Performance Prediction of Outer Rotor PMSM Considering 3-D Flux Coefficient Using Equivalent 2-D FEA

Abstract

1. Introduction

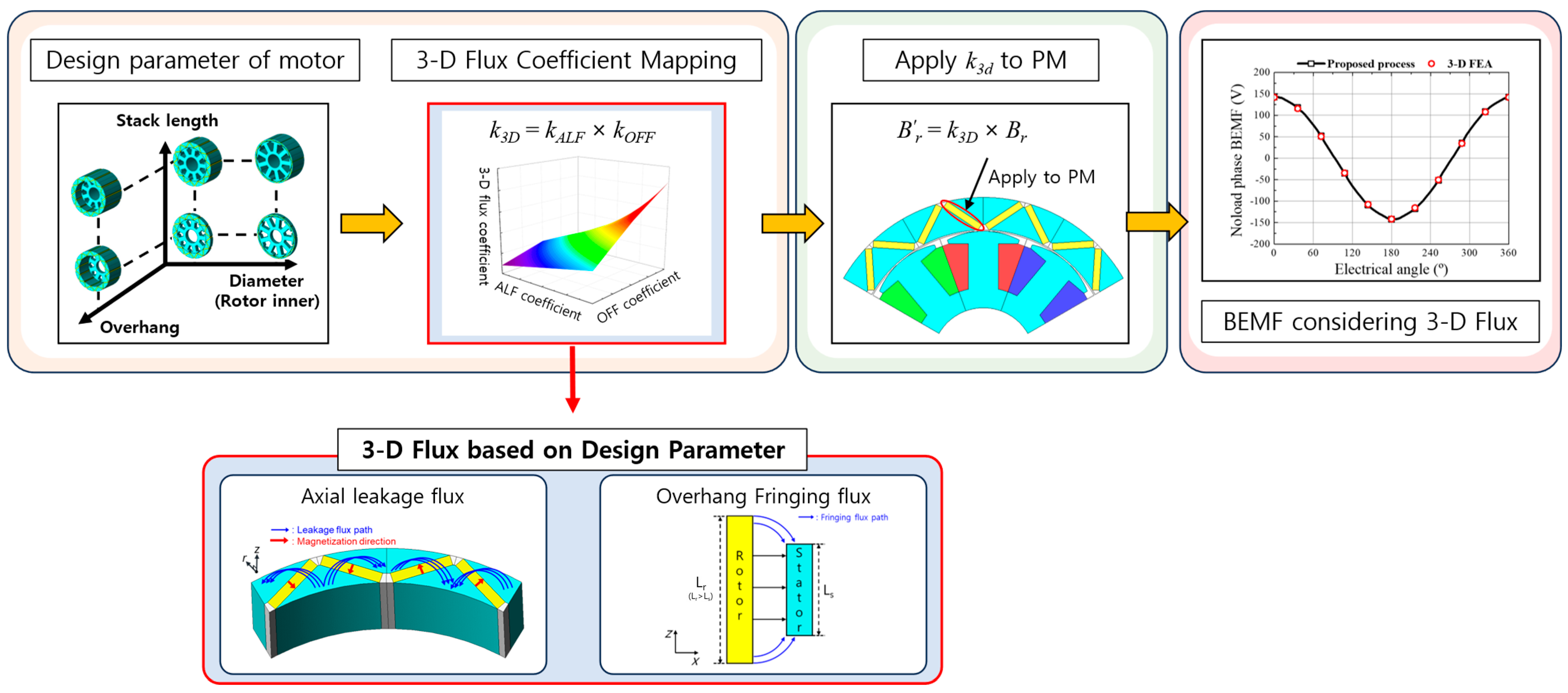

2. Design Variables Affecting 3-D Flux

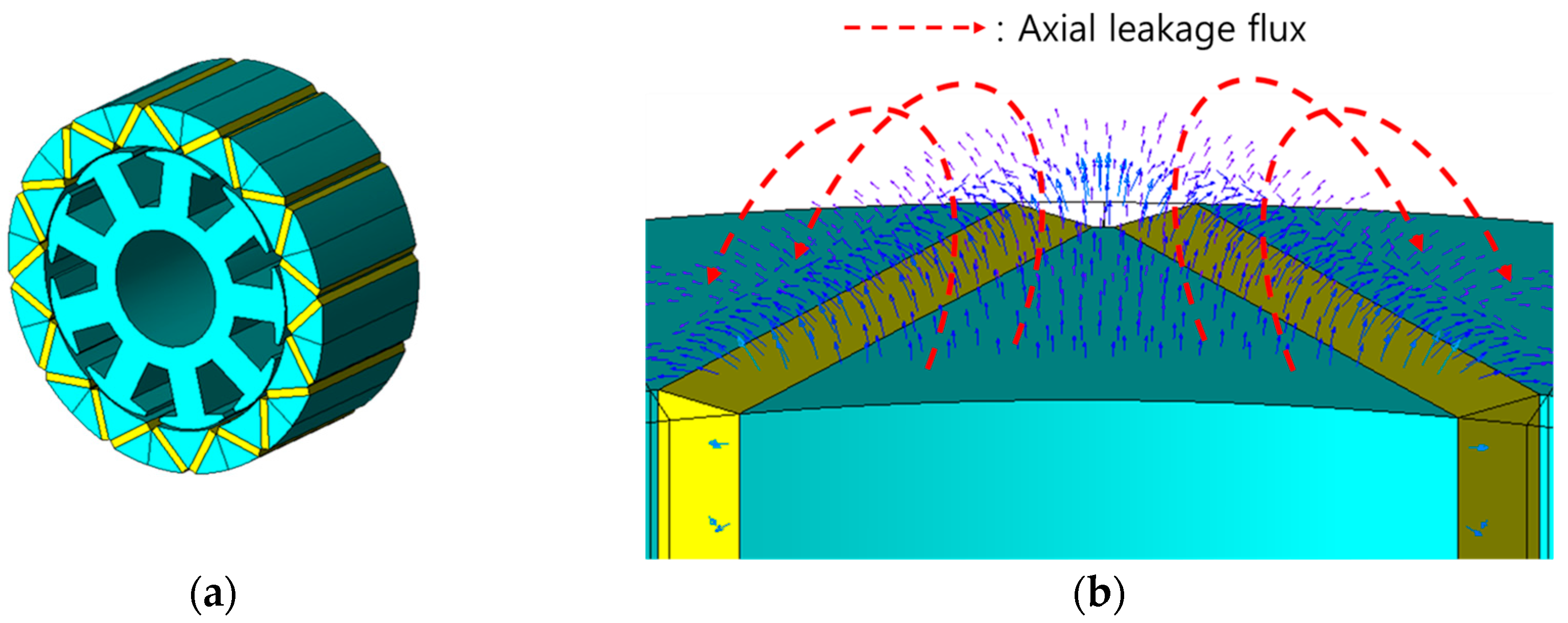

2.1. Axial Leakage Flux (ALF)

