4.2. Performance of DL Models

The results of the DNN model’s accuracy evaluation are shown in

Table 4. Among all the parameters, the temperature displayed the best level of accuracy. DNN-1’s forecast of the temperature after one minute had an SEP of 0.6% and an R

2 of 0.98. With SEPs of 3.04% and 3.45% and R

2 values of 0.96 and 0.81, the predictions for humidity and CO

2 were significantly less accurate. When the time period was five minutes, DNN achieved its highest performance, with R

2 values of 0.99, 0.95, and 0.97, and SEPs of 0.4, 3.65, and 1.08 for temperature, humidity, and CO

2 levels, respectively. Additionally, the DNN-15 predictions outperformed the other models with SEPs of 0.56% for temperature, 4.22% for humidity, and 2.15% for CO

2.

The results of the LSTM and 1D-CNN models are presented in

Table 5 and

Table 6, respectively. The 1D-CNN model performed worse than LSTMs and DNN overall, but it performed marginally better than these two models at predicting CO

2 when the time interval was one minute. As an illustration, the temperature, humidity, and CO

2 were correctly predicted by 1D-CNN-1, with R

2 values of 0.96, 0.96, and 0.97, respectively. On the other hand, when the prediction time increased beyond five minutes, the accuracy of the 1D-CNN model dropped, and the prediction of temperature and CO

2 at the 15 min mark produced the worst results. The LSTM model, on the other hand, outperformed all other models in terms of predicted accuracy. The SEP and R

2 values for the temperature prediction made by the LSTM-5 were 0.46% and 0.99, respectively.

Table 7 presents the performance metrics of the proposed novel deep neural network model for temperature, humidity, and CO

2 prediction in a smart greenhouse environment for all time intervals. The proposed model consistently exhibits high R

2 values, ranging from 0.975 to 0.99, indicating a strong correlation between the predicted and actual temperature values. SEP percentages, ranging from 0.35% to 0.47%, indicate the precision of the proposed model in predicting temperature levels within the smart greenhouse. Similar trends are observed for humidity predictions across the proposed model. High R

2 values (>0.94) and SEP percentages emphasize the models’ accuracy in predicting humidity levels. The proposed model demonstrates robust performance in predicting CO

2 levels, with R

2 values exceeding 0.91. SEP percentages further affirm the accuracy of CO

2 predictions.

As the complexity of the proposed model increases from model-1 to model-15, there is a consistent enhancement in predictive performance, as evident from the improvement in R2 values and SEP percentages. The proposed model showcases a high degree of accuracy in predicting temperature, humidity, and CO2 levels within the smart greenhouse environment. The systematic increase in performance metrics with the complexity of the model indicates the effectiveness of the proposed approach. These findings lay a strong foundation for the reliable integration of AI-driven predictions into autonomous smart greenhouse control systems, contributing to the optimization of crop production conditions.

