1. Introduction

Modern tall buildings are required to have elevators. In skyscrapers, the ratio of the elevator hoistway to the entire floor area might reach 30% for traditional elevators propelled by rotary traction machines, which is obviously not cost-effective. Additionally, in order to ensure safety, the steel cable’s mass must be quite great in high buildings, which increases the power of the traction machine. The vertical vibration of the cable will also cause control problems. The ropeless elevator propelled by linear motors has been proposed to counter these problems [

1,

2].

Similar to rotary machines (RMs), linear machines (LMs) are electromechanical devices that convert electrical energy into mechanical energy and vice versa. LMs and RMs are highly similar in terms of construction [

3,

4,

5]. With their numerous applications ranging from household to industrial, linear machines are in strong demand [

6]. Because linear machines generate force along the x-axis with greater efficiency, reliability, and minimal energy consumption, they are preferable to rotary machines [

7].

The linear induction machine (LIM) is a commonly used linear machine with a passive and simple stator structure [

8]. However, because of the eddy effect, a poor power factor and efficiency are two of the definite disadvantages of LIM [

9]. The advancement of permanent magnet (PM) materials and electronic power technologies has accelerated the development of permanent magnet linear motors [

10,

11]. Numerous PM linear machines in linear direct-drive systems have been established to meet the demand for the capability of high thrust force [

12]. Linear permanent magnet machines have outstanding Electromagnetic performance, i.e., high efficiency and high thrust density [

13]. Tubular permanent magnet linear machines can deliver high thrust density, but, due to the armature and PM, the mass increases, making the motor’s shaft likely to bend [

14]. There are many different kinds of linear motors available these days, but the synchronous linear permanent magnet motor (SLPMM) is among the most popular motors because of its greater thrust force density and high acceleration properties [

15,

16,

17,

18].

Flux-switching linear permanent magnet machines synthesize the characteristics of synchronous linear permanent magnet machines (SLPMMs) and linear switched reluctance machines (LSRMs). The high power density and robust stator of the flux-switching linear permanent magnet machine make it an excellent candidate for high-speed applications [

19,

20]. Moreover, greater temperature regulation reduces the cost of production [

21], which will make it resilient to challenging climatic conditions [

22]. The flux switching permanent magnet linear motor (FSPMLM) is regarded as a revolution in the motor industry. Researchers are taking great interest and attention in FSPMLM due to its robust and vigorous stator structure, bipolar linkage of flux, high power density, and greater thrust force density [

23,

24].

