Influence of Manufacturing Conditions on Inclusion Characteristics and Mechanical Properties of FeCrNiMnCo Alloy

Abstract

1. Introduction

2. Materials and Methods

2.1. Manufacturing of FeCrNiMnCo Alloys by Different Melting and Casting Conditions

2.2. Characterization of FeCrNiMnCo Alloys Manufactured by Different Processes

3. Experimental Results

3.1. Impurity Levels Depending upon Manufacturing Processes

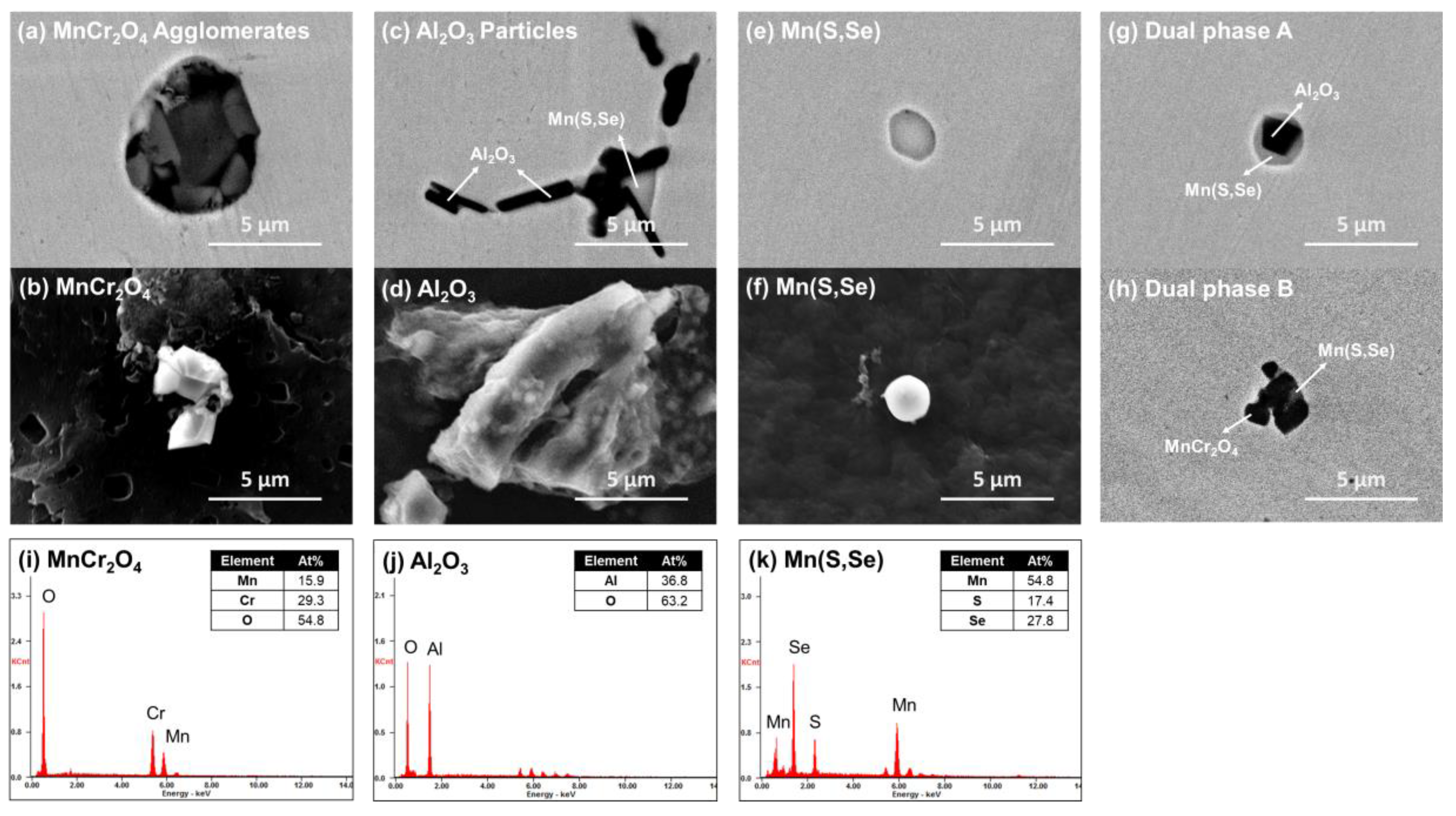

