On the Influence of the Convective Term in the Navier–Stokes Equation on the Forces in Hydrodynamic Bearings

Abstract

1. Introduction

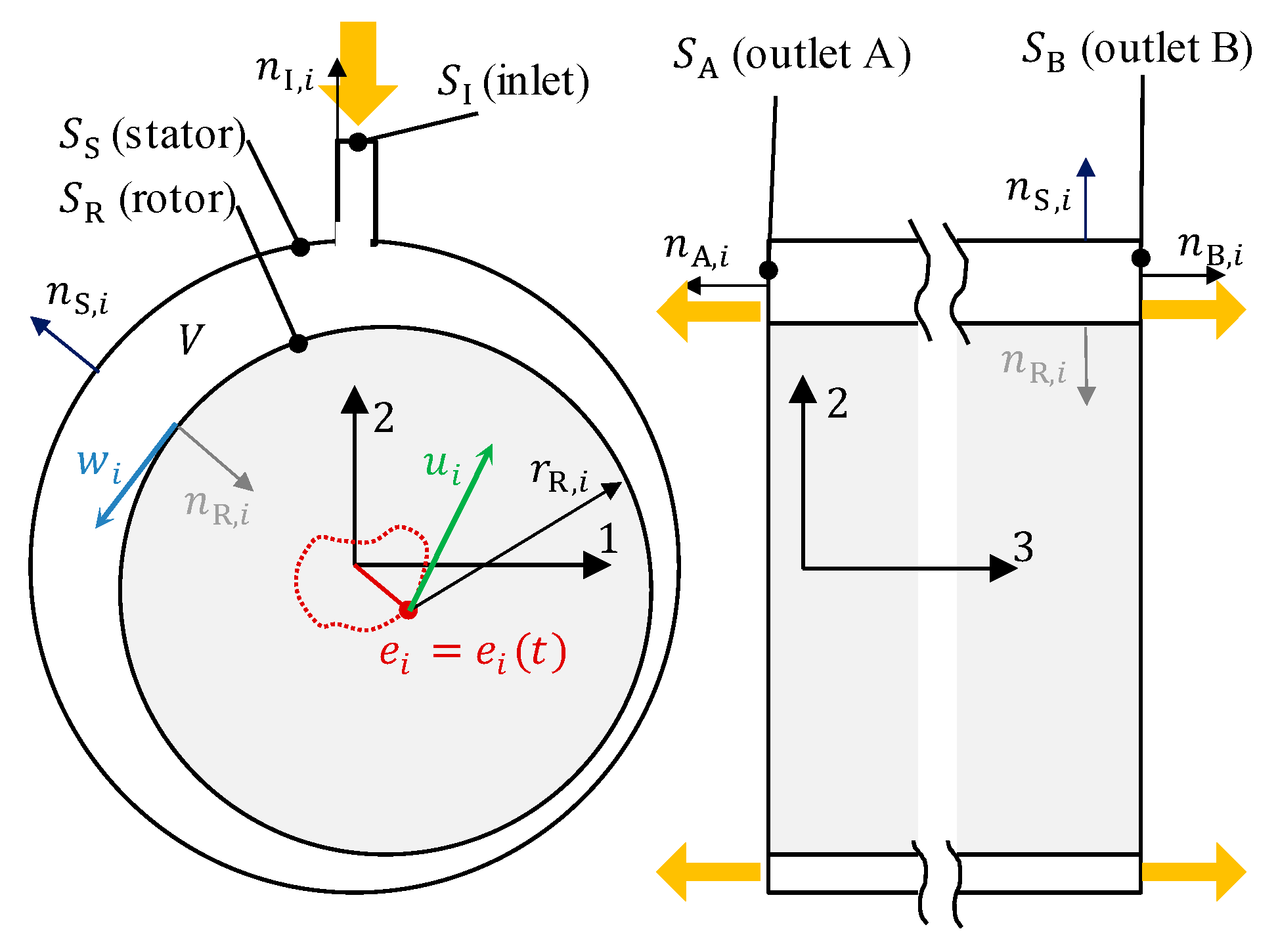

2. Materials and Methods

3. Results

3.1. Explanation of the Convective Term Influence on the Force on the Rotor

