{111}<110> Orientation Induced Anisotropy of Shape Memory Effect in NiTiNb Pipe Joints

Abstract

1. Introduction

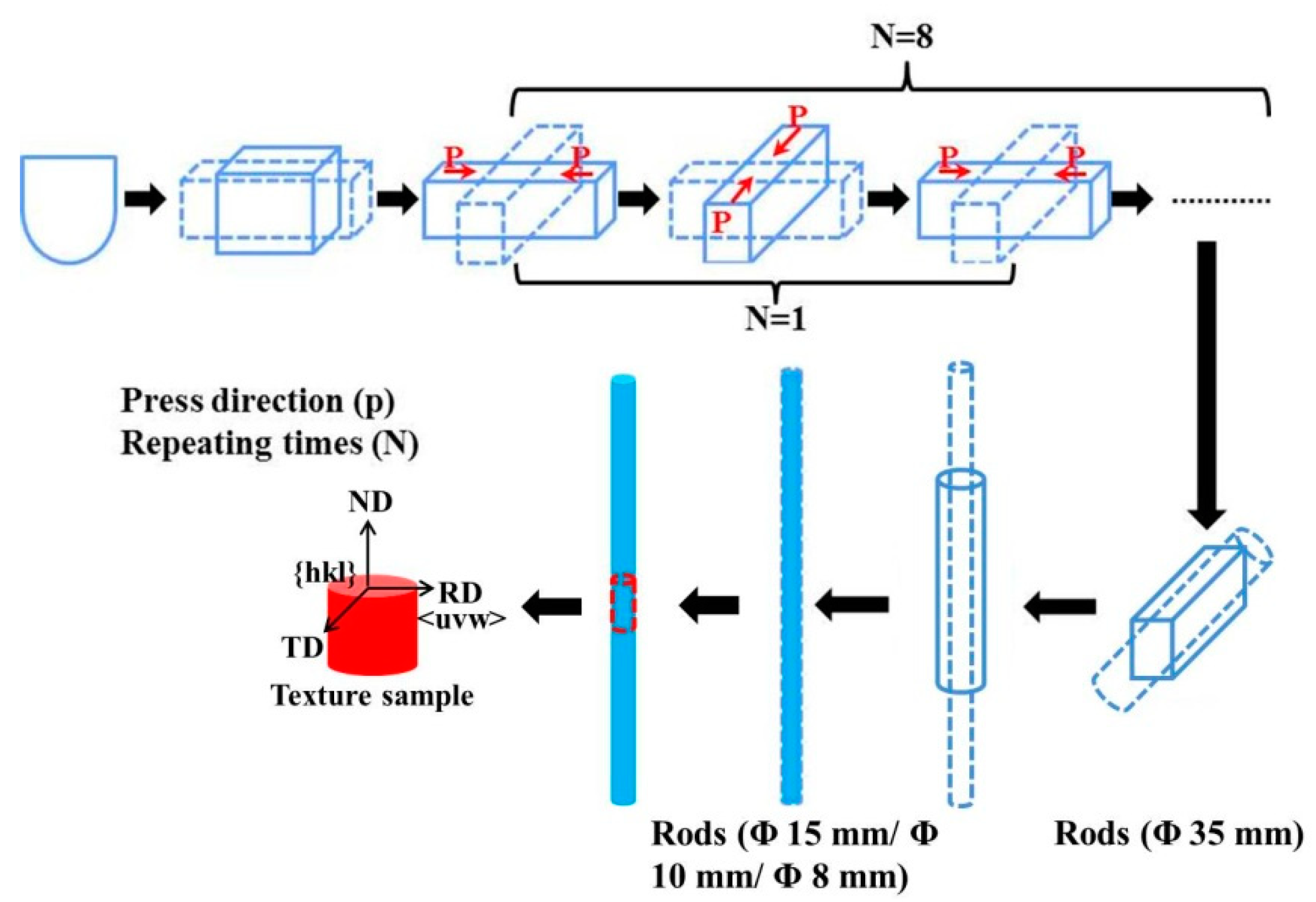

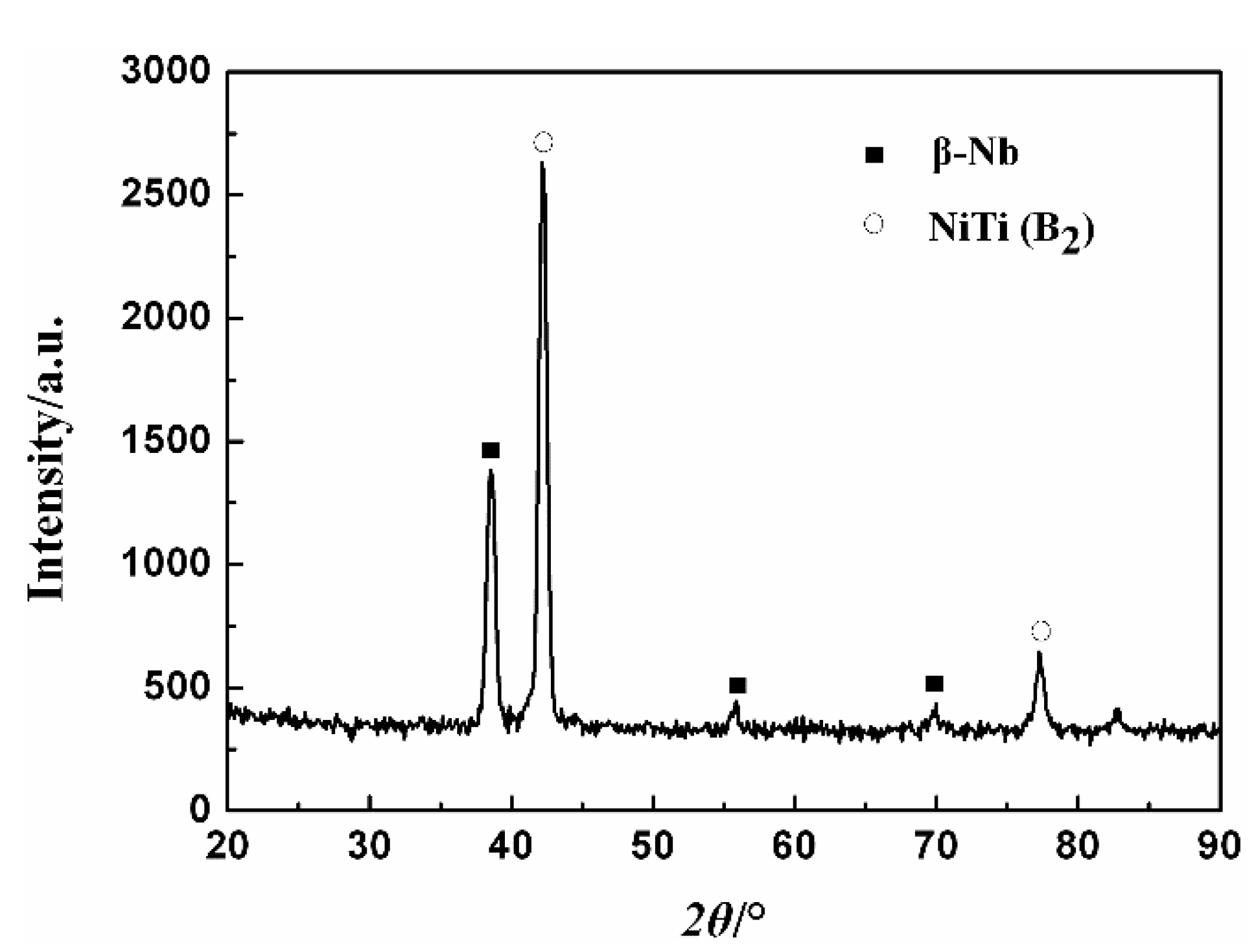

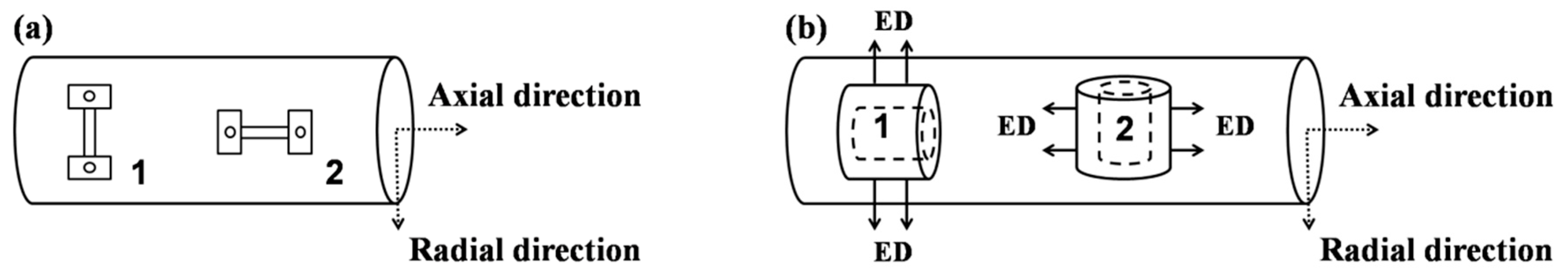

2. Experimental Procedures

3. Results

