Effect of Tool Pin Geometry on the Microhardness and Surface Roughness of Friction Stir Processed Recycled AA 6063

Abstract

:1. Introduction

2. Materials and Methods

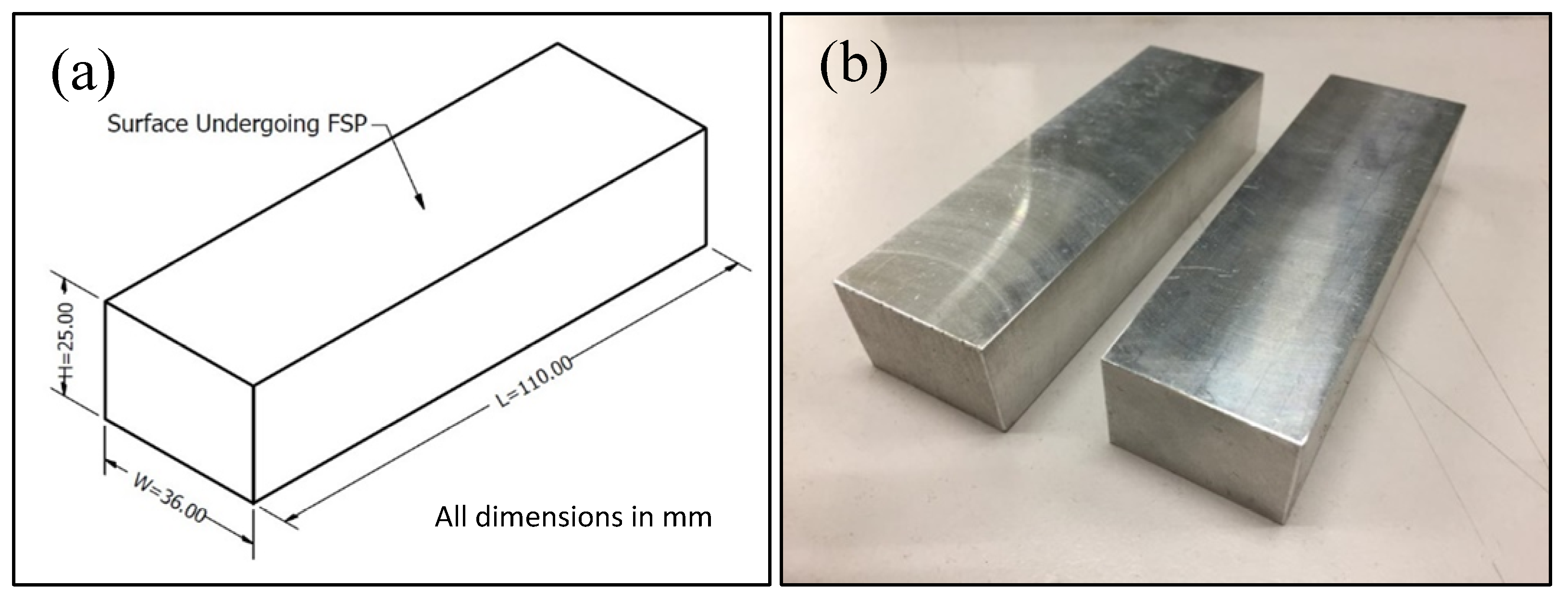

2.1. Substrate Material

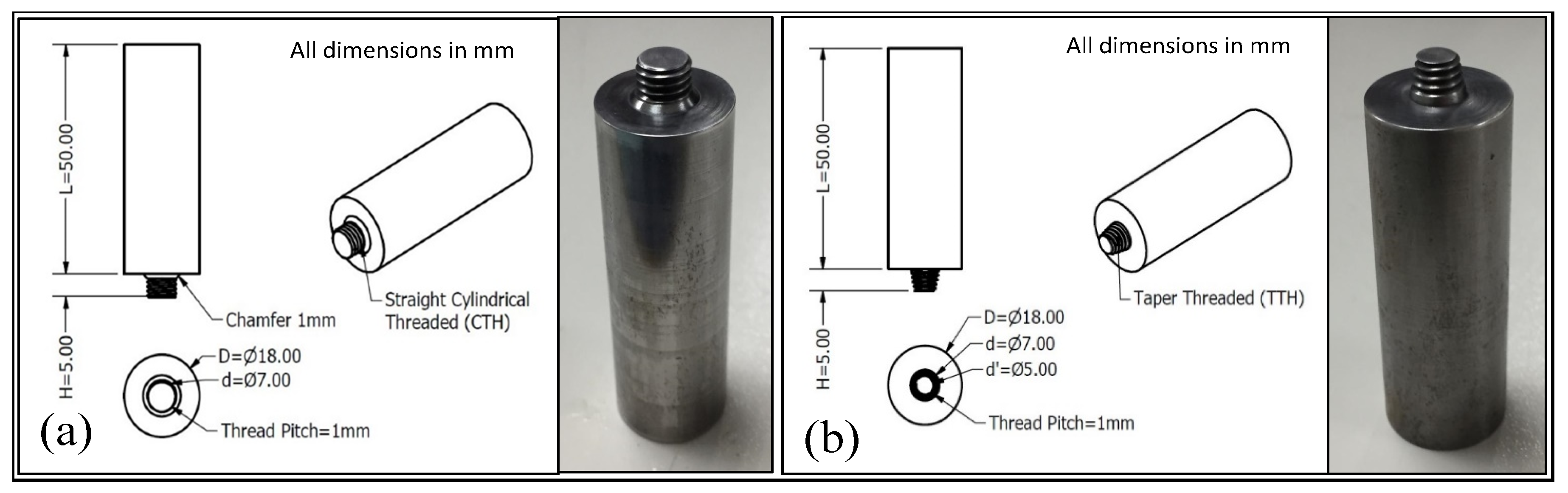

2.2. FSP Tool Design and Set-Up

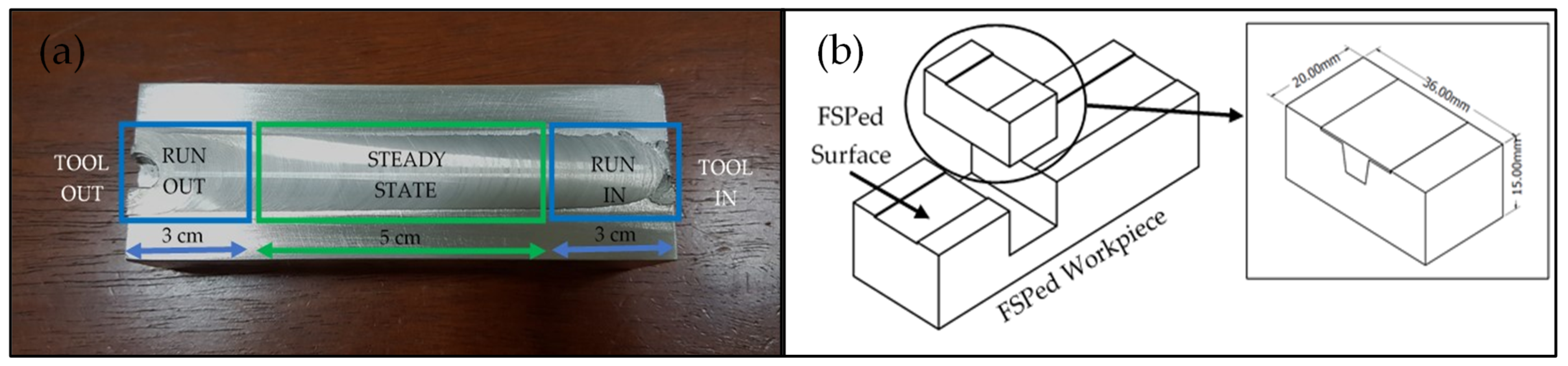

2.3. FSPed Samples Preparation

2.4. Microhardness and Microstructure Analysis