3.1.1. Inlet Surface

3.1.2. Stator Surface

3.1.3. Outlet Surfaces and

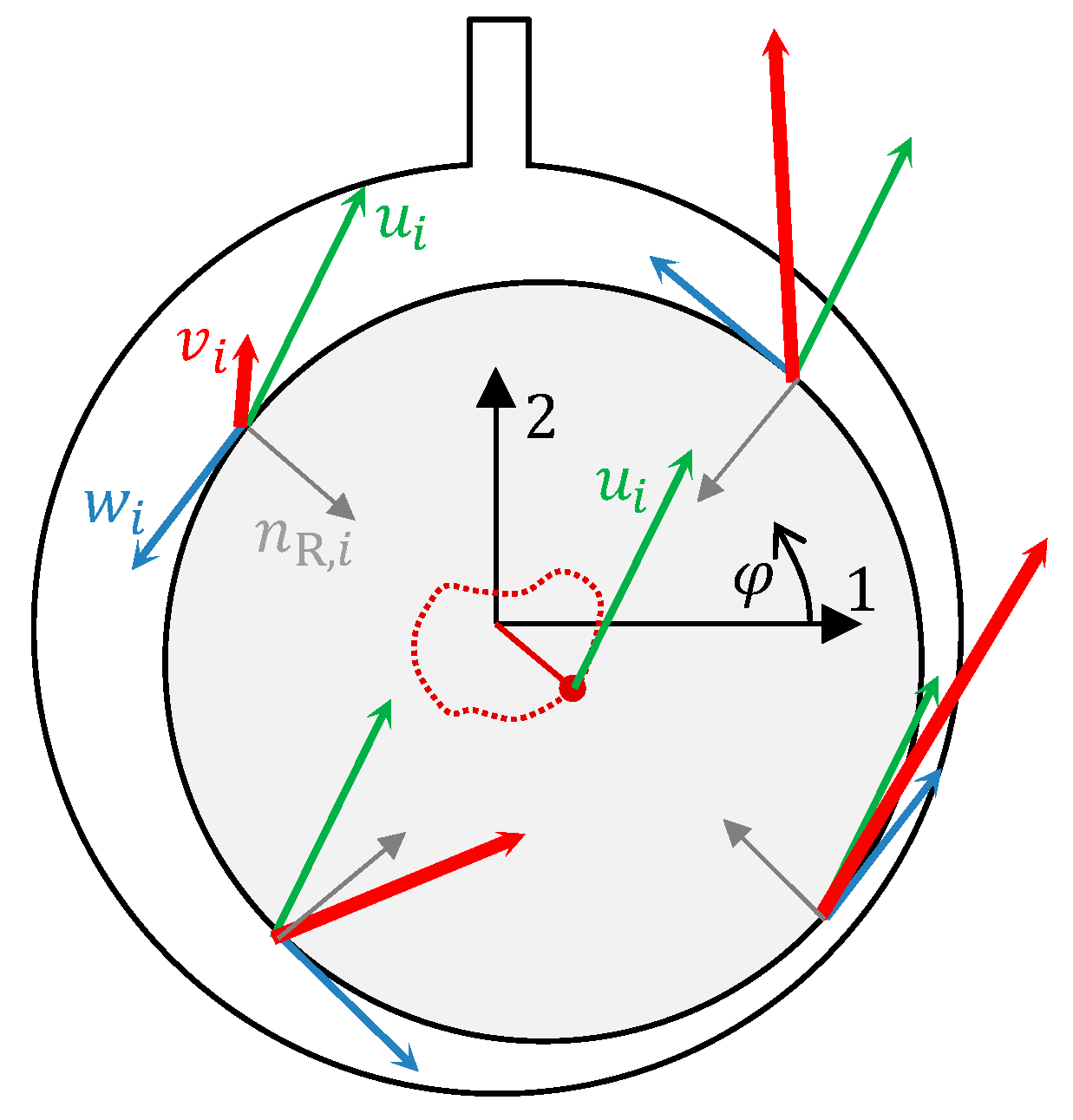

3.1.4. Rotor Surface

- The velocity vector of the rotor centre is the same at each point of the rotor surface; that is, it can be placed before the integral.

