2. Literature Review

Realistic emulation of EV charging profiles plays a crucial role in the design, analysis, and validation of control strategies, system-level simulations, and digital twins [

9]. Accurate replication of charging dynamics including power flow, state-of-charge (SOC) evolution, and charger control behavior is essential for building confidence in simulation environments and validating software-based control schemes under near-physical conditions. The existing research has primarily approached this challenge through data-driven modeling [

10] and offline simulations [

11], with comparatively limited attention given to high-fidelity real-time simulation environments.

A significant body of the literature focuses on modeling EV charging behavior using statistical, probabilistic, or machine learning-based techniques [

12]. Public datasets, such as those from the Alternative Fuels Data Center (AFDC), California’s ACN-Data, and NREL’s EVI-Pro, have been widely used to develop stochastic models of EV arrival times, dwell durations, and energy consumption patterns. Gaussian Mixture Models [

13], Markov chains [

14], and unsupervised clustering [

15] have been employed to capture daily or seasonal variability in charging behavior. While these models are effective for system-level planning and aggregated load forecasting, they lack the granularity and physical detail required for simulating the real-time behavior of charger hardware, power electronics, and battery interaction.

Moreover, such approaches often abstract away the dynamics of voltage/current regulation, control response, ramp rates, and other transient behaviors that emerge during actual charging sessions. Their reliance on limited or low-resolution data also restricts their capacity to reproduce high-fidelity charging trajectories. As access to detailed charging session data is limited due to privacy concerns and the cost of high-frequency data acquisition, the development of validated models capable of capturing both the temporal and dynamic nature of EV charging remains an open challenge.

In response, real-time simulators have emerged as powerful tools for emulating the behavior of power electronic systems with high accuracy and deterministic execution. Platforms such as Typhoon HIL, OPAL-RT, and RTDS Technologies enable high-resolution, time step-based simulation of converter models [

16], battery systems [

17], and control algorithms [

18,

19] in real time. Although often used in hardware-in-the-loop configurations, these platforms are equally valuable in purely software-based real-time simulation contexts, allowing for the validation of control logics, firmware algorithms, and system dynamics in a synchronized and time-bound simulation loop.

In recent years, real-time simulators have been employed to emulate onboard EV chargers [

20], DC fast-charging stations [

21], and battery dynamics [

22] under variable load conditions. These studies have demonstrated the potential of real-time environments for testing dynamic interactions between software control and power system models. However, many existing implementations focus only on specific subsystems, such as the charger controller or DC/DC converter, and do not replicate full EV charging behavior that includes realistic SOC evolution and time-series power demand aligned with real-world charging data.

In summary, despite significant advancements in modeling EV charging behavior and creating real-time simulation platforms, the literature lacks a comprehensive framework that replicates real-world EV charging sessions encompassing active power as well as SOC trajectories within a real-time simulation context and validation against empirical data. Most studies either rely on synthetic profiles or validate components in isolation without capturing the complete dynamics of the charging processes. This study addresses this critical gap by developing a validated EV charging emulation framework using a real-time simulator, where detailed charger and battery models are executed in real time and compared against real-world measurements to ensure high fidelity and reliability. This enables accurate prediction of grid impacts, facilitates testing of intelligent charging strategies under realistic conditions, and supports the development of digital twins for future electric mobility applications.

