Abstract

The demand for high-power density motors has been increasing due to their remarkable output capability and compact construction. To achieve a significant improvement in motor power density, lightweight design methods have been recognized as an effective enabler. Therefore, extensive investigations have been conducted to reduce motor mass and achieve lightweight configurations through the exploration of lightweight materials, structures and manufacturing techniques. This article provides a comprehensive review and summary of state-of-the-art lightweight implementation methods for electrical machines, including the utilization of lightweight materials, structural lightweight design, and incorporation of advanced manufacturing technologies, such as additive manufacturing techniques. The advantages and limitations of each approach are also discussed in this paper. Furthermore, some comments and forecasts on potential future methodologies for motor lightweighting are also provided.

1. Introduction

Due to their superior output power per unit weight or volume, there is an increasing demand for high-power density motors in various vehicle applications, including electric vehicles, electrified aircraft, rail transportation, and maritime applications [1,2,3,4,5]. According to the definition of motor power density, there are two potential avenues for enhancing motor power density: firstly, by augmenting its output capacity through improving its cooling efficiency [6,7,8]; and secondly, by reducing the weight or volume of the motor. Compared to the previous method, lightweight design has emerged as a critical technique for achieving high specific power targets, which has gained significant attention and has undergone extensive investigations [9,10].

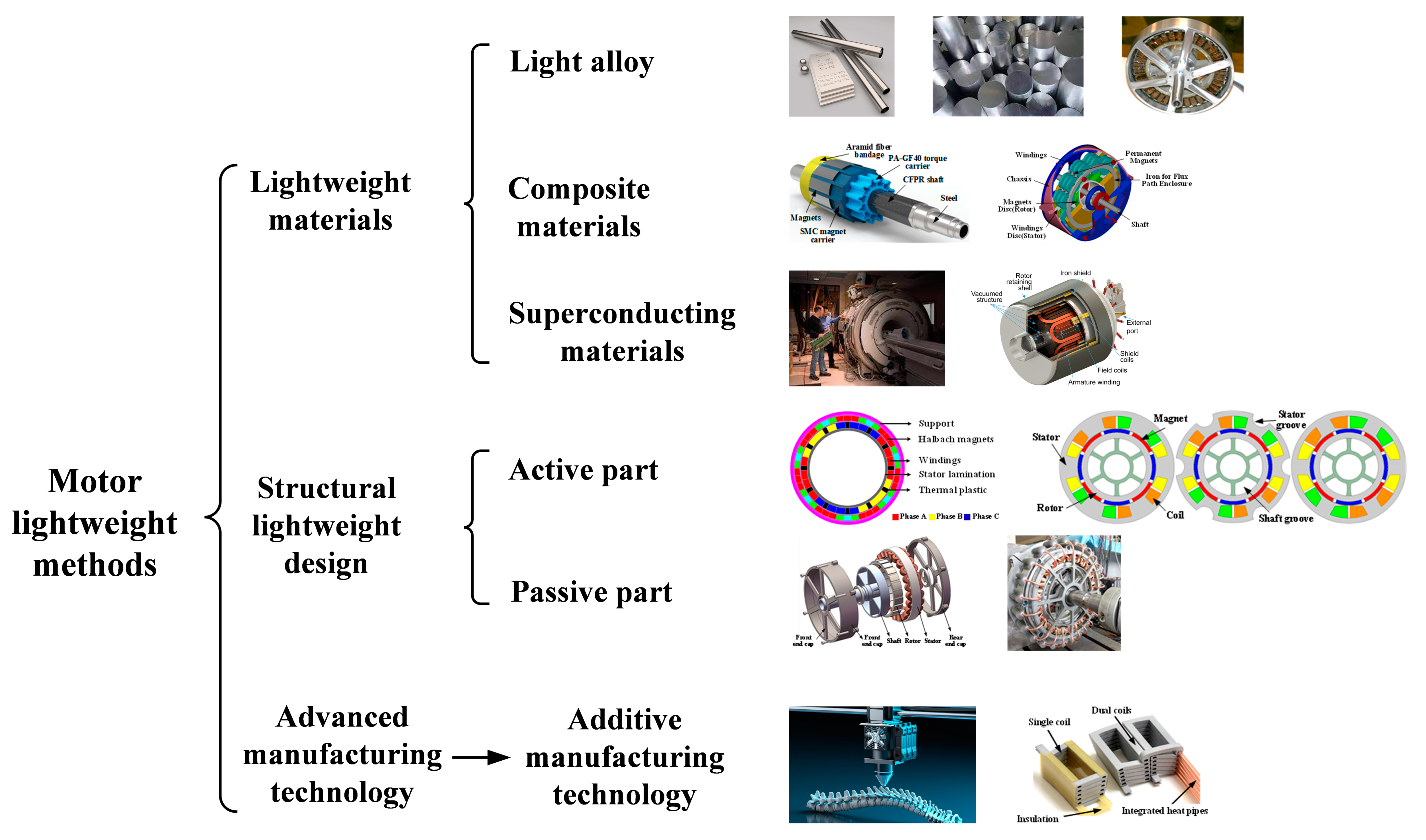

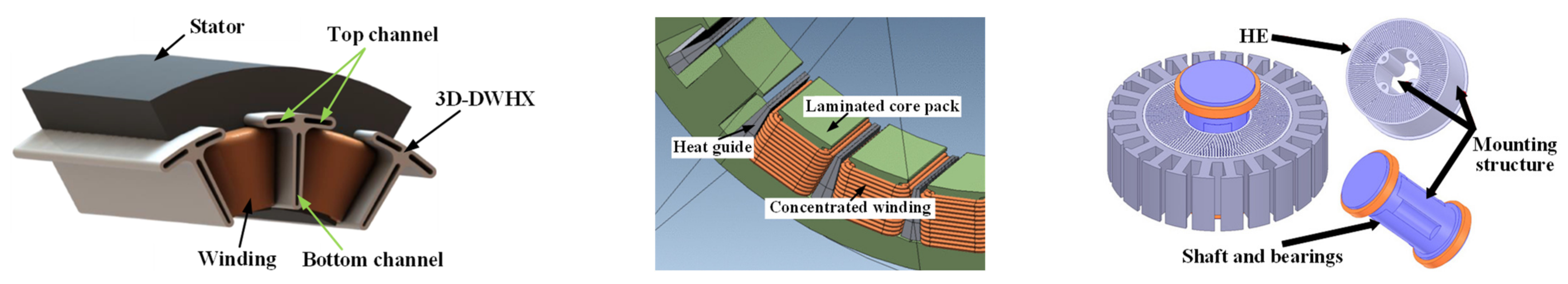

Several approaches have been employed with favorable outcomes in the pursuit of achieving lightweight motor construction [11,12,13]. As depicted in Figure 1, typical methods for motor lightweight design can be classified into two categories: the utilization of lightweight materials [10] and the implementation of structural lightweight design [14,15]. Common lightweight materials primarily encompass light alloys, such as aluminum, magnesium, and titanium, as well as various composite materials. These materials can be applied to motors to facilitate weight reduction without compromising their electromagnetic and mechanical properties [16]. In terms of the structural lightweight design, motor configurations can be appropriately simplified or optimized to achieve weight reduction while ensuring favorable motor performance [17]. In addition to these conventional approaches, advanced manufacturing technologies have recently garnered extensive attention from motor engineers and are increasingly being employed in constructing complex motor configurations for lightweight considerations, particularly additive manufacturing technology [18,19,20].

Figure 1.

Illustration of typical methods for motor lightweight design.

