High Cycle Fatigue Data Transferability of MAR-M 247 Superalloy from Separately Cast Specimens to Real Gas Turbine Blade

Abstract

1. Introduction

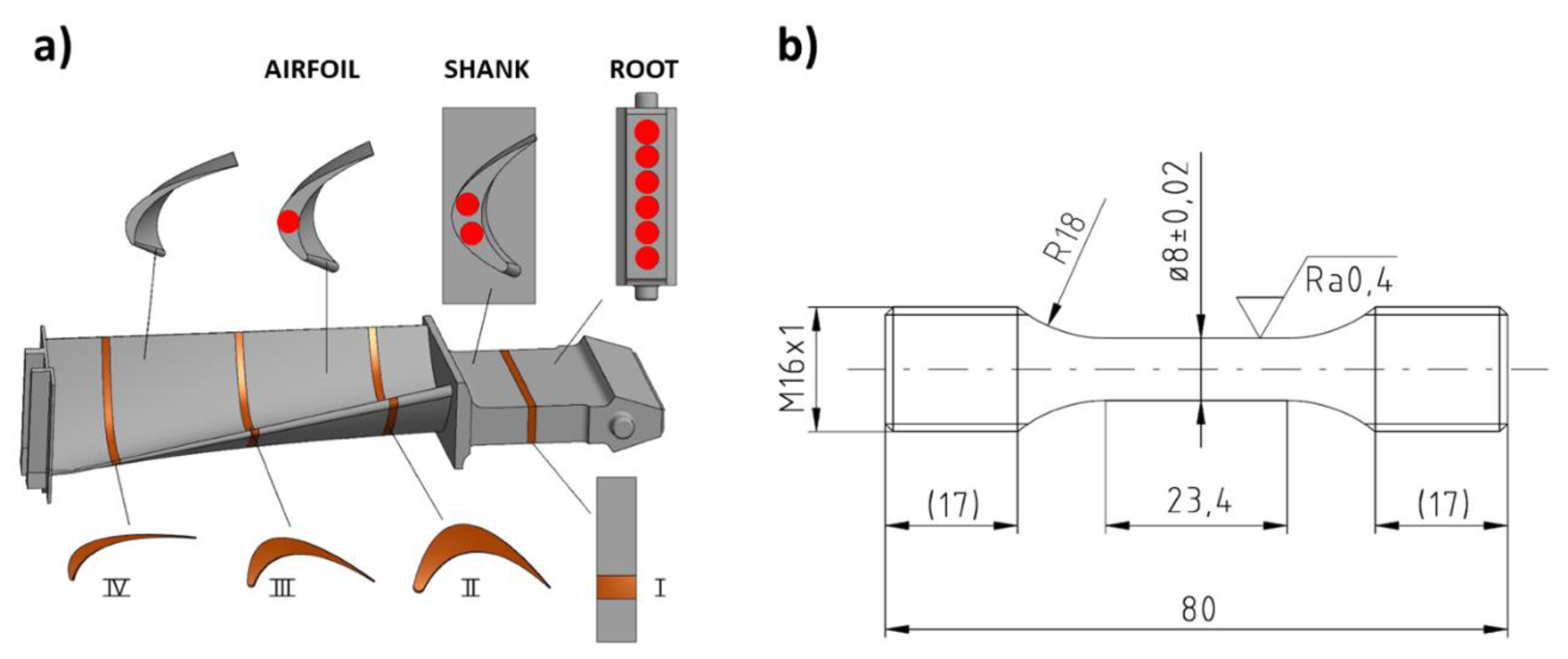

2. Materials and Methods

3. Results

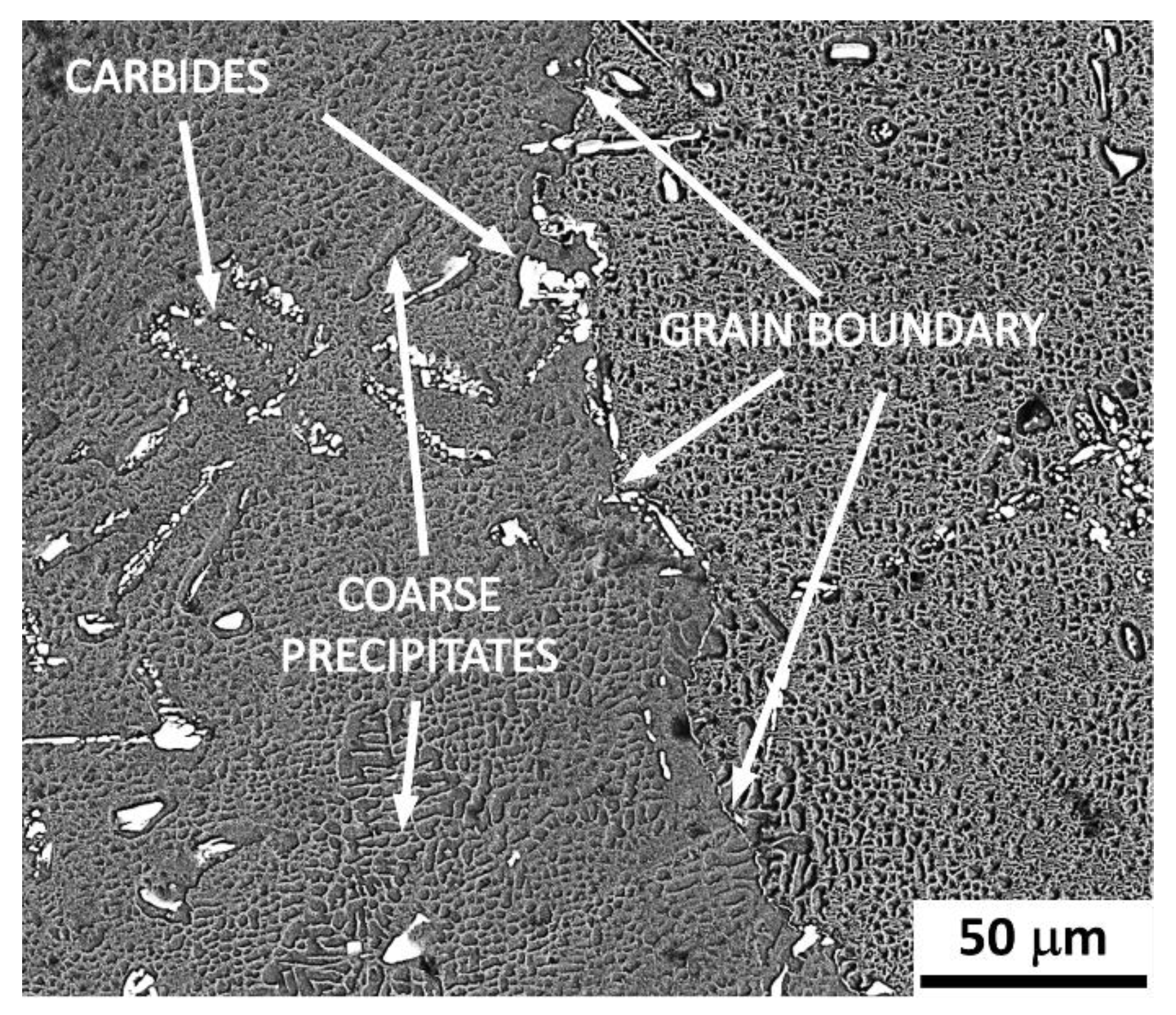

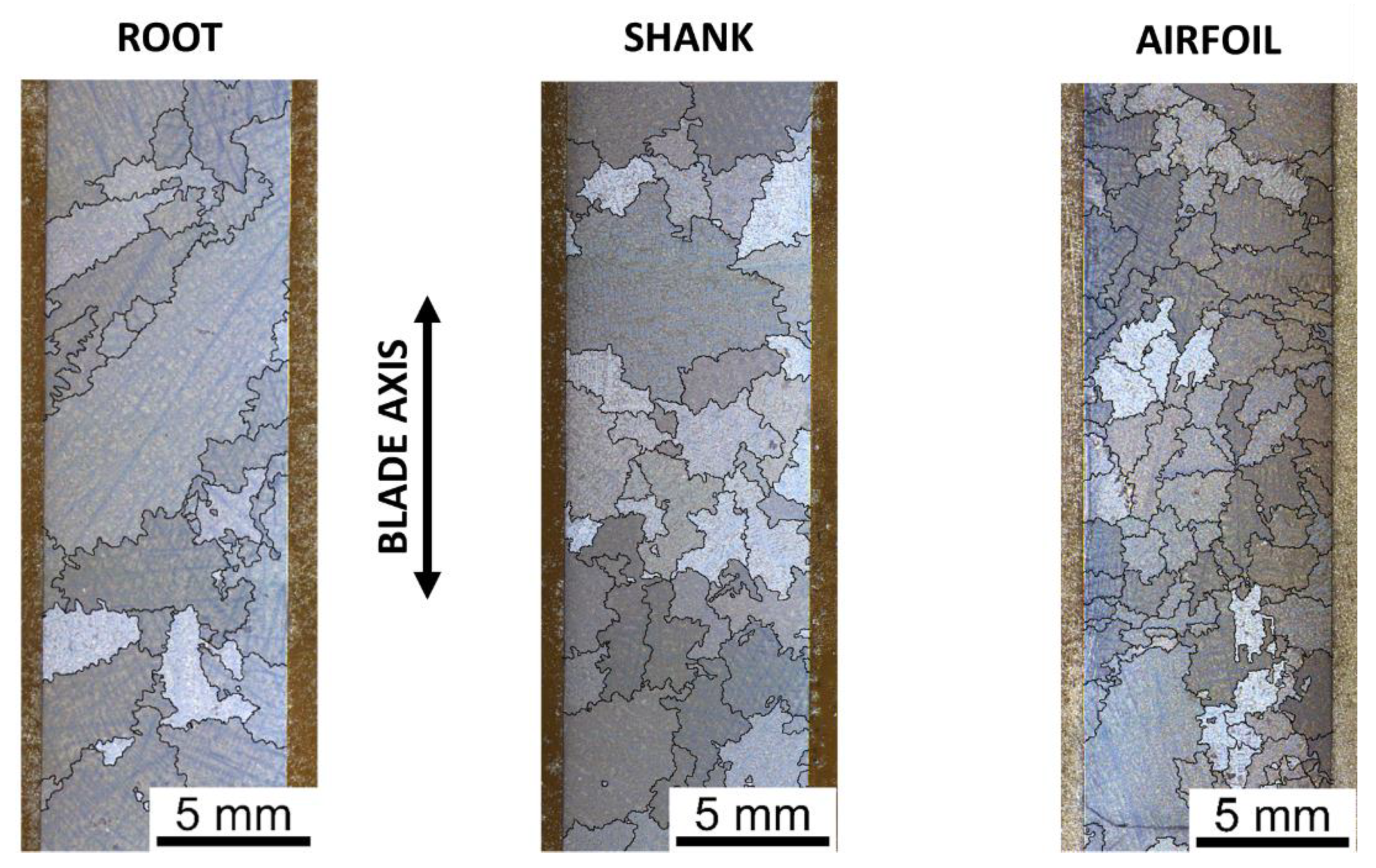

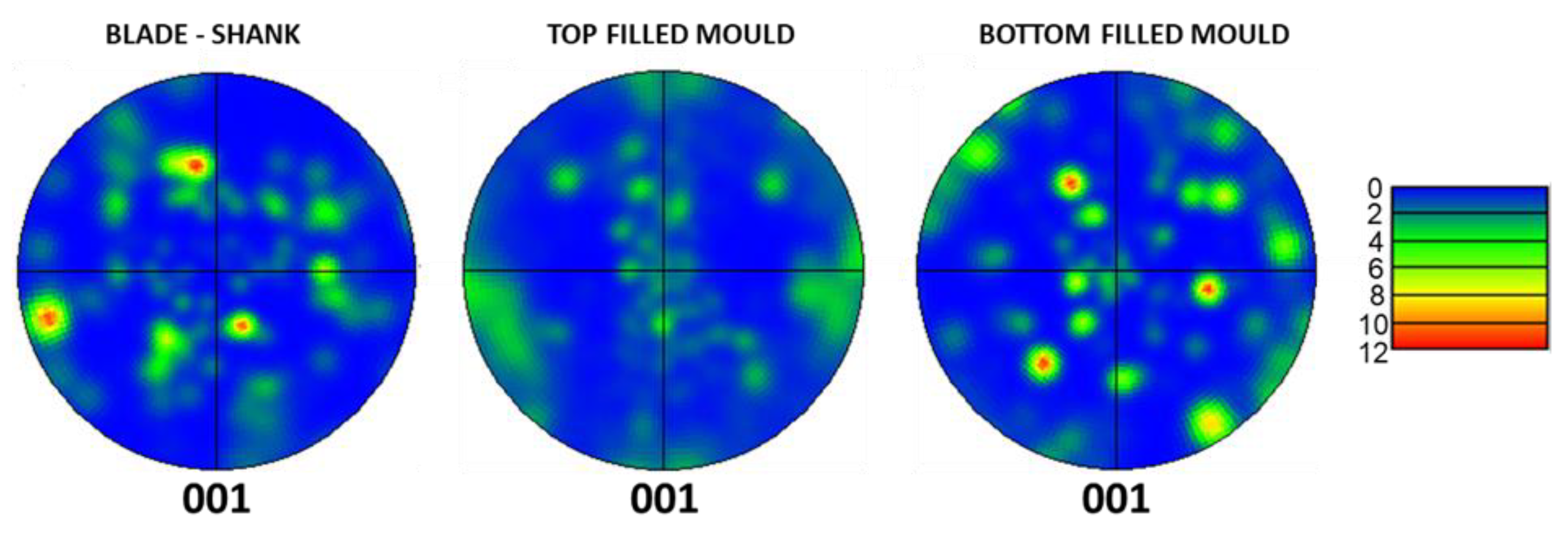

3.1. Microstructural Characterization

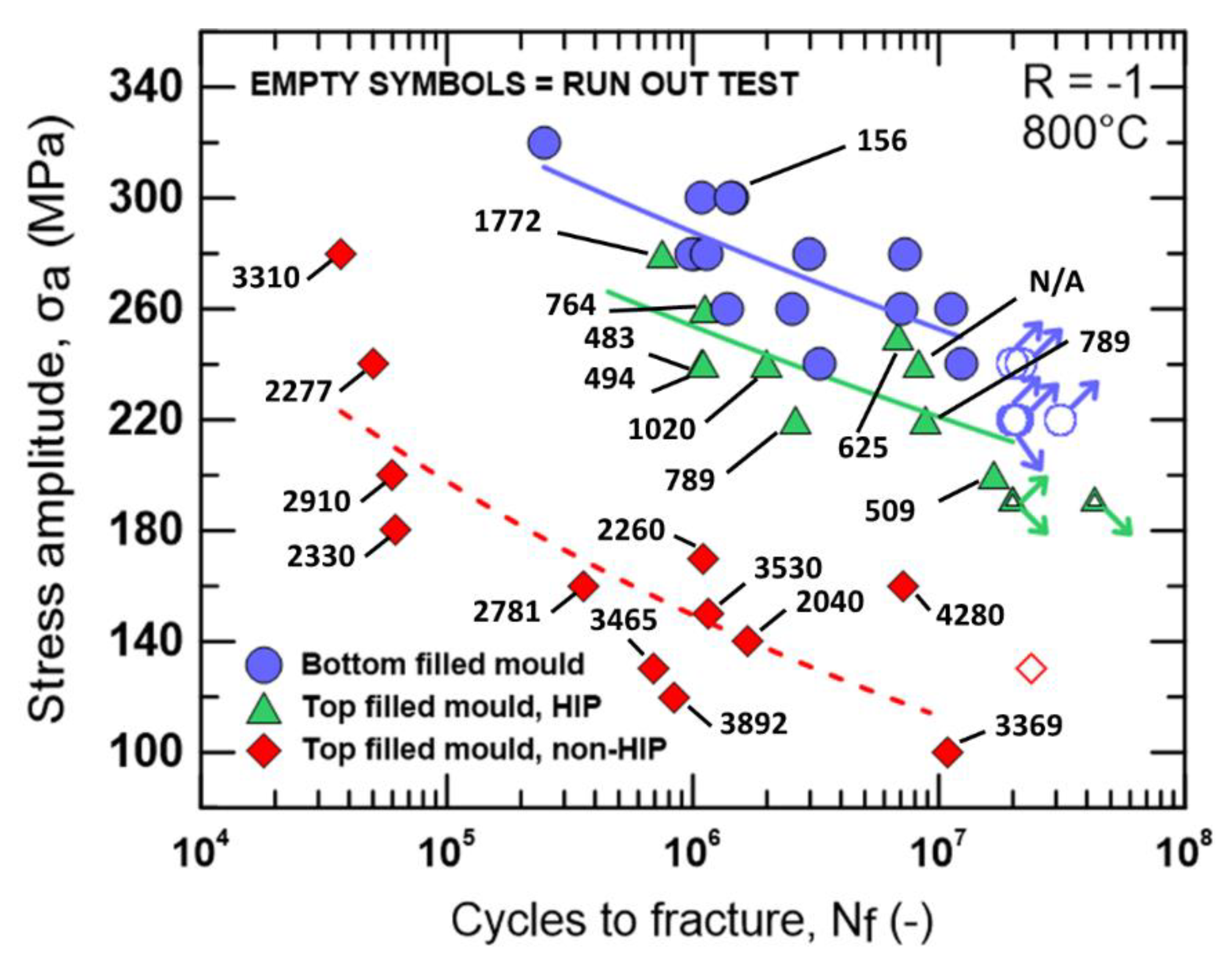

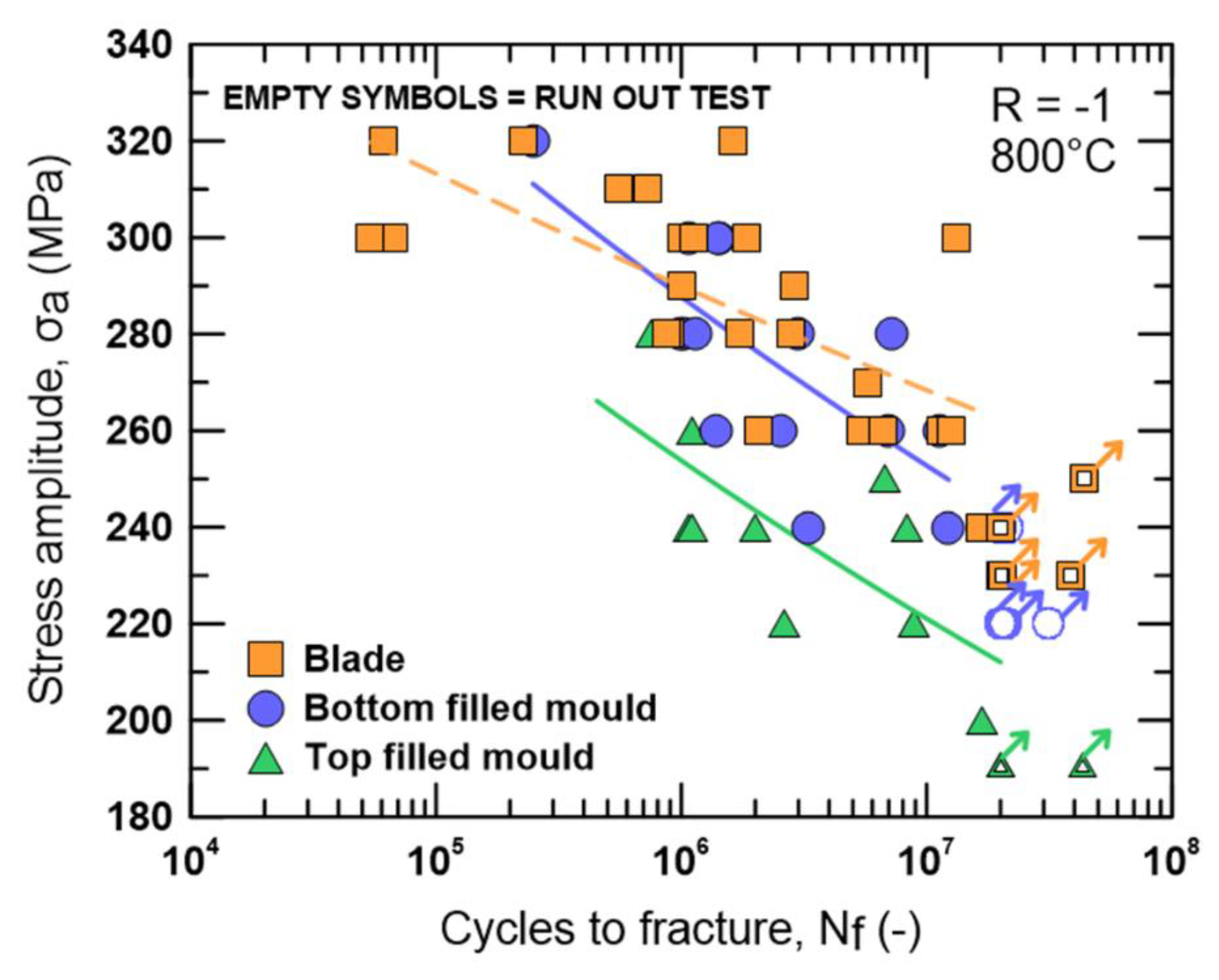

3.2. Fatigue Life

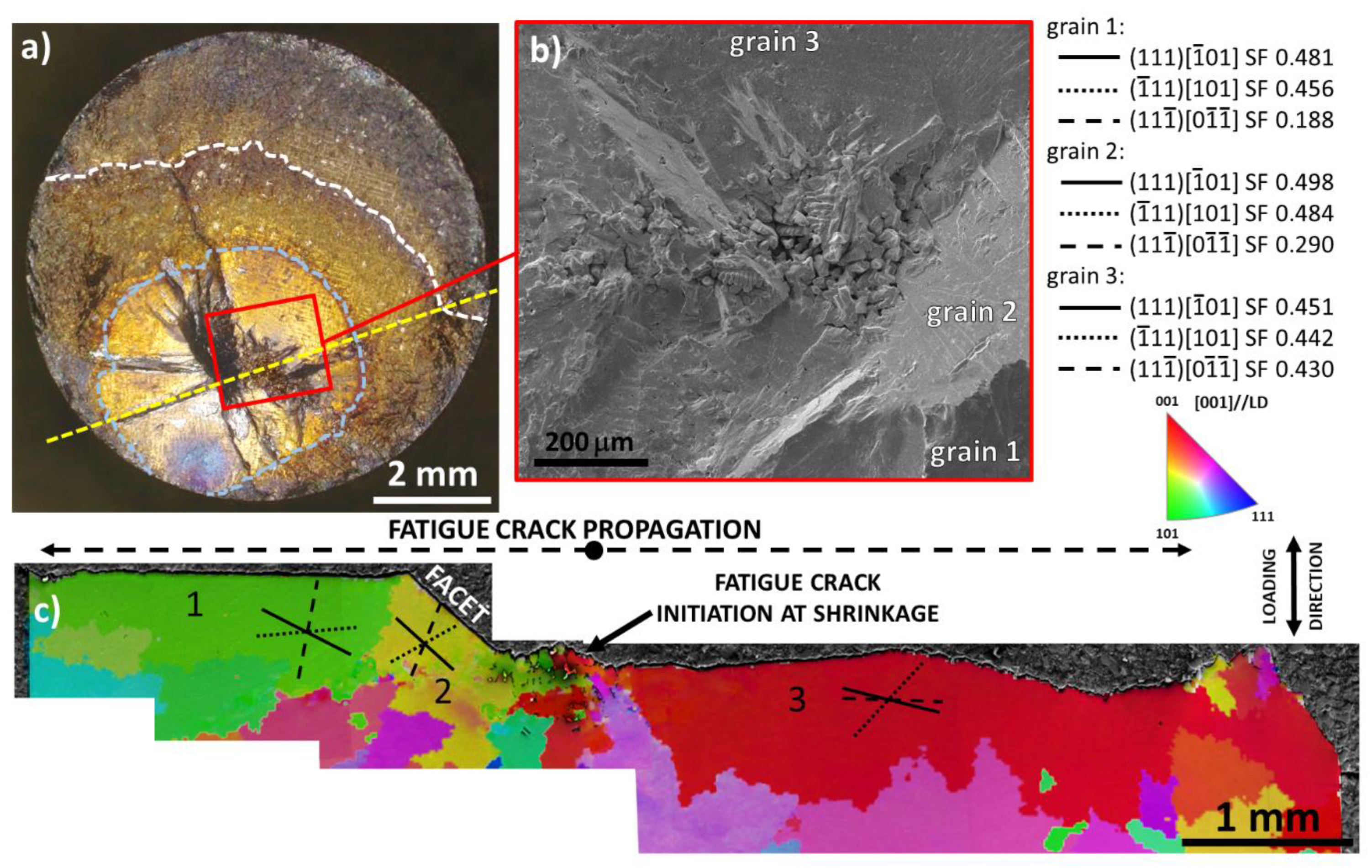

3.3. Fractographic Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lin, H.; Geng, H.P.; Zhang, Y.Y.; Li, H.; Liu, X.Y.; Zhou, X.F.; Yu, L. Fatigue Strength