4. Modeling of EV Charging Setup

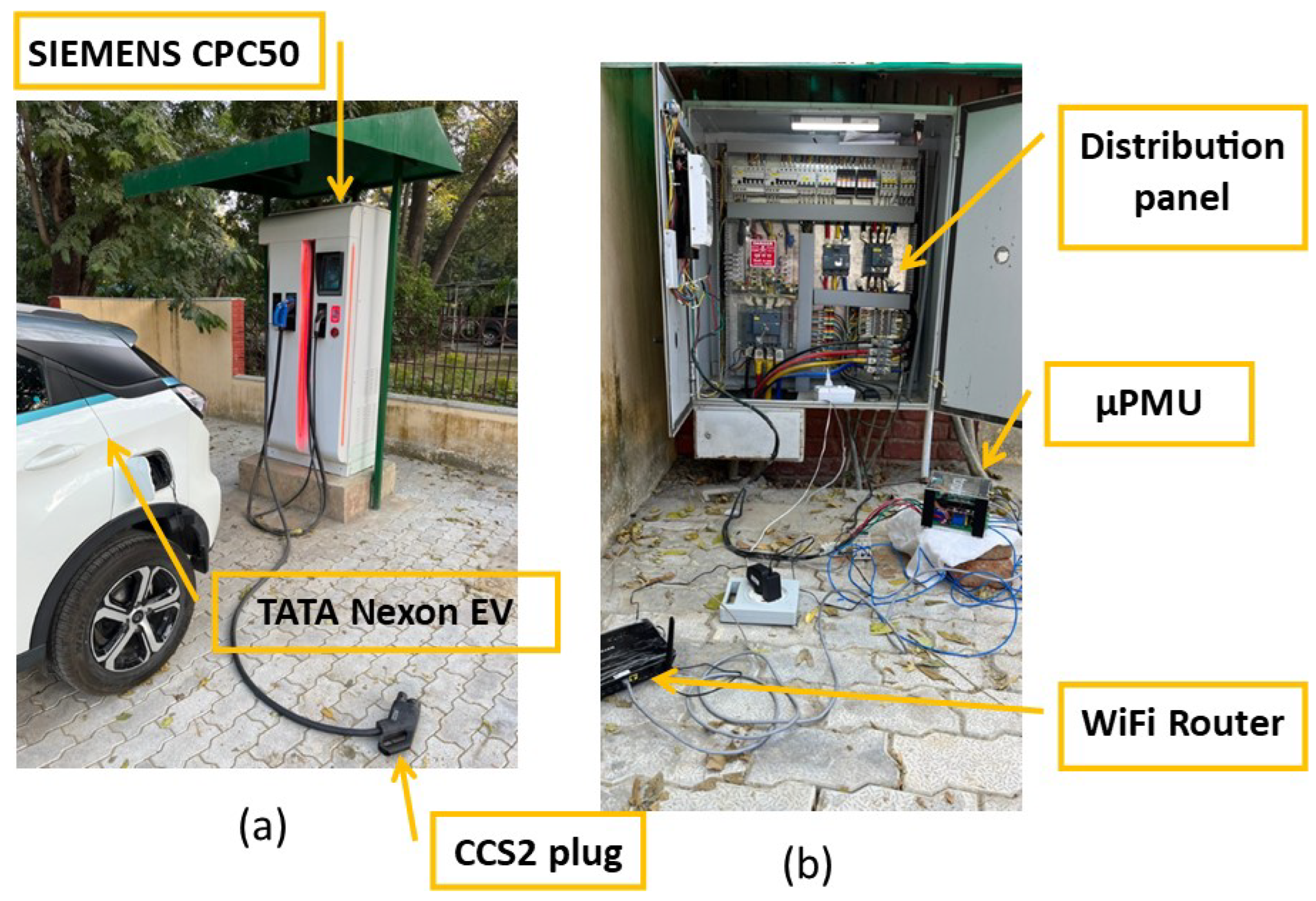

To evaluate and replicate the behavior of a real-world EV charging station, a detailed simulation model was developed on the Typhoon HIL platform. This model aims to reproduce the dynamic electrical characteristics observed in the field, including active power, and SOC evolution during charging events. The modeling process is further refined by on-site measurements and tailored to reflect the configuration, control strategy, and load dynamics of the actual charging infrastructure. The subsequent subsection provides a comprehensive overview of the architectural design and functional components of the EV charging station, including its power electronic interfaces and control strategies. It outlines how the charging system operates under real-world conditions and explains the design considerations taken into account for modeling the power flow control, charger coordination, and system-level interactions within the simulation environment. As illustrated in

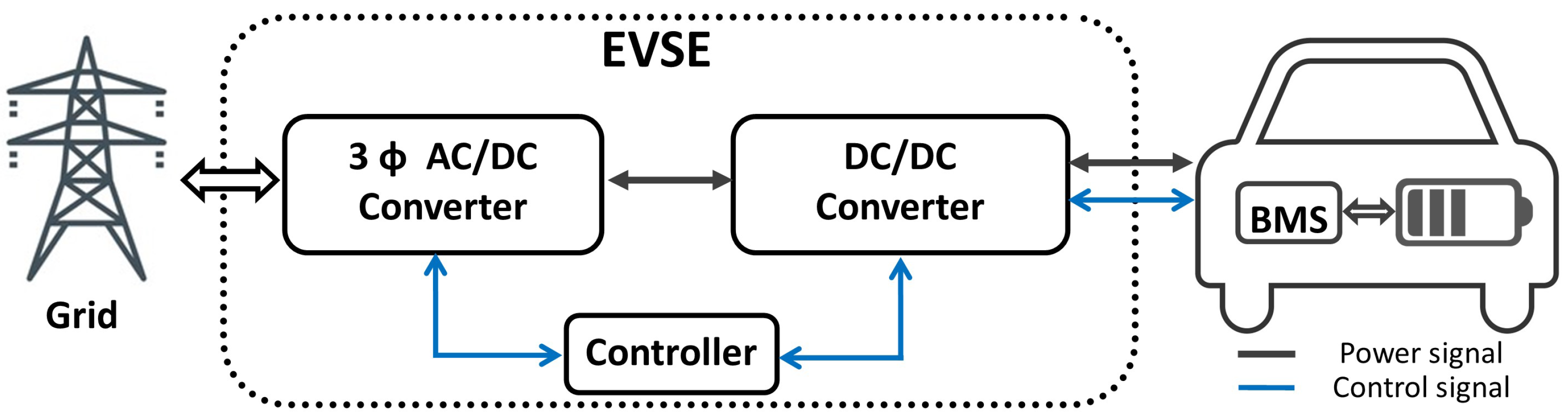

Figure 3, the EV charging station model comprises three key components: the utility grid, the electric vehicle supply equipment (EVSE), featuring a bidirectional fast charger, and the EV itself, which includes the battery management system (BMS) and the battery. The EVSE is capable of delivering power back to the grid via vehicle-to-grid (V2G), known as discharging mode, and extracting power from the grid via grid-to-vehicle (G2V), known as charging mode.

The EVSE modeled in this work is a Level 3 charger with a nominal rating of 50 kW at 415 V employing a two-stage power conversion topology. This configuration was selected due to its widespread adoption and relatively straightforward implementation in fast-charging applications. As depicted in

Figure 3, the system comprises two distinct power electronic stages: the first stage is a three-phase full-bridge AC/DC converter, and the second stage is a bidirectional buck–boost DC/DC converter. The primary function of the AC/DC converter is to regulate the DC link voltage while simultaneously ensuring the desired power factor at the grid connection point. Concurrently, the DC/DC converter is responsible for managing the charging and discharging processes of the EV battery based on the demanded active power. To facilitate independent control of the power flow, the regulation of active and reactive power is decoupled: reactive power is handled by the AC/DC converter, while active power is regulated by the DC/DC converter. The subsequent sections provide a detailed explanation of the control approach that enables this decoupled power regulation. Given the established advantages in power electronics control, the direct-quadrature (dq) control method is employed for reactive power regulation via the AC/DC stage.

The EVSE model, along with its corresponding control algorithm, was effectively implemented and executed on the Typhoon HIL604 real-time hardware, with the Typhoon HIL Control Center (v2024.3) software environment being used for validation. The experiments were executed on a workstation with the following configuration: an Intel Core i7 processor (2.9 GHz), 16 GB RAM, and a Windows 11 (64-bit) operating system. This setup ensured reliable execution of the real-time models and efficient handling of the data acquisition process. The charging station model to be simulated is composed of six primary components:

Three-phase AC/DC PWM converter;

DC/DC converter;

Controller for AC/DC converter;

Controller for DC/DC converter;

EV battery;

Controller for EV or BMS.