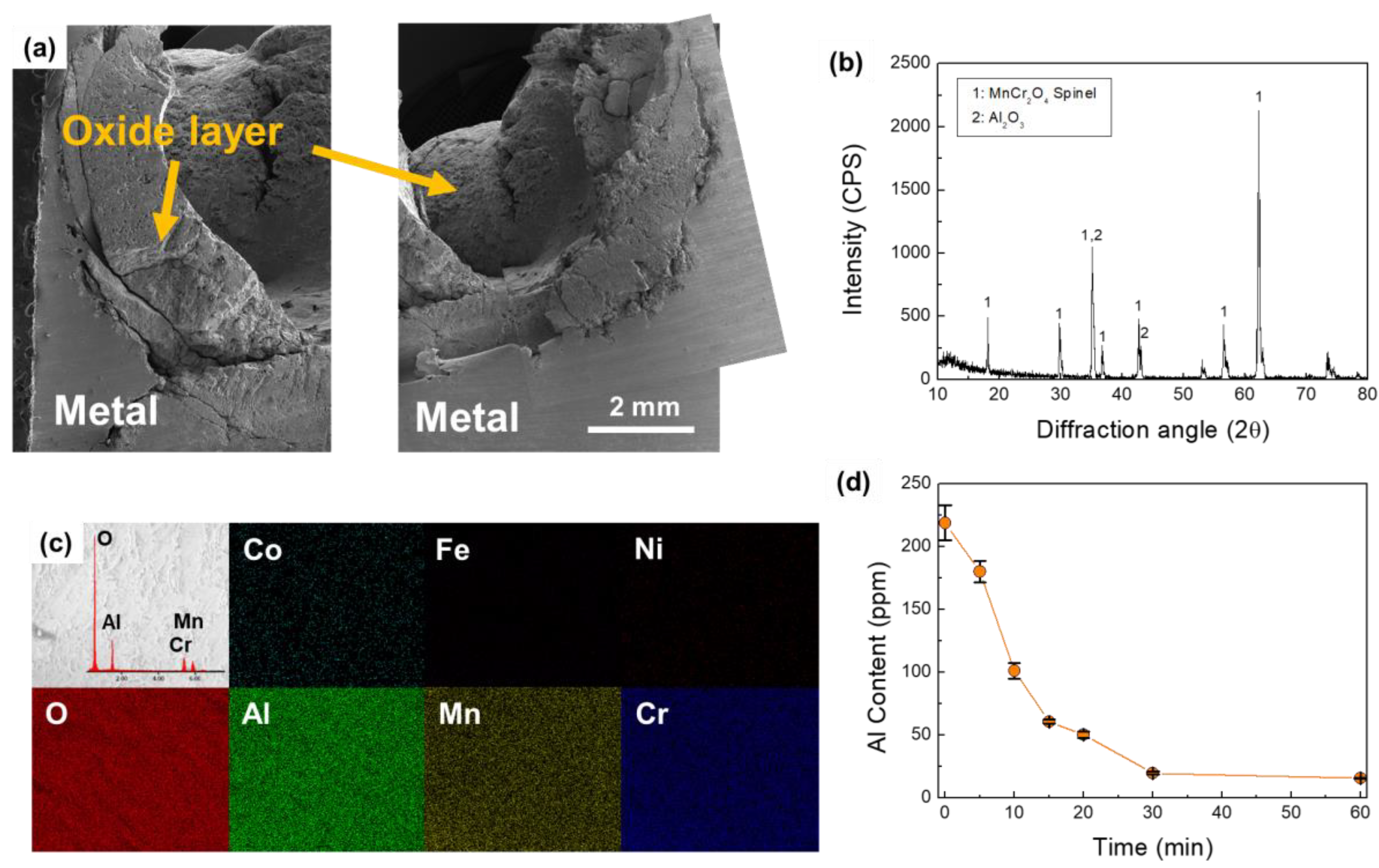

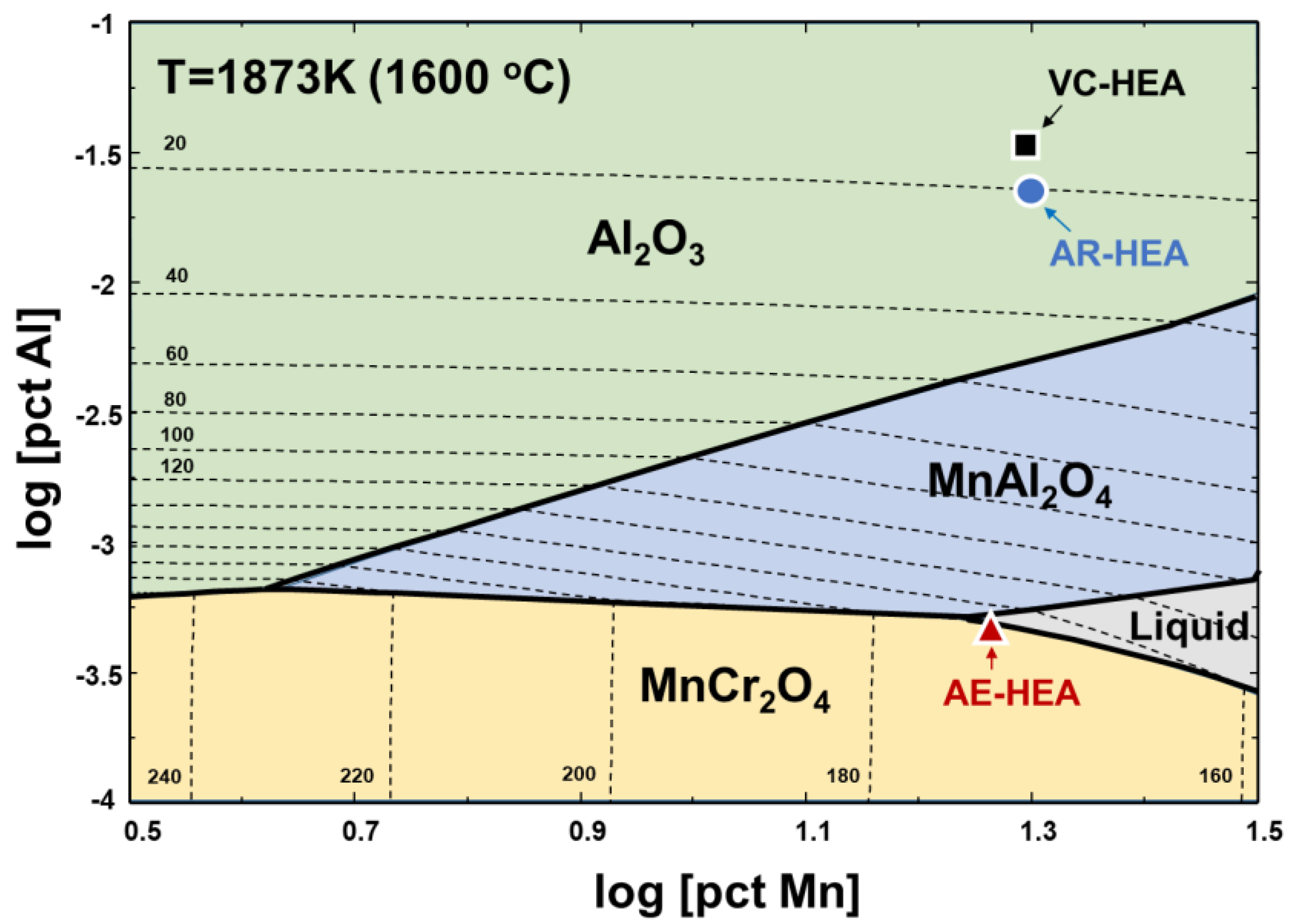

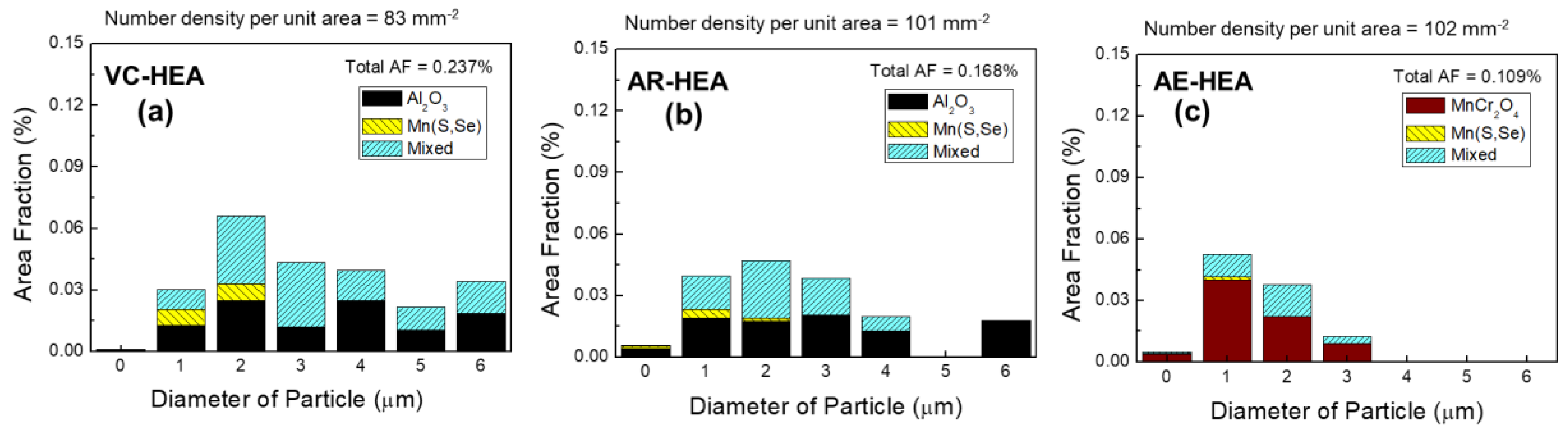

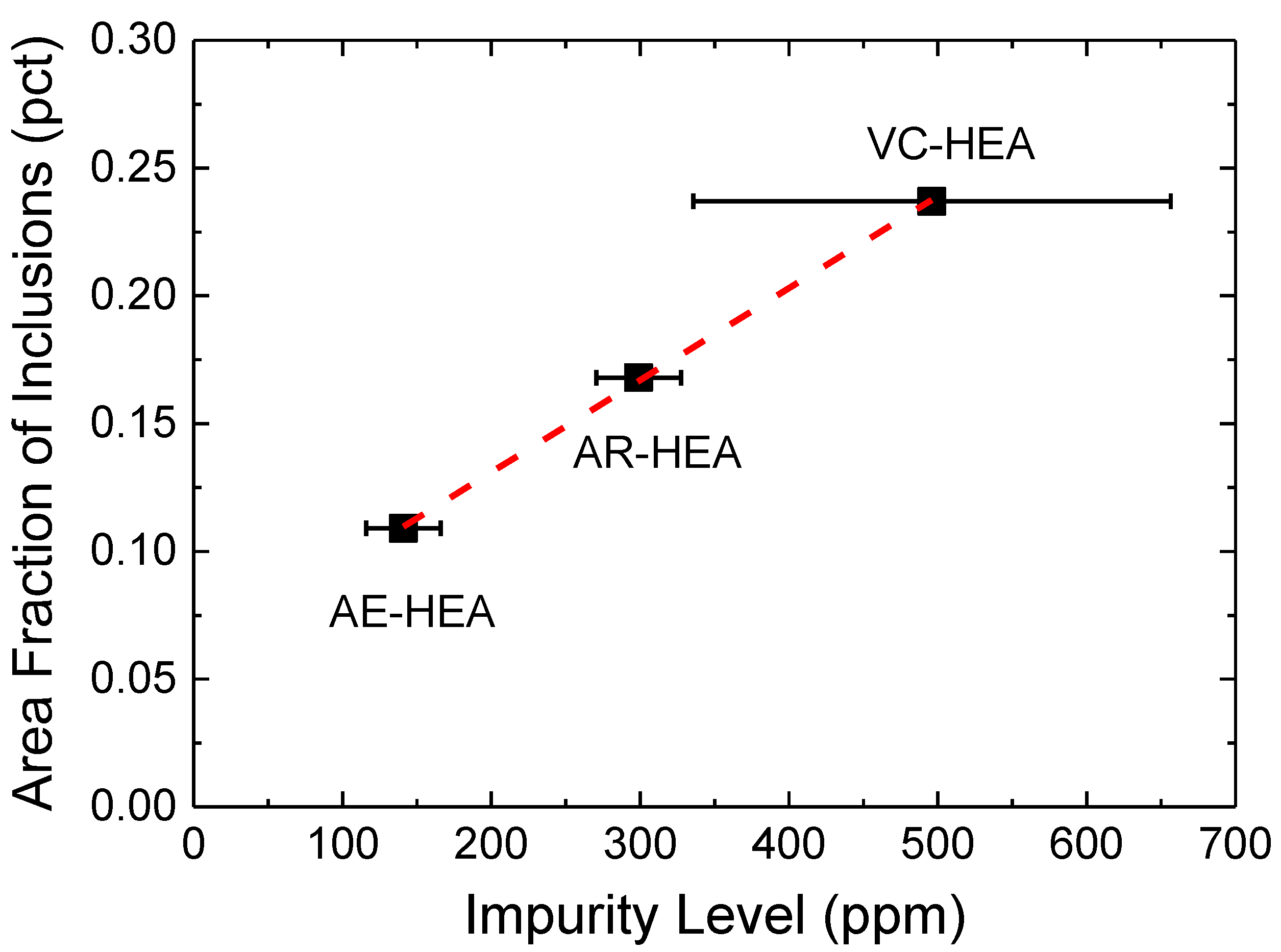

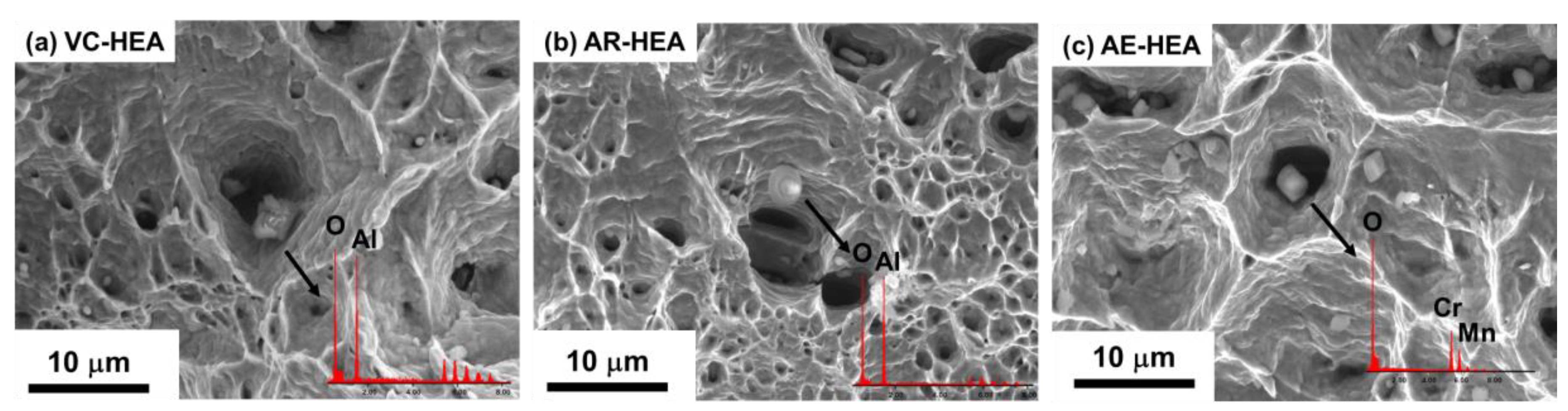

3.2. Characterization of Non-Metallic Inclusions

