Advances in Nanocatalysts Mediated Biodiesel Production: A Critical Appraisal

Abstract

1. Introduction

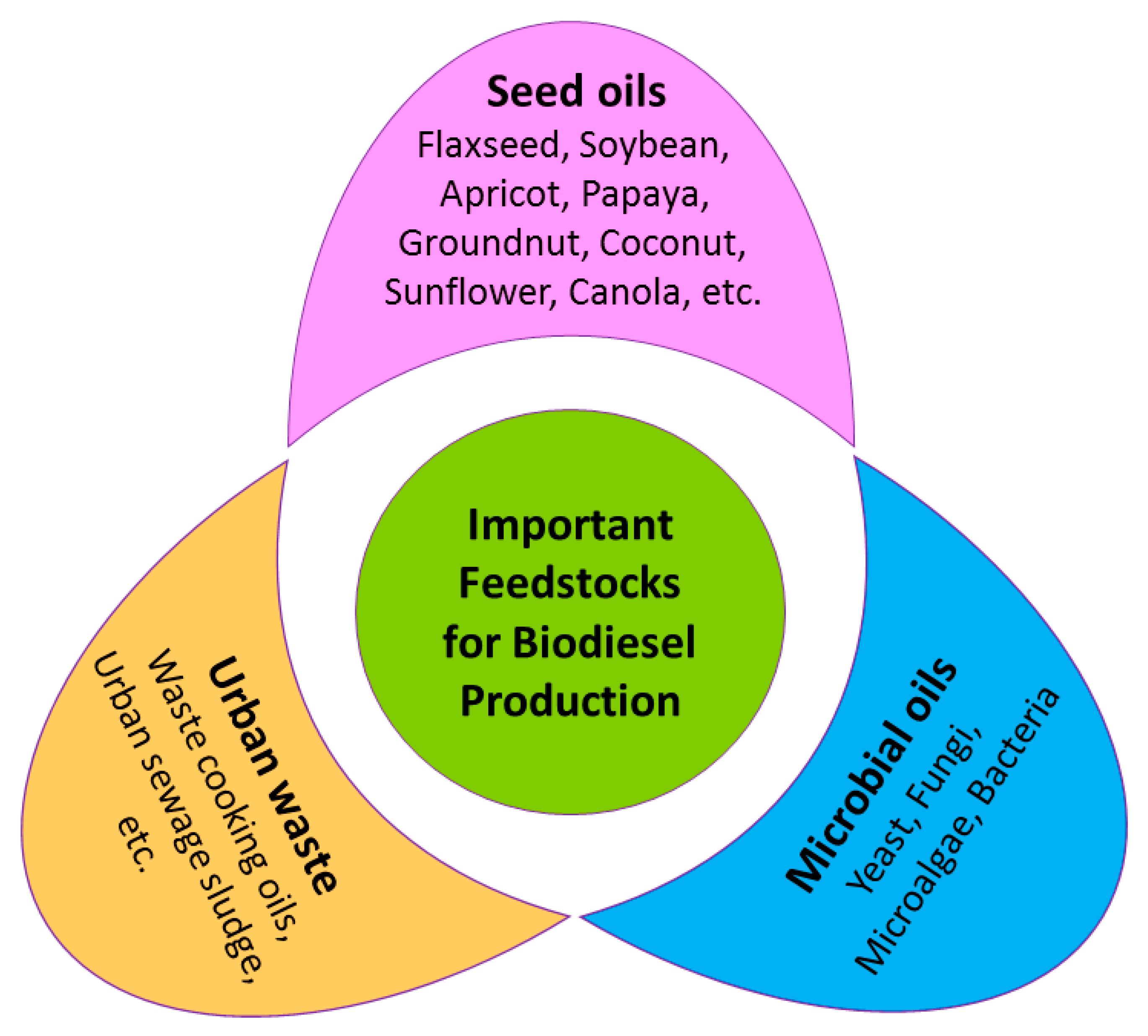

2. Important Feedstocks Used in Biodiesel Production

2.1. Seed Oils

2.2. Microbial Oils

2.3. Urban Wastes

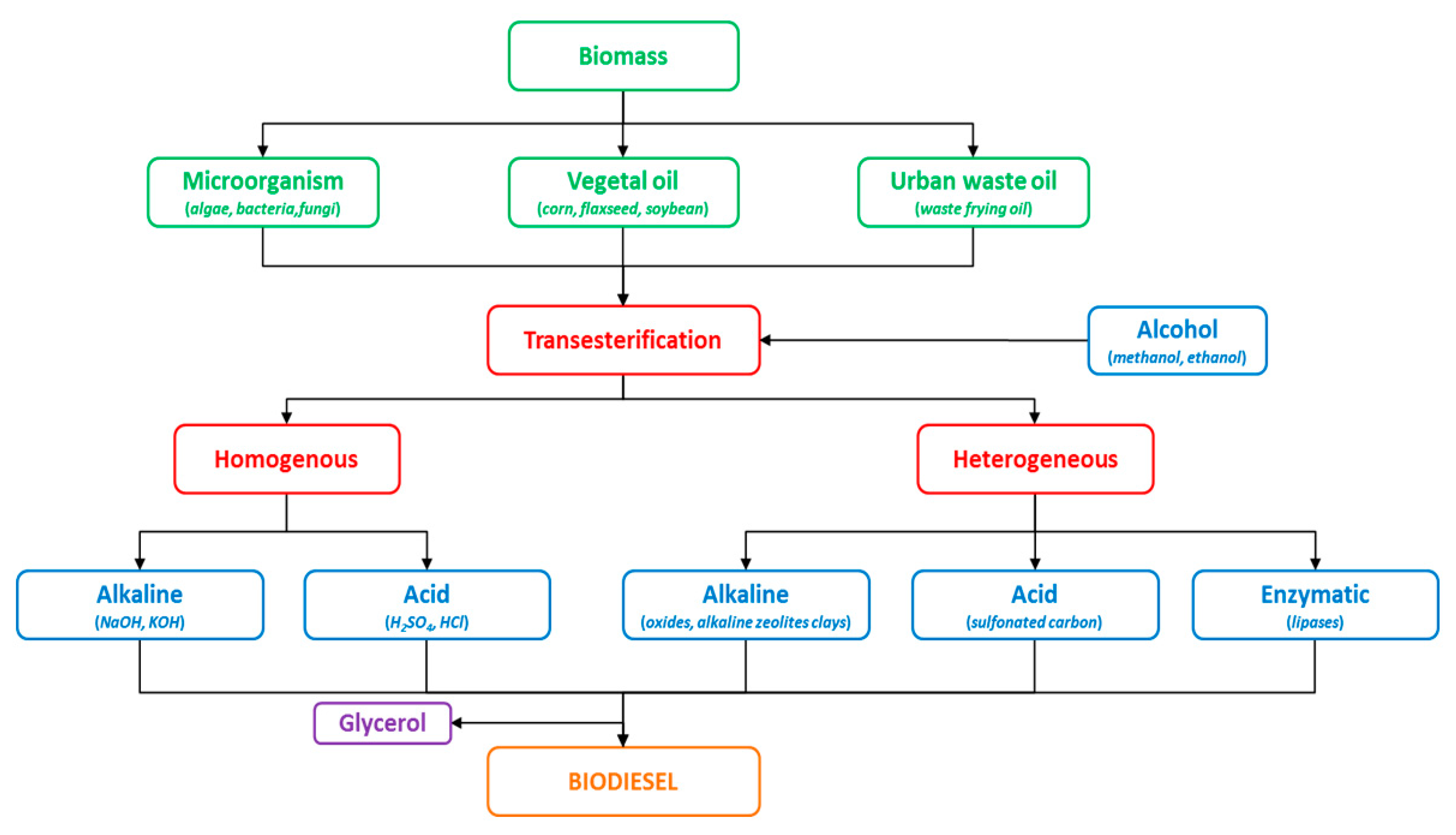

3. Conventional Methods Used for Biodiesel Production

3.1. Catalyst-Assisted Methods

3.1.1. Alkaline-Catalyzed Methods

3.1.2. Acid-Catalyzed Methods

3.2. Lipase-Catalysed Methods

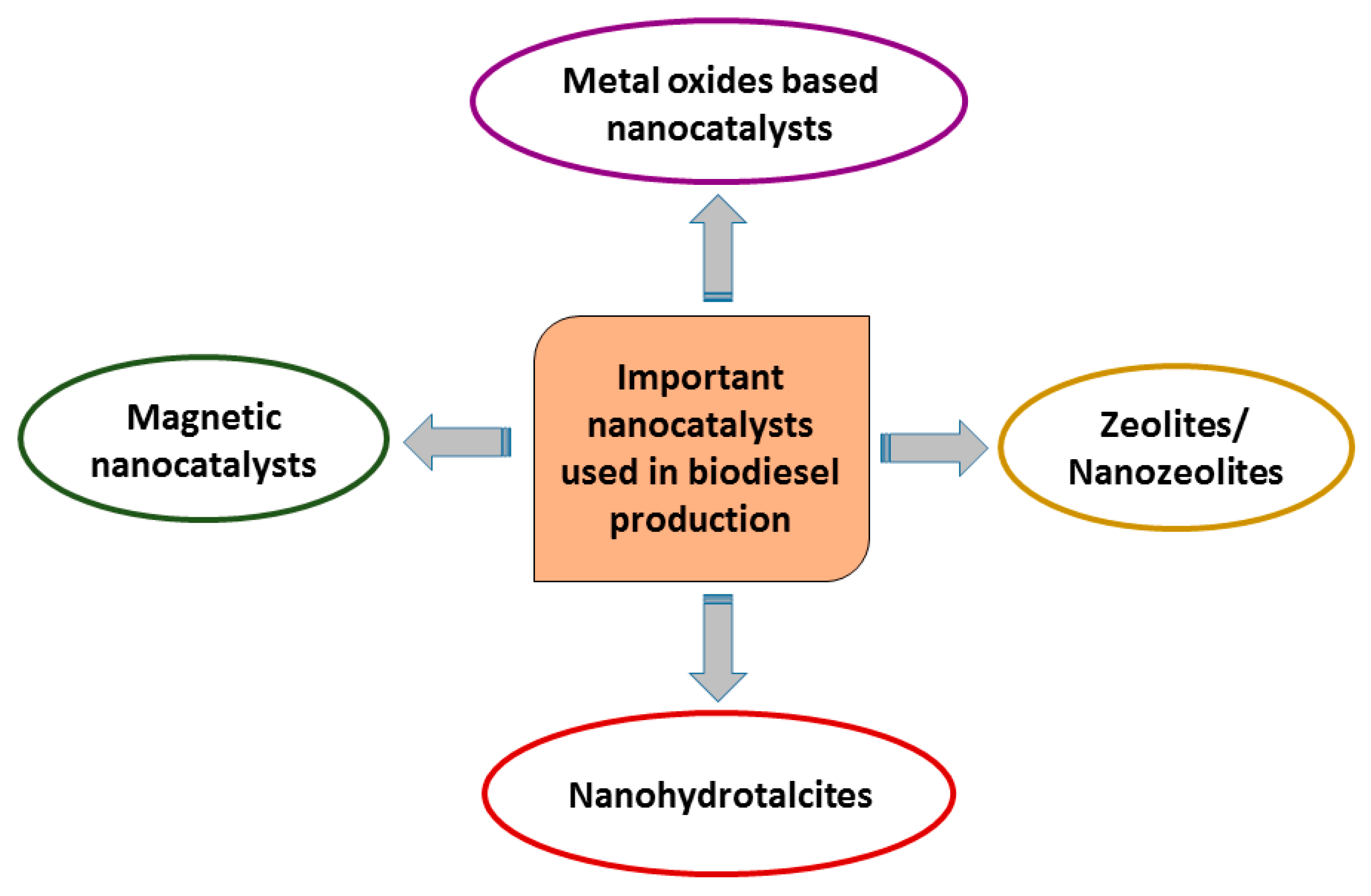

4. Nanocatalysts in Biodiesel Production

4.1. Metal Oxide-Based Nanocatalysts

4.2. Nanohydrotalcites