4.1. System Modeling

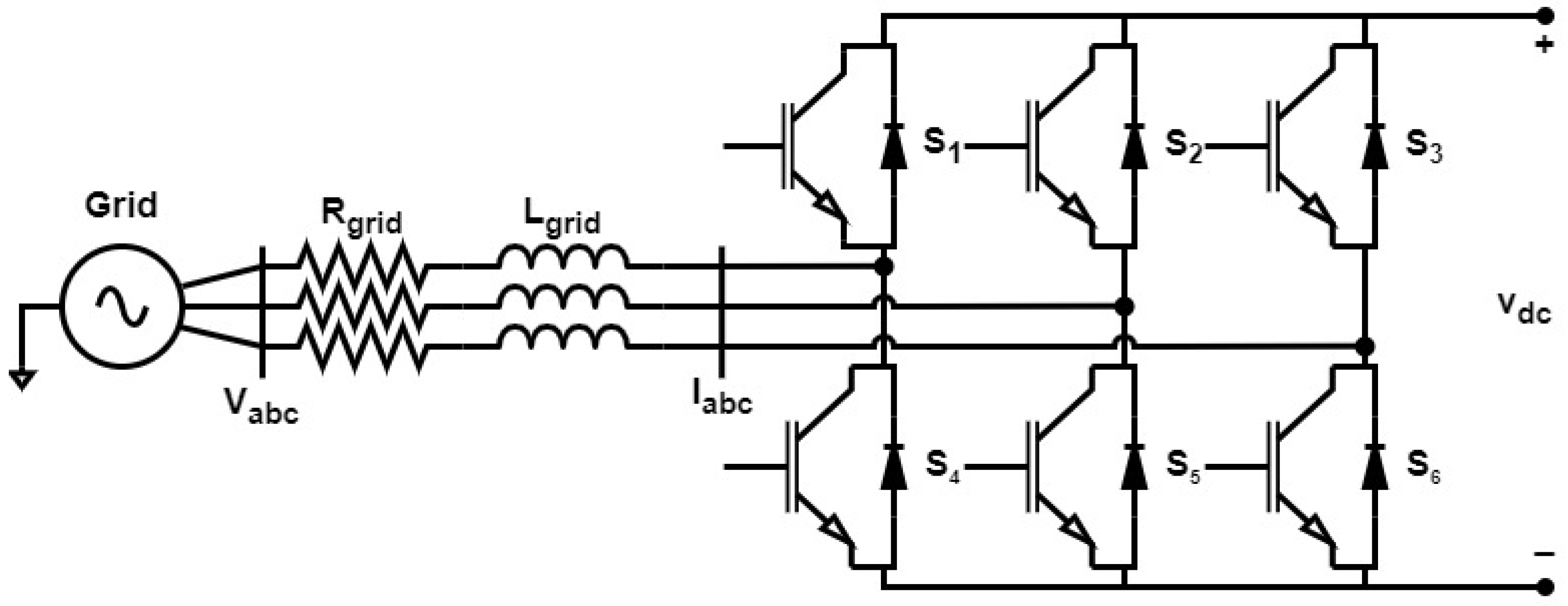

The primary interface between the grid and the DC link in the EVSE is the AC/DC converter (the first component of the EVSE in

Figure 3), whose robust operation is critical for efficient power transfer. A well-established and robust control methodology is essential to ensure effective management of the interaction between the charging station and the utility grid. Currently, the majority of pulse-width modulation (PWM) voltage-source converter (VSC) implementations employ the PWM Current Control approach. This method offers several notable advantages, including effective current regulation, precise control over the DC link voltage, and inherent compensation for voltage drops across semiconductor devices and dead-time effects within switching elements. Numerous studies have established that the two primary choices for linear, non-predictive current control strategies are the proportional-resonant (PR) controller, operating in the stationary reference frame, and the direct-quadrature (dq) controller, implemented in the synchronous rotating reference frame.

In grid-connected converter systems, precise control of current is critical to ensure stability, power quality, and adherence to grid codes. Among the various control strategies employed, vector control techniques have proven to be highly effective, especially in managing the dynamics of three-phase VSCs. One widely adopted approach within this framework is the use of synchronous reference frame control [

29]. The synchronous rotating reference frame controller is particularly prevalent in the current control of three-phase VSCs, primarily due to its inherent ability to achieve a zero steady-state error for AC quantities. The fundamental concept behind this approach involves transforming time-varying AC quantities, such as currents and voltages, into constant DC values within a synchronously rotating reference frame. This transformation significantly simplifies the application of conventional linear control techniques, such as proportional–integral (PI) controllers. In three-phase systems, this transformation is typically achieved using the direct-quadrature-zero (dq0) transformation. This method enables precise and decoupled control of active and reactive power by separating the system dynamics into orthogonal components (d-axis for active power, q-axis for reactive power). A crucial element in this control scheme is the incorporation of a phase-locked loop (PLL), which accurately determines the system’s fundamental frequency and generates the necessary angle

to synchronize the rotating dq frame with the grid voltage.

A typical block diagram illustrating a dq-based VSC controller is presented in

Figure 4. In this configuration, the error in the DC link voltage

is processed through a proportional–integral (PI) controller to generate the reference for the direct-axis current

, which directly correlates with the active power flow. Conversely, the quadrature axis current reference

is typically set based on the desired reactive power injection or absorption. Consequently, with the quadrature component of the grid voltage

ideally driven to zero through PLL synchronization, the converter output voltage equation can be expressed as follows:

Among the terms in Equation (

1), the only variable that can be directly controlled is

. This is because

is defined by the system voltage

, and

depends on the battery current and inherent system losses. By adjusting the reference value

, reactive power can be regulated independently of active power control. In the control scheme, the reference reactive power

is subtracted from the measured reactive power

Q, and the resulting error is fed to a PI controller to produce the reference quadrature-axis current

. Similarly, the reference DC-link voltage

is subtracted from the measured DC-link voltage

, and the error is processed through a PI controller to generate the reference direct-axis current

. In the inner current control loop, these reference currents are compared with their corresponding measured currents, where

is subtracted from the measured quadrature-axis current

, and

is subtracted from the measured direct-axis current

. The respective errors are then fed into PI controllers to regulate the currents effectively, ensuring accurate tracking of both reactive power and DC-link voltage references. This approach enables straightforward calculation of reactive power while maintaining independent control from active power regulation. The vector control block diagram is shown in

Figure 5.

While the dq control method provides a robust framework for decoupled power regulation, its practical implementation necessitates careful consideration of the energy flow dynamics within the charging system. The flow of active power between the grid and the system is directly influenced by the battery’s current and voltage and the efficiency of the charger. The critical role of the AC/DC controller is to maintain the stability of the DC link voltage. When properly configured, it can dynamically adjust to fluctuations in the DC link voltage, drawing power from the grid when the voltage decreases or supplying power back to the grid when it increases. Consequently, by managing the battery’s charge and discharge cycles through the DC/DC converter within the charger, effective control of active power is achieved.