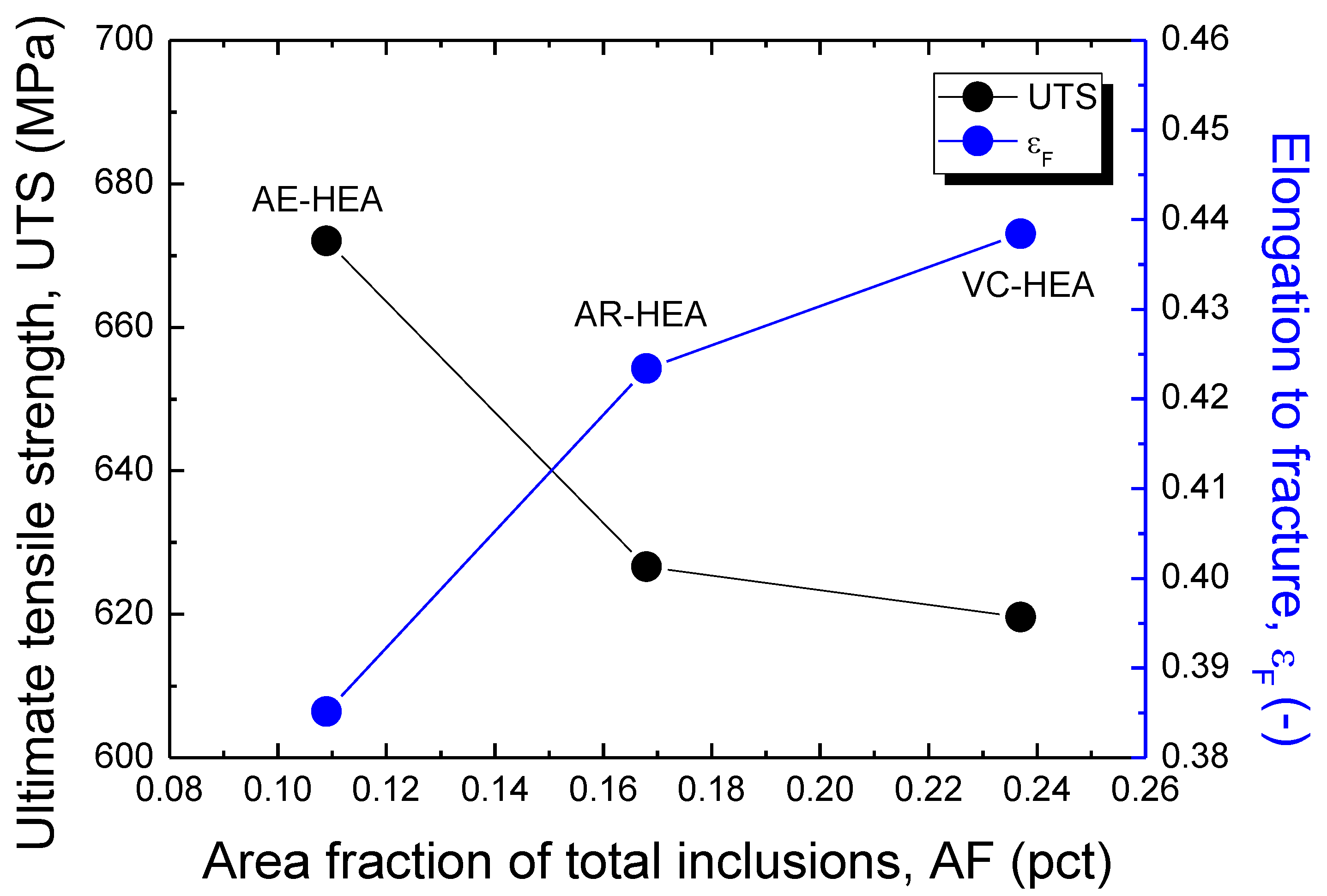

3.3. Mechanical Properties and Fracture Behavior

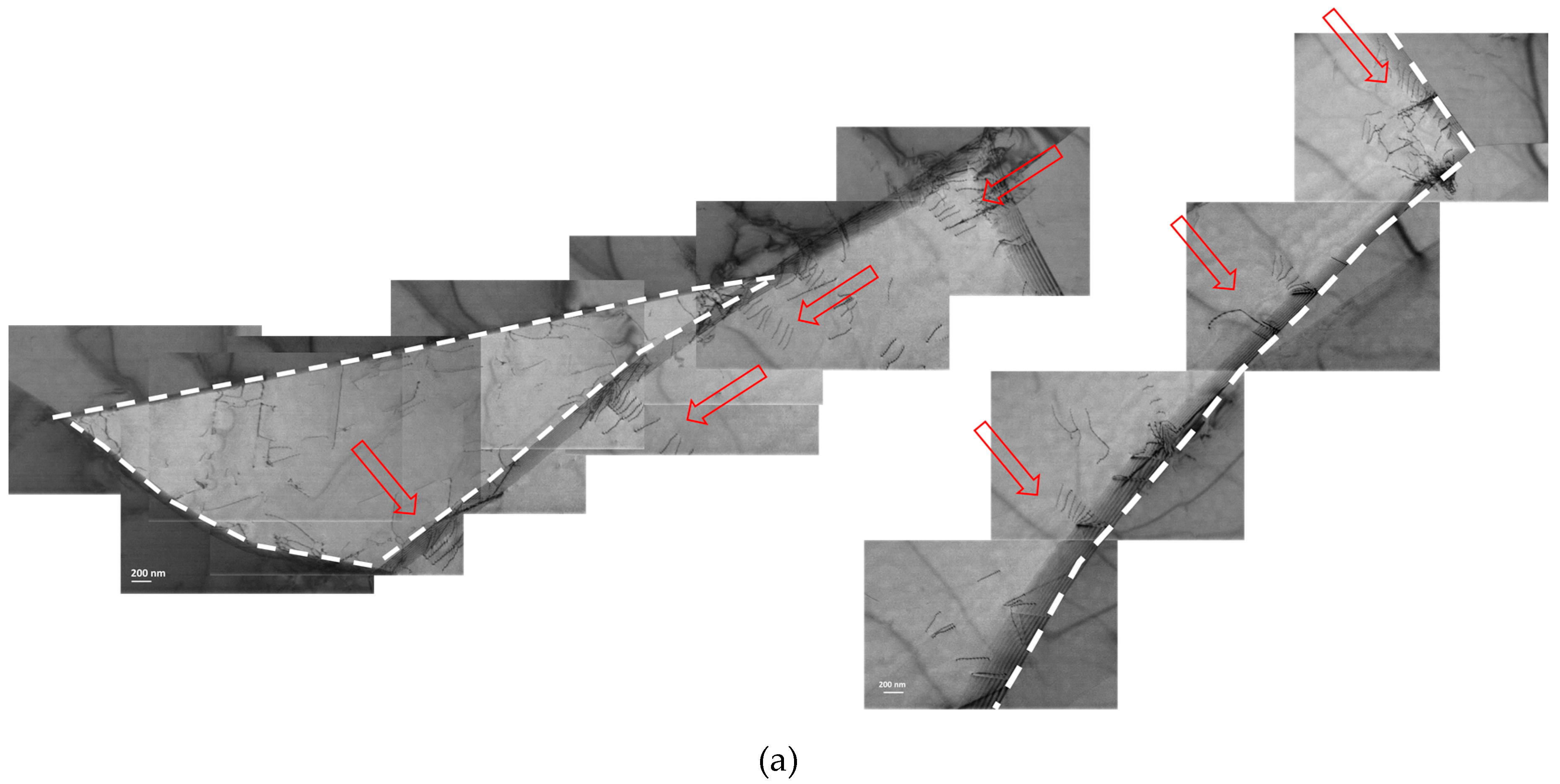

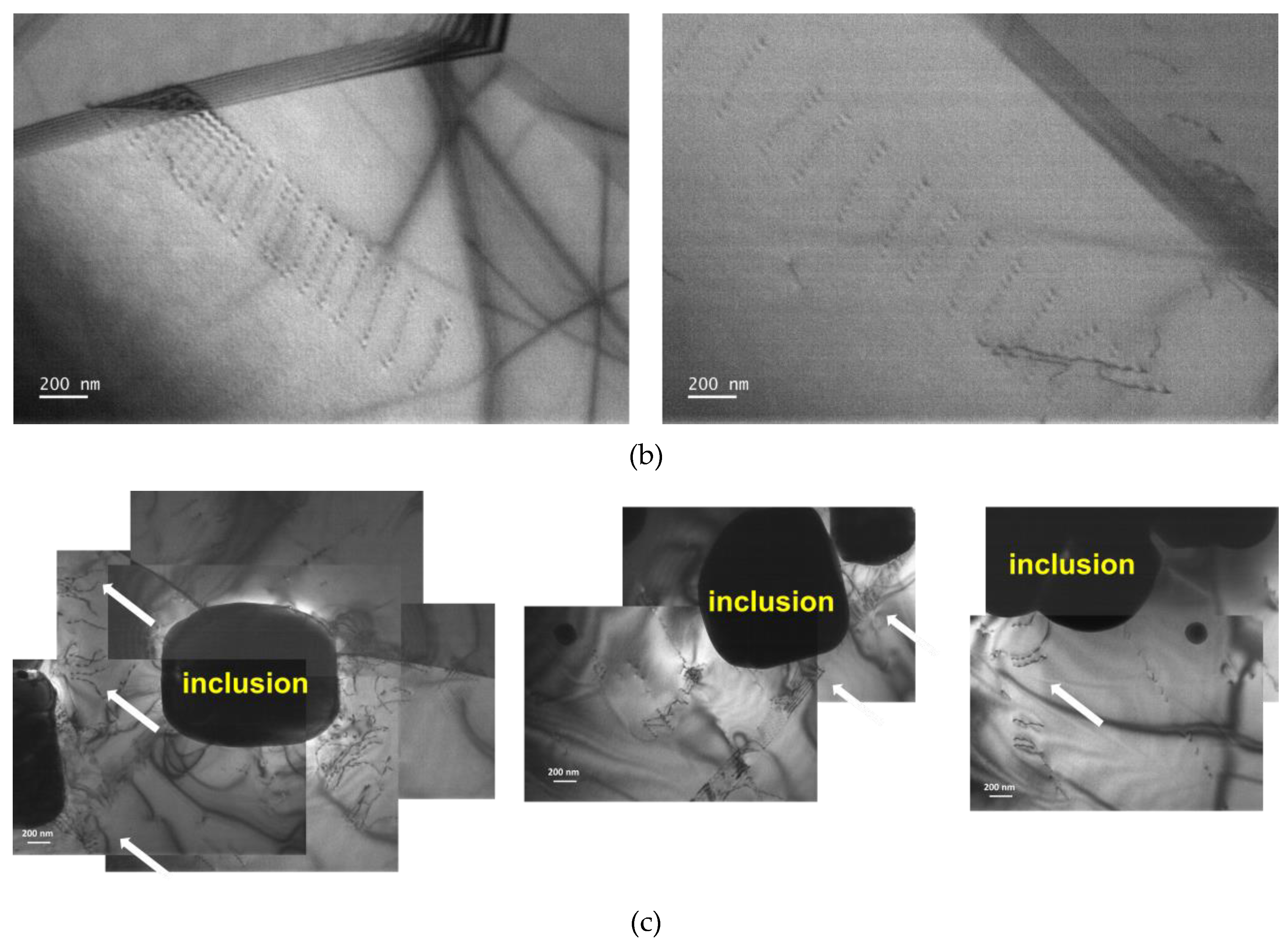

3.4. Microstructural Change upon Tensile Deformation

4. Discussion

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high-entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural development in equiatomic multicomponent alloys. Mater. Sci. Eng. A 2004, 375, 213–218. [Google Scholar] [CrossRef]