- At each point, the circumferential velocity vector on the rotor surface is perpendicular to the unit normal vector of the rotor surface . This fact holds for a circular cross-section of the rotor.

3.2. Notes on the Influence of the Convective Term

- The lubrication layer includes two or more rotationally symmetrical inlets .

- The fluid has a constant density and viscosity.

- The rotor performs the CCO movement or oscillates in the radial direction and does not rotate.

- The outlet velocity has either a non-zero only axial velocity component at each point of the outlet surface, or the outlet velocity is rotationally periodic.

- The effect of non-constant density due to cavitation or fluid compressibility.

- The influence of the outlet velocity whose surface integral in the radial direction is not zero.

- The influence of inlet velocity.

- The inborn character of numerical methods in nonlinear systems of equations.

4. Discussion

- Non-moving stator .

- Small influence of the temporal term on inlet surface and outlet surfaces and .

- Small influence of the viscous and pressure terms on inlet surface and outlet surfaces and .

- Small influence of the convective term on inlet surface and outlet surfaces and .

5. Conclusions

- Non-constant density (compressible fluid or cavitation).

- Non-zero area integral of the convective term on all inlet and outlet surfaces.

- Simultaneous rotation of the rotor surface and non-zero velocity of its centre.

- The computational model should first be tested under simplified conditions:

- Constant fluid density.

- Rotor CCO motion or oscillations in one direction without rotation.

- Stationary stator.

- No axial outflow.

- No radial inflow.

- No convective term.

- 2.

- The force calculation must incorporate both the pressure field and the velocity field, e.g., both Equations (8) and (9).

- 3.

- The convective term should be introduced into the model. If the implementation is correct, the computed force should remain unchanged.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Nomenclature | |

| radial clearance | |

| force | |

| rotor centre position vector | |

| frequency of periodic motion | |

| non-dimensional parameter | |

| maximum amplitude of periodic motion | |

| general position vector | |

| time | |

| pressure | |

| bearing length | |

| surface | |

| normal vector | |

| V | volume |

| radius | |

| non-dimensional variable | |

| rotor centre velocity vector | |

| absolute velocity vector | |

| rotating velocity vector | |

| Greek letters | |

| Kronecker‘s delta | |

| Levi-Civita tensor | |

| Cauchy stress tensor | |

| viscous stress tensor | |

| dynamic viscosity | |

| bulk viscosity | |

| fluid density | |

| general surface | |

| polar angle | |

| angular velocity vector | |

| angular velocity of periodic motion | |

| Subscripts | |

| friction | |

| mean | |

| maximum | |

| pressure | |

| number indices | |

| inlet surface I | |

| outlet surface A | |

| outlet surface B | |

| rotor | |

| stator | |

| Abbreviations | |

| SFD | squeeze film damper |

| CCO | circular centred orbit |

| CFD | computational fluid dynamics |

References

- Reynolds, O. On the theory of lubrication and its application to Mr. Beauchamp tower’s experiments, including an experimental determination of the viscosity of olive oil. Phil. Trans. R. Soc. 1886, 177, 157–234. [Google Scholar]

- Sommerfeld, A. Zur hydrodynamische theorie derschmiermittelreibung. Zeit. Math. Phys. 1904, 50, 97–155. [Google Scholar]

- Gümbel, L. Das problem der lagerreibung. Mon. Berl. Bezirksverein. V.D.I. 1914, 5, 87–104+109–120. [Google Scholar]

- Temperley, H.N.V.; Dowson, D.; Godet, M.; Taylor, C.M. The tensile strength of liquids. Cavitation and related phenomena in lubrication. In Proceedings of the 1st Leeds-Lyon Symposium on Tribology, London, UK, 14–17 September 1974; Mechanical Engineering Publications Ltd.: London, UK, 1974; pp. 11–14. [Google Scholar]