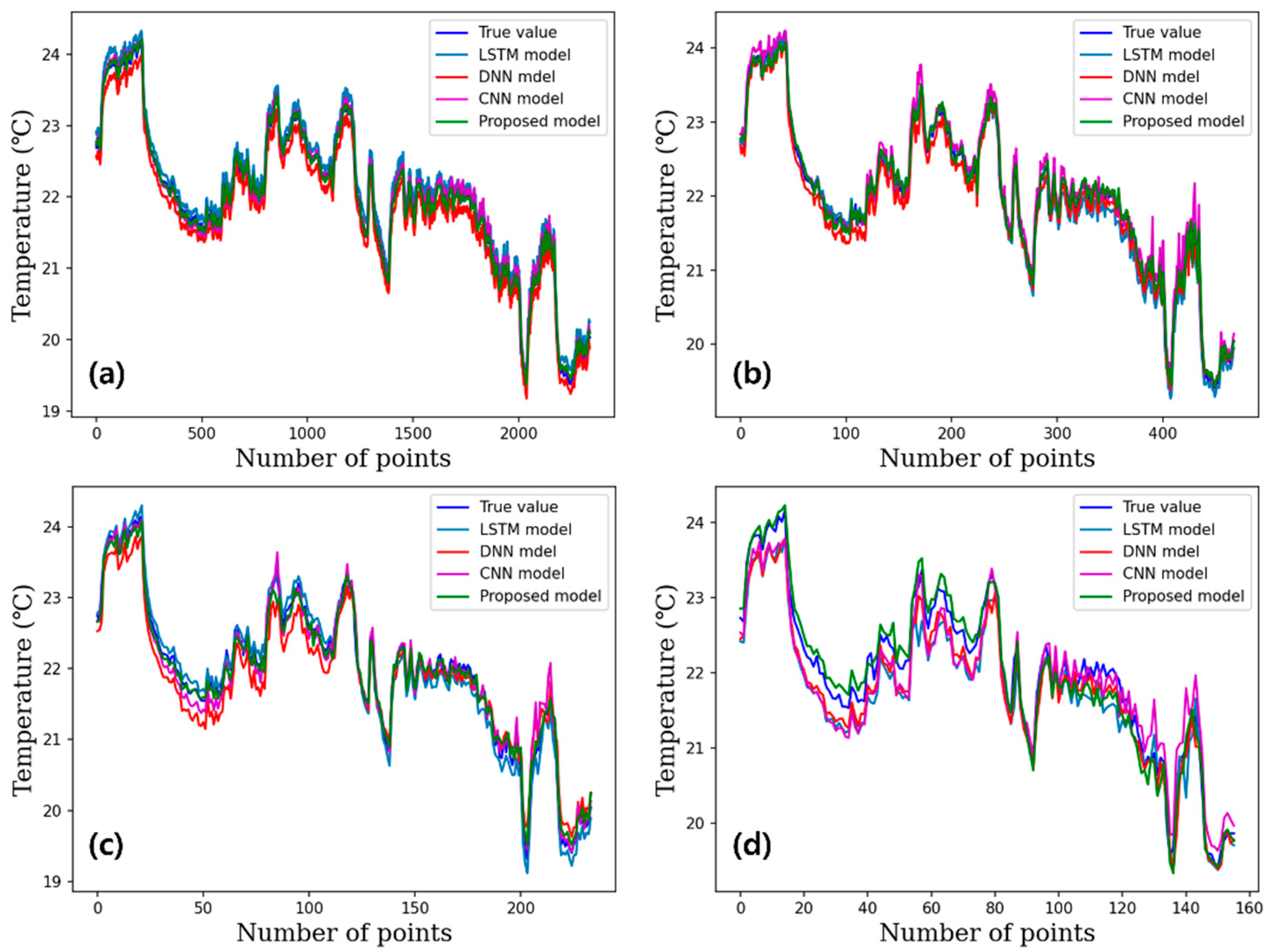

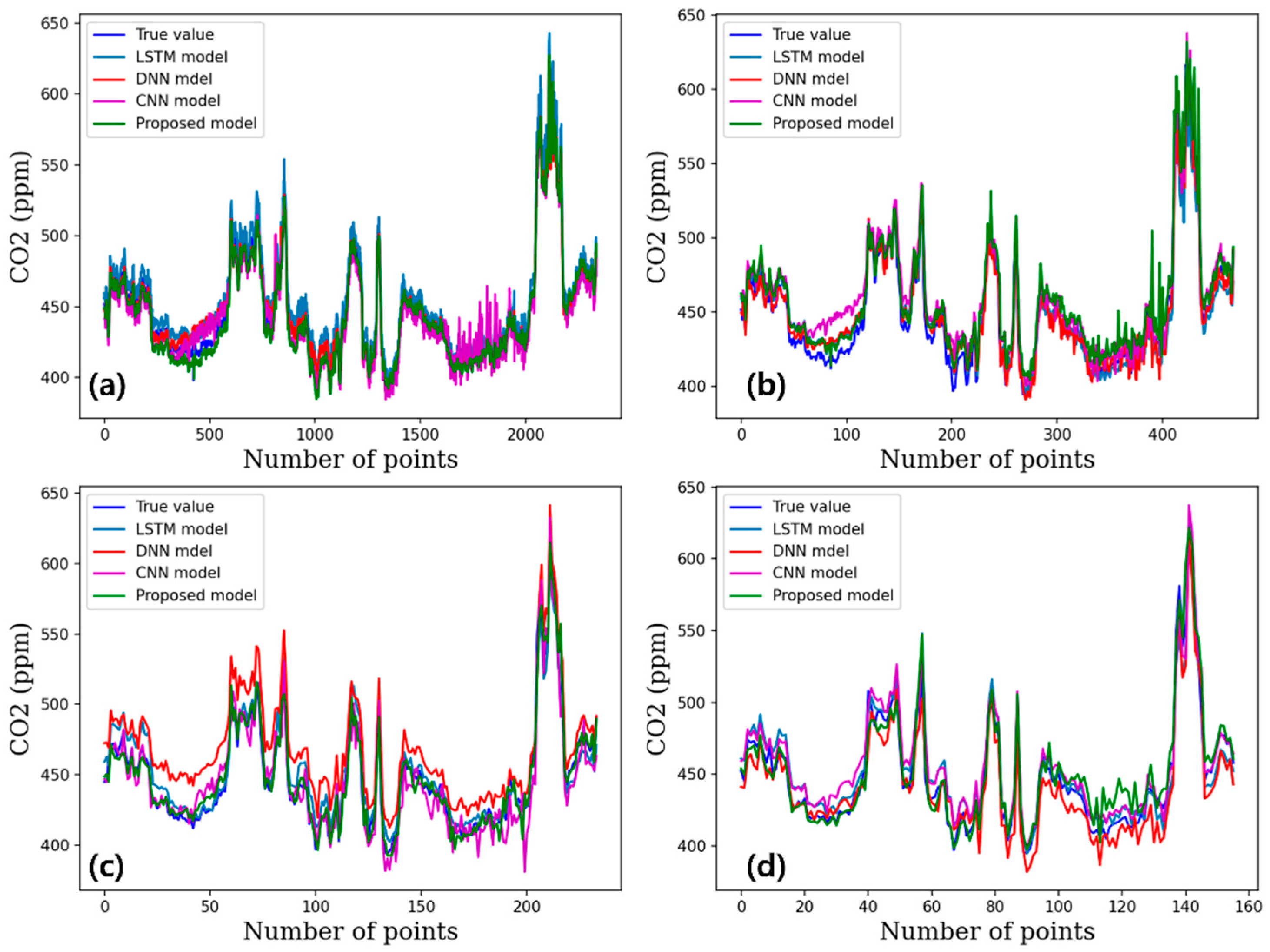

The effectiveness of the DNN, 1D-CNN, LSTM and the proposed novel DL model for forecasting temperature, humidity, and CO

2 levels over a range of time steps is shown in

Figure 6,

Figure 7 and

Figure 8. All models are fairly accurate in predicting the temperature under all different climatic conditions, while predicting CO

2 level is challenging for all DL models. The graphs display each model’s prediction accuracy for temperature, humidity, and CO

2.

This study demonstrates how data-based modeling tools may be used to predict environmental changes in smart greenhouses. The performance of the proposed novel DL model is superior to that of the traditional neural network-based models. Therefore, it is advantageous to apply a more dynamic modeling technique that takes into account prior experiences in order to predict ongoing and recurring changes in the unique smart greenhouse environment. Similar conclusions have been reported by earlier research [

21,

22].

These results underline how crucial it is to pick the right time series deep learning model for predicting the environment in indoor hydroponic smart greenhouses. For precise time-interval predictions, the proposed novel DL model is the best option, whereas the DNN, 1D-CNN, and LSTM models have relatively poor accuracy. This study emphasizes the relevance of expanding the training dataset in order to enhance model performance. The use of numerous deep learning models, various time frames, and a variety of performance indicators for evaluation are some of this study’s strong points. For researchers and professionals in hydroponics and agriculture interested in utilizing deep learning models to anticipate the environment, the study also offers useful insights. However, there are certain restrictions on this study, as well. A hydroponic smart greenhouse’s long-term environment may not be accurately represented by the dataset utilized in the study, which is first limited to one week. Second, the study only considers three deep learning models; other models might be more effective in predicting the climate. Finally, the study ignored outside variables that might have an impact on the smart greenhouse climate, like weather and plant growth.