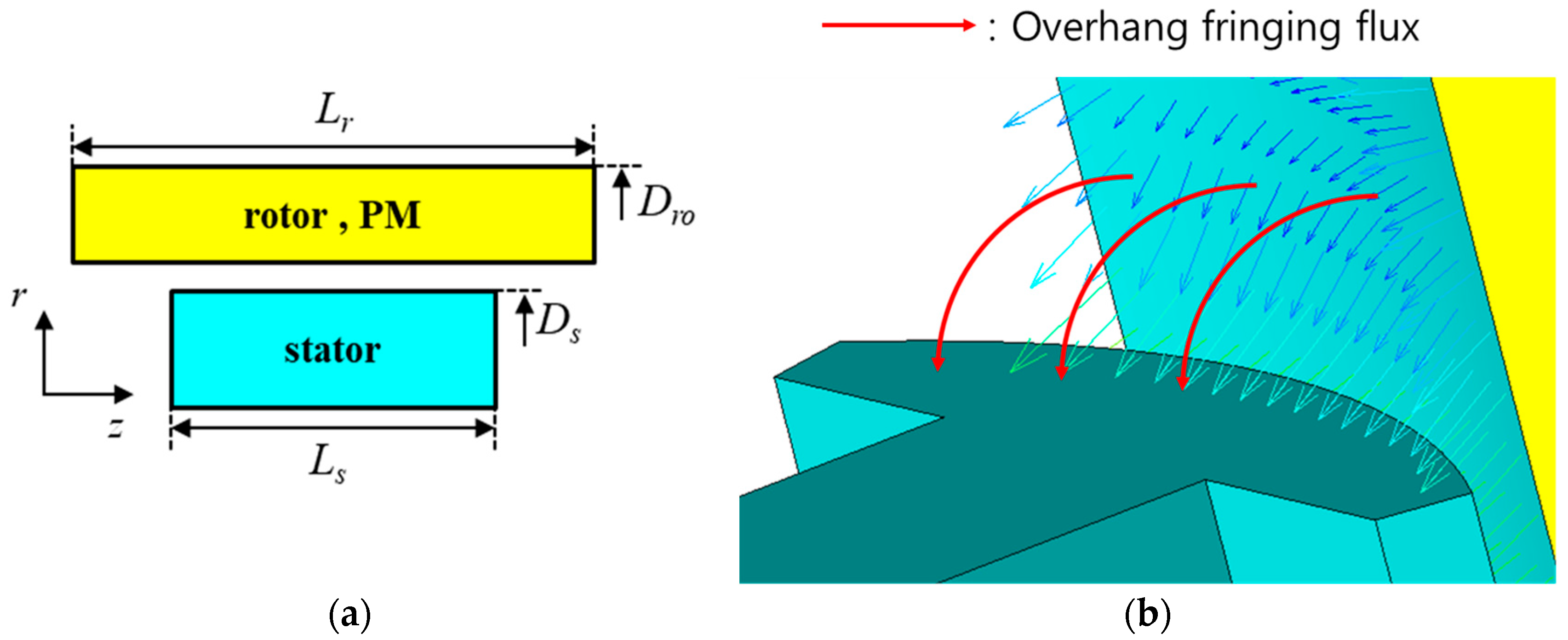

2.2. Overhang Fringing Flux (OFF)

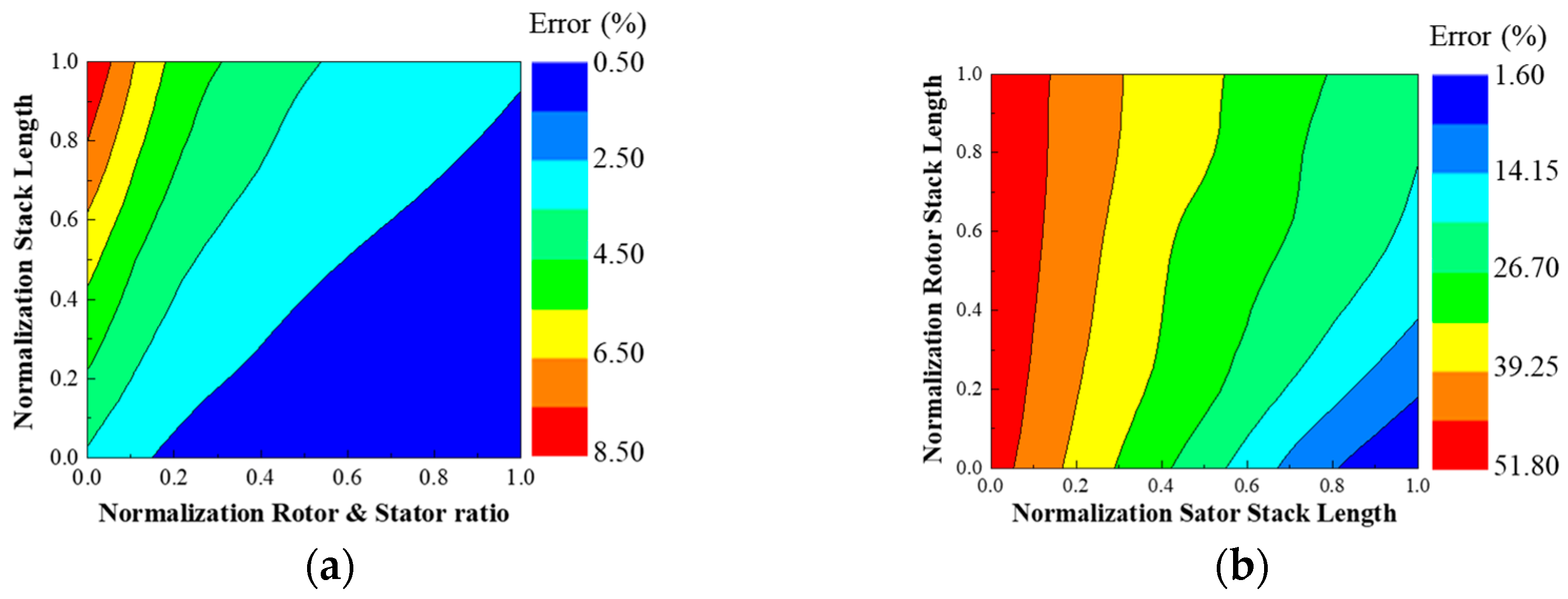

2.3. Influence of Design Variables on 3-D Flux Effects

3. Performance Prediction Method Considering 3-D Flux

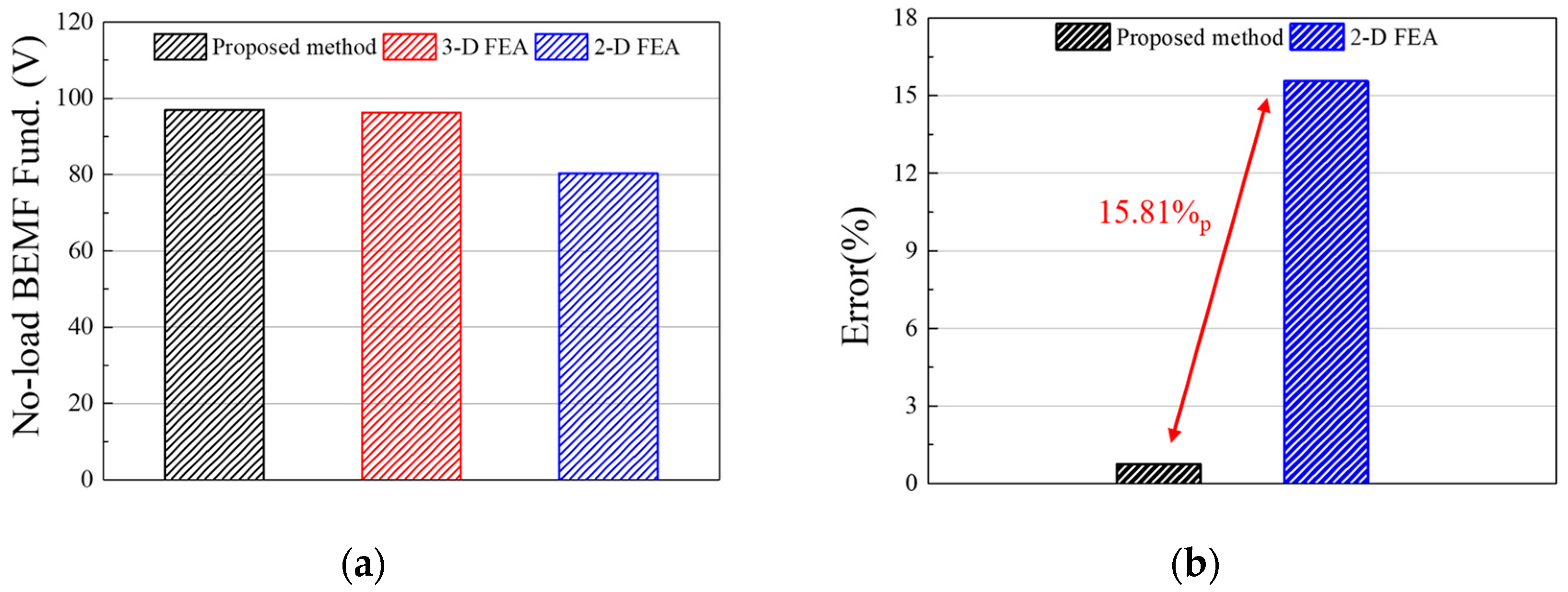