4.3. Zeolites/Nanozeolites

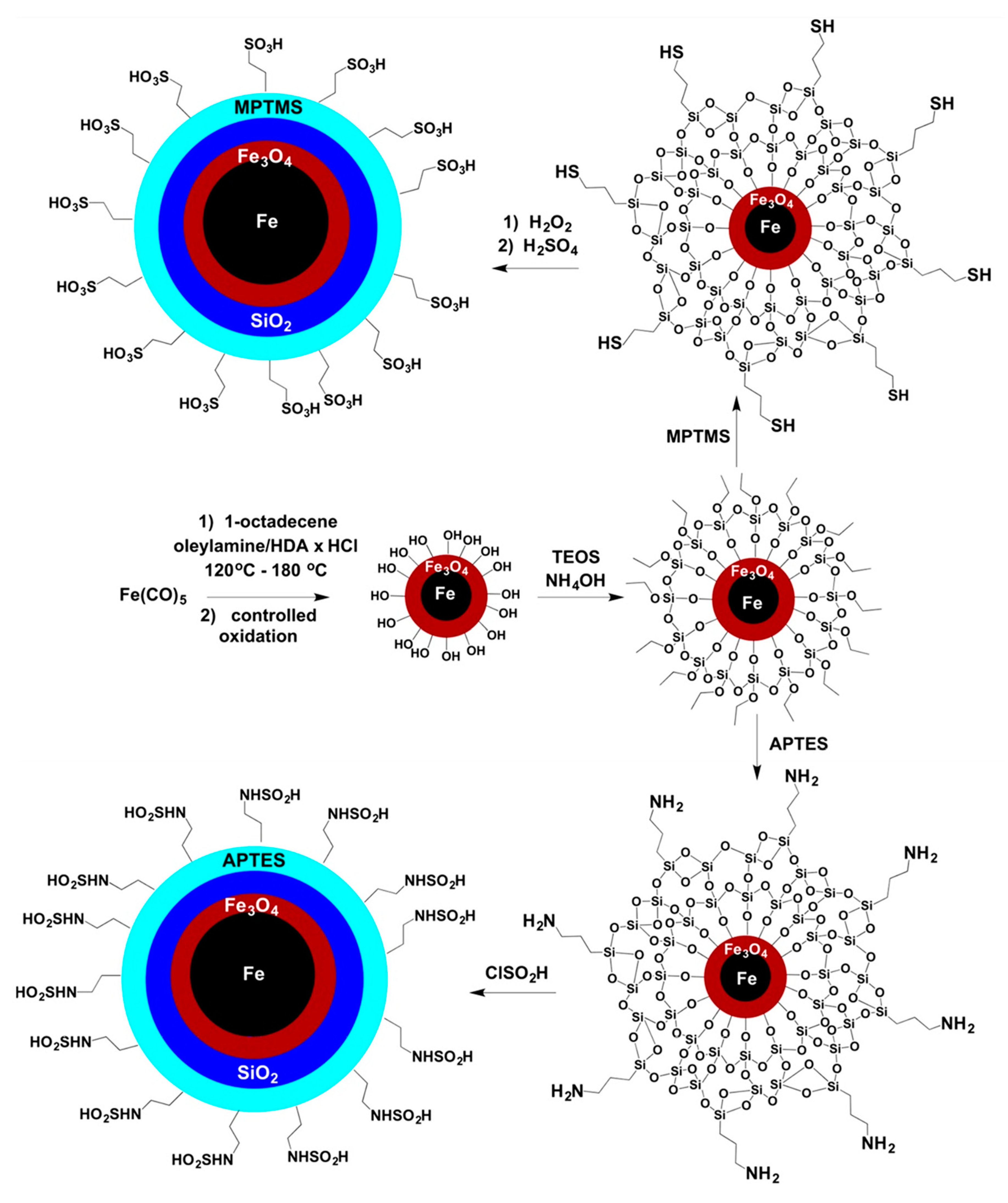

4.4. Magnetic Nanocatalysts

5. Conclusions and Future Directions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Perez, V.H.; Junior, E.G.S.; Cubides, C.; David, G.F.; Justo, O.R.; Castro, M.P.P.; Sthel, M.S.; de Castro, H.F. Trends in biodiesel production: Present status and future directions. In Biofuels in Brazil; Springer: Cham, Switzerland, 2014; pp. 281–302. [Google Scholar]

- Pohit, S.; Biswas, P.K. India’s biodiesel programme: Status, prospects, and shortcomings. In Sustainable Biofuels Development in India; Springer: Cham, Switzerland, 2017; pp. 247–259. [Google Scholar]

- Ambat, I.; Srivastava, V.; Sillanpää, M. Recent advancement in biodiesel production methodologies using various feedstock: A review. Renew. Sustain. Energy Rev. 2018, 90, 356–369. [Google Scholar] [CrossRef]

- Fjerbaek, L.; Christensen, K.V.; Norddahl, B. A review of the current state of biodiesel production using enzymatic transesterification. Biotechnol. Bioeng. 2009, 102, 1298–1315. [Google Scholar] [CrossRef] [PubMed]

- Sharma, Y.C.; Singh, B. Development of biodiesel: Current scenario. Renew. Sustain. Energy Rev. 2009, 13, 1646–1651. [Google Scholar] [CrossRef]