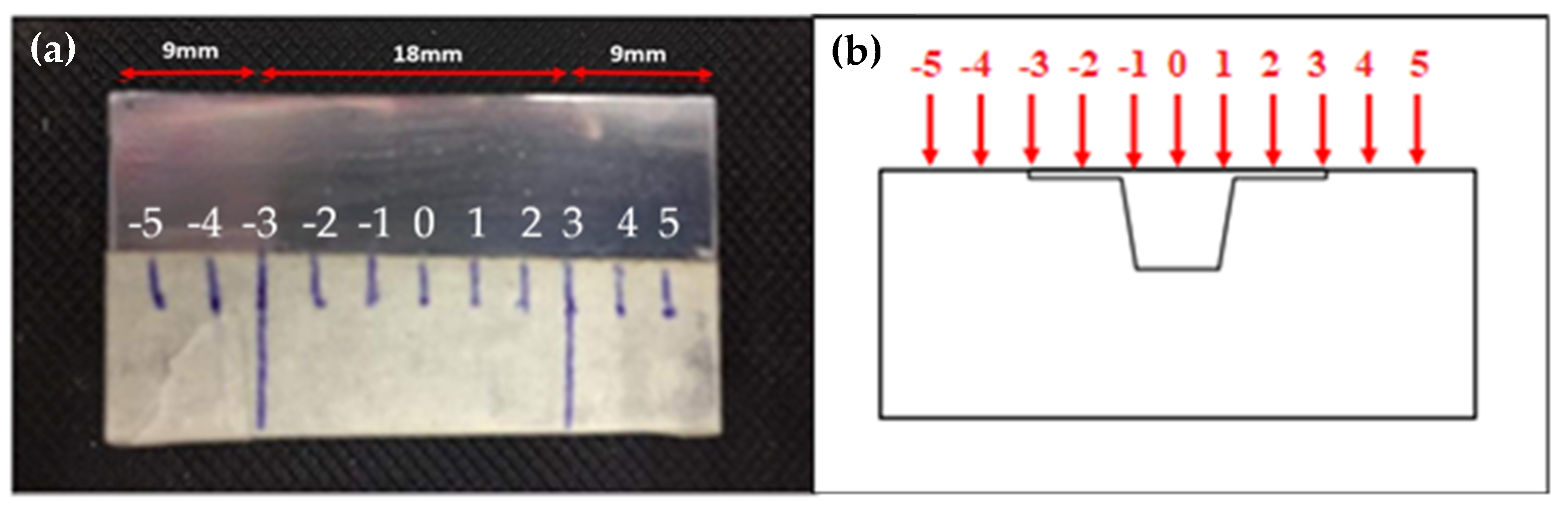

2.5. Surface Roughness Measurement

3. Results and Discussion

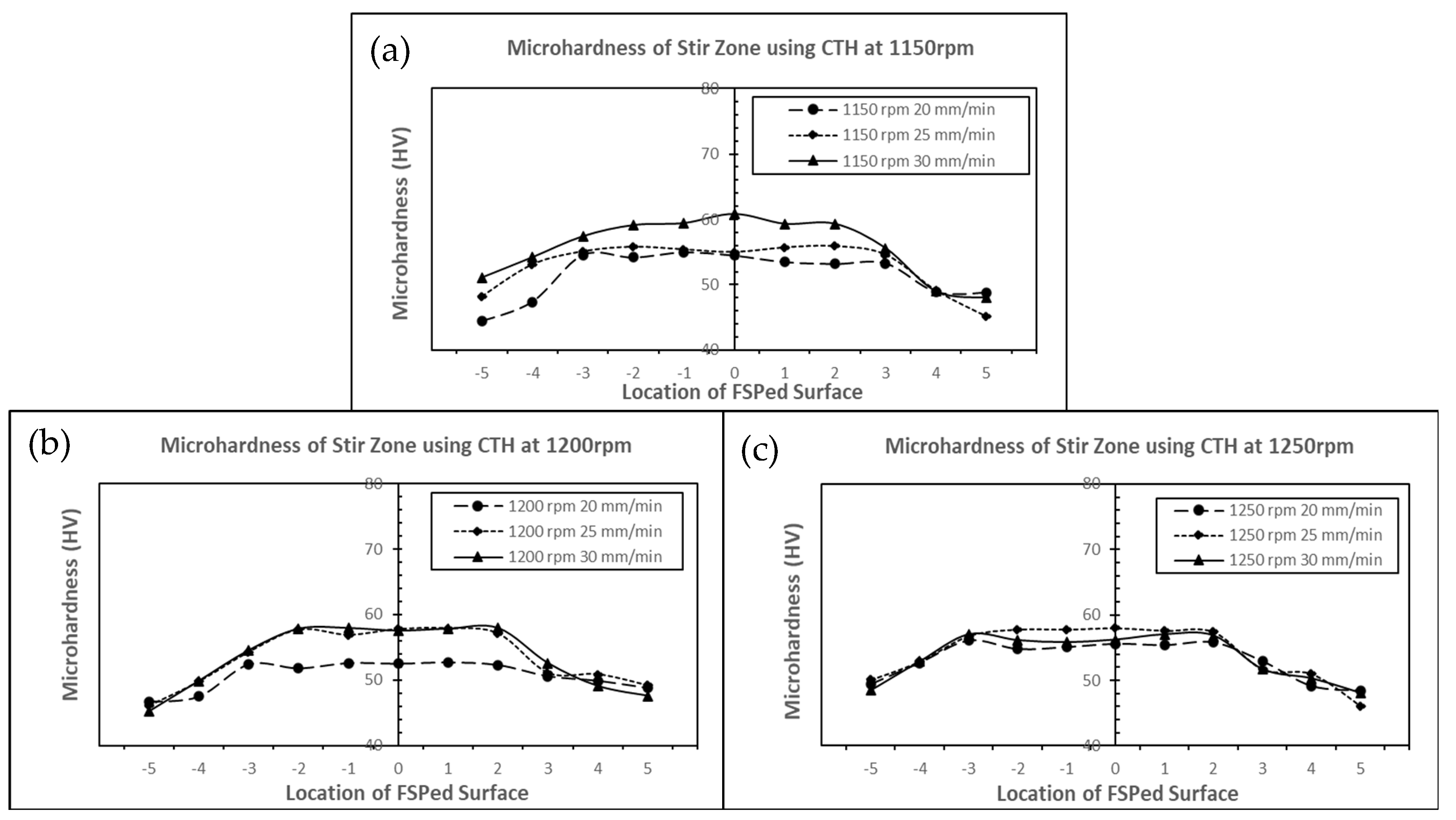

3.1. Microhardness Test

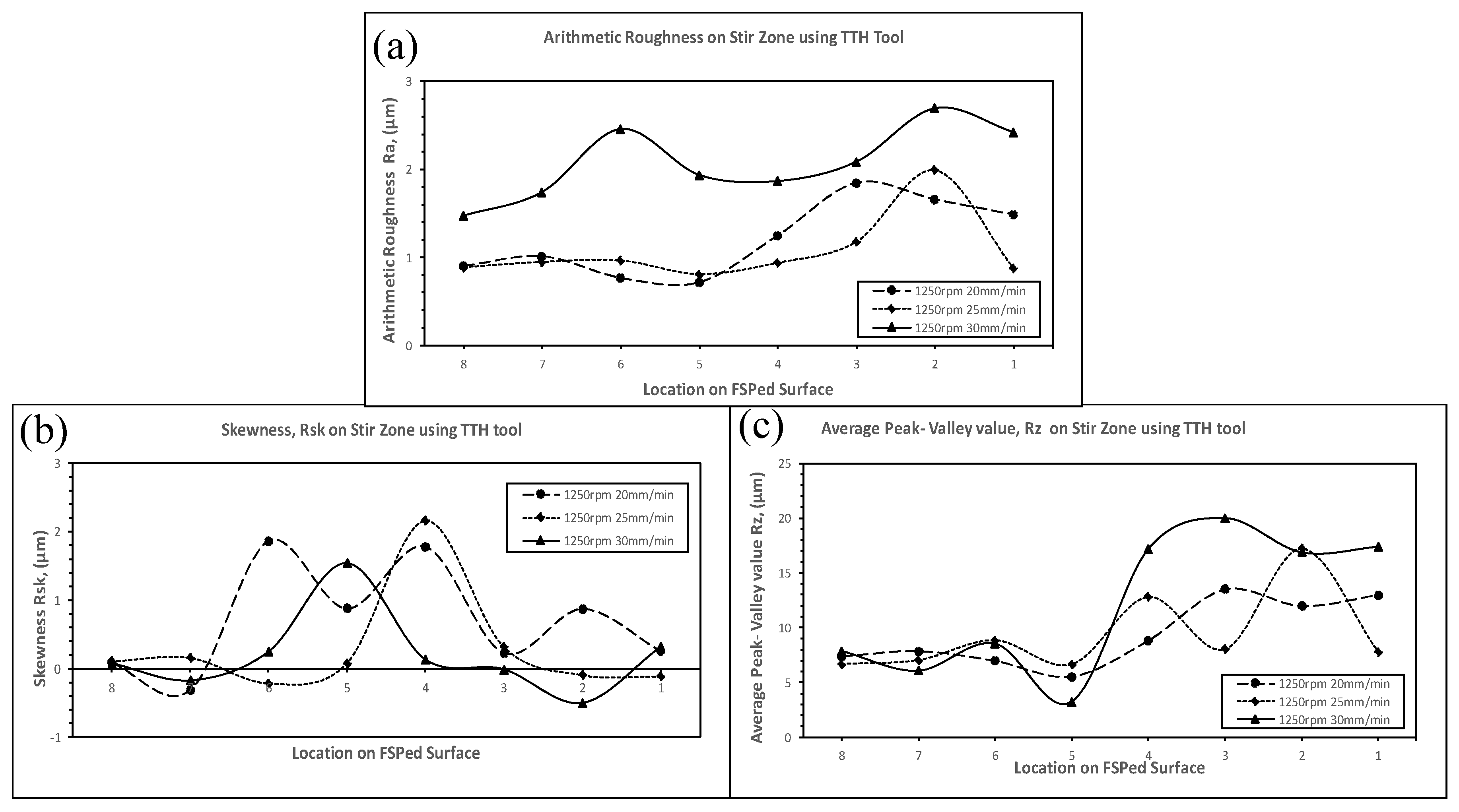

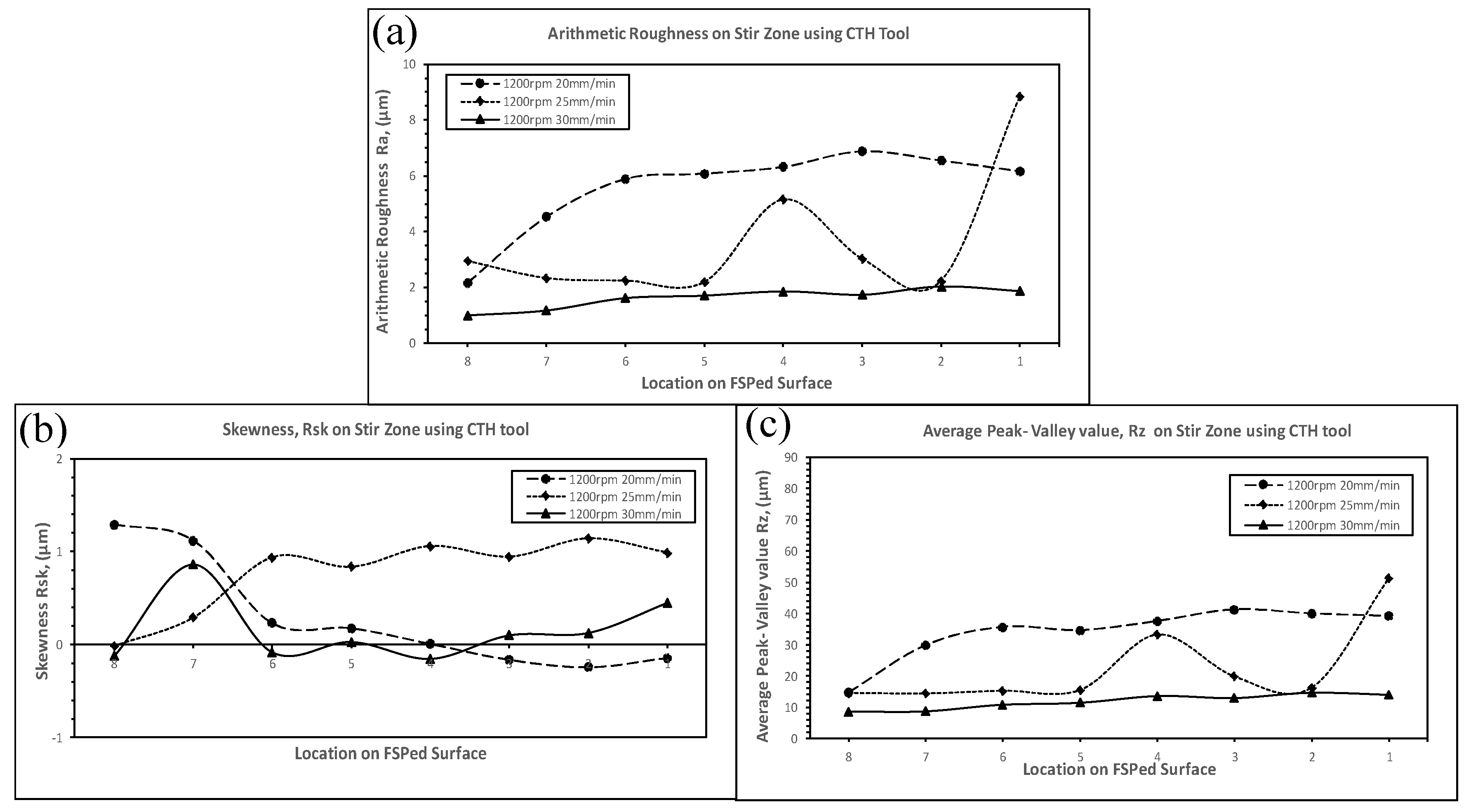

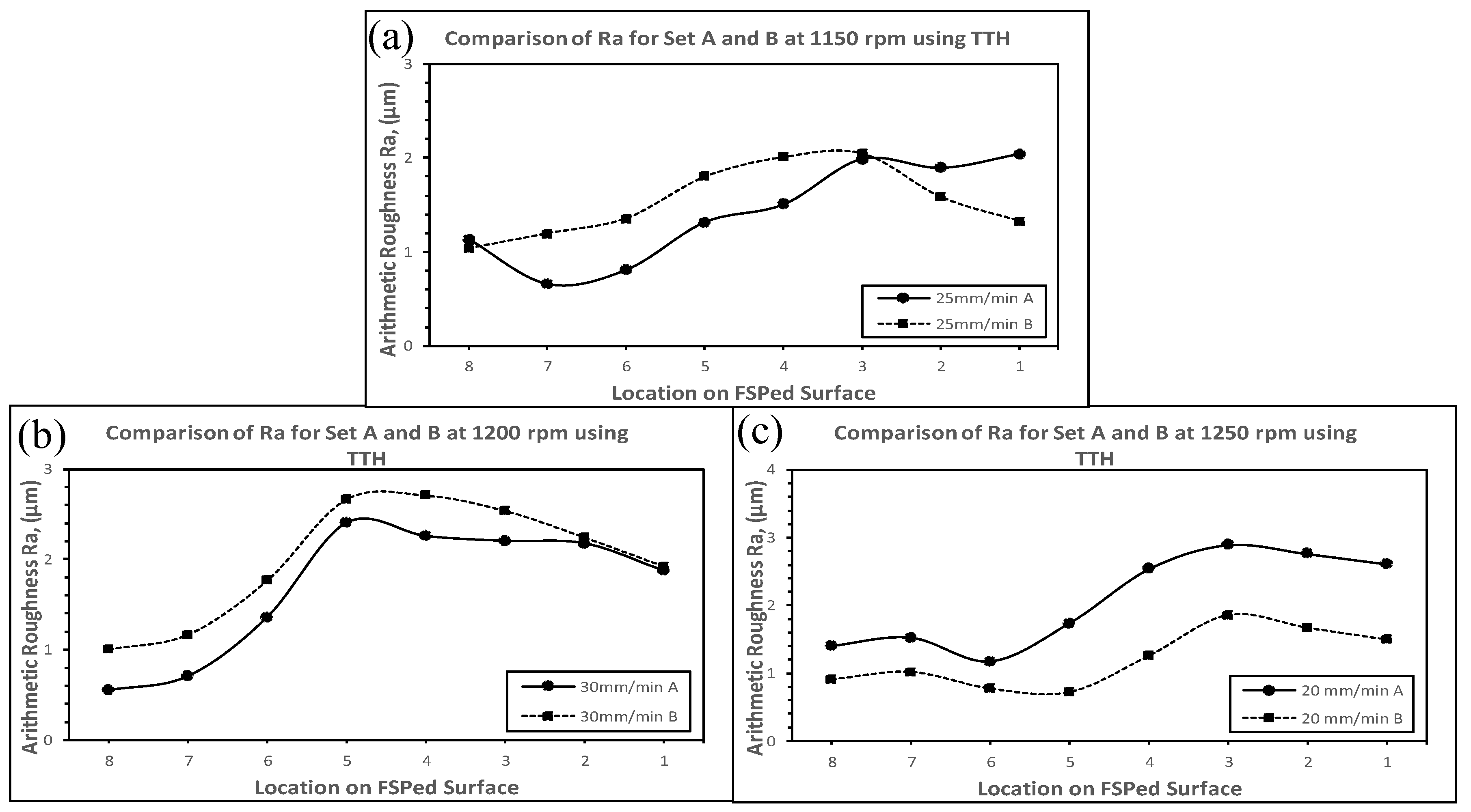

3.2. Surface Roughness Measurement

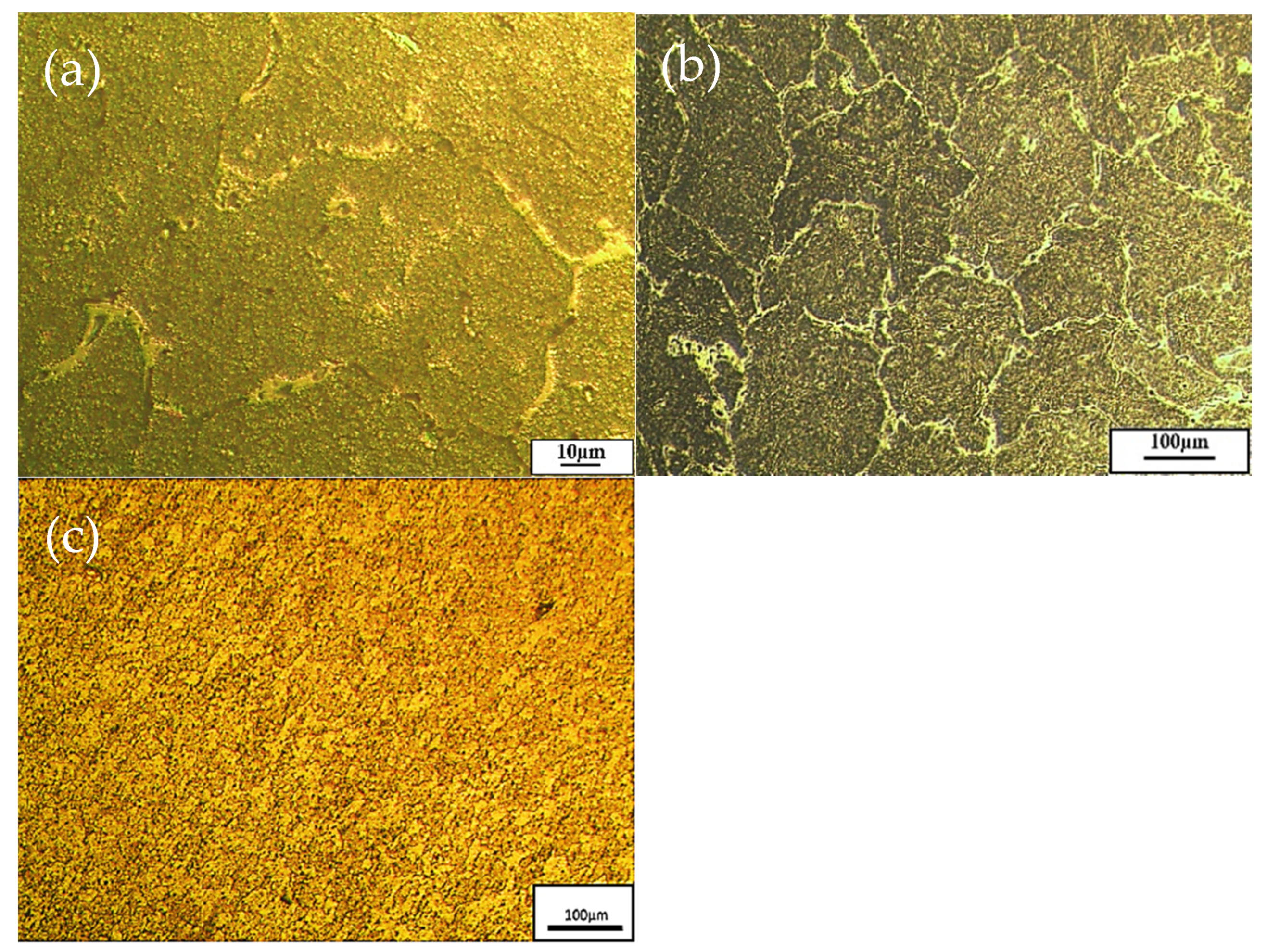

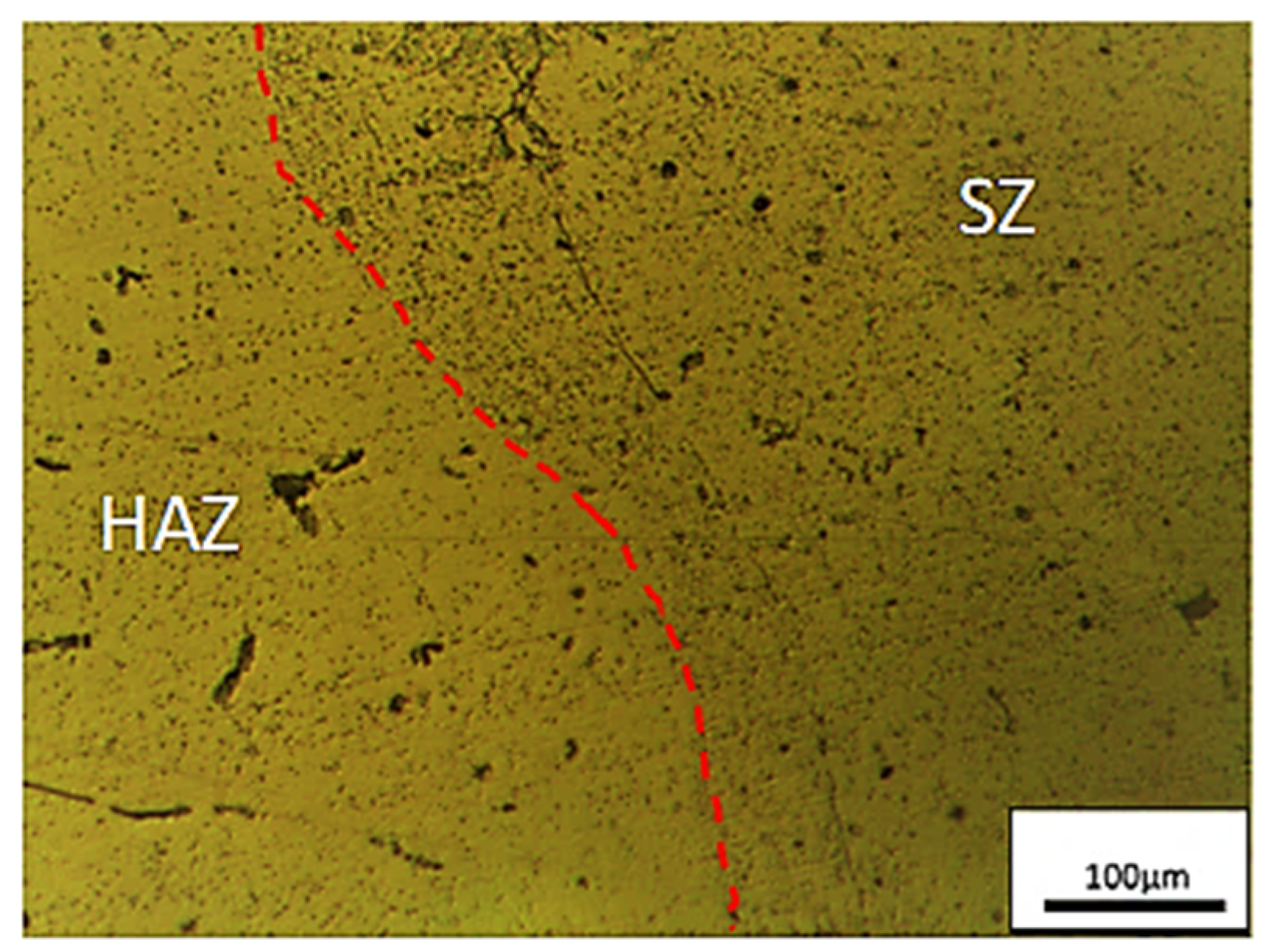