- Zhang, F.; Zhang, C.; Chen, S.L.; Zhu, J.; Cao, W.S.; Kattner, U.R. An understanding of high entropy alloys from phase diagram calculations. Calphad 2014, 45, 1–10. [Google Scholar] [CrossRef]

- Haglund, A.; Koehler, M.; Catoor, D.; George, E.P.; Keppens, V. Polycrystalline elastic moduli of a high-entropy alloy at cryogenic temperatures. Intermetallics 2015, 58, 62–64. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: a critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Ye, Y.F.; Wang, Q.; Lu, J.; Liu, C.T.; Yang, Y. High-entropy alloy: challenges and prospects. Mater. Today 2016, 19, 349–362. [Google Scholar] [CrossRef]

- Raabe, D.; Tasan, C.C.; Springer, H.; Bausch, M. From high-entropy alloys to high-entropy steels. Steel Res. Int. 2015, 86, 1127–1138. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Somsen, C.; Bei, H.; Eggeler, G.; George, E.P. The influences of temperature and microstructure on the tensile properties of a CoCrFeMnNi high-entropy alloy. Acta Mater. 2013, 61, 5743–5755. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Catoor, D.; Chang, E.H.; George, E.P.; Ritchie, R. A fracture-resistant high-entropy alloy for cryogenic applications. Science 2014, 345, 1153–1158. [Google Scholar] [CrossRef]

- Joo, S.H.; Kato, H.; Jang, M.J.; Moon, J.; Tsai, C.W.; Yeh, J.W.; Kim, H.S. Tensile deformation behavior and deformation twinning of an equimolar CoCrFeMnNi high-entropy alloy. Mater. Sci. Eng. A 2017, 689, 122–133. [Google Scholar] [CrossRef]

- Mizumachi, S.; Koyama, M.; Fukushima, Y.; Tsuzaki, K. Growth behavior of a mechanically long fatigue crack in an FeCrNiMnCo high entropy alloy: A comparison with an austenitic stainless steel. ISIJ Int. 2020, 60, 175–181. [Google Scholar] [CrossRef]

- Huang, S.; Li, W.; Lu, S.; Tian, F.; Shen, J.; Holmström, E.; Vitos, L. Temperature dependent stacking fault energy of FeCrCoNiMn high entropy alloy. Scr. Mater. 2015, 108, 44–47. [Google Scholar] [CrossRef]

- Liu, W.H.; Wu, Y.; He, J.Y.; Nieh, T.G.; Lu, Z.P. Grain growth and the Hall-Petch relationship in a high-entropy FeCrNiCoMn alloy. Scr. Mater. 2013, 68, 526–529. [Google Scholar] [CrossRef]

- Wu, Z.; Parish, C.M.; Bei, H. Nano-twin mediated plasticity in carbon-containing FeNiCoCrMn high entropy alloys. J. Alloys Compd. 2015, 647, 815–822. [Google Scholar] [CrossRef]

- He, J.Y.; Wang, H.; Huang, H.L.; Xu, X.D.; Chen, M.W.; Wu, Y.; Liu, X.J.; Nieh, T.G.; An, K.; Lu, Z.P. A precipitation-hardened high-entropy alloy with outstanding tensile properties. Acta Mater. 2016, 102, 187–196. [Google Scholar] [CrossRef]

- Thornto, P.A. The influence of nonmetallic inclusions on the mechanical properties of steel: A review. J. Mater. Sci. 1971, 6, 347–356. [Google Scholar] [CrossRef]

- Umezawa, O.; Nagai, K. Effects of test temperature on internal fatigue crack generation associated with nonmetallic particles in austenitic steels. Metall. Mater. Trans. A 1998, 29A, 3017–3028. [Google Scholar] [CrossRef]

- Webb, E.G.; Suter, T.; Alkire, R.C. Microelectrochemical measurements of the dissolution of single MnS inclusions, and the prediction of the critical conditions for pit initiation on stainless steel. J. Electrochem. Soc. 2001, 148, B186–B195. [Google Scholar] [CrossRef]

- Yang, C.L.; Zhang, Z.J.; Zhang, P.; Zhang, Z.F. The premature necking of twinning-induced plasticity steels. Acta Mater. 2017, 136, 1–10. [Google Scholar] [CrossRef]

- Jablonski, P.D.; Licavoli, J.J.; Gao, M.C.; Hawk, J.A. Manufacturing of high entropy alloys. JOM 2015, 67, 2278–2287. [Google Scholar] [CrossRef]

- Licavoli, J.J.; Gao, M.C.; Sears, J.S.; Jablonski, P.D.; Hawk, J.A. Microstructure and mechanical behavior of high-entropy alloys. J. Mater. Eng. Perform. 2015, 24, 3685–3698. [Google Scholar] [CrossRef]

- Gludovatz, B.; George, E.P.; Ritchie, R.O. Processing, Microstructure and mechanical properties of the CrMnFeCoNi high-entropy alloy. JOM 2015, 67, 2262–2270. [Google Scholar] [CrossRef]

- Gali, A.; George, E.P. Tensile properties of high- and medium-entropy alloys. Intermetallics 2013, 39, 74–78. [Google Scholar] [CrossRef]

- He, J.Y.; Zhu, C.; Zhou, D.Q.; Liu, W.H.; Nieh, T.G.; Lu, Z.P. Steady state flow of the FeCoNiCrMn high entropy alloy at elevated temperatures. Intermetallics 2014, 55, 9–14. [Google Scholar] [CrossRef]

- Schuh, B.; Martin, F.M.; Völker, B.; George, E.P.; Clemens, H.; Pippan, R.; Hohenwarter, A. Mechanical properties, microstructure and thermal stability of a nanocrystalline CoCrFeMnNi high-entropy alloy after severe plastic deformation. Acta Mater. 2015, 96, 258–268. [Google Scholar] [CrossRef]

- Wu, C.Z.; Shih, T.S. Effects of inclusion particles on the microstructure and mechanical properties of high strength austempered ductile iron. Mater. Trans. 2003, 44, 995–1003. [Google Scholar] [CrossRef][Green Version]

- Yakura, R.; Matsuda, M.; Sakai, T.; Ueno, A. Effect of inclusion size on fatigue properties in very high cycle region of low alloy steel used for solid type crankshaft. Kobleco Technol. Rev. 2017, 35, 7–13. [Google Scholar]