- Atadashi, I.M.; Aroua, M.K.; Abdul-Aziz, R.; Sulaiman, N.M.N. The effects of catalysts in biodiesel production: A review. J. Ind. Eng. Chem. 2013, 19, 14–26. [Google Scholar] [CrossRef]

- Gardy, J.; Rehan, M.; Hassanpour, A.; Lai, X.; Nizami, A.S. Advances in nano-catalysts based biodiesel production from non-food feedstocks. J. Environ. Manag. 2019, 249, 109316. [Google Scholar] [CrossRef]

- de Vasconcellos, A.; Miller, A.H.; Aranda, D.A.G.; Nery, J.G. Biocatalysts based on nanozeolite-enzyme complexes: Effects of alkoxysilane surface functionalization and biofuel production using microalgae lipids feedstock. Colloids Surf. B Biointerfaces 2018, 165, 150–157. [Google Scholar] [CrossRef]

- Ramsurn, H.; Gupta, R.B. Nanotechnology in solar and biofuels. ACS Sustain. Chem. Eng. 2013, 1, 779–797. [Google Scholar] [CrossRef]

- Jiang, C.; Jia, J.; Zhai, S. Mechanistic understanding of toxicity from nanocatalysts. Int. J. Mol. Sci. 2014, 15, 13967–13992. [Google Scholar] [CrossRef]

- Polshettiwar, V.; Varma, R.S. Green chemistry by nano-catalysis. Green Chem. 2010, 12, 743–754. [Google Scholar] [CrossRef]

- Christophe, G.; Kumar, V.; Nouaille, R.; Gaudet, G.; Fontanille, P.; Pandey, A.; Soccol, C.R.; Larroche, C. Recent developments in microbial oils production: A possible alternative to vegetable oils for biodiesel without competition with human food? Braz. Arch. Biol. Technol. 2012, 55, 29–46. [Google Scholar] [CrossRef]

- Duarte, S.H.; Ghiselli, G.; Maugeri, F. Influence of culture conditions on lipid production by Candida sp. LEB-M3 using glycerol from biodiesel synthesis. Biocatal. Agric. Biotechnol. 2013, 2, 339–343. [Google Scholar] [CrossRef]

- Eloka-Eboka, A.C.; Igbum, G.O.; Inambao, F.L. Biodiesel methyl ester production and testing from selected African tropical seed oil feedstocks. Energy Procedia 2017, 142, 755–767. [Google Scholar] [CrossRef]

- Gaurav, A.; Dumas, S.; Mai, C.T.Q.; Ng, T.T. A kinetic model for a single step biodiesel production from a high free fatty acid (FFA) biodiesel feedstock over a solid heteropolyacid catalyst. Green Energy Environ. 2019, 4, 328–341. [Google Scholar] [CrossRef]

- Santori, G.; Nicola, G.D.; Moglie, M.; Polonara, F. A review analyzing the industrial biodiesel production practice starting from vegetable oil refining. Appl. Energy 2012, 92, 109–132. [Google Scholar] [CrossRef]

- International Energy Agency. Transport Biofuels: Tracking Clean Energy Progress. 2019. Available online: https://www.iea.org/tcep/transport/biofuels/ (accessed on 20 July 2019).

- Ni, Z.; Li, F.; Wang, H.; Wang, S.; Gao, S. Antioxidative performance and oil-soluble properties of conventional antioxidants in rubber seed oil biodiesel. Renew. Energy 2020, 145, 93–98. [Google Scholar] [CrossRef]

- Ahmad, T.; Danish, M.; Kale, P.; Geremew, B.; Adeloju, S.B.; Nizami, M.; Ayoub, M. Optimization of process variables for biodiesel production by transesterification of flaxseed oil and produced biodiesel characterizations. Renew. Energy 2019, 139, 1272–1280. [Google Scholar] [CrossRef]

- Sánchez-Arreola, E.; Bach, H.; Hernández, L.R. Biodiesel production from Cascabela ovata seed oil. Bioresour. Technol. Rep. 2019, 7, 100220. [Google Scholar] [CrossRef]

- Liu, J.Z.; Cui, Q.; Kang, Y.-F.; Meng, Y.; Gao, M.Z.; Efferth, T.; Fu, Y.J. Euonymus maackii Rupr. Seed oil as a new potential non-edible feedstock for biodiesel. Renew. Energy 2019, 133, 261–267. [Google Scholar] [CrossRef]

- Anwar, M.; Rasul, M.G.; Ashwath, N.; Nabi, M.D.N. The potential of utilizing papaya seed oil and stone fruit kernel oil as non-edible feedstock for biodiesel production in Australia: A review. Energy Rep. 2019, 5, 280–297. [Google Scholar] [CrossRef]

- Sodamade, A.; Oyedepo, T.A.; Bolaji, O.S. Fatty acids composition of three different vegetable oils (soybean oil, groundnut oil and coconut oil) by high-performance liquid chromatography. Chem. Mater. Res. 2013, 3, 26–30. [Google Scholar]

- Predojević, Z.; Škrbić, B.; Đurišić-Mladenović, N. Transesterification of linoleic and oleic sunflower oils to biodiesel using CaO as a solid base catalyst. J. Serbian Chem. Soc. 2012, 77, 815–832. [Google Scholar] [CrossRef]

- Oliveira, M.B.; Barbedo, S.; Soletti, J.I.; Carvalho, S.H.V.; Queimada, A.J.; Coutinho, J.A.P. Liquid–liquid equilibria for the canola oil biodiesel + ethanol + glycerol system. Fuel 2011, 90, 2738–2745. [Google Scholar] [CrossRef]

- Martinez-Silveira, A.; Villarreal, R.; Garmendia, G.; Rufo, C.; Vero, S. Process conditions for a rapid in situ transesterification for biodiesel production from oleaginous yeasts. Electron. J. Biotechnol. 2019, 38, 1–9. [Google Scholar] [CrossRef]