This study evaluates the effectiveness of various time series deep learning models to analyze climate predictions in indoor hydroponic smart greenhouses. The study sheds light on the models’ advantages and disadvantages and emphasizes the significance of choosing the right models for precise prediction. In order to enhance the effectiveness of the models, further studies should take external influences into account and employ larger datasets.

4.3. Experimental Confirmation

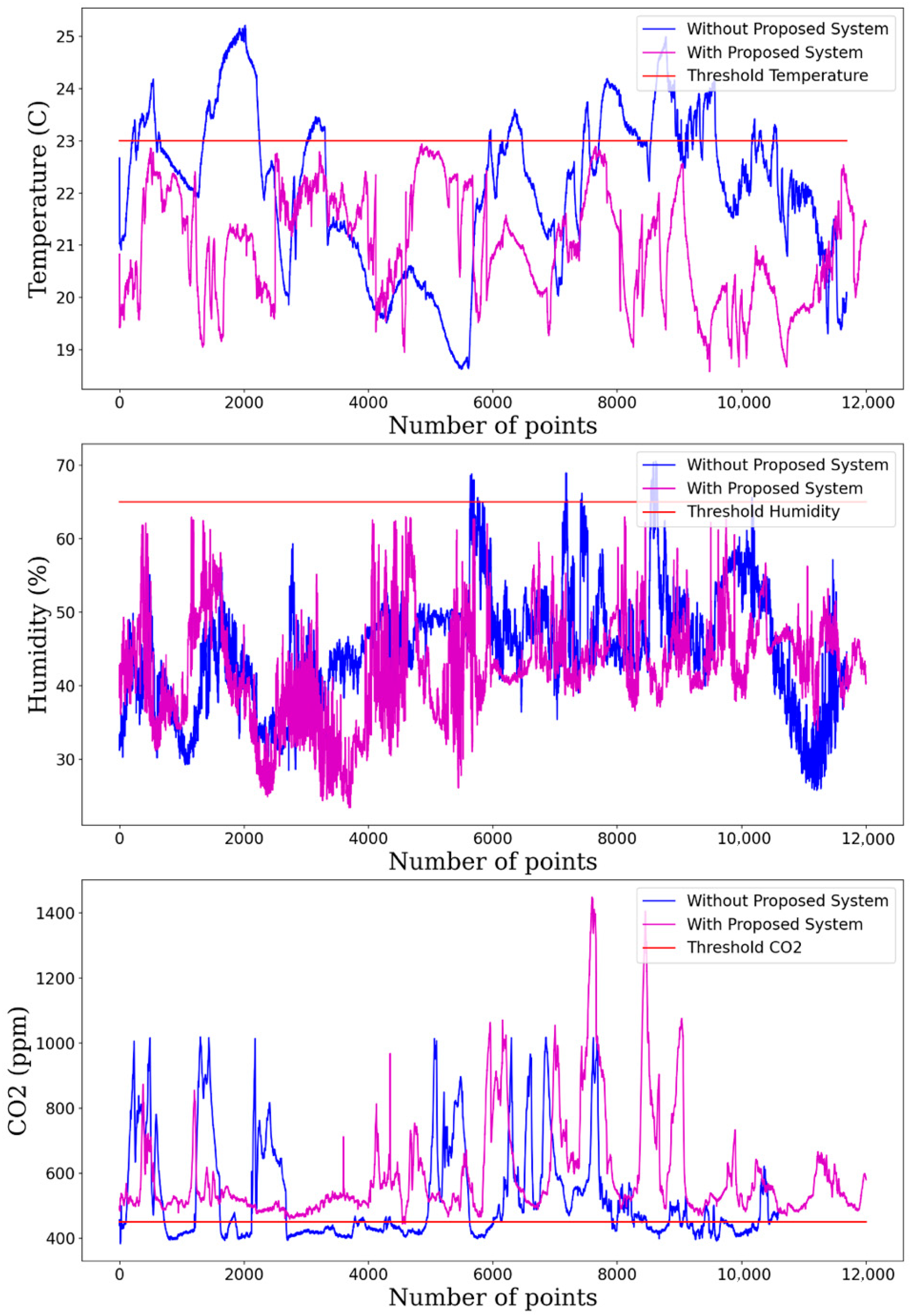

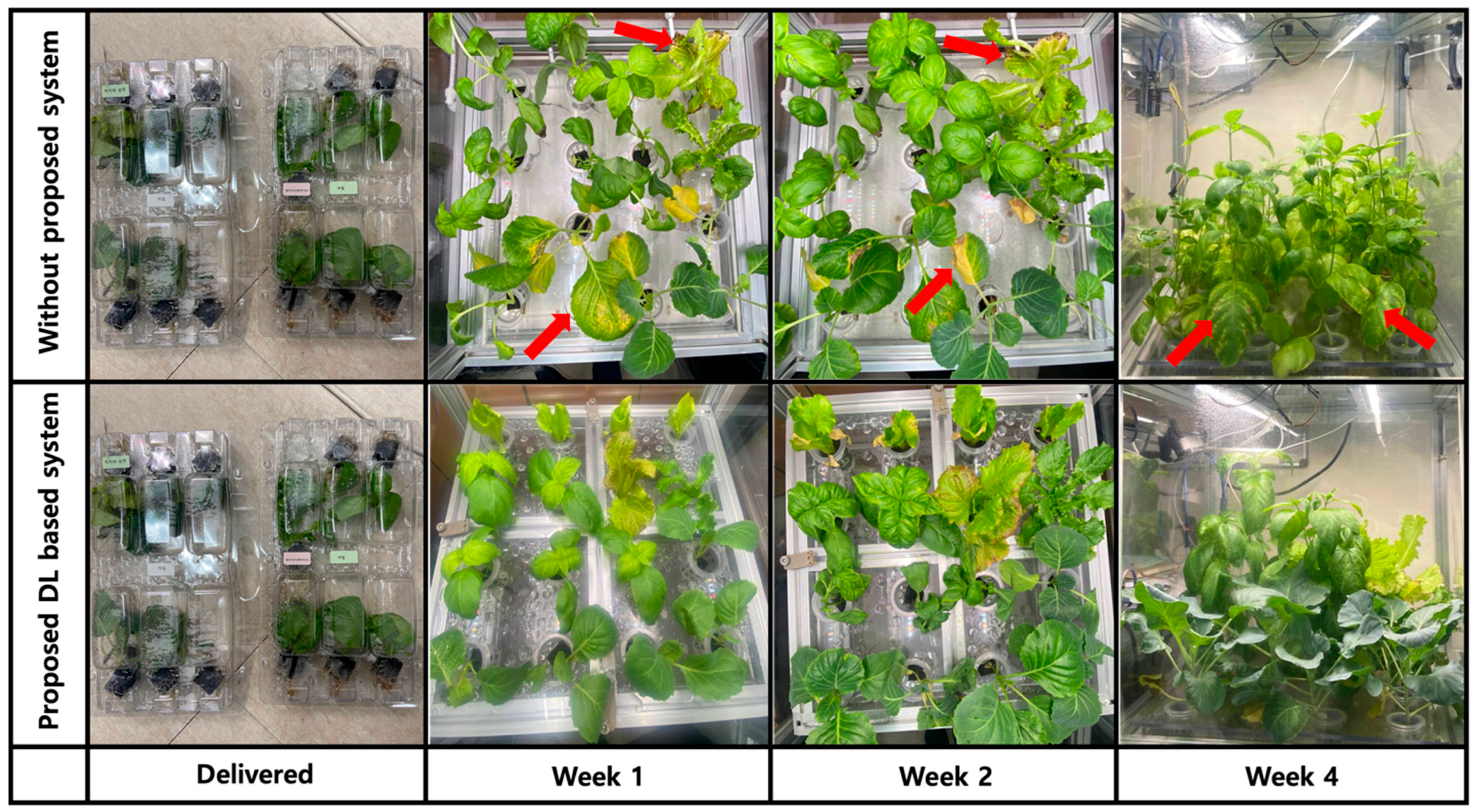

The utilization of the proposed DL-based control system in the smart greenhouse presents a stark contrast to traditional approaches lacking such sophisticated technology. The impact is evident across multiple facets of smart greenhouse management, fundamentally altering the dynamics of climate regulation, resource utilization, crop productivity, operational efficiency, and environmental sustainability. In the realm of climate regulation, the DL-based system takes the lead by dynamically optimizing environmental parameters such as temperature, humidity, and CO2 levels based on real-time predictions. This control mechanism establishes and maintains an ideal climate for plant growth. In stark contrast, conventional smart greenhouse environments, often reliant on manual adjustments or basic automation, witness fluctuations that can deviate from the optimal range, potentially impacting plant health and growth. Resource utilization undergoes a