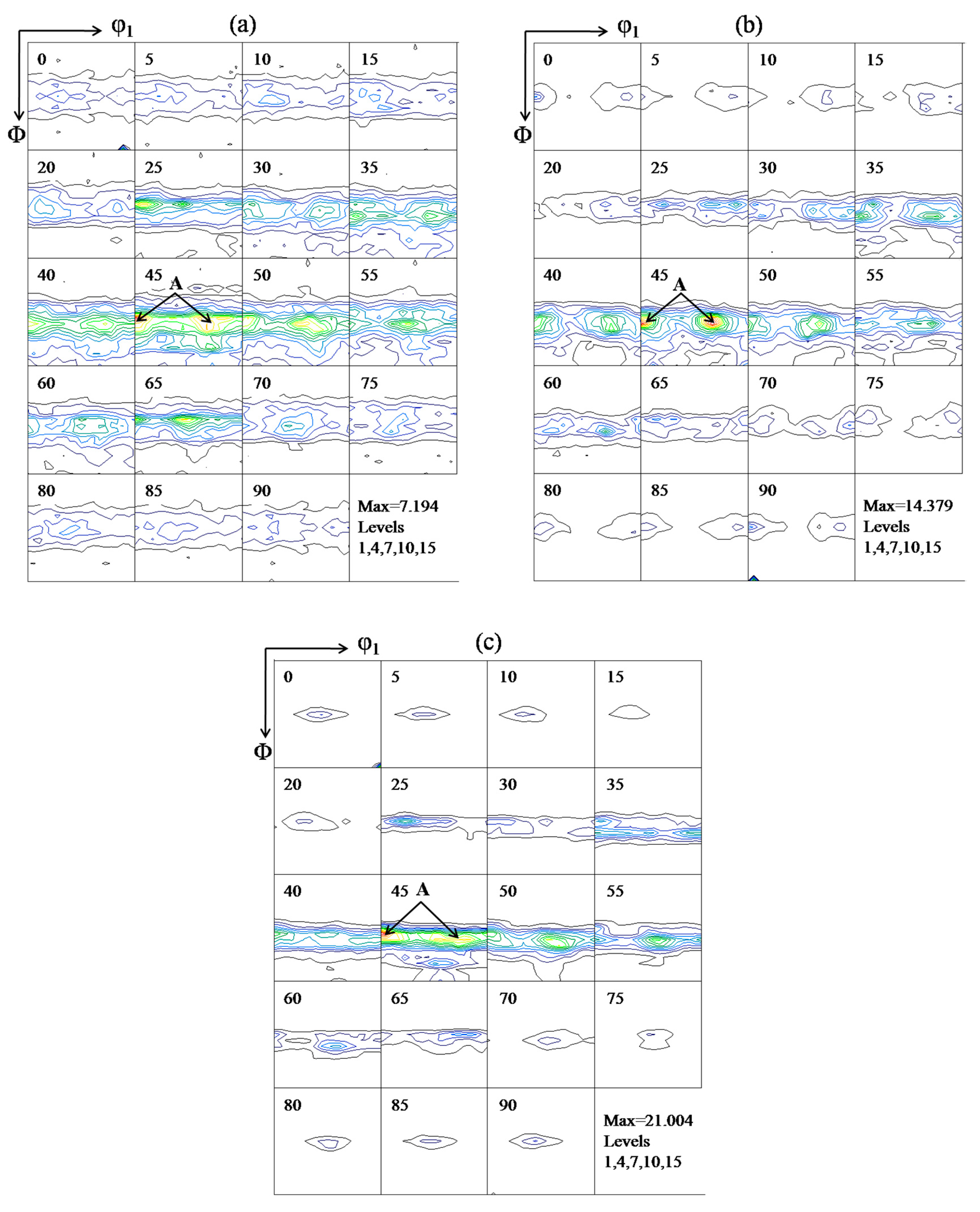

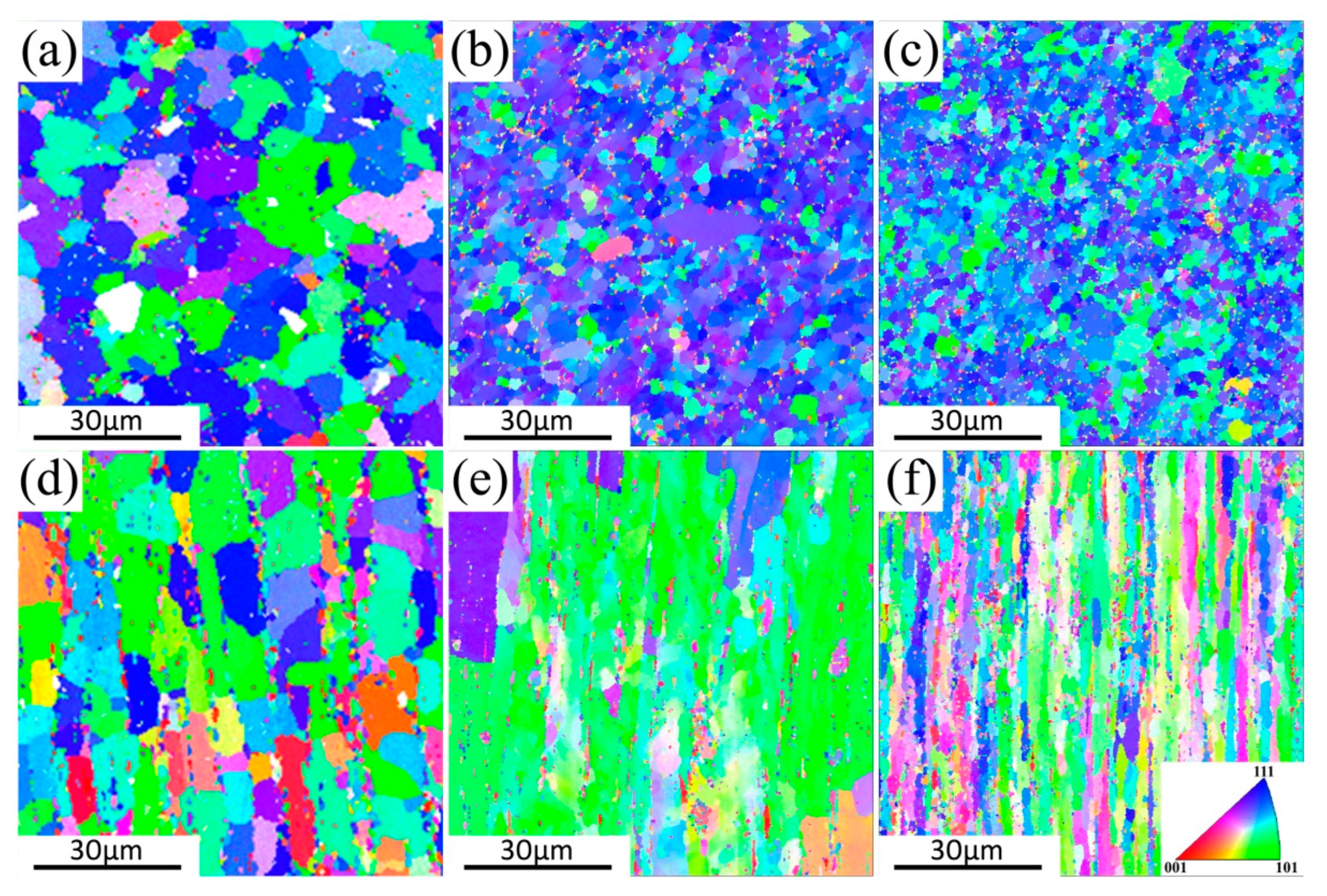

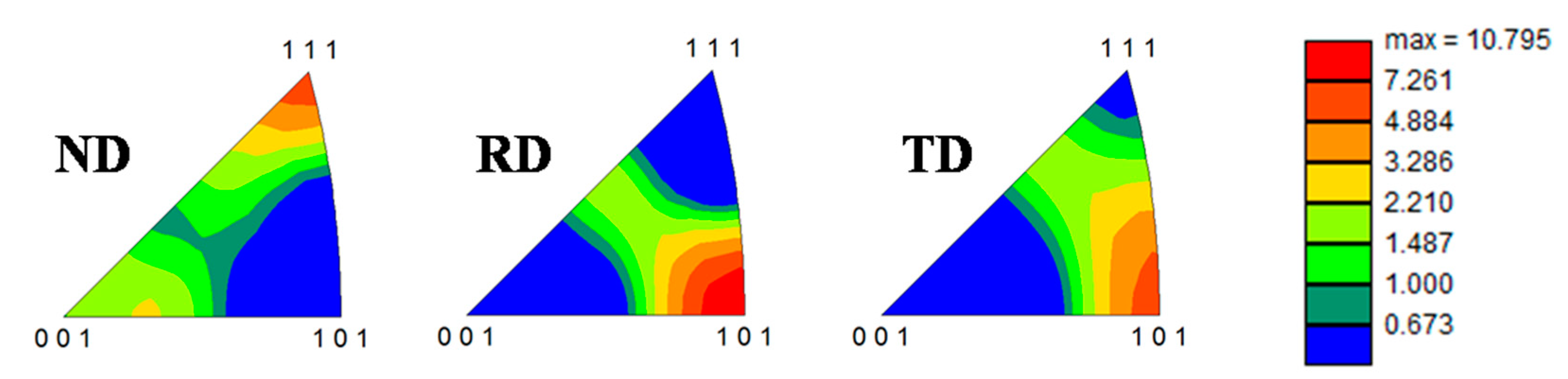

3.1. Texture Comparison and EBSD Characterization

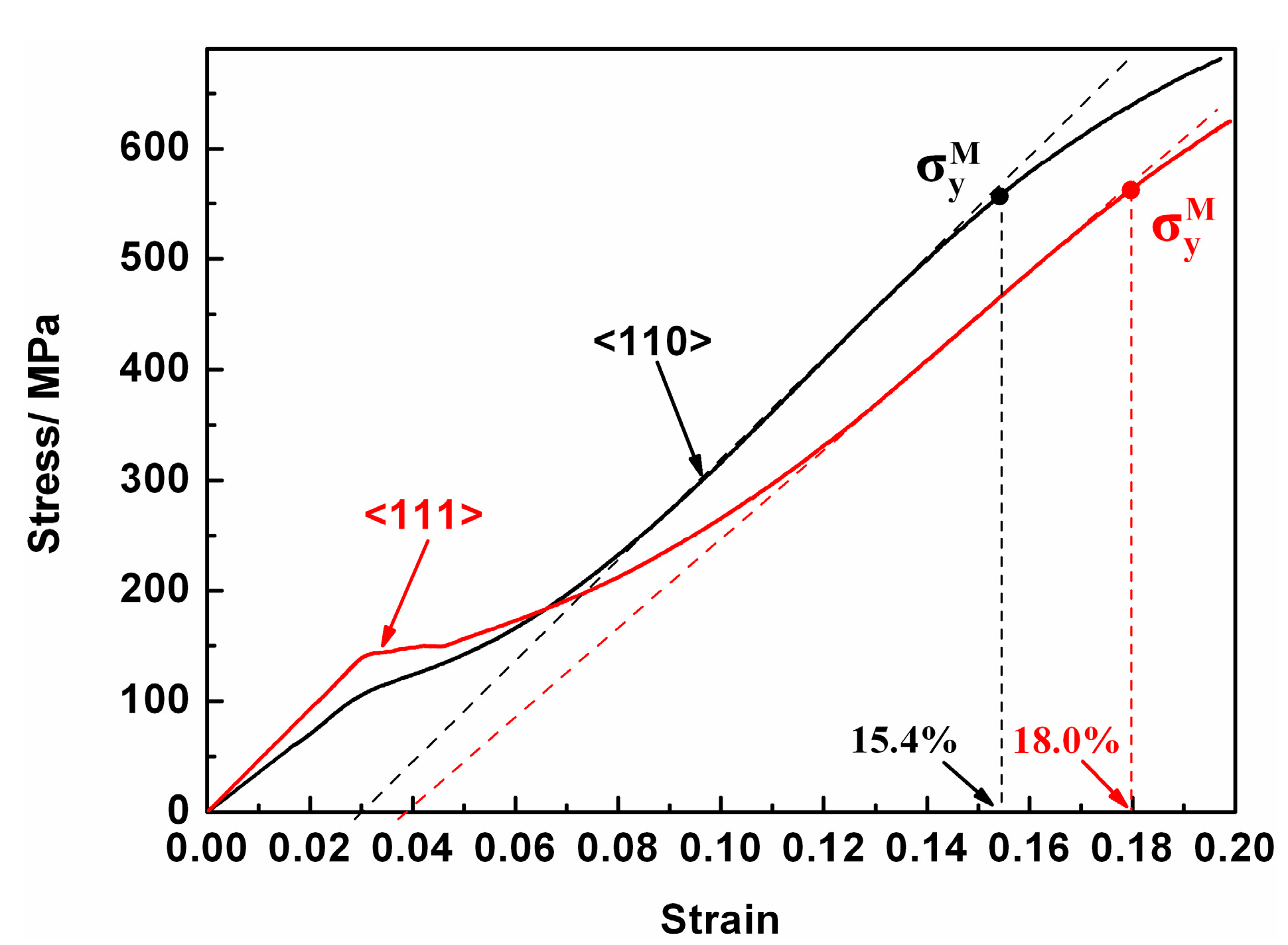

3.2. Tensile Tests and Corresponding Anisotropic SME in the Rods

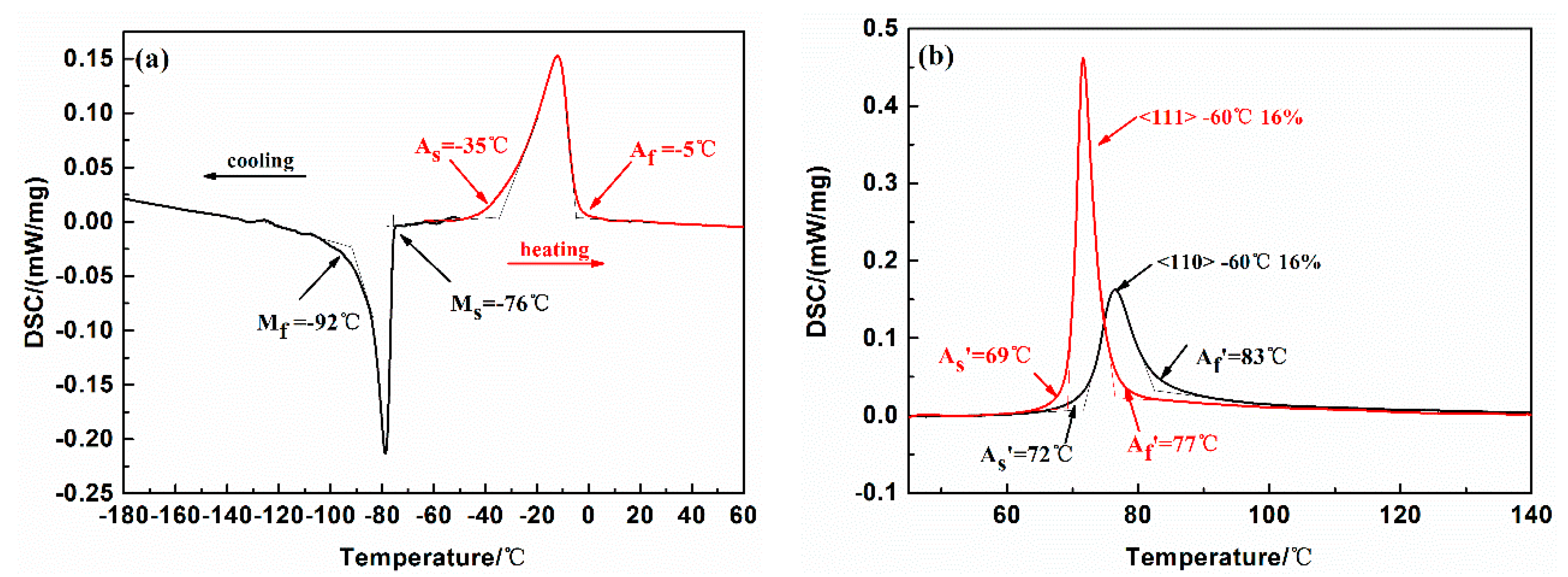