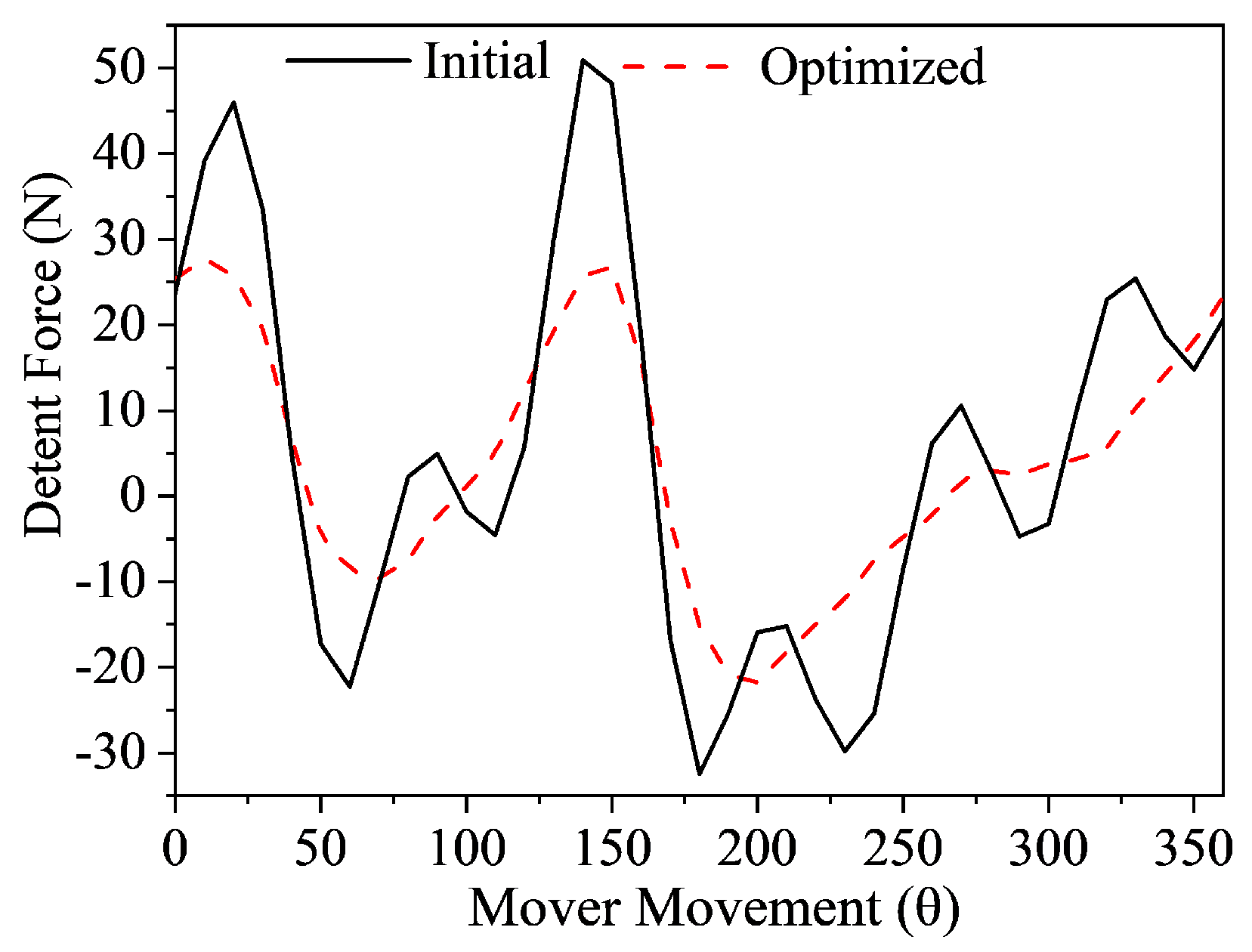

In [

13], a new FSPMLM was proposed with PMs and armature housed on the mover. The PMs were placed between the two U-shaped cores, which helps in balancing the magnetic circuit. However, the PMs are exposed to air which accounts for flux leakage, and the modular shape is a mechanically weak structure. Another modular double mover topology with a yokeless stator was proposed in [

25], having the advantage of high thrust force density. Again, apart from the modular structure, the proposed design suffered from high detent force and thrust force ripples. In [

26], the two PMs are connected with opposite polarity, sandwiching laminated steel between them. Constructing a mover pole was proposed, and the proposed design had high thrust force density; to minimize the detent force, a staggered stator and end PMs were used. However, the design used an enormous amount of PMs, and the overall structure was complex, making the machine’s manufacturing cost high.