- Li, W.; Deng, H.; Liu, P. Interior fracture mechanism analysis and fatigue life prediction of surface-hardened gear steel under axial loading. Materials 2016, 9, 843. [Google Scholar] [CrossRef]

- Srivastava, A.; Ponson, L.; Osovski, S.; Bouchaud, E.; Tvergaard, V.; Needleman, A. Effect of inclusion density on ductile fracture toughness and roughness. J. Mech. Phys. Solids 2014, 63, 62–79. [Google Scholar] [CrossRef]

- Hill, D.C.; Passoja, D. Understanding the role of inclusions and microstructure in ductile fracture. Weld. Res. Suppl. 1974, 53, 481–485. [Google Scholar]

- Urbano, M.F.; Cadelli, A.; Sczerzenie, F.; Luccarelli, P.; Beretta, S.; Coda, A. Inclusions size-based fatigue life prediction model of NiTi alloy for biomedical applications. Shape Mem. Superplast. 2015, 1, 240–251. [Google Scholar] [CrossRef]

- Ånmark, N.; Karasev, A.V.; Jonsson, P.G. The effect of different non-metallic inclusions on the machinability of steels. Materials 2015, 8, 751–783. [Google Scholar] [CrossRef] [PubMed]

- Park, J.H.; Kang, Y. Inclusions in Stainless Steels—A Review. Steel Res. Int. 2017, 88, 1700130. [Google Scholar] [CrossRef]

- Kiessling, R.; Lange, N. Non-Metallic Inclusions in Steel; Metals Society: London, UK, 1978. [Google Scholar]

- Ånmark, N.; Björk, T.; Ganea, A.; Ölund, P.; Hogmark, S.; Karasev, A.V.; Jönsson, P.G. The effect of inclusion composition on tool wear in hard part turning using PCBN cutting tools. Wear 2015, 334, 13–22. [Google Scholar] [CrossRef]

- Choi, N.; Lim, K.R.; Na, Y.S.; Glatzel, U.; Park, J.H. Characterization of non-metallic inclusions and their influence on the mechanical properties of a FCC single-phase high-entropy alloy. J. Alloys Compd. 2018, 763, 546–557. [Google Scholar] [CrossRef]

- Garrison, W.M.; Wojcieszynski, A.L. A discussion of the effect of inclusion volume fraction on the toughness of steel. Mater. Sci. Eng. A 2007, 464, 321–329. [Google Scholar] [CrossRef]

- Park, N.; Lee, B.J.; Tsuji, N. The phase stability of equiatomic CoCrFeMnNi high-entropy alloy: comparison between experiment and calculation results. J. Alloys Compd. 2017, 719, 189–193. [Google Scholar] [CrossRef]

- Choi, W.M.; Jung, S.; Jo, Y.H.; Lee, S.; Lee, B.J. Design of new face-centered cubic high entropy alloys by thermodynamic calculation. Met. Mater. Int. 2017, 23, 839–847. [Google Scholar] [CrossRef]

- ASTM E 8/E8M-09, Standard Test Methods for Tension Testing of Metallic Materials; ASTM International: West Conshohocken, PA, USA, 2009.

- Max, S. Process for the Production of Nickel and Cobalt Alloys by Aluminothermic Reduction. U.S. Patent No. 2,270,643, 20 January 1942. [Google Scholar]

- Yoshitaka, K.; Yang, J.; Liu, Z.; Kuwabara, M. Mechanism of aluminothermic reduction of chromium oxide. J. High Temp. Soc. 2009, 34, 20–25. [Google Scholar] [CrossRef]

- Martirosyan, V.; Torosyan, G.; Sasuntsyan, M.; Torosyan, N. Obtaining of ferrosilicochromium alloy by silicothermic reduction of the tapasar chromites and slags of copper casting factories. Meridian Eng. 2012, 2, 68–72. [Google Scholar]

- Fan, X.; Xi, S.; Sun, D.; Liu, Z.; Du, J.; Tao, C. Mn–Se interactions at the cathode interface during the electrolytic-manganese process. Hydrometallurgy 2012, 127–128, 24–29. [Google Scholar] [CrossRef]

- Park, J.H.; Kim, D.J.; Min, D.J. Characterization of nonmetallic inclusions in high-manganese and aluminum-alloyed austenitic steels. Metall. Mater. Trans. A 2012, 43A, 2316–2324. [Google Scholar] [CrossRef]

- Bracq, G.; Brocq, M.L.; Perrière, L.; Pirès, R.; Joubert, J.M.; Guillot, I. The fcc solid solution stability in the Co-Cr-Fe-Mn-Ni multi-component system. Acta Mater. 2017, 128, 327–336. [Google Scholar] [CrossRef]

- Gaskell, D.R.; Laughlin, D.E. Introduction to the Thermodynamics of Materials; CRC Press, Taylor and Francis Group: Boca Raton, FL, USA, 2017. [Google Scholar]

- Pickering, E.J.; Moreno, R.M.; Stone, H.J.; Jones, N.G. Precipitation in the equiatomic high-entropy alloy CrMnFeCoNi. Scr. Mater. 2016, 113, 106–109. [Google Scholar] [CrossRef]

- Park, J.S.; Park, J.H. Effect of Mg–Ti deoxidation on the formation behavior of equiaxed crystals during rapid solidification of iron alloys. Steel Res. Int. 2014, 85, 1303–1309. [Google Scholar] [CrossRef]

- Lee, M.H.; Park, J.H. Synergistic effect of nitrogen and refractory material on TiN formation and equiaxed grain structure of ferritic stainless steel. Metall. Mater. Trans. B 2018, 49B, 877–893. [Google Scholar] [CrossRef]

- Kwon, S.K.; Park, J.S.; Park, J.H. Influence of refractory-steel interfacial reaction on the formation behavior of inclusions in Ce-containing stainless steel. ISIJ Int. 2015, 55, 2589–2596. [Google Scholar] [CrossRef]

- Kwon, S.K.; Kong, Y.M.; Park, J.H. Effect of Al deoxidation on the formation behavior of inclusions in Ce-added stainless steel melt. Met. Mater. Int. 2014, 20, 959–966. [Google Scholar] [CrossRef]

- Shin, J.H.; Park, J.H. Effect of CaO/Al2O3 ratio of ladle slag on formation behavior of inclusions in Mn and V alloyed steel. ISIJ Int. 2018, 58, 88–97. [Google Scholar] [CrossRef]