transformative shift with the introduction of the DL-based control system. This system excels at precision in delivering water, nutrients, and energy, tailoring distribution to the specific needs of individual plants. The outcome is a reduction in wastage and an overall improvement in resource efficiency. On the contrary, traditional smart greenhouse settings may experience less targeted resource distribution, leading to suboptimal utilization and increased overall consumption.

The impact on crop productivity is substantial. The DL-based system’s predictive capabilities and adaptive control contribute to enhanced productivity as plants experience consistent and optimized growth environments. In a contrasting scenario, traditional greenhouse setups, lacking sophisticated control mechanisms, may witness fluctuations in environmental conditions, potentially hindering crop yields. Operational efficiency is another dimension where the DL-based system shines. Automation and intelligence reduce the need for constant manual oversight, contributing to increased operational efficiency. In contrast, traditional greenhouse management demands more manual intervention, potentially resulting in delays in responding to environmental changes and addressing issues promptly. From an environmental perspective, the DL-based control system aligns with sustainability goals. Precise control and optimization translate to reduced resource wastage, fostering eco-friendly agricultural practices. In contrast, traditional greenhouse models, with their inherent inefficiencies, may contribute to higher resource consumption and a larger environmental footprint. In essence, the adoption of a DL-based control system in the smart greenhouse environment marks a paradigm shift. The transformative impact across climate regulation, resource utilization, crop productivity, operational efficiency, and environmental sustainability underscores the potential of advanced technologies in shaping the future of agriculture. Numerous experimental trials were conducted within the framework of the envisioned smart indoor hydroponic greenhouse. A comprehensive assessment was undertaken by cultivating four distinct plant varieties during a specific experiment. The climatic conditions for this experiment were meticulously controlled, with the temperature, humidity, and CO

2 levels set at 23 °C, 65%, and 450 ppm, respectively (refer to

Figure 9). In parallel, an identical experiment was conducted without the integration of our proposed system. The outcomes of these comparative experiments are presented in

Figure 10. The results highlight potential plant health issues in the absence of the proposed system, evident in the form of yellowish discolorations on the leaves. These anomalies are attributed to unfavorable climate parameters, including elevated humidity, increased temperature, or decreased CO

2 levels. Conversely, the plants cultivated within the smart greenhouse equipped with our proposed system exhibit a healthier state.

