Abstract

In a large-scale operation, feed ores are introduced into the AG/SAG mill in a continuous mode at a given flow rate to replace the discharging slurry. Nonetheless, the variations in the feed characteristics, typically hardness and size distribution, could cause sudden disruption to the mill operation. This would be challenging to detect in practice, owing to the hostile environment of the mill. In this work, an acoustic sensing-based monitoring technique was utilized in a laboratory-scale AG/SAG mill locked-cycle study to keep track of fluctuations caused by feed ore heterogeneity. Analysis of the recorded mill acoustic response using statistical root mean square (RMS) and mill discharge sizes showed that the introduction of fresh feed with varying hardness and size distribution considerably altered the mill product undersize of −150 μm and acoustic emission. Overall, the acoustic sensing technique demonstrated that the AG/SAG mill stability as well as disturbances caused by different feed size fractions and hardness can be monitored using the mill acoustic response, an indication of real-time monitoring and optimisation.

1. Introduction

The application of autogenous/semi-autogenous (AG/SAG) mills is widespread in industrial mineral processing plants as first stage-grinding units for ore size reduction, mineral liberation purposes, and economic benefits [1,2,3]. These mills are used for grinding large quantities of ores of varying characteristics, which presents control challenges. Ore heterogeneity is an intrinsic and common characteristic of ore bodies. The variability of ore bodies spans from grade, mineralogy, hardness, and competence, as well as size distribution. Typically, the heterogeneity of ore bodies in terms of hardness and size distributions are well known to be sensitive and cause fluctuations or disturbances in AG/SAG grinding mills, significantly affecting the consistent processing behaviour of the feed ore inside the mill [1,4,5,6]. Accordingly, mill operators may lose control of the mill during the transient periods when there is a change in the feed ore characteristics [4], displaying notable effects in downstream processes (e.g., flotation and leaching) [3,7,8,9,10]. The traditional method that is usually deployed for controlling mill stability in real time has been load cells/bearing pressure and power monitoring information, but these lack specific details and are mostly poor indicators of the mechanism that causes fluctuations within the AG/SAG mill [6].

To provide more consistent feed processing characteristics and improve mill stability, pre-processing offline strategies are adopted prior to feeding the mill with ore charge. Knowledge of the ore hardness is usually determined using grindability test procedures, such as the Bond work index, SAG power index, SAG design test, and drop-weight test [11,12]. This is followed by the required feed ore size distributions, which are produced by the crushing and screening stages. Following that, knowledge and information about ore hardness and size distribution lead to proactive strategies such as blending to provide a more uniform ore charge and improve operational stability. However, in some situations where the feed ore is not well managed before grinding, it becomes practically challenging to monitor and adjust the optimum AG/SAG mill set points in real time (information delay), which undoubtedly creates a conundrum in terms of mill stability. Furthermore, the hostile environment of an AG/SAG mill limits the application of several sensor types (direct sensing elements) to the mill’s real-time monitoring and optimisation discourse [6]. Thus, it is critically important to investigate and provide a reliable, robust, and unsophisticated technique to support real-time AG/SAG mill monitoring of disturbances caused by ore hardness and size distribution (heterogeneity).

To investigate the real-time monitoring of feed ore hardness and size distribution, some attempts have been reported using vibro-acoustic signal information with promising results as a pathway for solving ore variability fluctuations [6,12,13,14,15,16,17,18,19,20,21,22]. Owusu et al. 2021 demonstrated the potential results of classifying two different rock hardnesses (model quartz and iron ore) in a laboratory ball-mill batch grind study using an acoustic sensing approach [12]. They reported different acoustic sensitivity of two rock grind characteristics, with high and low acoustic levels relating to model quartz and iron ore, respectively. Watson and Morrison [13] also studied the acoustic response of five minerals (coal, olivine, magnetite, dolomite and quartz) in a laboratory ball mill. They observed unique acoustic emissions for distinguishing the five minerals in the mill. In another study, Nayak, Das [14] reported that four different mineral ores can be classified based on their differential hardness in a laboratory mill by investigating their vibration signal signatures. Regarding feed size distribution, Das, Das [15] reported that a higher vibration signal was associated with coarser feed size relative to finer feed size distribution in a 1000 mm × 300 mm laboratory mill equipped with a piezoelectric-type tri-accelerometer. In an industrial SAG mill application, Pax and Cornish [6] investigated the effect of feed size distribution as a means of providing solutions to feed size disturbances using a 12-microphone array in the longitudinal centre position of the mill. However, most of these studies are limited to the batch mode of operation in laboratory-scale ball mills, owing to the economic sensitivity of an industrial scale of operation. Additionally, regarding ore heterogeneity, the impact of fluctuations is significant in AG/SAG mills where feed is introduced directly from crushers or stockpiles with varying size distribution coupled with different hardness. Since industrial grinding operations are also in a continuous mode, the batch mode of milling operation in the laboratory experiments does not considerably mimic the operation. Therefore, it would be more representative to study and monitor the effect of varying hardness and size distribution in a continuous mode.

To mimic an AG/SAG mill’s continuous mode of operations and demonstrate the disturbances caused by ore heterogeneity in a laboratory-scale AG/SAG mill set-up, the principle of locked-cycle (semi-batch) test procedures is employed to study plausible behaviour of grinding circuits under different operating conditions. Locked-cycle tests are commonly used to ascertain ore grindability for design and scaling-up purpose of industrial mills [23]. One of the best-known locked-cycle laboratory grinding studies is the Bond mill grindability test, which was first developed in 1952 (Bond) and modified in 1961 [24,25]. In summary, locked-cycle procedures involved feeding a fixed quantity of crushed ore into a tumbling mill (such as ball and rod mills) while keeping all other variables constant. The ground product is screened into oversized (coarse) and undersized (fine) fractions using a specified mesh screen. The oversize fraction is topped up with the fresh feed to maintain the initial weight of the ore charge before the start of the test. The grinding cycle is repeated multiple times until a steady state is reached, where the last three to four cycles of the undersized mass become nearly invariable. It should be pointed out that locked-cycle tests are laborious, time-demanding, and require a high degree of care and consistent procedures to attain a rapid steady state, reducing the number of cycles and accuracy [23].

This study aimed to determine how sensitive the mill acoustic response is to the abrupt changes in ore hardness and particle size distribution in locked-cycle grinding while monitoring the mass of the undersized target screen product. In addition, acoustic sensed data was collected during the grinding process using an acoustic sensing technique and correlated with the mass of the undersized product. This approach enables real-time monitoring of the charge dynamic in AG/SAG mill grind characteristics, which changes during the grinding operation. This study particularly addressed key problems, including: (1) What is the size distribution of oversized products in the final cycle? (2) What is the relationship between the acoustic emission response and undersized fractions (discharge) in a locked-cycle study? (3) Can a sudden change in feed ore heterogeneity (hardness and size distribution) cause fluctuations in AG/SAG mills? (4) Can a change in feed ore characteristics (hardness and size distribution) be detected by mill acoustic response after steady state? and (5) How sensitive is the change in feed ore type different from feed size distribution using acoustic emission response? The current study provides information on the locked-cycle experiments that is relevant in scaling up the acoustic sensing technology for large-scale operations.