3.3. Recoverability of the Pipe Joins

4. Discussions

4.1. Effects of {111}<110> Orientation on SME in the Uniaxial Tensile Samples

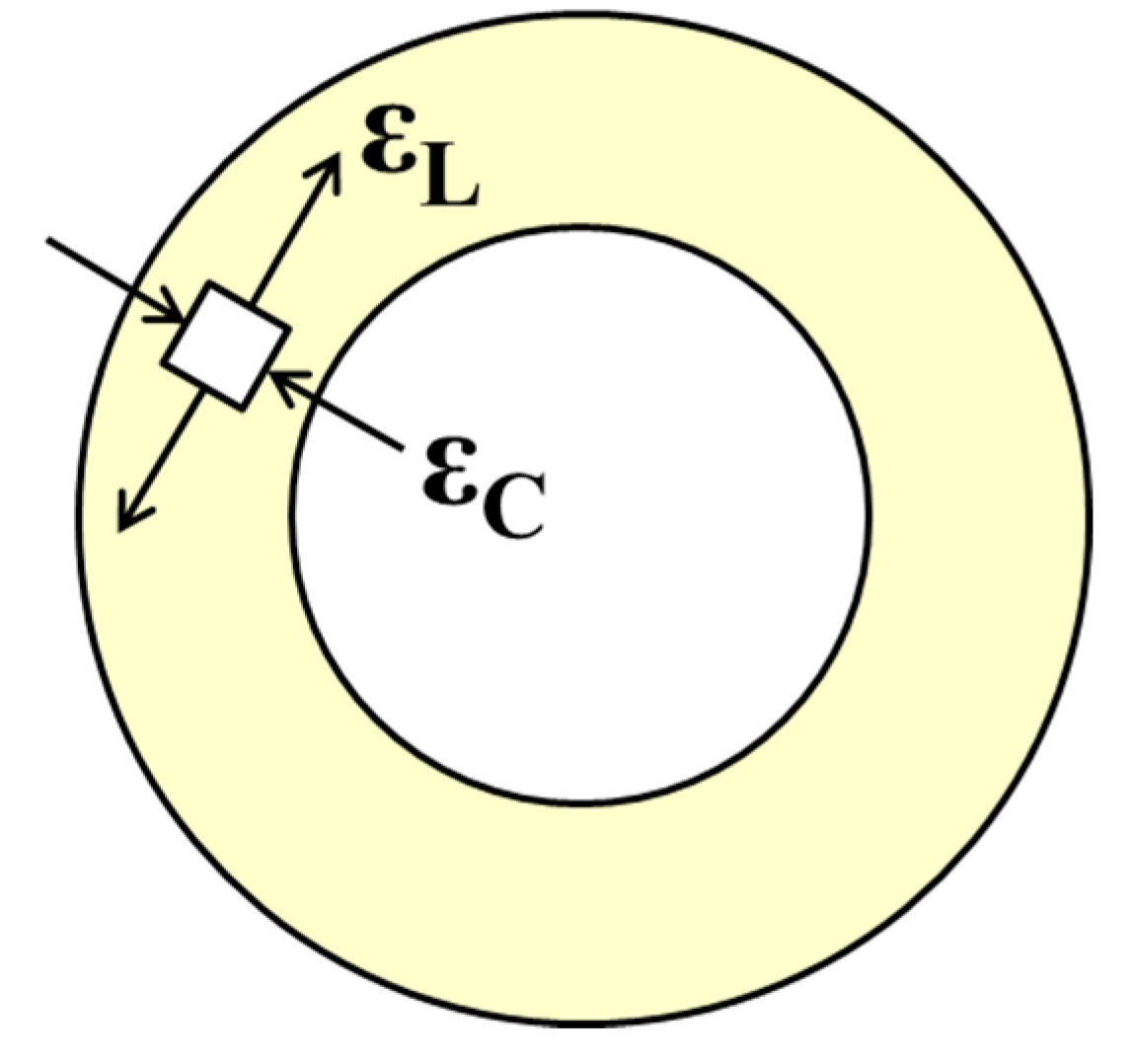

4.2. Effects of {111}<110> Orientation on SME in Pipe Joints

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Chen, X.; Liu, T.; Li, R.; Liu, J.S.; Zhao, Y. Molecular dynamics simulation on the shape memory effect and superelasticity in NiTi shape memory alloy. Comput. Mater. Sci. 2018, 146, 61–69. [Google Scholar] [CrossRef]

- Luo, J.; Bobanga, J.O.; Lewandowski, J. Microstructural heterogeneity and texture of as-received, vacuum arc-cast, extruded, and re-extruded NiTi shape memory alloy. J. Alloy. Compd. 2017, 712, 494–509. [Google Scholar] [CrossRef]

- Wang, X.B.; Verlinden, B.; Kustov, S. Multi-stage martensitic transformation in Ni-rich NiTi shape memory alloys. Funct. Mater. Lett. 2017, 10, 1740004. [Google Scholar] [CrossRef]

- Li, J.; Wang, H.F.; Liu, J.; Ruan, J.M. Effects of Nb addition on microstructure and mechanical properties of TiNiNb alloys fabricated by elemental powder sintering. Mater. Sci. Eng. A 2014, 609, 235–240. [Google Scholar] [CrossRef]