and Life Prediction of a MAR-M247 Nickel-Base Superalloy Gas Turbine Blade with Multiple Carbide Inclusions. Strength Mater. 2019, 51, 102–112. [Google Scholar] [CrossRef]

- Liu, G.; Salvat Cantó, J.; Winwood, S.; Rhodes, K.; Birosca, S. The effects of microstructure and microtexture generated during solidification on deformation micromechanism in IN713C nickel-based superalloy. Acta Mater. 2018, 148, 391–406. [Google Scholar] [CrossRef]

- Liu, Y.; Kang, M.; Wu, Y.; Wang, M.; Li, M.; Yu, J.; Gao, H.; Wang, J. Crack formation and microstructure-sensitive propagation in low cycle fatigue of a polycrystalline nickel-based superalloy with different heat treatments. Int. J. Fatigue 2018, 108, 79–89. [Google Scholar] [CrossRef]

- Lamm, M.; Singer, R.F. The Effect of Casting Conditions on the High-Cycle Fatigue Properties of the Single-Crystal Nickel-Base Superalloy PWA 1483. Metall. Mater. Trans. A 2007, 38, 1177–1183. [Google Scholar] [CrossRef]

- Kunz, L.; Lukáš, P.; Konečná, R.; Fintová, S. Casting defects and high temperature fatigue life of IN 713LC superalloy. Int. J. Fatigue 2012, 41, 47–51. [Google Scholar] [CrossRef]

- Smid, M.; Hornik, V.; Hutar, P.; Hrbacek, K.; Kunz, L. High Cycle Fatigue Damage Mechanisms of MAR-M 247 Superalloy at High Temperatures. Trans. Indian Inst. Met. 2016, 69, 393–397. [Google Scholar] [CrossRef]

