Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting

Abstract

1. Introduction

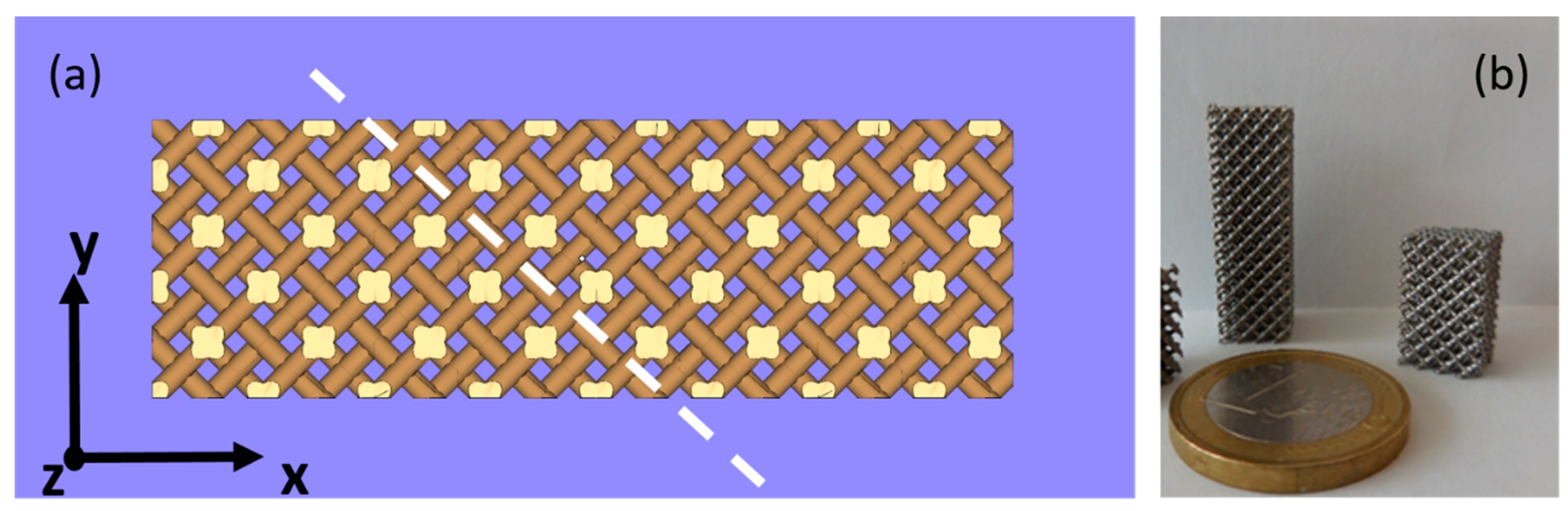

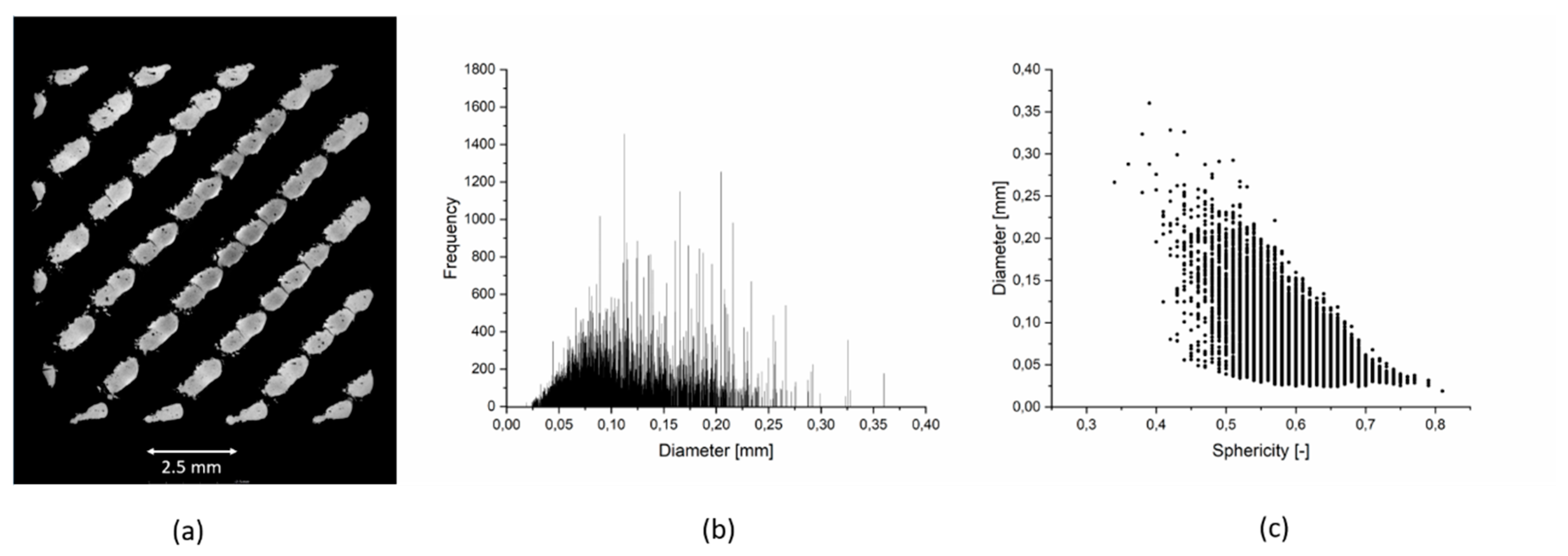

2. Experimental

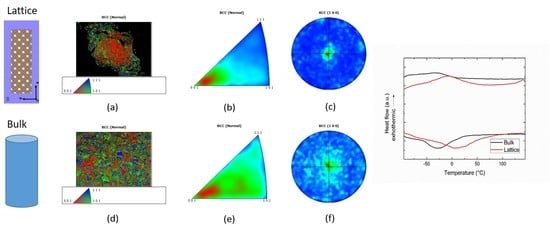

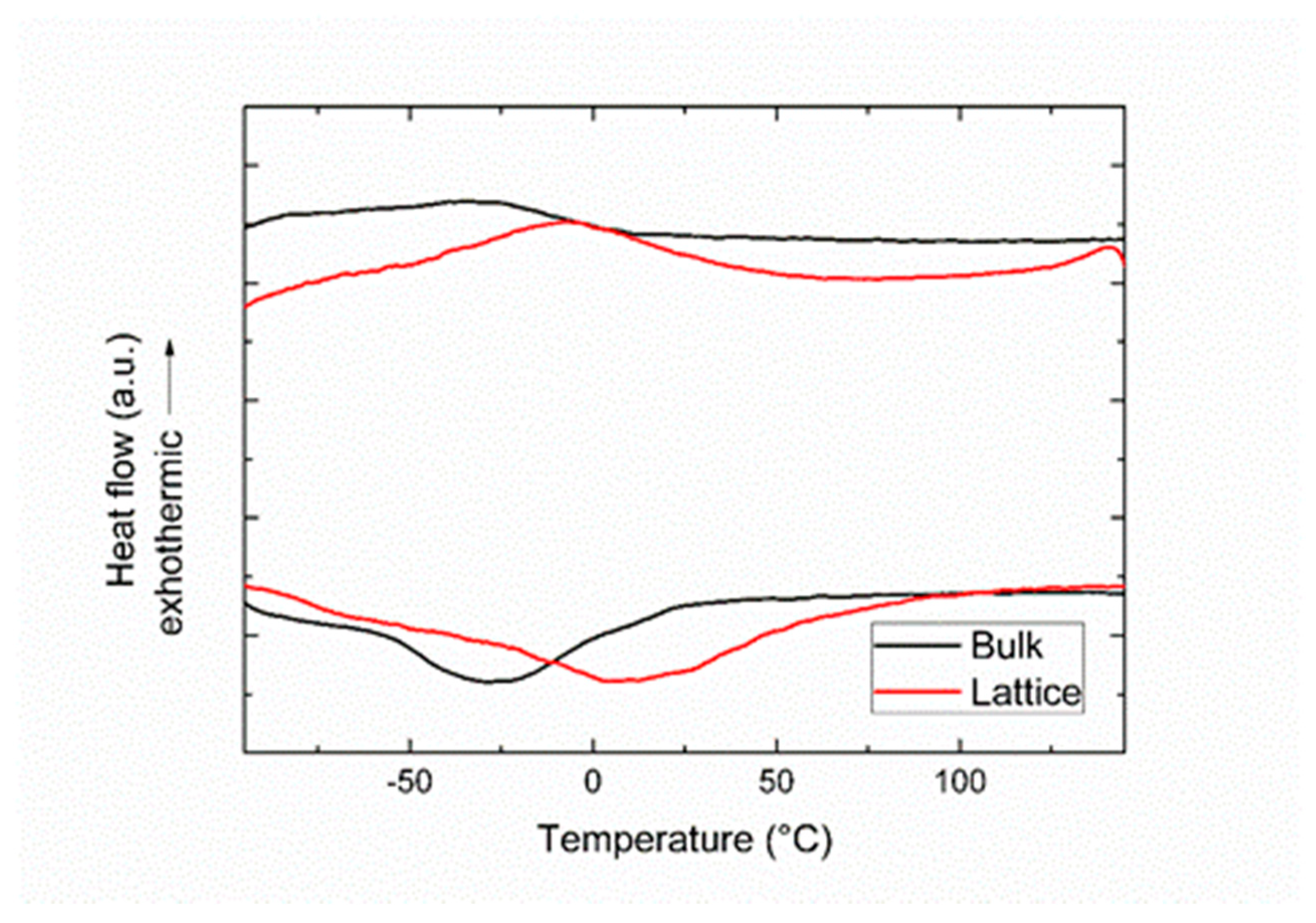

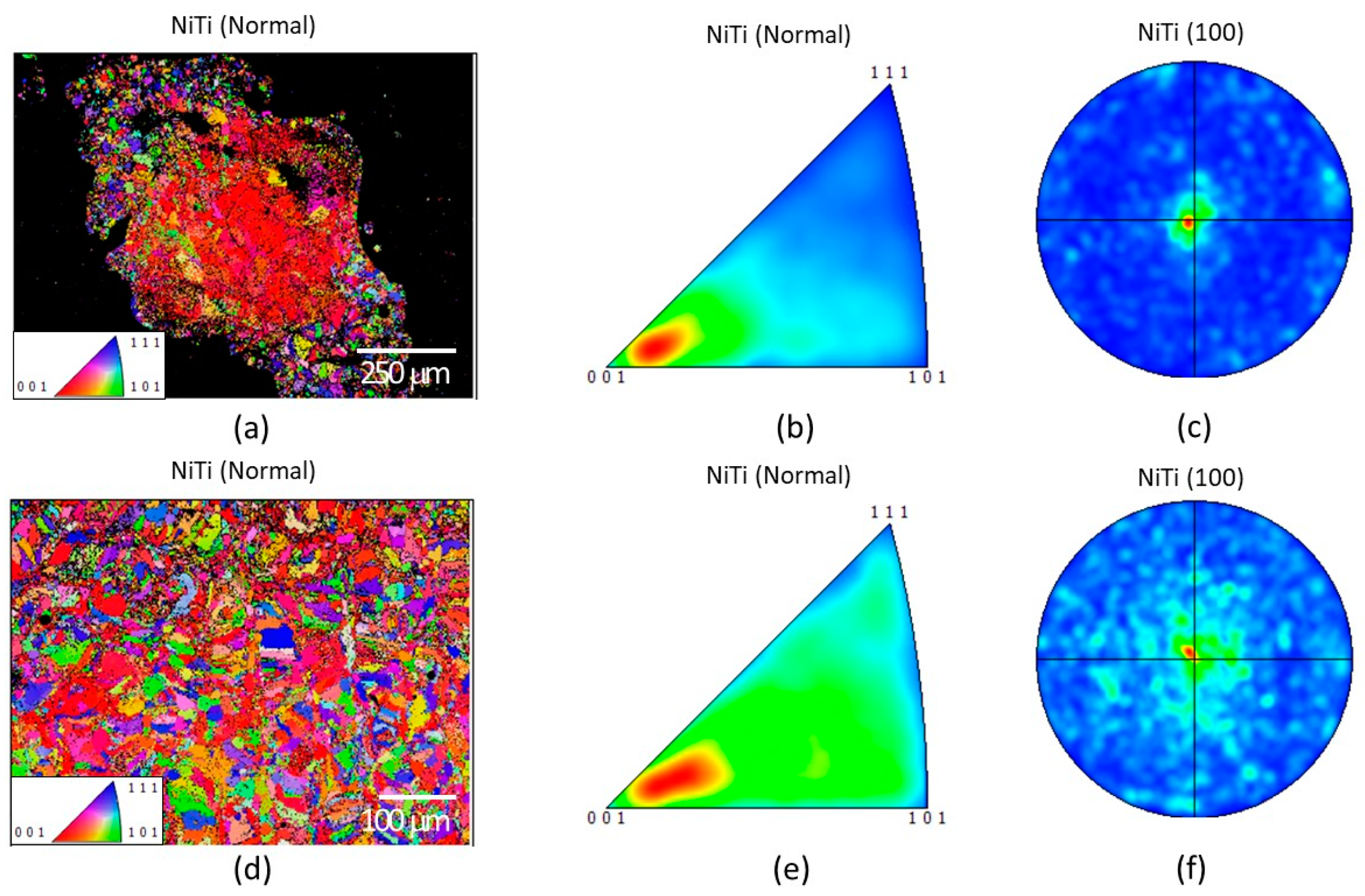

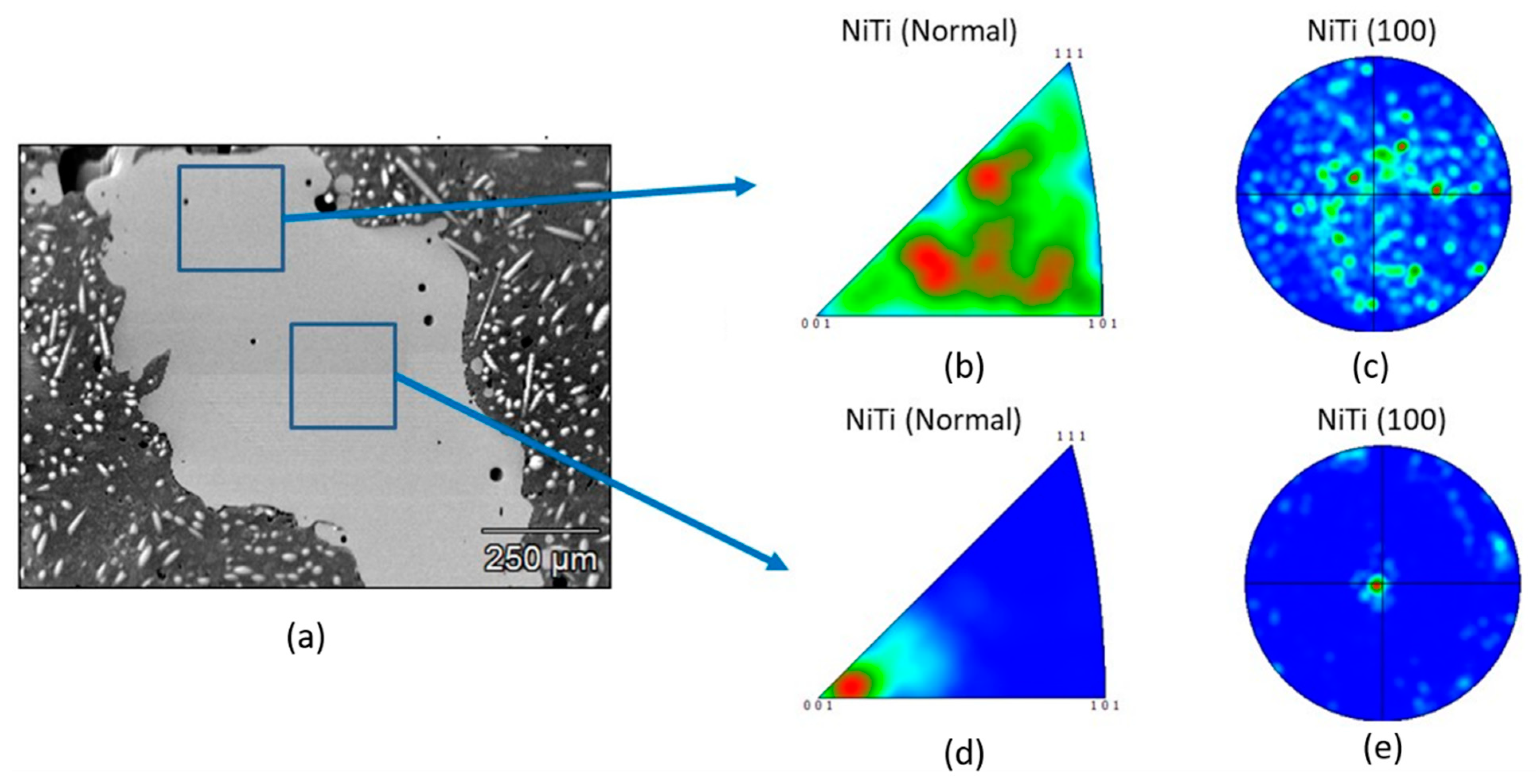

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tang, Y.; Zhao, Y.F. A survey of the design methods for additive manufacturing to improve functional performance. Rapid