Experimental Characterization of Tool Wear Morphology and Cutting Force Profile in Dry and Wet Turning of Titanium Metal Matrix Composites (Ti-MMCs)

Abstract

1. Introduction

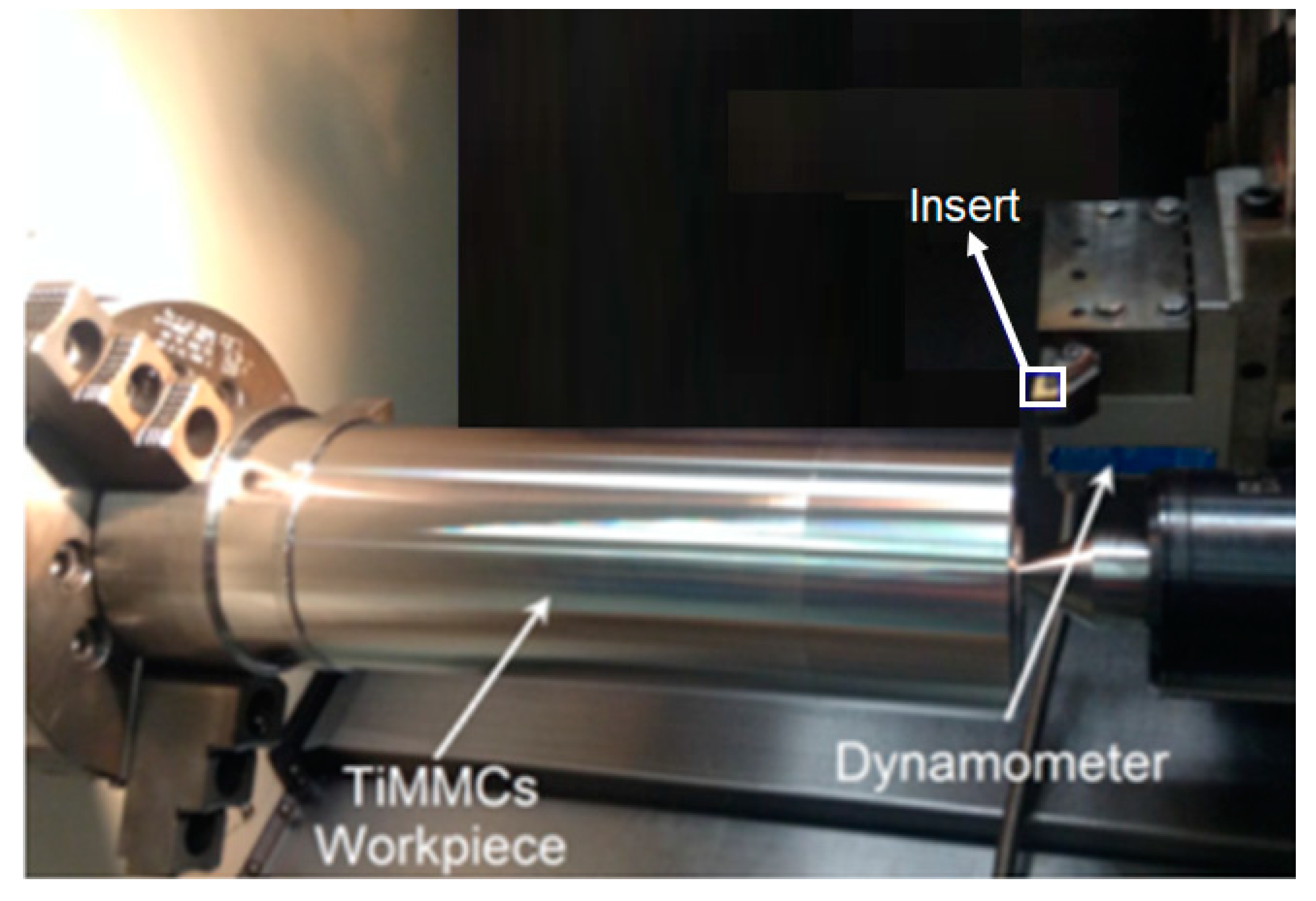

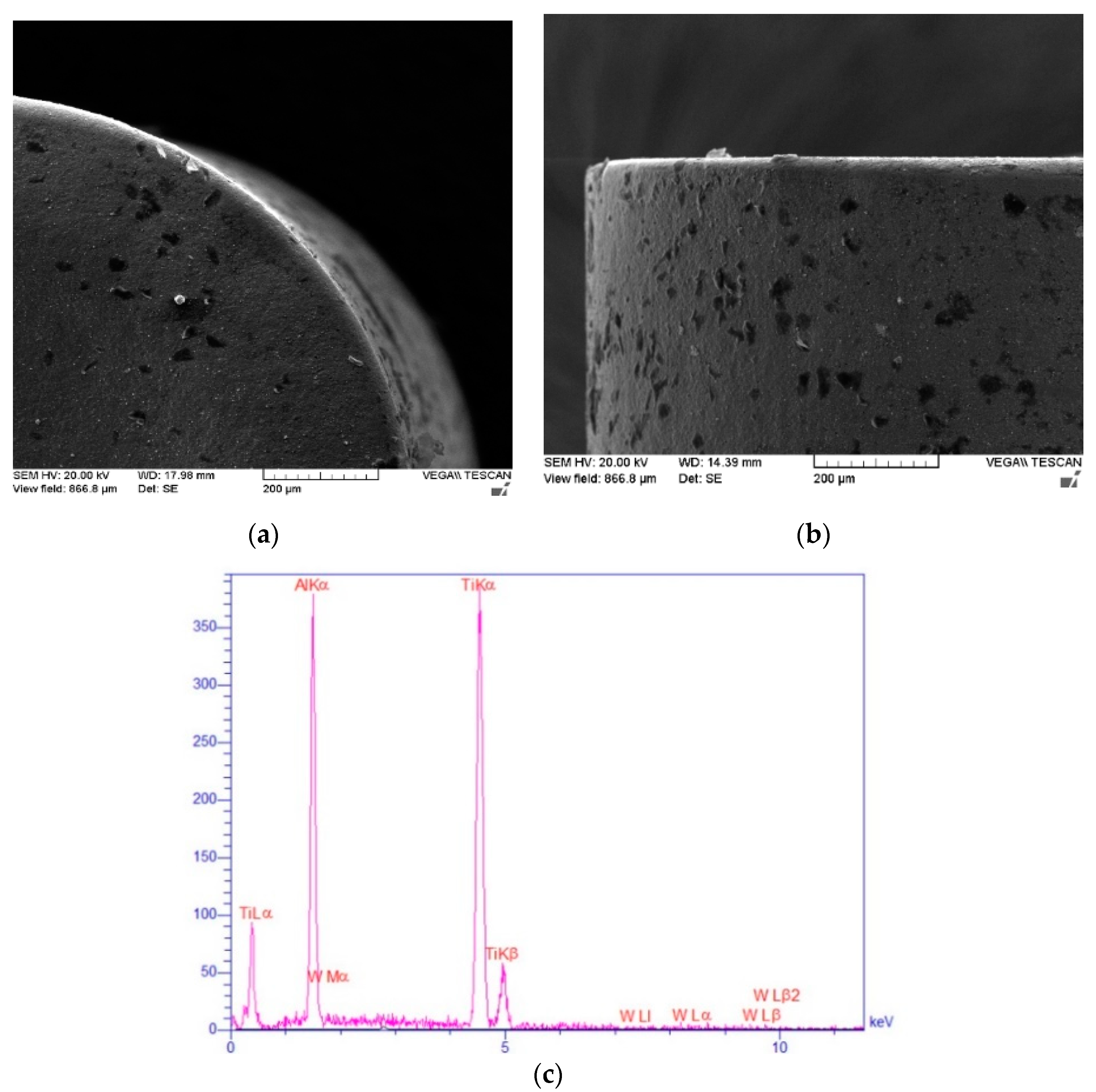

2. Materials and Methods

3. Results and Discussion

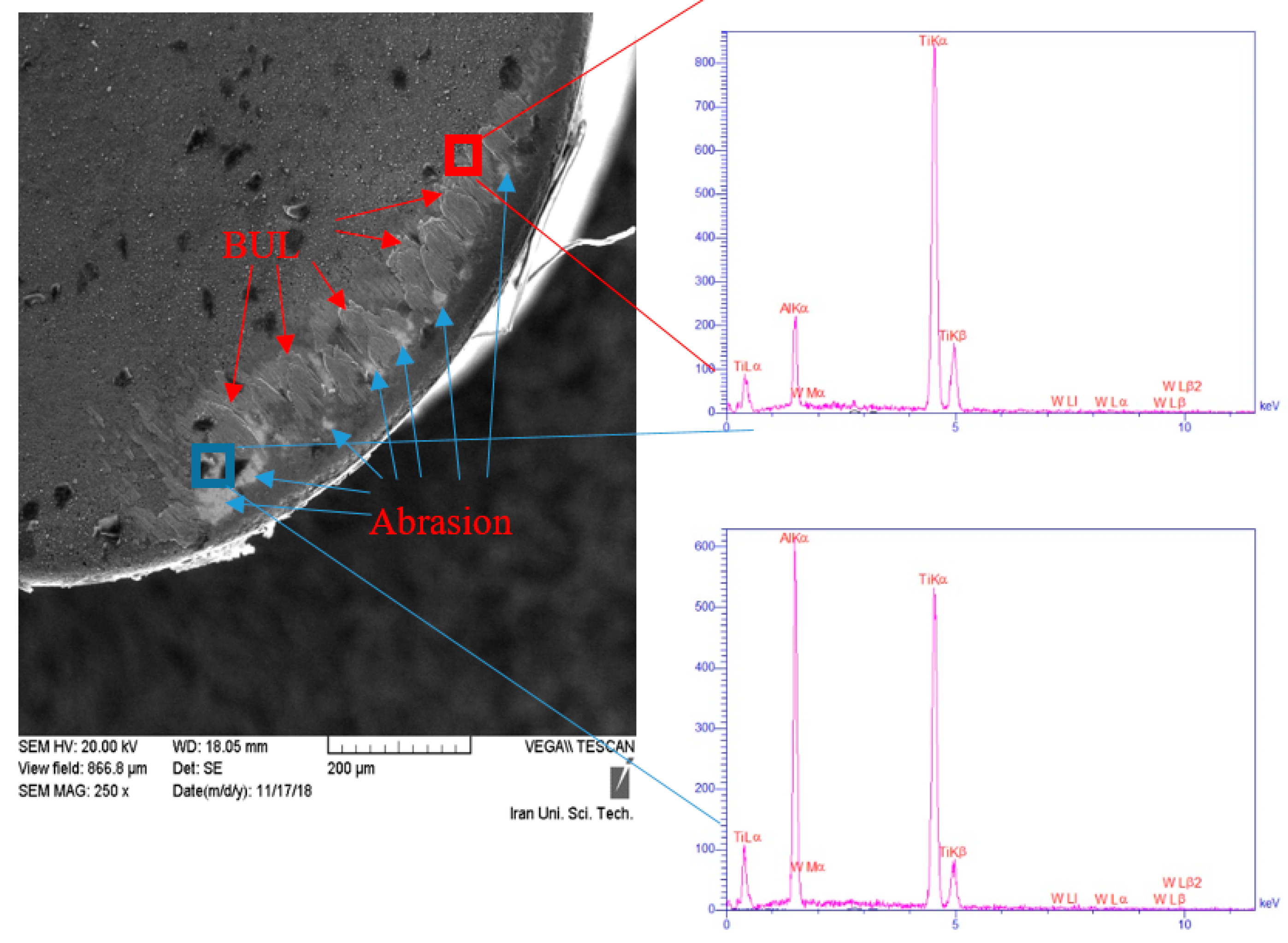

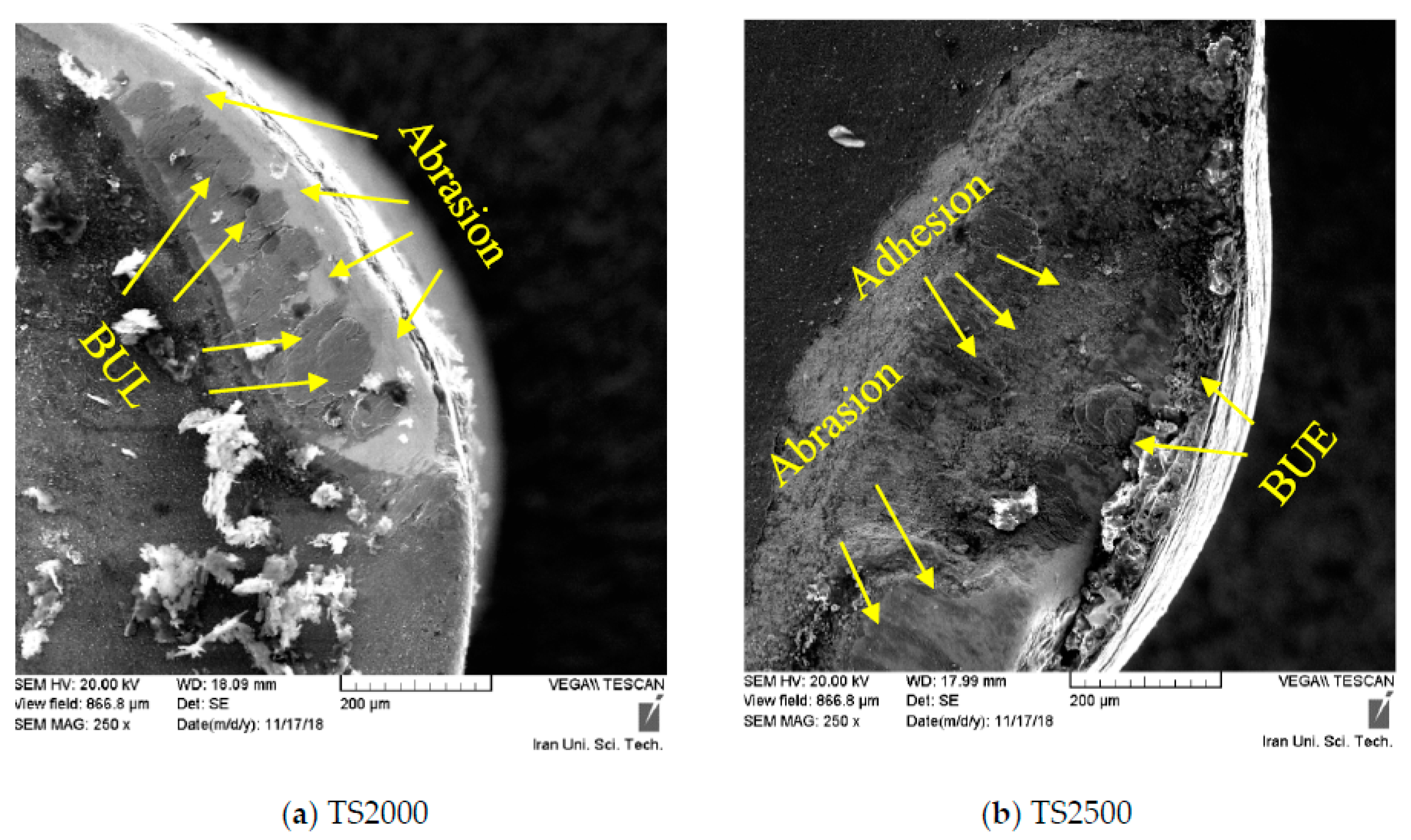

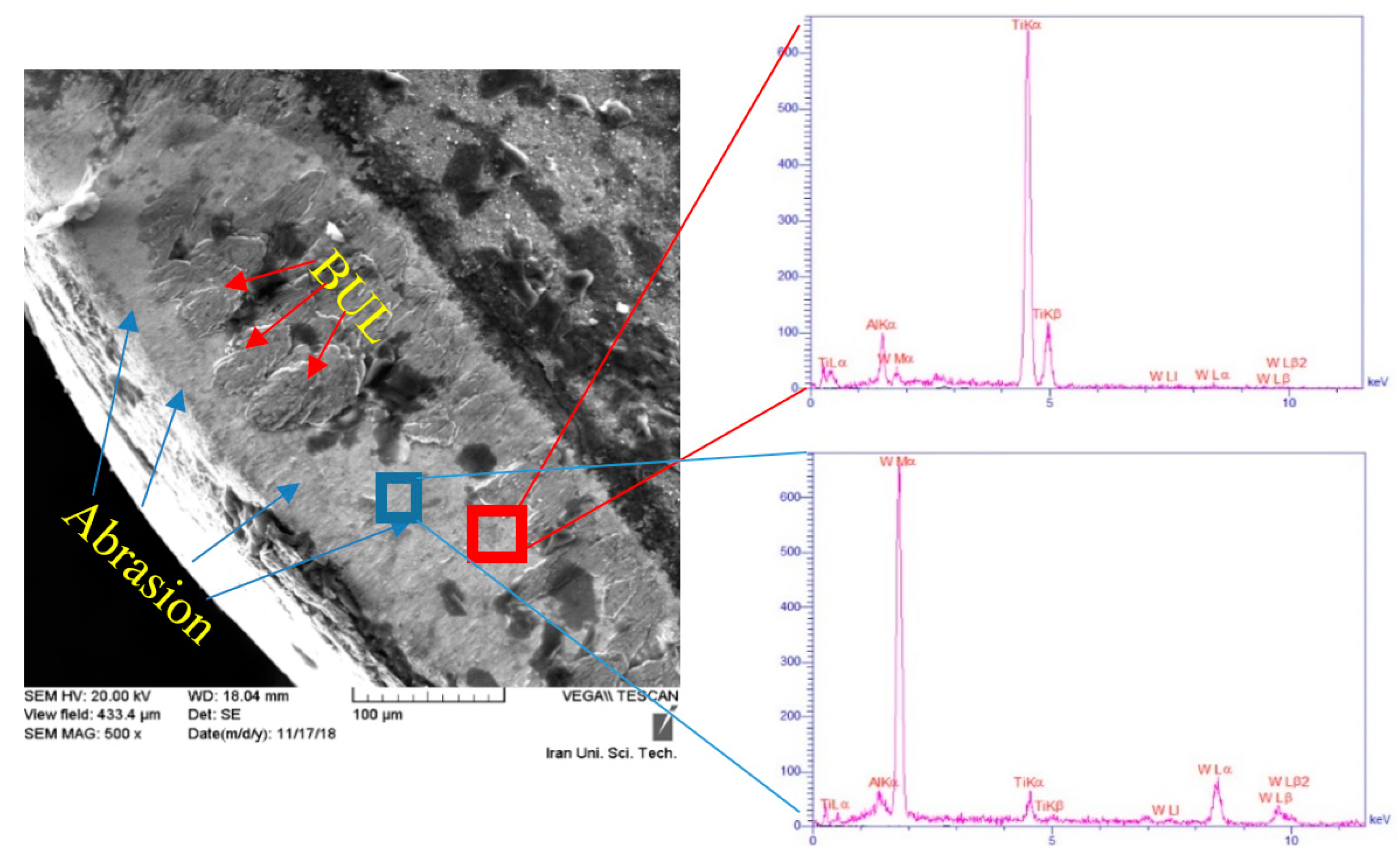

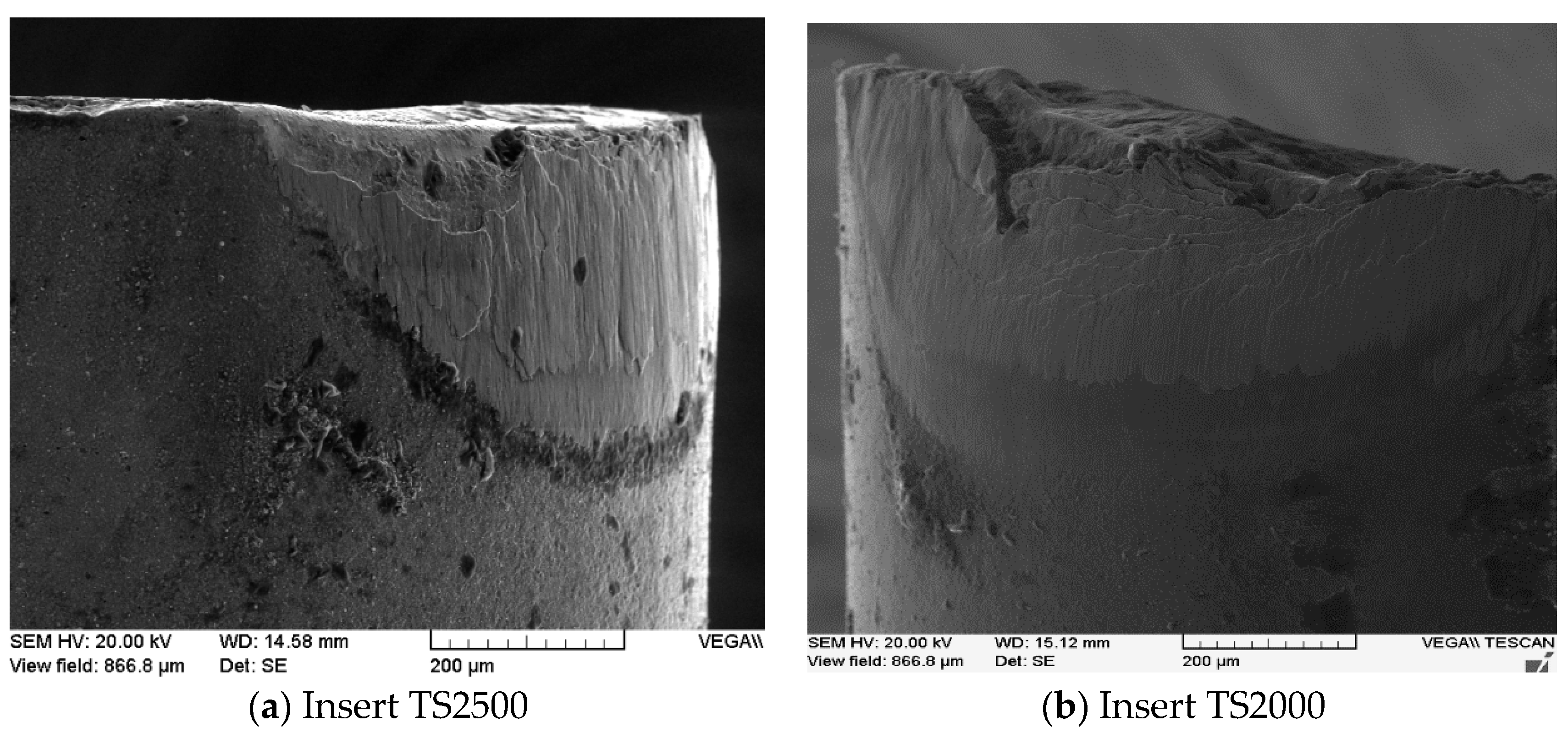

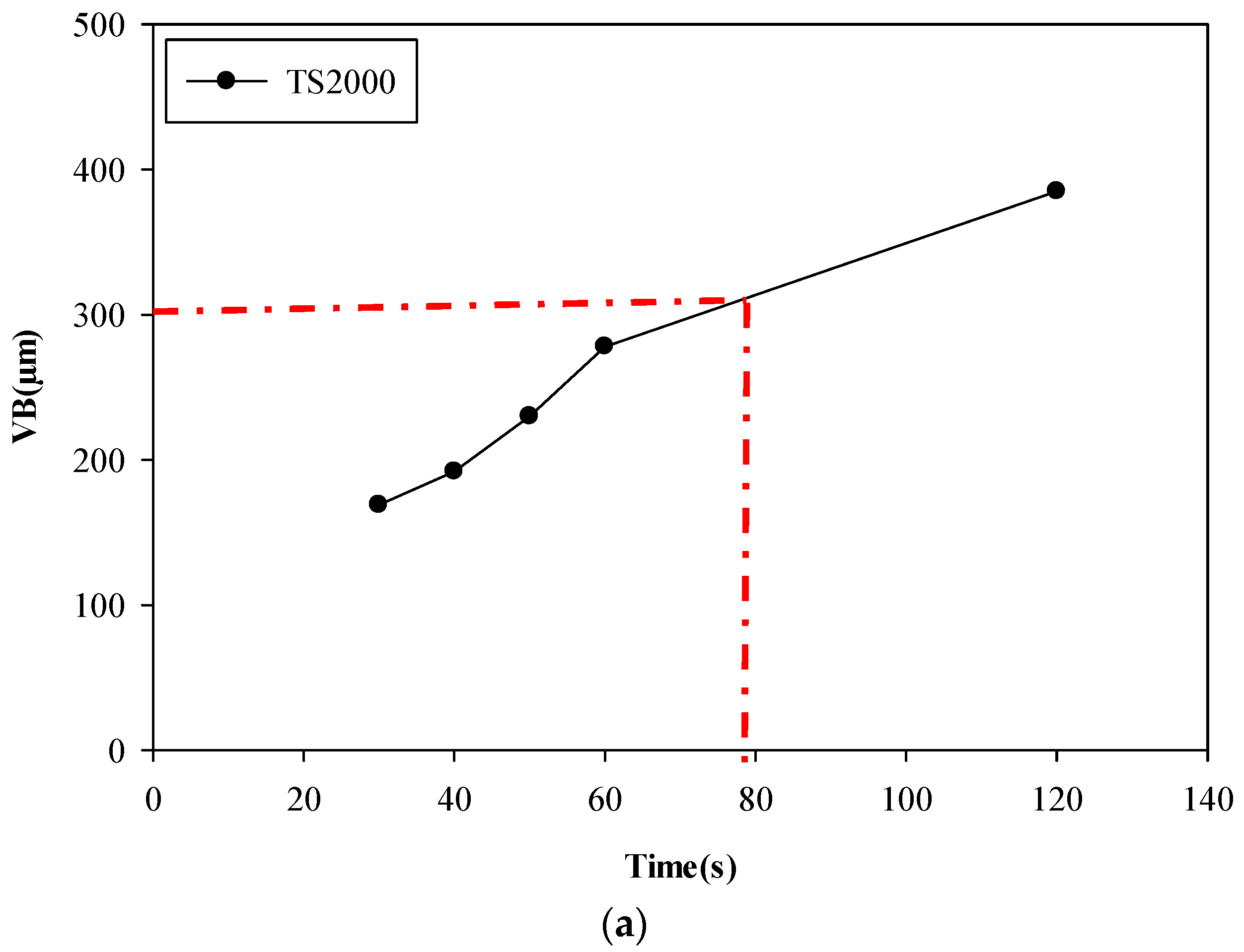

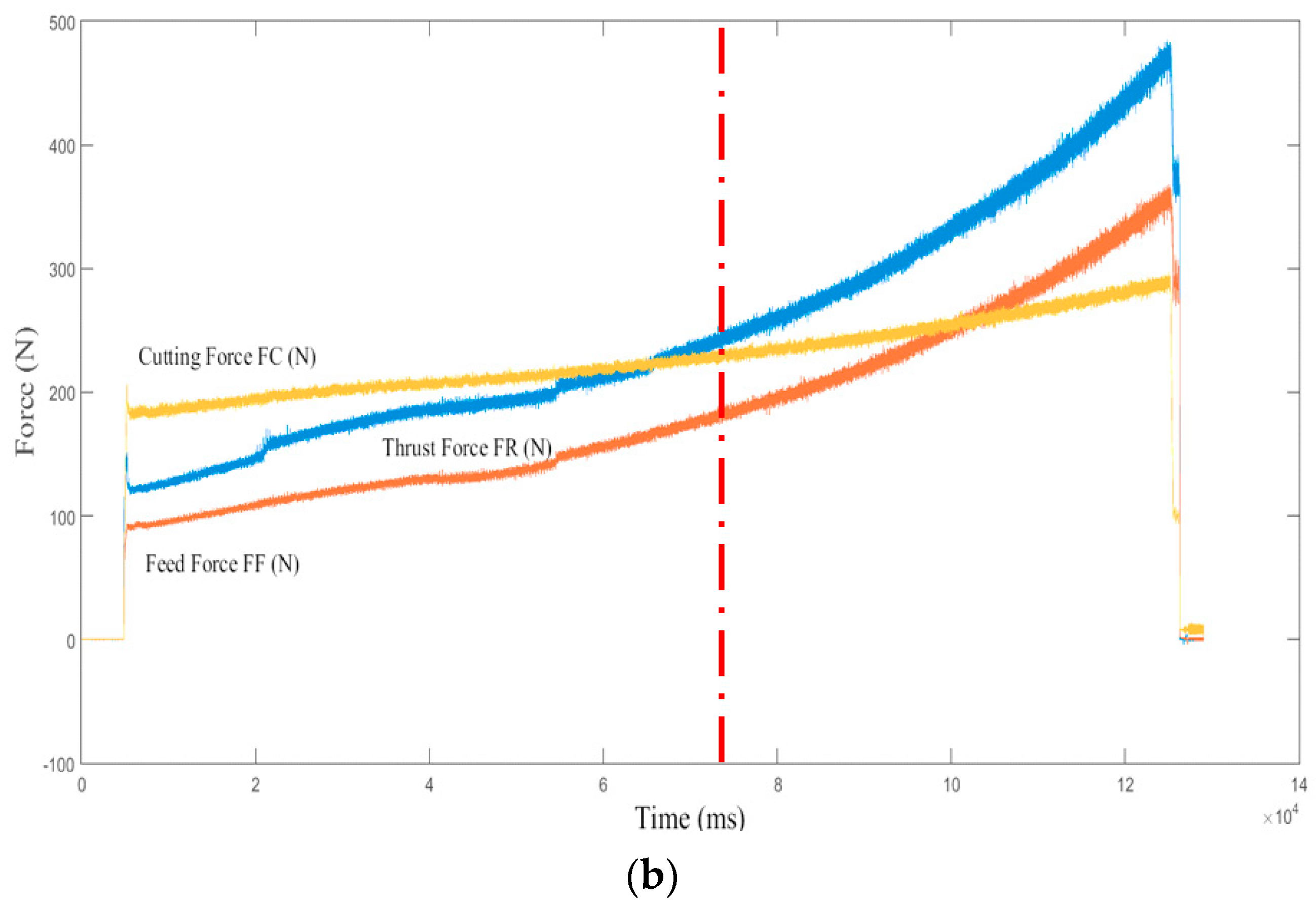

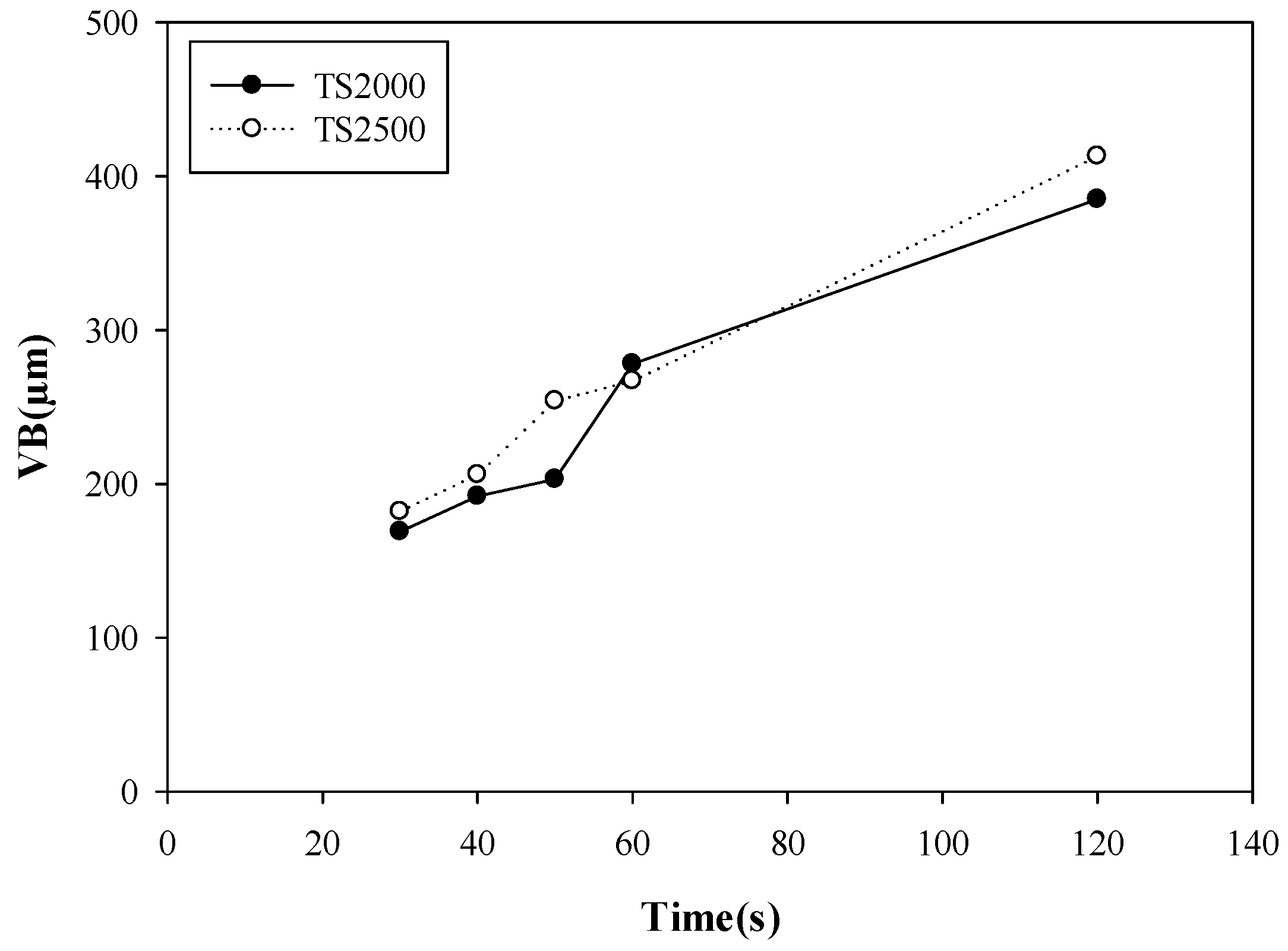

3.1. Dry Mode

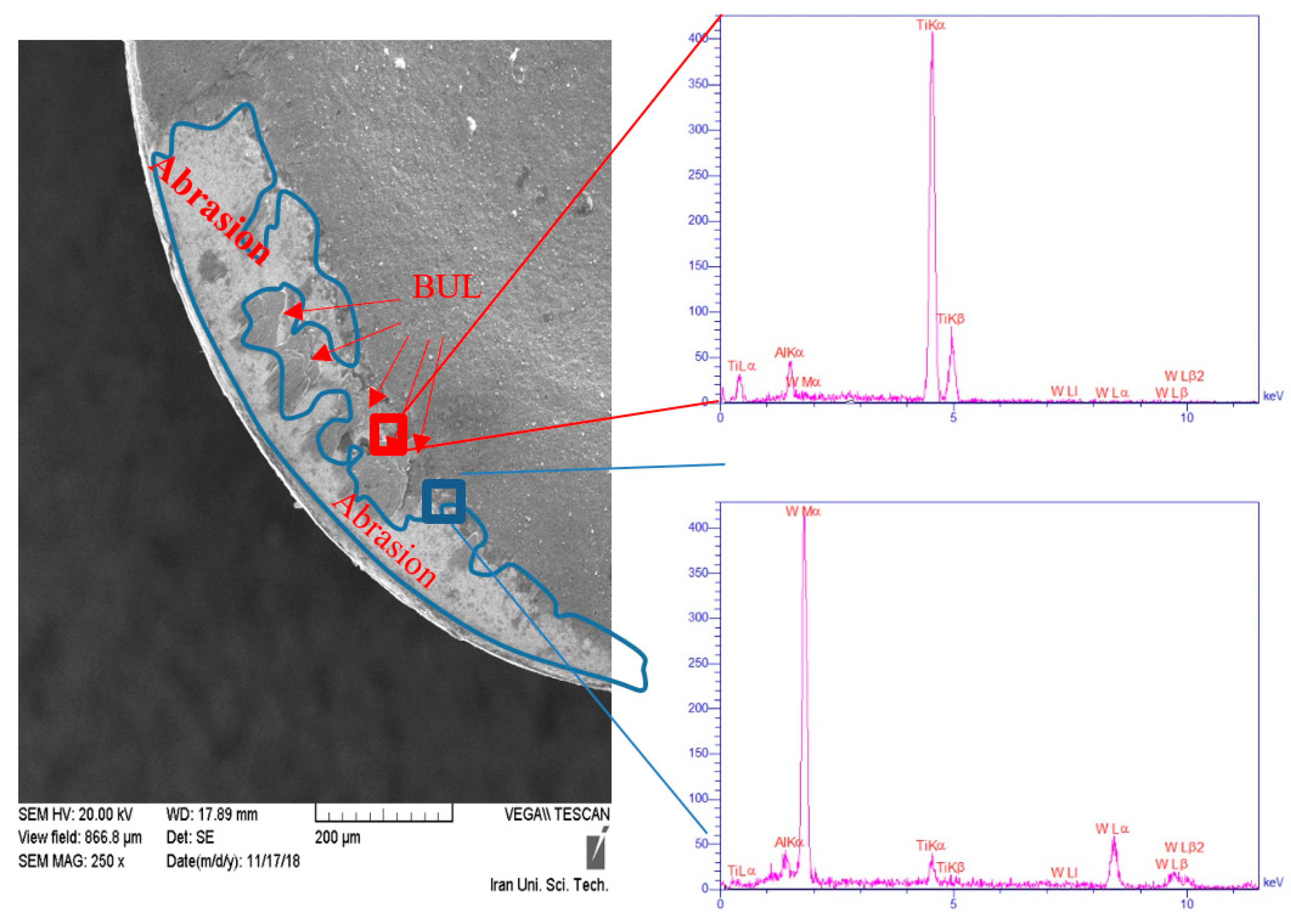