- Temperley, H.N.V.; Chambers, L.G. The behaviour of water under hydrostatic tension. Part I. Proc. Phys. Soc. 1946, 58, 420–436. [Google Scholar] [CrossRef]

- Temperley, H.N.V. The behaviour of water under hydrostatic tension. Part II. Proc. Phys. Soc. 1946, 58, 436–443. [Google Scholar] [CrossRef]

- Braun, M.J.; Hannon, W.M. Cavitation formation and modelling for fluid film bearings: A review. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2010, 224, 839–863. [Google Scholar] [CrossRef]

- Floberg, L. On the tensile strength of liquids. In Transactions of Machine Elements Division; Lund Engineering University: Lund, Sweden, 1973; pp. 1–13. [Google Scholar]

- Franc, J.P. The Rayleigh-Plesset equation: A simple and powerful tool to understand various aspects of cavitation. In Fluid Dynamics of Cavitation and Cavitating Turbopumps; CISM International Centre for Mechanical Sciences; Springer: Vienna, Austria, 2007; Volume 496, pp. 1–41. [Google Scholar]

- Brennen, C. A numerical solution of axisymmetric cavity flows. J. Fluid Mech. 1969, 37, 671–688. [Google Scholar] [CrossRef]

- Taylor, G.I. Stability of a Viscous Liquid Contained between Two Rotating Cylinders. Philos. Trans. R. Soc. Lond. Ser. A 1923, 223, 289–343. [Google Scholar]

- Childs, P.R.N. Rotating Cylinders, Annuli, and Spheres. In Rotating Flow; Butterworth-Heinemann: Oxford, UK, 2011; pp. 177–247. [Google Scholar] [CrossRef]

- Donnelly, R.J.; Simon, N.J. An empirical torque relation for supercritical flow between rotating cylinders. J. Fluid Mech. 1960, 7, 401–418. [Google Scholar] [CrossRef]

- Schwarz, K.W.; Springett, B.E.; Donnelly, R.J. Modes of instability in spiral flow between rotating cylinders. J. Fluid Mech. 1964, 20, 281–289. [Google Scholar] [CrossRef]

- Coles, D. Transition in circular Couette flow. J. Fluid Mech. 1965, 21, 385–425. [Google Scholar] [CrossRef]

- Snyder, H.A. Waveforms in rotating Couette flow. Int. J. Non-Linear Mech. 1970, 5, 659–685. [Google Scholar] [CrossRef]

- Fenstermacher, P.R.; Swinney, H.L.; Gollub, J.P. Dynamical instabilities and the transition to chaotic Taylor vortex flow. J. Fluid Mech. 1979, 94, 103–129. [Google Scholar] [CrossRef]

- Andereck, C.D.; Liu, S.S.; Swinney, H.L. Flow regimes in a circular Couette system with independently rotating cylinders. J. Fluid Mech. 1986, 164, 155–183. [Google Scholar] [CrossRef]

- Brandstater, A.; Swinney, H.L. Strange attractors in weakly turbulent Couette-Taylor flow. Phys. Rev. A 1987, 35, 2207–2220. [Google Scholar] [CrossRef] [PubMed]

- Smith, D.M. Journal Bearing Dynamic Characteristics—Effect of Inertia of Lubricant. Proc. Inst. Mech. Eng. 1964, 179, 37–44. [Google Scholar] [CrossRef]

- San Andres, L.A.; Vance, J.M. Effect of Fluid Inertia on Squeeze-Film Damper Forces for Small-Amplitude Circular-Centered Motions. ASLE Trans. 1987, 30, 63–68. [Google Scholar] [CrossRef]

- Modest, M.F.; Tichy, J.A. Squeeze Film Flow in Arbitrarily Shaped Journal Bearings Subject to Oscillations. J. Lubr. Technol. 1978, 100, 323–329. [Google Scholar] [CrossRef]

- Szeri, A.Z.; Raimondi, A.A.; Giron-Duarte, A. Linear Force Coefficients for Squeeze-Film Dampers. J. Lubr. Technol. 1983, 105, 326–334. [Google Scholar] [CrossRef]