- Madani, M.; Enshaeieh, M.; Abdoli, A. Single cell oil and its application for biodiesel production. Process Saf. Environ. Protect. 2017, 111, 747–756. [Google Scholar] [CrossRef]

- Louhasakul, Y.; Cheirsilp, B.; Maneerat, S.; Prasertsan, P. Potential use of flocculating oleaginous yeasts for bioconversion of industrial wastes into biodiesel feedstocks. Renew. Energy 2019, 136, 1311–1319. [Google Scholar] [CrossRef]

- Karatay, S.E.; Demiray, E.; Dönmez, G. Efficient approaches to convert Coniochaeta hoffmannii lipids into biodiesel by in-situ transesterification. Bioresour. Technol. 2019, 285, 121321. [Google Scholar] [CrossRef]

- Bagy, M.M.K.; Abd-Alla, M.H.; Morsy, F.M.; Hassan, E.A. Two stage biodiesel and hydrogen production from molasses by oleaginous fungi and Clostridium acetobutylicum ATCC 824. Int. J. Hydrog. Energy 2014, 39, 3185–3197. [Google Scholar] [CrossRef]

- Pereira, F.M.; Loures, C.L.A.; Amaral, M.S.; Gomes, F.M.; Pedro, G.A.; Machado, M.A.G.; Reis, C.E.R.; Silva, M.B. Evaluation of fatty acids production by Chlorella minutissima in batch bubble-column photobioreactor. Fuel 2018, 230, 155–162. [Google Scholar] [CrossRef]

- Hernández-García, A.; Velásquez-Orta, S.B.; Novelo, B.; Yáñez-Noguez, I.; Monje-Ramírez, I.; Ledesma, M.T.O. Wastewater-leachate treatment by microalgae: Biomass, carbohydrate and lipid production. Ecotoxicol. Environ. Saf. 2019, 174, 435–444. [Google Scholar] [CrossRef]

- Kumar, M.; Thakur, I.S. Municipal secondary sludge as carbon source for production and characterization of biodiesel from oleaginous bacteria. Bioresour. Technol. Rep. 2018, 4, 106–113. [Google Scholar] [CrossRef]

- Cea, M.; Sangaletti-Gerhard, N.; Acuña, P.; Fuentes, I.; Jorquera, M.; Godoy, K.; Osses, F.; Navia, R. Screening transesterifiable lipid accumulating bacteria from sewage sludge for biodiesel production. Biotechnol. Rep. 2015, 8, 116–123. [Google Scholar] [CrossRef] [PubMed]

- Thushari, I.; Babel, S.; Samart, C. Biodiesel production in an autoclave reactor using waste palm oil and coconut coir husk derived catalyst. Renew. Energy 2019, 134, 125–134. [Google Scholar] [CrossRef]

- Sakdasri, W.; Sawangkeaw, R.; Ngamprasertsith, S. An entirely renewable biofuel production from used palm oil with supercritical ethanol at low molar ratio. Braz. J. Chem. Eng. 2017, 34, 1023–1034. [Google Scholar] [CrossRef]

- Giraçol, J.; Passarini, K.C.; Silva Filho, S.C.; Calarge, F.A.; Tambourgi, E.B.; Santana, J.C.C. Reduction in ecological cost through biofuel production from cooking oils: An ecological solution for the city of Campinas, Brazil. J. Clean. Prod. 2011, 19, 1324–1329. [Google Scholar] [CrossRef]

- Tran, N.N.; Tišma, M.; Budžaki, S.; McMurchie, E.J.; Gonzalez, O.M.M.; Hessel, V.; Ngothai, Y. Scale-up and economic analysis of biodiesel production from recycled grease trap waste. Appl. Energy 2019, 229, 142–150. [Google Scholar] [CrossRef]

- Kech, C.; Galloy, A.; Frippiat, C.; Piel, A.; Garot, D. Optimization of direct liquid-liquid extraction of lipids from wet urban sewage sludge for biodiesel production. Fuel 2018, 212, 132–139. [Google Scholar] [CrossRef]

- Quah, R.V.; Tan, Y.H.; Mubarak, N.M.; Khalid, M.; Abdullah, E.C.; Nolasco-Hipolito, C. An overview of biodiesel production using recyclable biomass and non-biomass derived magnetic catalysts. J. Environ. Chem. Eng. 2019, 4, 103219. [Google Scholar] [CrossRef]

- Knothe, G.; Steidley, K.R. The effect of metals and metal oxides on biodiesel oxidative stability from promotion to inhibition. Fuel Proc. Technol. 2018, 177, 75–80. [Google Scholar] [CrossRef]

- Bouaid, A.; Vázquez, R.; Martinez, M.; Aracil, J. Effect of free fatty acids contents on biodiesel quality. Pilot plant studies. Fuel 2016, 174, 54–62. [Google Scholar] [CrossRef]

- Kalavathy, G.; Baskar, G. Synergism of clay with zinc oxide as nanocatalyst for production of biodiesel from marine Ulva lactuca. Bioresour. Technol. 2019, 281, 234–238. [Google Scholar] [CrossRef]

- Fonseca, J.M.; Teleken, J.G.; de Cinque Almeida, V.; da Silva, C. Biodiesel from waste frying oils: Methods of production and purification. Energy Convers. Manag. 2019, 184, 205–218. [Google Scholar] [CrossRef]

- Marchetti, J.M.; Miguel, V.U.; Errazu, A.F. Possible methods for biodiesel production. Renew. Sustain. Energy Rev. 2007, 11, 1300–1311. [Google Scholar] [CrossRef]

- Giakoumis, E.G.; Sarakatsanis, C. A comparative assessment of biodiesel cetane number predictive correlations based on fatty acid composition. Energies 2019, 12, 422. [Google Scholar] [CrossRef]

- Farobie, O.; Matsumura, Y. State of the art of biodiesel production under supercritical conditions. Prog. Energy Combust. Sci. 2017, 63, 173–203. [Google Scholar] [CrossRef]