2. Experimental Studies

2.1. Material and Feed Sample Preparation

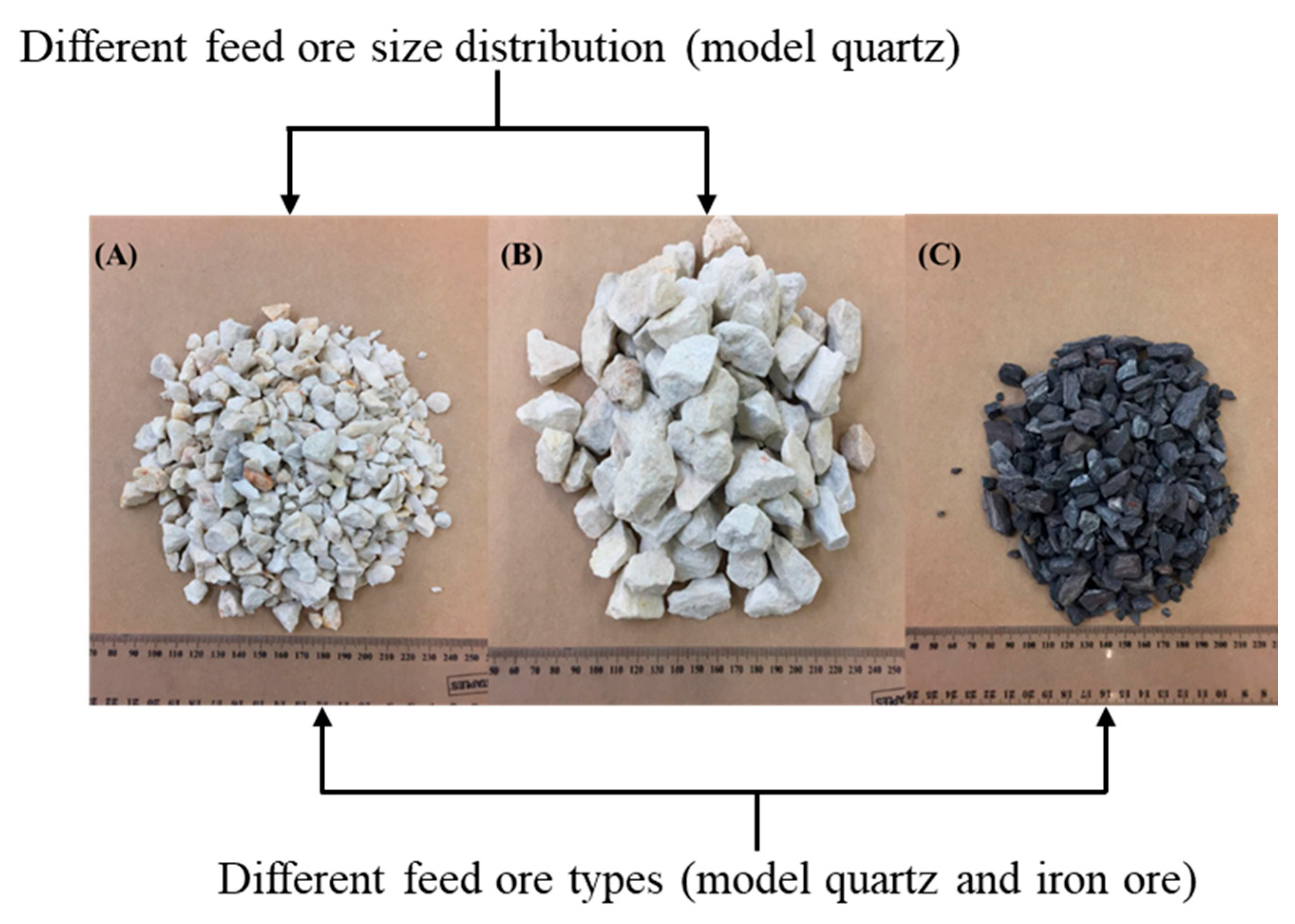

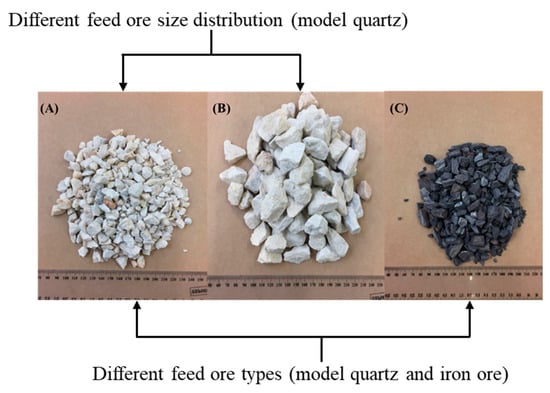

Model quartz mineral (99.99%) and iron ore (B) sourced from laboratory and mine sites, respectively, in South Australia were used for the study. The mill feed size distribution was prepared by crushing the model quartz with a laboratory jaw crusher and sized into −12.7 + 2 mm and −26.5 + 16 mm feed particle size fractions. The iron ore was also subjected to crushing and screened into −12.7 + 2 mm feed size distribution. The quartz feed size of −12.7 + 2 mm was used as a baseline for the locked-cycle study until equilibrium, before the different size fractions of −26.5 + 16 mm and iron ore (−12.7 + 2 mm) were added. Figure 1 depicts the different feed size fractions used in this experiment.

Figure 1.

Feed size distribution of (A) model quartz size fraction of −12.7 + 2 mm, (B) model quartz size fraction of −26.5 + 16 mm, and (C) iron ore size fraction of −12.7 + 2 mm.

2.2. Locked-Cycle Grinding Studies and Acoustics

A purpose-built laboratory-scale AG/SAG mill integrated with six equally spaced lifters was used for the grinding studies. Details and description of the laboratory-scale AG/SAG mill used for this research has been provided in our previous articles [26,27,28]. The acoustic sensor (AudioBox iOne, PreSonus, Baton Rouge, LA, USA) employed was placed close to the toe angle of the mill.

The locked-cycle wet grinding procedure was started by preparing 2 kg model quartz mineral feed (9.7 vol.%), 5 kg of different steel ball sizes (10.2 vol.% (small ball size, ~20 mm (22) and big ball size, ~40 (15)), and 860 mL of water. The mill was operated at 54 rpm, representing ~ 70% of the critical speed of the mill for 20 min. The 20 min grinding time was selected due to the significant fraction of undersize produced by the prescribed screen aperture size after testing at various times. After the first grinding cycle, the slurry charge was separated into undersized (−150 μm) and oversized (+150 μm) fractions. The wet filtered undersized and oversized samples were weighed separately and subsequently dried in an electric oven (50 °C). The weight of the dried undersized and oversized fractions was taken and the moisture content (wet fraction—dry fraction) was estimated from each fraction. The percentage moisture of undersize and oversize samples was estimated as ~23% and 6.5%, respectively. The percentage moisture content in the undersized and oversized samples was assumed to be constant throughout the entire study to maintain water balance as well as estimate the dry mass of the undersized sample. Fresh quartz mineral feed of equal mass was added to the oversized sample, making sure the volume of water was maintained at 70 vol.%, and the grinding was repeated multiple times until a steady state (negligible undersize mass variations) was achieved. The locked-cycle test procedure was carefully performed and repeated twice to confirm reproducibility.