- Tichy, J.; Bou-Saïd, B. Hydrodynamic Lubrication and Bearing Behavior with Impulsive Loads. Tribol. Trans. 1991, 34, 505–512. [Google Scholar] [CrossRef]

- Constantinescu, V.N. On the Influence of Inertia Forces in Turbulent and Laminar Self-Acting Films. J. Lubr. Technol. 1970, 92, 473–480. [Google Scholar] [CrossRef]

- Osterle, J.F.; Chou, Y.T.; Saibel, E.A. The Effect of Lubricant Inertia in Journal-Bearing Lubrication. J. Appl. Mech. 1957, 24, 494–496. [Google Scholar] [CrossRef]

- Reinhardt, E.; Lund, J.W. The Influence of Fluid Inertia on the Dynamic Properties of Journal Bearings. J. Lubr. Technol. 1975, 97, 159–165. [Google Scholar] [CrossRef]

- Han, Y.; Rogers, R.J. Nonlinear fluid forces in cylindrical squeeze films. Part I: Short and long lengths. J. Fluids Struct. 2001, 15, 151–169. [Google Scholar] [CrossRef]

- Han, Y.; Rogers, R.J. Nonlinear fluid forces in cylindrical squeeze films. Part II: Finite length. J. Fluids Struct. 2001, 15, 171–206. [Google Scholar] [CrossRef]

- Zhang, J.; Ellis, J.; Roberts, J.B. Observations on the Nonlinear Fluid Forces in Short Cylindrical Squeeze Film Dampers. J. Tribol. 1993, 115, 692–698. [Google Scholar] [CrossRef]

- El-Shafei, A.; Crandall, S.M. Fluid Inertia Forces in Squeeze Film Dampers. In Proceedings of the 13th Biennial Conference on Mechanical Vibration and Noise: Rotating Machinery and Vehicle Dynamics, Miami, FL, USA, 22–25 September 1991; ASME: New York, NY, USA, 1991; pp. 219–228. [Google Scholar] [CrossRef]

- Crandall, S.H.; El-Shafei, A. Momentum and Energy Approximations for Elementary Squeeze-Film Damper Flows. J. Appl. Mech. 1993, 60, 728–736. [Google Scholar] [CrossRef]

- San Andres, L.A.; Vance, J.M. Effects of Fluid Inertia on Finite-Length Squeeze-Film Dampers. ASLE Trans. 1987, 30, 384–393. [Google Scholar] [CrossRef]

- San Andrés, L.; Vance, J.M. Effects of Fluid Inertia and Turbulence on the Force Coefficients for Squeeze Film Dampers. J. Eng. Gas Turbines Power 1986, 108, 332–339. [Google Scholar] [CrossRef]

- Tichy, J.A. A Study of the Effect of Fluid Inertia and End Leakage in the Finite Squeeze Film Damper. J. Tribol. 1987, 109, 54–59. [Google Scholar] [CrossRef]

- Hamzehlouia, S.; Behdinan, K. A Study of Lubricant Inertia Effects for Squeeze Film Dampers Incorporated into High-Speed Turbomachinery. Lubricants 2017, 5, 43. [Google Scholar] [CrossRef]

- Hamzehlouia, S.; Behdinan, K. Squeeze Film Dampers Executing Small Amplitude Circular-Centered Orbits in High-Speed Turbomachinery. Int. J. Aerosp. Eng. 2016, 2016, 5127096. [Google Scholar] [CrossRef]

- Bonello, P.; Brennan, M.J.; Holmes, R. Non-linear modelling of rotor dynamic systems with squeeze film dampers—An efficient integrated approach. J. Sound Vib. 2002, 249, 743–773. [Google Scholar] [CrossRef]

- Hamzehlouia, S.; Behdinan, K. Squeeze film dampers supporting high-speed rotors: Rotordynamics. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2021, 235, 495–508. [Google Scholar] [CrossRef]

- Shen, G.; Xiao, Z.; Zhang, W.; Zheng, T. Nonlinear Behavior Analysis of a Rotor Supported on Fluid-Film Bearings. J. Vib. Acoust. 2006, 128, 35–40. [Google Scholar] [CrossRef]