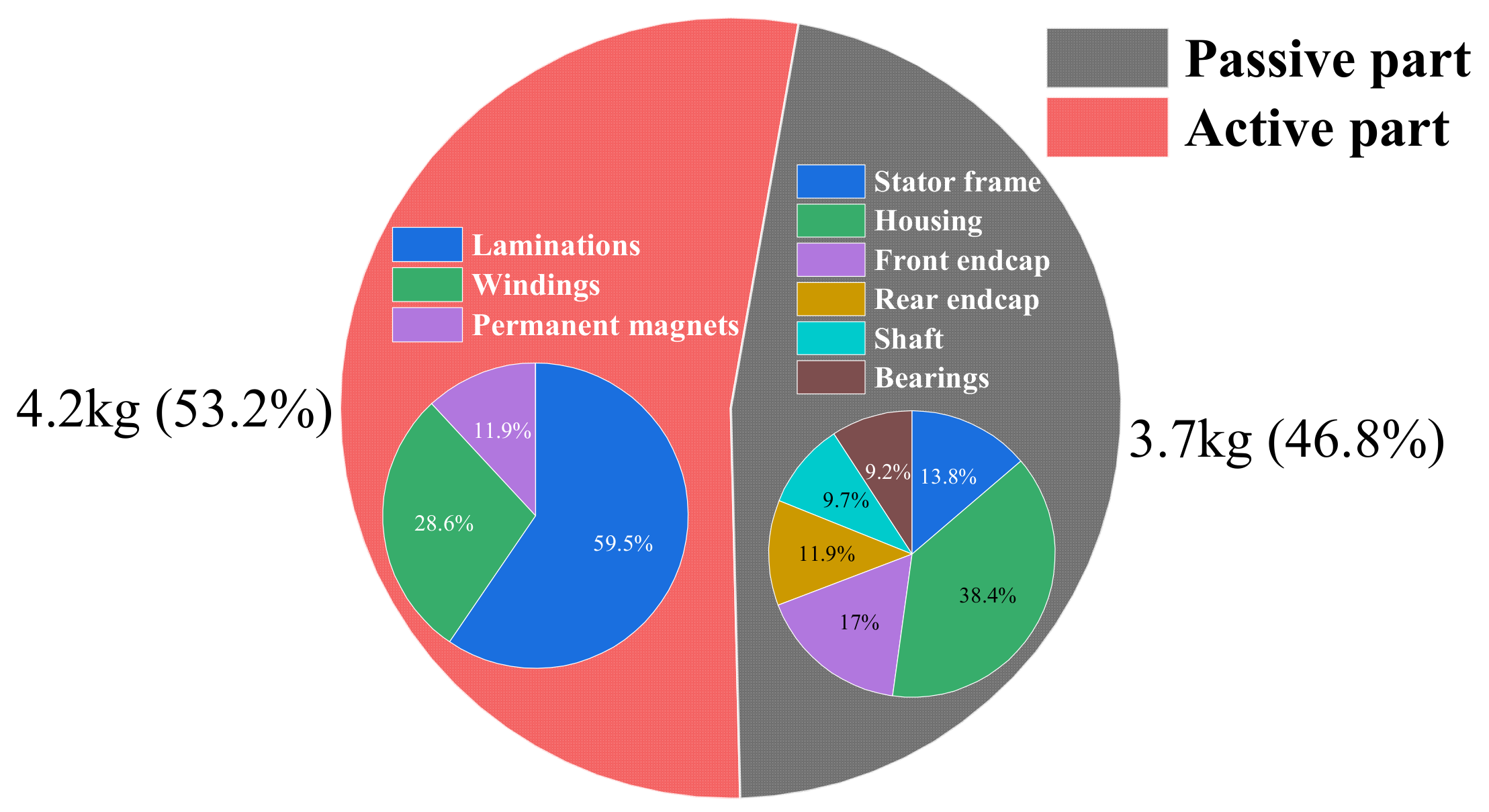

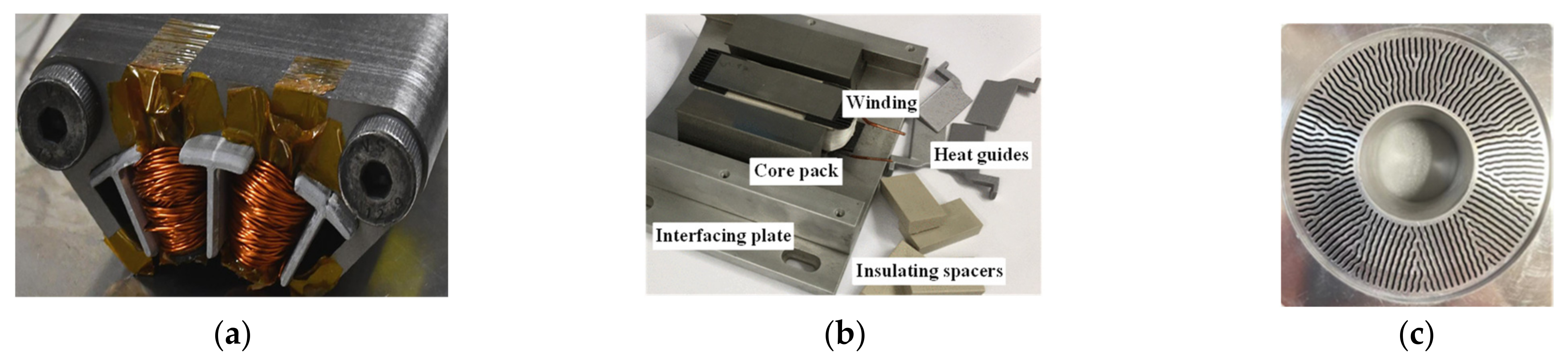

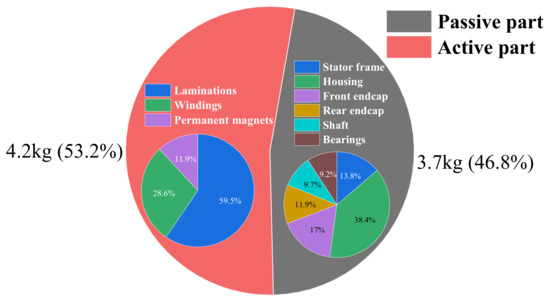

The construction of an electrical machine can be commonly classified into two primary components: the electromagnetic component (active part) responsible for achieving electromechanical conversion and the mechanical component (passive part) providing mechanical support, fixation and torque transmission. Figure 2 illustrates the mass distribution of a propulsion motor developed for an electrified aircraft. It can be observed that the motor active part, which accounts for 53.2% of its total weight, presents a comparatively larger weight than the mechanical part (46.8%) [21,22], aligning with the general law of motor mass distribution [23]. The aforementioned methods can be applied to both active and passive parts of motors to facilitate weight reduction. Regarding the motor active part, various lightweight materials have been extensively utilized, such as aluminum wires [24] and superconducting materials [25] in windings, as well as soft magnetic composite (SMC) in motor cores [26]. Moreover, novel topologies such as slotless and coreless machines have also been explored to achieve reduced mass and enhance power density [27]. Similarly, the lightweight design of the motor’s passive part also involves the utilization of lightweight materials and structural lightweight design [28]. Under the premise of ensuring adequate mechanical properties, achieving lightweight can be accomplished by utilizing light metal alloys and composite materials, along with simplified and optimized mechanical structures. Additionally, additive manufacturing technology has also been explored for fabricating both motor active and passive components for mass reduction [29].

Figure 2.

Mass distribution of a propulsion motor for electrified aircraft.

Despite extensive investigations conducted on lightweight motors, there remains a lack of comprehensive review and summary regarding existing methods for motor lightweight. This paper aims to bridge this gap by providing an overview of the state-of-the-art lightweight implementation methods for electrical machines, including the application of lightweight materials, structural lightweight design, and incorporation of advanced manufacturing technologies in motor fabrication. The remainder of this article is organized as follows. Section 2 provides a review of lightweight motors using lightweight materials, followed by a demonstration of the implementation of structural lightweight design in machines in Section 3. Section 4 further presents an exploration of advanced manufacturing technologies employed in machines, particularly additive manufacturing that enables the realization of lightweight motor configurations. Finally, a conclusion is drawn in Section 5.

2. Application of Lightweight Materials

In terms of motor lightweight methods, the utilization of lightweight materials is one of the most direct and commonly adopted approaches, which has been implemented in both motor active and passive parts [10]. Various lightweight materials have been explored in electrical machines with significantly reduced motor weight and enhanced power density, including composite materials, aluminum windings, soft magnetic composite, and superconducting materials [30]. Meanwhile, the introduction of lightweight materials also has an impact on motor electromagnetic and thermal performance, as well as mechanical strength, which requires further investigation and tradeoff design. The following provides a comprehensive summary of the application cases for each material, highlighting both advantages and limitations.

2.1. Composite Materials

Compared with conventional metal materials in motors, composite materials are mainly characterized by lower density, improved corrosion resistance, and enhanced insulating performance, which are more suitable for weight reduction purposes in motor applications [30]. Moreover, composite materials offer another advantage by using additive manufacturing technology to achieve complex configurations that are unattainable with conventional metal materials through CNC machining.

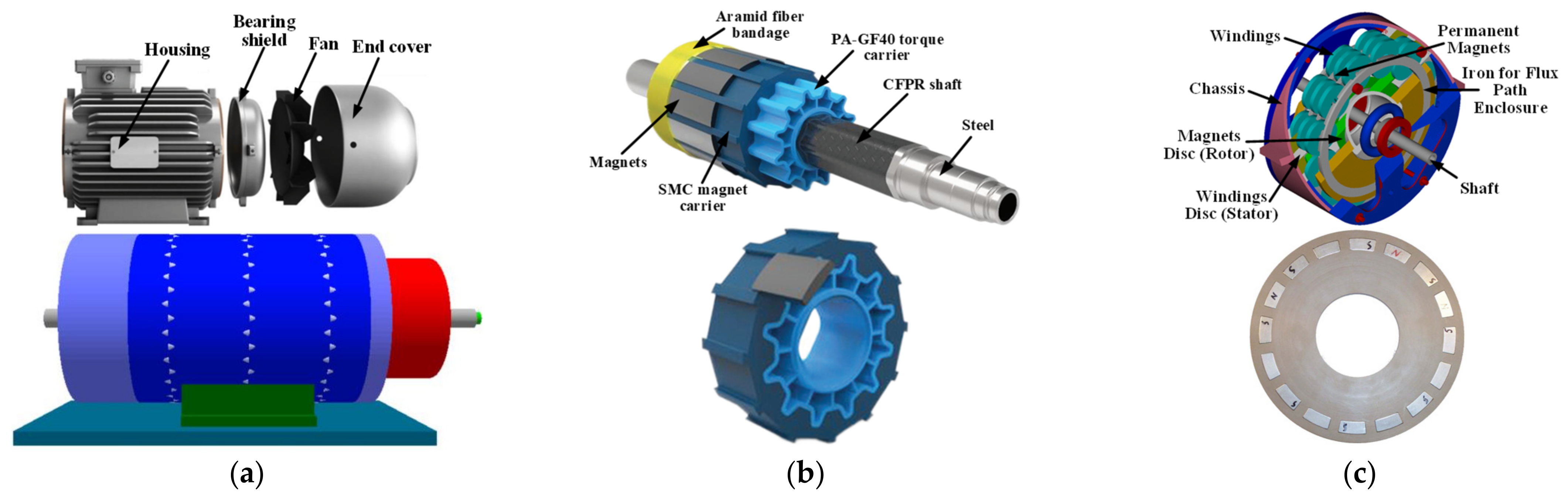

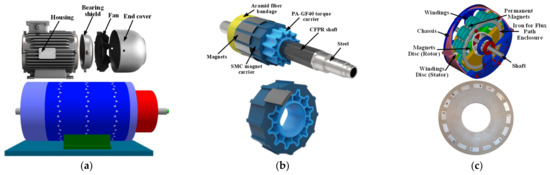

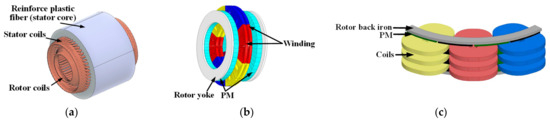

In Figure 3a, a kind of lightweight material, i.e., PA6GF30 30% glass fiber-reinforced polymer, is explored in the motor casing to reduce motor weight and remain compatible with the water-cooling system [11]. Compared to the aluminum casing, the cooling efficiency of the motor using composite materials is slightly reduced, i.e., the winding maximum temperature increases from 127 °C to 131 °C, while its weight is greatly reduced by 20.27%. Two approaches are attempted in [16] to reduce motor mass, as illustrated in Figure 3b. The first method involves the utilization of carbon-reinforced plastic and stainless steel to fabricate a hybrid shaft, thus enabling a remarkable weight reduction of 50%. The second method is to replace laminated rotor cores with soft magnetic compounds (SMC), together with a torque carrier made of polyamide plastic, which can achieve both the functions of a conventional rotor: torque transmission and the magnetically active part. As a result, the weight of the rotor module is merely 398 g. [31] develops an axial flux multi-disc permanent magnet (PM) motor for a stratospheric unmanned aircraft, as presented in Figure 3c. To implement a lightweight structure, advanced plastic materials are used as structural materials in both machine rotor and stator discs. Moreover, quasi-ironless magnetic circuits are also adopted to eliminate iron losses and further reduce motor mass. Finally, the simulation results indicate a potential weight reduction of 30%, and the prototype torque density reaches 1 Nm/kg, which is superior to conventional industrial motors considering the ambient environment and mechanical factors.

Figure 3.

State-of-the-art composite materials applied in electrical machines: (a) Application of PA6GF30 30% glass fiber-reinforced polymer in the motor casing to reduce motor weight [11]; (b) A lightweight rotor made of composites and steel [16]; (c) An axial flux plastic multi-disc brushless PM motor for a stratospheric unmanned aircraft [31].

Meanwhile, the mechanical strength and thermal properties of composite materials should be fully considered, particularly applied in motor mechanical structures, such as housing, end caps, and shafts. The mechanical components in electrical machines are typically required with sufficient mechanical robustness for stable operation, as well as good thermal conductivity to enable heat conduction and heat exchange. The thermal conductivity of composite materials is generally lower than that of metals, which poses challenges for heat dissipation and thermal management in motors, and thus necessitates a careful consideration between weight reduction and cooling performance in practical applications.

2.2. Aluminum Windings

Aluminum demonstrates numerous advantages over copper in motor applications: (1) a lower mass density, accounting for only 30% of that of copper; (2) a reduced cost, i.e., approximately 10% the price per unit volume compared to copper; (3) a higher heat capacity, roughly double that of copper per unit mass; and (4) enhanced recyclability. Consequently, aluminum is being increasingly utilized as a substitute for conventional copper materials in specific scenarios, with the expectation of achieving lightweight configurations and cost-effectiveness [32,33,34].