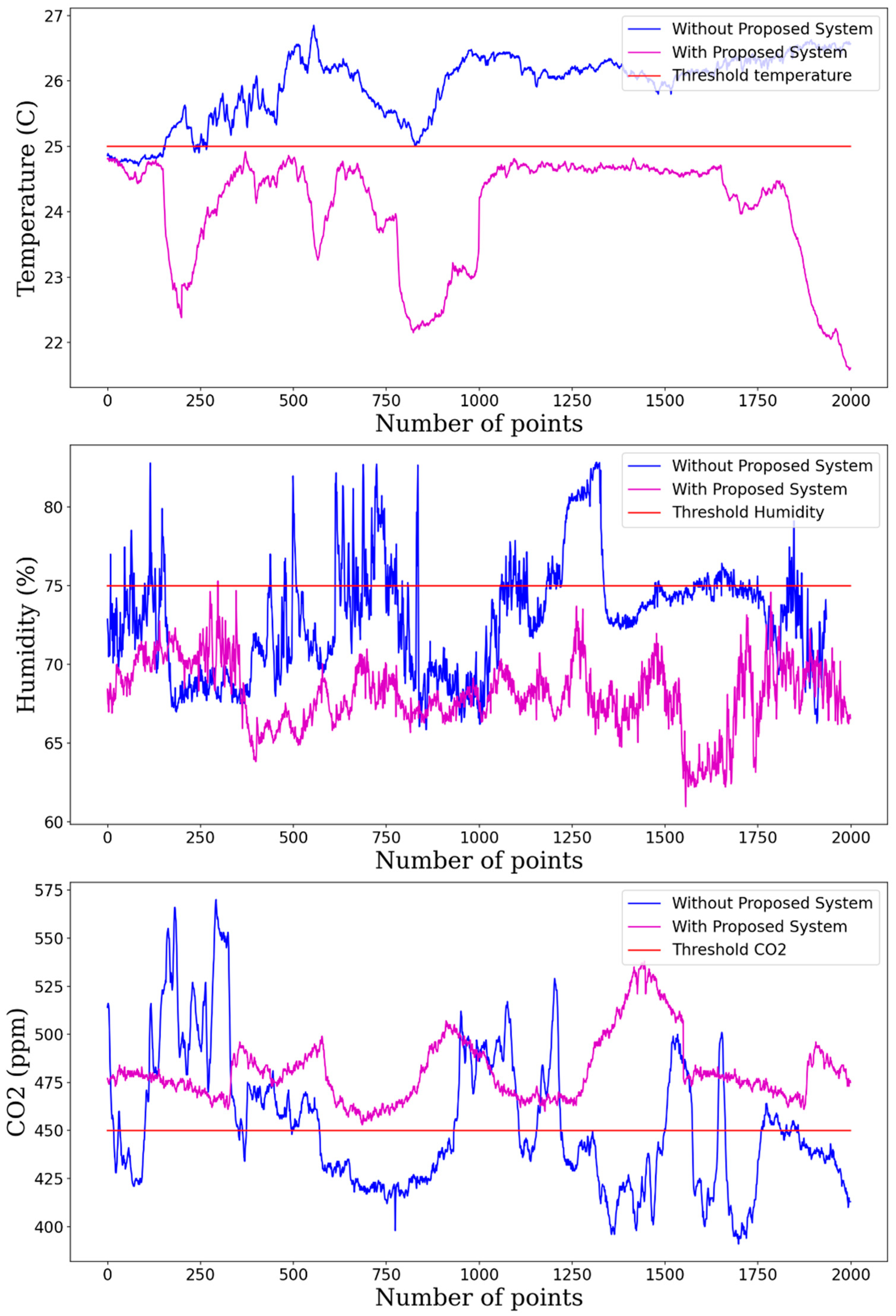

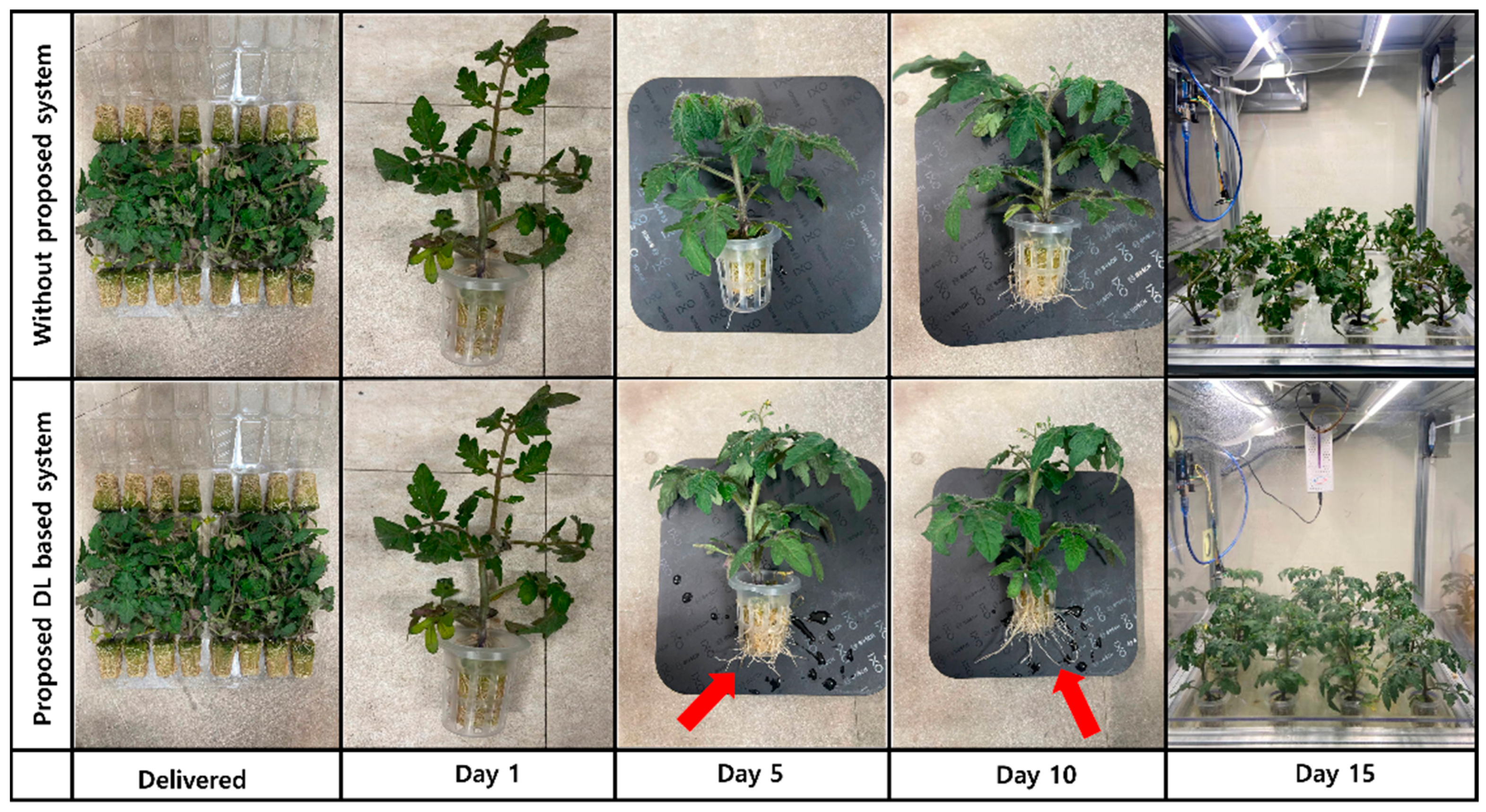

Furthermore, specific experimentation involving the cultivation of tomato plants was undertaken. Illustrated in

Figure 11, the tomato plants within our smart greenhouse exhibited accelerated growth compared to those in a conventional hydroponic smart greenhouse. This disparity in growth rates is attributed to the substantially longer roots observed in tomato plants cultivated within the smart greenhouse. The controlled parameters for this experiment, encompassing temperature, humidity, and CO

2 levels, were maintained at 25 °C, 75%, and 450 ppm, respectively. Climate parameter measurements from hydroponic smart greenhouses, both with and without our proposed DL-based controlling system, are presented in

Figure 12. The experimental findings demonstrate that the climate parameters crucial for optimal plant growth and health consistently fall within the prescribed range when the DL-based autonomous controlling system is employed. In contrast, the absence of the proposed DL-based autonomous controlling system results in fluctuating and unstable climate parameters, potentially compromising the well-being of the cultivated plants within the hydroponic smart greenhouse.

From a hardware standpoint, the proposed system demonstrates high efficiency due to the lightweight 1D-CNN model and the use of the Jetson Nano platform, which offers a balance of computational power and energy efficiency suitable for edge AI applications. However, when considering deployment at a commercial scale, several challenges arise. These include the need for a denser sensor network to cover larger growing areas, increased computational overhead for real-time predictions from multiple zones, and integration difficulties with diverse greenhouse automation systems. Moreover, ensuring consistent wireless connectivity, data integrity, and fault-tolerant operation becomes increasingly important. Addressing these challenges will require further research into distributed model inference, low-power AI hardware, and standardized communication protocols to support reliable large-scale deployment in real-world agricultural environments.