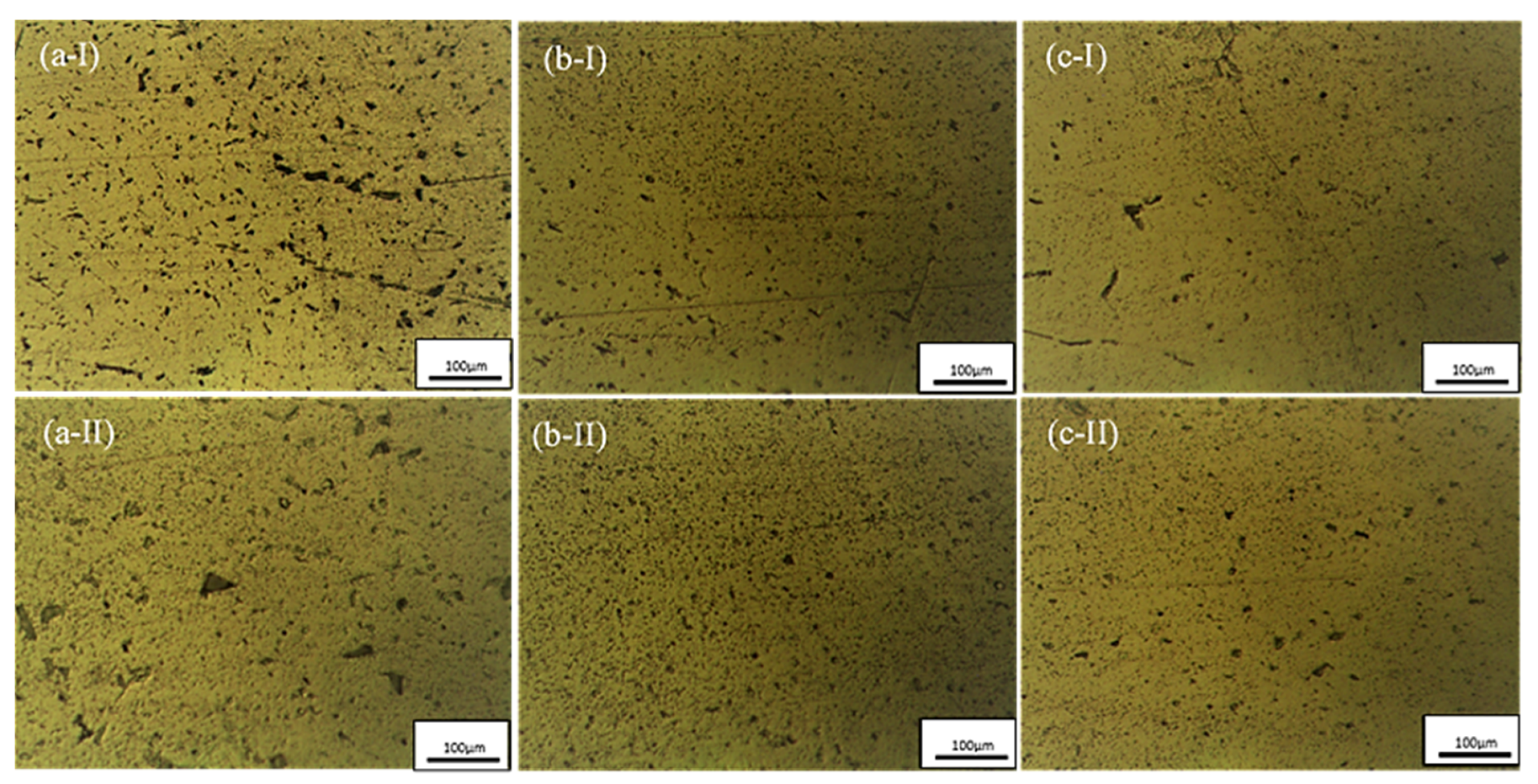

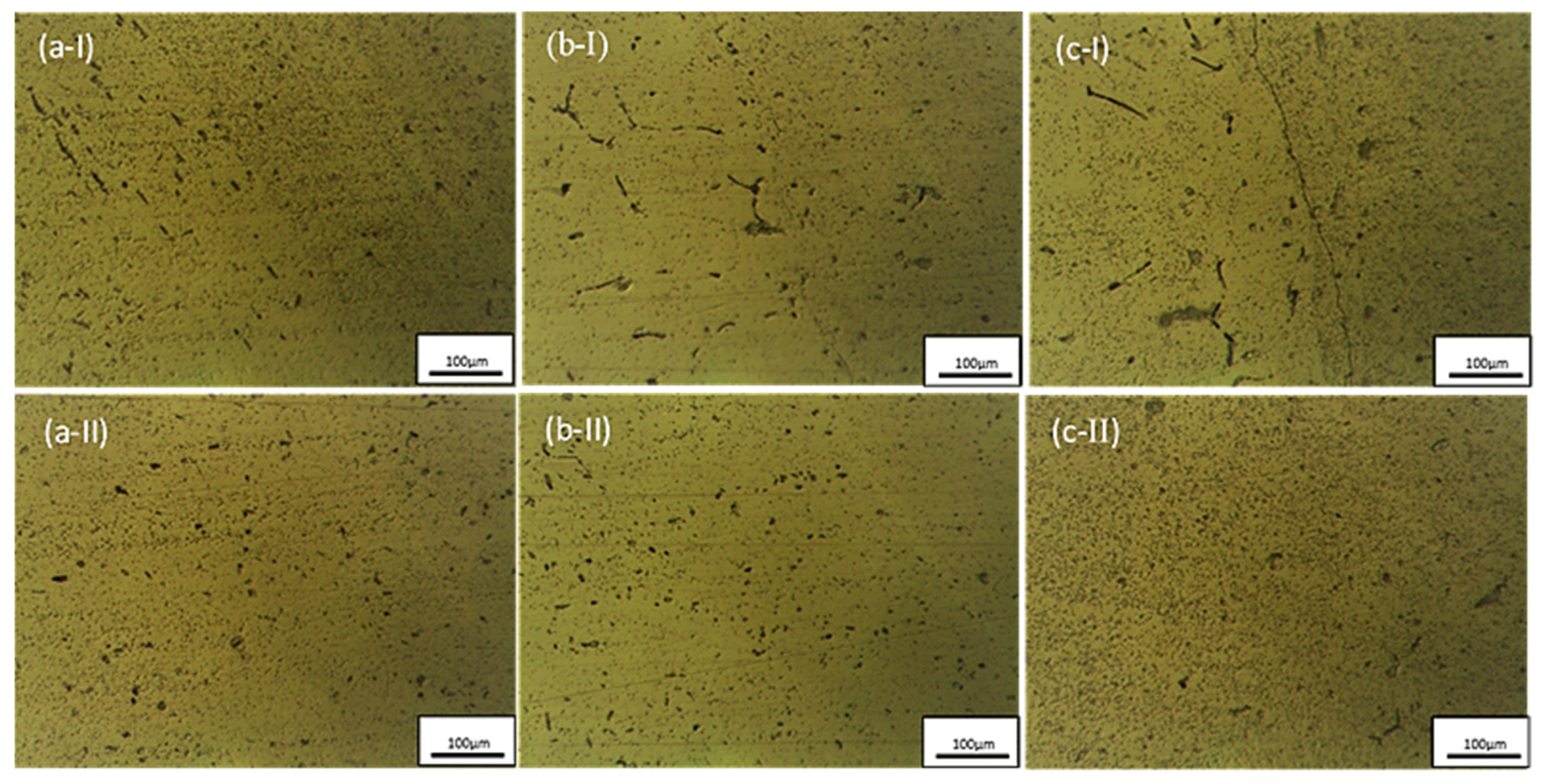

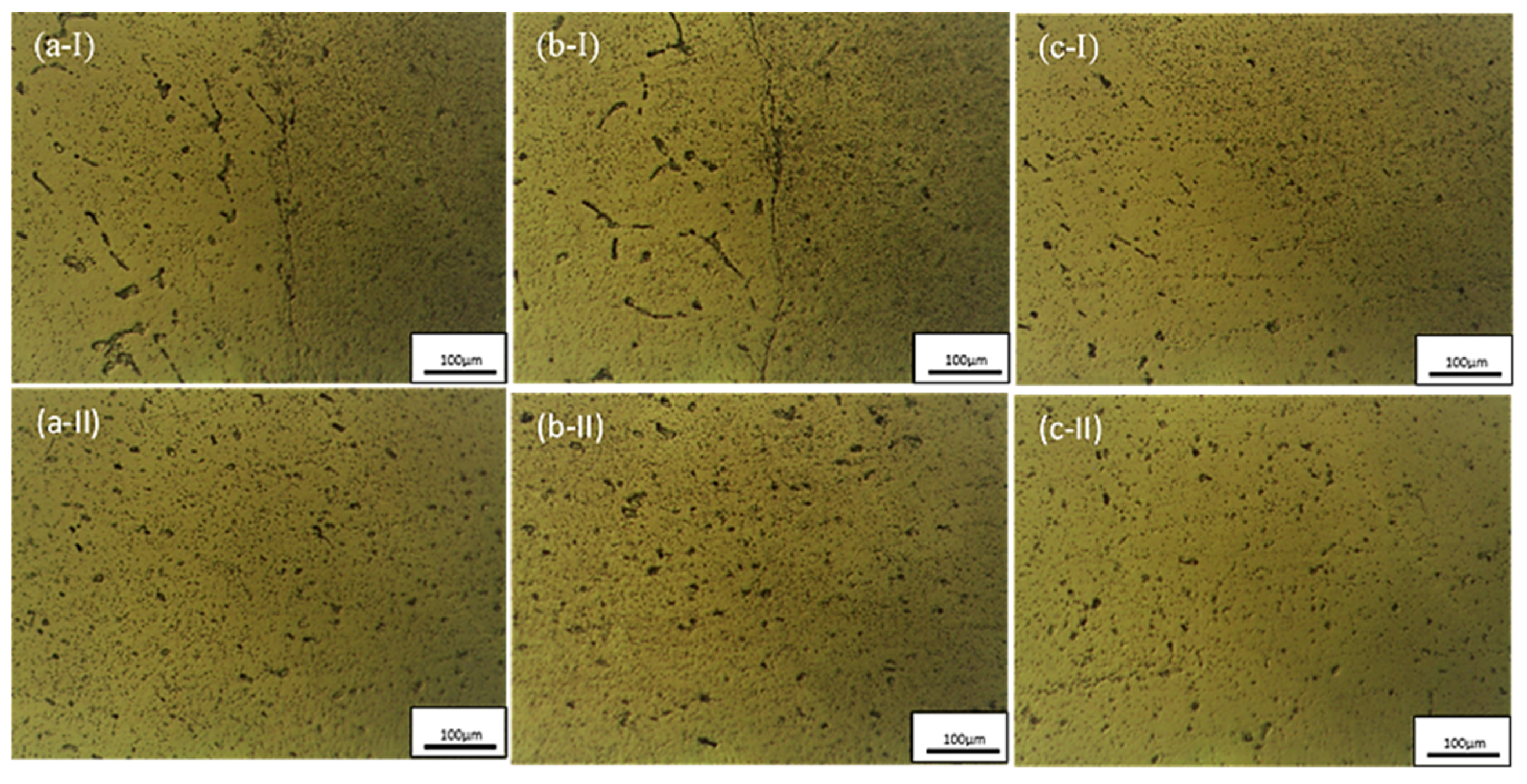

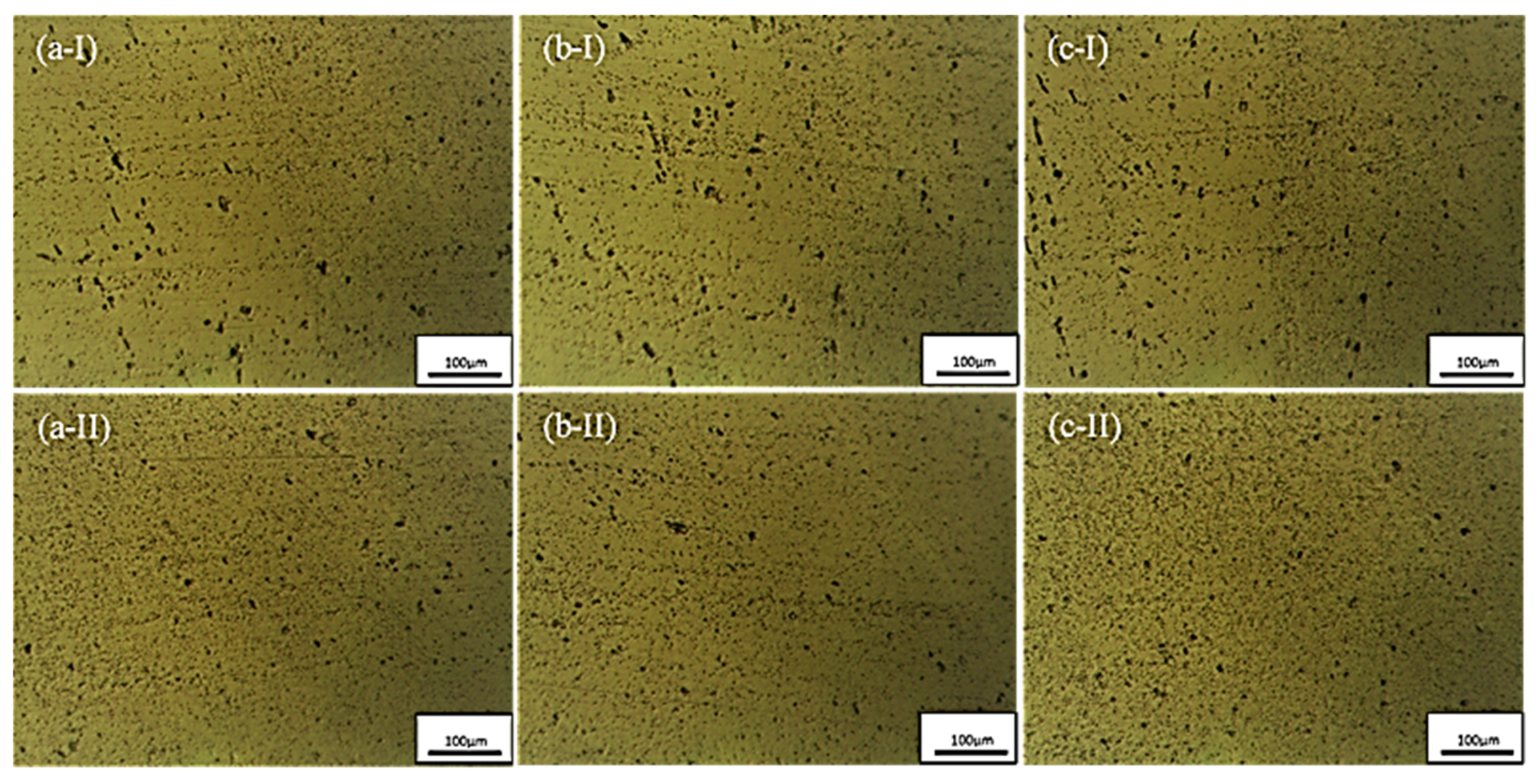

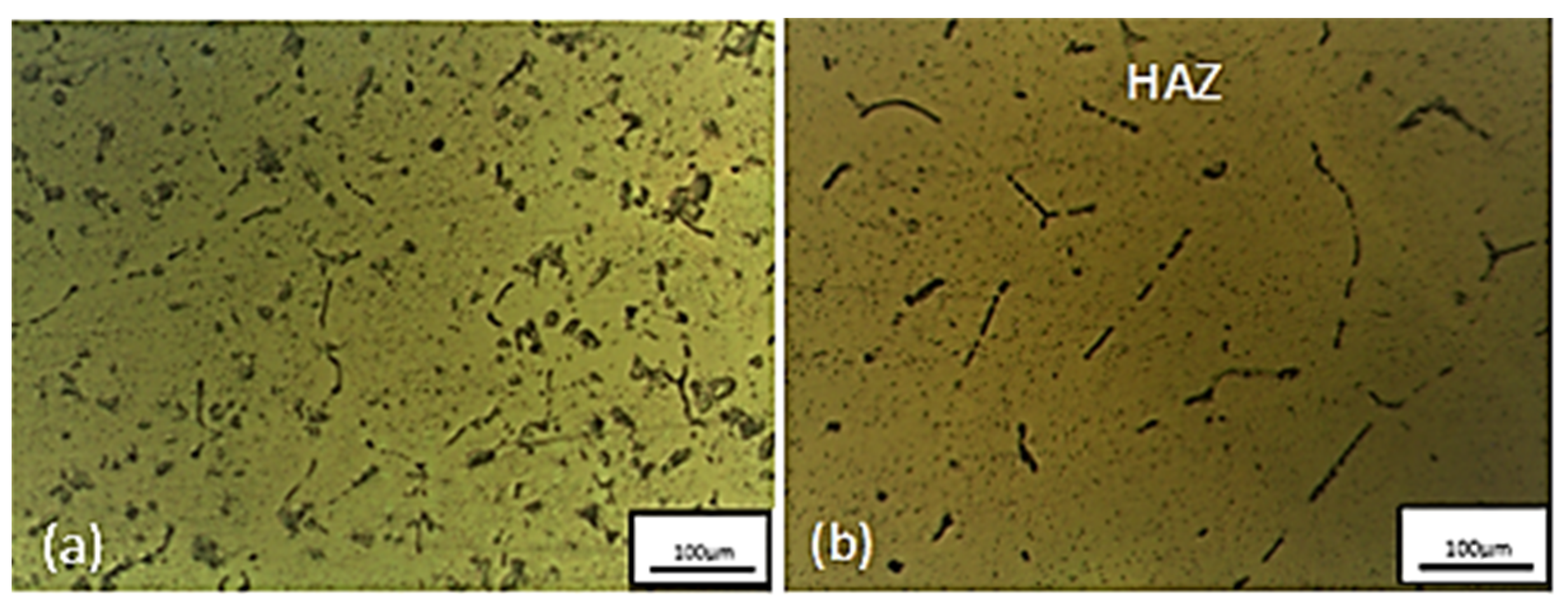

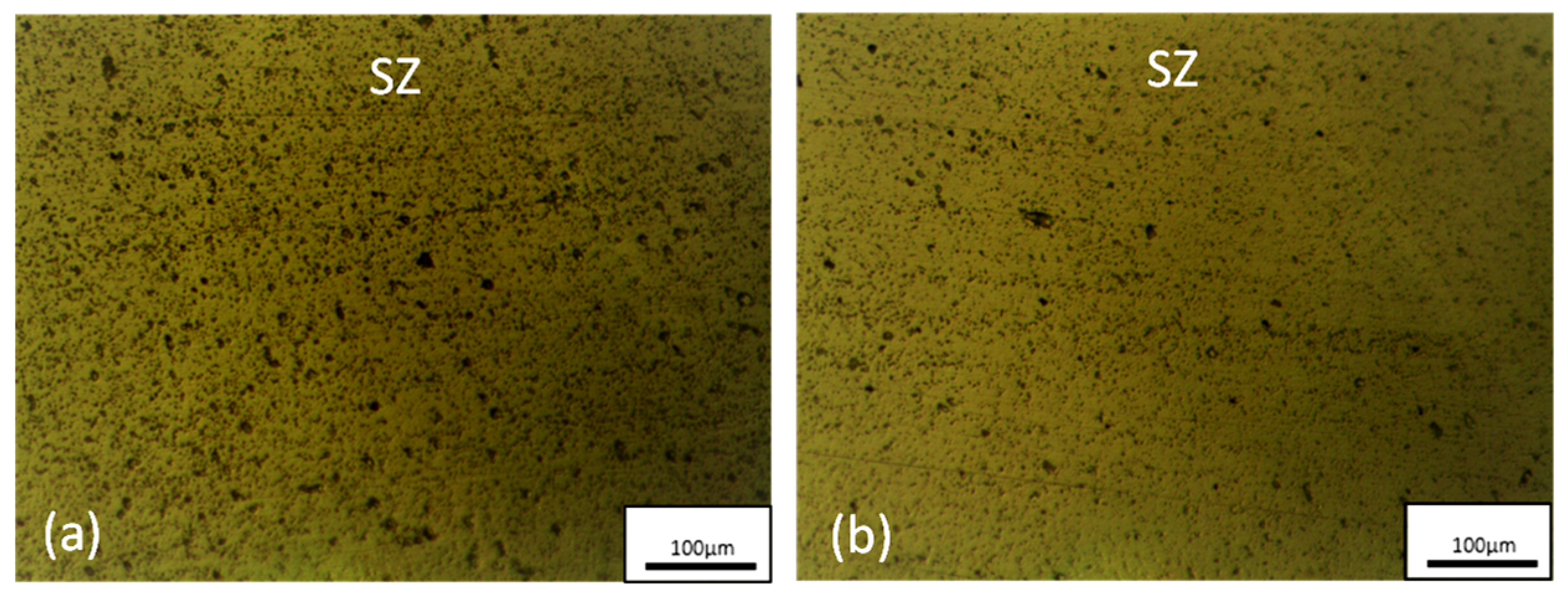

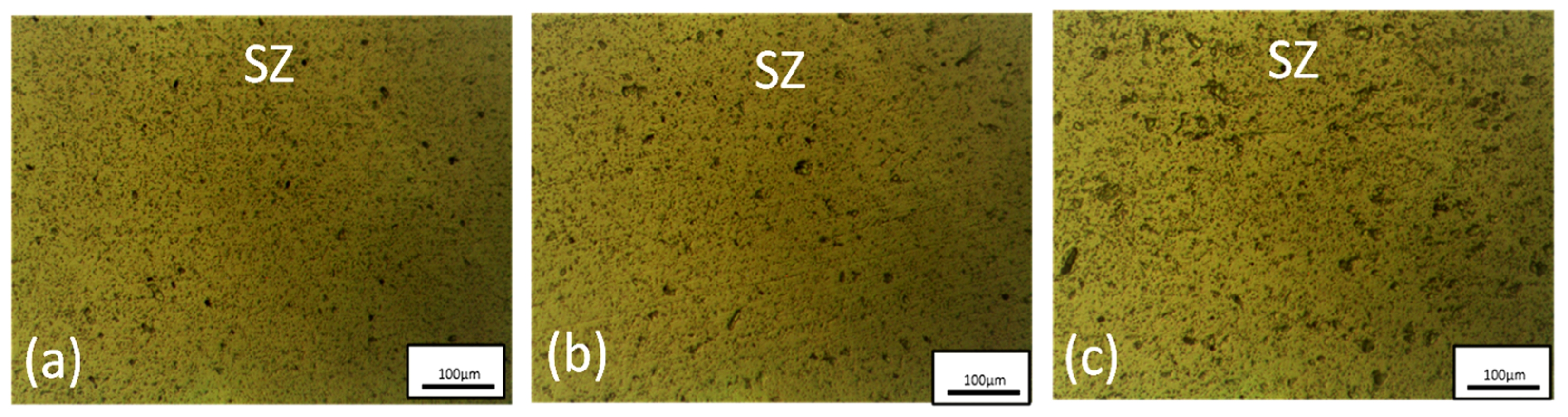

3.3. Microstructure Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wan, B.; Chen, W.; Lu, T.; Liu, F.; Jiang, Z.; Mao, M. Review