L.; Du, Y.; Qian, D.; Sun, M.; Wang, F. Influence of Prior Cold Rolling on Bainite Transformation of High Carbon Bearing Steel. Mater. Sci. Eng. A 2025, 56, 640–654. [Google Scholar]

- Jia, D.; Zhang, C.; Wang, Q.; Wang, H.; Yang, Z.; Zhang, F. Unleashing the potential of nano-bainite bearing steels: Controllable selection of microstructure evolution enables concurrent improvement of toughness and hardness by pre-cold deformation. Mater. Sci. Eng. A 2024, 906, 146715. [Google Scholar] [CrossRef]

- Miranda, R.S.; Rezende, A.B.; Carvalho, A.C.; Fonseca, S.T.; Sinatora, A.; Mei, P.R. The role of microstructure on the wear and rolling contact fatigue of railway steels: The performance of bainite. Wear 2024, 548–549, 205398. [Google Scholar] [CrossRef]

- Fan, Y.; Gui, X.; Liu, M.; Wang, X.; Bai, B.; Gao, G. Effect of microstructure on wear and rolling contact fatigue behaviors of bainitic/martensitic rail steels. Wear 2022, 508–509, 204474. [Google Scholar] [CrossRef]

- Li, Q.; Huang, X.; Huang, W. Fatigue property and microstructure deformation behaviour of multiphase microstructure in a medium-carbon bainite steel under rolling contact condition. Int. J. Fatigue 2019, 125, 381–393. [Google Scholar] [CrossRef]

- Ruijie, Z.; Chunlei, Z.; Bo, L.; Xubiao, W.; Xiaofeng, L.; Yanguo, L.; Fucheng, Z. Research progress on rolling contact fatigue damage of bainitic rail steel. Eng. Fail. Anal. 2023, 143, 106875. [Google Scholar] [CrossRef]

- Solano-Alvarez, W.; Pickering, E.J.; Bhadeshia, H.K.D.H. Degradation of nanostructured bainitic steel under rolling contact fatigue. Mater. Sci. Eng. A 2014, 617, 156–164. [Google Scholar] [CrossRef]

- Qin, Y.-M.; Liu, C.-B.; Zhang, C.-S.; Wang, X.-B.; Long, X.-Y.; Li, Y.-G.; Yang, Z.-N.; Zhang, F.-C. Comparison on wear resistance of nanostructured bainitic bearing steel with and without residual cementite. J. Iron Steel Res. Int. 2022, 29, 339–349. [Google Scholar] [CrossRef]

- Podder, A.S.; Bhadeshia, H. Thermal stability of austenite retained in bainitic steels. Mater. Sci. Eng. A 2010, 527, 2121–2128. [Google Scholar] [CrossRef]

- Sidoroff, C.; Perez, M.; Dierickx, P.; Girodin, D. Advantages and Shortcomings of Retained Austenite in Bearing Steels: A Review. Bear. Steel Technol. 2015, 10, 312–348. [Google Scholar] [CrossRef]

- Yang, Z.N.; Ji, Y.L.; Zhang, F.C.; Zhang, M.; Nawaz, B.; Zheng, C.L. Microstructural evolution and performance change of a carburized nanostructured bainitic bearing steel during rolling contact fatigue process. Mater. Sci. Eng. A 2018, 725, 98–107. [Google Scholar] [CrossRef]

- Fu, H.; Song, W.; Galindo-Nava, E.I.; Rivera-Díaz-del-Castillo, P.E. Strain-induced martensite decay in bearing steels under rolling contact fatigue: Modelling and atomic-scale characterisation. Acta Mater. 2017, 139, 163–173. [Google Scholar] [CrossRef]

- ASTM E975-22; Standard Practice for X-Ray Determination of Retained Austenite in Steel with Near Random Crystallographic Orientation. ASTM International: Conshohocken, PA, USA, 2022.

- ISO 1143:2010; Metallic Materials—Rotating Bar Bending Fatigue Testing. ISO: Geneva, Switzerland, 2010.

- ISO 148-1:2016; Metallic Materials—Charpy Pendulum Impact Test, Part 1: Test Method. ISO: Geneva, Switzerland, 2016.

- Kalpakjian, S.; Schmid, S.R. Manufacturing and Engineering and Technology, 7th ed.; Pearson Education Ltd.: London, UK, 2014. [Google Scholar]

- ISO 6892-1:2019; Metallic Materials—Tensile Testing, Part 1: Method of test at Room Temperature. ISO: Geneva, Switzerland, 2019.

- ISO 12107: 2012; Metallic Materials—Fatigue Testing—Statistical Planning and Analysis of Data. ISO: Geneva, Switzerland, 2012.