To investigate the impact of feed ore heterogeneity (hardness and size distribution) on steady-state grinding operation, different feed size of quartz mineral (coarser than the initial feed size, −26 + 16 mm) was added as fresh feed to the oversized fraction and the grinding was carried out twice more. Similarly, a different ore type (iron ore) of the same size fraction (−12.7 + 2 mm) was added to the quartz mineral feed that was used to achieve equilibrium in the duplicate set of experiments. The grinding was continued for two additional cycles.

During the locked-cycle processes for the duplicate sets, an acoustic sensor was concurrently used to collect acoustic data in real time. The acoustic sensed data were recorded using the Audacity software programme installed on a laptop computer, with a sampling rate of 44.1 kHz, yielding a sum of 52,920,000 data points over 20 min of grinding time.

2.3. Acoustic Sensed Data Processing

The mill acoustic response data were initially subjected to two pre-processing stages: developing a filter to eliminate background noise (negligible noise free-environment) and pre- and post-signal edge cutting. The statistical root mean square (RMS) feature extraction was further used in the signal data analysis. In this study, the acoustic signal analysis was largely focused on the last minute, when the grinding was near completion. The last-minute acoustic signal relates to the nature of the mill product at the end of the grinding process. The acoustic response variation at the start (first minute) and end of the experiment was also compared.

3. Results and Discussion

3.1. Product Particle Mass and Size Distribution

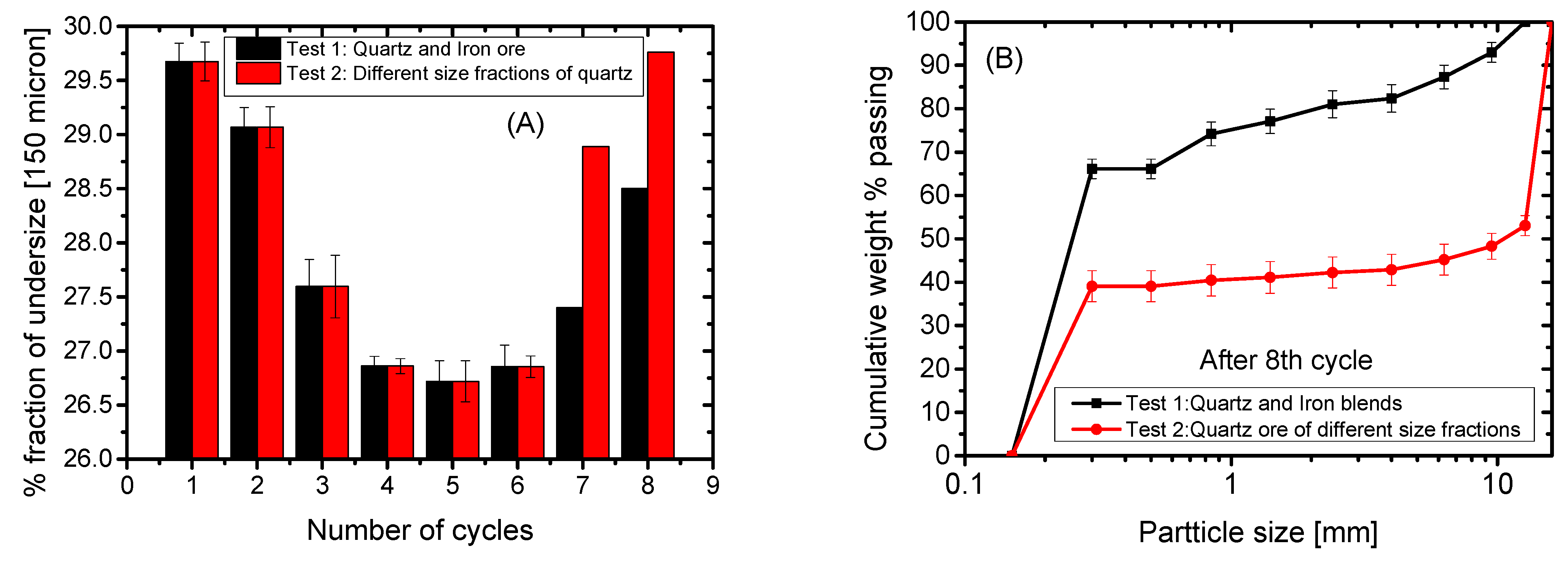

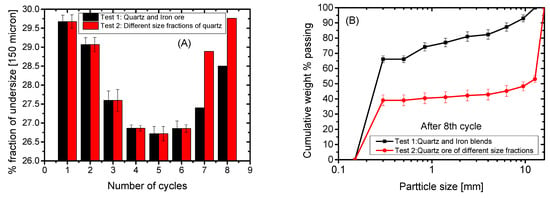

Figure 2 shows the grinding product after the locked-cycle grinding study. Cycles 1–6 in Figure 2A (Test 1 and Test 2) provide the baseline study with model quartz mineral of the same size distribution (−12.7 + 2 mm) to achieve the mill steady state in separate experiments. The results show that the mass of the undersized product using 150 μm mesh screen reduced significantly from cycle 1 to cycle 3. The following three cycles (cycles 4–6) produced similar mass fractions, an indication that the locked-cycle grinding had reached a quasi-steady state (steady state). The observed behaviour showed a decrease in degree of fine-particle production, aligning with the feed characteristics. The production of fine particles by abrasion and attrition, with links to the irregularly shaped feed particles (Figure 1) reduced with the grinding cycle. Additionally, fine particles associated with feed impact breakage in the mill reduced. This was ascribed to the cushioning effect of progeny particles produced by the earlier cycles. The results of the two separate tests were observed to show a marginal difference and a high level of accuracy. After the steady state had been maintained, Test 1 and Test 2 were continued by adding fresh feeds of coarser quartz minerals (−26.5 + 16 mm) and iron ore type (−12.7 + 2 mm), respectively, for two more cycles. Evidently, the equilibrium states of the two tests were significantly distorted by producing a higher fraction of the undersized mass. It was demonstrated that the addition of the iron ore type of the same-sized fraction similar to the start of the experiment produced a relatively lower undersized mass fraction than the quartz mineral of coarse size fractions (−26.5 + 16). This difference appears to suggest that in AG/SAG mill operation, coarser feed size distribution aided the production of finer product particle size than less coarse feed size.

Figure 2.

(A) Percentage of the product mass of each cycle, including the change in ore type and size distribution; (B) cumulative undersize particle distribution of the mill product (wt.%) after the 8th cycle of the two separate tests.