- Von Osmanski, S.; Santos, I.F. Gas foil bearings with radial injection: Multi-domain stability analysis and unbalance response. J. Sound Vib. 2021, 508, 116177. [Google Scholar] [CrossRef]

- Novotný, P.; Jonák, M.; Vacula, J. Evolutionary Optimisation of the Thrust Bearing Considering Multiple Operating Conditions in Turbomachinery. Int. J. Mech. Sci. 2021, 195, 106240. [Google Scholar] [CrossRef]

- Zhang, J.; Han, D.; Xie, Z.; Huang, C.; Rao, Z.; Song, M.; Su, Z. Nonlinear behaviors analysis of high-speed rotor system supported by aerostatic bearings. Tribol. Int. 2022, 170, 107111. [Google Scholar] [CrossRef]

- Manshoor, B.; Jaat, M.; Izzuddin, Z.; Amir, K. CFD Analysis of Thin Film Lubricated Journal Bearing. Procedia Eng. 2013, 68, 56–62. [Google Scholar] [CrossRef]

- Sahu, M.; Giri, A.K.; Das, A. Thermohydrodynamic Analysis of a Journal Bearing Using CFD as a Tool. Int. J. Sci. Res. Publ. 2012, 2, 1–7. [Google Scholar]

- Shahmohamadi, H.; Rahmani, R.; Rahnejat, H.; Garner, C.P.; Dowson, D. Big End Bearing Losses with Thermal Cavitation Flow Under Cylinder Deactivation. Tribol. Lett. 2015, 57, 2. [Google Scholar] [CrossRef]

- Song, Y.; Gu, C.; Ren, X. Development and validation of a gaseous cavitation model for hydrodynamic lubrication. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2015, 229, 1227–1238. [Google Scholar] [CrossRef]

- Ding, A.; Xiao, Y. Numerical Investigation for Characteristics and Oil-Air Distributions of Oil Film in a Tilting-Pad Journal Bearing. In Turbo Expo: Power for Land, Sea, and Air; Volume 7B: Structures and Dynamics; ASME: New York, NY, USA, 2018; Volume 7B, pp. 1–11. [Google Scholar] [CrossRef]

- Ding, A.; Ren, X.; Li, X.; Gu, C. A new gaseous cavitation model in a tilting-pad journal bearing. Sci. Prog. 2021, 104, 1–19. [Google Scholar] [CrossRef]

- Wang, L.; Liu, Z.; Yuan, G.; Wei, Y. Combined Influence of Noncondensable Gas Mass Fraction and Mathematical Model on Cavitation Performance of Bearing. Int. J. Rotating Mach. 2020, 2020, 8409231. [Google Scholar] [CrossRef]

- Ochiai, M.; Sakai, F.; Hashimoto, H. Reproducibility of Gaseous Phase Area on Journal Bearing Utilizing Multi-Phase Flow CFD Analysis under Flooded and Starved Lubrication Conditions. Lubricants 2019, 7, 74. [Google Scholar] [CrossRef]

- Rasep, Z.; Yazid, M.N.A.W.M.; Samion, S. A study of cavitation effect in a journal bearing using CFD: A case study of engine oil, palm oil and water. J. Tribol. 2021, 28, 48–62. [Google Scholar]

- Geller, M.; Schemmann, C.; Kluck, N. Simulation of radial journal bearings using the FSI approach and a multi-phase model with integrated cavitation. Prog. Comput. Fluid Dyn. 2014, 14, 14–23. [Google Scholar] [CrossRef]

- Ramdhani, S.; Haryanto, I.; Tauviqirrahman, M. 3D simulation of the lubrication film in journal bearing using Fluid-Structure Interaction (FSI). J. Phys. Conf. Ser. 2018, 1090, 012025. [Google Scholar] [CrossRef]