- Tervo, H.; Kaijalainen, A.; Pikkarainen, T.; Mehtonen, S.; Porter, D. Effect of impurity level and inclusions on the ductility and toughness of an ultra-high-strength steel. Mater. Sci. Eng. A 2017, 697, 184–193. [Google Scholar] [CrossRef]

- Gludovatz, B.; Hohenwarter, A.; Thurston, K.V.S.; Bei, H.; Wu, Z.; George, E.P.; Ritchie, R.O. Exceptional damage-tolerance of a medium-entropy alloy CrCoNi at cryogenic temperatures. Nat. Commun. 2016, 7, 10602. [Google Scholar] [CrossRef]

- Goodwin, S.J.; Noble, F.W.; Eyre, B.L. Inclusion nucleated ductile fracture in stainless steel. Acta Metall. 1989, 37, 1389–1398. [Google Scholar] [CrossRef]

- Eshelby, J.D.; Peierls, R.E. The determination of the elastic field of an ellipsoidal inclusion, and related problems. Math. Phys. Sci. 1957, 241, 376–396. [Google Scholar]

- Eshelby, J.D.; Peierls, R.E. The elastic field outside an ellipsoidal inclusion. Math. Phys. Sci. 1959, 252, 561–569. [Google Scholar]

- Simmons, J.A.; deWit, R.; Bullough, R. Fundamental Aspects of Dislocation Theory Conference Proceedings; National Bureau of Standards: Gaithersburg, MD, USA, 1970. [Google Scholar]

- Kords, C. On the Role of Dislocation Transport in the Constitutive Description of Crystal Plasticity. Ph.D. Thesis, RWTH Aachen University, Aachen, Germany, 2013. [Google Scholar]

- Reformatskaya, I.I.; Freiman, L.I. Precipitation of sulfide inclusions in steel structure and their effect on local corrosion processes. Prot. Met. 2001, 37, 459–464. [Google Scholar] [CrossRef]

- Horstemeyer, M.F.; Gokhale, A.M. A void–crack nucleation model for ductile metals. Int. J. Solids Struct. 1999, 36, 5029–5055. [Google Scholar] [CrossRef]

- Wefers, K.; Misra, C. Oxides and Hydroxides of Aluminum; Alcoa Laboratories, Aluminum Company of America: Pittsburg, PA, USA, 1987. [Google Scholar]

- Anthony, J.W.; Bideaux, R.A.; Bladh, K.W.; Nichols, M.C. Handbook of Mineralogy; Mineral Data Publ.: Tucson, AZ, USA, 1990. [Google Scholar]

- Kim, Y.K.; Choe, J.; Lee, K.A. Selective laser melted equiatomic CoCrFeMnNi high-entropy alloy: microstructure, anisotropic mechanical response, and multiple strengthening mechanism. J. Alloys Compd. 2019, 805, 680–691. [Google Scholar] [CrossRef]

- AlMangour, B.; Kim, Y.K.; Grzesiak, D.; Lee, K.A. Novel TiB2-reinforced 316L stainless steel nanocomposites with excellent room- and high-temperature yield strength developed by additive manufacturing. Compos. Part B Eng. 2019, 156, 51–63. [Google Scholar] [CrossRef]

- Queyreau, S.; Monnet, G.; Devincre, B. Orowan strengthening and forest hardening superposition examined by dislocation dynamics simulations. Acta Mater. 2010, 58, 5586–5595. [Google Scholar] [CrossRef]

- Bi, Y.; Karasev, A.V.; Jönsson, P.G. Three-dimensional investigations of inclusions in ferroalloys. Steel Res. Int. 2014, 85, 659–669. [Google Scholar] [CrossRef]

- Ånmark, N.; Karasev, A.V.; Jönsson, P.G. The influence of microstructure and non-Metallic inclusions on the machinability of clean steels. Steel Res. Int. 2016, 88, 1600111. [Google Scholar] [CrossRef]

| Raw Material | Al | Si | Se |

|---|---|---|---|

| Cobalt | 3300 | 60 | - |

| Chromium | 680 | 1600 | - |

| Iron | - | - | - |

| Manganese | - | - | 650 |

| Nickel | 30 | 30 | - |

| Alloys | ← Alloy Elements, Mass% (at%) → | ← Impurities, Mass ppm → | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Cr | Ni | Mn | Co | Al | C | S | N | O | |

| VC-HEA | 20.2 (20.3) | 17.6 (19.0) | 21.3 (20.3) | 19.6 (20.0) | 21.3 (20.3) | 340 (±60) | 72 (±6) | 121 (±20) | 56 (±4) | 35 (±6) |

| AR-HEA | 20.1 (20.2) | 17.9 (19.3) | 21.1 (20.2) | 19.8 (20.2) | 21.1 (20.1) | 230 (±20) | 78 (±8) | 40 (±6) | 120 (±20) | 29 (±8) |

| AE-HEA | 20.9 (21.0) | 17.6 (19.0) | 22.0 (21.0) | 17.5 (17.9) | 22.0 (21.0) | 15 (±5) | 89 (±6) | 37 (±6) | 875 (±40) | 99 (±3) |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choi, N.; Park, N.; Kim, J.-k.; Karasev, A.V.; Jönsson, P.G.; Park, J.H. Influence of Manufacturing Conditions on Inclusion Characteristics and Mechanical Properties of FeCrNiMnCo Alloy. Metals 2020, 10, 1286. https://doi.org/10.3390/met10101286

Choi N, Park N, Kim J-k, Karasev AV, Jönsson PG, Park JH. Influence of Manufacturing Conditions on Inclusion Characteristics and Mechanical Properties of FeCrNiMnCo Alloy. Metals. 2020; 10(10):1286. https://doi.org/10.3390/met10101286

Chicago/Turabian StyleChoi, Nuri, Nokeun Park, Jin-kyung Kim, Andrey V. Karasev, Pär G. Jönsson, and Joo Hyun Park. 2020. "Influence of Manufacturing Conditions on Inclusion Characteristics and Mechanical Properties of FeCrNiMnCo Alloy" Metals 10, no. 10: 1286. https://doi.org/10.3390/met10101286

APA StyleChoi, N., Park, N., Kim, J.-k., Karasev, A. V., Jönsson, P. G., & Park, J. H. (2020). Influence of Manufacturing Conditions on Inclusion Characteristics and Mechanical Properties of FeCrNiMnCo Alloy. Metals, 10(10), 1286. https://doi.org/10.3390/met10101286