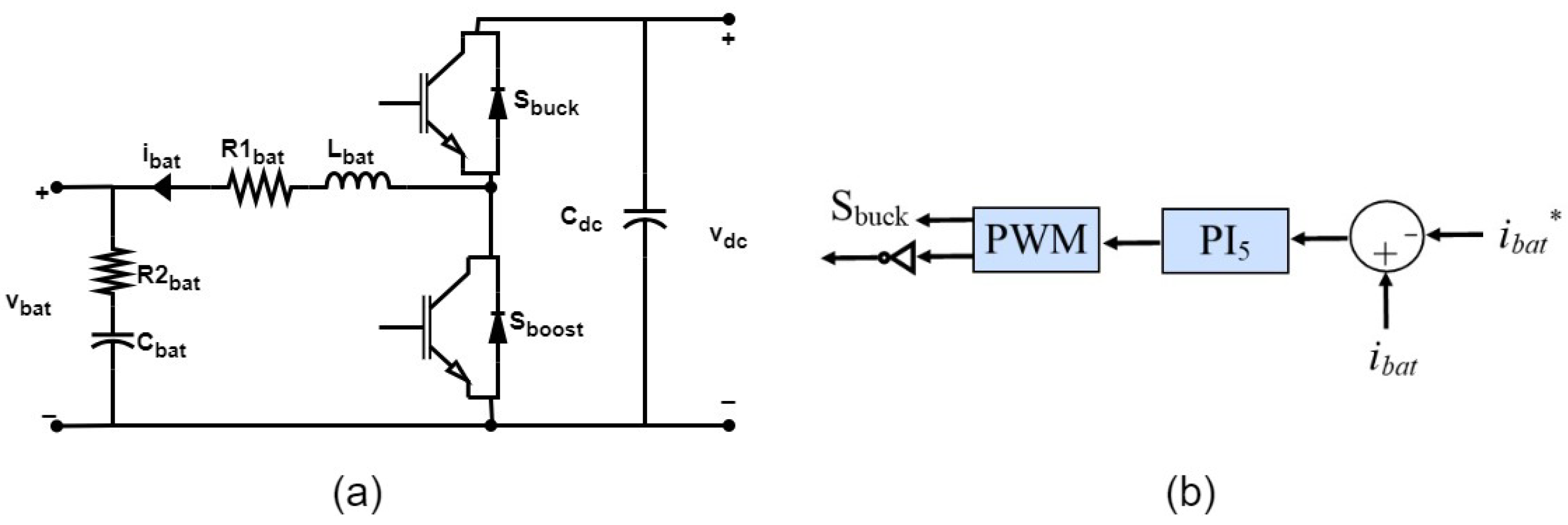

The schematic illustrates a high-efficiency bidirectional DC/DC converter, crucial for seamless power transfer between a battery energy storage system and a DC bus, as shown in

Figure 6a. While currently discussed for power flow from the DC bus to the battery (operating in buck mode for charging), its design inherently supports power transfer in both directions. The core of the power conversion lies in the half-bridge configuration, featuring two actively controlled power semiconductor switches,

and

. In buck mode,

is modulated to step down the DC bus voltage (

), while

acts as a commutating diode, enabling controlled current flow into the battery. Conversely, for power transfer from the battery to the DC bus (boost mode),

would be actively modulated to step up

, with

acting as a diode. A DC link capacitor,

, is strategically placed on the DC bus side to effectively smooth voltage ripples and maintain a stable

.

The control strategy for regulating the battery current (

) is depicted in

Figure 6b. This feedback control loop compares the actual battery current (

) with a desired reference current (

). The error signal is then processed by a PI controller, which generates the appropriate control signal for the PWM module. The PWM module then produces the switching signals for

and

, ensuring precise and stable regulation of power flow. The comprehensive set of electrical parameters is meticulously detailed in

Table 1. Crucially, the current reference (

) for this charging strategy is dynamically provided by a feedback system from the EV battery management system (BMS), ensuring optimal charging until the desired SOC% is achieved.

The battery system in EVs serves as the primary energy storage unit, supplying power to traction motors and auxiliary subsystems. Accurate modeling of battery dynamics is essential for predicting EV performance under varying operational conditions and for developing robust energy management strategies. This study employs the lithium-ion (Li-ion) battery model available in the Typhoon HIL Control Center, which is specifically optimized for real-time simulation environments with a nominal voltage of 320 V and 94.5 Ah capacity.

Battery modeling approaches in the literature can be broadly classified into electrochemical, experimental, and equivalent circuit-based methods [

30]. While electrochemical models offer high fidelity, their reliance on partial differential equations renders them computationally intensive [

31]. Experimental models require extensive empirical data and complex curve fitting, limiting their suitability for real-time applications.

To address these limitations, Typhoon HIL utilizes an equivalent circuit-based approach that strikes a balance between accuracy and computational efficiency. The model consists of a controlled voltage source in series with internal resistance, effectively representing terminal behavior during charging and discharging [

13]. The terminal voltage is given by the following:

where

is the open-circuit voltage as a function of extracted capacity

,

is the internal resistance, and

I is the instantaneous current (positive during discharge). The SOC, a key indicator of battery health and available energy, is computed internally and optionally available as an output signal:

The model supports both charging and discharging by interpreting the sign of the current. A positive current indicates discharge, while a negative value corresponds to charging. Although the voltage equation remains unchanged, the current direction influences capacity dynamics, resulting in distinct charge/discharge behavior. This efficient modeling structure facilitates real-time system-level testing of the EV BMS, power converters, and grid interfaces.

4.2. Control Strategy

Building upon the detailed modeling of the EV charger and its integrated control architecture presented in the previous section, this section focuses on the control strategy employed for managing the battery charging process. Lithium-ion batteries are pivotal in modern energy storage, notably in electric vehicles, owing to their high energy density and impressive power capabilities. These batteries inherently support high charging rates, often exceeding

(which means they can be fully charged in

of an hour, or 6 min, under ideal conditions) [

32], which is a critical attribute for the rapid-charging demands of contemporary applications. Despite this inherent capability, conventional charging methodologies, primarily the constant current–constant voltage (CC-CV) approach, frequently underutilize the battery’s full potential for accelerated charging. In this context, an intelligent control strategy is essential to optimize the charging profile while ensuring battery longevity, safety, and compliance with power system constraints.