The cumulated product size distribution of the oversize (+150 μm) after the last (eighth) cycle of the two experiments is presented in Figure 2B. In the case where a different ore type was added from the seventh cycle until the eighth cycle (blend ratio of model quartz and iron), it was observed that significantly finer size distribution was produced relative to when the coarser quartz size fraction was introduced. In contrast to Figure 2A, where the coarser feed size fraction of the quartz mineral yielded more undersize (−150 μm), the oversize (+150 μm) fraction of the fresh feed (−26.5 + 16 mm) underwent little breakage rate and augmented the breakage of relatively finer particle sizes. This could also mean that the diameter of the mill (30 cm) did not provide enough collision energy to rapidly fragment specific coarse feed size ranges.

In general, it is suggested that abrupt changes in mill feed characteristics, such as hardness and size distribution, should not be overlooked, because they can impose considerable fluctuations and instability in AG/SAG mill performance. Identifying these disturbances will necessitate a proactive response or action to control and stabilise the mill operation.

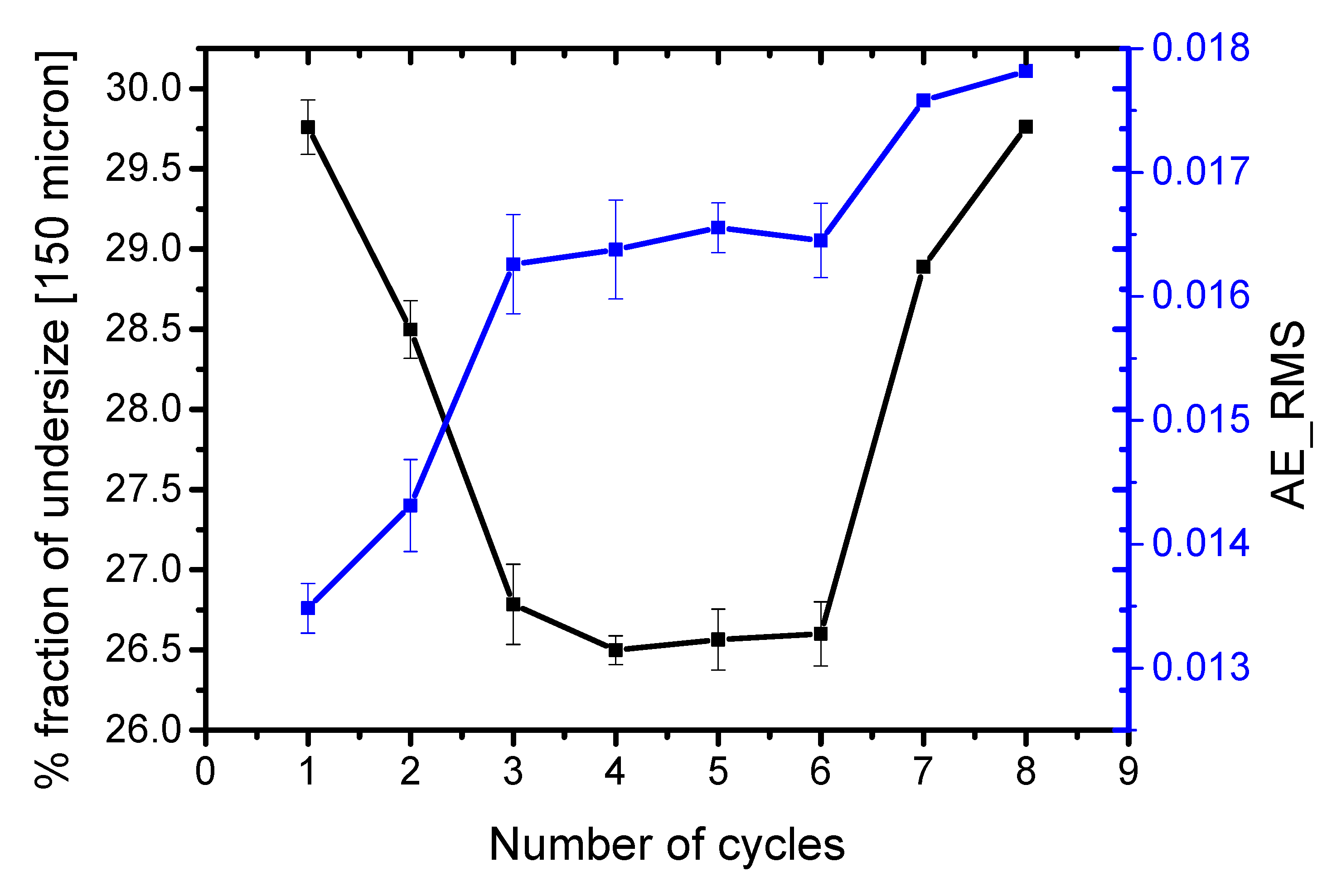

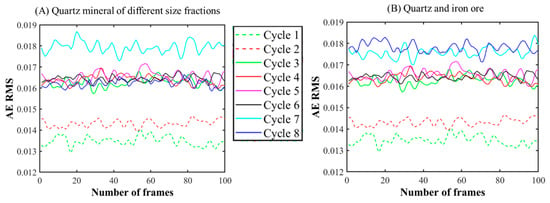

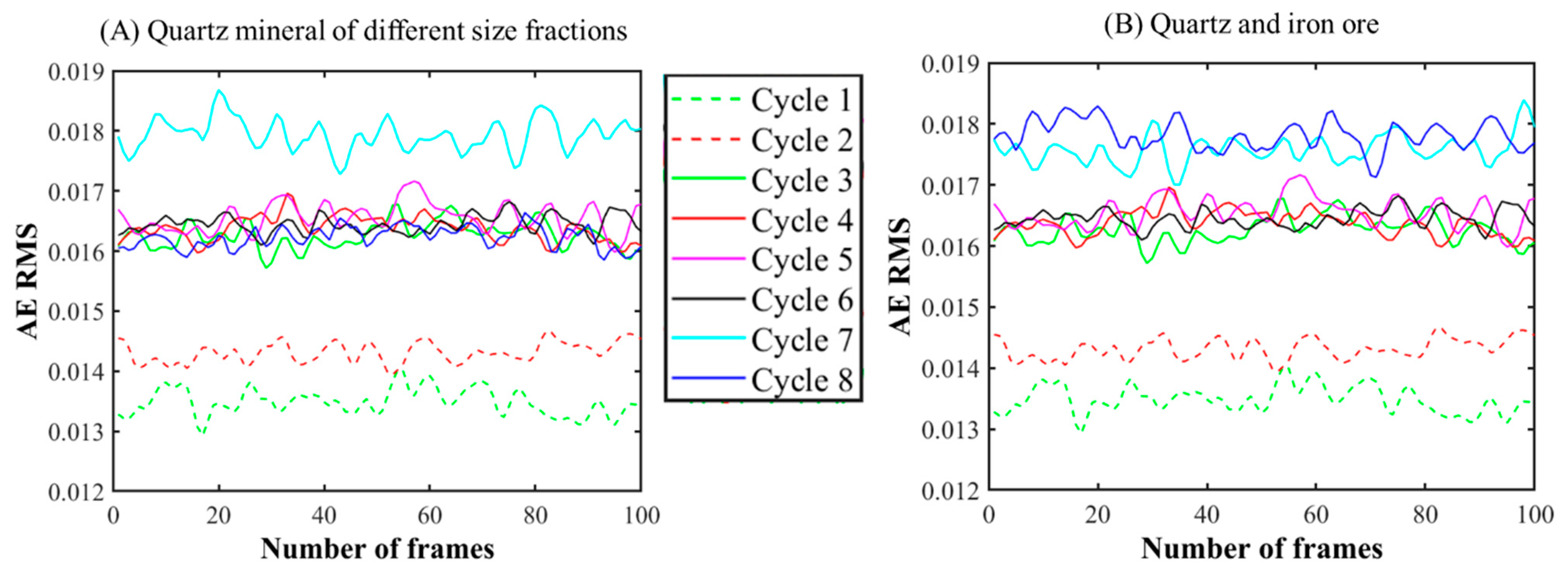

3.2. Frame-by-Frame Root Mean Square (RMS) Analysis of Mill Acoustics

To simplify the compacted acoustic emissions of the AG/SAG mill with a sampling frequency of 44.1 kHz characterised by random excessive spikes, the frame-by-frame RMS technique was applied to the last minute of acoustic data (2,646,000 data points) as illustrated in Figure 3A,B. The acoustic emissions of the first six cycles are similarly presented as baseline results in Figure 3A,B from a model quartz size distribution of −12.7 + 2 mm. The results of the acoustic levels of the initial six cycles saw a significant increase from cycle 1 to cycle 2 until closely related signals were identified in cycles 3 to 6, which reflected well the mass of the product undersize in Figure 2A. Our previous work [29] showed that a decrease in mill product particle size leads to an increase in the mill acoustic response, as also reflected in this study.