Prototyp. J. 2016, 22, 569–590. [Google Scholar] [CrossRef]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge Univ. Press: Cambridge, UK, 1998. [Google Scholar]

- Otsuka, K.; Ren, X. Physical Metallurgy of Ti-Ni based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Non medical applications of shape memory alloys. Mater. Sci. Eng. A 1999, 273, 134–148. [Google Scholar] [CrossRef]

- Duerig, T.; Pelton, A.; Stöckel, D. An overview of nitinol medical applications. Mater. Sci. Eng. A 1999, 273, 149–160. [Google Scholar] [CrossRef]

- Elahinia, M.; Shayesteh Moghaddam, N.; Taheri Andani, M.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Saedi, S.; Moghaddam, N.S.; Amerinatanzi, A.; Elahinia, M.; Karaca, H.E. On the effects of selective laser melting process parameters on microstructure and thermomechanical response of Ni-rich NiTi. Acta Mater. 2018, 14, 552–560. [Google Scholar] [CrossRef]

- Speirs, M.; Wang, X.; van Baelen, S.; Ahadi, A.; Dadbakhsh, S.; Kruth, J.P.; Van Humbeck, J. On the Transformation Behavior of NiTi Shape-Memory Alloy Produced by SLM. Shape Mem. Superelasticity 2016, 2, 310. [Google Scholar] [CrossRef]

- Dadbakhsh, S.; Speirs, M.; Van Humbeck, J.; Kruth, J.P. Laser additive manufacturing of bulk and porous shape memory NiTi alloys: From processes to potential biomedical applications. MRS Bull. 2016, 41, 765–774. [Google Scholar] [CrossRef]

- Andani, M.T.; Saedi, S.; Turabi, A.S.; Karamooz, M.R.; Haberland, C.; Karaca, H.E.; Elahinia, M. Mechanical and Shape Memory properties of porous Ni50.1Ti49.9 alloys manufactured by selective laser melting. J. Mech. Behav. Biomed. Mater. 2017, 68, 224–231. [Google Scholar] [CrossRef] [PubMed]

- Fiocchi, J.; Biffi, C.A.; Scaccabarozzi, D.; Saggin, B.; Tuissi, A. Enhancement of the Damping Behavior of Ti6Al4V Alloy through the Use of Trabecular Structure Produced by Selective Laser Melting. Adv. Eng. Mater. 2019. [Google Scholar] [CrossRef]

- Demir, A.G.; Previtali, B. Additive manufacturing of cardiovascular CoCr stents by selective laser melting. Mater. Des. 2017, 119, 338–350. [Google Scholar] [CrossRef]

