Joining Ti6Al4V to Alumina by Diffusion Bonding Using Titanium Interlayers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Base Materials

2.2. Titanium Interlayer

2.3. Adhesion

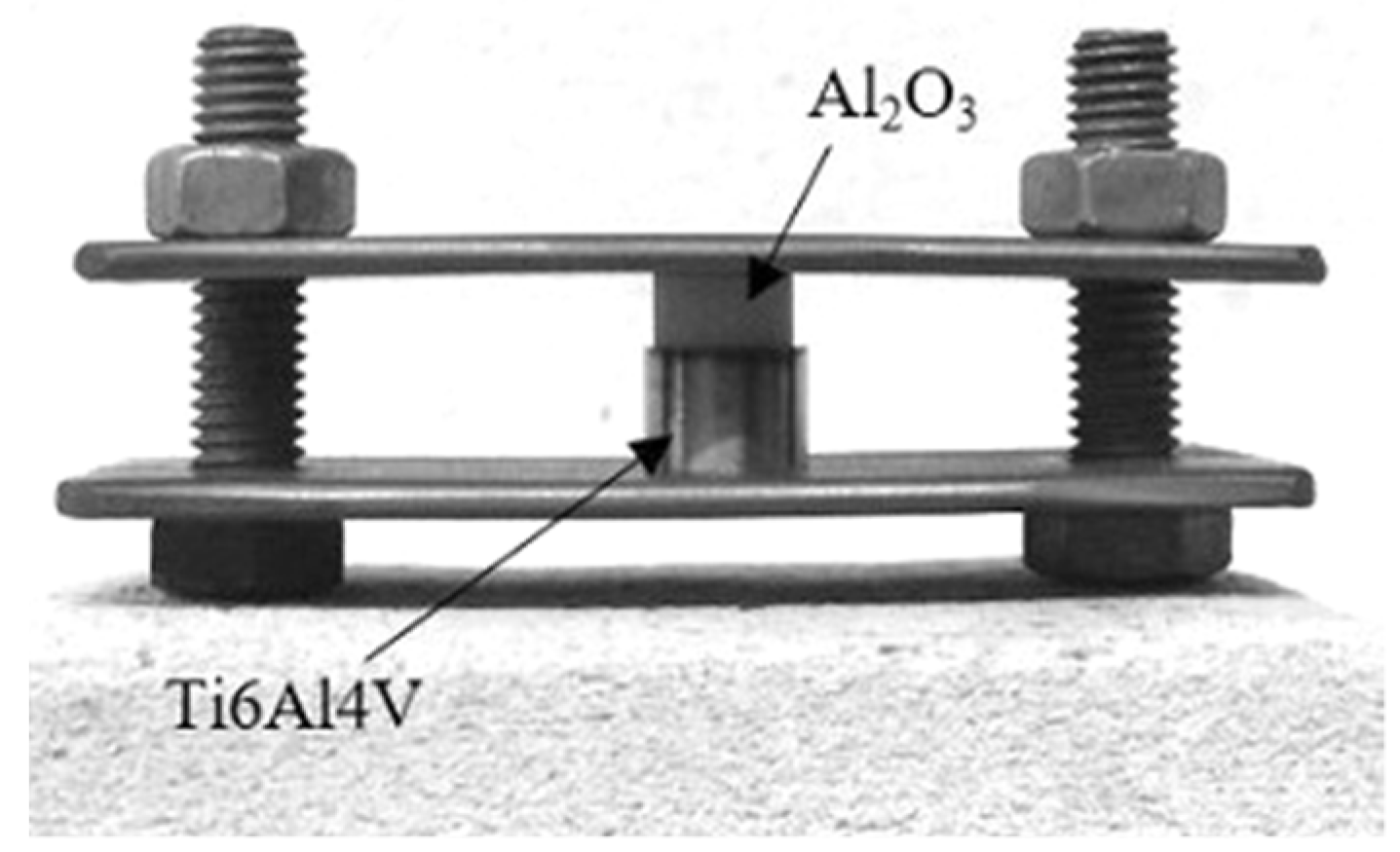

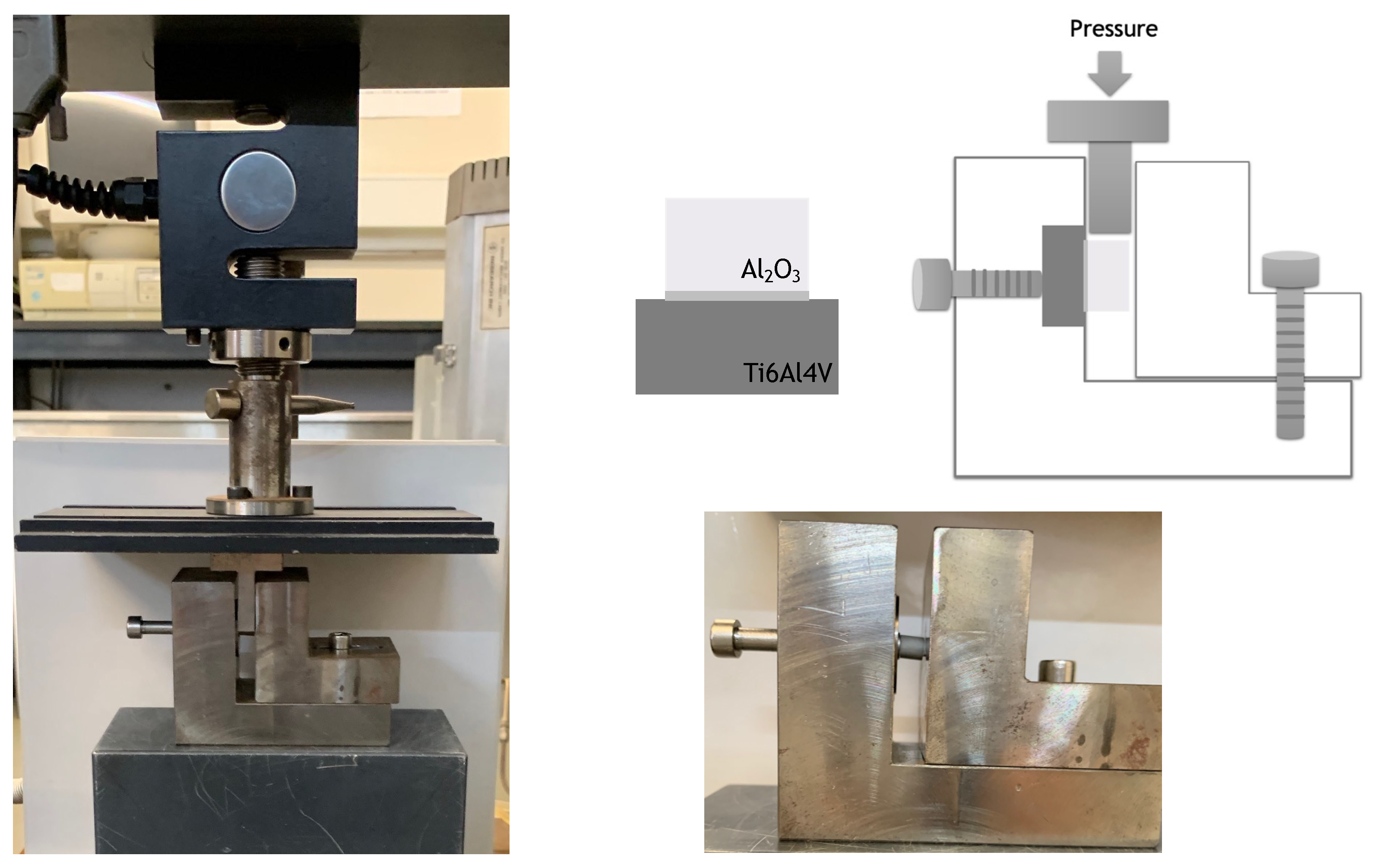

2.4. Diffusion Bonding

2.5. Microstructural Characterization

2.6. Mechanical Characterization

3. Results and Discussion

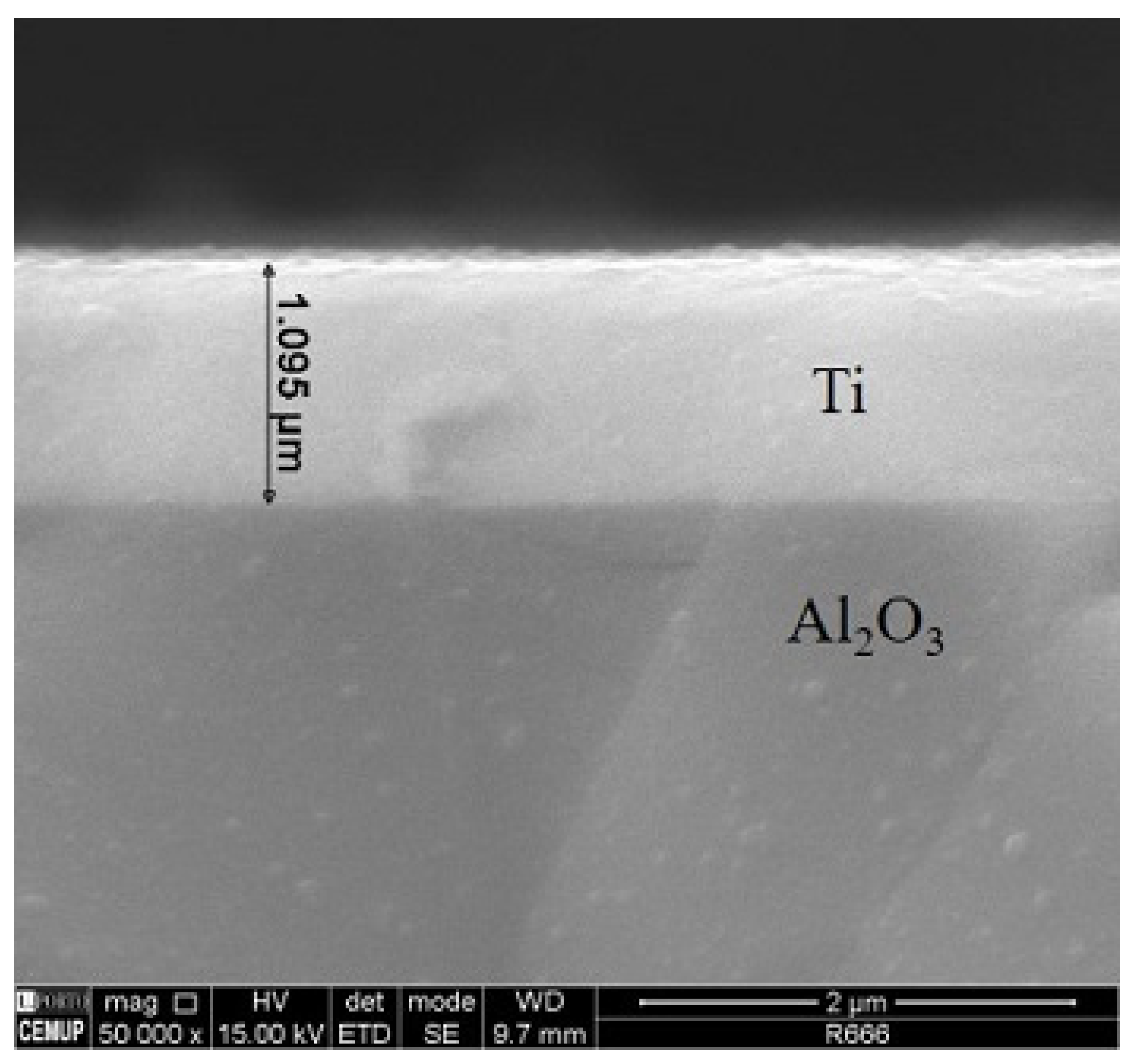

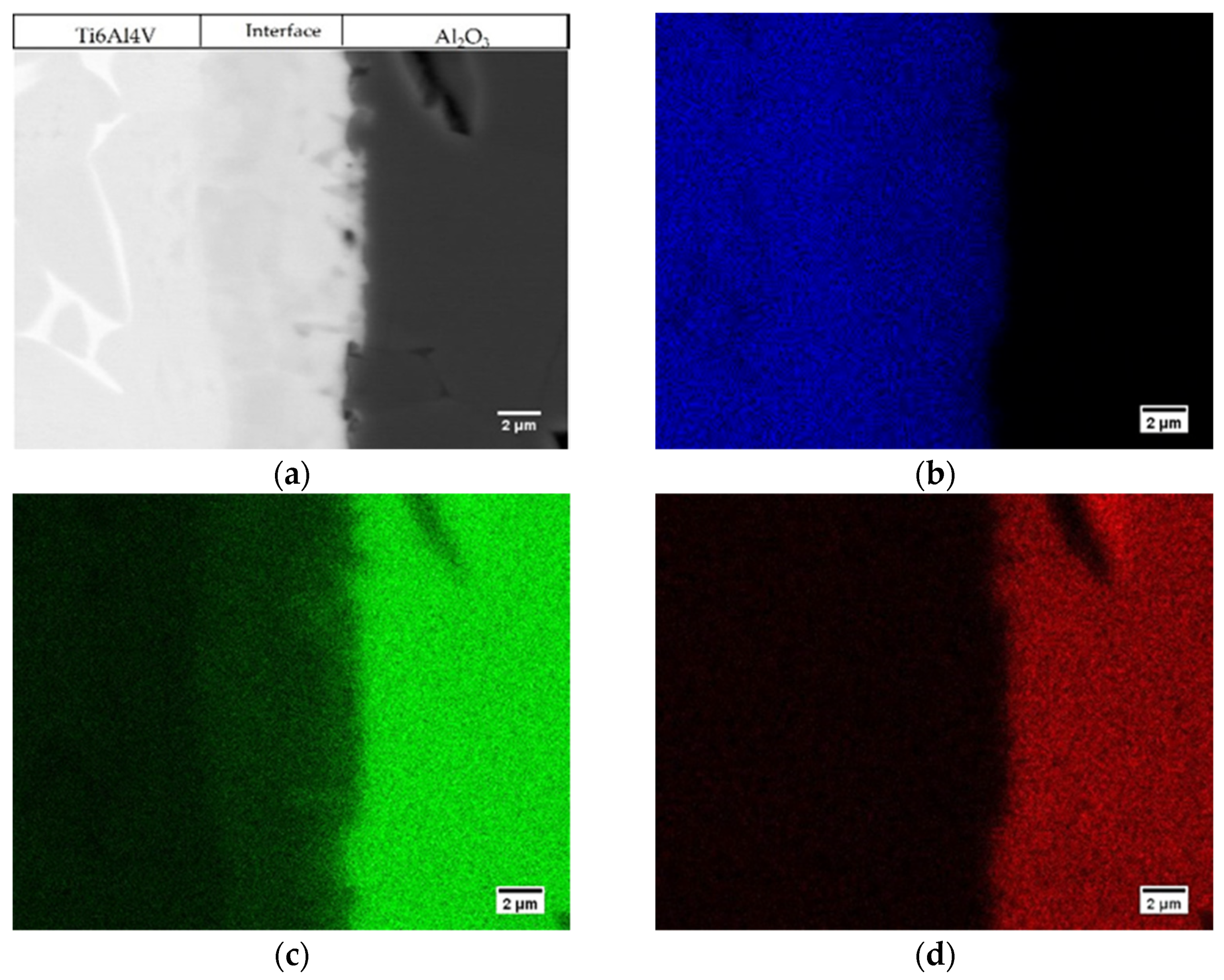

3.1. Ti Thin Films Deposited onto Al2O3

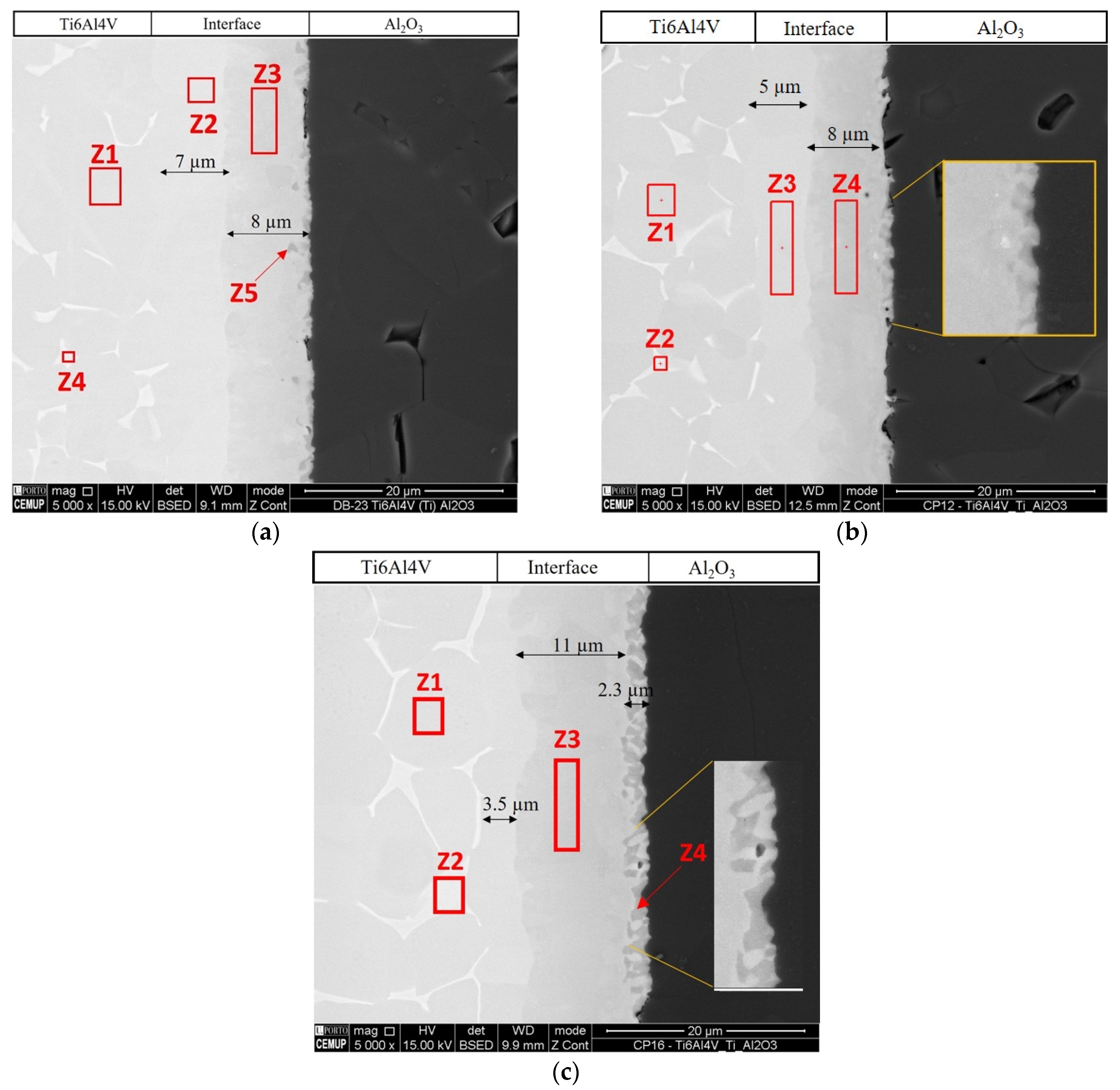

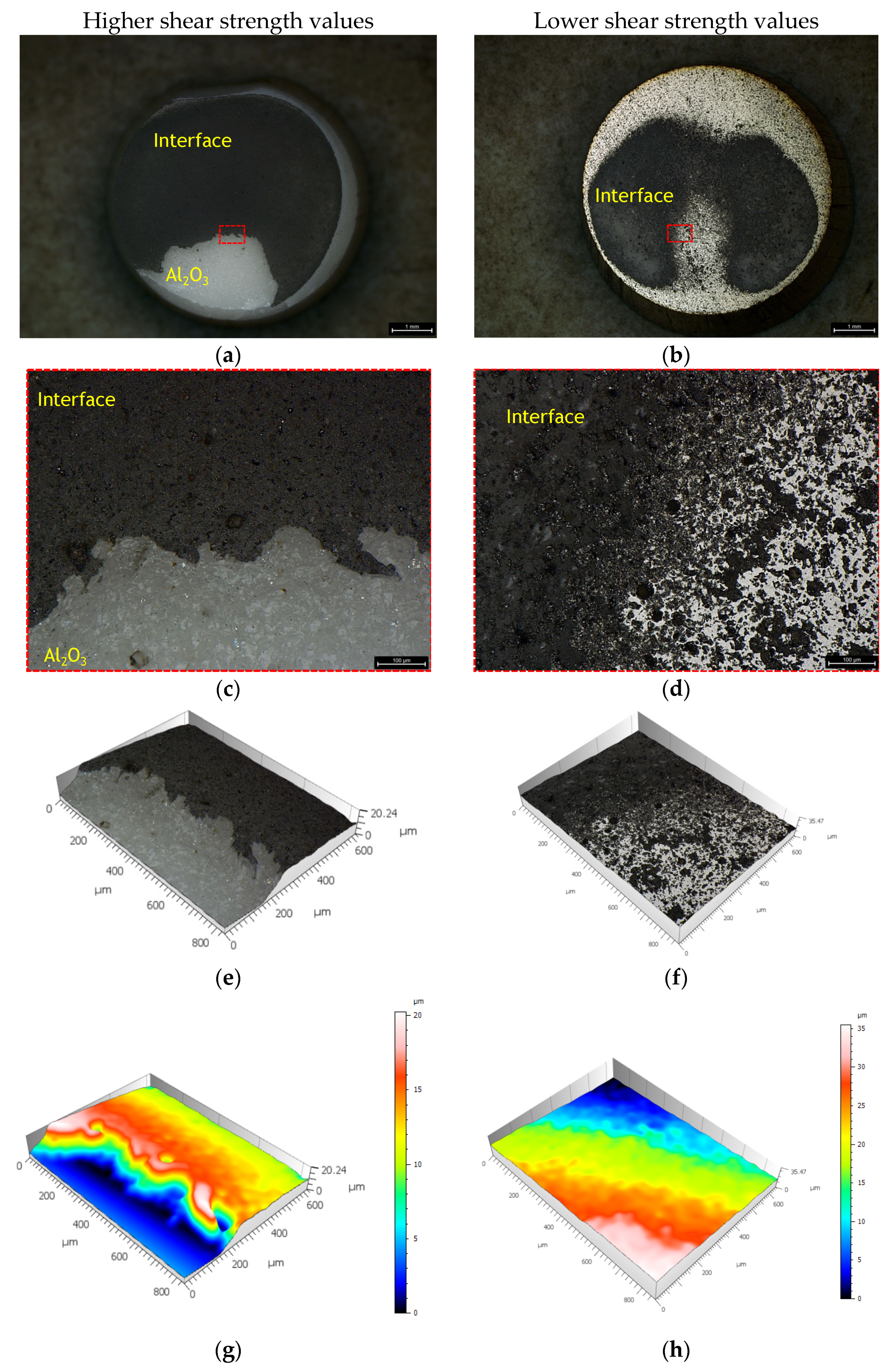

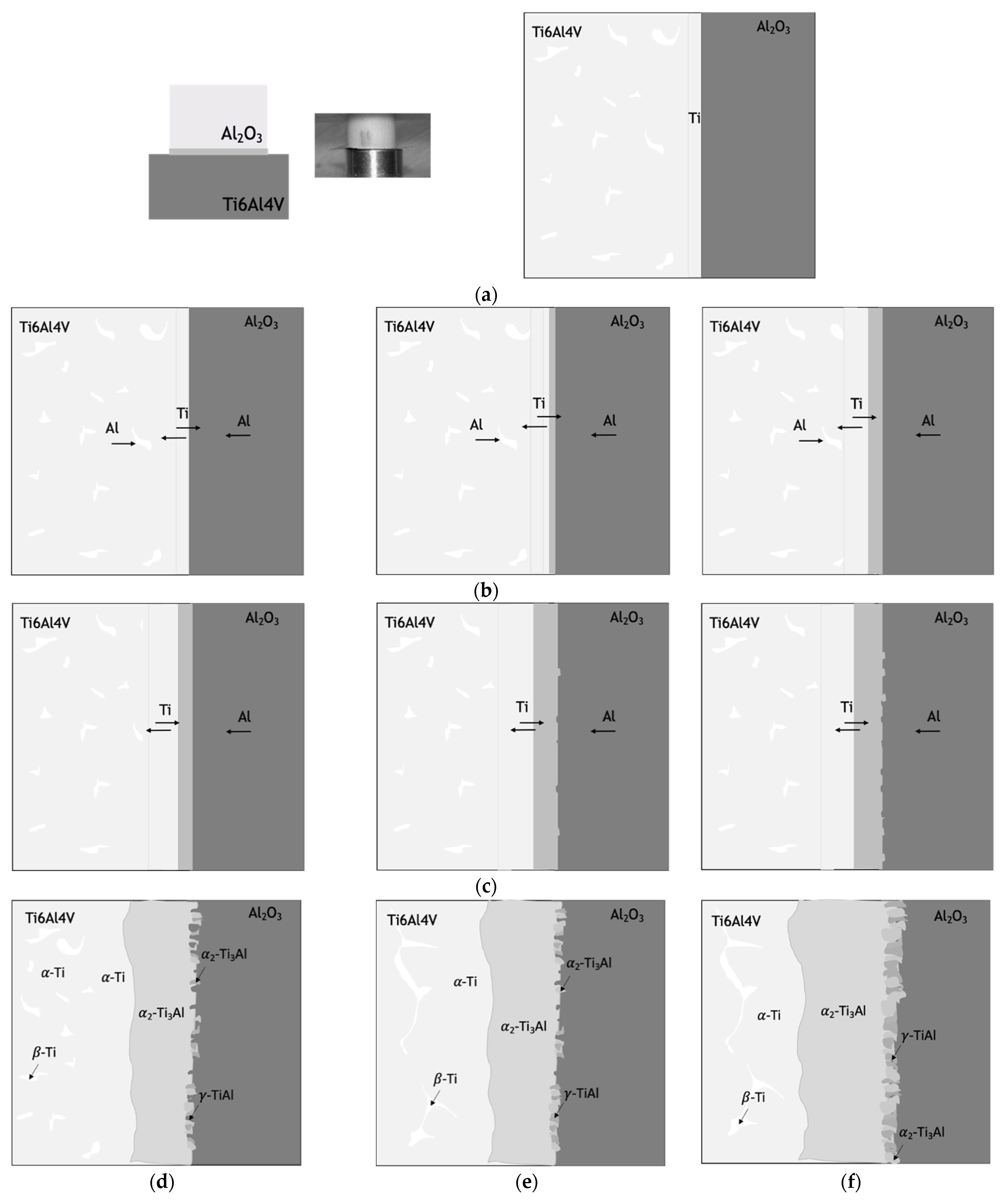

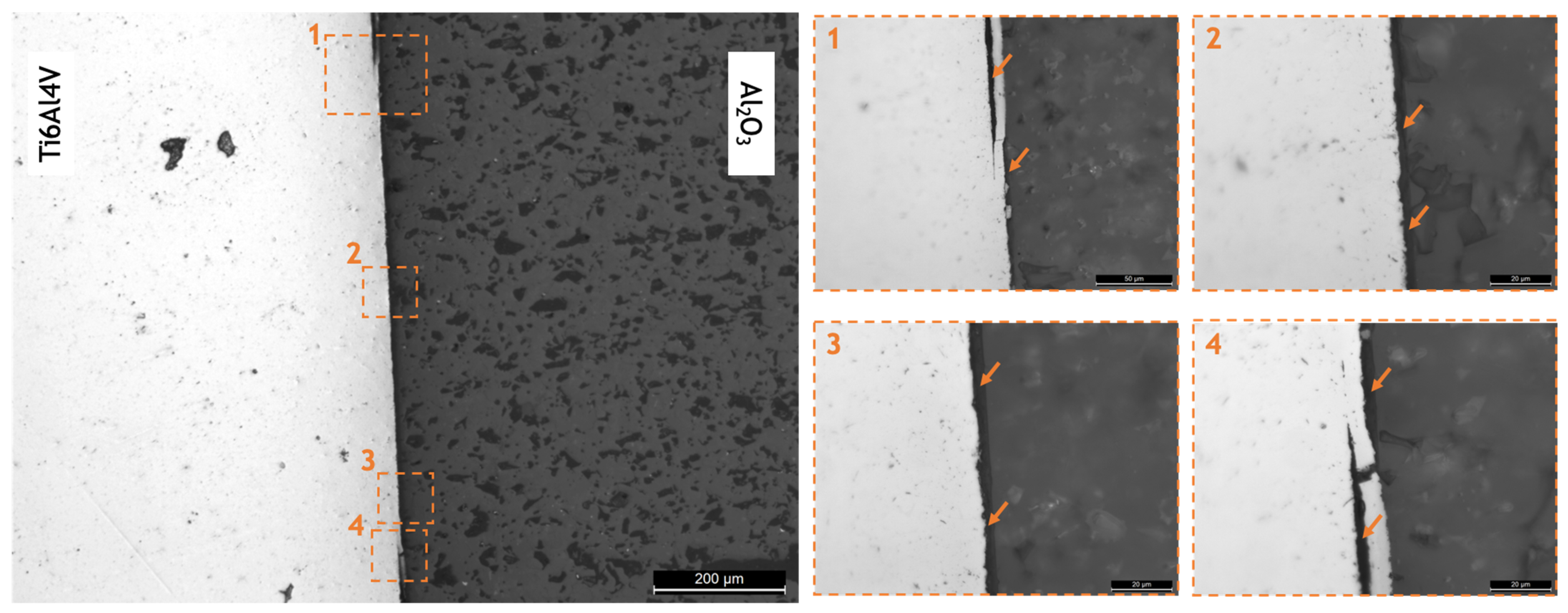