In cycles 7 and 8, where the top feed size was substituted with an entirely different coarser size fraction of model quartz (26.5 + 2 mm) and ore type (iron ore, −12.7 + 2 mm), differential acoustic intensities were noted. Regarding the addition of coarse feed size (Figure 3A), the mill noise increase at cycle 7 and dropped further at cycle 8. On the other hand, where iron ore was added, the mill noise at both the seventh and eighth cycles was considerable (Figure 3B).

Figure 3.

Frame-by-frame acoustic RMS analysis of model quartz mineral locked-cycle test: (A) model mineral of varying coarser size fraction and (B) different ore types (quartz and iron ore) in cycles 7 and 8.

Figure 3.

Frame-by-frame acoustic RMS analysis of model quartz mineral locked-cycle test: (A) model mineral of varying coarser size fraction and (B) different ore types (quartz and iron ore) in cycles 7 and 8.

3.3. Relationship between Locked Cycle and Acoustics

3.3.1. Effect of Feed Ore Types

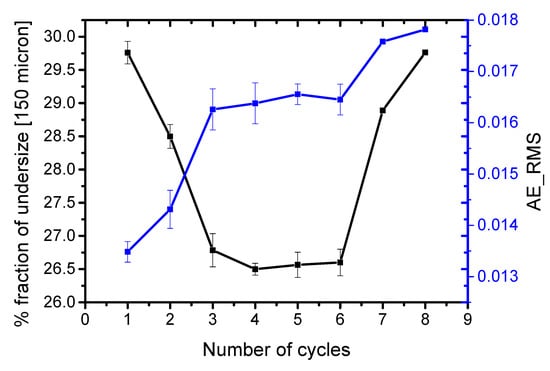

Figure 4 shows the relationship between locked-cycle study and acoustic emission response in a laboratory AG/SAG mill. The results inform the acoustic response sensitivity of the AG/SAG mill from the changing ore-type characteristics after the equilibrium state was attained. In the results, it can be seen that as the mass of the product undersize of the 150 μm mesh screen reduces significantly from cycles 1 to cycle 3, the mill acoustic emission also increases.

Figure 4.

The relationship between locked-cycle studies with changes in ore type and acoustic response in a laboratory-scale AG/SAG mill.

Following the quasi-steady state with a different ore type (−12.7 + 2 mm) being fed to the mill in cycles 7 and 8, a significant distortion in the undersized product fraction and mill acoustics was observed. Herein, the interaction of the two feed ores produced a spontaneous increase in the percentage fraction of the undersize coupled with mill acoustics. This could be explained that as the proportion of feed ore property changes (blend ratios), typically the hardness, it tends to alter the breakage dynamics, as demonstrated in laboratory-scale batch studies in the literature [12,30,31]. Thus, the mill’s acoustic level responds differently to changes in the feed ore type (different from the equilibrium stage), an indication of a change in the mill feed characteristics.