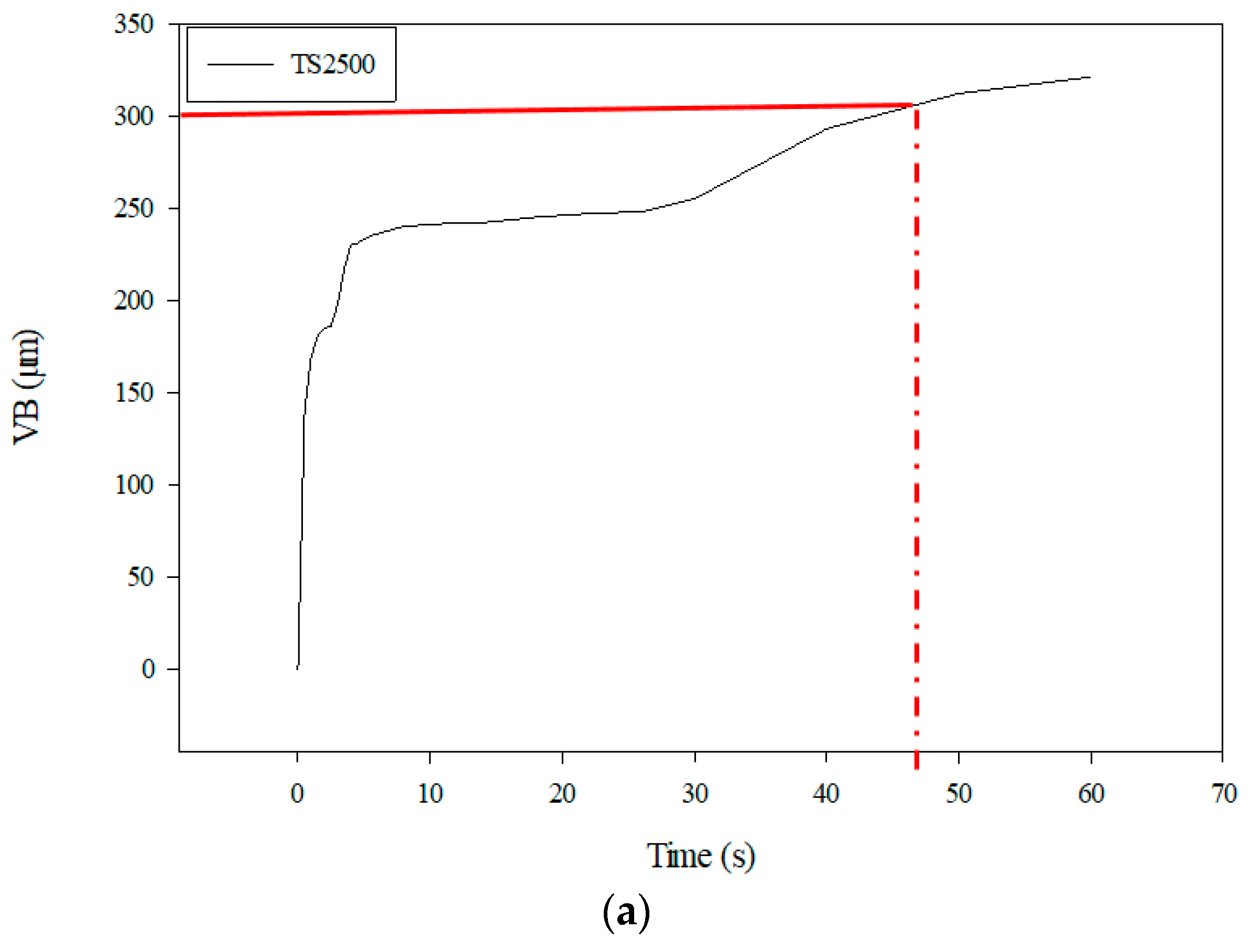

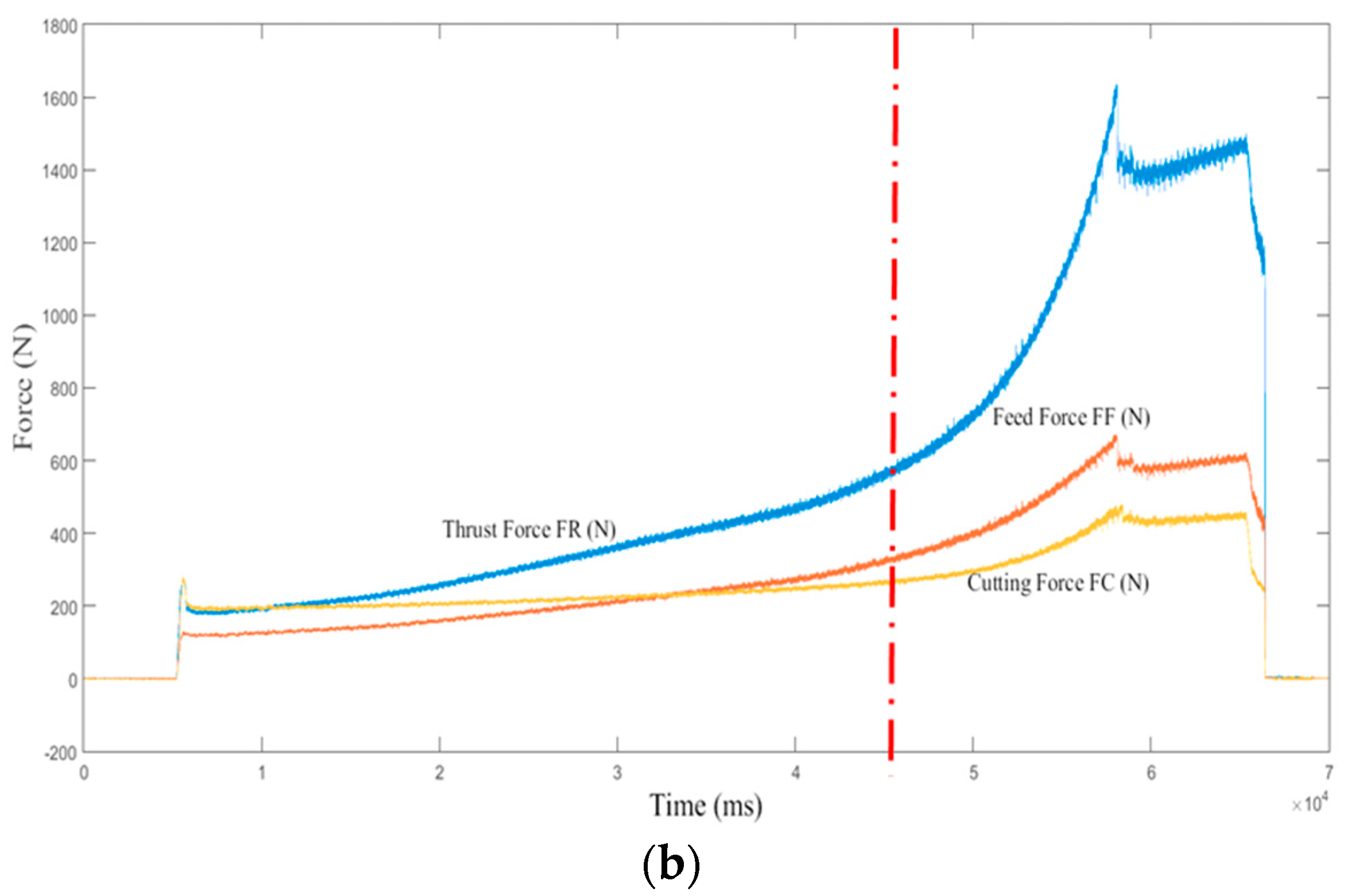

3.2. Wet Mode

4. Conclusions

- High flank wear occurred in the first few seconds of machining a Ti-MMC under both dry and wet modes.

- Abrasive particles could be understood as the essential problem observed under high-speed machining of Ti-MMCs. The matrix behavior and hydrostatic pressure of the cutting edge play prominent roles at low levels of cutting speeds. In this case, the cutting tool acquires sufficient hardness to prevent abrasion and resists the deflection forces.

