Abstract

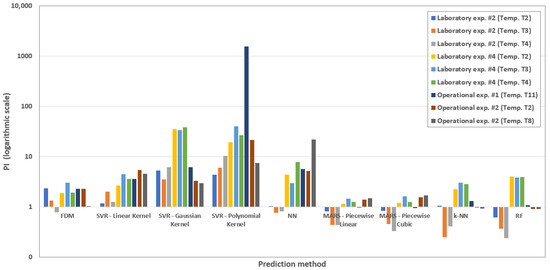

Annealing of steel coils in bell-type furnaces is a critical process in steel production, requiring precise temperature control to ensure desired mechanical properties and microstructure. However, direct measurement of inner coil temperatures is impractical in industrial conditions, necessitating model-based estimation. This study presents a comparative analysis of physics-based and machine learning (ML) approaches for predicting internal temperatures during annealing. A finite difference method (FDM) was developed as a physics-based model and validated against experimental data from both laboratory and industrial annealing cycles. Furthermore, several ML models, including support vector regression (SVR), neural networks (NN), multivariate adaptive regression splines (MARS), k-nearest neighbors (k-NN), and random forests (RFs), were trained on surface temperature measurements to predict inner temperatures. The results demonstrate that the MARS, k-NN, and RF models achieved high prediction accuracy with performance index (PI) values below 1.0 on unseen data, demonstrating excellent generalization capabilities. In contrast, SVR with polynomial kernels and NN exhibited poor performance in specific configurations, highlighting their sensitivity to overfitting and data variability. The findings suggest that combining physics-based models with data-driven techniques offers a robust framework for soft-sensing in annealing operations, enabling improved process monitoring and control.

1. Introduction

Annealing of steel coils in bell-type furnaces is a critical heat treatment process aimed at restoring the ductility and mechanical properties of cold-rolled steel through recrystallization. During cold rolling, steel undergoes significant plastic deformation, which leads to work hardening and increased internal stresses. Recrystallization annealing serves to eliminate these effects by heating the material to a temperature at which new, strain-free grains form, thereby improving formability and reducing residual stresses.

The competitiveness of a steel production company is strongly influenced by the quality and cost efficiency of its products. In the context of annealing processes, the temperature distribution within steel coils plays a key role in determining both product quality and overall energy consumption. Excessively high temperatures lead to unnecessary energy costs, while insufficient heating can result in products that do not meet quality requirements. Although various sensors are available for measuring the surface temperature of steel coils, the internal temperature cannot be measured directly without damaging the material. Therefore, model-based soft sensors are essential for estimating internal temperature values. These soft sensors make it possible to monitor and control the temperature behavior of the material in real time, even in processes characterized by significant time delays.

In industrial practice, bell-type annealing furnaces are widely used due to their flexibility and suitability for batch processing of coiled steel. Each annealing cycle involves controlled heating, holding at the target temperature, and subsequent cooling, all of which must be carefully managed to ensure uniform microstructural transformation throughout the coil volume. However, due to the considerable thermal mass and layered geometry of steel coils, temperature gradients often develop between the outer and inner layers, significantly influencing the kinetics of recrystallization.

Accurate knowledge of the temperature distribution within the steel coil is essential not only for ensuring product quality but also for optimizing furnace operation and energy consumption. In practice, the internal coil temperature is not directly measurable during each annealing cycle, as embedding thermocouples into every coil is impractical and economically unfeasible. As a result, furnace operators often rely on empirical rules and accumulated experience to manage the process, which can lead to conservative heating strategies and suboptimal fuel usage.

To address this limitation, mathematical models capable of estimating the internal temperature evolution in real time have been developed. Such models support better control strategies, reduce unnecessary fuel consumption, and improve process repeatability. Traditional approaches are based on the solution of the unsteady heat conduction equation, typically the one-dimensional Fourier heat equation, with appropriate boundary and initial conditions tailored to the geometry of coiled steel.

More recently, data-driven techniques based on machine learning (ML) have emerged as promising alternatives or complements to physics-based models. Methods such as support vector regression (SVR), multivariate adaptive regression splines (MARS), neural networks (NNs), and random forests (RF) can capture complex thermal dynamics from historical process data without requiring detailed knowledge of material properties or furnace configurations.

The modeling and prediction of temperature inside steel coils during annealing in bell-type furnaces represent a complex technological challenge at the intersection of heat transfer science, process control, and artificial intelligence. Accurate temperature prediction is essential for ensuring metallurgical quality, energy optimization, and real-time process control. Here, we systematically analyze the current state-of-the-art, spanning traditional mathematical models through contemporary machine learning (ML) approaches, and provide a comparison of their performance and applicability.

This study presents the theoretical foundation for soft-sensor modeling and evaluates the proposed models using data from laboratory measurements and real industrial operations. The objective was to develop a soft-sensor model capable of estimating internal coil temperatures from surface temperature measurements. For validation purposes, thermocouples were used to measure inner temperatures during selected annealing cycles.

This article presents a comparative study of temperature prediction methods for the annealing of steel coils in bell-type furnaces. We begin by formulating a physical model based on the transient Fourier heat conduction equation and validating it against available data. Subsequently, we introduce several machine learning techniques trained on recorded furnace data and evaluate their performance in predicting internal coil temperatures. The aim is to highlight the trade-offs between physical interpretability, prediction accuracy, and operational usability of the various approaches.

In previous work, the authors developed methods for soft-sensing surface temperatures of steel coils based on the temperature of the annealing atmosphere in a bell-type furnace [1,2]. In addition to this, a second approach focused on the estimation of internal coil temperatures was partially verified using machine learning techniques, specifically support vector regression (SVR), a form of support vector machines (SVMs) [3].

This study continues from previous research to analyze other ML methods like multivariate adaptive regression splines (MARS), neural networks (NNs), and random forests (RFs), which were employed.

The results obtained from these black-box machine learning models are compared in this paper with those derived from an analytical model based on heat conduction theory. The proposed approaches are intended for potential use in online estimation of internal temperatures, thereby enabling better monitoring and control of the annealing process. This paper presents both experimental data and simulation results to validate the proposed methods.

This study addresses the critical challenge of accurately estimating internal temperatures during annealing using surface measurements. While various machine learning methods have been applied in different metallurgical processes, their use for real-time prediction of internal strip temperatures based on operational data remains limited. The novelty of this work lies in the comprehensive comparison of physics-based and multiple machine learning models under both laboratory and industrial conditions. The proposed workflow integrates experimental measurements, preprocessing, model training, and evaluation, offering a practical solution for enhancing soft-sensing capabilities in annealing operations. By evaluating the generalization capabilities of each model on real unseen data, this study contributes valuable insights into the selection and deployment of predictive models in metallurgical practice.

Common abbreviations are listed at the end of the paper.

2. Review of the Related Literature

Recent research has addressed various aspects of annealing processes and their influence on the microstructure and properties of steels. Couchet et al. [4] conducted a numerical investigation of phase transformations during intercritical annealing, incorporating interface thermodynamic conditions into their simulations, which provides a relevant framework for thermal cycle modeling in steel coils. Yang et al. [5] examined the effect of annealing temperature on the microstructure and mechanical properties of DH steel, optimizing hole expansion properties through precise control of thermal parameters. Similarly, Chu et al. [6] studied the evolution of microstructure, mechanical performance, and fracture behavior of complex-phase steels across different annealing temperatures, offering valuable insights into linking temperature profiles to material behavior.

Steel strip annealing is commonly performed in two ways: batch annealing, where coiled strips are processed in bell-type furnaces, and continuous annealing, in which strips pass through a furnace line. Many studies have addressed temperature evolution in these processes, as it strongly influences the final mechanical properties. Modeling approaches fall broadly into physics-based and data-driven categories, with recent work focusing on hybrid strategies that integrate both.

2.1. Physics-Based Modeling Approaches

Finite difference and finite element methods (FDM/FEM) discretize transient heat conduction equations based on Fourier’s law to simulate temperature fields in coils. These models capture conduction, convection, and radiation effects, and have been validated with industrial data for process optimization [7,8]. Examples include intelligent soft-sensing systems for internal coil temperature [9,10] and simplified heat-flow models for surface temperature estimation [1]. Lumped parameter models (LPMs) approximate the coil as uniform thermal masses, trading spatial resolution for computational speed, making them suitable for real-time prediction [8]. Hybrid approaches combine physical equations with parameter tuning derived from measurements, thereby improving adaptability while maintaining interpretability [11,12,13]. Durdán et al. [2] and Kostúr [14] introduced a soft-sensing approach that estimates internal and surface coil temperatures based on the protective atmosphere’s temperature, as measured by thermocouples. Their system uses unsteady heat conduction models and is validated against operational data from an annealing plant. In their methodology, surface temperature is predicted using a regression model, while the inner temperature is estimated via differential equations.

2.2. Machine Learning and Data-Driven Methods

The integration of data-driven approaches into steel processing has also gained increasing attention. Zhou et al. [15] applied machine learning techniques for composition design of high-yield-strength TWIP steels, demonstrating the potential of AI-based tools in optimizing input parameters for predictive models. Bachmann et al. [16] proposed reproducible quantification of complex steel microstructures using advanced machine learning methods, enabling improved material characterization for simulation purposes. Tiwari et al. [17] developed artificial neural network models to predict the mechanical properties of industrial C–Mn cast steels, confirming that AI-based methods can complement physics-based models in steel property prediction.

Artificial neural networks (ANNs) and related models have been trained on process data to capture nonlinear relations between furnace parameters and coil temperature [18,19,20]. Various applications of neural networks in annealing can be found in [21,22,23,24,25,26,27]. Applications include batch and continuous annealing, with methods ranging from backpropagation to generalized regression neural networks [28,29,30]. While flexible, these models risk overfitting and require careful training/validation [21,25,26]. Ensemble learning and incremental updates improve robustness and adaptability [19]. Support Vector Regression (SVR) has also been explored for furnace temperature prediction and process optimization [31,32,33]. Bayesian methods offer uncertainty quantification in predictions [34].

2.3. Trends and Synthesis

Recent trends emphasize hybridization of physics-based and ML models, computational feasibility for online control, robust learning for noisy industrial data, and adaptability through model updating [8,35]. These developments align with the move towards digital twins in annealing operations. A concise comparison of physics-based, machine learning, and hybrid modeling approaches is provided in Appendix A (see Table A1). This table summarizes the main approaches for temperature modeling in steel coil annealing. Reviews by Smith and Yates [36] and Łach and Svyetlichnyy [37] summarize modern hybrid strategies that combine PDE-based models with machine learning components, providing improved accuracy, interpretability, and computational efficiency in heat transfer simulations.