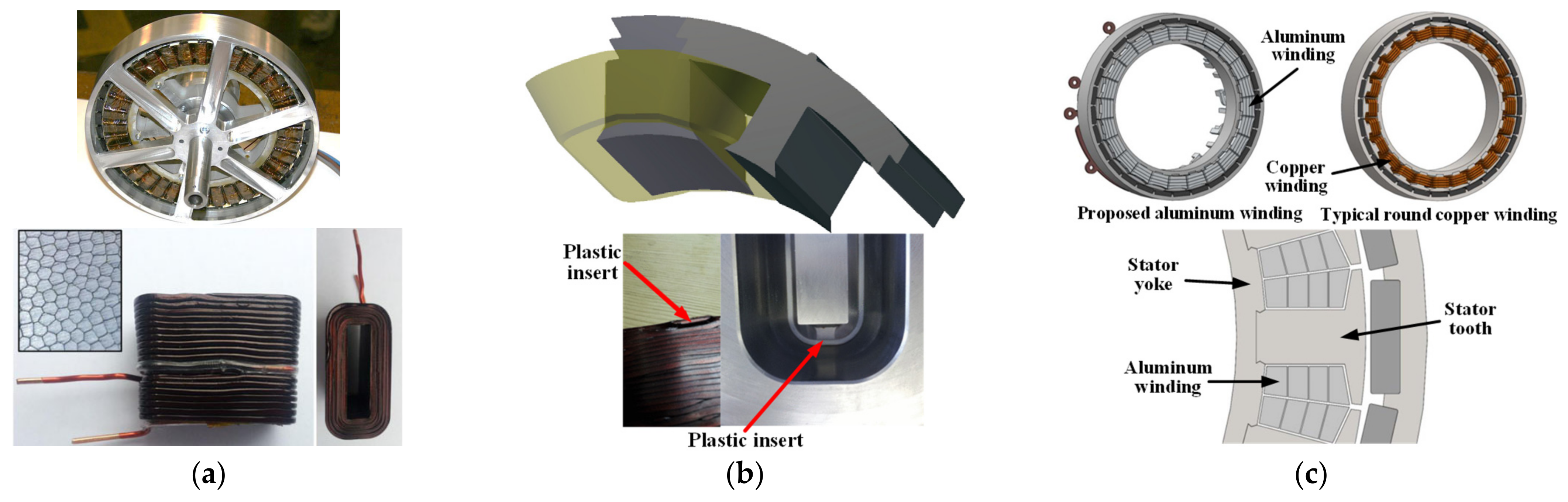

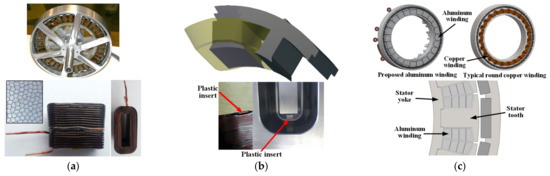

In [35], pre-compressed aluminum stator windings have been explored in a propulsion motor for a solar-powered aircraft to achieve high slot fill factor, weight reduction, low cost and also thermal improvement, as illustrated in Figure 4a. Due to the lightweight properties of aluminum, the mass of each aluminum coil is 17.2 g lower than the copper coil, leading to a 9% reduction in the motor’s total weight. Benefiting from the compressing process, the motor with aluminum windings reaches a slot fill factor of 75%, compared to 42% for conventional copper windings. Moreover, the temperature rise of the motor with aluminum windings is tested to be 26% lower than that of copper wound machines. To further mitigate high AC losses caused by skin and proximity effects, [36] proposes a new method of fabricating pre-compressed aluminum windings using stranded/Litz wire, as presented in Figure 4b. The proposed method results in a reduction of 18% in winding DC resistance and a 10% decrease in overall motor mass, as well as a remarkable 84% decline in winding material costs, compared to copper strands. The slot fill factor further increases to 77.9%. In [37], a PMSM featuring aluminum windings in an irregular cross-sectional shape achieves an even higher slot fill factor of 83.8% and is compared to an identical motor using typical round copper windings in terms of losses, efficiency, and thermal performance, as shown in Figure 4c. The experimental results demonstrate that the proposed aluminum winding machine can effectively reduce overall winding losses across a wide frequency range, especially within the low-frequency region. Therefore, when subjected to the same weight, the measured efficiencies of the proposed machine are significantly higher than those of conventional machines with copper windings. Meanwhile, the proposed aluminum windings demonstrate a slow and low-temperature rise at various operating frequencies, owing to the material properties and design of aluminum windings.

Figure 4.

State-of-the-art aluminum windings used in electrical machines: (a) A propulsion motor using pre-compressed aluminum stator windings for a solar-powered aircraft [35]; (b) A new method of fabricating pre-compressed aluminum windings using stranded/Litz wire [36]; (c) A design of high slot fill aluminum winding in PM machines for reducing winding losses [37].

However, aluminum as a motor winding material is also subject to a significant drawback, i.e., its higher electrical resistivity compared to copper, which results in increased motor losses and reduced efficiency. To achieve an equivalent resistance to that of the copper winding, the most straightforward method is to increase the cross-sectional area of the aluminum wires, which requires a larger slot area and motor size, thereby offsetting part of the weight reduction brought by aluminum windings. In this case, the utilization of compressed aluminum windings can effectively reduce winding resistance while increasing the motor slot fill factor. Nevertheless, the mechanical compression process may affect the reliability of the wire insulation layer, and the insulation issue of the compressed aluminum windings should be further considered and addressed. Therefore, it is imperative to conduct a comprehensive trade-off design by thoroughly considering the material properties and motor performance, aiming to maximize the benefits of aluminum windings.

2.3. Soft Magnetic Composite

In recent years, the application of soft magnetic composite (SMC) could be another feasible alternative to reduce motor weight due to their remarkable magnetic properties compared to conventional silicone steel sheets, particularly for high-speed and high-frequency applications. SMC primarily refers to Fe-based amorphous nanocrystalline, which is used to fabricate motor cores by molding. SMC is featured with high saturation magnetization, low eddy current loss and density, which can increase the electromagnetic load during motor design and thus reduce motor volume [38,39]. Additionally, due to the isotropic magnetic and thermal properties of SMC, some novel motor topologies with 3D magnetic circuits can be realized, thereby improving material utilization and reducing motor mass [40].

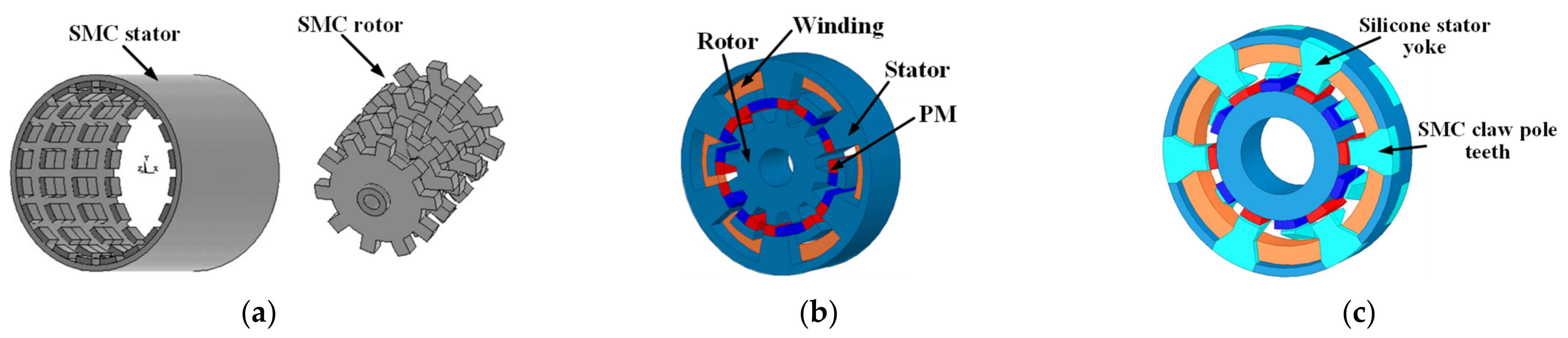

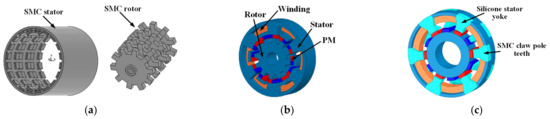

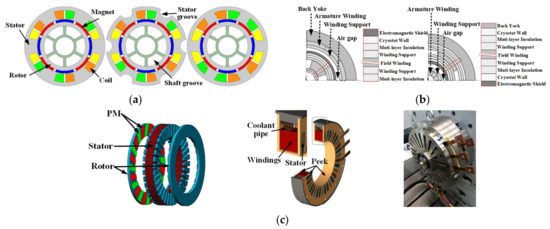

In [41], a PM transverse flux motor with SMC cores has been developed and verified with higher power and torque density compared with other motors, as presented in Figure 5a. [42] proposes a novel flux reversal claw pole machine, which combines the advantages of both flux reversal PM machine and claw pole machine. Due to the application of SMC cores, a 3D magnetic circuit can be achieved, thus resulting in relatively high torque capability, as presented in Figure 5b. Furthermore, a PM claw pole machine with hybrid cores containing steel sheets and SMC cores is proposed in [43], aiming to take advantage of the magnetic properties of SMC materials while enhancing mechanical strength, as depicted in Figure 5c. The results indicate both greatly improved torque ability and higher efficiency for a wide operation frequency range.

Figure 5.

Some typical SMC applications in electrical machines: (a) A PM transverse flux motor with SMC cores [41]; (b) A novel flux reversal claw pole machine with SMC cores [42]; (c) A PM claw pole machine with hybrid cores [43].

On the downside, SMC materials exhibit some apparent limitations, such as lower permeability than silicone steel sheets and thus higher hysteresis losses. Moreover, motor cores made of SMC materials demonstrate inferior mechanical strength than conventional laminated iron cores. Consequently, it is not appropriate to directly substitute silicon steel sheets with SMC materials in the current motor design. To fully harvest the advantages of SMC material, it is necessary to conduct a redesign of the motor topology and geometry with full consideration of SMC material properties.

2.4. Superconducting Materials

Superconducting materials are also applied in motor windings to develop superconducting electrical machines (SEM), particularly for aircraft propulsion applications with ultra-high lightweight and power density requirements. Due to the zero resistance properties of superconducting wires, superconducting windings can achieve much higher current density than conventional copper windings, which greatly improves the motor’s electromagnetic load and reduces motor size. According to the integration location of superconducting materials, SEM can be divided into partial SEMs using superconducting coils in only field windings or armature windings, and full SEMs with superconducting wires in both windings, of which the latter can achieve higher thermal load and specific power [44,45].

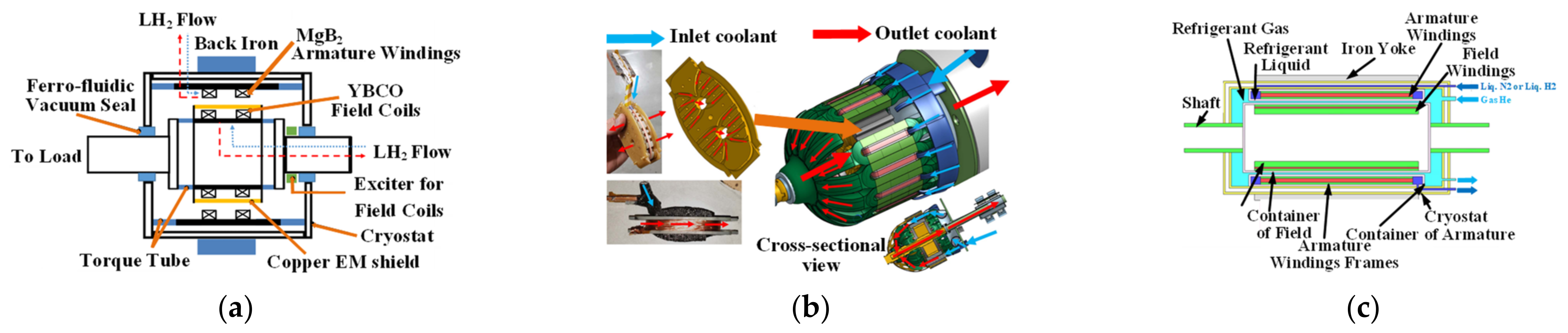

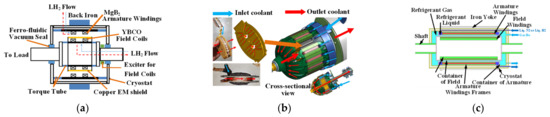

Figure 6 illustrates several state-of-the-art SEMs with lightweight construction and high specific power. A lightweight fully SEM has been developed for an electrical aircraft propulsion system, as shown in Figure 6a, and the following specifications have been achieved: 19.4 kW/kg for a 3 MW motor and over 20 kW/kg for a 5 MW motor, respectively [46]. Figure 6b presents a double rotor flux switching machine with superconducting field coils and a thermal management system [47]. The proposed motor features an air-core stator, litz wire for armature windings and high-temperature superconducting material for the field coil. The motor power density considering the overall system is about 18.5 kW/kg and the efficiency can be higher than 98.7%. As shown in Figure 6c, A 10 MW fully superconducting synchronous generator with REBCO superconducting tapes is designed for electric aircraft and its performance is evaluated in terms of the ac loss of the superconducting windings, the iron loss of the yoke, efficiency, dry weight, and output power density [48]. The theoretically achievable power density and efficiency can be up to 26.7 kW/kg and 99.2%. Furthermore, the analysis results suggest that the full SEM has the potential to achieve higher output density, expected to theoretically exceed 30 kW/kg.

Figure 6.

Some state-of-the-art SEMs: (a) A lightweight fully SEM for electrical aircraft propulsion system [46]; (b) A double rotor flux switching machine with superconducting field coils and thermal management system [47]; (c) A 10 MW fully superconducting synchronous generator with REBCO superconducting tapes for electric aircraft [48].

Despite the clear benefits of weight and size reduction, there are still critical challenges that require careful consideration. The zero-resistance properties of superconducting materials require additional cryogenic cooling, which brings considerable weight, complicates the entire system, and offsets the improvement of the overall power density. Although there is no DC loss due to superconducting, SEMs still suffer from AC loss caused by flux leakage. Consequently, further investigation and holistic motor design are required to maximize the benefits of superconducting materials.