In [

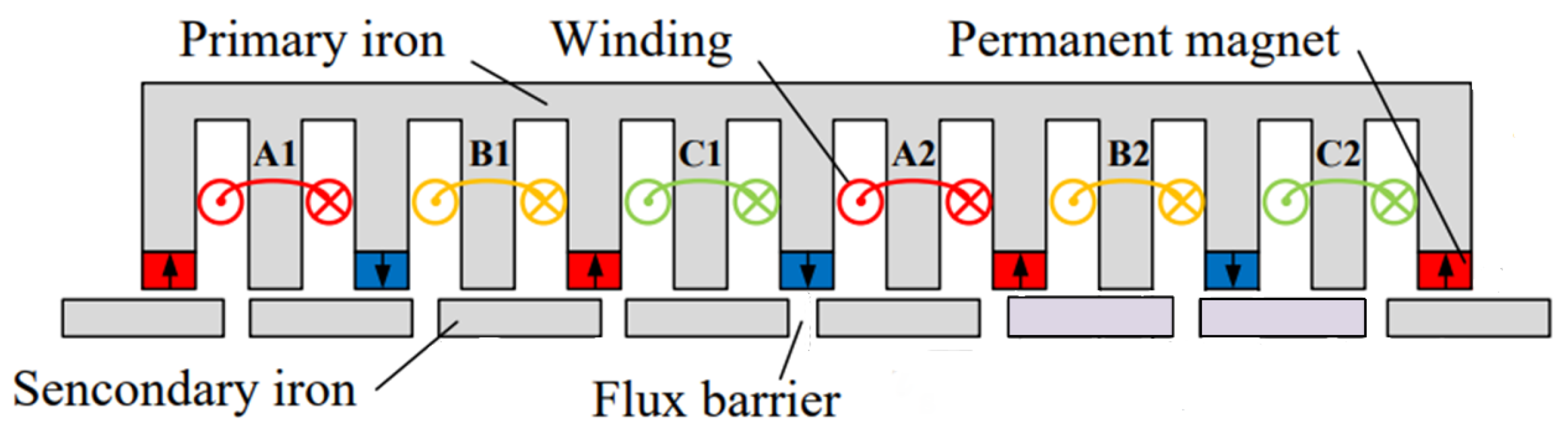

27], an FSPMLM was presented as shown in

Figure 1. Single-layer fractional-slot concentrated windings were implemented on the mover. The iron core teeth were categorized into two kinds: long teeth and short teeth. The windings were placed on the long teeth, while the PMs were housed on the short teeth. This arrangement resulted in a bipolar linkage flux, but the PMs were placed on the tip, which becomes a relatively weak mechanical structure, and there is a chance of falling off at high speeds. Based on the FSPMLM, a new topology is presented in this paper and is shown in

Figure 2. In the proposed topology, the PMs are shifted and sandwiched between stator pieces. This helps in the separation of the armature winding from the PMs; also, the usage of iron in the stator part is reduced, which, in turn, minimizes iron losses and hence improves efficiency.

The rest of the sections in the paper are ordered as follows: the topology of the machine and operational principle are covered in

Section 2. Furthermore, the FSPML machines with various winding configurations are analyzed and compared. The genetic optimization is covered in

Section 3. The electromagnetic performance analysis is overviewed in

Section 4. Suppression of unbalanced flux linkage is presented in

Section 5. The comparison with regular design is focused on in

Section 6.

Section 7 is dedicated to conclusions.

3. Genetic Optimization

Today’s genetic algorithms comprise the effective global optimization methods family used to solve the complex real-life problems that ascend in science and technology. They can investigate enormous data sets despite their computational complexity. In order to solve optimization-related issues, this procedure is frequently implemented in order to produce valuable solutions. Genetic optimization is independent of the starting point of the search; thus, it is least likely to become stuck in local minima. It also requires no trivial knowledge of the objective function or constraint function.

JMAG software has in-built multiobjective genetic optimization (GO), and the proposed design employed GO to enhance the foremost CAD variables of the proposed machine. The complete GO flowchart is illustrated in

Figure 6. Improving the average thrust force (

) and reducing thrust force ripples (

) were the primary goals of this optimization.

In Equations (

1) and (

2), the objective function and constraints of this GO are expressed correspondingly. The primary objective of employing this genetic algorithm is to maximize the

but minimize the

. The initial design is created in the geometry editor and then brought into the designer window. In