- Funakubo, H. Shape Memory Alloys; Gordon and Breach Science Publishers: Amsterdam, The Netherlands, 1987. [Google Scholar]

- Nishida, M.; Wayman, C.; Honma, T. Precipitation processes in near-equiatomic TiNi shape memory alloys. Metall. Trans. A 1986, 17, 1505–1515. [Google Scholar] [CrossRef]

- Mahmoudi, M.; Tapia, G.; Franco, B.; Ma, J.; Arroyave, R.; Karaman, I.; Elwany, A. On the printability and transformation behavior of nickel-titanium shape memory alloys fabricated using laser powder-bed fusion additive manufacturing. J. Manuf. Process. 2018, 35, 672–680. [Google Scholar] [CrossRef]

- Bormann, T.; Muller, B.; Schinhammer, M.; Kessler, A.; Thalmann, P.; de Wild, M. Microstructure of selective laser melted nickel-titanium. Mater. Charact. 2014, 94, 189–202. [Google Scholar] [CrossRef]

- Biffi, C.A.; Fiocchi, J.; Bassani, P.; Tuissi, A. Selective Laser Melting of NiTi Shape Memory Alloy: Processability, microstructure and superelasticity. Shape Mem. Superelasticity 2020. Under consideration. [Google Scholar]

- Biffi, C.A.; Fiocchi, J.; Ferrario, E.; Fornaci, A.; Riccio, M.; Romeo, M.; Tuissi, A. Effects of the scanning strategy on the microstructure and mechanical properties of a TiAl6V4 alloy produced by electron beam additive manufacturing. Int. J. Adv. Manuf. Technol. 2020, 1–12. [Google Scholar] [CrossRef]

- Fiocchi, J.; Biffi, C.A.; Tuissi, A. Selective laser melting of high-strength primary AlSi9Cu3 alloy: Processability, microstructure, and mechanical properties. Mater. Des. 2020. [Google Scholar] [CrossRef]

- Shiva, S.; Palani, I.A.; Mishra, S.K.; Paul, C.P.; Kukreja, L.M. Investigation on the influence of composition in the development of Ni-Ti shape memory alloy using laser based additive manufacturing. Opt. Laser Technol. 2015, 69, 44–51. [Google Scholar] [CrossRef]

- Ashby, M.F.; Evans, A.G.; Fleck, N.A.; Gibson, L.J.; Hutchinson, J.W. Metal Foams: A Design Guide, Butterworth-Heinemann; United States of America: Boston, MA, USA, 2000.

| Parameters | Values |

|---|---|

| Power | 75 W |

| Exposure time | 75 μs |

| Atmosphere | Argon |

| Layer thickness | 30 μm |

| Hatch distance | 50 μm |

| Point distance | 50 μm |

| Laser spot size | 65 μm |

| Sample: | As (°C) | Ap (°C) | Af (°C) | HM→A (J/g) | Ms (°C) | Mp (°C) | Mf (°C) | HA→M (J/g) |

|---|---|---|---|---|---|---|---|---|

| Lattice | −47 | 9 | 76 | 10.5 | 44 | −5 | −52 | 7.5 |

| Bulk | −61 | −22 | 30 | 5.4 | 11 | −28 | −86 | 4.0 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Biffi, C.A.; Bassani, P.; Fiocchi, J.; Tuissi, A. Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals 2020, 10, 814. https://doi.org/10.3390/met10060814

Biffi CA, Bassani P, Fiocchi J, Tuissi A. Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals. 2020; 10(6):814. https://doi.org/10.3390/met10060814

Chicago/Turabian StyleBiffi, Carlo Alberto, Paola Bassani, Jacopo Fiocchi, and Ausonio Tuissi. 2020. "Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting" Metals 10, no. 6: 814. https://doi.org/10.3390/met10060814

APA StyleBiffi, C. A., Bassani, P., Fiocchi, J., & Tuissi, A. (2020). Microstructural and Mechanical Response of NiTi Lattice 3D Structure Produced by Selective Laser Melting. Metals, 10(6), 814. https://doi.org/10.3390/met10060814