The applications of lightweight materials in electrical machines are summarized in Table 1, where common materials, extended performance boundaries, and limitations are included.

Table 1.

Summary of application of lightweight materials.

3. Structural Lightweight Design

In addition to the utilization of lightweight materials, structural lightweight design serves as another effective approach to achieving motor lightweight design, which is mainly aimed at both the electromagnetic configuration and mechanical structure of the motor. Generally, the motor topology and geometry are optimized and improved to reduce motor weight while ensuring the motor’s electromagnetic performance and mechanical strength. This section provides a comprehensive overview of lightweight structural design for both motor active and passive components [49,50].

3.1. Active Part

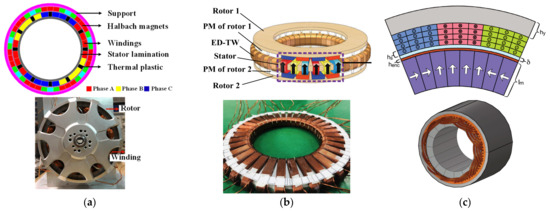

Regarding structural lightweight design in the motor active part, some novel motor topologies such as slotless machines [51], ironless or coreless machines [52] have been developed to effectively minimize motor weight while maintaining functionality. Slotless machines are currently being intensively explored due to their reduced weight and enhanced power density, as well as other merits, i.e., zero cogging torque, very smooth rotation, no laminated core loss, and negligible eddy current losses in rotor magnets [53].

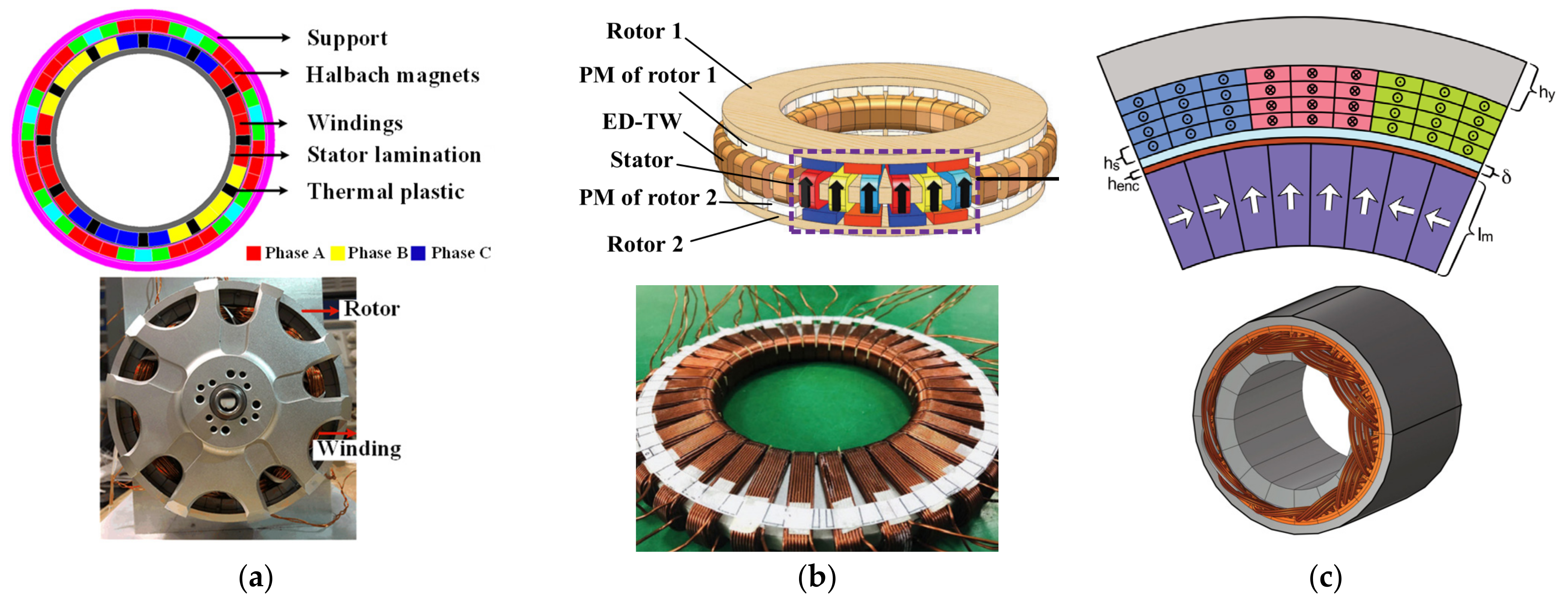

Several typical state-of-the-art slotless machines are illustrated in Figure 7. A slotless, lightweight PM machine with high pole pairs and outer rotor Halbach PM configuration is proposed and investigated for a drone, as shown in Figure 7a [54]. Compared to the conventional slotted radial flux machine, the slotless machine presents a significant reduction in overall weight (from 0.7 kg to 0.465 kg) due to significantly decreased lamination weight (from 0.53 kg to 0.08 kg), while experiencing an increase in the weight of magnets (from 0.083 kg to 0.215 kg) and conductors (from 0.09 kg to 0.17 kg). Figure 7b presents an axial-flux dual-rotor slotless PM motor with novel equidirectional toroidal winding [55]. Compared with the axial flux machine with traditional toroidal winding, the proposed motor presents advantages in terms of back-EMF amplitude, torque density and motor efficiency due to the absence of phase difference between the EMF induced by each coil within one phase of the equidirectional toroidal winding. Additionally, a high-speed slotless generator system is developed for a hybrid-electric aircraft, where a power density of 24.38 kW/kg (considering the motor active part) is achieved at a current density of 15 A/mm2 and motor efficiency of 99%, as shown in Figure 7c [56]. The power density can be further increased to 40 kW/kg by enhancing the current density to 27.5 A/mm2 and increasing the number of pole pairs.

Figure 7.

State-of-the-art slotless electrical machines. (a) A slotless lightweight motor for aerial applications [54]; (b) An axial-flux dual-rotor slotless PM motor with novel equidirectional toroidal winding [55]; (c) A high-speed slotless generator system for hybrid-electric aircraft [56].

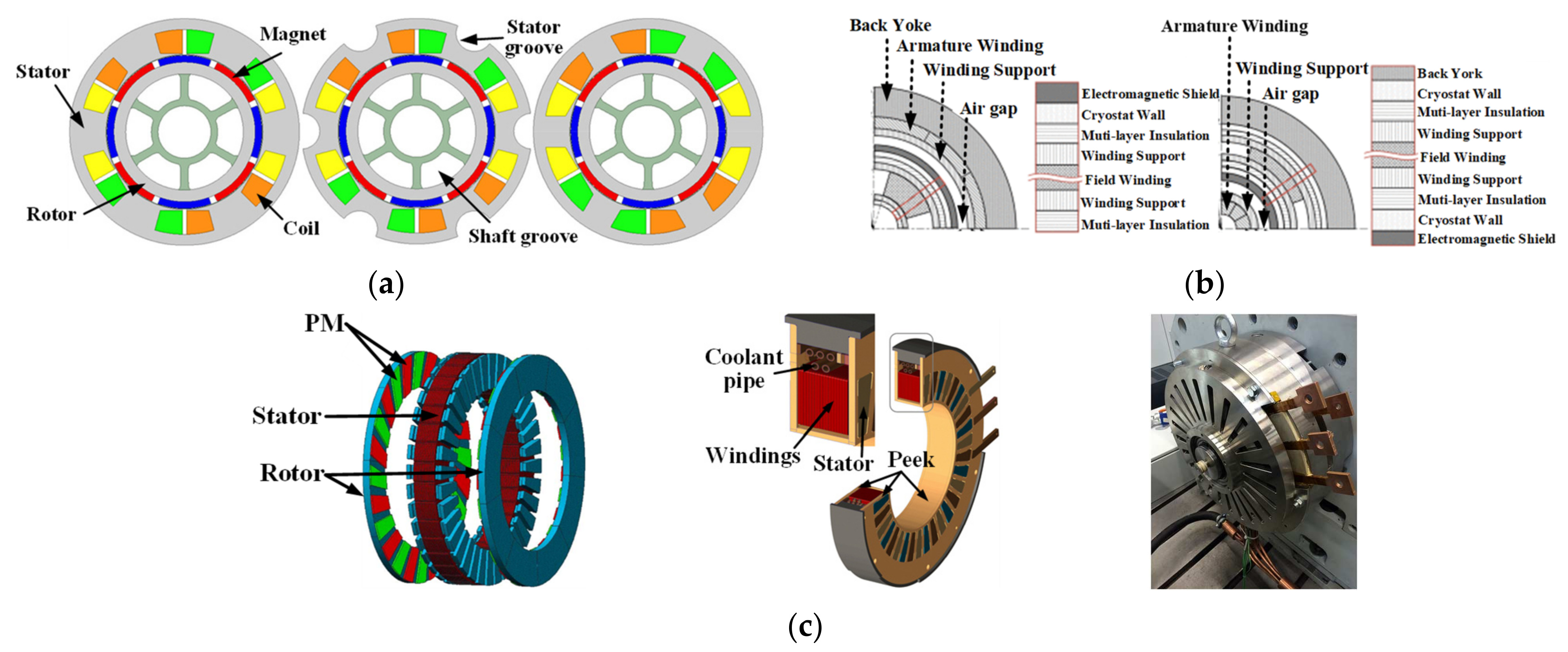

Apart from the elimination of stator teeth for slotless machine construction, the stator yoke is also narrowed and optimized to reduce its mass and achieve high specific power, with typical application cases in Figure 8. The proposed lightweight structure, which incorporates stator grooves in the stator yoke, has been validated to demonstrate reduced motor weight while having little impact on the no-load back-EMF, output torque, and motor losses [28]. Another case is a 3 MW partially superconducting synchronous machine developed for electric aircraft propulsion [57]. This motor features the application of an electromagnetic Halbach array for field excitation, which narrows the back yoke and thus enhances the overall output power density. The results demonstrate a yoke thickness reduction of up to 85% and a yoke weight decrease of up to 78%, which results in an increase in motor power density by up to 30%. Furthermore, a novel design is proposed in [58], presenting a yokeless and segmented armature axial flux PMSM with integrated copper pipes serving as an effective cooling system. The investigation primarily focuses on the mechanical construction of the motor including stress, deformation, thermal and modal analyses, and finally, a prototype is successfully fabricated and tested.

Figure 8.

Application cases for narrowed stator yoke in electrical machines: (a) A high-power density PMSM with lightweight structure [28]; (b) A superconducting synchronous motor with Halbach array field excitation [57]; (c) A yokeless and segmented armature axial flux machine with copper pipes for cooling [58].