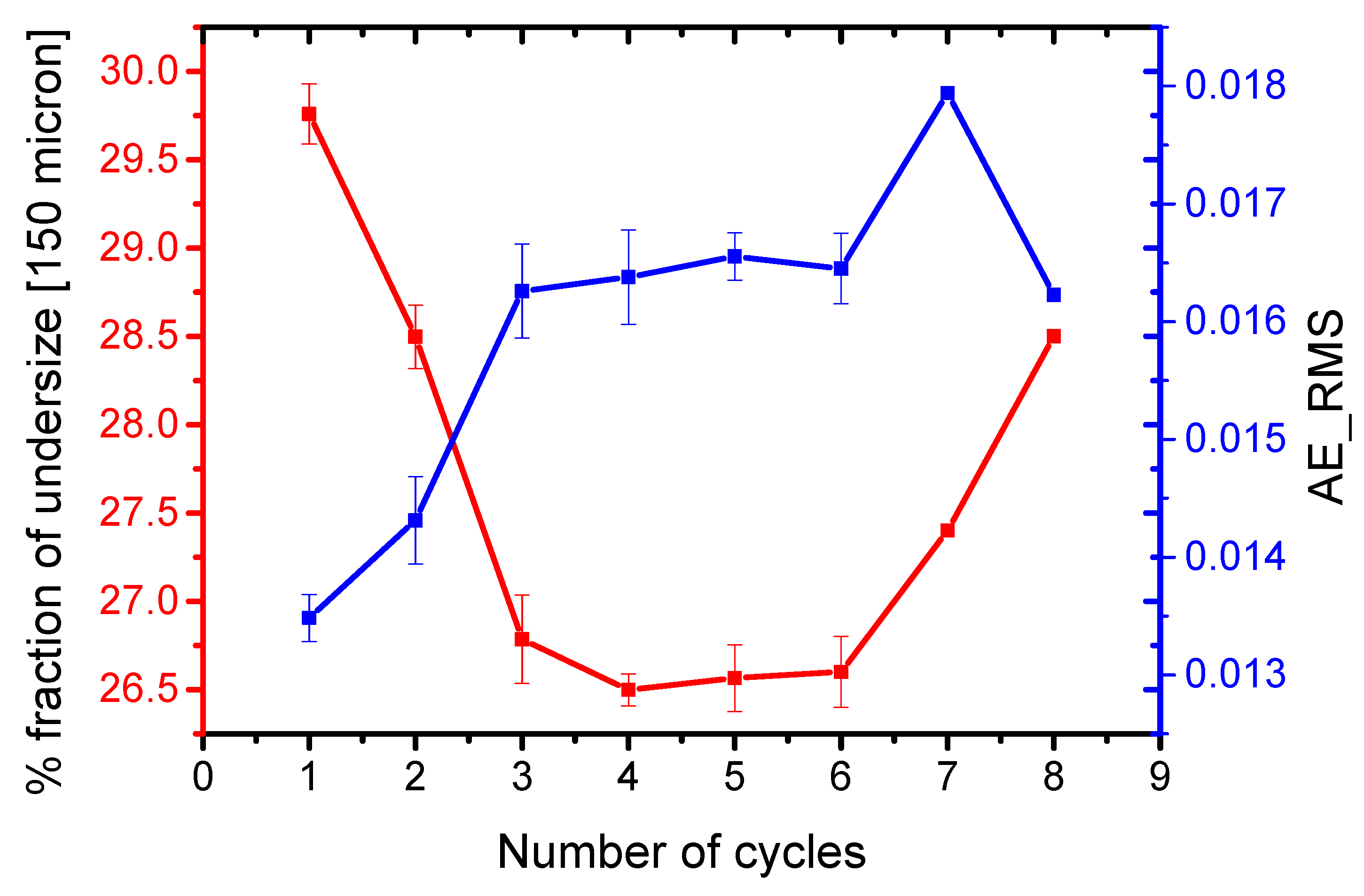

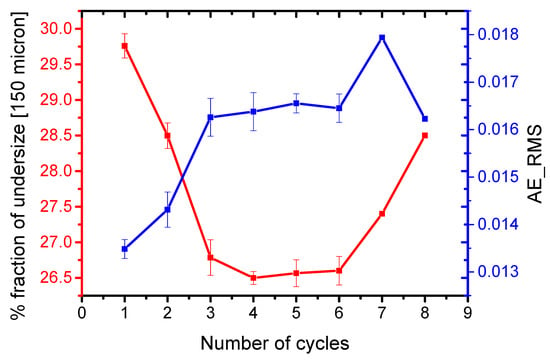

3.3.2. Effect of Feed Size Distribution

Similarly to Figure 5, changes in feed size (−26 + 16 mm) in the seventh and eighth cycles resulted in a continuous increase in undersized product with corresponding fluctuations in mill noise. When different feed size distribution was first added to the mill in cycle 7, the discharge product (−150 m) and emitted noise both increased. It can be noted that the coarser feed size supported and accelerated the breakage rate of finer size distribution. In the grinding process, the mill’s acoustic level increased, possibly as a result of the coarser feed size fraction that was added. However, the mill noise was reduced at the eighth cycle, when a coarser feed size distribution was further added, along with a further increase in finer particle size and less oversized breakage, as shown in Figure 2B. While this observation warrants additional studies to explicate the mill’s internal behaviour, it suggests that the coarser fresh feed size in cycle 8 reduced the impact of the falling balls and the acoustic emission dropped to the quasi-steady state level. At this stage, the trend of the mill’s acoustic emission in cycles 7 and 8 could suggest a high level of fluctuations, rather than approaching the quasi-steady state (in cycle 8). Near equilibrium can only be considered after less variation in the mill’s acoustic emission and undersized product mass, respectively, for multiple cycles, as demonstrated in cycles 3–6. Notably, the grinding equilibrium of the AG/SAG mill could be disturbed when the mill feed size distribution is altered, which is also sensitive to the mill’s acoustic response.

Figure 5.

The relationship between locked-cycle studies with changes in feed size fraction and acoustic response in a laboratory-scale AG/SAG mill.