- Despite the wet cutting mode used, abrasion and BUL was the main wear mode in both inserts. This was attributed to ceramic and SiC particles that are abrasive and hard and consequently may accelerate the coating removal process right after the cutting process. Moreover, the tendency for BUL and BUE was intensified at higher levels of cutting time.

- Regardless of the cutting insert and lubrication mode used, machining Ti-MMCs was associated with limited tool life, although better life was observed under wet mode.

- Other major problems that may tend to hinder the machinability of Ti-MMCs is elevated temperature in the cutting zone, which was shown as sparks and burnt chips in the cutting operations. Thus, the tool/insert should resist the high abrasion and thermal loads (i.e., CBN). In addition, further studies with respect to the presence of chatter vibration in dry and wet machining of Ti-MMCs with carbide tools and other commercial tools are of prime importance in prospective studies.

Author Contributions

Funding

Conflicts of Interest

References

- Bejjani, R. Machinability and Modeling of Cutting Mechanism for Titanium Metal Matrix Composites; École Polytechnique de Montréal: Montréal, QC, Canada, 2012. [Google Scholar]

- Bejjani, R.; Balazinski, M.; Attia, H.; Plamondon, P.; L’Éspérance, G.; Plamondon, P. Chip formation and microstructure evolution in the adiabatic shear band when machining titanium metal matrix composites. Int. J. Mach. Tools Manuf. 2016, 109, 137–146. [Google Scholar] [CrossRef]

- Duong, X.; Mayer, J.; Balazinski, M. Initial tool wear behavior during machining of titanium metal matrix composite (TiMMCs). Int. J. Refract. Met. Hard Mater. 2016, 60, 169–176. [Google Scholar] [CrossRef]

- Niknam, S.A.; Kouam, J.; Songmene, V.; Balazinski, M. Dry and semi-dry turning of Titanium Metal Matrix Composites (Ti-MMCs). Procedia CIRP 2018, 77, 62–65. [Google Scholar] [CrossRef]