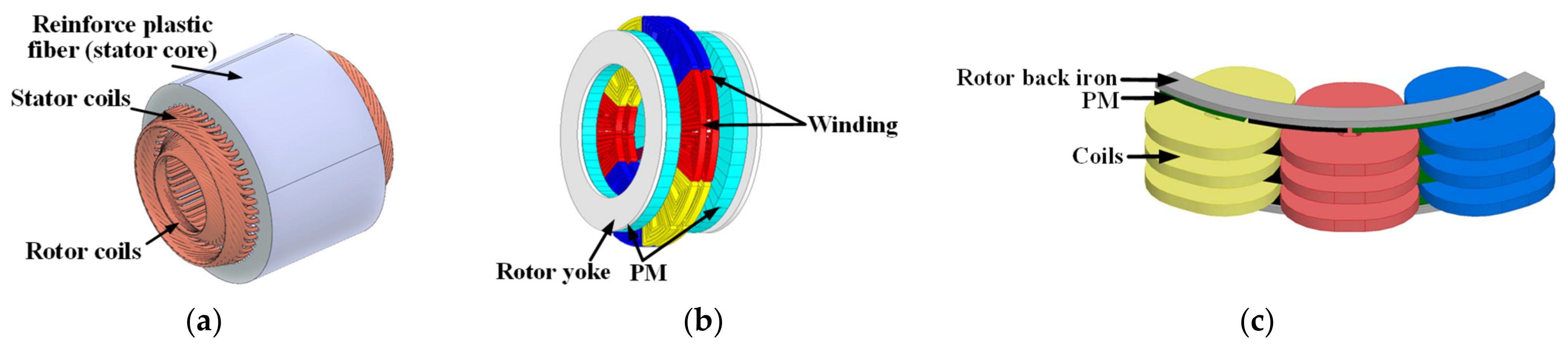

Another more advanced topology is an ironless machine, also known as a coreless machine or air-core machine, where no ferromagnetic material is used in the motor to achieve extreme weight reduction. As presented in Figure 9a, a coreless multi-phase electric machine based on magnetic resonant coupling has been proposed to realize lightweight configuration [59]. To make the machine coreless, the stator and rotor cores of the motor are fabricated using reinforced plastic fibers through additive manufacturing techniques. The analysis results indicate an output torque of 2.89 Nm at an estimated weight of 12 kg, which has not been validated by prototyping and testing. Another case involves a high-speed axial-flux PM machine with an ironless stator and a Halbach-array PM rotor, as depicted in Figure 9b [60]. A new hybrid sleeve and PM fixation method have been proposed to ensure rotor mechanical strength in high-speed machines. The motor output power can reach 53.8 kW at 9000 rpm, which has been fully validated through motor prototype testing. Furthermore, the weight of coreless machines can be reduced by utilizing alternative winding materials, such as aluminum wires and carbon nanotube (CNT) windings, which have been investigated in [61]. CNT is characterized by lightweight properties, absence of skin effect, and negligible temperature coefficient of resistance. The weight of the coreless axial flux machine with aluminum windings and CNT is reduced to 66% of that of the machine equipped with conventional copper coils, while maintaining the same output power.

Figure 9.

State-of-the-art coreless or ironless electrical machines: (a) A coreless multi-phase electric machine using magnetic resonant coupling [59]; (b) A high-speed axial-flux PM machine with a Halbach-array PM rotor and an ironless stator [60]; (c) A coreless multidisc axial flux PM machine with CNT windings [61].

Although the lightweight properties of coreless machines have been mentioned in some existing literature, most studies only refer to the improvement in motor efficiency rather than specific advancements in motor mass or power density. The possible reasons are as follows. Due to the absence of iron cores, the magnetic permeability in the magnetic circuit is lower, and thus the airgap flux density is lower than that of conventional motors with iron cores. To achieve the same output capability, one approach is to enhance the airgap flux density by using more PMs or increasing the motor size to augment the airgap surface area, which entails higher cost and additional weight. Moreover, the increased flux leakage and copper losses due to the absence of iron cores are also non-negligible. Therefore, there is no general law for weight reduction in ironless machines, and comprehensive tradeoff designs are required to achieve lightweight motor configurations on a case-by-case basis.

3.2. Passive Part

Apart from the motor active part, the mechanical structure constitutes another significant contributor to overall weight, thereby allowing sufficient space for mass reduction. The mechanical structure of the motor primarily serves as a support, fixation, and torque transmission component [62]. Therefore, it is imperative to ensure its functionality and mechanical strength while simultaneously reducing weight. Currently, lightweight construction is mainly achieved by simplifying the mechanical components, such as thinned housing, ribbed endcap and hollow shaft, with effective weight reduction reported in existing literature.

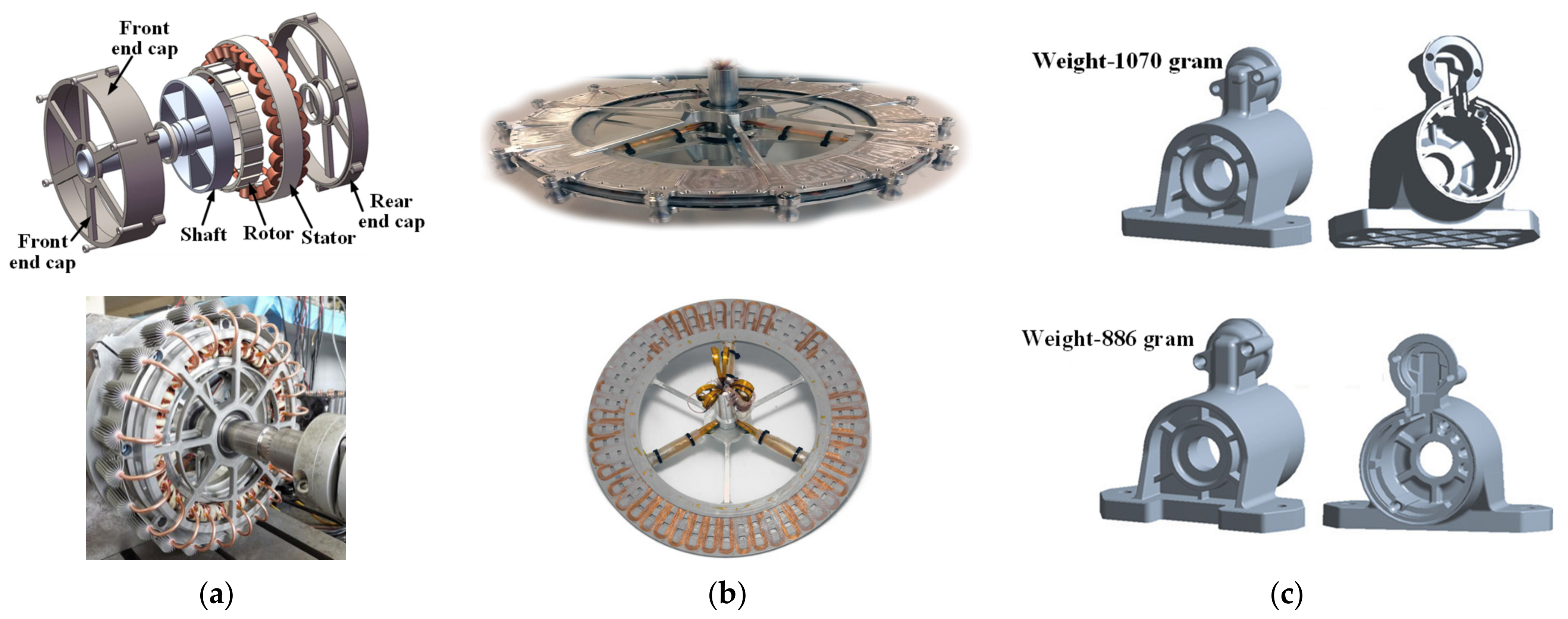

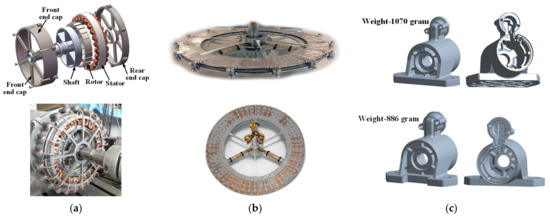

A mass optimization approach based on a coupled electromagnetic and mechanical analytical model is proposed to achieve a lightweight mechanical structure of a PMSM for a solar-powered aircraft, as presented in Figure 10a [23]. The strength and stiffness of mechanical components are fully considered based on the motor load, and a multi-physics analytical model including electromagnetic and mechanical properties was established. A 4 kW and a 167 W motor are designed based on the proposed analytical model and prototyped for validation as well. Compared to the propulsion for Zephyr 6, the mechanical mass ratio has reduced from 41.8% to 34% and 23%, respectively. Similarly, the weight optimization of an axial-flux machine for airborne wind turbines is performed by employing a multi-objective optimization approach based on a combined electrical, thermal, and structural analytical model, as depicted in Figure 10b [63]. The optimization results indicate a motor power density of 6.4 kW/kg at a total weight of 2.065 kg, an efficiency of 95% and a rated speed of 3200 rpm. In Figure 10c, the over-engineering issue of an existing housing bracket is addressed, where the finite element analysis results are utilized to improve its design [64]. Consequently, the weight of the bracket is reduced from its original value of 1070 g to a more efficient 886 g. During the optimization, the manufacturing feasibility has been fully considered and design rules are proposed, including wall thickness for housing, transition radius and fillet for cast flow, as well as porosity factor.

Figure 10.

Typical structural lightweight designs in motor passive part: (a) A surface-mounted PMSM based on a lightweight structure [23]; (b) An axial-flux machine for airborne wind turbines [63]; (c) A lightweight housing bracket design [64].

Compared to the motor active part, investigation on weight reduction of motor mechanical structure is comparatively limited, which presents significant potential for further mass reduction through both simplified structural design and utilization of lightweight materials. Therefore, further studies on motor lightweight structures can be conducted to facilitate its integration with specific application scenarios in the future. For instance, in the context of aviation electric propulsion, which is highly weight-sensitive, the motor mechanical structure can be further streamlined based on operating conditions to enhance motor power density and also aircraft flight capability.

The incorporation of structural lightweight design in electrical machines, including both active and passive parts, is summarized in Table 2, which involves common topologies, extended performance boundaries, and limitations.

Table 2.

Summary of structural lightweight design.

4. Advanced Manufacturing Technology

Advanced manufacturing technology is a crucial facilitator in achieving lightweight motor design, thereby being extensively employed in recent years for the implementation of lightweight motor construction. Among various fabrication technologies, additive manufacturing is emerging as the most cutting-edge technique for motor fabrication [65]. Additive manufacturing technology is distinguished by its ability to produce almost unconstrained and three-dimensional motor components through rapid prototyping, while minimizing material waste. Furthermore, another advantage lies in the versatility of this technique, as it allows for the application of a wide range of materials including metal alloys, composite materials, and ceramics. Therefore, this technology can be employed to fabricate motor components with complex configurations that pose challenges for conventional processing methods, thereby facilitating the flexible design of motor components and achieving lightweight objectives [20]. According to the existing literature, additive manufacturing has demonstrated its capability in fabricating nearly all motor components, with particular emphasis on windings, cores, and cooling systems, where significant effects on weight reduction or performance enhancement are presented [66]. The following provides a brief overview of additive manufacturing technologies applied in various motor components for weight reduction, as well as discussions on their merits and limitations.