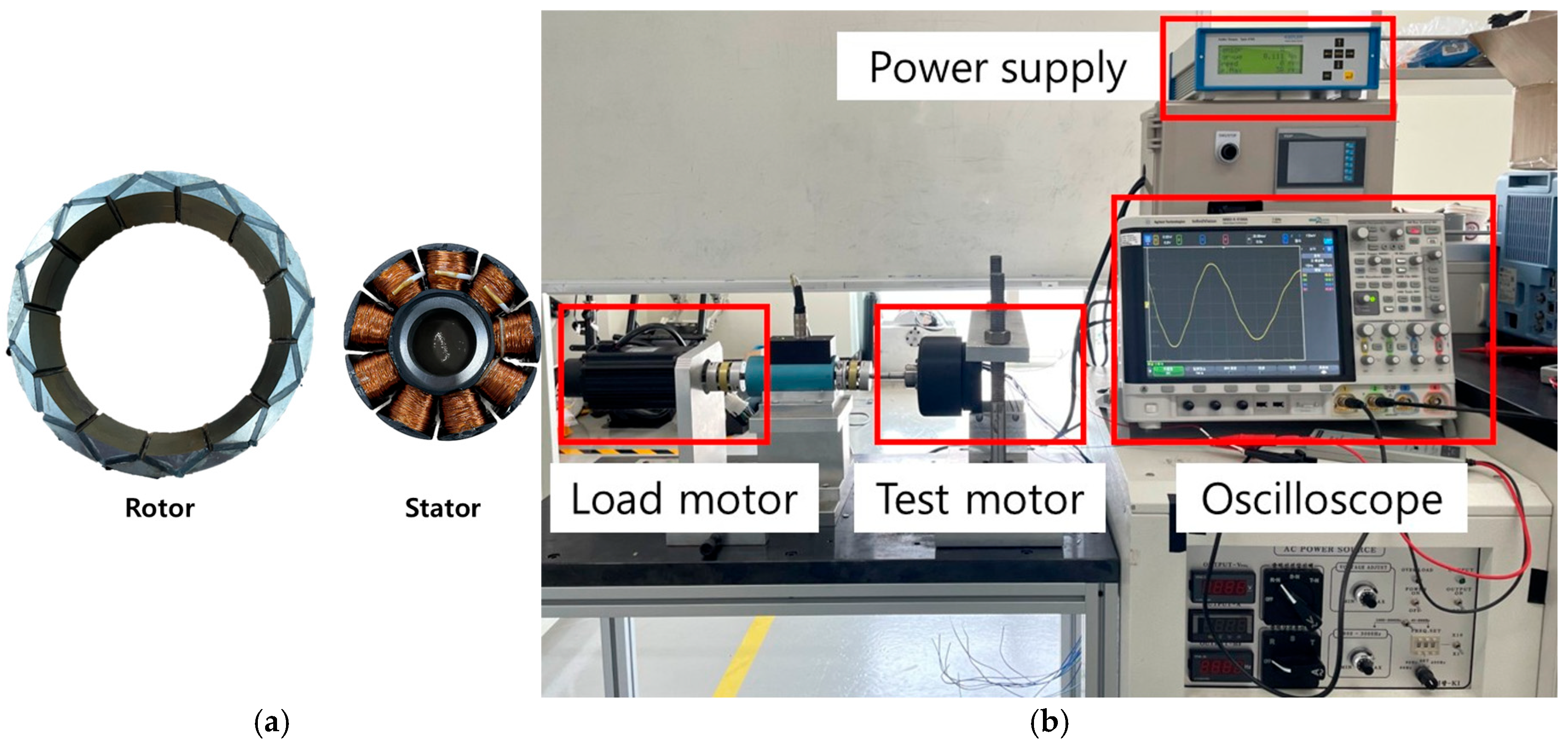

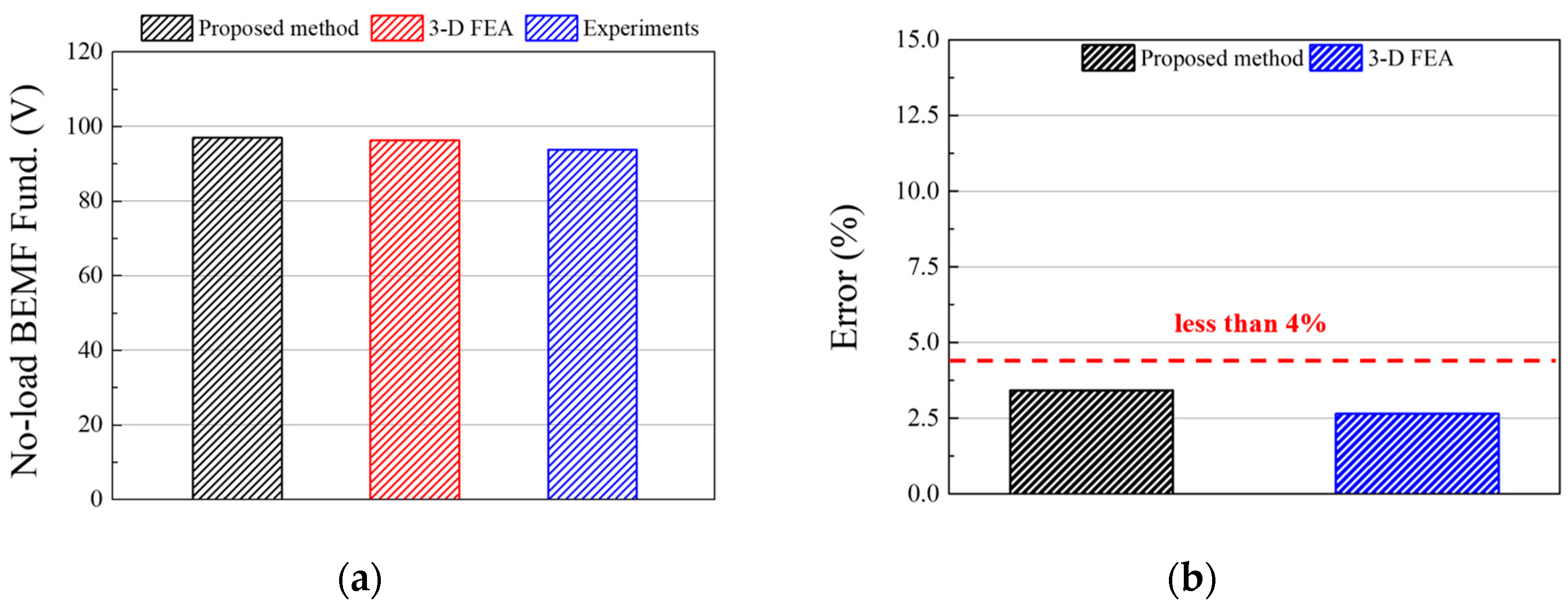

4. Simulation and Experimental Verification

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PMSM | Permanent Magnet Synchronous Motor |

| FEA | Finite Element Analysis |

| 2-D | Two-Dimensional |

| 3-D | Three-Dimensional |

| BEMF | Back Electromotive Force |

| ALF | Axial Leakage Flux |

| OFF | Overhang Fringing Flux |

| EMC | Equivalent Magnetic Circuit |

References

- Huynh, T.A.; Che, V.H.; Hsieh, M.F. Maximization of High-Efficiency Operating Range of Spoke-Type PM E-Bike Motor by Optimization Through New Motor Constant. IEEE Trans. Ind. Appl. 2023, 59, 1328–1339. [Google Scholar] [CrossRef]

- Park, C.S.; Kim, J.H.; Park, S.H.; Yoon, Y.D.; Lim, M.S. Multi-Physics Characteristics of PMSM for Compressor According to Driving Mode Considering PWM Frequency. IEEE Access 2022, 10, 114490–114500. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, J.; Fu, J.; Xia, Y.; Wang, W.; Li, X. Performance Comparison of Permanent Magnet Vernier Motors and Permanent Magnet Synchronous Motors. Machines 2025, 13, 390. [Google Scholar] [CrossRef]