3. Understanding Steel Coil Annealing

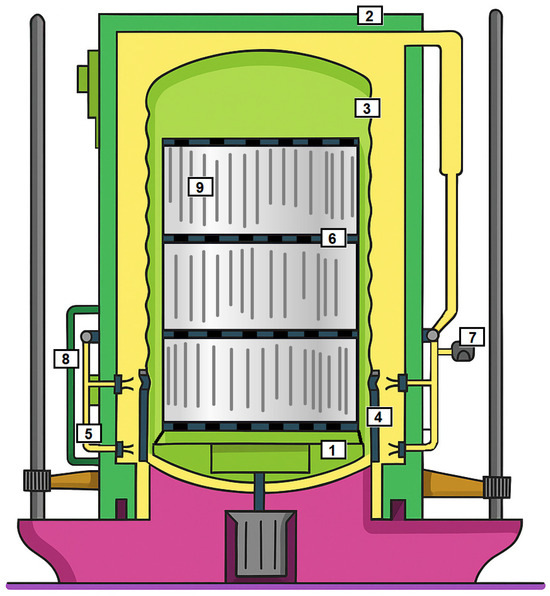

Bell-type furnaces are widely used for annealing steel coils, such as strips or wires, and can be heated electrically or by fuel. They are applicable for various heat treatments up to 1100 °C (Figure 1) [38]. The furnace consists of a fixed base with a cylindrical heating hood, inner muffle, convection rings, and burners or catalytic pads for efficient, low-emission heating [39,40].

Figure 1.

Scheme of bell furnace. Legend: (1) stand, (2) heating cap, (3) muffle with pads, (4) catalytic pads in combustion zone, (5) burners, (6) convection rings, (7) fuel supply control, (8) recuperative oxidizer and fuel system, and (9) steel coil.

During annealing, the steel is heated above the recrystallization temperature to improve ductility and reduce hardness [38,41]. The process involves recovery, recrystallization, and grain growth [42,43]. Coils are stacked in layers, covered with an inert gas to avoid oxidation, and heated tangentially via the inner cover. Due to the coil’s thermal mass, heating, holding, and cooling stages are prolonged to ensure uniform temperature distribution [44].

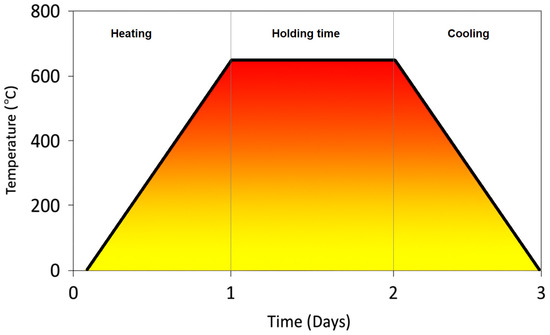

Figure 2 shows a typical batch annealing cycle. Recrystallization generally starts around 550 °C and its progression depends on both temperature and atmosphere [41,45].

Figure 2.

Typical batch annealing cycle (temperature vs. time).

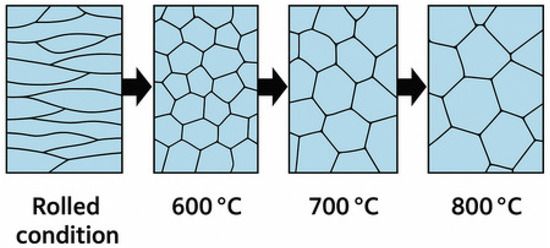

Large coil dimensions and a tightly wound geometry often lead to significant thermal gradients between the outer and inner layers. If the inner coil does not reach the target temperature, microstructural inhomogeneity may occur, affecting properties and downstream formability. Figure 3 illustrates microstructure evolution during annealing at different temperatures [46,47,48,49,50]. Accurate prediction of the inner coil temperature is therefore critical for process optimization and quality control.

Figure 3.

Evolution of microstructure (grain growth) in a rolled steel sheet during annealing at different temperatures (qualitative visualization only, not analyzed quantitatively in this study).

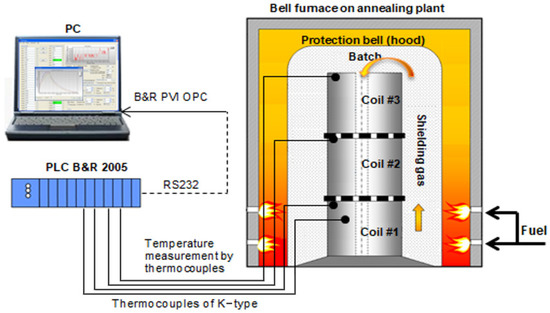

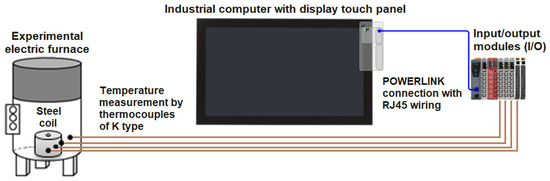

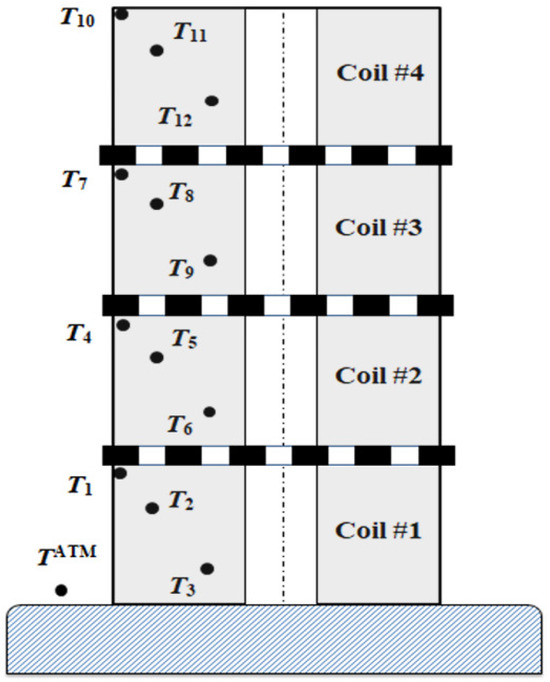

In this study, data from operational measurement (real annealing cycles) have also been used. In the industrial setup, thermocouples were manually placed on the surface and inside the steel coils before the start of the annealing cycle. The coils were loaded into the bell-type furnace and subjected to the standard heating program used in production. Temperature data were collected throughout the process using the PLC, serial link (RS232), and the PC for data recording. The resulting datasets reflect real operational conditions and were used for model proposal and validation. Figure 4 depicts the experimental measurement system used for annealing tests. The setup includes K-type thermocouples, a PLC unit (B&R 2005), and a PC with OPC-based communication. The authors of this study have developed custom software for recording and visualizing temperature profiles on a lab scale and in operation [51]. For verification of model-based (soft-sensor) temperature estimation, control measurements were also conducted by placing thermocouples between the coil windings.

Figure 4.

Measurement system used during experimental annealing.

This overview of the annealing process and measurement setup provides the context for developing and validating the individual physics-based and machine learning models whose predictive performance is compared in the following sections.

4. Materials and Methods

4.1. Experimental Annealing Furnace

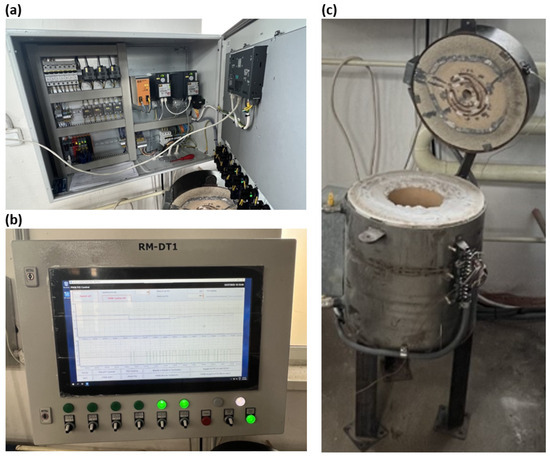

A series of experiments was conducted using an electric-heated laboratory bell furnace, adapted for testing temperature modeling techniques (see Figure 5). For validation purposes, a physical model of a steel coil was placed inside the furnace, where electric spirals provided heating. The model coil was instrumented with K-type thermocouples to measure temperatures at three critical locations: directly on the heating spirals (i.e., control temperatures), on the surface of the coil (i.e., surface temperatures), and within the coil (i.e., internal temperatures).

Figure 5.

Electric furnace with a control system: (a) electrical switchboard with an industrial computer (Quad core-Intel Atom E3940 1.60 GHz, 8 GB SDRAM B&R 5PPC2200.AL18-00; B&R Industrial Automation GmbH, Eggelsberg, Austria), I/Os and communication module; (b) front wall of the switchboard with a display touch panel (18.5″ Full HD TFT B&R 5AP1130.185C-000; B&R Industrial Automation GmbH, Eggelsberg, Austria); (c) experimental electric furnace.

The actual internal temperatures, along with surface temperatures, were measured during annealing using thermocouples. The internal temperatures were obtained from thermocouples inserted into the inner windings at various positions within the selected steel coils. These measurements were recorded continuously throughout the heating, holding, and cooling phases of the annealing cycle, providing accurate reference data for model development and validation.

The experimental setup enabled the investigation of soft-sensing techniques for internal coil temperature estimation under realistic annealing conditions. Due to the technical limitations of the furnace, continuous control of electric power (400 VAC) was not possible. Therefore, heating was controlled using a digital signal (24 VDC) to switch the spirals on and off, maintaining a desired power level. On the side of the furnace, there are inlet valves for supplying nitrogen to prevent the rapid oxidation of the charge. A physical model of a steel coil was used as the charge for this laboratory furnace. The furnace has a volume of 0.00502 m3, the height of the furnace space is 0.25 m, and the diameter of the furnace space is 0.16 m.

The experimental procedure consisted of placing the coiled steel sheet into the laboratory furnace and initiating a controlled annealing cycle. Thermocouples were inserted into selected inner windings and attached to surface locations to capture temperature profiles during the process. The annealing cycle included a heating ramp, a holding period at the target temperature, and natural cooling, all of which were recorded by a self-made data acquisition system. Each annealing experiment followed the same procedure to ensure consistency for model proposal and validation.