- Cao, F.; Chen, Y.; Zhai, F.; Li, J.; Wang, J.; Wang, X.; Wang, S.; Zhu, W. Biodiesel production from high acid value waste frying oil catalyzed by superacid heteropolyacid. Biotechnol. Bioeng. 2008, 101, 93–100. [Google Scholar] [CrossRef]

- Abukhadra, M.R.; Ibrahim, S.M.; Yakout, S.M.; El-Zaidy, M.E.; Abdeltawab, A.A. Synthesis of Na+ trapped bentonite/zeolite-P composite as a novel catalyst for effective production of biodiesel from palm oil; Effect of ultrasonic irradiation and mechanism. Energy Convers. Manag. 2019, 196, 739–750. [Google Scholar] [CrossRef]

- Jung, J.M.; Oh, J.I.; Park, I.K.; Lee, J.; Kwon, E.E. Biodiesel synthesis from fish waste via thermally-induced transesterification using clay as porous material. J. Hazard. Mater. 2019, 371, 27–32. [Google Scholar] [CrossRef]

- Li, Z.; Ding, S.; Chen, C.; Qu, S.; Du, L.; Lu, J.; Ding, J. Recyclable Li/NaY zeolite as a heterogeneous alkaline catalyst for biodiesel production: Process optimization and kinetics study. Energy Convers. Manag. 2019, 192, 335–345. [Google Scholar] [CrossRef]

- Jeon, Y.; Chi, W.S.; Hwang, J.; Kim, D.H.; Kim, J.H.; Shul, Y.G. Core-shell nanostructured heteropoly acid-functionalized metal-organic frameworks: Bifunctional heterogeneous catalyst for efficient biodiesel production. Appl. Catal. B: Environ. 2018, 242, 51–59. [Google Scholar] [CrossRef]

- Hama, S.; Noda, H.; Kondo, A. How lipase technology contributes to evolution of biodiesel production using multiple feedstocks. Curr. Opin. Biotechnol. 2018, 50, 57–64. [Google Scholar] [CrossRef]

- Amoah, J.; Ho, S.H.; Hama, S.; Yoshida, A.; Nakanishi, A.; Hasunuma, T.; Ogino, C.; Kondo, A. Converting oils high in phospholipids to biodiesel using immobilized Aspergillus oryzae whole-cell biocatalysts expressing Fusarium heterosporum lipase. Biochem. Eng. J. 2016, 105, 10–15. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, J.H.; Kim, D.S.; Yoo, H.Y.; Park, C.; Kim, S.W. Biodiesel production by lipases co-immobilized on the functionalized activated carbon. Bioresour. Technol. Rep. 2019, 7, 100248. [Google Scholar] [CrossRef]

- Zhao, X.; Qi, F.; Yuan, C.; Du, W.; Liu, D. Lipase-catalyzed process for biodiesel production: Enzyme immobilization, process simulation and optimization. Renew. Sustain. Energy Rev. 2015, 44, 182–197. [Google Scholar] [CrossRef]

- Fukuda, H.; Hama, S.; Tamalampudi, S.; Noda, H. Whole-cell biocatalysts for biodiesel fuel production. Trends Biotechnol. 2008, 26, 668–673. [Google Scholar] [CrossRef] [PubMed]

- Aguieiras, E.C.G.; Cavalcanti-Oliveira, E.D.; Freire, D.M.G. Current status and new developments of biodiesel production using fungal lipases. Fuel 2015, 159, 52–67. [Google Scholar] [CrossRef]

- Zhang, X.L.; Yan, S.; Tyagi, R.S.; Surampalli, R.Y. Biodiesel production from heterotrophic microalgae through transesterification and nanotechnology application in the production. Renew. Sustain. Energy Rev. 2013, 26, 216–223. [Google Scholar] [CrossRef]

- Palaniappan, K. An overview of applications of nanotechnology in biofuel production. World Appl. Sci. J. 2017, 35, 1305–1311. [Google Scholar]

- Khan, I.; Saeed, K.; Khan, I. Nanoparticles: Properties, applications and toxicities. Arab. J. Chem. 2019, 12, 908–931. [Google Scholar] [CrossRef]

- Sudarsanam, P.; Zhong, R.; Van den Bosch, S.; Coman, S.M.; Parvulescu, V.I.; Sels, B.F. Functionalised heterogeneous catalysts for sustainable biomass valorisation. Chem. Soc. Rev. 2018, 47, 8349–8402. [Google Scholar] [CrossRef]

- Kumar, D.; Sharma, S.; Srivastava, N.; Shukla, S.; Gaurav, K. Advancement in the utilization of nanocatalyst for transesterification of triglycerides. J. Nanosci. Tech. 2018, 4, 374–379. [Google Scholar] [CrossRef]

- Mallesham, B.; Sudarsanam, P.; Reddy, B.M. Production of biofuel additives from esterification and acetalization of bioglycerol over SnO2-based solid acids. Ind. Eng. Chem. Res. 2014, 53, 18775–18785. [Google Scholar] [CrossRef]

- Zuliani, A.; Ivars, F.; Luque, R. Advances in nanocatalysts design for biofuels production. ChemCatChem 2018, 10, 1968–1981. [Google Scholar] [CrossRef]

- Faria, E.A.; Marques, J.S.; Dias, I.M.; Andrade, R.D.A.; Suareza, P.A.Z.; Prado, A.G.S. Nanosized and reusable SiO2/ZrO2 catalyst for highly efficient biodiesel production by soybean transesterification. J. Braz. Chem. Soc. 2009, 20, 1732–1737. [Google Scholar] [CrossRef]

- Qiu, F.; Li, Y.; Yang, D.; Li, X.; Sun, P. Heterogeneous solid base nanocatalyst: Preparation, characterization and application in biodiesel production. Bioresour. Technol. 2011, 102, 4150–4156. [Google Scholar] [CrossRef]