3.2. Diffusion Bonding without Interlayer

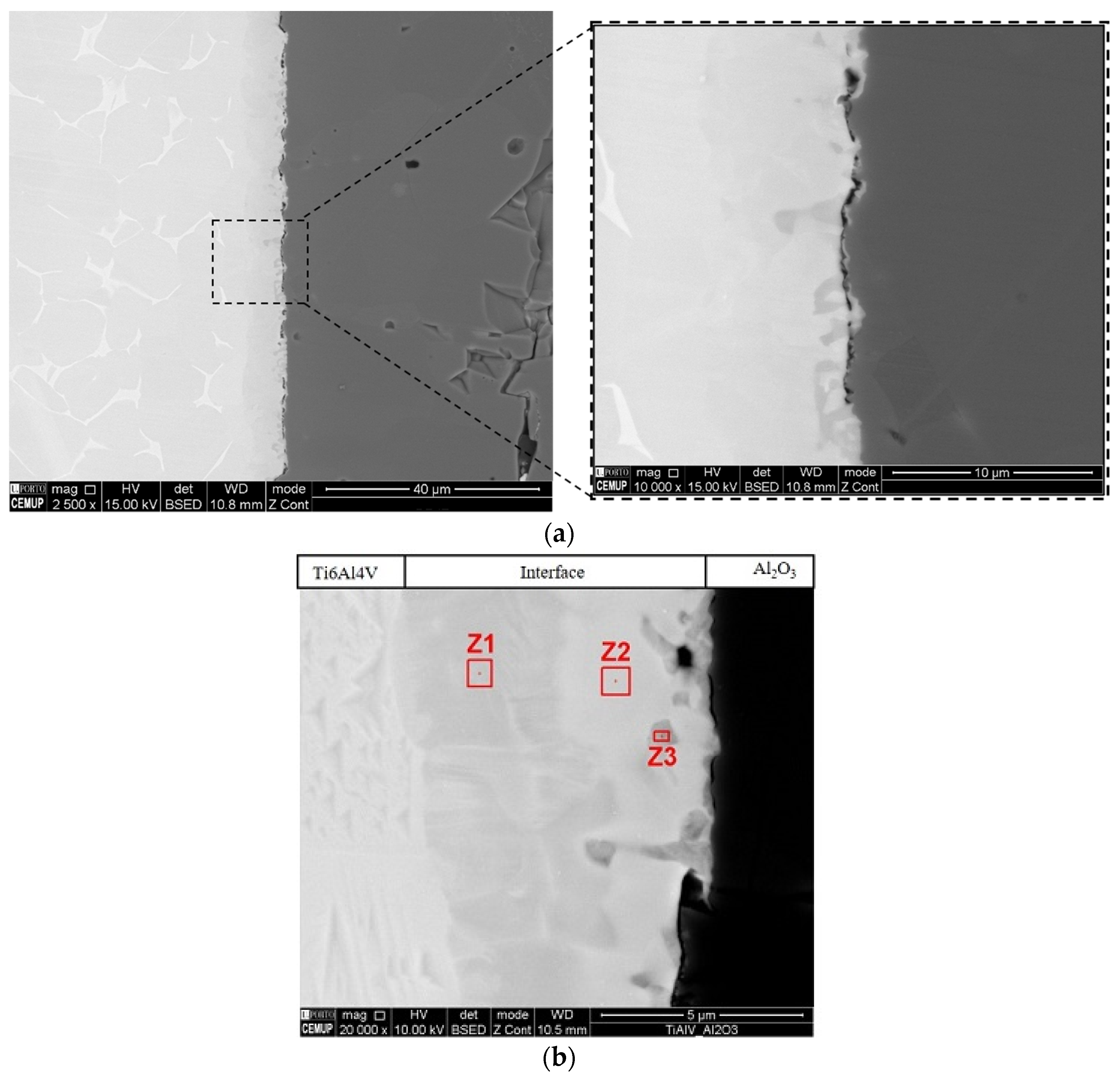

3.3. Diffusion Bonding Using Ti Thin Films Deposited onto Al2O3

3.4. Diffusion Bonding with Freestanding Ti Thin Foils

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Titanium and Titanium Alloys; Leyens, C.; Peters, M. (Eds.) Wiley: Hoboken, NJ, USA, 2003; ISBN 9783527305346. [Google Scholar]

- Carter, C.B.; Norton, M.G. Ceramic Materials; Springer: New York, NY, USA, 2007; ISBN 978-0-387-46270-7. [Google Scholar]

- Simões, S. Recent Progress in the Joining of Titanium Alloys to Ceramics. Metals 2018, 8, 876. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Ma, Y.; Xu, B.; Bridges, D.; Zhang, L.; Feng, Z.; Hu, A. Laser welding of Ti6Al4V assisted with nanostructured Ni/Al reactive multilayer films. Mater. Des. 2019, 181, 108097. [Google Scholar] [CrossRef]

- Kaneko, A.; Katayama, T.; Morishita, S. Micro Fabrication of Au Thin-Film by Transfer-Printing Using Atomic Diffusion Bonding. Int. J. Autom. Technol. 2019, 13, 810–816. [Google Scholar] [CrossRef]

- Cazajus, V.; Seguy, S.; Welemane, H.; Karama, M. Residual Stresses in a Ceramic-Metal Composite. Appl. Mech. Mater. 2012, 146, 185–196. [Google Scholar] [CrossRef] [Green Version]

- Shi, G.; Zhang, L.; Wang, Z. Modelling the Elements Reaction–Diffusion Behavior on Interface of Ti/Al2O3 Composite Prepared by Hot Pressing Sintering. Metals 2020, 10, 259. [Google Scholar] [CrossRef] [Green Version]

- Misra, A.K. Reaction of Ti and Ti-Al alloys with alumina. Met. Mater. Trans. A 1991, 22, 715–721. [Google Scholar] [CrossRef]

- Lu, Y.-C.; Sass, S.; Bai, Q.; Kohlstedt, D.; Gerberich, W. The influence of interfacial reactions on the fracture toughness of Ti-Al2O3 interfaces. Acta Met. Mater. 1995, 43, 31–41. [Google Scholar] [CrossRef]

- Yu, W.; Zhao, H.; Huang, Z.; Chen, X.; Aman, Y.; Li, S.; Zhai, H.; Guo, Z.; Xiong, S. Microstructure evolution and bonding mechanism of Ti2SnC-Ti6Al4V joint by using Cu pure foil interlayer. Mater. Charact. 