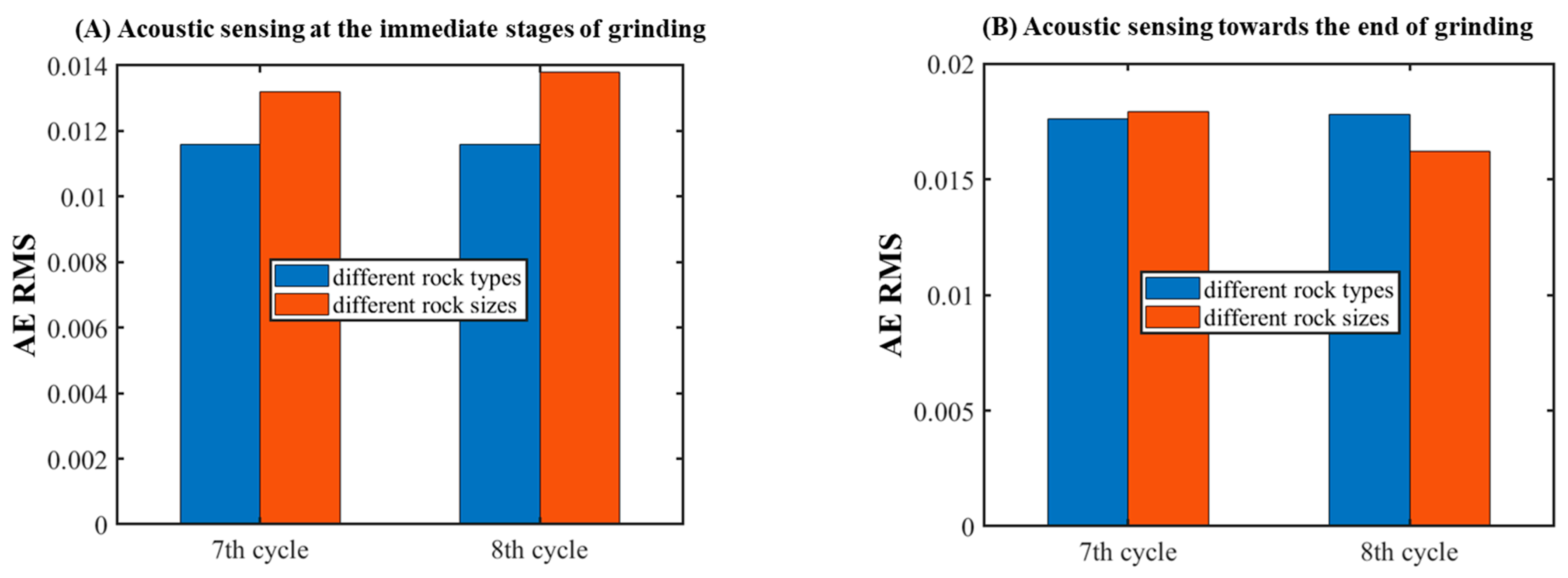

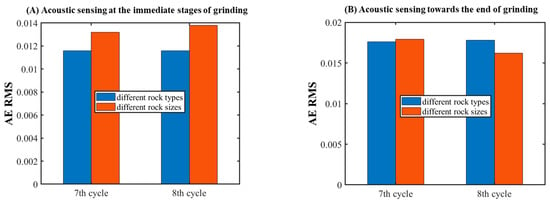

3.3.3. Acoustic Sensitivity between Different Ore Types and Size Distribution after Steady State

Figure 6 shows the differences in acoustic sensitivity between the tested feed size distribution and feed ore types addition in the seventh and eighth cycles. In Figure 6A, the emitted acoustics of the mill for a few seconds after the addition of the different feed size fractions and ore types are presented. The results show that coarse feed size distribution produced higher acoustic emissions than the ore-type size fraction. This demonstrated that the impact of coarser feed size contributes to emission of higher noise than different less coarse size fractions. As grinding proceeds to the end of the grinding time in the seventh and eighth cycles, a marginal acoustic difference existed between the ore type and the size distribution. This could suggest that as the particle size reduces with an increase in the number of particles, the differential acoustic emission of the test conditions is narrowed. The dampening effect of slurry conditions at that moment may behave similarly, producing the close level of noise emission. In the eighth cycle in Figure 6B, it was noted that the significantly higher acoustic response was related to the addition of different ore types, rather than different size distribution. This could be explained by the product size distribution of the oversize fractions presented by the blends of different ore types and varying coarser size ranges in Figure 2B, such that the relative coarser size fraction limited the acoustic blocking abilities of cataracting steel balls compared with the finer size distribution. From the results, it could be deduced that the immediate acoustic sensing of coarser size fractions is more sensitive than different ore types after steady state and vice versa at the end of the eighth cycle. The sensitivity of the tested condition became similar at the end of the seventh cycle. In general, the feed ore characteristics entering a primary mills such as the AG/SAG mill is sensitive to the acoustic response, as well as impacting the product quality. It is worth indicating that large-scale operations are complex, and hence large unique differences in the feed ore characteristics may be required at that level. This could be achieved using other acoustic signal processing techniques.

Figure 6.

Comparison of AG/SAG mill acoustic sensitivity between the tested feed size and ore type. (A) Acoustic sensing at the innediate stages of grinding; (B) Acoustic sensing towards the end of grinding.

4. Conclusions

In this study, acoustic emissions—which are monitored in real time—were used to understand the effect of different feed hardness and size distribution, as a means of tracking feed disturbances under semi-batch or locked-cycle experimental conditions using a laboratory-scale mill. The following key findings were deduced from the study.

- The mass of the mill product size passing 150 µm reduced with the increase in the grinding locked cycle to a limit where no further significant reduction in mass was observed. This represented the quasi-steady state, allowing monitoring of mill fluctuations with feed variations.

- The particle size distribution of the oversized product after the end of the experiments (eighth cycle) showed that poor particle size reduction occurred when the mill feed size was increased to −26.5 + 16 mm compared with addition of a different ore type (iron ore) with the same size range as the initial feed (−12.7 + 2 mm).

- The mill acoustic response of the initial six cycles saw a significant increase from cycle 1 to cycle 2 until closely related signals were identified in cycles 3 to 6, which reflected well the mass of the undersized product.

- Feed ore heterogeneity (hardness and size distribution) has been demonstrated to considerably cause fluctuations in AG/SAG mill under the locked-cycle experimental conditions. With the feed size ranges and ore types selected, the increase in the mill feed size to −26.5 + 16 mm produced higher mass of −150 µm product in the seventh and eighth cycles than the change in the ore type.

- Acoustic sensing can be used to track the fluctuations caused by feed ore heterogeneity in AG/SAG mill locked-cycle experiments and shows significant promise for large-scale operation real-time monitoring.

- During the seventh and eighth grinding cycles, different mill acoustic sensitivity behaviour was observed at the beginning and end of the grinding process, reflecting changes in the mill.

Author Contributions

Conceptualization, K.B.O., W.S., C.G. and R.K.A.; methodology, K.B.O., C.G. and R.K.A.; validation, K.B.O. and R.K.A.; formal analysis, K.B.O., W.S., C.G. and R.K.A.; investigation, K.B.O. and R.K.A.; resources, W.S., C.G. and R.K.A.; data curation, K.B.O.; writing—original draft preparation, K.B.O.; writing—review and editing, K.B.O., W.S., C.G. and R.K.A.; visualization, K.B.O., W.S., C.G. and R.K.A.; supervision, W.S., C.G. and R.K.A.; project administration, W.S., and R.K.A.; funding acquisition, W.S., C.G. and R.K.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research is funded by the SA Government through the PRIF RCP Industry Consortium.

Acknowledgments

This research has been supported by the SA Government through the PRIF RCP Industry Consortium. The authors also acknowledge the support from the Future Industries Institute (FII), University of South Australia, Australia. The support from the Australia-India Strategic Research Fund for Advanced Recovery of the Battery Materials and REE from Ores and Wastes is also acknowledged. Support from the Australian Research Council Centre of Excellence for Enabling Eco-Efficient Beneficiation of Minerals (grant number CE200100009) is gratefully acknowledged.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Morrell, S.; Valery, W. Influence of Feed Size on AG/SAG Mill Performance; SAG: Vancouver, BC, Canada, 2001; pp. 203–214. [Google Scholar]

- Asamoah, R.K.; Baawuah, E.; Greet, C.; Skinner, W. Characterisation of metal debris in grinding and flotation circuits. Miner. Eng. 2021, 171, 107074. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Butterworth-Heinemann: Oxford, UK, 2015; p. 512. [Google Scholar]

- Thornton, A.; Pethybridge, T.; Rivett, T.; Dunn, R. SAG Mill Control at Northparkes Mines (Not so Hard after All); MIPAC Report; MIPAC: Albion, QLD, Australia, 2005. [Google Scholar]

- Behnamfard, A.; Namaei Roudi, D.; Veglio, F. The performance improvement of a full-scale autogenous mill by setting the feed ore properties. J. Clean. Prod. 2020, 271, 122554. [Google Scholar] [CrossRef]

- Pax, R.A.; Cornish, B. Understanding Size Effects of Semi-autogenous Grinding (SAG) Mill Operation as a Pathway to Solving Feed Disturbances—Case Study Using the MMG Century SAG Mill. In Proceedings of the 13th AusIMM Mill Operators’ Conference 2016, Perth, WA, Australia, 10–12 October 2016; pp. 321–329. [Google Scholar]

- Forson, P.; Zanin, M.; Skinner, W.; Asamoah, R. Differential flotation of pyrite and Arsenopyrite: Effect of pulp aeration and the critical importance of collector concentration. Miner. Eng. 2022, 178, 107421. [Google Scholar] [CrossRef]

- Amankwaa-Kyeremeh, B.; Zhang, J.; Zanin, M.; Skinner, W.; Asamoah, R.K. Feature selection and Gaussian process prediction of rougher copper recovery. Miner. Eng. 2021, 170, 107041. [Google Scholar] [CrossRef]