The control system was implemented on a B&R PLC platform (see Figure 6), as described in [11,52]. It utilized a combination of pulse-width modulation (PWM), classical PID control, ON–OFF regulation, and sliding mode control (SMC) [52]. The monitoring system enabled heating control based on either measured surface temperatures or model-estimated inner coil temperatures via a soft sensor.

Figure 6.

Hardware configuration of the control system of an electric furnace.

4.2. Modeling Methods for Modeling Internal Temperatures

This section presents two distinct approaches suitable for estimating the internal temperature of steel coils during the annealing process. The first approach utilizes the theory of transient (non-stationary) heat conduction, while the second applies support vector regression (SVR), a machine learning technique. The former follows a physics-based analytical formulation, whereas the latter operates as a data-driven black-box model.

4.2.1. Modeling Basedd on Finite Difference Method

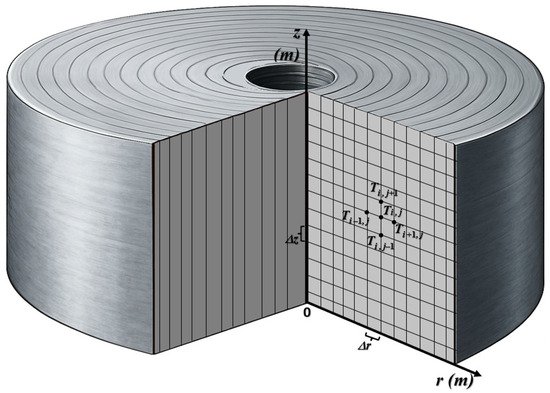

The transient heat conduction within the steel coil was modeled using the Fourier–Kirchhoff equation in cylindrical coordinates under the assumption of rotational symmetry (no dependence on the azimuthal coordinate ). This formulation better represents the actual geometry of the coil, where temperature gradients predominantly occur in the radial and axial directions [53,54]:

where T is the temperature , is the thermal diffusivity , is the thermal conductivity , is the density , and is the specific heat capacity , and is the time .

The computational domain was defined as a two-dimensional axisymmetric cross-section of the coil. The coil was discretized into a uniform grid with and spacing. The explicit finite difference scheme was applied for time integration. The discrete form of Equation (1) at node and time step n is [54,55]:

where

and is the radial position of the i-th grid point. Parameter is the radial grid spacing (m), represents axial grid spacing (m), and is the time step (s).

The scheme stability is governed by the following condition:

Figure 7 illustrates the computational mesh for the axisymmetric finite difference model of the steel coil. The r-axis represents the radial direction from the coil’s center, and the z-axis corresponds to the coil’s vertical symmetry axis. Temperature values are computed at each internal grid node, while and denote the four neighboring nodes used in the discretized heat conduction equation.

Figure 7.

The scheme of coil grid parameters.

Boundary conditions were derived from experimental measurements and the physical characteristics of the annealing process. Table 1 summarizes the applied boundary conditions and the thermophysical properties used in the simulation.

Table 1.

Boundary conditions and thermophysical properties of the FDM model.

Typical ranges are based on literature values for low-carbon steels during heating [56]. For the numerical simulations in this study, constant values within these ranges were adopted: , , , and . These values were calibrated against laboratory and industrial annealing measurements to ensure that the FDM model realistically represents the thermal behavior of the coil.

The model allows for flexible incorporation of experimentally measured surface temperatures as time-dependent Dirichlet boundary conditions. This approach ensures that the simulated internal temperature evolution reflects realistic heating conditions during the annealing process.

The core of the FDM-based simulation lies in the discretization of the transient heat conduction Equation (2) in axisymmetric cylindrical coordinates .

The domain was represented as a 2D axisymmetric grid spanning and . The grid resolution was defined by the number of nodes M in the radial direction and N in the axial direction, with uniform spacings and . The time step was selected to satisfy the stability criterion , where and . The physical model of the steel-sheet coil had the following setup ( m, m, M = 5, ) [3].

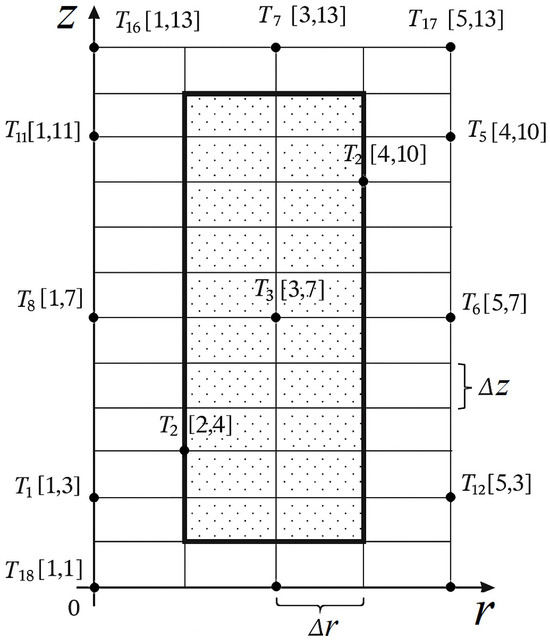

Figure 8 shows the placement of thermocouples mapped onto the r-z cross-section of the coil. At the coil centerline (), a symmetry condition was applied. At the radial outer boundary (), time-varying Dirichlet boundary conditions were assigned based on measured surface temperatures. The axial ends ( and ) were treated as adiabatic or as Dirichlet boundaries when measurements were available. Missing boundary measurements were interpolated linearly from neighboring points.

Figure 8.

Placement of thermocouples mapped onto the 2D grid.

The algorithm computed the temperature at each interior grid node iteratively in time, while boundary nodes were fixed at their prescribed values for each time step. All computed temperature fields were stored for post-processing and analysis.

To improve accuracy, an adaptive calibration procedure adjusted , , and c to minimize the mean absolute deviation between simulated and measured temperatures at selected control points inside the coil:

where is the number of time steps, is the number of control points, is the simulated temperature, and is the measured temperature at point j and time k. The optimization combined gradient-based and dynamic programming methods [51].

Recently, Durdán et al. [57] applied a similar axisymmetric FDM approach to estimate thermal diffusivity during annealing using deterministic nonlinear optimization, achieving significant error reduction when validated against experimental data from a bell-type furnace.

4.2.2. Modeling Based on Machine Learning (ML)

Support Vector Regression (SVR)

Support vector regression (SVR) is a powerful machine learning (ML) technique used for modeling nonlinear regression problems. Its theoretical foundation is based on the concept of mapping the original input space into a higher-dimensional feature space, where a linear regression function is constructed. This approach enables the approximation of complex nonlinear dependencies while maintaining good generalization performance, especially when the number of training samples is limited [58,59].

Input data (i.e., the coil’s surface temperatures as observations) are represented by the vector , where l denotes the size of the sample. Given a training dataset consisting of input–output pairs , , SVR seeks a function that deviates from the true targets by no more than a margin for each training sample while remaining as flat as possible. In our case, this function finds the target internal temperature in the annealed coil based on input observations (surface temperatures of the coil). The regression function takes the following form:

where and are Lagrange multipliers, b is a bias term, and is a symmetric, positive kernel matrix, such as linear, Gaussian, or polynomial, generated directly by a kernel function, i.e., . Only a subset of the training samples with nonzero or , called support vectors, contribute to the final prediction [60,61].

The optimization task is to minimize the following objective:

To determine the optimal values of , the optimization problem involves minimizing the Lagrange function [62,63] while guaranteeing compliance with the Karush–Kuhn–Tucker (KKT) complementary conditions [58,64].

In this study, SVR was used to estimate internal coil temperatures during annealing based on surface temperature measurements. To assess generalization, SVR models were tested on datasets other than the training dataset. The SVR implementation in MATLAB was used with a linear, Gaussian, and polynomial kernel [62,63]:

- Linear kernel:

- Gaussian kernel:where is the kernel width parameter.

- Polynomial kernel:where d is an integer.

Sequential minimal optimization (SMO) was employed to solve the underlying quadratic programming problem efficiently. The advantage of SVR in this application lies in its ability to handle nonlinear relationships between surface and internal temperatures while relying on a limited number of support vectors, making the model computationally efficient and robust to overfitting. The use of support vector regression (SVR) in modeling annealing operations is reported in [3].

The SVR model was trained on real measured data (laboratory and operational) collected during experimental annealing cycles, with input–output pairs formed by surface and internal temperatures obtained from thermocouples. This approach allows estimation of inner temperatures using only surface measurements in practical applications where internal sensors are not feasible.

For SVR modeling, the MATLAB Statistics and Machine Learning toolbox [62,63] was utilized.

Feed-Forward Neural Networks

Another approach being investigated for modeling internal coil temperatures is based on a neural network (NN). Feed-forward neural networks (FNNs) represent a class of supervised learning models capable of approximating nonlinear functions through layered processing of input data. In this work, a classical back-propagation neural network (BPNN) was used to predict the internal temperature of a steel coil during annealing, based on surface temperature measurements. The network structure consists of an input layer, two hidden layers with N neurons in the first hidden layer, and a single output neuron. The number of neurons in the hidden layer was set based on the recommendation in [65]. Similar applications of FNN to the annealing process can be found in [28].

In neural network training, the goal is to compute the weights and thresholds that relate the input vector of activities to the expected output vector [65].

Each neuron in the hidden layer computes a weighted sum of its inputs and applies a nonlinear activation function to the result. The output of the j-th hidden neuron is calculated as follows:

where are the input features (surface temperatures), are the connection weights, is the bias term, and is the transfer function. In our experiments, the log-sigmoid activation function was used.

The output neuron aggregates the contributions from hidden neurons and subtracts a bias:

where are the output layer weights, and a is the output neuron bias [66].

Training was performed using the gradient descent method with momentum and adaptive learning rate. The network minimizes the mean squared error between predicted and true internal temperatures:

where M is the number of training samples. The learning parameters (i.e., learning rate, momentum, and number of epochs) were experimentally tuned to ensure stability and convergence.

The number of input features (i.e., measured surface temperatures) varied between experiments. In the case of laboratory data, 15 inputs were used, resulting in a neural network architecture of 15-31-1-1. For the two industrial datasets, the number of input features was 5 and 4, leading to architectures of 5-11-1-1 and 4-9-1-1, respectively. These configurations were derived from the commonly used heuristic for the number of neurons in the hidden layer. Despite the differences in structure, all neural networks were trained using the same algorithm and hyperparameters: a log-sigmoid activation function, gradient descent with momentum 0.9, an adaptive learning rate (), and a maximum of 1000 epochs. The output of each network was a single neuron representing the predicted internal temperature.