- Madhuvilakku, R.; Piraman, S. Biodiesel synthesis by TiO2-ZnO mixed oxide nanocatalyst catalyzed palm oil transesterification process. Bioresour. Technol. 2013, 150, 55–59. [Google Scholar] [CrossRef]

- Gardy, J.; Hassanpour, A.; Laia, X.; Ahmed, M.H. Synthesis of Ti(SO4)O solid acid nano-catalyst and its application for biodiesel production from used cooking oil. Appl. Catal. A Gen. 2016, 527, 81–95. [Google Scholar] [CrossRef]

- Gardy, J.; Hassanpour, A.; Laia, X.; Ahmed, M.H.; Rehan, M. Biodiesel production from used cooking oil using a novel surface functionalized TiO2 nano-catalyst. Appl. Catal. B Environ. 2017, 207, 297–310. [Google Scholar] [CrossRef]

- Ambursa, M.M.; Ali, T.H.; Voon, L.H.; Sudarsanam, P.; Bhargava, S.K.; Abd-Hamid, S.B. Hydrodeoxygenation of dibenzofuran to bicyclic hydrocarbons using bimetallic Cu-Ni catalysts supported on metal oxides. Fuel 2016, 180, 767–776. [Google Scholar] [CrossRef]

- Ambursa, M.M.; Sudarsanam, P.; Voon, L.H.; Abd-Hamid, S.B.; Bhargava, S.K. Bimetallic Cu-Ni catalysts supported on MCM-41 and Ti-MCM-41 porous materials for hydrodeoxygenation of lignin model compound into transportation fuels. Fuel Proc. Technol. 2017, 162, 87–97. [Google Scholar] [CrossRef]

- Baskar, G.; Gurugulladevi, A.; Nishanthini, T.; Aiswarya, R.; Tamilarasan, K. Optimization and kinetics of biodiesel production from Mahua oil using manganese doped zinc oxide nanocatalyst. Renew. Energy 2017, 103, 641–646. [Google Scholar] [CrossRef]

- Wang, H.; Covarrubias, J.; Prock, H.; Wu, X.; Wang, D.; Bossmann, S.H. Acid-functionalized magnetic nanoparticle as heterogeneous catalysts for biodiesel synthesis. J. Phys. Chem. C 2015, 119, 26020–26028. [Google Scholar] [CrossRef]

- Alves, M.B.; Medeiros, F.C.M.; Sousa, M.H.; Rubim, J.C.; Suarez, P.A.Z. Cadmium and tin magnetic nanocatalysts useful for biodiesel production. J. Braz. Chem. Soc. 2014, 25, 2304–2313. [Google Scholar] [CrossRef]

- Banković-Ilić, I.B.; Miladinović, M.R.; Stamenković, O.S.; Veljković, V.B. Application of nano CaO-based catalysts in biodiesel synthesis. Renew. Sustain. Energy Rev. 2017, 72, 746–760. [Google Scholar] [CrossRef]

- Reddy, C.R.V.; Oshel, R.; Verkade, J.G. Room-temperature conversion of soybean oil and poultry fat to biodiesel catalyzed by nanocrystalline calcium oxides. Energy Fuels 2006, 20, 1310–1314. [Google Scholar] [CrossRef]

- Yoosuk, B.; Udomsap, P.; Puttasawat, B.; Krasae, P. Modification of calcite by hydration–dehydration method for heterogeneous biodiesel production process: The effects of water on properties and activity. Chem. Eng. J. 2010, 162, 135–141. [Google Scholar] [CrossRef]

- Wen, L.; Wang, Y.; Lu, D.; Hu, S.; Han, H. Preparation of KF/CaO nanocatalyst and its application in biodiesel production from Chinese tallow seed oil. Fuel 2010, 89, 2267–2271. [Google Scholar] [CrossRef]

- Hu, S.; Wen, L.; Wang, Y.; Zheng, X.; Han, H. Gas-liquid countercurrent integration process for continuous biodiesel production using a microporous solid base KF/CaO as catalyst. Bioresour. Technol. 2012, 123, 413–418. [Google Scholar] [CrossRef]

- Zu, Y.; Tang, J.; Zhu, W.; Zhang, M.; Liu, G.; Liu, Y.; Zhang, W.; Jia, M. Graphite oxide-supported CaO catalysts for transesterification of soybean oil with methanol. Bioresour. Technol. 2011, 102, 8939–8944. [Google Scholar] [CrossRef]

- Tahvildari, K.; Anaraki, Y.N.; Fazaeli, R.; Mirpanji, S.; Delrish, E. The study of CaO and MgO heterogenic nano-catalyst coupling on transesterification reaction efficacy in the production of biodiesel from recycled cooking oil. J. Environ. Health Sci. Eng. 2015, 13, 73. [Google Scholar] [CrossRef]

- Shekoohi, K.; Hosseini, F.S.; Haghighi, A.H.; Sahrayian, A. Synthesis of some Mg/Co-Al type nano hydrotalcites and characterization. MethodsX 2017, 4, 86–94. [Google Scholar] [CrossRef]

- Chelladurai, K.; Rajamanickam, M. Environmentally benign neem biodiesel synthesis using Nano-Zn-Mg-Al hydrotalcite as solid base catalysts. J. Catal. 2014, 2014, 326575. [Google Scholar] [CrossRef]

- Deng, X.; Fang, Z.; Liu, Y.H.; Yu, C.L. Production of biodiesel from Jatropha oil catalyzed by nanosized solid basic catalyst. Energy 2011, 36, 777–784. [Google Scholar] [CrossRef]

- Dias, A.P.S.; Bernardo, J.; Felizardo, P.; Correia, M.J.N. Biodiesel production over thermal activated cerium modified Mg-Al hydrotalcites. Energy 2012, 41, 344–353. [Google Scholar] [CrossRef]