2017, 127, 53–59. [Google Scholar] [CrossRef] [Green Version]

- Loh, N.L.; Wu, Y.L. Diffusion bonding of ceramic to metals. Mater. Manuf. Proc. 1993, 8, 159–181. [Google Scholar] [CrossRef]

- Nicholas, M.G.; Crispin, R.M. Diffusion bonding stainless steel to alumina using aluminium interlayers. J. Mater. Sci. 1982, 17, 3347–3360. [Google Scholar] [CrossRef]

- Yin, X.; Li, M.; Zhou, Y. Microstructure and mechanical strength of diffusion-bonded Ti3SiC2/Ni joints. J. Mater. Res. 2006, 21, 2415–2421. [Google Scholar] [CrossRef]

- Hattali, M.; Valette, S.; Ropital, F.; Mesrati, N.; Tréheux, D. Interfacial behavior on Al2O3/HAYNES® 214™ joints fabricated by solid state bonding technique with Ni or Cu–Ni–Cu interlayers. J. Eur. Ceram. Soc. 2012, 32, 2253–2265. [Google Scholar] [CrossRef]

- Uday, M.B.; Ahmad-Fauzi, M.N.; Noor, A.M.; Rajoo, S. Current Issues and Problems in the Joining of Ceramic to Metal. In Joining Technologies; Ishak, M., Ed.; InTech: Rijeka, Croatia, 2016; Chapter 8. [Google Scholar]

- Elssner, G.; Petzow, G. Metal/ceramic joining. ISIJ Int. 1990, 30, 1011–1032. [Google Scholar] [CrossRef]

- Zhang, Y.; Feng, D.; He, Z.-Y.; Chen, X.-C. Progress in Joining Ceramics to Metals. J. Iron Steel Res. Int. 2006, 13, 1–5. [Google Scholar] [CrossRef]