Multivariate Adaptive Regression Splines (MARS)

Multivariate adaptive regression splines (MARS) is a flexible, non-parametric regression method introduced by Friedman [67], capable of modeling nonlinear relationships and variable interactions without requiring a priori functional forms. MARS has been effectively applied in various fields, including recent studies on temperature prediction in steelmaking [68]. However, the MARS application for predicting temperatures in the annealing process has not yet been published.

The core idea of MARS is to approximate the target variable as a sum of basis functions (BFs), which are constructed from piecewise-linear or piecewise-cubic splines. The model takes the following form:

where is the predicted inner temperature in the coil, denotes the input vector (e.g., surface temperatures), is the intercept, M indicates the total number of basis functions (BFs) in the model (i.e., spline functions), are coefficients of basis functions , and is the error term.

To construct BFs, MARS introduces knots at observed data points, splitting the input domain and generating reflected pairs for each variable. Piecewise-linear splines typically use the hinge function:

where t is the knot.

The cubic basis function, utilized in some implementations [69], can be written in the following form:

with the following coefficients:

A mirrored form is defined analogously:

with

The MARS algorithm proceeds in two stages: forward selection, where an overfitted model is built by adding BFs, and backward pruning, where unimportant terms are removed. The final model strikes a balance between accuracy and generalizability. In our study, the implementation by Jekabsons [70] was used, testing both linear and cubic variants. A rule of thumb constrained the number of basis functions: , where d is the number of predictors.

Although all MARS models were initialized using the same configuration parameters, the final number of basis functions (BFs) selected after pruning varied depending on the dataset. Specifically, the model trained on laboratory data with 15 input features resulted in 8 final BFs. For the two industrial datasets, which used 5 and 4 input variables, respectively, the final models retained 19 and 18 BFs. These differences reflect the adaptive nature of the MARS algorithm, which adjusts model complexity based on the data dimensionality and structure.

k-Nearest Neighbors Regression

The k-nearest neighbors (k-NN) algorithm is a non-parametric approach, initially introduced by Fix and Hodges [71] and later refined for broader machine learning applications [72,73,74]. In this work, k-NN regression was utilized as an alternative strategy for predicting the internal temperatures of annealed steel coils from their surface temperature measurements.

The method estimates the output for an unseen input by averaging the values of its k nearest neighbors in the training data. In the basic variant with uniform weighting, the estimate is computed as follows:

where denotes the index set of the k closest training samples to under a chosen metric.

The distance metric used in our implementation was Euclidean distance, the most common choice in practice. Optionally, distance-based weighting can be applied, where closer neighbors contribute more to the following prediction:

where is the distance between and the i-th neighbor.

Our implementation was based on the open-source k-NN regressor by Ferreira [75], and used with uniform weights. The training phase involved storing the whole training dataset without model fitting, and predictions were made by distance-based lookups at test time. This lazy learning property makes the k-NN conceptually simple yet powerful for local approximation.

Random Forests

Random forests (RFs) are robust ensemble learning algorithms suitable for both classification and regression, initially introduced by Ho [76] and later extended by Breiman [77]. The technique builds multiple decision trees on bootstrapped subsets of the data and aggregates their outputs. In regression tasks, the final prediction is the average of the outputs from all individual trees [73,74].

The RF algorithm operates by randomly selecting training samples with replacement and fitting unpruned decision trees to each subset. If the input training dataset consists of n samples with input vectors and corresponding temperature responses , then the model constructs B trees via bootstrap aggregation (bagging) as follows:

- For each ,

- –

- generate and by sampling n instances with a replacement from the original dataset;

- –

- train a regression tree on this sample.

Once the ensemble is trained, the prediction for a new input is provided by the following:

where denotes the predicted internal temperature, and is the b-th decision tree in the forest.

In our study, we employed a generic implementation of the Random Forest (RF) algorithm, as proposed by Banerjee [78], adapted for regression tasks in MATLAB. The number of trees was set to , which provides a balance between prediction accuracy and computational efficiency. Euclidean distance was implicitly used during tree construction to split nodes based on input features. The script utilized for training and prediction ensures that each tree is built independently on randomized subsets of surface temperature data, allowing the ensemble to generalize well to unseen annealing cycles.

All random forest models were trained using the same configuration across all datasets, regardless of the number of input features. Each model used 5000 decision trees, trained on bootstrap samples of the input data. The splitting criterion used for node splits was the mean squared error (MSE), which is the default in the employed MATLAB R2020b implementation. No additional pruning or depth limitation was applied. This consistent setup ensured fair comparison between experiments while preserving the robustness and generalization capability of the ensemble models.

In summary, all machine learning models were developed using consistent training parameters and methodologies across experiments, while accounting for differences in the number of input features (i.e., measured surface temperatures). The laboratory dataset used 15 inputs, whereas the industrial experiments used 5 and 4 inputs, respectively. This variation naturally led to different model structures: neural networks with 15-31-1-1, 5-11-1-1, and 4-9-1-1 architectures, and MARS models with 8, 19, and 18 final basis functions. Random forest models were configured uniformly across all cases, with 5000 decision trees and MSE as the splitting criterion. These configurations ensured a fair and reproducible comparison of data-driven modeling approaches under varying measurement conditions.

4.2.3. Pros and Cons of Applied Methods

The finite difference method (FDM) is a widely used numerical technique for solving heat conduction problems by discretizing the governing partial differential equations. While FDM provides a physically grounded framework for thermal modeling, its accuracy and computational cost depend on grid resolution and boundary condition handling. Machine learning algorithms, in contrast, rely on previous successful strategies to make accurate predictions for the future. Each method has its strengths and limitations, which affect its suitability for specific modeling tasks. Below is a concise overview of the advantages and disadvantages of the investigated methods.

- Finite Difference Method (FDM) for Heat Conduction Modeling

- –

- Advantages: Based on first principles and physical laws; provides interpretable results; suitable for extrapolation beyond training data; does not require data-driven learning; useful for simulating spatial and temporal temperature evolution in solid materials.

- –

- Disadvantages: Requires precise knowledge of material properties and boundary conditions; limited adaptability to unknown dynamics; sensitive to discretization errors; may become computationally intensive for fine grids or 3D simulations.

- Support Vector Regression (SVR)

- –

- Advantages: Strong capability for modeling nonlinear relationships; robust against overfitting and noisy inputs; exhibits low generalization errors.

- –

- Disadvantages: Requires careful kernel selection; needs input normalization; harder to interpret.

- Neural Networks (NN)

- –

- Advantages: Powerful for nonlinear problems; flexible architecture; robust to noise and missing data.

- –

- Disadvantages: Computationally expensive; sensitive to hyperparameters; prone to overfitting; difficult to interpret; requires large datasets.

- Multivariate Adaptive Regression Splines (MARS)

- –

- Advantages: Handles both linear and nonlinear relationships; automatically detects interactions; works with mixed data types.

- –

- Disadvantages: Susceptible to overfitting; slower training on large datasets; complex interpretation.

- k-Nearest Neighbors (k-NN)

- –

- Advantages: Simple and intuitive; no training phase; non-parametric and adaptable.

- –

- Disadvantages: Memory-intensive; prediction can be slow; sensitive to choice of k and distance metric.

- Random Forests (RF)

- –

- Advantages: High accuracy; handles missing data; robust to noise; suitable for both classification and regression.

- –

- Disadvantages: Computationally demanding; potentially complex models; slower training with large datasets.

4.2.4. Evaluation of Model Performance

To assess the quality of temperature prediction models, several standard statistical metrics were employed. These indicators compare the predicted (simulated) and measured temperature values over a validation dataset. Rather than listing all commonly known formulas, we summarize the indicators used and their interpretations.

The predictive accuracy was primarily evaluated using the following:

- The correlation coefficient (), which quantifies the linear association between predicted (simulated, Y) and measured values (y).

- The coefficient of determination (), representing the proportion of variance in the measured data explained by the model. An value of 1 indicates a perfect fit.

- The mean squared error (MSE), which reflects the average squared difference between predicted (simulated) and actual values.

- The root mean squared error (RMSE) and its normalized form, relative RMSE (RRMSE), which measure average prediction error in absolute and relative terms.

- The mean absolute percentage error (MAPE), a scale-independent indicator commonly used in regression tasks. Although some studies refer to the mean of relative errors as the mean relative error (MRE) and others as the mean absolute percentage error (MAPE), both metrics are mathematically equivalent when expressed as a percentage. Therefore, results reported using either term can be directly compared in terms of model prediction accuracy.

In addition to these classical metrics, a composite performance index (PI) was used, defined as the ratio of RRMSE to the correlation coefficient incremented by one (22). This index offers a robust yet straightforward comparison across models: the lower its value, the better the prediction performance [79,80].

Moreover, the maximum deviation between the measured temperatures and the corresponding model predictions was assessed. For each approach, the training time was also recorded to evaluate computational efficiency.

5. Results and Discussion

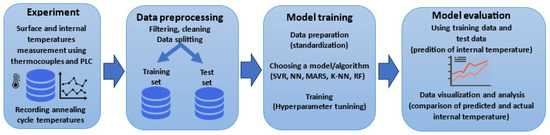

The following section presents and analyzes the results obtained from the application of physics-based and machine learning models to experimental data. A structured workflow was applied in the ML modeling process, as illustrated in Figure 9. Surface and internal temperatures were measured during laboratory and industrial annealing experiments. After preprocessing, the dataset was split into training and testing subsets. For all evaluated machine learning models, the training and testing datasets were derived from distinct annealing experiments. Specifically, three annealing cycles were used for training and one for testing, resulting in a 75:25 split. This approach ensured consistent and fair comparison across all predictive methods, while enabling evaluation of the models’ generalization capabilities to unseen data.

Figure 9.

Workflow of the proposed approach: from experimental data acquisition to ML model training and evaluation.

5.1. Temperature Modeling Based on Lab-Scale Measurement

In simulations of FDM, surface temperatures obtained from experimental annealing of the coils served as the primary input data for the modeling framework. A total of four laboratory electric furnace annealing experiments were performed (i.e., experiments #1–#4), using the same steel coil. The laboratory coiled sheet, serving as a physical model, exhibited a chemical composition of 0.05 wt% C, 0.3 wt% Mn, and 0.05–0.1 wt% Si.