of solid state recycling of aluminum chips. Resour. Conserv. Recycl. 2017, 125, 37–47. [Google Scholar] [CrossRef]

- Baffari, D.; Reynolds, A.P.; Masnata, A.; Fratini, L.; Ingarao, G. Friction stir extrusion to recycle aluminum alloys scraps: Energy efficiency characterization. J. Manuf. Process. 2019, 43, 63–69. [Google Scholar] [CrossRef]

- Rao, P.N.; Kaurwar, A.; Singh, D.; Jayaganthan, R. Enhancement in strength and ductility of Al-Mg-Si alloy by cryorolling followed by warm rolling. Procedia Eng. 2014, 75, 123–128. [Google Scholar] [CrossRef] [Green Version]

- Qu, J.; Xu, H.; Feng, Z.; Frederick, D.A.; An, L.; Heinrich, H. Improving the tribological characteristics of aluminum 6061 alloy by surface compositing with sub-micro-size ceramic particles via friction stir processing. Wear 2011, 271, 1940–1945. [Google Scholar] [CrossRef]

- Das, G.; Das, M.; Ghosh, S.; Dubey, P.; Ray, A.K. Effect of aging on mechanical properties of 6063 Al-alloy using instrumented ball indentation technique. Mater. Sci. Eng. A 2010, 527, 1590–1594. [Google Scholar] [CrossRef]

- Shamsudin, S.; Lajis, M.A.; Zhong, Z.W. Evolutionary in solid state recycling techniques of aluminium: A review. Procedia CIRP 2016, 40, 256–261. [Google Scholar] [CrossRef] [Green Version]

- Tekkaya, A.E.; Schikorra, M.; Becker, D.; Biermann, D.; Hammer, N.; Pantke, K. Hot profile extrusion of AA-6060 aluminum chips. J. Mater. Process. Technol. 2009, 209, 3343–3350. [Google Scholar] [CrossRef]

- Dhayalan, R.; Kalaiselvan, K.; Sathiskumar, R. Characterization of AA6063/SiC-Gr surface composites produced by FSP technique. Procedia Eng. 2014, 97, 625–631. [Google Scholar] [CrossRef] [Green Version]