- Sesana, R.; Ossola, E.; Pagliassotto, S.; Rizzo, S.; Brusa, E. Influence of microinclusion in life of rolling elements: Experimental, microstructural, analytical and numerical investigation. Int. J. Fatigue 2020, 139, 105774. [Google Scholar] [CrossRef]

- Guo, Y.B.; Liu, C.R. Mechanical Properties of Hardened AISI 52100 Steel in Hard Machining Processes. J. Manuf. Sci. Eng. 2002, 124, 1–9. [Google Scholar] [CrossRef]

- Moosbrugger, C. Atlas of Stress-Strain Curves, 2nd ed.; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Mayer, H.; Haydn, W.; Schuller, R.; Issler, S.; Bacher-Höchst, M. Very high cycle fatigue properties of bainitic high carbon-chromium steel under variable amplitude conditions. Int. J. Fatigue 2009, 31, 1300–1308. [Google Scholar] [CrossRef]

- Kunz, L.; Lukáš, P.; Činčala, M.; Nicoletto, G. Fatigue Lifetime of Bearing Steel in Ultra High-Cycle Region. In Fracture of Nano and Engineering Materials and Structures, Athens (GR); Springer: Berlin/Heidelberg, Germany, 2006; pp. 877–878. [Google Scholar]

- Boniardi, M.; Casaroli, A.; Sandrini, V. Acciai per Cuscinetti a Rotolamento, Organi di Trasmissione; Tecniche Nuove: Milano, Italy, 2013. (In Italian) [Google Scholar]

- Püttgen, W.; Hallstedt, B.; Bleck, W.; Löffler, J.F.; Uggowitzer, P.J. On the Microstructure and Properties of 100Cr6 Steel Processed in the Semi-Solid State; Elsevier Ltd.: Amsterdam, The Netherlands, 2007. [Google Scholar]

- Bhadeshia, H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Kingsbury, E.P.; Falcon, K.C.; Andrew, C. Angular contact ball bearings: Track position at high speeds. Inst. Mech. Eng. 1970, 184, 24. [Google Scholar]

- Sesana, R.; Pessolano Filos, I.; Rizzo, S.; Uva, A. Precessional Slip and Microinclusion Effect on Fatigue Life of Bearing Rolling Element: An Integrated Life Estimation Model through Experimental and Analytical Investigation. STP 2024, 1649, 249–262. [Google Scholar] [CrossRef]

- Serbino, E.M.; Tschiptschin, A.P. Fatigue behavior of bainitic and martensitic super clean Cr–Si high strength steels. Int. J. Fatigue 2014, 61, 87–92. [Google Scholar] [CrossRef]

- Wei, Z.; Wang, W.; Liu, M.; Tian, J.; Xu, G. Comparison of wear performance of bainitic and martensitic structure with similar fracture toughness and hardness at different wear conditions. Wear 2023, 512–513, 204512. [Google Scholar] [CrossRef]

| C | Cr | Si | Mn | Cu | Ni | Mo | Al | P | S |

|---|---|---|---|---|---|---|---|---|---|

| 1.012 | 1.423 | 0.301 | 0.309 | 0.175 | 0.106 | 0.023 | 0.025 | 0.010 | 0.009 |

| Material | Items | Lot | Austenitizing | Quenching | Tempering |

|---|---|---|---|---|---|

| Mart. | Balls | A | 845 °C, 15 min | Oil, room temperature | 150 °C, 120 min |

| Cylindrical Spec. | B | 830 °C, 12 min | Oil, room temperature | 150 °C, 30 min | |