- Sarac, V.; Minovski, D.; Aneva, S.; Janiga, P.; Smitkova, M.F.; Bogatinov, D.; Atanasova, A. Various Designs of Spoke-Type Permanent Magnet Motor for Performance Optimization. Machines 2025, 13, 375. [Google Scholar] [CrossRef]

- Lee, S.H.; Im, S.Y.; Ryu, J.Y.; Lim, M.S. Optimum Design Process of Coaxial Magnetic Gear Using 3D Performance Prediction Method Considering Axial Flux Leakage. IEEE Trans. Ind. Appl. 2024, 60, 3075–3085. [Google Scholar] [CrossRef]

- Johnson, M.; Gardner, M.C.; Toliyat, H.A. A parameterized linear magnetic equivalent circuit for analysis and design of radial flux magnetic gears—Part I: Implementation. IEEE Trans. Energy Convers. 2018, 33, 784–791. [Google Scholar] [CrossRef]

- Rasmussen, P.O.; Andersen, T.O.; Jorgensen, F.T.; Nielsen, O. Development of a high-performance magnetic gear. IEEE Trans. Ind. Appl. 2005, 41, 764–770. [Google Scholar] [CrossRef]

- Seo, J.M.; Jung, I.S.; Jung, H.K.; Ro, J.S. Analysis of Overhang Effect for a Surface-Mounted Permanent Magnet Machine Using a Lumped Magnetic Circuit Model. IEEE Trans. Magn. 2014, 50, 8201207. [Google Scholar] [CrossRef]

- Liang, P.; Chai, F.; Yu, Y.; Chen, L. Analytical Model of a Spoke-Type Permanent Magnet Synchronous In-Wheel Motor with Trapezoid Magnet Accounting for Tooth Saturation. IEEE Trans. Ind. Electron. 2019, 66, 1162–1171. [Google Scholar] [CrossRef]

- Carraro, E.; Bianchi, N.; Zhang, S.; Koch, M. Design and performance comparison of fractional slot concentrated winding spoke type synchronous motors with different slot-pole combinations. IEEE Trans. Ind. Appl. 2018, 54, 2276–2284. [Google Scholar] [CrossRef]

- Jiang, S.; Liu, G.; Zhao, W.; Xu, L.; Chen, Q. Modeling and analysis of spoke-type permanent magnet Vernier machine based on equivalent magnetic network method. Chin. J. Electr. Eng. 2018, 4, 96–103. [Google Scholar] [CrossRef]

- Lee, D.; Song, J.Y.; Seo, M.K.; Jung, H.C.; Kim, J.W.; Jung, S.Y. Development of Differing Extent Mesh Adaptive Direct Search Applied for Optimal Design of Spoke-Type PMSM. IEEE Trans. Magn. 2018, 54, 8205905. [Google Scholar] [CrossRef]

- Jung, J.W.; Park, H.I.; Hong, J.P.; Lee, B.H. A Novel Approach for 2-D Electromagnetic Field Analysis of Surface Mounted Permanent Magnet Synchronous Motor Taking Into Account Axial End Leakage Flux. IEEE Trans. Magn. 2017, 53, 8208104. [Google Scholar] [CrossRef]

- Lee, S.G.; Bae, J.; Kim, W.H. Study on the Axial Leakage Magnetic Flux in a Spoke Type Permanent Magnet Synchronous Motor. IEEE Trans. Ind. Appl. 2019, 55, 5881–5887. [Google Scholar] [CrossRef]

- Kim, J.M.; Chai, S.H.; Yoon, M.H.; Hong, J.P. Plastic Injection Molded Rotor of Concentrated Flux-Type Ferrite Magnet Motor for Dual-Clutch Transmission. IEEE Trans. Magn. 2015, 51, 8205204. [Google Scholar] [CrossRef]

- Park, M.R.; Jung, J.W.; Kim, D.Y.; Hong, J.P.; Lim, M.S. Design of High Torque Density Multi-Core Concentrated Flux-Type Synchronous Motors Considering Vibration Characteristics. IEEE Trans. Ind. Appl. 2019, 55, 1351–1359. [Google Scholar] [CrossRef]