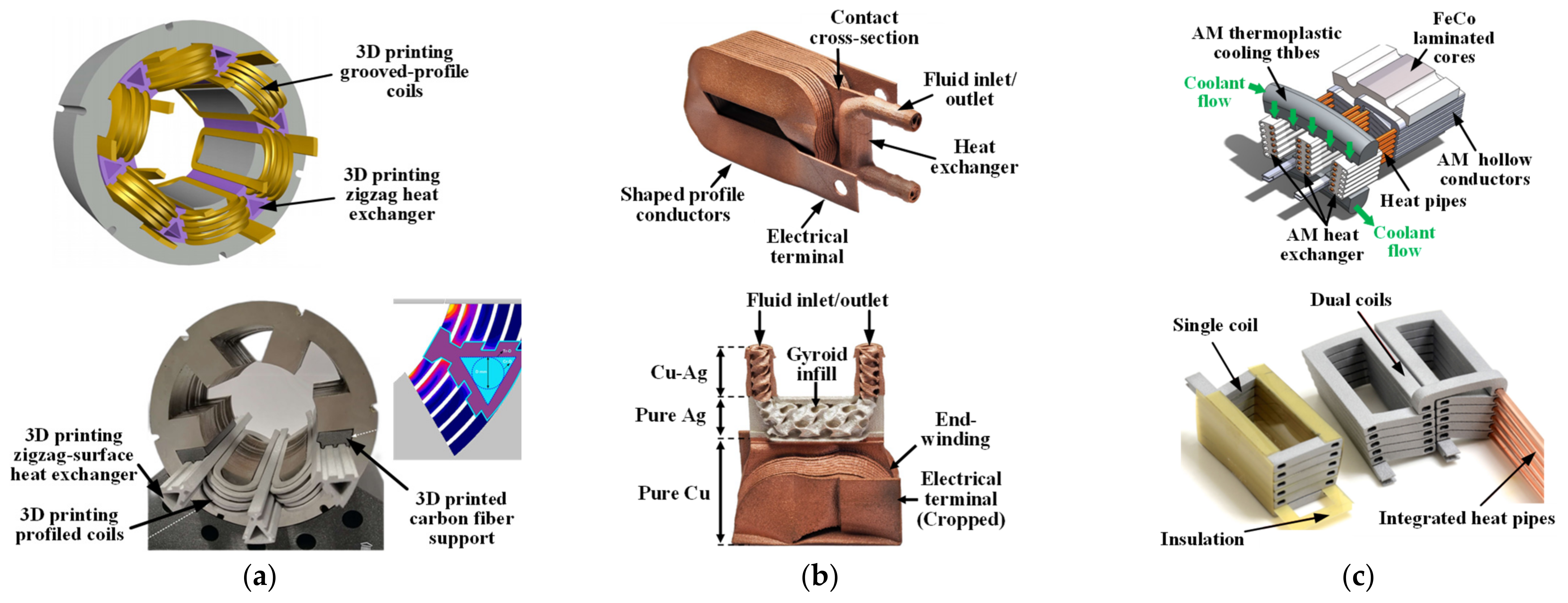

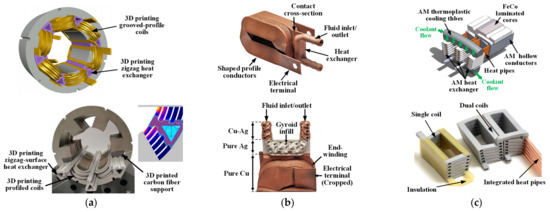

4.1. Windings

The predominant application scenario of additive manufacturing technology in electrical machines lies in winding modules, primarily aimed at maximizing slot fill factor or integrating winding direct cooling configurations. This approach improves motor thermal performance and consequently contributes to lightweighting objectives. In [67], a novel grooved-profile coil for in-slot direct cooling has been proposed, which is manufactured using additive manufacturing technology and aluminum material, as presented in Figure 11a. Compared to conventional copper wire coils, the proposed design achieves a remarkable slot filling factor of 58.6%, resulting in a twofold increase in ampere turn limit and a weight reduction of 47%, as well as a maximum temperature reduction from 197.5 °C to only 65.4 °C. Another approach described in Figure 11b focuses on end-winding cooling, where a modular cooling configuration is introduced to integrate the fluid heat exchanger directly into the end-winding using additive manufacturing [68]. This configuration reduces the occupied stator slots and enables winding direct cooling, thereby minimizing the volume of non-active windings. Experimental results demonstrate an 81% increase in continuous current capability when ignoring AC losses, thus leading to higher thermal load and enhanced power density. Another more direct way is to insert heat pipes directly into additively manufactured hollow windings for enhanced cooling and lightweight design, which is implemented in a 250 kW high specific power direct drive PM motor, as illustrated in Figure 11c [69]. Heat pipes are used as cooling components, with one end integrated within the coil cavities, while the other end connected with fluid-cooled heat exchangers. This efficient cooling structure facilitates high current densities, resulting in a significant reduction in motor mass and volume. The analysis results demonstrate that the motor with additively manufactured coils achieves a high specific power of 20.10 kW/kg and an efficiency of 96.18%. However, a significant drawback lies in the generally higher resistivity and lower thermal conductivity of 3D printed windings, which leads to increased losses and compromised thermal performance. Furthermore, the mechanical strength of 3D-printed windings can be further enhanced due to the inherent limitations of the machining process.

Figure 11.

State-of-the-art additively manufactured windings in electrical machines: (a) A novel shaped profile coil with direct cooling channels [67]; (b) Windings enabled by additive manufacturing for direct thermal management [68]; (c) Additively manufactured hollow conductors integrated with heat pipes [69].

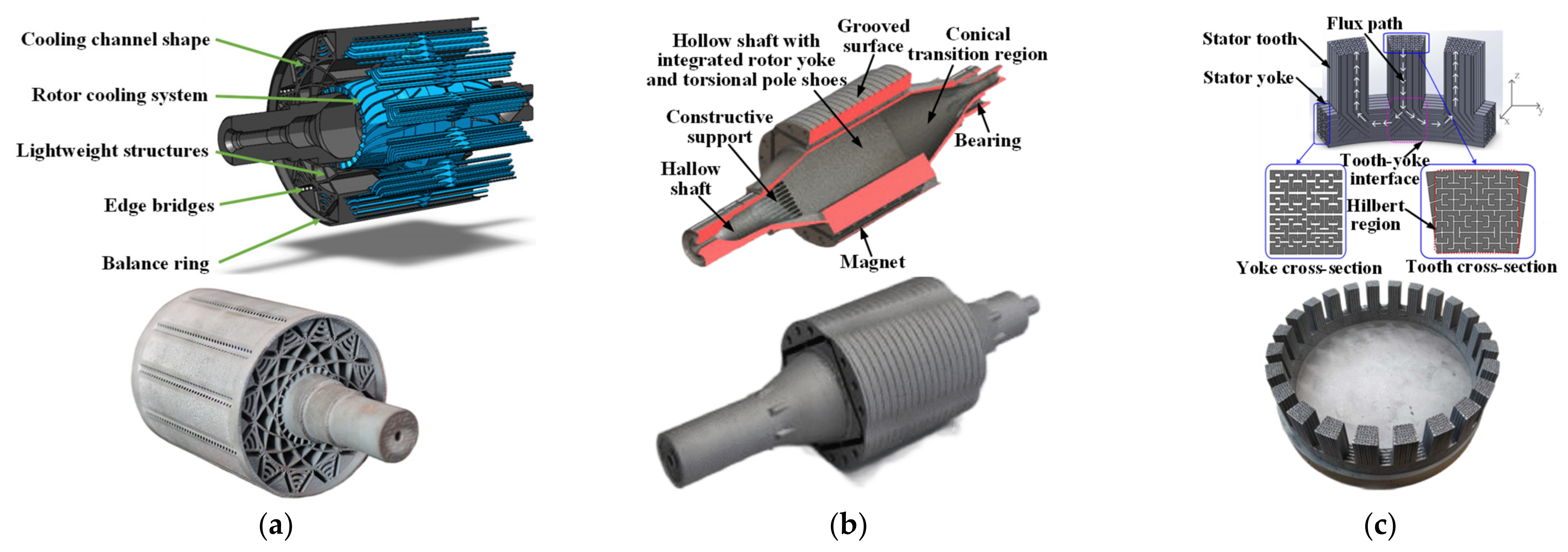

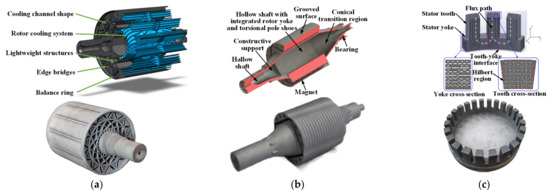

4.2. Cores

Additive manufacturing technology is commonly employed in motor core production to overcome the limitations of conventional laminated cores and achieve a more flexible electromagnetic design. A rotor design incorporating an additively manufactured air-cooling system is proposed in [70] for lightweight structures of automotive PMSMs, as shown in Figure 12a. Compared to traditionally manufactured reference motors, the combined weight of the rotor and shaft is decreased by 33%, together with a 13% decrease in mass moment of inertia, thereby further enhancing motor dynamic performance. Moreover, this study involves the redesigning and additive manufacturing of the motor casing, resulting in a significant 45% reduction in weight. Based on additive manufacturing technology, another lightweight rotor with internal magnets is proposed in [71], as presented in Figure 12b. The active components of the rotor are made of soft magnetic silicon alloy and the surface of the functional model was treated with grooves to reduce eddy current losses. Additionally, several other lightweight structures are also adopted, including a lightweight motor end structure, a hollow shaft, and a new conical transition zone between the moving parts and the bearing. Compared to the reference rotor, the proposed rotor achieves a weight reduction of 52.7%, and an average motor torque enhancement of 5.4%, as well as a decrease in cogging torque by 90%. In addition to rotors, the motor stator can also be fabricated using additive manufacturing technology to achieve lightweighting. The study in [72] introduces a novel 3D-printed laminated stator to address the issue of 3D magnetic flux paths in axial flux machines during the manufacturing process of radial laminated stator cores, as depicted in Figure 12c. The proposed stator is fabricated using silicon steel powder and incorporates a novel Hilbert lamination technique to emulate geometric structures, thereby mitigating eddy current losses. The analysis results demonstrate a 50% reduction in eddy current losses compared to solid structures containing 3% silicon steel content, with an additional 24% decrease when employing 6.5% silicon steel content. Moreover, the additively manufactured stator presents a weight reduction of about 30% compared to conventional counterparts. Despite a decrease of approximately 22% in peak static torque, the net torque density of the motor is still enhanced by the new design.

Figure 12.

State-of-the-art additively manufactured cores in electrical machines: (a) An additively manufactured air-cooled lightweight rotor for automotive electric machines [70]; (b) An additively manufactured lightweight rotor made of soft magnetic silicon alloy [71]; (c) An additively manufactured stator with Hilbert pattern for axial flux machines [72].

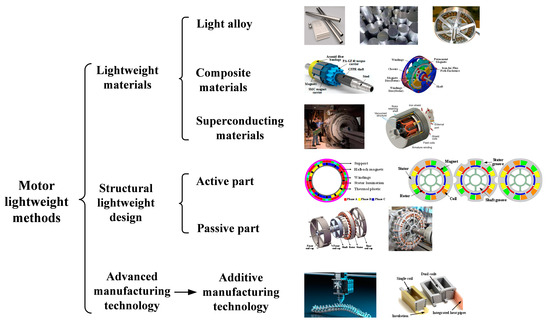

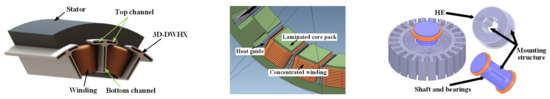

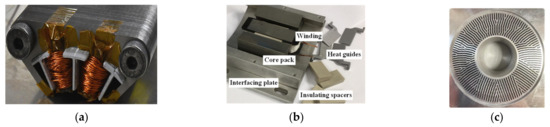

4.3. Cooling Configurations

The thermal issue has consistently been one of the most critical concerns in motor design, and additive manufacturing is being adopted to address this challenge by enabling more integrated and efficient cooling configurations. To enhance winding direct cooling, a specific heat exchanger with unique geometry enabled by 3D printing technology is proposed in Figure 13a for high-power density motors and integrated into double-layer concentrated windings [73]. Compared to other materials, ceramic materials are characterized by high thermal conductivity, high stiffness, and strength at extremely high temperatures. After experimental validation in a motorette, a continuous DC current density of 35.7 A/mm2 is achieved, thereby enabling the attainment of a power density of 12.1 kW/kg in the reference motor. Another similar investigation in Figure 13b involves the implementation of thermally conductive heat guides as a novel heat dissipation approach to provide an efficient cooling path in machines [74]. Additive manufacturing technology is employed to fabricate the heat guide with complex geometry, resulting in improved thermal performance and minimized losses, while remaining unaffected by external magnetic fields. The test results demonstrate a reduction of 30% and 40% in temperature rises at both the winding end and active area, along with an 85% improvement in heat dissipation efficiency. Remarkably, the contribution of heat guide to the total weight of stator winding assemblies is only 3% to 4%, which significantly enhances power density. Apart from motor windings, 3D-printed cooling configurations can also be integrated within other motor regions to improve thermal performance. An additively manufactured heat exchanger with a multi-finned structure is integrated within the original internal space to address the overheating issue in the stator components of outer-rotor motors, as shown in Figure 13c [75]. The proposed cooling configuration enables a temperature reduction of 9.1 K to 18 K under various conditions compared to conventional heat sinks. Furthermore, the temperature gap between the windward and leeward sides has also been narrowed, which is beneficial for the thermal management of the entire motor.

Figure 13.

State-of-the-art additively manufactured cooling configurations in electrical machines: (a) A 3-D Printed Heat Exchanger [73]; (b) An additively manufactured Heat Guides for Enhanced Heat Transfer [74]; (c) An AM Heat Exchanger for Outer-Rotor PMSM [75].

Despite great potential, additive manufacturing technology at the current stage also presents certain limitations that require further refinement. Due to the rapid melting and solidification, some small structural imperfections such as porosity, cracks, residual stresses, spheroidization, and anisotropy are generated during the manufacturing process, which poses significant implications on the electromagnetic, thermal, and mechanical performance of the component. Additionally, its applicability in electrical machines may be further constrained by limited machining accuracy and material restrictions [20,76]. The exploration of additive manufacturing technology in electrical machines is summarized in Table 3, encompassing common methods, extended performance boundaries and limitations.