A more advanced and demonstrably effective charging paradigm involves the implementation of Multiple-Stage Constant Current (MSCC) charging, which strategically employs several distinct constant current phases while entirely circumventing the constant voltage stage. This innovative method has been shown to offer dual benefits: a significant reduction in the overall charging duration and a notable enhancement in battery cycle life [

18]. The determination of optimal C-rates for each phase within an MSCC strategy has been a significant area of research. Investigators have employed a diverse range of methodologies, including rigorous analytical derivations, sophisticated optimization algorithms, and extensive experimental validations, to precisely define these optimal current levels. Furthermore, the seamless transition from one constant current stage to the subsequent phase within an MSCC protocol is meticulously governed by satisfying at least one of four predefined criteria: a set time duration for the current stage, the attainment of a specific SOC, reaching a predetermined voltage threshold, or the activation of a critical cutoff voltage [

33]. This nuanced approach to charging represents a significant advancement in maximizing the performance and longevity of lithium-ion batteries.

Building upon these foundational principles, this research leverages real-world operational data to empirically determine optimal C-rates for implementing an MSCC charging profile. A robust SOC-based transition strategy is employed to adaptively control the charging current as the battery state evolves. As outlined in Algorithm 1, the process begins by retrieving the initial SOC and battery voltage from the BMS. The algorithm then compares the SOC against a predefined set of threshold levels. For each SOC range, a corresponding fraction of the maximum allowable charging current derived from the C-rate is applied. This current reference is periodically updated and transmitted to the DC/DC converter controller. Throughout the process, the battery voltage is actively monitored to ensure it remains within safe operational limits. If the voltage exceeds the safety threshold, charging is immediately terminated. Once the SOC reaches the target value, the charging current is reduced to zero, thereby completing a calibrated and controlled charging cycle.

| Algorithm 1 Multi-Stage SOC-Based MSCC Charging Profile |

|

The TATA NEXON EV, having a nominal capacity of 94.5 Ah, follows a four-stage charging process. The charging profile begins with an initial phase at , which subsequently transitions to and then to , and concludes with a final initial phase at . These transitions are critically governed by the battery reaching specific SOC thresholds , where , , and .

The practical implementation of this four-stage, SOC-based MSCC charging strategy yielded significant performance enhancements. Notably, it resulted in an approximate 15.3% reduction in overall charging time when compared to the conventional CCCV method [

34]. This substantial time saving was achieved with only a marginal impact on charging efficiency (approximately a 0.4% reduction) and a slight decrease in the battery’s peak temperature rise during charging. Complementing these performance metrics, researchers conducted comprehensive postmortem examinations of the battery cells to thoroughly assess the long-term effects of the MSCC approach on critical degradation mechanisms, including graphite exfoliation and crystallization-related phenomena. Their compelling findings revealed that the MSCC method effectively suppressed the growth of the Solid Electrolyte Interphase (SEI) layer on the anode, significantly reduced the battery’s internal resistance, and ultimately contributed to a substantial extension of the lithium-ion battery’s operational lifespan [

19].

5. Results and Discussion

The performance of the proposed EV charging model was assessed by comparing its simulation results against real-world field data across multiple dimensions—namely, the active power profile, SOC trajectory, and associated error metrics. The analysis demonstrated the model’s ability to capture the essential physical characteristics of the charging process with high accuracy and robustness across all phases of operation.