- Li, K.; Liu, X.; Zhao, Y. Research status and prospect of friction stir processing technology. Cast 2019, 9, 129. [Google Scholar] [CrossRef] [Green Version]

- Sarmadi, H.; Kokabi, A.H.; Seyed Reihani, S.M. Friction and wear performance of copper–graphite surface composites fabricated by friction stir processing (FSP). Wear 2013, 304, 1–12. [Google Scholar] [CrossRef] [Green Version]

- García-Bernal, M.A.; Mishra, R.S.; Verma, R.; Hernández-Silva, D. Influence of friction stir processing tool design on microstructure and superplastic behavior of Al-Mg alloys. Mater. Sci. Eng. A 2016, 670, 9–16. [Google Scholar] [CrossRef]

- Emamikhah, A.; Abbasi, A.; Atefat, A.; Besharati Givi, M.K. Effect of tool pin profile on friction stir butt welding of high-zinc brass (CuZn40). Int. J. Adv. Manuf. Technol. 2013, 1–10. [Google Scholar] [CrossRef]

- Aissani, M.; Gachi, S.; Boubenider, F.; Benkedda, Y. Design and optimization of friction stir welding tool. Mater. Manuf. Process. 2010, 25, 1199–1205. [Google Scholar] [CrossRef]

- Ullegaddi, K.; Murthy, V.; Harsha, R.N. Manjunatha, Friction stir welding tool design and their effect on welding of AA-6082 T6. Mater. Today Proc. 2017, 4, 7962–7970. [Google Scholar] [CrossRef]

- Patel, V.V.; Badheka, V.; Kumar, A. Effect of polygonal pin profiles on friction stir processed superplasticity of AA7075 alloy. J. Mater. Process. Technol. 2017, 240, 68–76. [Google Scholar] [CrossRef]

- Abrahams, R.; Mikhail, J.; Fasihi, P. Effect of friction stir process parameters on the mechanical properties of 5005-H34 and 7075-T651 aluminium alloys. Mater. Sci. Eng. A 2019, 751, 363–373. [Google Scholar] [CrossRef]

- Palani, K.; Elanchezhian, C.; Vijaya Ramnath, B.; Bhaskar, G.B.; Naveen, E. Effect of pin profile and rotational speed on microstructure and tensile strength of dissimilar AA8011, AA01-T6 friction stir welded aluminum alloys. Mater. Today Proc. 2018, 5, 24515–24524. [Google Scholar] [CrossRef]

- Vijayavel, P.; Balasubramanian, V. Effect of pin profile volume ratio on microstructure and tensile properties of friction stir processed aluminum based metal matrix composites. J. Alloys Compd. 2017, 729, 828–842. [Google Scholar] [CrossRef]

- Venkata Rao, C.; Madhusudhan Reddy, G.; Srinivasa Rao, K. Influence of tool pin profile on microstructure and corrosion behaviour of AA2219 Al–Cu alloy friction stir weld nuggets. Def. Technol. 2015, 11, 197–208. [Google Scholar] [CrossRef] [Green Version]

- Elangovan, K.; Balasubramanian, V. Influences of pin profile and rotational speed of the tool on the formation of friction stir processing zone in AA2219 aluminium alloy. Mater. Sci. Eng. A 2007, 459, 7–18. [Google Scholar] [CrossRef]

- Azmal Hussain, M.; Zaman Khan, N.; Noor Siddiquee, A.; Akhtar Khan, Z. Effect of different tool pin profiles on the joint quality of friction stir welded AA 6063. Mater. Today Proc. 2018, 5, 4175–4182. [Google Scholar] [CrossRef]

- Yang, M.; Bao, R.-J.; Liu, X.-Z.; Song, C.-Q. Thermo-mechanical interaction between aluminum alloy and tools with different profiles during friction stir welding. Trans. Nonferrous Met. Soc. 2019, 29, 495–506. [Google Scholar] [CrossRef]

- Emamian, S. A review of friction stir welding pin profile. In Proceedings of the 2nd International Conference on Mechanical, Manufacturing and Process Plant Engineering, Kuala Lumpur, Malaysia, 23–24 November 2016; pp. 1–18. [Google Scholar]

- Muthu, M.F.X.; Jayabalan, V. Effect of pin profile and process parameters on microstructure and mechanical properties of friction stir welded Al–Cu joints. Trans. Nonferrous Met. Soc. 2016, 26, 984–993. [Google Scholar] [CrossRef]

- ASM International Materials Park. ASM Handbook, Heat Treating; ASM International Materials Park: Materials Park, OH, USA, 1991; pp. 841–879. [Google Scholar]

- Gan, W.-Y.; Zheng, Z.; Zhang, H.; Tao, P. Evolution of microstructure and hardness of aluminum after friction stir processing. Trans. Nonferrous Met. Soc. 2014, 24, 975–981. [Google Scholar] [CrossRef]

- Nandan, R.; DebRoy, T.; Bhadeshia, H.K.D.H. Recent advances in friction-stir welding—Process, weldment structure and properties. Prog. Mater. Sci. 2008, 53, 980–1023. [Google Scholar] [CrossRef] [Green Version]

- Beygi, R.; Mehrizi, M.Z.; Verdera, D.; Loureiro, A. Influence of tool geometry on material flow and mechanical properties of friction stir welded Al-Cu bimetals. J. Mater. Process. Technol. 2018, 255, 739–748. [Google Scholar] [CrossRef]

- Amirafshar, A.; Pouraliakbar, H. Effect of tool pin design on the microstructural evolutions and tribological characteristics of friction stir processed structural steel. Measurement 2015, 68, 111–116. [Google Scholar] [CrossRef]

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 0.430 | 0.309 | 0.0338 | 0.0252 | 0.561 | 0.0335 | 0.0333 | 0.0331 | 0.269 | Balance |

| FSP Parameters | Taper Threaded Tool | Cylindrical Threaded Tool | |||||

|---|---|---|---|---|---|---|---|

| Rotational Speed (RPM) | Feed Rate (mm/min) | Max. Ra (µm) | Max. Rsk (µm) | Max. Rz (µm) | Max. Ra (µm) | Max. Rsk (µm) | Max. Rz (µm) |

| 1150 | 20 | 1.972 | 0.832 | 14.18 | 4.533 | 0.742 | 29.65 |

| 1150 | 25 | 2.143 | 2.273 | 22.46 | 2.313 | 0.578 | 43.41 |

| 1150 | 30 | 2.714 | 1.005 | 18.28 | 3.893 | 0.718 | 24.28 |

| 1200 | 20 | 2.082 | 0.786 | 17.14 | 6.878 | 1.290 | 41.28 |

| 1200 | 25 | 1.914 | 0.994 | 12.70 | 8.849 | 1.141 | 51.28 |

| 1200 | 30 | 2.404 | 0.930 | 14.26 | 2.037 | 0.863 | 14.70 |

| 1250 | 20 | 1.851 | 1.864 | 13.49 | 18.36 | 0.885 | 84.89 |

| 1250 | 25 | 1.995 | 2.161 | 17.21 | 11.90 | 1.399 | 59.24 |

| 1250 | 30 | 2.701 | 0.249 | 17.36 | 3.074 | 1.589 | 19.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liew, K.W.; Chung, Y.Z.; Teo, G.S.; Kok, C.K. Effect of Tool Pin Geometry on the Microhardness and Surface Roughness of Friction Stir Processed Recycled AA 6063. Metals 2021, 11, 1695. https://doi.org/10.3390/met11111695

Liew KW, Chung YZ, Teo GS, Kok CK. Effect of Tool Pin Geometry on the Microhardness and Surface Roughness of Friction Stir Processed Recycled AA 6063. Metals. 2021; 11(11):1695. https://doi.org/10.3390/met11111695

Chicago/Turabian StyleLiew, Kia Wai, Yu Zorn Chung, Guo Sheng Teo, and Chee Kuang Kok. 2021. "Effect of Tool Pin Geometry on the Microhardness and Surface Roughness of Friction Stir Processed Recycled AA 6063" Metals 11, no. 11: 1695. https://doi.org/10.3390/met11111695

APA StyleLiew, K. W., Chung, Y. Z., Teo, G. S., & Kok, C. K. (2021). Effect of Tool Pin Geometry on the Microhardness and Surface Roughness of Friction Stir Processed Recycled AA 6063. Metals, 11(11), 1695. https://doi.org/10.3390/met11111695