Table 3.

Summary of additive manufacturing technology in electrical machines.

5. Discussions and Conclusions

With the increasing electrification in the context of transportation, there is a growing demand for motors with high power/torque density. Lightweighting techniques for motors have emerged as an effective approach to achieve compact motor structures, lightweight construction, and thus expanded performance boundaries. The effectiveness of these methods has been validated through extensive investigations including motor design, prototyping, and testing.

The state-of-the-art implementation methods for lightweight motors have been comprehensively reviewed in terms of the utilization of lightweight materials, structural lightweight design, and the incorporation of additive manufacturing technology in machine construction. Among these, the adoption of lightweight materials and structural lightweight design has yielded favorable outcomes. However, it is important to note that the incorporation of lightweight materials and topologies presents a non-negligible impact on motor electromagnetic and thermal performance, as well as mechanical strength, which requires further investigation and meticulous design trade-offs. Future research may focus on achieving further motor lightweighting by employing lightweight materials and structures based on a comprehensive evaluation of the combined electromagnetic, thermal, and mechanical performance of the motor. Additionally, additive manufacturing technology is increasingly being applied to fabricate lightweight motors with promising potential. However, this technology still suffers from some limitations, such as a restricted range of printable materials, diminished material properties post-3D printing, and suboptimal processing efficiency. To promote the wider application of additive manufacturing technology in motor production, improvements in processing technology are required. Furthermore, cost poses a significant concern in the implementation of the aforementioned lightweighting methods, particularly in cost-sensitive scenarios, where careful calculations and trade-offs are necessary to strike a balance between weight reduction purposes and increased expenses.

In the future, more high-strength lightweight materials may be adopted for motor lightweighting, such as titanium alloys, magnesium–aluminum alloys, and cutting-edge nano materials. As for topology optimization, specific operational conditions of vehicles, such as electric vehicles and electrified aircraft, can be fully considered to minimize performance and material redundancy. Additionally, the utilization of pressure casting technology, already employed in automotive manufacturing, presents a promising avenue for the production of motor components with complex structures to achieve lightweight configurations.

Author Contributions

Conceptualization, J.L., X.Z. and B.X.; writing—original draft preparation, H.Z. (Han Zhao), C.Z. and Y.R.; writing—review and editing, H.W., J.Z. and Z.L.; supervision, X.H. and H.Z. (He Zhang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science & Technology under National Key R&D Program of China under grant 2021YFE0108600, and this research was also funded by Ningbo Key Technology Research and Development Programme under grant 2021Z035.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors on request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, F.; Gerada, D.; Xu, Z.; Zhang, X.; Tighe, C.; Zhang, H.; Gerada, C. Back-iron extension thermal benefits for electrical machines with concentrated windings. IEEE Trans. Ind. Electron. 2019, 67, 1728–1738. [Google Scholar] [CrossRef]

- Wang, X.; Li, B.; Gerada, D.; Huang, K.; Stone, I.; Worrall, S.; Yan, Y. A critical review on thermal management technologies for motors in electric cars. Appl. Therm. Eng. 2022, 201, 117758. [Google Scholar] [CrossRef]

- Cao, W.; Mecrow, B.C.; Atkinson, G.J.; Bennett, J.W.; Atkinson, D.J. Overview of Electric Motor Technologies Used for More Electric Aircraft (MEA). IEEE Trans. Ind. Electron. 2012, 59, 3523–3531. [Google Scholar]

- Wrobel, R.; McGlen, R.J. Opportunities and challenges of employing heat-pipes in thermal management of electrical machines. In Proceedings of the 2020 International Conference on Electrical Machines (ICEM), Gothenburg, Sweden, 23–26 August 2020. [Google Scholar]

- Zhao, H.; Zhang, X.; Zhang, F.; Wang, S.; Zhao, W.; Li, J.; Zhang, H.; Gerada, D. A Comprehensive Review and Experimental Investigation on Heat Pipes Application in Electrical Machines. IEEE Trans. Transp. Electrif. 2022, 9, 2267–2281. [Google Scholar] [CrossRef]

- Dong, C.; Qian, Y.; Zhang, Y.; Zhuge, W. A Review of Thermal Designs for Improving Power Density in Electrical Machines. IEEE Trans. Transp. Electrif. 2020, 6, 1386–1400. [Google Scholar] [CrossRef]

- Xu, Z.; Xu, Y.; Gai, Y.; Liu, W. Thermal Management of Drive Motor for Transportation: Analysis Methods, Key Factors in Thermal analysis, and Cooling Methods—A Review. IEEE Trans. Transp. Electrif. 2023, 9, 4751–4774. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, X.; Li, J.; Wang, H.; Zhang, F.; Zhang, H.; Zhu, X.; Gerada, D. Heat Pipe Bending Effect on Cooling Effectiveness in Electrical Machines. IEEE Trans. Energy Convers. 2023, 38, 2011–2021. [Google Scholar] [CrossRef]

- Solomon, D.G.; Greco, A.; Masselli, C.; Gundabattini, E.; Rassiah, R.S.; Kuppan, R. A review on methods to reduce weight and to increase efficiency of electric motors using lightweight materials, novel manufacturing processes, magnetic materials and cooling methods. Ann. Chim.-Sci. Matér. 2020, 44, 1–14. [Google Scholar] [CrossRef]

- Gnanaraj, S.D.; Gundabattini, E.; Singh, R.R. Materials for lightweight electric motors—A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020. [Google Scholar]

- Boopathi, N.G.; Muthuraman, M.S.; Palka, R.; Wardach, M.; Prajzendanc, P.; Gundabattini, E.; Rassiah, R.S.; Solomon, D.G. Modeling and simulation of electric motors using lightweight materials. Energies 2022, 15, 5183. [Google Scholar] [CrossRef]

- Peter, M.; Fleischer, J.; Sell-Le Blanc, F.; Jastrzembski, J.P. New conceptual lightweight design approaches for integrated manufacturing processes: Influence of alternative materials on the process chain of electric motor manufacturing. In Proceedings of the 2013 3rd International Electric Drives Production Conference (EDPC), Nuremberg, Germany, 29–30 October 2013. [Google Scholar]

- Ruhland, P.; Matveev, A.; Nielsen, K.; Kvinnesland, K.; Coutandin, S.; Fleischer, J. New Production Techniques for Electric Motors in High Performance Lightweight Applications. In Proceedings of the 2020 10th International Electric Drives Production Conference (EDPC), Ludwigsburg, Germany, 8–9 December 2020. [Google Scholar]

- Lizarribar, B.; Prieto, B.; Martinez-Iturralde, M.; Artetxe, G. Novel Topology Optimization Method for Weight Reduction in Electrical Machines. IEEE Access 2022, 10, 67521–67531. [Google Scholar] [CrossRef]

- Wu, S.; Tian, C.; Zhao, W.; Zhou, J.; Zhang, X. Design and Analysis of an Integrated Modular Motor Drive for More Electric Aircraft. IEEE Trans. Transp. Electrif. 2020, 6, 1412–1420. [Google Scholar] [CrossRef]

- Koch, S.F.; Peter, M.; Fleischer, J. Lightweight design and manufacturing of composites for high-performance electric motors. Procedia CIRP 2017, 66, 283–288. [Google Scholar] [CrossRef]

- Fang, S.; Liu, H.; Wang, H.; Yang, H.; Lin, H. High Power Density Permanent Magnet Synchronous Motor With Lightweight Structure and High-Performance Soft Magnetic Alloy Core. In Proceedings of the 2018 IEEE International Conference on Applied Superconductivity and Electromagnetic Devices (ASEMD), Tianjin, China, 15–18 April 2018. [Google Scholar]

- Wrobel, R.; Mecrow, B. Additive Manufacturing in Construction of Electrical Machines—A Review. In Proceedings of the 2019 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Athens, Greece, 22–23 April 2019. [Google Scholar]

- Szabó, L. Survey on Applying 3D Printing in Manufacturing the Cooling Systems of Electrical Machines. In Proceedings of the 2022 IEEE International Conference on Automation, Quality and Testing, Robotics (AQTR), Cluj-Napoca, Romania, 19–21 May 2022. [Google Scholar]

- Wu, F.; Refaie, A.M.E. Toward Additively Manufactured Electrical Machines: Opportunities and Challenges. IEEE Trans. Ind. Appl. 2020, 56, 1306–1320. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, X.; Li, J.; Xu, L.; Wang, S.; Zhang, H. An Advanced Propulsion Motor with Enhanced Winding Cooling System for A Solar-Powered Aircraft. IEEE Trans. Transp. Electrif. 2023, 10, 2034–2044. [Google Scholar] [CrossRef]

- Zhao, H.; Zhang, H.; Zhang, X.; Gerada, D.; Li, J.; Zhang, J. Multi-Objective Optimization of the Iron Bridge between Segmeted PMs for an Outer-Rotor Brushless DC Motor. In Proceedings of the 2022 IEEE International Conference on Industrial Technology (ICIT), Shanghai, China, 22–25 August 2022. [Google Scholar]

- Zhang, X.; Li, L.; Zhang, C. Mass Optimization Method of a Surface-Mounted Permanent Magnet Synchronous Motor Based on a Lightweight Structure. IEEE Access 2020, 8, 40431–40444. [Google Scholar] [CrossRef]

- Wrobel, R.; Salt, D.; Simpson, N.; Mellor, P.H. Comparative study of copper and aluminium conductors—Future cost effective PM machines. In Proceedings of the 7th IET International Conference on Power Electronics, Machines and Drives (PEMD 2014), Manchester, UK, 8–10 April 2014. [Google Scholar]

- Sayed, E.; Abdalmagid, M.; Pietrini, G.; Sa’adeh, N.M.; Callegaro, A.D.; Goldstein, C.; Emadi, A. Review of Electric Machines in More-/Hybrid-/Turbo-Electric Aircraft. IEEE Trans. Transp. Electrif. 2021, 7, 2976–3005. [Google Scholar] [CrossRef]

- Ahmed, N.; Atkinson, G.J. A Review of Soft Magnetic Composite Materials and Applications. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022. [Google Scholar]

- Dave, N.; Vakil, G.; Xu, Z.; Gerada, C.; Zhang, H.; Gerada, D. Comparison of slotted and slotless PM machines for high kW/kg aerospace applications. In Proceedings of the 2020 23rd International Conference on Electrical Machines and Systems (ICEMS), Hamamatsu, Japan, 24–27 November 2020. [Google Scholar]

- Fang, S.; Liu, H.; Wang, H.; Yang, H.; Lin, H. High power density PMSM with lightweight structure and high-performance soft magnetic alloy core. IEEE Trans. Appl. Supercond. 2019, 29, 0602805. [Google Scholar] [CrossRef]

- Vaimann, T.; Kallaste, A. Additive Manufacturing of Electrical Machines—Towards the Industrial Use of a Novel Technology. Energies 2023, 16, 544. [Google Scholar] [CrossRef]

- El-Refaie, A. Role of advanced materials in electrical machines. CES Trans. Electr. Mach. Syst. 2019, 3, 124–132. [Google Scholar] [CrossRef]

- Profumo, F.; Tenconi, A.; Cerchio, M.; Eastham, J.F.; Coles, P.C. Axial flux plastic multi-disc brushless pm motors: Performance assessment. In Proceedings of the Nineteenth Annual IEEE Applied Power Electronics Conference and Exposition, 2004. APEC’04, Anaheim, CA, USA, 22–26 February 2004. [Google Scholar]

- Lakatos, I.; Szauter, F.; Czeglédi, D. Investigating the appliance of aluminum as a winding material with high efficiency electric motor. In Proceedings of the 2016 12th IEEE/ASME International Conference on Mechatronic and Embedded Systems and Applications (MESA), Auckland, New Zealand, 29–31 August 2016. [Google Scholar]

- Babicz, S.; Djennad, S.A.-A.; Velu, G. Preliminary study of using anodized aluminum strip for electrical motor windings. In Proceedings of the 2014 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Des Moines, IA, USA, 19–22 October 2014. [Google Scholar]

- Damme, J.V.; Vansompel, H.; Crevecoeur, G. Anodized Aluminum Foil Winding Axial Flux Machine for Direct-Drive Robotic Applications. IEEE Trans. Ind. Electron. 2023, 70, 10409–10419. [Google Scholar] [CrossRef]