- He, L.Z.; Zheng, Q.; Sun, X.F.; Guan, H.R.; Hu, Z.Q.; Tieu, A.K.; Lu, C.; Zhu, H.T. Effect of carbides on the creep properties of a Ni-base superalloy M963. Mater. Sci. Eng. A 2005, 397, 297–304. [Google Scholar] [CrossRef]

- Liu, L.R.; Jin, T.; Zhao, N.R.; Wang, Z.H.; Sun, X.F.; Guan, H.R.; Hu, Z.Q. Effect of carbon addition on the creep properties in a Ni-based single crystal superalloy. Mater. Sci. Eng. A 2004, 385, 105–112. [Google Scholar] [CrossRef]

- Ruttert, B.; Meid, C.; Mujica Roncery, L.; Lopez-Galilea, I.; Bartsch, M.; Theisen, W. Effect of porosity and eutectics on the high-temperature low-cycle fatigue performance of a nickel-base single-crystal superalloy. Scr. Mater. 2018, 155, 139–143. [Google Scholar] [CrossRef]

- Asquith, G.; Pickard, A.C. Fatigue testing of gas turbine components. High Temp. Technol. 1988, 6, 131–143. [Google Scholar] [CrossRef]

- Hu, D. Combined fatigue experiments on full scale turbine components. Aircr. Eng. Aerosp. Technol. 2013, 85, 4–9. [Google Scholar] [CrossRef]

- Kiyak, Y.; Fedelich, B.; May, T.; Pfennig, A. Simulation of crack growth under low cycle fatigue at high temperature in a single crystal superalloy. Eng. Fract. Mech. 2008, 75, 2418–2443. [Google Scholar] [CrossRef]

- Witek, L. Simulation of crack growth in the compressor blade subjected to resonant vibration using hybrid method. Eng. Fail. Anal. 2015, 49, 57–66. [Google Scholar] [CrossRef]

- Chen, L.; Liu, Y.; Xie, L. Power-exponent function model for low-cycle fatigue life prediction and its applications – Part II: Life prediction of turbine blades under creep–fatigue interaction. Int. J. Fatigue 2007, 29, 10–19. [Google Scholar] [CrossRef]

- Lin, B.; Zhao, L.G.; Tong, J.; Christ, H.J. Crystal plasticity modeling of cyclic deformation for a polycrystalline nickel-based superalloy at high temperature. Mater. Sci. Eng. A 2010, 527, 3581–3587. [Google Scholar] [CrossRef]

- Xue, X.; Xu, L. Numerical simulation and prediction of solidification structure and mechanical property of a superalloy turbine blade. Mater. Sci. Eng. A 2009, 499, 69–73. [Google Scholar] [CrossRef]