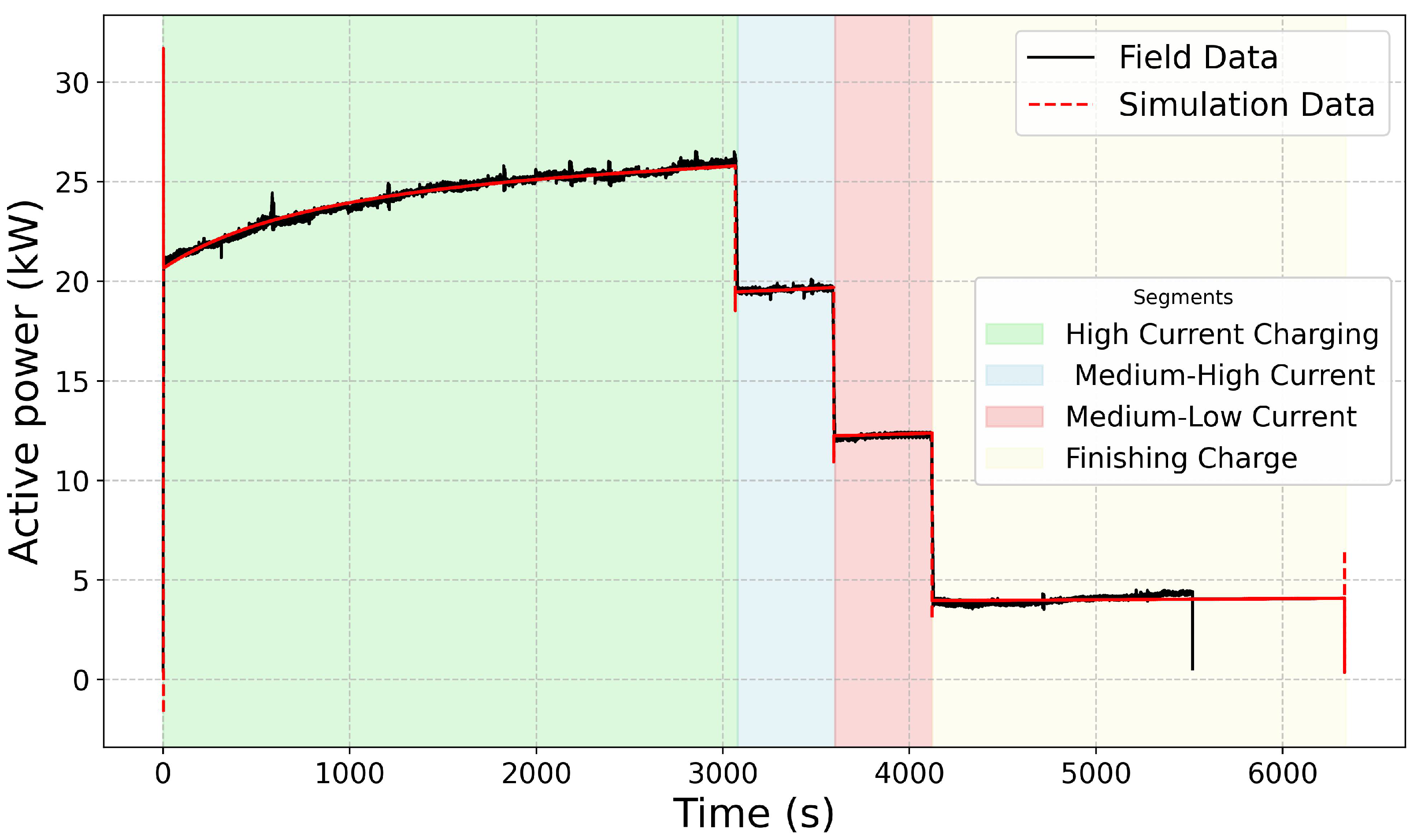

Figure 7 presents the active power (in kW) over time for both simulation and field data. The charging cycle is divided into four color-coded regions corresponding to different SOC-dependent current control phases: high current charging, medium-high current, medium-low current, and finishing charge. In the first phase, spanning from the beginning of the charging process up to approximately 3100 s, the battery is charged at a high current rate (around 0.7 C-rate). During this interval, active power increases gradually, and the simulation data align closely with the field data, demonstrating the model’s ability to accurately capture the initial power ramp-up. Minor deviations observed in the field data can be attributed to fluctuations in the grid voltage or noise in the measurement instruments.

The second phase, from around 3100 to 3600 s, marks a transition to medium-high current charging (0.5 C-rate) as the SOC approaches 80%. This is characterized by a step-down in active power. The simulation again follows this transition well, maintaining a consistent power level that matches the field measurements, thereby validating the model’s response to SOC-triggered control events.

Following this, the third phase occurs between approximately 3600 and 4100 s, where a further reduction in charging current (0.3 C-rate) is initiated near 87% SOC. This is reflected in another step-wise decrease in power. The simulation accurately mirrors this behavior, with both datasets showing a similar drop in active power, confirming the robustness of the control logic representation in the model.

Finally, in the finishing charge phase, from roughly 4100 s onward, the system reduces the current significantly (0.01 C-rate) to protect battery health as the SOC nears full capacity (above 92%). A sharp decline in active power is observed, followed by a low, slowly varying power profile. The simulation data continue to closely follow the field measurements, although slight discrepancies are noted toward the end of the cycle. This discrepancy is not a modeling error but reflects a deliberate control strategy implemented in real-world EV BMSs. In practice, most EVs discontinue charging at around 96–97% true SOC but display a full 100% SOC on the dashboard. This strategy is employed to safeguard battery health, minimize stress on battery cells, and enhance long-term performance by avoiding full-charge saturation, which accelerates degradation [

35,

36]. Therefore, the apparent mismatch arises due to the difference between the actual SOC at the BMS level and the SOC displayed to the user. The simulation, being driven purely by physical modeling and ideal charging logic, continues until 100% SOC is reached, while the field system terminates charging earlier, as per the embedded manufacturer-specific BMS protocol.

This behavior is further corroborated by the SOC progression shown in

Figure 8. Both field and simulation SOC curves increase linearly during the early high-current phase and begin to flatten as the current is reduced. Up to approximately 90–93% SOC, the simulation closely tracks the measured SOC. However, similar to the power profile, the simulation continues beyond 97% SOC while the field data flatten again, confirming the BMS-induced early cutoff.