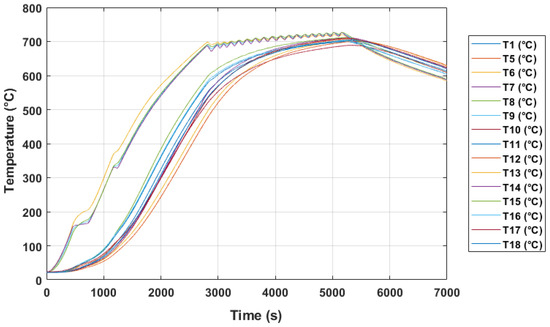

The coil was heated in a laboratory furnace, and surface temperatures were monitored and logged. The measurement setup followed the schematic representation in Figure 6. An illustration of surface temperatures captured by thermocouples during the experimental laboratory annealing is presented in Figure 10. The labels , , and indicate thermocouples placed at nodes where the recorded temperatures were compared with model predictions. The thermocouple numbering corresponds to the configuration depicted in Figure 8.

Figure 10.

Example of input observation as measured surface temperatures.

A total of 15 surface temperature observations were used to train the machine learning models (i.e., SVR, NN, MARS, k-NN, and RF) from three individual annealing experiment, i.e., where = , = , = , = , = , = , = , = , = , = , = , = , = , = , and = . The target variable y was always a selected internal coil temperature (i.e., , , ), which was measured by a thermocouple to train the machine models and assess their performance. The actual measured temperatures in the coil were also used to assess the performance of the FDM. The length of the training data was 22,000 samples (for each surface temperature). Time alignment was carefully handled by trimming the beginning and end of the time series to synchronize with the available predicted temperature values, ensuring a correct comparison and evaluation of prediction accuracy. Model testing was performed on a single experiment with data that was not used in model training. The length of the testing data was always 7000 samples. The models’ accuracy was evaluated using standard statistical metrics. In both the training and test datasets, temperatures were recorded at 1-s intervals.

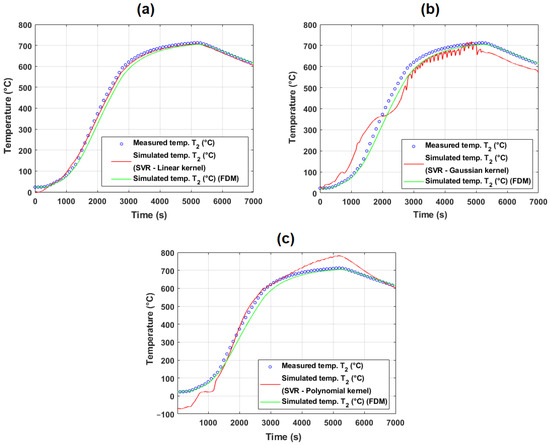

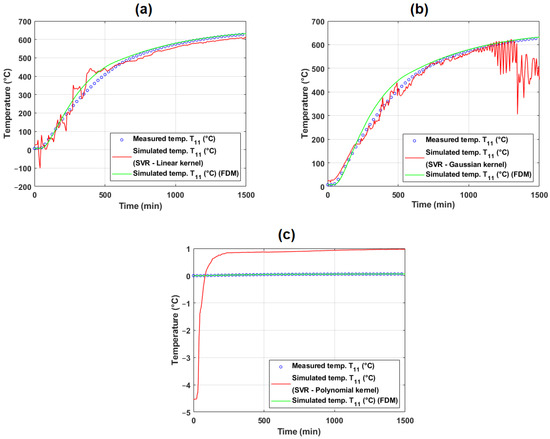

Several SVR models were created for temperature modeling, specifically for estimating inner temperatures , , and during laboratory annealing. In modeling and simulation, according to Equation (6), linear (7), Gaussian (8), and polynomial (9) kernels were used.

Figure 11 shows the results of simulated (predicted) inner temperature using FDM and SVR models applied on test annealing (i.e., experiment #2). For the performance assessment of the models, the plots also display the actual measured temperature obtained using a thermocouple. Similarly, Figure 12 shows results where experiment #4 was used as the annealing test.

Figure 11.

Measured and simulated temperature by FDM and SVR (experiment #2): (a) SVR, linear kernel; (b) Gaussian kernel; (c) polynomial kernel.

Figure 12.

Measured and simulated temperature by FDM and SVR (experiment #4): (a) SVR, linear kernel; (b) Gaussian kernel; (c) polynomial kernel.

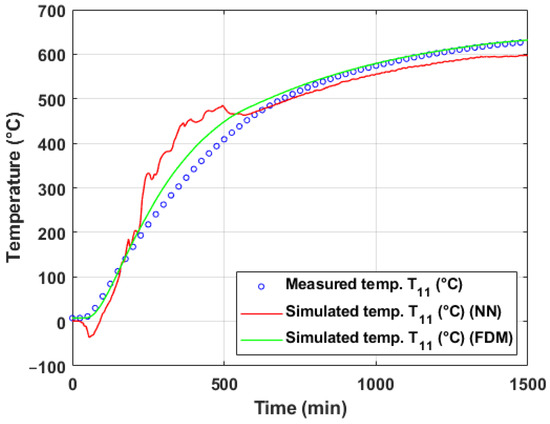

The neural network (NN) used in this study comprised two hidden layers and was trained on data from three annealing experiments, with one experiment reserved for testing. The first hidden layer contained neurons, where input neurons, resulting in 31 neurons in total. The second hidden layer and output layer each had one neuron for predicting the target temperature. Doubling the number of hidden neurons did not improve model performance. Training was performed for up to 1000 epochs with a learning rate of using gradient descent with adaptive learning rate and momentum (set to 0.9) to avoid local minima. The sigmoid (logistic) function was used as the activation function.

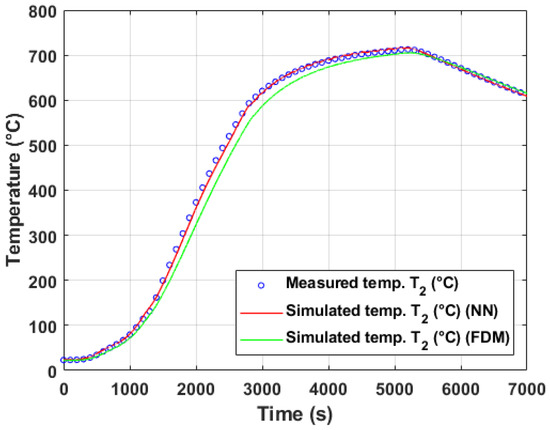

Figure 13 shows the results of the simulated (predicted) inner temperature using FDM and NN models applied on test annealing (i.e., experiment #2). For the performance assessment of the models, the plots also display the actual measured temperature obtained using a thermocouple. Similarly, Figure 14 shows the results where experiment #4 was used as the annealing test.

Figure 13.

Measured and simulated temperature using FDM and NN (experiment #2).

Figure 14.

Measured and simulated temperature using FDM and NN (experiment #4).

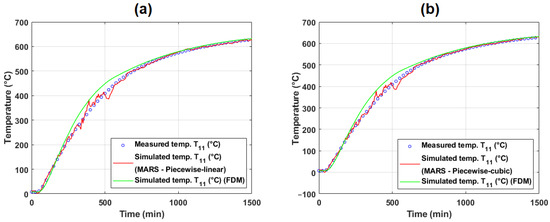

The MARS regression model is constructed in two stages. During the forward phase, the process starts with a model containing only the intercept term, incrementally adding pairs of reflected basis functions (BFs) to minimize training error until a predefined maximum number of BFs is reached. In the backward phase, the model is pruned by sequentially removing the least significant BFs, further reducing the error. It yields a set of candidate models of varying complexity, from which the final model is selected based on the lowest generalized cross-validation (GCV) score, subject to the maximum allowed number of BFs.

Several different variants of simulation with MARS have been performed. The created models for inner temperature prediction are portable and can be presented in the piecewise linear or cubic form. The initial number of BFs was set to 31 in all simulations. This number was reduced in the forward and backward phases of the MARS model creation. During modeling, we considered maximal interactivity between input variables without self-interactions. Since there were no smoother data, the piecewise-cubic and piecewise-linear types of modeling were analyzed to determine their prediction performance. By default, all MARS models are created as piecewise linear and transformed into piecewise cubic after the backward phase. These MARS models were created to be portable, i.e., can be presented in the form of equations and can be easily implemented in monitoring systems. The examples of mathematical equations for the selected MARS models, including all basis functions, are provided in Appendix B (see Equations (A1)–(A4)).

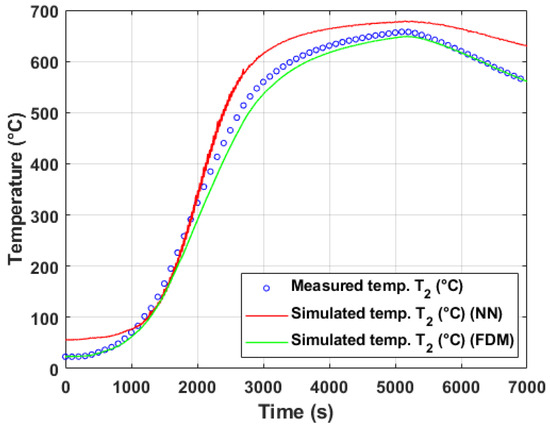

Figure 15 shows the results of the simulated (predicted) inner temperature using FDM and MARS models applied on test annealing (i.e., experiment #2). For the performance assessment of the models, the plots also display the actual measured temperature obtained using a thermocouple. Similarly, Figure 16 shows the results where experiment #4 was used as the annealing test.

Figure 15.

Measured and simulated temperature using FDM and MARS (experiment #2): (a) MARS, piecewise-linear; (b) MARS, piecewise-cubic.

Figure 16.

Measured and simulated temperature using FDM and SVR (experiment #4): (a) MARS, piecewise-linear; (b) MARS, piecewise-cubic.

The k-nearest neighbors (k-NN) regression method was the fourth method employed to predict internal temperatures within the steel coil based on surface measurements. Before model training, feature vectors were standardized using z-score normalization to ensure a uniform scale. The optimal number of neighbors, denoted as k, was set to five, based on empirical testing. It means that each prediction is derived from the five most similar observations in the training dataset. The similarity between observations was calculated using the Euclidean distance, which measures the straight-line distance in multi-dimensional feature space. To increase the influence of closer neighbors, an inverse distance weighting was applied. This assigns higher importance to nearby neighbors and reduces the impact of more distant ones, leading to smoother and more locally sensitive predictions.