- Dhande, D.Y.; Pande, D.W. Multiphase flow analysis of hydrodynamic journal bearing using CFD coupled Fluid Structure Interaction considering cavitation. J. King Saud Univ. Eng. Sci. 2018, 30, 345–354. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, Y.B. Development of an evaluation method of floating ring bearings by CFD with mesh motion. IOP Conf. Ser. Earth Environ. Sci. 2018, 163, 012080. [Google Scholar] [CrossRef]

- Song, Y.; Gu, C. Development and Validation of a Three-Dimensional Computational Fluid Dynamics Analysis for Journal Bearings Considering Cavitation and Conjugate Heat Transfer. J. Eng. Gas Turbines Power 2015, 137, 122502. [Google Scholar] [CrossRef]

- Xing, C.; Braun, M.J.; Li, H. Damping and added mass coefficients for a squeeze film damper using the full 3-D Navier-Stokes equation. Tribol. Int. 2010, 43, 654–666. [Google Scholar] [CrossRef]

- Shi, X.; Ni, T. Effects of groove textures on fully lubricated sliding with cavitation. Tribol. Int. 2011, 44, 2022–2028. [Google Scholar] [CrossRef]

- Nie, T.; Yang, K.; Zhou, L.; Wu, X.; Wang, Y. CFD analysis of load capacity of journal bearing with surface texture. Energy Rep. 2022, 8, 327–334. [Google Scholar] [CrossRef]

- Gengyuan, G.; Zhongwei, Y.; Dan, J.; Xiuli, Z. CFD analysis of load-carrying capacity of hydrodynamic lubrication on a water-lubricated journal bearing. Ind. Lubr. Tribol. 2015, 67, 30–37. [Google Scholar] [CrossRef]

- Pérez-Viguera, D.; Colín-Ocampo, J.; Blanco-Ortega, A.; Campos-Amézcua, R.; Mazón-Valadez, C.; Rodríguez-Reyes, V.I.; Landa-Damas, S.J. Fluid Film Bearings and CFD Modeling: A Review. Machines 2023, 11, 1030. [Google Scholar] [CrossRef]

- Brindley, J.; Elliott, L.; McKay, J.T. Flow in a Whirling Rotor Bearing. J. Appl. Mech. 1979, 46, 767–771. [Google Scholar] [CrossRef]

- May, R.M. Simple mathematical models with very complicated dynamics. Nature 1976, 261, 459–467. [Google Scholar] [CrossRef]

- Hall, P.; Papageorgiou, D.T. The onset of chaos in a class of Navier-Stokes solutions. J. Fluid Mech. 1999, 393, 59–87. [Google Scholar] [CrossRef]

- Stuart, J.T.; DiPrima, R.C.; Eagles, P.M.; Davey, A. On the instability of the flow in a squeeze lubrication film. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1990, 430, 347–375. [Google Scholar] [CrossRef]

- Fialová, S.; Pochylý, F.; Šedivý, D.; Dančová, P.; Novosad, J. A new form of equation for force determination based on Navier-Stokes equations. EPJ Web Conf. 2019, 213, 02018. [Google Scholar] [CrossRef]

| Type of Motion | ||||

|---|---|---|---|---|

| Rotation | ||||

| CCO | ||||

| Compound |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vacula, J.; Novotný, P. On the Influence of the Convective Term in the Navier–Stokes Equation on the Forces in Hydrodynamic Bearings. Lubricants 2025, 13, 293. https://doi.org/10.3390/lubricants13070293

Vacula J, Novotný P. On the Influence of the Convective Term in the Navier–Stokes Equation on the Forces in Hydrodynamic Bearings. Lubricants. 2025; 13(7):293. https://doi.org/10.3390/lubricants13070293

Chicago/Turabian StyleVacula, Jiří, and Pavel Novotný. 2025. "On the Influence of the Convective Term in the Navier–Stokes Equation on the Forces in Hydrodynamic Bearings" Lubricants 13, no. 7: 293. https://doi.org/10.3390/lubricants13070293

APA StyleVacula, J., & Novotný, P. (2025). On the Influence of the Convective Term in the Navier–Stokes Equation on the Forces in Hydrodynamic Bearings. Lubricants, 13(7), 293. https://doi.org/10.3390/lubricants13070293