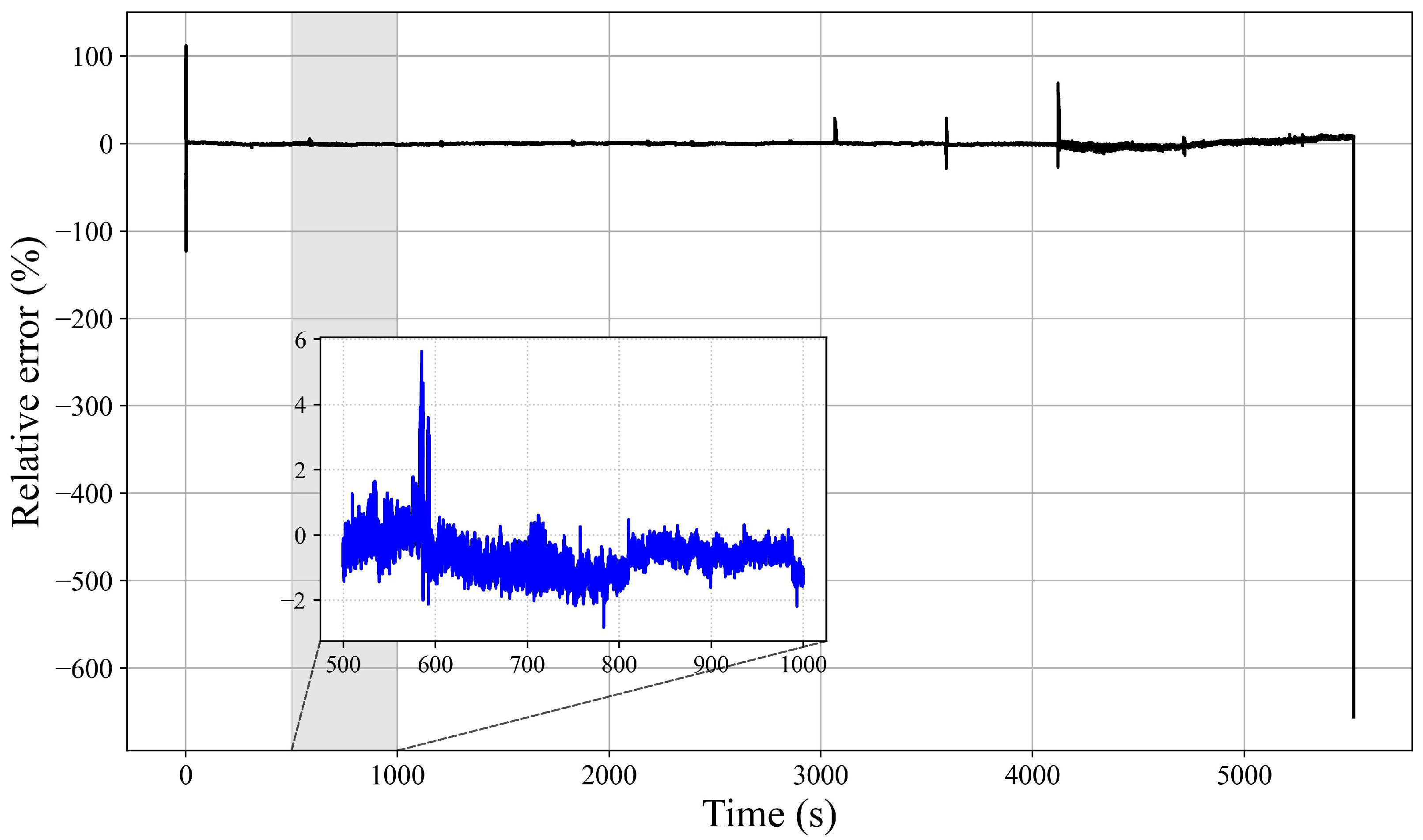

To quantify this agreement,

Figure 9 presents the relative error (%) between the simulation and field data over time. Predominantly, the error remains tightly clustered around zero, indicating strong predictive performance. The inset provides a zoomed-in view of the relative error during the 500–1000 s window, highlighting minor deviations, primarily within a ±2% range. Occasional spikes correspond to abrupt step transitions in the charging power in field measurements, which are expected in practical deployment scenarios.

Beyond such routine numerical mismatches stemming from sampling rate, interpolation, and synchronization differences, the remaining deviations arise from inherent model plant differences that contribute to the small but persistent bias over longer durations. Specifically, the temperature dependence of battery internal resistance and charger efficiency influences the field measurements, as real units may undergo thermal derating or operate auxiliary components such as cooling fans and pumps. These parasitic loads, typically a few hundred Watts, are not represented in the simulation [

37,

38]. Additionally, SOC estimation and OCV curve mismatches, resulting from coulomb count drift, chemistry variations, or battery aging, can slightly modify the tapering behavior during later charging stages [

39]. The BMS logic of the field unit further introduces effects such as cell balancing, soft current ramping, and early charge termination; in practice, charging is often curtailed near 97% actual SOC (reported as 100%), which leads to a shortened taper tail and the characteristic end spike in relative error. Finally, grid-side variations including feeder impedance, harmonics, and phase imbalance perturb the measured active power but are treated in an idealized manner within the simulation [

40]. Taken together, these factors comprehensively explain the small yet consistent deviations observed between the simulated and field charging profiles.

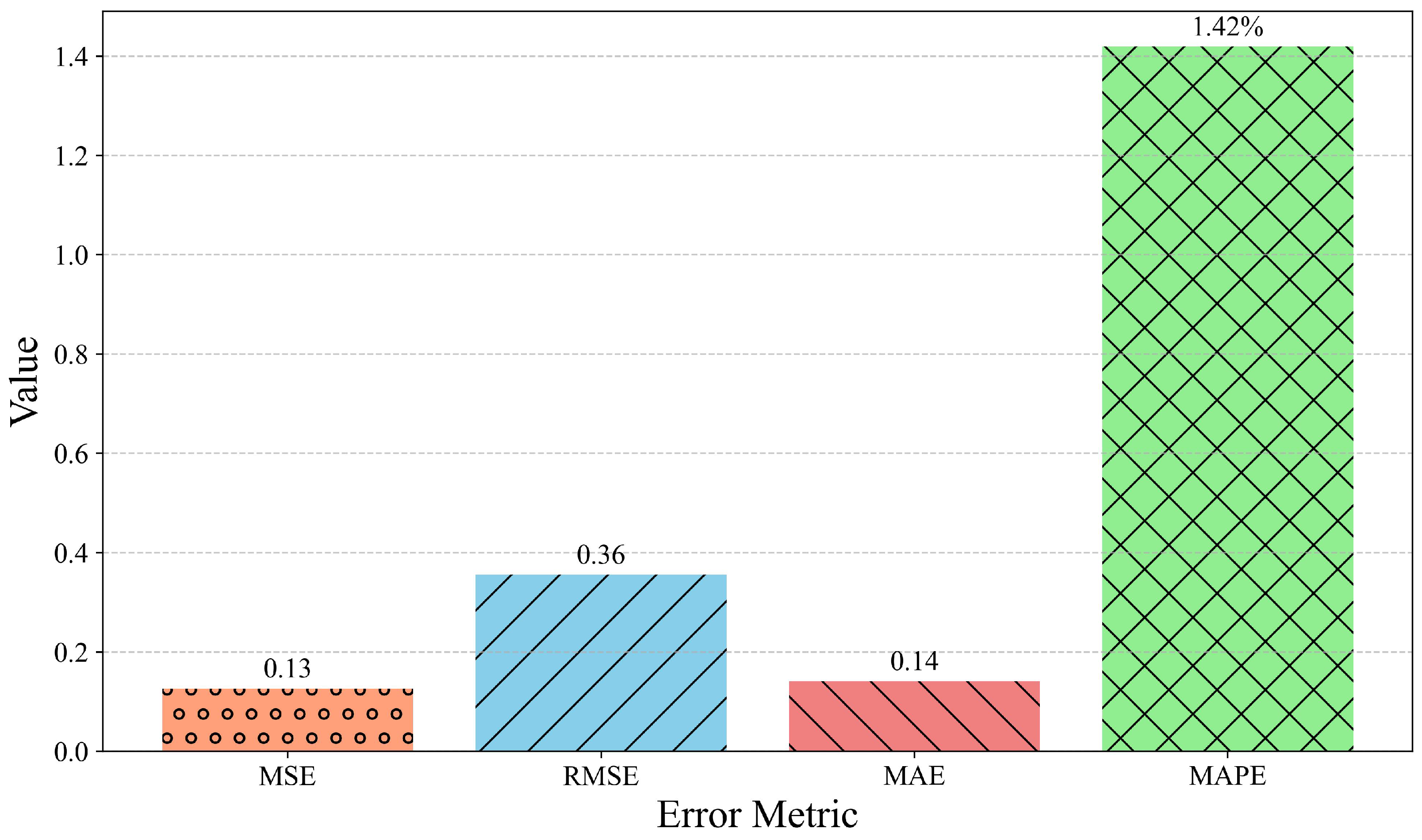

To quantitatively evaluate the accuracy of the simulation model,

Figure 10 illustrates four commonly used error metrics: the Mean Squared Error (MSE), the Root Mean Squared Error (RMSE), the Mean Absolute Error (MAE), and the Mean Absolute Percentage Error (MAPE). These are defined as follows:

To ensure a fair and consistent comparison between the field data and simulation output, the error metrics were computed over the overlapping time range shared by both datasets. Specifically, the time interval

was determined using the following equations:

where

and

represent the time arrays of the field and simulation datasets, respectively. Both datasets were filtered to retain only the data points within this common interval, and the number of samples

N used in the error metric formulas corresponds to the length of this filtered time range. The MSE and MAE values were found to be 0.13 and 0.14, respectively. These values indicate that, on average, the squared and absolute deviations between the simulated and real SOC values are quite small, pointing to the model’s capability to closely track actual charging trends.

The RMSE, computed as the square root of the MSE, was 0.36. This metric provides a sense of the standard deviation of prediction errors and penalizes larger errors more significantly than the MAE. A low RMSE value, as observed here, further reinforces the notion that large deviations between the simulation and real-world data are rare, thereby validating the reliability of the simulation model.

Additionally, the MAPE was observed to be just 1.42%, which measures the mean absolute deviation as a percentage of actual values. Since the MAPE is a scale-independent measure, it allows for a normalized assessment of accuracy. An MAPE below 2% signifies exceptional agreement between simulated and measured data across the entire charging cycle, indicating that the model maintains high fidelity not only in terms of absolute magnitude but also in terms of the relative trend, even at different SOC levels.

To further contextualize the contribution of the proposed HIL SCADA model,

Table 2 benchmarks it against representative simulation approaches reported in the literature. Conventional offline models (e.g., MATLAB/Simulink, Dymola) capture electro-thermal behavior and SOC evolution but remain limited to non-real-time studies and lack hardware integration [

41]. Optimization-based methods improve charging efficiency and load scheduling, yet their focus is primarily on scheduling outcomes rather than detailed charger-level dynamics [

42]. Co-simulation environments (e.g., EV-EcoSim) enable grid–EV interaction studies, though they often simplify charger representation, reducing fidelity when compared with field data [

43].

In contrast, the proposed real-time HIL SCADA framework demonstrates both high fidelity and real-time capability, while directly incorporating hardware-in-the-loop validation. This dual advantage makes it a suitable platform for digital twin applications, enabling predictive diagnostics, controller testing, and practical distribution grid impact assessment.

5.1. Practical Reliability Considerations

The reliability of the proposed EVSE charging scheme is ensured through multiple layers of validation and safety considerations. Firstly, the framework is built upon a physics-informed representation of the converter–battery interaction, which captures the actual dynamic behavior of the charging process. This approach reduces the risk of mismatches between simulated and real-world operation.

Secondly, the multi-stage charging control algorithm has been designed with explicit SOC thresholds and battery voltage safety limits. This ensures that the charging current is automatically adjusted at different stages, thereby preventing overcharging and protecting the battery from unsafe voltage excursions. Such adaptive current regulation significantly enhances the robustness of the charging process under varying SOC and load conditions.

Thirdly, the proposed control strategy has been validated in a real-time environment using the Typhoon HIL604 platform. By executing the algorithm on a hardware-grade simulator that replicates realistic system constraints, the scheme’s performance in different operating scenarios could be assessed reliably. The results demonstrated consistent adherence to reference signals, stable convergence toward the target SOC, and safe termination of charging.

Lastly, the framework is designed to be scalable and extendable, allowing for integration of more advanced features such as temperature-aware dynamics and aging-aware models. These extensions will further enhance long-term reliability by accounting for changes in internal resistance, capacity fade, and thermal effects.

Overall, the combination of physics-informed modeling, adaptive SOC-based current regulation, and real-time validation ensures that the proposed scheme provides a reliable, safe, and practically viable solution for EV charging applications.

5.2. Future Work

In future developments, the proposed EVSE control framework can be extended to incorporate temperature-dependent battery dynamics since charging efficiency and safety margins are highly sensitive to thermal conditions. By embedding thermal sub-models, the charging profile can be adaptively modified to avoid overheating, which is critical in fast-charging scenarios.

Future investigations will focus on validating the proposed scheme under diverse charging conditions, including slow, standard, and fast charging. Such testing will not only highlight the adaptability of the algorithm across different C-rates but also provide insights into thermal and degradation effects, which become more pronounced at higher charging rates. This will strengthen the reliability and practical applicability of the proposed EVSE control framework.

Another important research direction is to evaluate the system performance under different grid constraints, such as varying feeder capacities, renewable energy fluctuations, or time-of-use tariff signals. This will allow the EVSE control algorithm to be optimized not only for the battery side but also for grid-interactive smart charging applications, enhancing its applicability to real distribution networks.

Although this work assumes a fresh battery profile, future extensions may incorporate aging-aware models. Battery aging is an inevitable phenomenon that alters the electrochemical characteristics of lithium-ion cells, leading to gradual capacity fade and increased internal resistance. These changes directly affect the correspondence between SOC and terminal voltage, potentially reducing the accuracy of charging control if not considered. To mitigate this issue, the proposed EVSE model can be extended by embedding physics-informed or empirical battery aging models into the simulation framework [

44]. Such models dynamically track the evolution of battery parameters, thereby adjusting the SOC–voltage relationship automatically as the cell ages. By incorporating these mechanisms, the charging algorithm can remain adaptive and reliable throughout the battery’s lifetime, ensuring that SOC thresholds and current references reflect the true condition of the battery under realistic operating conditions.

Future work can also explore multi-EV charging coordination, where multiple EVs connected to the same charging station are managed optimally using the proposed control strategy. This will involve real-time decision-making and communication protocols to balance charging demand with available infrastructure capacity.

Finally, the framework may be extended toward the development of a digital twin of the EVSE system, where continuous data-driven updates from real charging sessions are fed back into the simulation model. This would ensure higher fidelity between the virtual model and the physical system, enabling predictive maintenance, anomaly detection, and long-term operational reliability assessment.