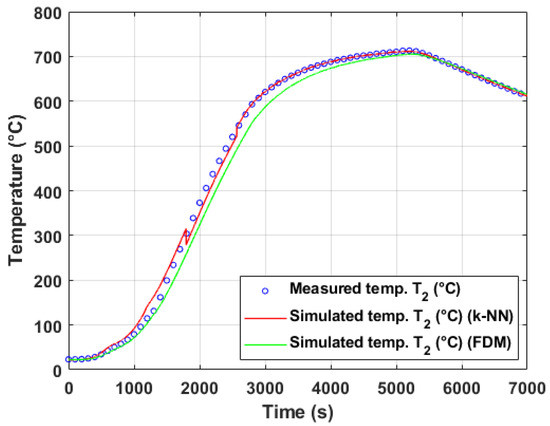

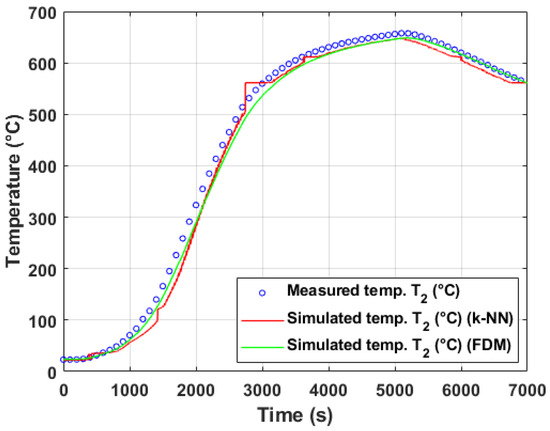

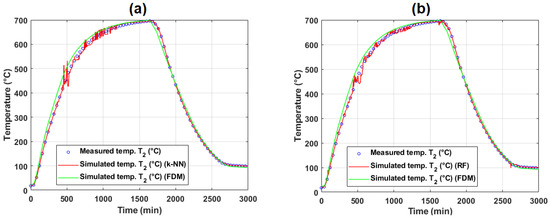

Figure 17 shows the results of the simulated (predicted) inner temperature using FDM and k-NN models applied on test annealing (i.e., experiment #2). For the performance assessment of the models, the plots also display the actual measured temperature obtained using a thermocouple. Similarly, Figure 18 shows the results where experiment #4 was used as the annealing test.

Figure 17.

Measured and simulated temperature using FDM and k-NN (experiment #2).

Figure 18.

Measured and simulated temperature using FDM and k-NN (experiment #4).

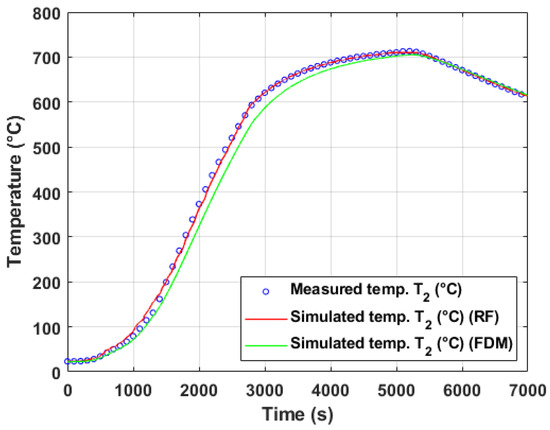

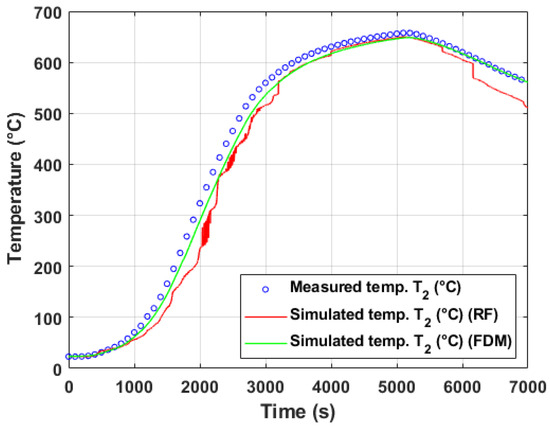

The random forest (RF) method was the last employed method to predict internal temperatures of annealed steel coils based on experimental data. The RF model utilizes a bootstrap aggregation strategy with a high number of decision tree ensembles, specifically, bags_number = 5000. This large ensemble aims to ensure model robustness and accuracy by reducing variance through resampling.

Figure 19 shows the results of the simulated (predicted) inner temperature using FDM and RF models applied on test annealing (i.e., experiment #2). For the performance assessment of the models, the plots also display the actual measured temperature obtained using a thermocouple. Similarly, Figure 20 shows the results where experiment #4 was used as the annealing test.

Figure 19.

Measured and simulated temperature using FDM and RF (experiment #2).

Figure 20.

Measured and simulated temperature using FDM and RF (experiment #4).

5.1.1. Evaluation of Model Performance on Training and Test Data (Experiment #2)

The effectiveness of the evaluated methods was assessed using multiple statistical metrics: the correlation coefficient (), coefficient of determination (), mean squared error (MSE), root mean squared error (RMSE), relative RMSE (RRMSE), mean absolute percentage error (MAPE), performance index (PI), and maximum deviation between predicted and measured temperatures.

Detailed numerical results of the training phase for all models are presented in Appendix C (see Table A2). On the training dataset (experiment #2), all methods exhibited very high accuracy, with values approaching 1.0000 and values close to 1.0000, indicating excellent fitting capabilities. Among the machine learning (ML) methods, the k-NN and RF achieved the lowest PI values across all three target temperatures (, , and ), followed by the MARS models with both piecewise linear and cubic splines. SVR with polynomial kernels exhibited significantly higher errors and deviations, indicating potential overfitting issues or poor generalization for this kernel type. Training times varied significantly, with RF requiring the longest computational time due to the large number of trees in the ensemble.

In contrast, the test dataset results (Table 2) highlight the models’ generalization ability. Here, the FDM method demonstrated competitive performance, achieving high values (above 0.995 for and ) and relatively low PI values. Among the ML methods, RF and MARS again performed exceptionally well, maintaining low error metrics and PI values, which demonstrates their robustness and ability to extrapolate beyond training data. Notably, SVR with polynomial kernels showed the weakest performance, characterized by large MSE, RMSE, and PI values, as well as high maximum deviations. It reinforces the earlier observation of its limited applicability for this task.

Table 2.

Performance of FDM and ML methods in temperature prediction on test data (experiment #2).

Overall, RF achieved the best predictive accuracy, closely followed by MARS, k-NN, and the neural network (NN). These findings confirm that ensemble-based and spline-based methods are well-suited for modeling and predicting internal temperatures during the annealing process. Despite the FDM being physics-based and requiring no training, it performed comparably to ML models, supporting its use in real-time simulations where computational efficiency is critical.

5.1.2. Evaluation of Model Performance on Training and Test Data (Experiment #4)

Table A3 in Appendix C summarizes the performance of individual machine learning (ML) methods during training on surface temperature data obtained from three experimental annealing cycles. The fitting accuracy of internal temperatures , , and was evaluated using several statistical indicators, including , , MSE, RMSE, RRMSE, MAPE, PI, and maximum deviation. The training time for each method was also recorded. As shown in Table A3, the k-NN method and Random Forest (RF) achieved the lowest performance index (PI), indicating a nearly perfect fit on the training dataset. Multivariate Adaptive Regression Splines (MARS), in both linear and cubic variants, also provided excellent results with very low prediction errors and minimal deviations from the measured data. Support Vector Regression (SVR) with a polynomial kernel exhibited significantly higher PI values and larger deviations, indicating poorer performance in capturing the training data trend.

Table 3 presents the predictive performance of FDM and ML methods on test data obtained from experiment #4. This dataset was not used during training and thus provides an unbiased evaluation of each model’s generalization capability. The FDM method, based on the analytical solution of the heat conduction problem, served as a reference for comparison with ML models. As shown in Table 3, MARS and RF maintained their excellent performance on the test dataset, with PI values below two and minimal deviations. In contrast, SVR models with Gaussian and polynomial kernels performed poorly on the test data, showing high PI values and large maximum deviations. It suggests a tendency to overfit the training data. Neural networks (NN) demonstrated moderate performance, while k-NN, with a perfect fit during training, showed a slight increase in prediction error but still outperformed SVR methods.

Table 3.

Performance of FDM and ML methods in temperature prediction on test data (experiment #4).

Overall, MARS and RF methods exhibited robust generalization capabilities across different datasets, making them highly suitable for temperature prediction in steel coil annealing processes. The FDM method, although analytical, achieves comparable accuracy to the best ML models, highlighting its potential as a reliable alternative where physical parameters are well-defined.

5.1.3. Discussion of Model Generalization and Experimental Variability

In the conducted experiments, machine learning (ML) models were trained on three annealing cycles and subsequently tested on a fourth cycle, which was excluded from the training dataset. This approach allowed for a realistic assessment of the models’ generalization capabilities, as each experiment involved different thermal profiles and boundary conditions during the annealing process of a laboratory-scale steel coil in an electric bell furnace.

The results demonstrate that while most methods achieved excellent accuracy on training data, their performance on unseen experimental data varied considerably. For instance, methods such as MARS and RF exhibited robust predictive performance across different experiments, suggesting a higher ability to generalize beyond the training set. In contrast, SVR models, particularly those with polynomial kernels, exhibited signs of overfitting, resulting in significant errors during testing.

These findings underline the importance of considering the variability in physical processes when developing data-driven models. The differences between experiments stem from inherent changes in the heating cycles, coil geometry, and thermodynamic conditions within the furnace. Therefore, the comparative study highlights that no single ML method can be universally recommended without careful evaluation on a diverse set of scenarios.

This variability also reinforces the complementary value of physics-based methods such as the finite difference method (FDM), which, despite not requiring training, provided competitive performance in predicting internal coil temperatures.

5.2. Temperature Modeling Based on Operational Measurement

Detailed numerical results of the training phase for all models are presented in Appendix C (see Table A4 and Table A5). Detailed numerical results of the test phase are presented in Table 4 and Table 5. The configuration of the node matrix used in the model is illustrated in Figure 21. Data were obtained from two distinct annealing experiments conducted in an industrial annealing plant. The sheet metal coils have different dimensions in individual experiments.

Figure 21.

Arrangement of thermocouples on a stack of four steel coils during the annealing process.