- Whitesell, H.S.; Li, L.; Overfelt, R.A. Influence of solidification variables on the dendrite arm spacings of Ni-based superalloys. Metall. Mater. Trans. B 2000, 31, 546–551. [Google Scholar] [CrossRef]

- El-Bagoury, N.; Nofal, A. Microstructure of an experimental Ni base superalloy under various casting conditions. Mater. Sci. Eng. A 2010, 527, 7793–7800. [Google Scholar] [CrossRef]

- Holländer, D.; Kulawinski, D.; Weidner, A.; Thiele, M.; Biermann, H.; Gampe, U. Small-scale specimen testing for fatigue life assessment of service-exposed industrial gas turbine blades. Int. J. Fatigue 2016, 92, 262–271. [Google Scholar] [CrossRef]

- Yan, X.J.; Qi, M.J.; Deng, Y.; Chen, X.; Sun, R.J.; Lin, L.S.; Nie, J.X. Investigation on Material’s Fatigue Property Variation Among Different Regions of Directional Solidification Turbine Blades-Part II: Fatigue Tests on Bladelike Specimens. J. Eng. Gas Turbines Power-Trans. ASME 2014, 136, 102503. [Google Scholar] [CrossRef]

- Harris, K.; Erickson, G.L.; Schwer, R.E. MAR M 247 derivations—CM 247 LC DS alloy, CMSX® single crystal alloys, properties and performance. In Proceedings of the 1984, Seven Springs Mountain Resort, Champion, PA, USA, 2 October 1984. [Google Scholar]

- Janowski, G.M. The Effect of Tantalum on the Structure/Properties of Two Polycrystalline Nickel-Base Superalloys: B-1900+ Hf MAR-M247. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 1985. [Google Scholar]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification, 4th ed.; Trans Tech Publications: Aedermannsdorf, Switzerland, 1998. [Google Scholar]

- Mujica Roncery, L.; Lopez-Galilea, I.; Ruttert, B.; Huth, S.; Theisen, W. Influence of temperature, pressure, and cooling rate during hot isostatic pressing on the microstructure of an SX Ni-base superalloy. Mater. Des. 2016, 97, 544–552. [Google Scholar] [CrossRef]

- Haocheng, Z.; Anqiang, W.; Zhixun, W.; Zhufeng, Y.; Chengjiang, Z. Effects of Hot Isostatic Pressing (HIP) on Microstructure and Mechanical Properties of K403 Nickel-Based Superalloy. High Temp. Mater. Process. 2016, 35, 463–471. [Google Scholar] [CrossRef]

- Suresh, S. Fatigue of Materials, 2 ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Kunz, L.; Lukáš, P.; Konečná, R. High-cycle fatigue of Ni-base superalloy Inconel 713LC. Int. J. Fatigue 2010, 32, 908–913. [Google Scholar] [CrossRef]

- Yan, X.J.; Chen, X.; Sun, R.J.; Deng, Y.; Lin, L.S.; Nie, J.X. Investigation on Material’s Fatigue Property Variation Among Different Regions of Directional Solidification Turbine Blades-Part I: Fatigue Tests on Full Scale Blades. J. Eng. Gas Turbines Power-Trans. ASME 2014, 136, 102502. [Google Scholar] [CrossRef]

- Miao, J.; Pollock, T.M.; Wayne Jones, J. Crystallographic fatigue crack initiation in nickel-based superalloy René 88DT at elevated temperature. Acta Mater. 2009, 57, 5964–5974. [Google Scholar] [CrossRef]

- Šulák, I.; Obrtlík, K. AFM, SEM AND TEM study of damage mechanisms in cyclically strained mar-M247 at room temperature and high temperatures. Theor. Appl. Fract. Mech. 2020, 108, 102606. [Google Scholar] [CrossRef]

- Jiang, R.; Bull, D.J.; Evangelou, A.; Harte, A.; Pierron, F.; Sinclair, I.; Preuss, M.; Hu, X.T.; Reed, P.A.S. Strain accumulation and fatigue crack initiation at pores and carbides in a SX superalloy at room temperature. Int. J. Fatigue 2018, 114, 22–33. [Google Scholar] [CrossRef]

- Du, B.; Yang, J.; Cui, C.; Sun, X. Effects of grain size on the high-cycle fatigue behavior of IN792 superalloy. Mater. Design (1980-2015) 2015, 65, 57–64. [Google Scholar] [CrossRef]

- Gao, Y.; Stölken, J.S.; Kumar, M.; Ritchie, R.O. High-cycle fatigue of nickel-base superalloy René 104 (ME3): Interaction of microstructurally small cracks with grain boundaries of known character. Acta Mater. 2007, 55, 3155–3167. [Google Scholar] [CrossRef]

- Liu, G.; Winwood, S.; Rhodes, K.; Birosca, S. The effects of grain size, dendritic structure and crystallographic orientation on fatigue crack propagation in IN713C nickel-based superalloy. Int. J. Plast. 2020, 125, 150–168. [Google Scholar] [CrossRef]

- Leverant, G.R.; Gell, M. The influence of temperature and cyclic frequency on the fatigue fracture of cube oriented nickel-base superalloy single crystals. Metall. Trans. A 1975, 6, 367. [Google Scholar] [CrossRef]