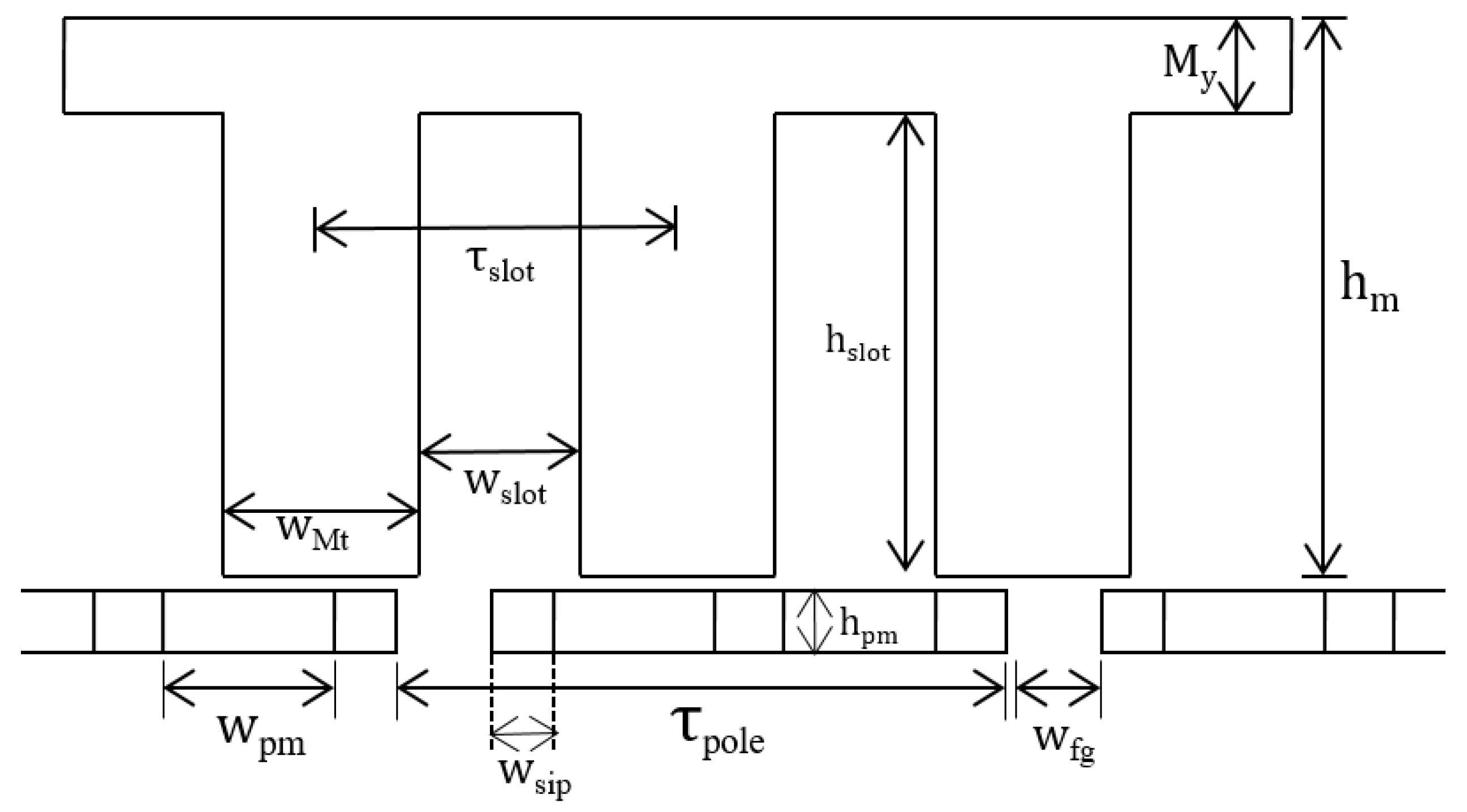

Table 2, the ranges of the geometry parameters, selected for optimization, are listed. Afterward, the simulation of a total of 438 cases was conducted across several generations; the number of children, the population size, and the genetic optimization converged to achieve a global value of the objective function and an optimized structure of the proposed design. The genetic optimization was performed on an HAIER-PC 64-bit operating system with 8 GB RAM, Intel(R), Core(TM) m3-7Y30 CPU running at 1.00 GHz and took 11 h and 20 min; it occupied 7.8 GBs space on the drive.