In experiment #1, the coils had a diameter of 1800 mm, a height of 966 mm, and an approximate weight of 17 t. For this case, the internal temperature (i.e., measured in Coil #4) was modeled to estimate the temperature distribution during annealing. In experiment #2, the coils had a diameter of 1600 mm, a height of 966 mm, and an approximate weight of 18 t. Here, the internal temperatures and (measured in Coil #1 and Coil #3, respectively) were modeled to estimate their thermal behavior during annealing.

In this study, a set of coiled sheets with a density of 7.15 g/cm3 was used. The chemical composition (in wt%) is as follows: 0.039% C, 0.012% Si, 0.265% Mn, 0.006% P, 0.013% Cr, 0.014% Ni, 0.030% Cu, 0.005% S, 0.057% Al, and 0.003% N. Measurements on real coils had a smaller number of surface temperatures than in the case of annealing a physical model in an electric furnace. Additionally, the temperature of the annealing atmosphere (), corresponding to the HNX protective gas mixture, was monitored. All measurements were conducted on actual steel coils processed in an industrial annealing plant.

At the locations of the modeled internal temperatures, control thermocouples were installed, similar to the setup used in the laboratory coil. The coils were stacked vertically on a support stand. In experiment #1, four coils were stacked, while in experiment #2, only three coils were arranged. Convective rings were placed between the coils to enhance heat transfer.

To train ML models, the following setup was regarded.

In the first operational experiment, surface temperatures , , , , and were considered as input observations a temperature as target variable. The training dataset consisted of three combined measurements (annealing cycles) with a total of 4800 samples. The test dataset consisted of a single measurement (i.e., one annealing cycle), with 15,000 samples recorded for each measured temperature. In both the training and test datasets, temperatures were recorded at 60-s intervals.

In the second operational experiment, surface temperatures , , , and were considered as input observations. Temperatures and have been regarded as target variables. The training dataset consisted of three combined measurements (annealing cycles) with a total of 89,000 samples. The test dataset consisted of a single measurement (i.e., one annealing cycle), with 29,000 samples recorded for each measured temperature. In both the training and test datasets, temperatures were recorded at 60-s intervals.

5.2.1. Evaluation of Model Performance on Training and Test Data (Operational Experiment #1)

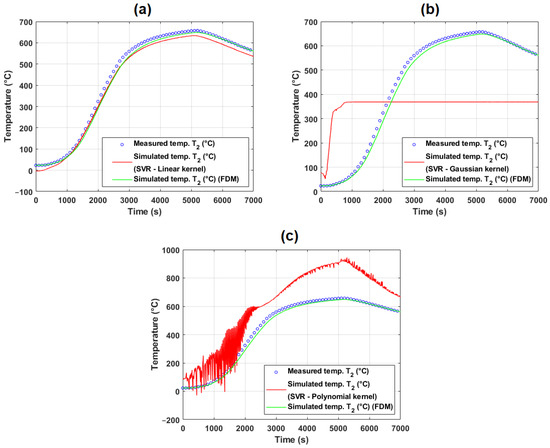

The detailed numerical results for the ML models applied to the training dataset from operational experiment #1 are presented in Appendix C (see Table A4). Among the evaluated methods, k-NN and RF achieved the highest accuracy, with nearly perfect correlation coefficients () and very low errors (e.g., PI values of 0.1225 and 0.1860, respectively). MARS models (both piecewise-linear and piecewise-cubic) also demonstrated excellent fitting capabilities, maintaining and RRMSE below 2%. In contrast, the SVR with a polynomial kernel performed poorly, exhibiting high prediction errors and an extremely high PI value due to overfitting and poor generalization on training data. A neural network with the structure 5-11-1-1 provided a reasonable fit with and PI = 5.5165, but was outperformed by other models. These results indicate that ensemble methods and non-parametric approaches, such as k-NN and RF, are highly effective in capturing the nonlinear thermal dynamics during annealing when sufficient training data are available.

The generalization ability of the trained models was evaluated on unseen test data, and the results are presented in Table 4. Here, the physics-based FDM approach served as a baseline, achieving , RRMSE = 4.63%, and PI = 2.3182, demonstrating robust predictive capability without requiring prior training. Among the ML models, MARS (PI = 0.9487 for piecewise-cubic) and RF (PI = 1.0922) provided highly accurate predictions, closely approximating the measured temperature profile. The k-NN model also performed well, but its accuracy decreased slightly compared to the training data (RRMSE = 2.60%). On the other hand, SVR with polynomial and Gaussian kernels failed to generalize, producing very substantial errors and PI values, highlighting their sensitivity to extrapolation beyond the training domain. Neural networks achieved moderate performance (PI = 5.6823), indicating partial overfitting to the training set.

Table 4.

Performance of FDM and ML methods in temperature prediction on test data (operational experiment #1).

Table 4.

Performance of FDM and ML methods in temperature prediction on test data (operational experiment #1).

| Temperature | Method | MSE | MAPE (%) | RMSE | RRMSE (%) | PI | Max. Deviation (°C) | ||

|---|---|---|---|---|---|---|---|---|---|

| FDM | 0.9966 | 0.9933 | 415.2310 | 5.4459 | 20.3772 | 4.6286 | 2.3182 | 45.8609 | |

| SVR (linear kernel) | 0.9862 | 0.9727 | 1001.9793 | 25.1101 | 31.6541 | 7.1901 | 3.6199 | 111.7091 | |

| SVR (Gaussian kernel) | 0.9685 | 0.9379 | 2870.5070 | 16.7263 | 53.5771 | 12.1698 | 6.1824 | 311.7023 | |

| SVR (polynomial kernel) | 0.5719 | 0.3270 | 118,449,324.5368 | 19,275.1619 | 10,883.4427 | 2472.1307 | 1572.7473 | 45,295.0617 | |

| Feed-forward NN | 0.9664 | 0.9340 | 2419.8762 | 21.6994 | 49.1922 | 11.1738 | 5.6823 | 131.7777 | |

| MARS (piecewise-linear) | 0.9989 | 0.9979 | 76.2742 | 3.9521 | 8.7335 | 1.9838 | 0.9924 | 49.1798 | |

| MARS (piecewise-cubic) | 0.9990 | 0.9980 | 69.7127 | 3.3933 | 8.3494 | 1.8965 | 0.9487 | 43.7511 | |

| k-NN regression | 0.9982 | 0.9965 | 130.7727 | 1.7991 | 11.4356 | 2.5975 | 1.2999 | 55.2761 | |

| RF | 0.9988 | 0.9977 | 92.3713 | 1.8243 | 9.6110 | 2.1831 | 1.0922 | 53.9474 |

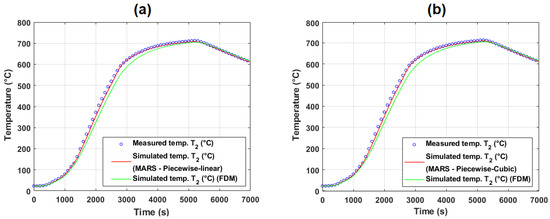

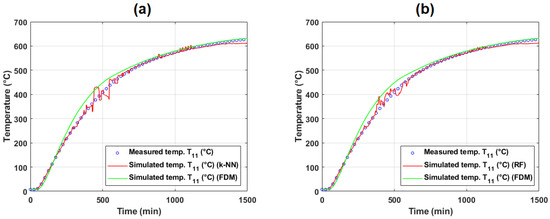

Figure 22, Figure 23, Figure 24 and Figure 25 illustrate the predicted (simulated) inner temperature compared to measured values for each modeling approach. These plots demonstrate the ability of certain ML models (e.g., RF and MARS) to reproduce the thermal behavior with high fidelity. In contrast, others (e.g., SVR with a polynomial kernel) exhibit considerable deviations, especially during heating and cooling phases.

Figure 22.

Measured and simulated temperature using FDM and SVR (operational experiment #1): (a) SVR, linear kernel; (b) SVR, Gaussian kernel; (c) SVR, polynomial kernel.

Figure 23.

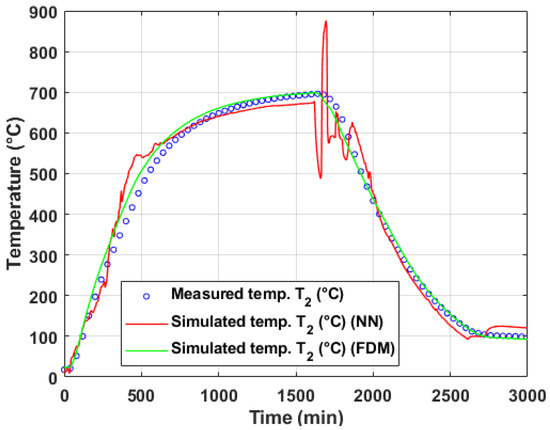

Measured and simulated temperature using FDM and NN (operational experiment #1).

Figure 24.

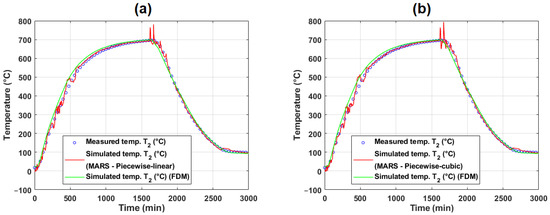

Measured and simulated temperature using FDM and MARS (operational experiment #1): (a) MARS, piecewise-linear; (b) MARS, piecewise-cubic.

Figure 25.

Measured and simulated temperature using FDM, k-NN, and RF (operational experiment #1): (a) k-NN; (b) RF.

The examples of mathematical equations for the selected MARS models, including all basis functions, are provided in Appendix B (see Equations (A5) and (A6). These models are portable and can be easily implemented in monitoring systems. The outputs from the MARS models are shown in Figure 24a,b.