- Yang, Z.; Lin, J.; Wang, Y.; Wang, D. Characterization of microstructure and mechanical properties of Al2O3/TiAl joints vacuum-brazed with Ag-Cu-Ti + W composite filler. Vacuum 2017, 143, 294–302. [Google Scholar] [CrossRef]

- Cao, J.; Zheng, Z.; Wu, L.; Qi, J.; Wang, Z.; Feng, J. Processing, microstructure and mechanical properties of vacuum-brazed Al2O3/Ti6Al4V joints. Mater. Sci. Eng. A 2012, 535, 62–67. [Google Scholar] [CrossRef]

- Niu, G.; Wang, D.; Yang, Z.; Wang, Y. Microstructure and mechanical properties of Al2O3/TiAl joints brazed with B powders reinforced Ag-Cu-Ti based composite fillers. Ceram. Int. 2017, 43, 439–450. [Google Scholar] [CrossRef]

- Xue, H.; Wei, X.; Guo, W.; Zhang, X. Bonding mechanism study of active Ti element and α-Al2O3 by using first-principle calculation. J. Alloys Compd. 2020, 820, 153070. [Google Scholar] [CrossRef]

- Qiu, Q.; Wang, Y.; Yang, Z.; Wang, D. Microstructure and mechanical properties of Al2O3 ceramic and Ti6Al4V alloy joint brazed with inactive Ag–Cu and Ag–Cu + B. J. Eur. Ceram. Soc. 2016, 36, 2067–2074. [Google Scholar] [CrossRef]

- Wang, Z.M.; Yang, J.H.; Qi, F.Q.; Hou, A.L.; Yang, Z.W.; Wang, Y.; Wang, D.P. Interfacial characterization and mechanical properties of reactive air brazed ZrO2 ceramic joints with Ag-CuO-Al2TiO5 composite filler metal. Ceram. Int. 2021, 47, 29128–29138. [Google Scholar] [CrossRef]

- Xin, C.; Yan, J.; Li, N.; Liu, W.; Du, J.; Cao, Y.; Shi, H. Microstructural evolution during the brazing of Al2O3 ceramic to kovar alloy by sputtering Ti/Mo films on the ceramic surface. Ceram. Int. 2016, 42, 12586–12593. [Google Scholar] [CrossRef]

- Dai, X.; Cao, J.; Liu, J.; Wang, D.; Feng, J. Interfacial reaction behavior and mechanical characterization of ZrO2/TC4 joint brazed by Ag–Cu filler metal. Mater. Sci. Eng. A 2015, 646, 182–189. [Google Scholar] [CrossRef]

- Barbier, F.; Peytour, C.; Revcolevschi, A. Microstructural Study of the Brazed Joint between Alumina and Ti-6AI-4V Alloy. J. Am. Ceram. Soc. 1990, 73, 1582–1586. [Google Scholar] [CrossRef]

- Emadinia, O.; Guedes, A.; Tavares, C.; Simões, S. Joining Alumina to Titanium Alloys Using Ag-Cu Sputter-Coated Ti Brazing Filler. Materials 2020, 13, 4802. [Google Scholar] [CrossRef]

- Peytour, C.; Barbier, F.; Revcolevschi, A. Characterization of ceramic/TA6V titanium alloy brazed joints. J. Mater. Res. 1990, 5, 127–135. [Google Scholar] [CrossRef]

- Mishra, S.; Sharma, A.; Jung, D.H.; Jung, J.P. Recent Advances in Active Metal Brazing of Ceramics and Process. Met. Mater. Int. 2019, 26, 1087–1098. [Google Scholar] [CrossRef]

- Akselsen, O.M. Diffusion bonding of ceramics. J. Mater. Sci. 1992, 27, 569–579. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M.T. Microstructural Characterization of Dissimilar Titanium Alloys Joints Using Ni/Al Nanolayers. Metals 2018, 8, 715. [Google Scholar] [CrossRef] [Green Version]

- Simões, S.; Viana, F.; Ramos, A.S.; Vieira, M. Diffusion Bonding of TiAl to Ti6Al4V Using Nanolayers. J. Mater. Eng. Perform. 2018, 27, 5064–5068. [Google Scholar] [CrossRef]

- Simões, S.; Viana, F.; Koçak, M.; Ramos, A.S.; Vieira, M. Diffusion bonding of TiAl using reactive Ni/Al nanolayers and Ti and Ni foils. Mater. Chem. Phys. 2011, 128, 202–207. [Google Scholar] [CrossRef]

- Aucott, L.; Bamber, R.; Lunev, A.; Darby, T.; Maquet, P.; Gimbert, N.; Pak, S.; Walsh, M.; Udintsev, V.; Eaton, G.; et al. Solid-State Diffusion Bonding of Glass-Metal for the International Thermonuclear Experimental Reactor (ITER) Diagnostic Windows. In TMS 2020 149th Annual Meeting & Exhibition Supplemental Proceedings; Springer International Publishing: Cham, Switzerland, 2020; pp. 2085–2094. [Google Scholar]

- Cavaleiro, A.; Ramos, A.; Fernandes, F.B.; Schell, N.; Vieira, M. Follow-up structural evolution of Ni/Ti reactive nano and microlayers during diffusion bonding of NiTi to Ti6Al4V in a synchrotron beamline. J. Mater. Process. Technol. 2020, 275, 116354. [Google Scholar] [CrossRef]

- Weiqi, Y.; Jincheng, L.; Run, A.; Lili, X. High shear strength and ductile ZrC–SiC/austenitic stainless steel joints bonded with Ti/Ni foam interlayer. Ceram. Int. 2020, 46, 3036–3042. [Google Scholar] [CrossRef]

- Niu, J.B.; Wang, Y.; Yang, Z.W.; Wang, D.P. Microstructure and Mechanical Properties of Titanium–Zirconium–Molybdenum and Ti2AlNb Joint Diffusion Bonded with and without a Ni Interlayer. Adv. Eng. Mater. 2019, 21, 1900713. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, G.-Q.; Wang, K.; Fu, X.-S.; Zhou, W.-L. Microstructural evolution and growth kinetics of interfacial compounds in TiAl/Ti3SiC2 diffusion bonding joints. Mater. Sci. Eng. A 2019, 756, 149–155. [Google Scholar] [CrossRef]

- Zhang, Y.; Chen, Y.; Yu, D.; Sun, D.; Li, H. A review paper on effect of the welding process of ceramics and metals. J. Mater. Res. Technol. 2020, 9, 16214–16236. [Google Scholar] [CrossRef]