- Tabesh, M.; Boyd, J.; Atli, K.; Karaman, I.; Lagoudas, D. Design, fabrication, and testing of a multiple-actuation shape memory alloy pipe coupler. J. Intell. Mater. Syst. Struct. 2017, 29, 1165. [Google Scholar] [CrossRef]

- Niccoli, F.; Garion, C.; Maletta, C.; Sgambitterra, E.; Furgiuele, F.; Chiggiato, P. Beam-pipe coupling in particle accelerators by shape memory alloy rings. Mater. Des. 2017, 114, 603–611. [Google Scholar] [CrossRef]

- Niccoli, F.; Garion, C.; Maletta, C.; Chiggiato, P. Shape-memory alloy rings as tight couplers between ultrahigh-vacuum pipes: Design and experimental assessment. J. Vac. Sci. Technol. A 2017, 35, 031601. [Google Scholar] [CrossRef]

- Piotrowski, B.; Ben Zineb, T.; Patoor, E.; Eberhardt, A. Modeling of niobium precipitates effect on the Ni47Ti44Nb9 Shape Memory Alloy behavior. Int. J. Plast. 2012, 36, 130–147. [Google Scholar] [CrossRef]

- Zhu, R.; Tang, G.; Shi, S.-Q.; Fu, M. Effect of electroplastic rolling on deformability and oxidation of NiTiNb shape memory alloy. J. Mater. Process. Technol. 2013, 213, 30–35. [Google Scholar] [CrossRef]

- Jiang, S.Y.; Mao, Z.N.; Zhang, Y.Q.; Hu, L. Mechanisms of nanocrystallization and amorphization of NiTiNb shape memory alloy subjected to severe plastic deformation. Procedia Eng. 2017, 207, 1493–1498. [Google Scholar] [CrossRef]

- Fan, Q.; Zhang, Y.; Zhang, Y.; Wang, Y.; Yan, E.; Huang, S.; Wen, Y. Influence of Ni/Ti ratio and Nb addition on martensite transformation behavior of NiTiNb alloys. J. Alloy. Compd. 2019, 790, 1167–1176. [Google Scholar] [CrossRef]

- Fan, Q.C.; Sun, M.Y.; Zhang, Y.H.; Wang, Y.Y.; Zhang, Y.; Peng, H.B.; Sun, K.H.; Fan, X.H.; Huang, S.K.; Wen, Y.H. Influence of precipitation on phase transformation and mechanical properties of Ni-rich NiTiNb alloys. Mater. Charact. 2019, 154, 148–160. [Google Scholar] [CrossRef]

- Liu, W.; Zhao, X.Q. Mechanical Properties and Transformation Behavior of NiTiNb Shape Memory Alloys. Chin. J. Aeronaut. 2009, 22, 540–543. [Google Scholar]

- He, X.M.; Rong, L.J. Effect of Deformation on the Stress-Induced Martensitic Transformation in (Ni47Ti44)100-xNbx Shape Memory Alloys with Wide Hysteresis. Met. Mater Int. 2006, 12, 279–288. [Google Scholar] [CrossRef]

- He, X.M.; Rong, L.J. DSC analysis of reverse martensitic transformation in deformed Ti–Ni–Nb shape memory alloy. Scr. Mater. 2004, 51, 7–11. [Google Scholar] [CrossRef]

- Wang, L.; Rong, L.J.; Yan, D.S.; Jiang, Z.M.; Li, Y.Y. DSC study of the reverse martensitic transformation behavior in a shape memory alloy pipe-joint. Intermetallics 2005, 13, 403–407. [Google Scholar] [CrossRef]

- Tabesh, M.; Atli, K.; Rohmer, J.; Franco, B.; Karaman, I.; Boyd, J.G.; Lagoudas, D. Design of shape memory alloy pipe couplers: Modeling and experiments. Ind. Commer. Appl. Smart Struct. Technol. 2012, 8343, 83430J. [Google Scholar] [CrossRef]

- Yang, G.L.; Ni, Z.M.; Han, J.; Wang, E.M. Simulation on Pipe Joints Expansion Technology of NiTiNb Shape Memory Alloy. Adv. Mater. Res. 2011, 189–193, 1711–1717. [Google Scholar] [CrossRef]

- Uchida, K.; Shigenaka, N.; Sakuma, T.; Sutou, Y.; Yamauchi, K. Effects of Pre-Strain and Heat Treatment Temperature on Phase Transformation Temperature and Shape Recovery Stress of Ti-Ni-Nb Shape Memory Alloys for Pipe Joint Applications. Mater. Trans. 2008, 49, 1650–1655. [Google Scholar] [CrossRef]

- Zhang, C.S. Effects of deformation on the transformation hysteresis and shape memory effect in a Ni47Ti44Nb9 alloy. Scr. Mater. 1990, 24, 1807–1812. [Google Scholar] [CrossRef]

- Wang, K.L.; Lu, S.Q.; Li, G.F.; Liu, J.W.; Wang, E.M. Influence of Pre-Deformation Strain on Recovery Performance of Ni47Ti44Nb9 Alloy Φ8mm Pipe Joint. Adv. Mater. Res. 2015, 1095, 140–144. [Google Scholar] [CrossRef]