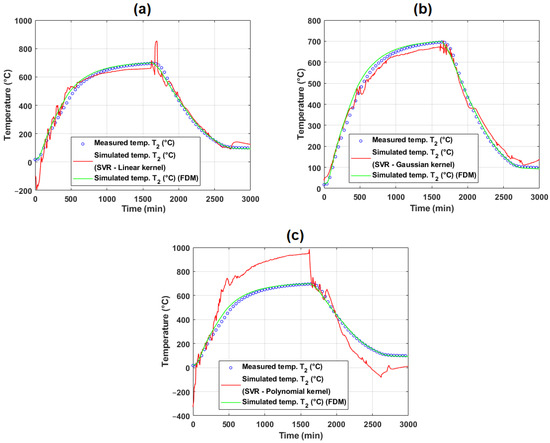

5.2.2. Evaluation of Model Performance on Training and Test Data (Operational Experiment #2)

The detailed numerical results for the ML models applied to the training dataset from operational experiment #2 are presented in Appendix C (see Table A5). Both temperatures and were modeled simultaneously. Similar to the previous experiment, k-NN and RF achieved nearly perfect predictions, with correlation coefficients approaching unity and extremely low errors (e.g., PI values below 0.3). MARS models (piecewise-linear and piecewise-cubic) also demonstrated excellent fitting capabilities, with and RRMSE under 3%. SVR with a Gaussian kernel achieved reasonable accuracy but performed worse than MARS and ensemble methods. SVR with a polynomial kernel again struggled with overfitting, as indicated by substantial errors and high PI values. A neural network with the structure 4–9–1–1 demonstrated acceptable performance for but failed for , where and the PI exceeded 21, indicating instability in learning for some configurations.

The test dataset results, shown in Table 5, demonstrate the generalization performance of both physics-based and ML approaches. The FDM model achieved robust predictions with for both and , and PI values around 1.0, confirming its capability to simulate inner coil temperatures without prior training. Among ML methods, RF and k-NN maintained high accuracy on unseen data, with PI values below 1.0 and maximum deviations comparable to FDM. MARS models also performed well, while SVR with a polynomial kernel exhibited significant errors and was unable to generalize effectively. Neural networks performed moderately on but showed poor accuracy for , consistent with their training results.

Table 5.

Performance of FDM and ML methods in temperature prediction on test data (operational experiment #2).

Table 5.

Performance of FDM and ML methods in temperature prediction on test data (operational experiment #2).

| Temperature | Method | MSE | MAPE (%) | RMSE | RRMSE (%) | PI | Max. Deviation (°C) | ||

|---|---|---|---|---|---|---|---|---|---|

| FDM | 0.9974 | 0.9948 | 359.6462 | 5.0291 | 18.9643 | 4.5607 | 2.2833 | 47.0768 | |

| SVR (linear kernel) | 0.9814 | 0.9632 | 1980.1651 | 28.2223 | 44.4990 | 10.7015 | 5.4009 | 212.8222 | |

| SVR (Gaussian kernel) | 0.9979 | 0.9957 | 773.1371 | 13.7086 | 27.8053 | 6.6869 | 3.3470 | 53.4657 | |

| SVR (polynomial kernel) | 0.9649 | 0.9311 | 30,436.9398 | 64.0292 | 174.4619 | 41.9562 | 21.3525 | 346.2543 | |

| Feed-forward NN | 0.9829 | 0.9661 | 1823.3756 | 10.2402 | 42.7010 | 10.2691 | 5.1789 | 209.2889 | |

| MARS (piecewise-linear) | 0.9988 | 0.9975 | 135.7857 | 3.7704 | 11.6527 | 2.8024 | 1.4020 | 84.7990 | |

| MARS (piecewise-cubic) | 0.9984 | 0.9969 | 170.1303 | 3.9005 | 13.0434 | 3.1368 | 1.5696 | 97.9619 | |

| k-NN regression | 0.9994 | 0.9988 | 65.8502 | 0.8771 | 8.1148 | 1.9515 | 0.9761 | 82.5804 | |

| RF | 0.9995 | 0.9990 | 56.2155 | 1.1998 | 7.4977 | 1.8031 | 0.9018 | 50.8717 | |

| FDM | 0.9994 | 0.9987 | 77.0031 | 2.1911 | 8.7751 | 2.0683 | 1.0345 | 23.8051 | |

| SVR (linear kernel) | 0.9842 | 0.9686 | 1513.8770 | 26.1283 | 38.9086 | 9.1709 | 4.6220 | 195.2460 | |

| SVR (Gaussian kernel) | 0.9979 | 0.9958 | 640.3879 | 11.8434 | 25.3059 | 5.9647 | 2.9855 | 47.1678 | |

| SVR (polynomial kernel) | 0.9627 | 0.9268 | 3936.6021 | 29.7861 | 62.7423 | 14.7886 | 7.5349 | 155.9811 | |

| Feed-forward NN | 0.6925 | 0.4796 | 24,952.9029 | 77.2680 | 157.9649 | 37.2330 | 21.9985 | 385.5039 | |

| MARS (piecewise-linear) | 0.9984 | 0.9968 | 157.3074 | 4.1271 | 12.5422 | 2.9563 | 1.4793 | 62.6750 | |

| MARS (piecewise-cubic) | 0.9978 | 0.9956 | 211.9201 | 5.1786 | 14.5575 | 3.4313 | 1.7175 | 77.9930 | |

| k-NN regression | 0.9993 | 0.9987 | 62.7630 | 0.9031 | 7.9223 | 1.8673 | 0.9340 | 81.5399 | |

| RF | 0.9994 | 0.9988 | 58.9727 | 1.2171 | 7.6794 | 1.8101 | 0.9053 | 51.5673 |

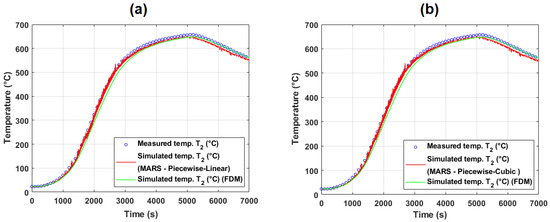

Figure 26 and Figure 27 in the main text, and Figure A1 and Figure A2 in Appendix C, illustrate the predicted inner temperature versus the measured values across different models. These plots highlight the strong predictive capability of FDM, MARS, k-NN, and RF, which closely follow the real temperature profile. In contrast, SVR and neural networks exhibit larger deviations, particularly during rapid heating and cooling phases.

Figure 26.

Measured and simulated temperature using FDM and SVR (operational experiment #2): (a) SVR, linear kernel; (b) SVR, Gaussian kernel; (c) SVR, polynomial kernel.

Figure 27.

Measured and simulated temperature using FDM, k-NN, and RF (operational experiment #2): (a) k-NN; (b) RF.

The examples of mathematical equations for the selected MARS models, including all basis functions, are provided in Appendix B (see Equations (A7) and (A8). These models can be easily implemented in monitoring systems. The outputs from the MARS models are presented in plots (see Figure A2a,b).

5.2.3. Discussion of Model Generalization and Experimental Variability

The comparative analysis of operational experiments #1 and #2 provides valuable insights into the generalization capacity of physics-based and data-driven approaches for modeling inner temperatures during steel coil annealing.

The finite difference method (FDM), a physics-based model grounded in the governing heat transfer equations, consistently exhibits high predictive accuracy across both experiments (see Table 4 and Table 5). It achieved correlation coefficients and relatively low performance index (PI) values (around 1.0), demonstrating robustness to variations in coil dimensions and stacking configurations. This robustness is expected, as FDM inherently accounts for the physical principles and boundary conditions of the annealing process. However, its computational cost and dependency on accurate material parameters and initial/boundary conditions remain notable limitations.

In contrast, machine learning (ML) models showed more variable performance between experiments. In operational experiment #1, ensemble methods like the random forest (RF) and non-parametric algorithms such as k-nearest neighbors (k-NN) achieved excellent results on both training and test datasets, with PI values often below 1.5 and maximum deviations comparable to FDM. The multivariate adaptive regression splines (MARS) models also performed well, achieving and low relative root mean square error (RRMSE) values less than 3%.

However, in operational experiment #2, the performance of some ML models deteriorated, particularly for the prediction of . Neural networks (NNs), which performed moderately on in the same experiment, failed to capture the dynamics of , with and a PI exceeding 21 (see Table A5). Similarly, support vector regression (SVR) with polynomial kernels exhibited poor generalization, producing large errors and significant deviations during heating and cooling phases (Figure 26). This behavior suggests a tendency for overfitting in the presence of complex or insufficiently diverse training data.

Several factors may explain the observed variability:

- Differences in experimental conditions: The two experiments featured distinct coil geometries, stacking configurations (four coils in experiment #1 vs. three in experiment #2), and convective ring placements, which likely altered heat transfer patterns within the stacks. Since ML models learn from data patterns rather than physical laws, they may struggle to extrapolate beyond the training domain if these operational variations are not adequately represented in the training set.

- Limited number of input observations: Compared to laboratory experiments, operational measurements included fewer surface thermocouples. The reduced spatial resolution of inputs could limit the ML models’ ability to infer the thermal behavior deep within the coil stack, particularly for internal thermocouples such as .

- Dataset imbalance and covariate shift: The training datasets were derived from specific annealing cycles. If the test dataset exhibits different dynamics or operating regimes (e.g., heating/cooling rates, atmospheric control), data-driven models may encounter covariate shift, leading to degraded predictive performance.

These findings emphasize that while ML models can achieve excellent accuracy in well-represented training domains, their generalization is not guaranteed under different operational conditions. Physics-based models, such as FDM, although computationally demanding, provide a reliable baseline and are less sensitive to such variability.

To mitigate these issues, several strategies could be explored in future work:

- Hybrid modeling approaches, combining physics-based models with ML techniques (e.g., physics-informed neural networks or residual learning), to integrate domain knowledge with data-driven flexibility.

- Data augmentation and inclusion of synthetic datasets generated by physical simulations to enrich the diversity of ML training data and improve extrapolation capabilities.

- Feature engineering, incorporating additional process parameters (e.g., coil weight, convective ring properties, or atmosphere flow rates) as inputs to the ML models.

- Cross-validation across different operational datasets to systematically assess model robustness and reduce overfitting.

Overall, these experiments highlight the complementary strengths of physics-based and data-driven approaches. While FDM ensures reliability under varying conditions, ML methods excel in speed and adaptability when trained on sufficiently representative data. The integration of these paradigms holds significant promise for robust and efficient temperature prediction in industrial annealing processes.

5.3. Discussion on Laboratory and Operational Measurements

The combined evaluation of laboratory and operational measurements provides critical insights into the strengths and limitations of both physics-based and machine learning (ML) models. Laboratory experiments, conducted under controlled conditions, enabled the dense placement of thermocouples and the fine-grained measurement of boundary and internal temperatures. This setup facilitated the precise calibration and validation of the finite difference model (FDM), enabling the accurate simulation of heat transfer dynamics. However, in operational experiments, the number of available surface measurements was limited due to practical constraints, such as coil stacking and the configuration of the industrial furnace.