- Bowles, C.Q.; Broek, D. On the formation of fatigue striations. Int. J. Fract. Mech. 1972, 8, 75–85. [Google Scholar] [CrossRef]

- Gunasegaram, D.R.; Farnsworth, D.J.; Nguyen, T.T. Identification of critical factors affecting shrinkage porosity in permanent mold casting using numerical simulations based on design of experiments. J. Mater. Process. Technol. 2009, 209, 1209–1219. [Google Scholar] [CrossRef]

- Flemings, M.C. Solidification processing. Metall. Trans. 1974, 5, 2121–2134. [Google Scholar] [CrossRef]

- Cox, M.; Wickins, M.; Kuang, J.P.; Harding, R.A.; Campbell, J. Effect of top and bottom filling on reliability of investment castings in Al, Fe, and Ni based alloys. Mater. Sci. Technol. 2000, 16, 1445–1452. [Google Scholar] [CrossRef]

- Wu, S.-P.; Li, C.-Y.; Guo, J.-J.; Su, Y.-Q.; Lei, X.-Q.; Fu, H.-Z. Numerical simulation and experimental investigation of two filling methods in vertical centrifugal casting. Trans. Nonferrous Met. Soc. China 2006, 16, 1035–1040. [Google Scholar] [CrossRef]

- Murakami, Y. Material defects as the basis of fatigue design. Int. J. Fatigue 2012, 41, 2–10. [Google Scholar] [CrossRef]

- Tammas-Williams, S.; Withers, P.J.; Todd, I.; Prangnell, P.B. The Influence of Porosity on Fatigue Crack Initiation in Additively Manufactured Titanium Components. Sci. Rep. 2017, 7, 7308. [Google Scholar] [CrossRef]

- Yi, J.Z.; Gao, Y.X.; Lee, P.D.; Flower, H.M.; Lindley, T.C. Scatter in fatigue life due to effects of porosity in cast A356-T6 aluminum-silicon alloys. Metall. Mater. Trans. A 2003, 34, 1879. [Google Scholar] [CrossRef]

- Wang, Q.G.; Apelian, D.; Lados, D.A. Fatigue behavior of A356-T6 aluminum cast alloys. Part I. Effect of casting defects. J. Light Met. 2001, 1, 73–84. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Yang, N.; Gall, K.; McDowell, D.; Fan, J.; Gullett, P. High cycle fatigue mechanisms in a cast AM60B magnesium alloy. Fatigue Fract. Eng. Mater. Struct. 2002, 25, 1045–1056. [Google Scholar] [CrossRef]

- Nicoletto, G.; Konečná, R.; Fintova, S. Characterization of microshrinkage casting defects of Al–Si alloys by X-ray computed tomography and metallography. Int. J. Fatigue 2012, 41, 39–46. [Google Scholar] [CrossRef]

| C | Cr | W | Co | Al | Ti | Ta | Hf | Mo | Nb | B | Ni |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.15 | 8.37 | 9.92 | 9.91 | 5.42 | 1.01 | 3.05 | 1.37 | 0.67 | 0.04 | 0.015 | bal. |

| Average Grain Area [mm2] | Grain Size Scatter [mm2] | SDAS [µm] | |

|---|---|---|---|

| Root | 4.91 | 0.1–51.21 | 136 ± 39 |

| Shank | 4.35 | 0.02–30.62 | 105 ± 24 |

| Airfoil | 1.46 | 0.01–19.36 | 101 ± 27 |

| Top filled mould without HIP * | 0.33 | 0.01–5.76 | 33 ± 5 |

| Top filled mould with HIP | 0.36 | 0.02–6.14 | 34 ± 8 |

| Bottom filled mould | 2.45 | 0.02–18.66 | 39 ± 8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šmíd, M.; Horník, V.; Kunz, L.; Hrbáček, K.; Hutař, P. High Cycle Fatigue Data Transferability of MAR-M 247 Superalloy from Separately Cast Specimens to Real Gas Turbine Blade. Metals 2020, 10, 1460. https://doi.org/10.3390/met10111460

Šmíd M, Horník V, Kunz L, Hrbáček K, Hutař P. High Cycle Fatigue Data Transferability of MAR-M 247 Superalloy from Separately Cast Specimens to Real Gas Turbine Blade. Metals. 2020; 10(11):1460. https://doi.org/10.3390/met10111460

Chicago/Turabian StyleŠmíd, Miroslav, Vít Horník, Ludvík Kunz, Karel Hrbáček, and Pavel Hutař. 2020. "High Cycle Fatigue Data Transferability of MAR-M 247 Superalloy from Separately Cast Specimens to Real Gas Turbine Blade" Metals 10, no. 11: 1460. https://doi.org/10.3390/met10111460

APA StyleŠmíd, M., Horník, V., Kunz, L., Hrbáček, K., & Hutař, P. (2020). High Cycle Fatigue Data Transferability of MAR-M 247 Superalloy from Separately Cast Specimens to Real Gas Turbine Blade. Metals, 10(11), 1460. https://doi.org/10.3390/met10111460