- Barrena, M.; Matesanz, L.; de Salazar, J.G. Al2O3/Ti6Al4V diffusion bonding joints using Ag–Cu interlayer. Mater. Charact. 2009, 60, 1263–1267. [Google Scholar] [CrossRef]

- Kliauga, A.; Ferrante, M. Interface compounds formed during the diffusion bonding of Al2O3 to Ti. J. Mater. Sci. 2000, 35, 4243–4249. [Google Scholar] [CrossRef]

- Travessa, D.; Ferrante, M. The Al2O3-t itanium adhesion in the view of the diffusion bonding process. J. Mater. Sci. 2002, 37, 4385–4390. [Google Scholar] [CrossRef]

- Rocha, L.; Ariza, E.; Costa, A.M.; Oliveira, F.J.; Silva, R.F. Electrochemical behavior of Ti/Al2O3 interfaces produced by diffusion bonding. Mater. Res. 2003, 6, 439–444. [Google Scholar] [CrossRef] [Green Version]

- Heikinheimo, L.S.K.; De With, G. Interface Structure and Fracture Energy of Al2O3-Ti Joints: Dissertation; VTT Technical Research Centre of Finland: Espoo, Finland, 1995. [Google Scholar]

- Lim, J.D.; Lee, P.M.; Chen, Z. Understanding the bonding mechanisms of directly sputtered copper thin film on an alumina substrate. Thin Solid Film. 2017, 634, 6–14. [Google Scholar] [CrossRef]

- Silva, M.; Ramos, A.; Vieira, M.; Simões, S. Diffusion Bonding of Ti6Al4V to Al2O3 Using Ni/Ti Reactive Multilayers. Metals 2021, 11, 655. [Google Scholar] [CrossRef]

- Oliver, W.; Pharr, G. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Lim, J.D.; Lee, P.M.; Rhee, D.M.W.; Leong, K.C.; Chen, Z. Effect of surface treatment on adhesion strength between magnetron sputtered copper thin films and alumina substrate. Appl. Surf. Sci. 2015, 355, 509–515. [Google Scholar] [CrossRef]

- Hayes, F.H. The Al-Ti-V (aluminum-titanium-vanadium) system. J. Phase Equilibria Diffus. 1995, 16, 163–176. [Google Scholar] [CrossRef]

- Zhu, S.; Włosiński, W. Joining of AlN ceramic to metals using sputtered Al or Ti film. J. Mater. Process. Technol. 2001, 109, 277–282. [Google Scholar] [CrossRef]

- Valenza, F.; Artini, C.; Passerone, A.; Cirillo, P.; Muolo, M.L. Joining of ZrB2 Ceramics to Ti6Al4V by Ni-Based Interlayers. J. Mater. Eng. Perform. 2014, 23, 1555–1560. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, G. Properties and Interface Structures of Ni and Ni-Ti Alloy Toughened A12O3 Ceramic Composites. J. Eur. Ceram. Soc. 1994, 15, 225–232. [Google Scholar] [CrossRef] [Green Version]

- Lu, Y.; Zhu, M.; Zhang, Q.; Hu, T.; Wang, J.; Zheng, K. Microstructure evolution and bonding strength of the Al2O3/Al2O3 interface brazed via Ni-Ti intermetallic phases. J. Eur. Ceram. Soc. 2020, 40, 1496–1504. [Google Scholar] [CrossRef]

- Yi, J.; Zhang, Y.; Wang, X.; Dong, C.; Hu, H. Characterization of Al/Ti Nano Multilayer as a Jointing Material at the Interface between Cu and Al2O3. Mater. Trans. 2016, 57, 1494–1497. [Google Scholar] [CrossRef] [Green Version]

- Gietzelt, T.; Toth, V.; Huell, A. Diffusion Bonding: Influence of Process Parameters and Material Microstructure. In Joining Technologies; Intech Open Publishers: London, UK, 2016; pp. 195–216. [Google Scholar] [CrossRef] [Green Version]

| Conditions | Zone | Element (at.%) | Possible Phases | ||

|---|---|---|---|---|---|

| Ti | Al | V | |||

| 950 °C/60 min | 1 | 88.5 | 10.3 | 1.2 | α-Ti |

| 2 | 88.3 | 10.3 | 1.5 | α-Ti | |

| 3 | 76.5 | 22.5 | 1.0 | α2-Ti3Al | |

| 4 | 80.3 | 6.7 | 13.0 | β-Ti | |

| 5 | 65.1 | 33.7 | 1.2 | α2-Ti3Al + γ-TiAl | |

| 1000 °C/10 min | 1 | 86.8 | 11.6 | 1.6 | α-Ti |

| 2 | 73.3 | 19.7 | 7.0 | β-Ti | |

| 3 | 86.0 | 11.9 | 2.1 | α-Ti | |

| 4 | 75.0 | 25.0 | * | α2-Ti3Al | |

| 1000 °C/60 min | 1 | 88.3 | 11.7 | * | α-Ti |

| 2 | 77.1 | 6.9 | 16.0 | β-Ti | |

| 3 | 74.5 | 25.5 | * | α2-Ti3Al | |

| 4 | 57.6 | 42.4 | * | α2-Ti3Al + γ-TiAl | |

| Joint Processing Conditions | Interlayers | Shear Strength (MPa) |

|---|---|---|

| 1000 °C for 60 min | without | 66 |

| 54 | ||

| 38 | ||

| 1000 °C for 60 min | Ti thin film | 77 |

| 41 | ||

| 27 | ||

| 950 °C for 60 min | Ti thin film | 43 1 |

| 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Silva, M., Jr.; Ramos, A.S.; Simões, S. Joining Ti6Al4V to Alumina by Diffusion Bonding Using Titanium Interlayers. Metals 2021, 11, 1728. https://doi.org/10.3390/met11111728

Silva M Jr., Ramos AS, Simões S. Joining Ti6Al4V to Alumina by Diffusion Bonding Using Titanium Interlayers. Metals. 2021; 11(11):1728. https://doi.org/10.3390/met11111728

Chicago/Turabian StyleSilva, Marcionilo, Jr., Ana S. Ramos, and Sónia Simões. 2021. "Joining Ti6Al4V to Alumina by Diffusion Bonding Using Titanium Interlayers" Metals 11, no. 11: 1728. https://doi.org/10.3390/met11111728

APA StyleSilva, M., Jr., Ramos, A. S., & Simões, S. (2021). Joining Ti6Al4V to Alumina by Diffusion Bonding Using Titanium Interlayers. Metals, 11(11), 1728. https://doi.org/10.3390/met11111728