| Charpy Spec. | D | 830 °C, 17 min | Oil, room temperature | 150 °C, 30 min |

| Material | Items | Lot | Austenitizing | Bainitic Transformation |

|---|---|---|---|---|

| Bain. | Balls | C | 860 °C, 65 min | Salt bath, 250 °C, 35 min |

| Cylindrical Spec. | C | 860 °C, 65 min | Salt bath, 250 °C, 30 min | |

| Charpy Spec. | D | 860 °C, 65 min | Salt bath, 250 °C, 30 min |

| Rp0.2 (MPa) | Rm (MPa) | E (GPa) | A% * | |

|---|---|---|---|---|

| Martensitic 1 | - | 2606 | - | 1 |

| Martensitic 2 | 1996 | 2624 | 198 | 3.33 |

| Martensitic 3 | 1918 | 2550 | 198 | 2.62 |

| average | 1957 | 2593 | 198 | 2.32 |

| Std. dev. | 55.2 | 38.6 | 0.0 | 1.2 |

| Bainitic 1 | - | 2331 | - | 2.2 |

| Bainitic 2 | 1922 | 2344 | 198 | 1.91 |

| Bainitic 3 | 1933 | 2326 | 198 | 2.1 |

| average | 1927.5 | 2333.7 | 198.0 | 2.1 |

| Std. dev. | 7.8 | 9.3 | 0.0 | 0.1 |

| KV8 (J) | |

|---|---|

| Martensitic 1 | 2 |

| Martensitic 2 | 2 |

| Martensitic 3 | 2 |

| average | 2 |

| Bainitic 1 | 3 |

| Bainitic 2 | 3.8 |

| Bainitic 3 | 3.8 |

| average | 3.5 |

| Martensitic Balls | Bainitic Balls | |||

|---|---|---|---|---|

| Sample | Before Tempering | After Tempering | Before Tempering | After Tempering |

| 1 | 11.43 | 1.38 | 4.91 | 5.42 |

| 2 | 10.67 | <1 | 3.37 | 1.42 |

| 3 | 11.37 | <1 | 4.82 | 3.13 |

| 4 | 8.85 | <1 | 5.27 | 6.23 |

| 5 | 10.65 | <1 | 2.57 | 3.76 |

| Average | 10.59 | <1 | 4.19 | 3.99 |

| Decrement (%) | ≈10.5 | ≈0.2 | ||

| Sample | ||

|---|---|---|

| 1 | 44 | 17 |

| 2 | 53 | 20 |

| 3 | 42 | 19 |

| 4 | 50 | 28 |

| 5 | 51 | 13 |

| 6 | 41 | 18 |

| 7 | 52 | 16 |

| 8 | 45 | 15 |

| 9 | 45 | 13 |

| 10 | 50 | 20 |

| Average | 47 | 18 |

| Test n° | Martensitic Balls | Bainitic Balls | ||||||

|---|---|---|---|---|---|---|---|---|

| Life (h) | Nb (106) | Nn (106) | Nc (106) | Life (h) | Nb (106) | Nn (106) | Nc (106) | |

| 1 | 183.1 | 7.58 | 38.54 | 5.75 | 105.2 | 4.36 | 22.15 | 3.31 |

| 2 | 127.5 | 5.28 | 26.84 | 4.01 | 183.1 | 7.58 | 38.54 | 5.75 |

| 3 | 183.1 | 7.58 | 38.54 | 5.75 | 22.9 | 0.95 | 4.82 | 0.72 |

| 4 | 183.1 | 7.58 | 38.54 | 5.75 | 147.7 | 6.11 | 31.09 | 4.64 |

| 5 | 183.1 | 7.58 | 38.54 | 5.75 | 97.3 | 4.03 | 20.48 | 3.06 |

| 6 | 183.1 | 7.58 | 38.54 | 5.75 | 70.6 | 2.92 | 14.86 | 2.22 |

| 7 | 90.9 | 3.76 | 19.14 | 2.86 | 51.3 | 2.12 | 10.8 | 1.61 |

| 8 | 183.1 | 7.58 | 38.54 | 5.75 | 61.4 | 2.54 | 12.93 | 1.93 |

| Average | 164.6 | 6.82 | 34.66 | 5.17 | 92.4 | 3.83 | 19.46 | 2.90 |

| Martensitic Balls | Bainitic Balls | ||||

|---|---|---|---|---|---|

| HV2 | HV Ratio (%) | HV2 | HV Ratio (%) | ||

| new ball | 886 | / | new ball | 736 | / |

| Test 7 | 861 | −2.82% | Test 3 | 734 | −0.27% |

| Test 2 | 862 | −2.71% | Test 5 | 742 | 0.82% |

| Test 8 | 852 | −3.84% | Test 2 | 726 | −1.36% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Matteis, P.; Sesana, R. Bainitic Transformation in 100Cr6 Steel for Bearing Balls: Effect on Fatigue Endurance. Metals 2025, 15, 931. https://doi.org/10.3390/met15090931

Matteis P, Sesana R. Bainitic Transformation in 100Cr6 Steel for Bearing Balls: Effect on Fatigue Endurance. Metals. 2025; 15(9):931. https://doi.org/10.3390/met15090931

Chicago/Turabian StyleMatteis, Paolo, and Raffaella Sesana. 2025. "Bainitic Transformation in 100Cr6 Steel for Bearing Balls: Effect on Fatigue Endurance" Metals 15, no. 9: 931. https://doi.org/10.3390/met15090931

APA StyleMatteis, P., & Sesana, R. (2025). Bainitic Transformation in 100Cr6 Steel for Bearing Balls: Effect on Fatigue Endurance. Metals, 15(9), 931. https://doi.org/10.3390/met15090931