- Park, J.H.; Jung, K.T.; Jung, Y.H.; Lim, M.S.; Yoon, M.H.; Hong, J.P.; Jung, J.W. Design and Verification for the Torque Improvement of a Concentrated Flux-Type Synchronous Motor for Automotive Applications. IEEE Trans. Ind. Appl. 2019, 55, 3534–3543. [Google Scholar] [CrossRef]

- Kim, H.J.; Jeong, J.S.; Yoon, M.H.; Moon, J.W.; Hong, J.P. Simple Size Determination of Permanent-Magnet Synchronous Machines. IEEE Trans. Ind. Electron. 2017, 64, 7972–7983. [Google Scholar] [CrossRef]

- Park, S.H.; Chin, J.W.; Cha, K.S.; Lim, M.-S. Deep Transfer Learning-Based Sizing Method of Permanent Magnet Synchronous Motors Considering Axial Leakage Flux. IEEE Trans. Magn. 2022, 58, 8206005. [Google Scholar] [CrossRef]

| Item | Unit | Value |

|---|---|---|

| Motor type | - | Outer rotor IPMSM |

| Number of poles/slots ratio | - | 4:3 |

| Permanent magnets | - | Ferrite |

| Stator/rotor core | - | 35PN270 |

| Maximum stack length | mm | 50 |

| Stator/Rotor volume ratio | - | 0.3–15.6 |

| Model Number | kALF | kOFF | No-Load BEMF Fund. (Vrms) | Error (%) | Analysis Time (hour) | Number of Elements (ea) | |||

|---|---|---|---|---|---|---|---|---|---|

| 3-D FEA | Proposed Method | 3-D FEA | Proposed Method | 3-D FEA | Proposed Method | ||||

| 1 | 0.92 | 1.22 | 98.97 | 98.90 | 0.07 | 6.0 | 0.2 | 888,080 | 27,150 |

| 2 | 0.95 | 1.24 | 99.60 | 99.54 | 0.06 | 888,341 | |||

| 3 | 0.91 | 1.17 | 85.16 | 84.50 | 0.78 | 807,116 | |||

| 4 | 0.83 | 1.25 | 102.70 | 102.80 | 0.10 | 873,902 | |||

| Item | Unit | Value |

|---|---|---|

| Stator/rotor volume ratio | - | 11.18 |

| Rotor/stator diameter ratio | - | 1.17 |

| Stack length ratio | - | 1.44 |

| Phase number | - | 3 |

| Phase resistance | Ω | 6.30 |

| Number of turns | turn | 720 |

| Maximum current | Arms | 2.00 |

| Cooling type | - | Natural convection |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sung, M.-H.; Cha, K.-S.; Jung, Y.-H.; Sim, J.-H.; Lim, M.-S. Performance Prediction of Outer Rotor PMSM Considering 3-D Flux Coefficient Using Equivalent 2-D FEA. Machines 2025, 13, 692. https://doi.org/10.3390/machines13080692

Sung M-H, Cha K-S, Jung Y-H, Sim J-H, Lim M-S. Performance Prediction of Outer Rotor PMSM Considering 3-D Flux Coefficient Using Equivalent 2-D FEA. Machines. 2025; 13(8):692. https://doi.org/10.3390/machines13080692

Chicago/Turabian StyleSung, Moo-Hyun, Kyoung-Soo Cha, Young-Hoon Jung, Jae-Han Sim, and Myung-Seop Lim. 2025. "Performance Prediction of Outer Rotor PMSM Considering 3-D Flux Coefficient Using Equivalent 2-D FEA" Machines 13, no. 8: 692. https://doi.org/10.3390/machines13080692

APA StyleSung, M.-H., Cha, K.-S., Jung, Y.-H., Sim, J.-H., & Lim, M.-S. (2025). Performance Prediction of Outer Rotor PMSM Considering 3-D Flux Coefficient Using Equivalent 2-D FEA. Machines, 13(8), 692. https://doi.org/10.3390/machines13080692