- Li, G.F.; Lu, S.Q.; Wang, K.L.; Liu, J.W.; Wang, E.M. Influence of Predeformation Temperature on Recovery Performance of Ni47Ti44Nb9 Alloy Φ16mm Pipe Joint. Adv. Mater. Res. 2014, 904, 41–45. [Google Scholar] [CrossRef]

- Wang, E.M.; Hong, Q.H.; Ni, Z.M.; Han, J. Influence of Processing State on Recovery Stress in NiTiNb Shape Memory Alloy. Adv. Mater. Res. 2014, 875–877, 1525–1528. [Google Scholar] [CrossRef]

- Cai, S.; Schaffer, J.E.; Ren, Y.; Wang, L. Deformation of a super-elastic NiTiNb alloy with controllable stress hysteresis. Appl. Phys. Lett. 2016, 108, 261901. [Google Scholar] [CrossRef]

- Hamilton, R.F.; Lanba, A.; Ozbulut, O.E.; Tittmann, B.R. Shape Memory Effect in Cast Versus Deformation-Processed NiTiNb Alloys. Shape Mem. Superelast. 2015, 1, 117–123. [Google Scholar] [CrossRef]

- Yan, Y.; Jin, W.; Li, X. Texture Development in the Ni47Ti44Nb9 Shape Memory Alloy During Successive Thermomechanical Processing and Its Effect on Shape Memory and Mechanical Properties. Met. Mater. Trans. A 2012, 44, 978–989. [Google Scholar] [CrossRef]

- Yin, X.; Mi, X.; Li, Y.; Gao, B. Microstructure and Properties of Deformation Processed Polycrystalline Ni47Ti44Nb9 Shape Memory Alloy. J. Mater. Eng. Perform. 2012, 21, 2684–2690. [Google Scholar] [CrossRef]

- Feng, Z.W.; Mi, X.J.; Wang, J.B.; Yuan, Z.S.; Zhou, J. Effect of Annealing Temperature on the Transformation Temperature and Texture of Ni47Ti44Nb9 Cold-Rolled Plate. Adv. Mater. Res. 2012, 557, 1281–1287. [Google Scholar] [CrossRef]

- Liu, H.; Sun, G.; Wang, Y.; Chen, B.; Tian, Q.; Wang, X.; Zhang, C. Texture evolution in shocked Ni47Ti44Nb9 shape memory alloys. Mater. Sci. Technol. 2013, 29, 1499–1502. [Google Scholar] [CrossRef]

- Gall, K.; Sehitoglu, H.; Chumlyakov, Y.I.; Kireeva, I.V. Tension-compression asymmetry of the stress-strain response in aged single crystal and polycrystalline. NiTi Acta Mater. 1999, 47, 1203–1217. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kimura, S.; Otsuka, K.; Suzuki, Y. The habit plane and transformation strains associated with the martensitic transformation in Ti-Ni single crystals. Scr. Metall. 1984, 18, 883. [Google Scholar] [CrossRef]

- Sun, G.A.; Wang, X.L.; Wang, Y.D.; Woo, W.C.; Wang, H.; Liu, X.P.; Chen, B.; Fu, Y.Q.; Sheng, L.S.; Ren, Y. In-situ high-energy synchrotron X-ray diffraction study of micromechanical behavior of multiple phases in Ni47Ti44Nb9 shape memory alloy. Mater. Sci. Eng. A 2013, 560, 458–465. [Google Scholar] [CrossRef]

- Chen, X.; Peng, X.; Chen, B.; Han, J.; Zeng, Z.; Hu, N. Experimental investigation on transformation, reorientation and plasticity of Ni47Ti44Nb9SMA under biaxial thermal–mechanical loading. Smart Mater. Struct. 2015, 24, 75025. [Google Scholar] [CrossRef]

- Lin, H.C.; Wu, S.K.; Chou, T.S.; Kao, H.P. The effects of cold rolling on the martensitic transformation of an equiatomic TiNi alloy. Acta Metall. Mater. 1991, 39, 2069–2080. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, M.; Fan, Q.; Wang, Y.; Yang, Q.; Chen, J.; Huang, S.; Zhang, Y. {111}<110> Orientation Induced Anisotropy of Shape Memory Effect in NiTiNb Pipe Joints. Metals 2020, 10, 776. https://doi.org/10.3390/met10060776

Sun M, Fan Q, Wang Y, Yang Q, Chen J, Huang S, Zhang Y. {111}<110> Orientation Induced Anisotropy of Shape Memory Effect in NiTiNb Pipe Joints. Metals. 2020; 10(6):776. https://doi.org/10.3390/met10060776

Chicago/Turabian StyleSun, Mingyan, Qichao Fan, Yingying Wang, Qin Yang, Jie Chen, Shuke Huang, and Yonghao Zhang. 2020. "{111}<110> Orientation Induced Anisotropy of Shape Memory Effect in NiTiNb Pipe Joints" Metals 10, no. 6: 776. https://doi.org/10.3390/met10060776

APA StyleSun, M., Fan, Q., Wang, Y., Yang, Q., Chen, J., Huang, S., & Zhang, Y. (2020). {111}<110> Orientation Induced Anisotropy of Shape Memory Effect in NiTiNb Pipe Joints. Metals, 10(6), 776. https://doi.org/10.3390/met10060776