- Widmer, J.D.; Spargo, C.M.; Atkinson, G.J.; Mecrow, B.C. Solar Plane Propulsion Motors With Precompressed Aluminum Stator Windings. IEEE Trans. Energy Convers. 2014, 29, 681–688. [Google Scholar] [CrossRef]

- Widmer, J.D.; Martin, R.; Mecrow, B.C. Precompressed and Stranded Aluminum Motor Windings for Traction Motors. IEEE Trans. Ind. Appl. 2016, 52, 2215–2223. [Google Scholar] [CrossRef]

- Yamada, Y.; Sugimoto, H.; Imae, K. Design of High Slot Fill Aluminum Winding in a Permanent Magnet Synchronous Machine With Reduced Winding Loss. IEEE Trans. Ind. Appl. 2023, 59, 1437–1445. [Google Scholar] [CrossRef]

- Ishikawa, T.; Sato, Y.; Kurita, N. Performance of Novel Permanent Magnet Synchronous Machines Made of Soft Magnetic Composite Core. IEEE Trans. Magn. 2014, 50, 8105304. [Google Scholar] [CrossRef]

- Guo, Y.; Ba, X.; Liu, L.; Lu, H.; Lei, G.; Yin, W.; Zhu, J. A Review of Electric Motors with Soft Magnetic Composite Cores for Electric Drives. Energies 2023, 16, 2053. [Google Scholar] [CrossRef]

- Du, W.; Zhao, S.; Zhang, H.; Zhang, M.; Gao, J. A Novel Claw Pole Motor With Soft Magnetic Composites. IEEE Trans. Magn. 2021, 57, 8200904. [Google Scholar] [CrossRef]

- Guo, Y.; Zhu, J.G.; Watterson, P.A.; Wu, W. Development of a PM transverse flux motor with soft magnetic composite core. IEEE Trans. Energy Convers. 2006, 21, 426–434. [Google Scholar] [CrossRef]

- Liu, C.C.; Wang, D.Y.; Wang, S.P.; Wang, Y.H. A Novel Flux Reversal Claw Pole Machine with Soft Magnetic Composite Cores. IEEE Trans. Appl. Supercond. 2020, 30, 5202905. [Google Scholar] [CrossRef]

- Liu, C.; Chao, Z.; Wang, S.; Wang, Y.; Lei, G.; Guo, Y.; Zhu, J. Design and Performance Analysis of Permanent Magnet Claw Pole Machine with Hybrid Cores. CES Trans. Electr. Mach. Syst. 2023, 7, 275–283. [Google Scholar] [CrossRef]

- Biasion, M.; Fernandes, J.F.; Vaschetto, S.; Cavagnino, A.; Tenconi, A. Superconductivity and its Application in the Field of Electrical Machines. In Proceedings of the 2021 IEEE International Electric Machines & Drives Conference (IEMDC), Hartford, CT, USA, 17–20 May 2021. [Google Scholar]

- Chow, C.C.; Ainslie, M.D.; Chau, K. High temperature superconducting rotating electrical machines: An overview. Energy Rep. 2023, 9, 1124–1156. [Google Scholar] [CrossRef]

- Terao, Y.; Seta, A.; Ohsaki, H.; Oyori, H.; Morioka, N. Lightweight design of fully superconducting motors for electrical aircraft propulsion systems. IEEE Trans. Appl. Supercond. 2019, 29, 5202305. [Google Scholar] [CrossRef]

- Saeidabadi, S.; Parsa, L.; Corzine, K.; Kovacs, C.; Haugan, T.J. A Double Rotor Flux Switching Machine With HTS Field Coils for All Electric Aircraft Applications. IEEE Trans. Appl. Supercond. 2023, 33, 5203107. [Google Scholar] [CrossRef]

- Komiya, M.; Aikawa, T.; Sasa, H.; Miura, S.; Iwakuma, M.; Yoshida, T.; Sasayama, T.; Tomioka, A.; Konno, M.; Izumi, T. Design study of 10 MW REBCO fully superconducting synchronous generator for electric aircraft. IEEE Trans. Appl. Supercond. 2019, 29, 5204306. [Google Scholar] [CrossRef]

- Sun, Y.; Liu, Y.; Pancheri, F.; Larg, T.L. LARG: A Lightweight Robotic Gripper with 3-D Topology Optimized Adaptive Fingers. IEEE/ASME Trans. Mechatron. 2022, 27, 2026–2034. [Google Scholar] [CrossRef]

- Hayes, A.C.; Träff, E.A.; Sørensen, C.V.; Willems, S.V.; Aage, N.; Sigmund, O.; Whiting, G.L. Topology optimization for structural mass reduction of direct drive electric machines. Sustain. Energy Technol. Assess. 2023, 57, 103254. [Google Scholar] [CrossRef]

- Lee, D.; Balachandran, T.; Sirimanna, S.; Salk, N.; Yoon, A.; Xiao, P.; Macks, J.; Yu, Y.; Lin, S.; Schuh, J.; et al. Detailed Design and Prototyping of a High Power Density Slotless PMSM. IEEE Trans. Ind. Appl. 2023, 59, 1719–1727. [Google Scholar] [CrossRef]

- Habib, A.; Mohd Zainuri, M.A.A.; Che, H.S.; Ibrahim, A.A.; Rahim, N.A.; Alaas, Z.M.; Ahmed, M.M.R. A systematic review on current research and developments on coreless axial-flux permanent-magnet machines. IET Electr. Power Appl. 2022, 16, 1095–1116. [Google Scholar] [CrossRef]

- Bolam, R.C.; Vagapov, Y.; Anuchin, A. A Review of Electrical Motor Topologies for Aircraft Propulsion. In Proceedings of the 2020 55th International Universities Power Engineering Conference (UPEC), Turin, Italy, 1–4 September 2020. [Google Scholar]

- Islam, M.S.; Mikail, R.; Husain, I. Slotless lightweight motor for aerial applications. IEEE Trans. Ind. Appl. 2019, 55, 5789–5799. [Google Scholar] [CrossRef]

- Si, J.; Zhang, T.; Hu, Y.; Gan, C.; Li, Y. An axial-flux dual-rotor slotless permanent magnet motor with novel equidirectional toroidal winding. IEEE Trans. Energy Convers. 2021, 37, 1752–1763. [Google Scholar] [CrossRef]

- Mikkelsen, E.K.; Matveev, A.; Nøland, J.K. High-Speed MW-Class Generator with Multi-Lane Slotless Winding for Hybrid-Electric Aircraft. IEEE Access 2023, 11, 84759–84771. [Google Scholar] [CrossRef]

- Tymosch, T.; Fischer, M.; Ketchedjian, V.; Terao, Y.; Ohsaki, H. Analysis of superconducting synchronous motors with Halbach array field excitation. IEEE Trans. Appl. Supercond. 2020, 31, 5200205. [Google Scholar] [CrossRef]

- Zhang, B.; Seidler, T.; Dierken, R.; Doppelbauer, M. Development of a yokeless and segmented armature axial flux machine. IEEE Trans. Ind. Electron. 2015, 63, 2062–2071. [Google Scholar] [CrossRef]

- Besong, J.E.; Fujimoto, Y. Design of a Coreless Multi-Phase Electric Motor Using Magnetic Resonant Coupling. IEEE Trans. Magn. 2022, 58, 8206611. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, C.; Geng, W. Design and optimization of Halbach-array PM rotor for high-speed axial-flux permanent magnet machine with ironless stator. IEEE Trans. Ind. Electron. 2019, 67, 7269–7279. [Google Scholar] [CrossRef]

- Rallabandi, V.; Taran, N.; Ionel, D.M.; Eastham, J.F. Coreless multidisc axial flux PM machine with carbon nanotube windings. IEEE Trans. Magn. 2017, 53, 8102904. [Google Scholar] [CrossRef]

- Mueller, M.; McDonald, A.; Macpherson, D. Structural analysis of low-speed axial-flux permanent-magnet machines. IEEE Proc.-Electr. Power Appl. 2005, 152, 1417–1426. [Google Scholar] [CrossRef]

- Subotic, I.; Gammeter, C.; Tüysüz, A.; Kolar, J.W. Weight optimization of an axial-flux PM machine for airborne wind turbines. In Proceedings of the 2016 IEEE International Conference on Power Electronics, Drives and Energy Systems (PEDES), Trivandrum, India, 14–17 December 2016. [Google Scholar]

- Neelakandan, V.; Ganesan, T.; Rao, P.C. Weight optimization of housing bracket for electrical starter motor using fea. Procedia Struct. Integr. 2019, 14, 345–353. [Google Scholar] [CrossRef]

- Wrobel, R.; Mecrow, B. A Comprehensive Review of Additive Manufacturing in Construction of Electrical Machines. IEEE Trans. Energy Convers. 2020, 35, 1054–1064. [Google Scholar] [CrossRef]

- Ghahfarokhi, P.S.; Podgornovs, A.; Kallaste, A.; Cardoso, A.J.M.; Belahcen, A.; Vaimann, T.; Tiismus, H.; Asad, B. Opportunities and Challenges of Utilizing Additive Manufacturing Approaches in Thermal Management of Electrical Machines. IEEE Access 2021, 9, 36368–36381. [Google Scholar] [CrossRef]

- Selema, A.; Van Den Abbeele, J.; Ibrahim, M.N.; Sergeant, P. Innovative 3D Printed Coil and Cooling Designs for Weight-Sensitive Energy-Saving Electrical Machine. IEEE Trans. Transp. Electrif. 2023, 1. [Google Scholar] [CrossRef]

- Simpson, N.; Yiannakou, G.; Felton, H.; Robinson, J.; Arjunan, A.; Mellor, P.H. Direct Thermal Management of Windings Enabled by Additive Manufacturing. IEEE Trans. Ind. Appl. 2023, 59, 1319–1327. [Google Scholar] [CrossRef]

- Wu, F.; Refaie, A.M.E.; Al-Qarni, A. Additively Manufactured Hollow Conductors Integrated with Heat Pipes: Design Tradeoffs and Hardware Demonstration. IEEE Trans. Ind. Appl. 2021, 57, 3632–3642. [Google Scholar] [CrossRef]

- Bieber, M.; Haase, M.; Tasche, F.; Zibart, A.; Ponick, B. Additively manufactured air-cooled lightweight rotor for an automotive electric motor. In Proceedings of the 2023 IEEE International Electric Machines & Drives Conference (IEMDC), San Francisco, CA, USA, 15–18 May 2023. [Google Scholar]

- Urbanek, S.; Frey, P.; Magerkohl, S.; Zimmer, D.; Tasche, L.; Schaper, M.; Ponick, B. Design and Experimental Investigation of an Additively Manufactured PMSM Rotor. In Proceedings of the 2021 IEEE International Electric Machines & Drives Conference (IEMDC), Hartford, CT, USA, 17–20 May 2021. [Google Scholar]

- Nishanth, F.; Goodall, A.D.; Todd, I.; Severson, E.L. Characterization of an Axial Flux Machine with an Additively Manufactured Stator. IEEE Trans. Energy Convers. 2023, 38, 2717–2729. [Google Scholar] [CrossRef]

- Sixel, W.; Liu, M.; Nellis, G.; Sarlioglu, B. Ceramic 3-D Printed Direct Winding Heat Exchangers for Thermal Management of Concentrated Winding Electric Machines. IEEE Trans. Ind. Appl. 2021, 57, 5829–5840. [Google Scholar] [CrossRef]

- Wrobel, R.; Hussein, A. A Feasibility Study of Additively Manufactured Heat Guides for Enhanced Heat Transfer in Electrical Machines. IEEE Trans. Ind. Appl. 2020, 56, 205–215. [Google Scholar] [CrossRef]

- Wang, Z.; Huang, X. Design and Preliminary Optimization of a Heat Exchanger Formed by Additive Manufacturing for Outer-Rotor PMSM. IEEE Trans. Energy Convers. 2023, 1–10. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Belahcen, A.; Rassõlkin, A.; Vaimann, T. Challenges of Additive Manufacturing of Electrical Machines. In Proceedings of the 2019 IEEE 12th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives (SDEMPED), Toulouse, France, 27–30 August 2019. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).