- Bejjani, R.; Balazinski, M.; Shi, B.; Attia, H.; Kishawy, H. Machinability and chip formation of titanium metal matrix composites. Int. J. Adv. Manuf. Syst. IJAMS 2011, 13, 75–90. [Google Scholar]

- Kim, J.-S.; Lee, K.-M.; Cho, D.-H.; Lee, Y.-Z. Fretting wear characteristics of titanium matrix composites reinforced by titanium boride and titanium carbide particulates. Wear 2013, 301, 562–568. [Google Scholar] [CrossRef]

- Kim, T.-W. Microstructural aspects of titanium metal matrix composites in consolidation processing. Mater. Lett. 2005, 59, 143–147. [Google Scholar] [CrossRef]

- Bejjani, R.; Shi, B.; Attia, H.; Balazinski, M. Laser assisted turning of Titanium Metal Matrix Composite. CIRP Ann. 2011, 60, 61–64. [Google Scholar] [CrossRef]

- Niknam, S.A.; Khettabi, R.; Songmene, V. Machinability and machining of titanium alloys: A review. In Machining of Titanium Alloys; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–30. [Google Scholar]

- Rajmohan, T.; Palanikumar, K. Application of the central composite design in optimization of machining parameters in drilling hybrid metal matrix composites. Measurement 2013, 46, 1470–1481. [Google Scholar] [CrossRef]

- Rajmohan, T.; Palanikumar, K.; Prakash, S. Grey-fuzzy algorithm to optimise machining parameters in drilling of hybrid metal matrix composites. Compos. Part B Eng. 2013, 50, 297–308. [Google Scholar] [CrossRef]