- Asamoah, R.K.; Zanin, M.; Amankwah, R.K.; Skinner, W.; Addai-Mensah, J. Characterisation of Tectonic Refractory Gold Ore. In Proceedings of the CHEMECA 2014, Perth, WA, Australia, 28 September–1 October 2014. [Google Scholar]

- Asamoah, R.K.; Skinner, W.; Addai-Mensah, J. Alkaline cyanide leaching of refractory gold flotation concentrates and bio-oxidised products: The effect of process variables. Hydrometallurgy 2018, 179, 79–93. [Google Scholar] [CrossRef]

- Razani, M.; Masoumi, A.; Rezaeizadeh, M.; Noaparast, M. Evaluating the effect of feed particles size and their hardness on the particle size distribution of semi-autogenous (SAG) mill’s product. Part. Sci. Technol. 2018, 36, 867–872. [Google Scholar] [CrossRef]

- Owusu, K.B.; Karageorgos, J.; Greet, C.; Zanin, M.; Skinner, W.; Asamoah, R.K. Predicting mill feed grind characteristics through acoustic measurements. Miner. Eng. 2021, 171, 107099. [Google Scholar] [CrossRef]

- Watson, J.L.; Morrison, S.D. Indications of grinding mill operations by mill noise parameters. Part. Sci. Technol. 1985, 3, 49–63. [Google Scholar] [CrossRef]

- Nayak, D.K.; Das, D.; Behera, S.; Das, S. Wavelet-based Classification of Mineral Hardness by Vibration Signal Processing of a Ball Mill. In Proceedings of the International Conference on Recent Trends in Computational Engineering and Technologies (ICTRCET), Bangalore, India, 30–31 May 2018; pp. 744–749. [Google Scholar]

- Das, S.P.; Das, D.P.; Behera, S.K.; Mishra, B.K. Interpretation of mill vibration signal via wireless sensing. Miner. Eng. 2011, 24, 245–251. [Google Scholar] [CrossRef]

- Owusu, K.B.; Karageorgos, J.; Greet, C.; Zanin, M.; Skinner, W.; Asamoah, R.K. Acoustic Monitoring of Mill Pulp Density. In Proceedings of the UMaT Biennial International Mining and Mineral Conference, Tarkwa, Ghana, 2–3 August 2020; Ghana UMaT: Tarkwa, Ghana, 2020; pp. 359–365. [Google Scholar]

- Owusu, K.B.; Karageorgos, J.; Greet, C.; Zanin, M.; Skinner, W.; Asamoah, R.K. Variations in mill feed characteristics and acoustic emissions. In Proceedings of the UMaT Biennial International Mining and Mineral Conference, Tarkwa, Ghana, 2–3 August 2020; Ghana UMaT: Tarkwa, Ghana, 2020; pp. 384–390. [Google Scholar]

- Owusu, K.B.; Skinner, W.; Asamoah, R. Acoustic Sensor Frequencies and Mill Feed Properties—A Brief Review; Chemeca Virtual, S., Ed.; Australia Engineers Australia: Perth, Australia, 2021; pp. 187–201. [Google Scholar]

- Owusu, K.B.; Skinner, W.; Asamoah, R. Acoustic Sensing of Different Ore Hardness and Breakage Characteristics in Semi-Autogenous (SAG) Mill; Chemeca Virtual, S., Ed.; Australia Engineers Australia: Perth, Australia, 2021; pp. 202–214. [Google Scholar]

- Owusu, K.B.; Greet, C.; Skinner, W.; Asamoah, R. SAG Mill Acoustic Monitoring of Process Variables: Mill Speed, Pulp Solid Loading, and Rock Filling. In Proceedings of the International Conference on Mineral Processing and Geometallurgy, Online, 20–22 October 2021; Chile Gecamin: Santiago, Chile, 2021. [Google Scholar]

- Owusu, K.B.; Skinner, W.; Asamoah, R.K. Differentiation of AG/SAG Mill Feed Particle Size Variations in Bath Milling Process Using Acoustic Emissions. In Proceedings of the International Future Mining Conference, Online, 6–10 December 2021; Australasian Institute of Mining and Metallurgy: Carlton, Australia, 2021. [Google Scholar]

- Owusu, K.B.; Karageorgos, J.; Greet, C.; Zanin, M.; Skinner, W.; Asamoah, R. Non-Contact Acoustic and Vibration Sensors in Autogenous and Semi-Autogenous (AG/SAG) Mills: A Brief Review. In Proceedings of the S.A.O. International Mineral Processing Congress, Cape Town, South Africa, 18–22 April 2021; South Africa International Mineral Processing Congress: Cape Town, South Africa, 2021; pp. 3228–3240. [Google Scholar]

- Kapur, P.; Fuerstenau, D. Simulation of locked-cycle grinding tests using multicomponent feeds. Powder Technol. 1989, 58, 39–48. [Google Scholar] [CrossRef]

- Ahmadi, R.; Shahsavari, S. Procedure for determination of ball Bond work index in the commercial operations. Miner. Eng. 2009, 22, 104–106. [Google Scholar] [CrossRef]

- Napier-Munn, T.J.; Morrell, S.; Morrison, R.D.; Kojovic, T. Mineral Comminution Circuits: Their Operation and Optimisation; JKMRC Monograph Series in Mining and Mineral Processing; Julius Kruttschnitt Mineral Research Centre, University of Queensland: Brisbane, Australia, 1996; Volume 2, p. 413. [Google Scholar]

- Owusu, K.B.; Zanin, M.; Skinner, W.; Asamoah, R.K. AG/SAG mill acoustic emissions characterisation under different operating conditions. Miner. Eng. 2021, 171, 107098. [Google Scholar] [CrossRef]

- Owusu, K.B.; Greet, C.; Skinner, W.; Asamoah, R. Purpose-Built Laboratory-Based AG/SAG Mill Development. In Proceedings of the 17th International Conference on Mineral Processing and Geometallurgy, Online, 20–22 October 2021; Chile Gecamin: Santiago, Chile, 2021; pp. 1–10. [Google Scholar]

- Owusu, K.B.; Greet, C.; Skinner, W.; Asamoah, R.K. Influence of lifter height on mill acoustics and performance. In Proceedings of the International Future Mining Conference, Online, 6–8 December 2021; Australasian Institute of Mining and Metallurgy: Carlton, Australia, 2021; pp. 1–13. [Google Scholar]

- Owusu, K.B.; Skinner, W.; Asamoah, R. Feed hardness and acoustic emissions of autogenous/semi-autogenous (AG/SAG) mills. Miner. Eng. 2022, 187, 107781. [Google Scholar] [CrossRef]

- Zhao, R.; Han, Y.; He, M.; Li, Y. Grinding kinetics of quartz and chlorite in wet ball milling. Powder Technol. 2017, 305, 418–425. [Google Scholar] [CrossRef]

- Mkurazhizha, H. The effects of ore blending on comminution behaviour and product quality in a grinding circuit-Svappavaara (LKAB) Case Study. In Minerals and Metallurgical Engineering; Department of Civil, Environmental and Natural Resources Engineering, Luleå University of Technology: Luleå, Sweden, 2018; pp. 1–86. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).