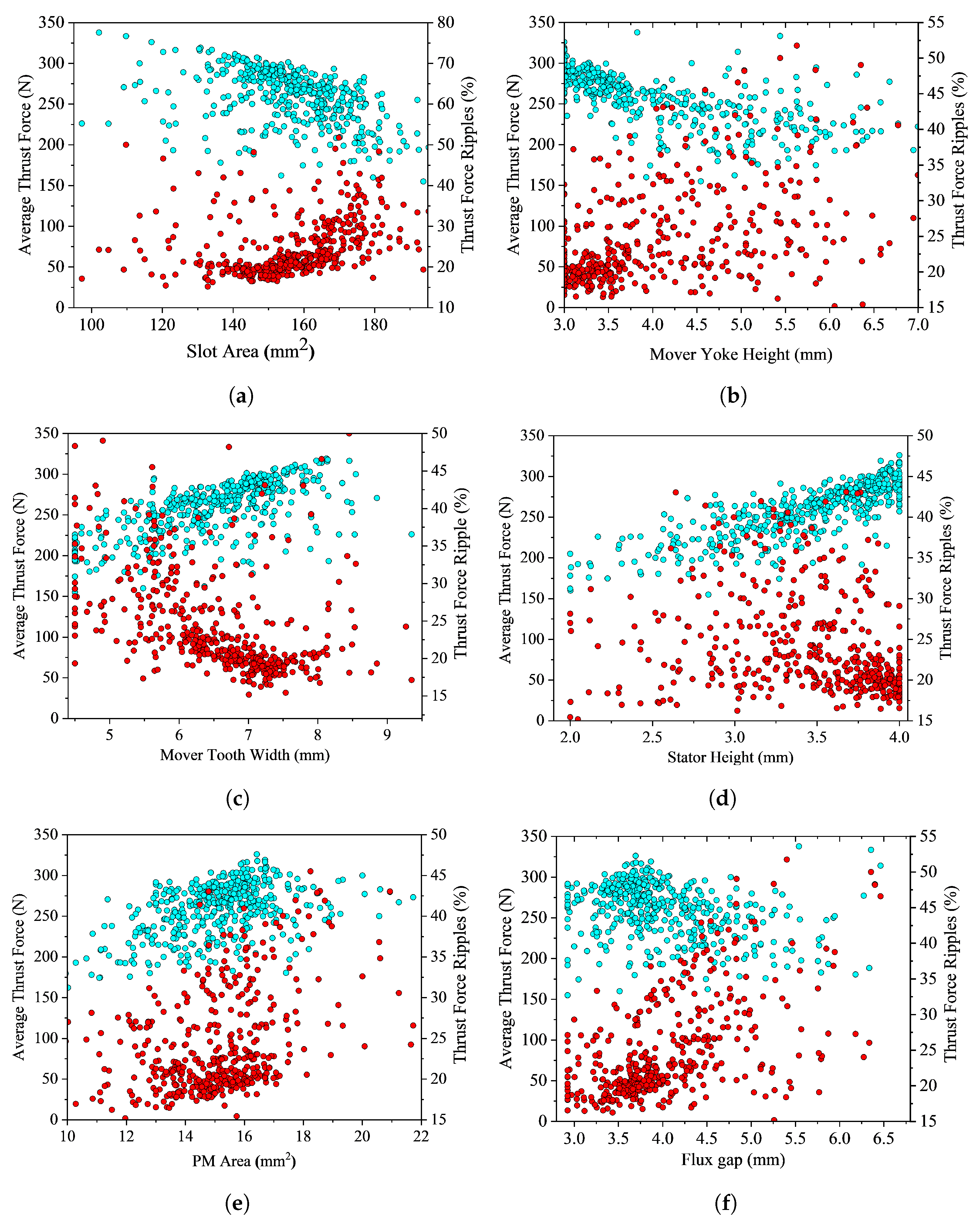

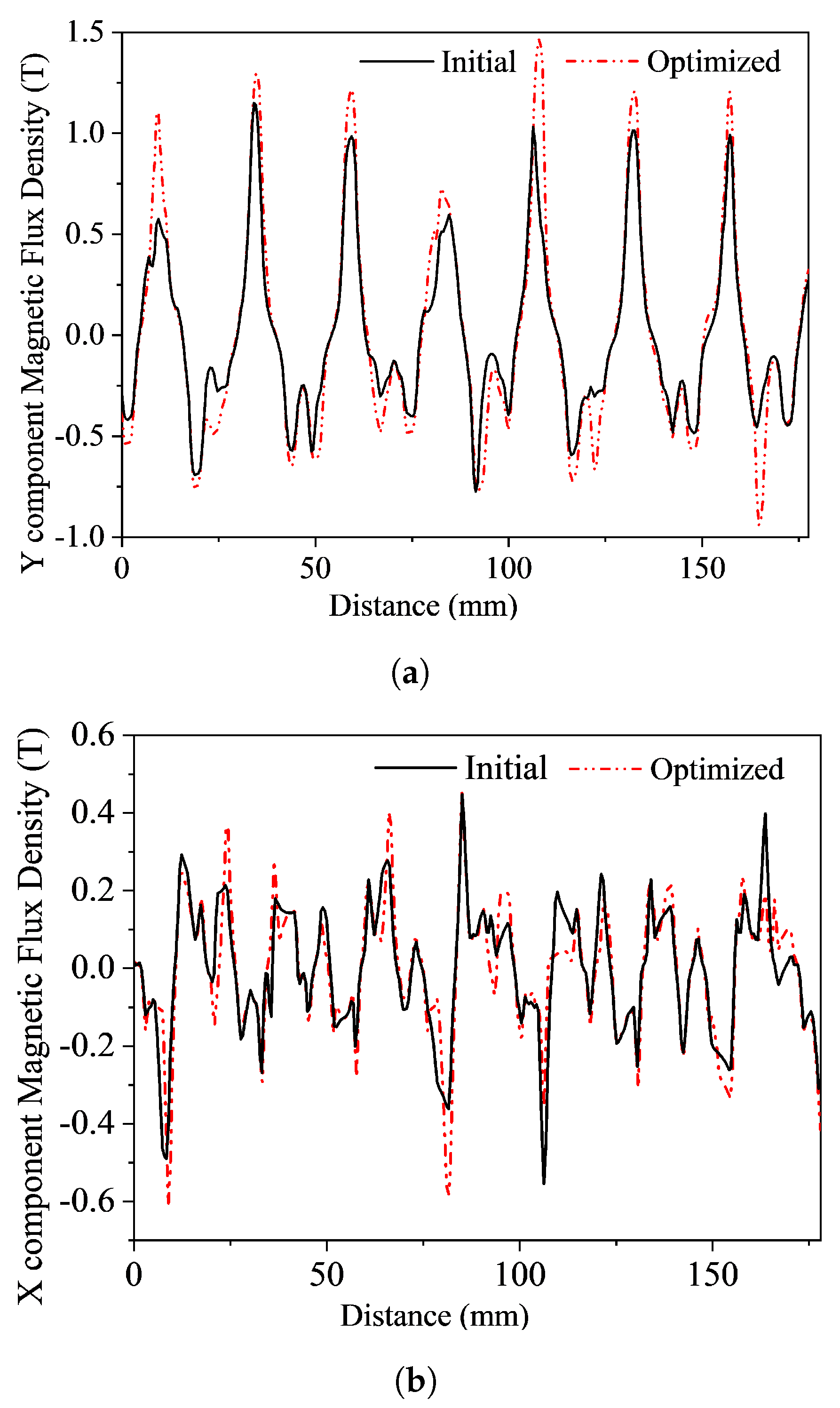

During the genetic optimization, the total number of cases simulated are plotted against the

and

in

Figure 7. The figure reveals that, after genetic optimization, a maximum thrust force value of 338.5N was obtained. The average thrust force and the thrust force ripples with respect to various geometry variables are shown in

Figure 8. A comparison of the performance after genetic optimization is provided in

Table 3.

6. Comparison with Traditional Design

Lastly, the proposed FSPMLM-PS is compared to the conventional design [

27]. The leading dimensions of both the topologies and the magnetic material type are kept the same. The results of the comparison are shown in

Table 5. The conventional and proposed designs use partitioned stators, keeping the current value, the volume of the PM, and the number of turns constant. The inset PM scheme opted for the proposed design while achieving a superior performance to that of the traditional design. Furthermore, the presented design reduced the stator’s volume, and this factor reduced the cost of the machine.

The proposed FSPMLM-PS is also compared with the surface-mounted PM linear motors proposed in the literature [

31]. In [

31], two motors are compared with surface-mounted PMs on a stator and another with a consequent pole stator structure and an inset PM in a mover yoke. The proposed and the conventional designs possess different dimensions; therefore, for a fair comparison, the machines are compared based on the thrust force per PM volume.

Table 6 reveals that the proposed machine uses less PM volume and offers a reasonable thrust force per PM volume compared to the conventional designs.