- Nicholls, C.J.; Boswell, B.; Davies, I.J.; Islam, M.N. Review of machining metal matrix composites. Int. J. Adv. Manuf. Technol. 2016, 90, 2429–2441. [Google Scholar] [CrossRef]

- Altintas, Y. Prediction of cutting forces and tool breakage in milling from feed drive current measurements. J. Eng. Ind. 1992, 114, 386–392. [Google Scholar] [CrossRef]

- Hocheng, H.; Yen, S.; Ishihara, T.; Yen, B. Fundamental turning characteristics of a tribology-favored graphite/aluminum alloy composite material. Compos. Part A: Appl. Sci. Manuf. 1997, 28, 883–890. [Google Scholar] [CrossRef]

- Yanming, Q.; Zehua, Z. Tool wear and its mechanism for cutting SiC particle-reinforced aluminium matrix composites. J. Mater. Process. Technol. 2000, 100, 194–199. [Google Scholar] [CrossRef]

- Li, X.; Seah, W. Tool wear acceleration in relation to workpiece reinforcement percentage in cutting of metal matrix composites. Wear 2001, 247, 161–171. [Google Scholar] [CrossRef]

- Asgari, A. Cutting Conditions Optimisation of Titanium Metal Matrix Composites in Turning and Face Milling; École Polytechnique de Montréal: Montréal, QC, Canada, 2015. [Google Scholar]

- Kishawy, H.; Kannan, S.; Balazinski, M. Analytical modeling of tool wear progression during turning particulate reinforced metal matrix composites. CIRP Ann. 2005, 54, 55–58. [Google Scholar] [CrossRef]

- Niknam, S.A.; Kamalizadeh, S.; Asgari, A.; Balazinski, M. Turning titanium metal matrix composites (Ti-MMCs) with carbide and CBN inserts. Int. J. Adv. Manuf. Technol. 2018, 97, 253–265. [Google Scholar] [CrossRef]

- Zhu, D.; Zhang, X.; Ding, H. Tool wear characteristics in machining of nickel-based superalloys. Int. J. Mach. Tools Manuf. 2013, 64, 60–77. [Google Scholar] [CrossRef]

- Taylor, F. On the art of cutting tools. Trans. ASME 1907, 28, 31–35. [Google Scholar]

- Viktor, P. Chapter 4 Cutting tool wear, tool life and cutting tool physical resource. Tribol. Interface Eng. Ser. 2006, 52, 220–275. [Google Scholar]

- Aramesh, M.; Shaban, Y.; Balazinski, M.; Attia, H.; Kishawy, H.; Yacout, S. Survival life analysis of the cutting tools during turning Titanium Metal Matrix Composites (Ti-MMCs). Procedia CIRP 2014, 14, 605–609. [Google Scholar] [CrossRef]

- Aramesh, M.; Attia, H.; Kishawy, H.A.; Balazinski, M. Observation of a unique wear morphology of cBN inserts during machining of titanium metal matrix composites (Ti-MMCs); leading to new insights into their machinability. Int. J. Adv. Manuf. Technol. 2017, 92, 519–530. [Google Scholar] [CrossRef]

- Kamali Zadeh, S. Initial Tool Wear Mechanisms in Turning of Titanium Metal Matrix Composites; École Polytechnique de Montréal: Montréal, QC, Canada, 2016. [Google Scholar]

- Joshi, S. Machining metal matrix composites using diamond tools. In Machining Technology for Composite Materials; Elsevier: Amsterdam, The Netherlands, 2012; pp. 426–459. [Google Scholar]

- Elgallab, M.S.; Sklad, M.P. Machining of Al/SiC particulate metal-matrix composites: Part I: Tool performance. J. Mater. Process. Technol. 1998, 83, 151–158. [Google Scholar] [CrossRef]

- Beste, U.; Jacobson, S. A new view of the deterioration and wear of WC/Co cemented carbide rock drill buttons. Wear 2008, 264, 1129–1141. [Google Scholar] [CrossRef]

- Ben Abdelali, H.; Courbon, C.; Rech, J.; Ben Salem, W.; Dogui, A.; Kapsa, P. Identification of a friction model at the tool-chip-workpiece interface in dry machining of a AISI 1045 steel with a TiN coated carbide tool. J. Tribol. 2011, 133, 042201. [Google Scholar] [CrossRef]

- Kagnaya, T.; Boher, C.; Lambert, L.; Lazard, M.; Cutard, T. Microstructural analysis of wear micromechanisms of WC–6Co cutting tools during high speed dry machining. Int. J. Refract. Met. Hard Mater. 2014, 42, 151–162. [Google Scholar] [CrossRef]

- Weinert, K.; König, W. A consideration of tool wear mechanism when machining Metal Matrix Composites (MMC). CIRP Ann. 1993, 42, 95–98. [Google Scholar] [CrossRef]

- Duong, X.-T.; Balazinski, M.; Mayer, R. Chaotic tool wear during machining of Titanium Metal Matrix Composite (TiMMCs). In Proceedings of ASME 2014 International Mechanical Engineering Congress and Exposition, Montreal, QC, Canada, 14–20 November 2014. [Google Scholar]

- Altintas, Y. Manufacturing Automation; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

| Insert Code | Grade | Coating |

|---|---|---|

| CNMG 120404-MF1 | TS2000 | PVD TiSiN-TiAlN coated carbide with W as the core element and Co and Cr as binders |

| CNMG120404-MF4 | TS2500 | PVD TiSiN-TiAlN coated carbide with W as the core element and Co and Cr as binders |

| Chemical Analysis of Ti-MMC | Al | V | C | O | Fe | N | H | Ti |

|---|---|---|---|---|---|---|---|---|

| Mass% | 5.5 | 3.8 | 0.9 | 0.2 | 0.004 | 0.2 | <0.003 | Remainder (89.2) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Safavi, M.; Balazinski, M.; Mehmanparast, H.; Niknam, S.A. Experimental Characterization of Tool Wear Morphology and Cutting Force Profile in Dry and Wet Turning of Titanium Metal Matrix Composites (Ti-MMCs). Metals 2020, 10, 1459. https://doi.org/10.3390/met10111459

Safavi M, Balazinski M, Mehmanparast H, Niknam SA. Experimental Characterization of Tool Wear Morphology and Cutting Force Profile in Dry and Wet Turning of Titanium Metal Matrix Composites (Ti-MMCs). Metals. 2020; 10(11):1459. https://doi.org/10.3390/met10111459

Chicago/Turabian StyleSafavi, Masoomeh, Marek Balazinski, Hedayeh Mehmanparast, and Seyed Ali Niknam. 2020. "Experimental Characterization of Tool Wear Morphology and Cutting Force Profile in Dry and Wet Turning of Titanium Metal Matrix Composites (Ti-MMCs)" Metals 10, no. 11: 1459. https://doi.org/10.3390/met10111459

APA StyleSafavi, M., Balazinski, M., Mehmanparast, H., & Niknam, S. A. (2020). Experimental Characterization of Tool Wear Morphology and Cutting Force Profile in Dry and Wet Turning of Titanium Metal Matrix Composites (Ti-MMCs). Metals, 10(11), 1459. https://doi.org/10.3390/met10111459