- Obadiah, A.; Kannan, R.; Ravichandran, P.; Ramasubbu, A.; Kumar, S.V. Nano hydrotalcite as a novel catalyst for biodiesel conversion. Dig. J. Nanomater. Biostruct. 2012, 7, 321–327. [Google Scholar]

- Woodford, J.J.; Dacquin, J.P.; Wilsona, K.; Lee, A.F. Better by design: Nanoengineered macroporous hydrotalcites for enhanced catalytic biodiesel production. Energy Environ. Sci. 2012, 5, 6145–6150. [Google Scholar] [CrossRef]

- Manivannan, R.; Karthikeyan, C. Synthesis of biodiesel from neem oil using Mg-Al nano hydrotalcite. Adv. Mater. Res. 2013, 678, 268–272. [Google Scholar] [CrossRef]

- Gao, L.; Teng, G.; Lv, J.; Xiao, G. Biodiesel synthesis catalyzed by the KF/Ca-Mg-Al hydrotalcite base catalyst. Energy Fuels 2010, 24, 646–651. [Google Scholar] [CrossRef]

- Prabu, M.; Manikandan, M.; Kandasamy, P.; Kalaivani, P.R.; Rajendiran, N.; Raja, T. Synthesis of biodiesel using the Mg/Al/Zn hydrotalcite/SBA-15 nanocomposite catalyst. ACS Omega 2019, 4, 3500–3507. [Google Scholar] [CrossRef]

- Thangaraj, B.; Solomon, P.R.; Muniyandi, B.; Ranganathan, S.; Lin, L. Catalysis in biodiesel production—A review. Clean Energy 2019, 3, 2–23. [Google Scholar] [CrossRef]

- Di Serio, M.; Cozzolino, M.; Giordano, M.; Tesser, R.; Patrono, P. From homogeneous to heterogeneous catalysts in biodiesel production. Ind. Eng. Chem. Res. 2007, 46, 6379–6384. [Google Scholar] [CrossRef]

- Gutiérrez-Ortega, N.; Ramos-Ramírez, E.; Serafín-Muñoz, A.; Zamorategui-Molina, A.; Monjaraz-Vallejo, J. Use of Co/Fe-mixed oxides as heterogeneous catalysts in obtaining biodiesel. Catalysts 2019, 9, 403. [Google Scholar] [CrossRef]

- Al-Ani, A.; Darton, R.J.; Sneddon, S.; Zholobenko, V. Nanostructured zeolites: The introduction of intracrystalline mesoporosity in basic Faujasite-type catalysts. ACS Appl. Nano Mater. 2018, 1, 310–318. [Google Scholar] [CrossRef]

- Kim, K.H.; Lee, O.K.; Lee, E.Y. Nano-immobilized biocatalysts for biodiesel production from renewable and sustainable resources. Catalysts 21018, 8, 68. [Google Scholar] [CrossRef]

- Al-Ani, A.; Mordvinova, N.E.; Lebedev, O.I.; Khodakov, A.Y.; Zholobenko, V. Ion-exchanged zeolite P as a nanostructured catalyst for biodiesel production. Energy Rep. 2019, 5, 357–363. [Google Scholar] [CrossRef]

- Saeedi, M.; Fazaeli, R.; Aliyan, H. Nanostructured sodium–zeolite imidazolate framework (ZIF-8) doped with potassium by sol-gel processing for biodiesel production from soybean oil. J. Sol-Gel Sci. Technol. 2016, 77, 404–415. [Google Scholar] [CrossRef]

- Amalia, S.; Khalifah, S.N.; Baroroh, M.; Muiz, A.; Rahmatullah, A.; Aini, N.; Aqli-Hs, M.R.; Umam, M.N.; Isnaini, I.A.; Suryana, R. Biodiesel production from castor oil using heterogeneous catalyst KOH/Zeolite of natural zeolite Bandung Indonesia. AIP Conf. Proc. 2019, 2120, 080016. [Google Scholar] [CrossRef]

- Brito, A.; Borges, M.E.; Otero, N. Zeolite Y as a heterogeneous catalyst in biodiesel fuel production from used vegetable oil. Energy Fuels 2007, 21, 3280–3283. [Google Scholar] [CrossRef]

- Hassani, M.; Najafpour, G.D.; Mohammadi, M.; Rabiee, M. Preparation, characterization and application of zeolite-based catalyst for production of biodiesel from waste cooking oil. J. Sci. Ind. Res. 2014, 73, 129–133. [Google Scholar]

- Hu, S.; Guan, Y.; Wang, Y.; Han, H. Nano-magnetic catalyst KF/CaO-Fe3O4 for biodiesel production. Appl. Energy 2011, 88, 2685–2690. [Google Scholar] [CrossRef]

- Feyzi, M.; Norouzi, L. Preparation and kinetic study of magnetic Ca/Fe3O4@SiO2 nanocatalysts for biodiesel production. Renew. Energy 2016, 94, 579–586. [Google Scholar] [CrossRef]

- Alaei, S.; Haghighi, M.; Toghiani, J.; Vahid, B.R. Magnetic and reusable MgO/MgFe2O4 nanocatalyst for biodiesel production from sunflower oil: Influence of fuel ratio in combustion synthesis on catalytic properties and performance. Ind. Crops Prod. 2018, 117, 322–332. [Google Scholar] [CrossRef]

- Salimi, Z.; Hosseini, S.A. Study and optimization of conditions of biodiesel production from edible oils using ZnO/BiFeO3 nano magnetic catalyst. Fuel 2019, 239, 1204–1212. [Google Scholar] [CrossRef]

- Ghalandari, A.; Taghizadeh, M.; Rahmani, M. Statistical optimization of the biodiesel production process using a magnetic core-mesoporous shell KOH/Fe3O4@g-Al2O3 nanocatalyst. Chem. Eng. Technol. 2019, 42, 89–99. [Google Scholar] [CrossRef]

- Zillillah Ngu, T.A.; Li, Z. Phosphotungstic acid-functionalized magnetic nanoparticles as an efficient and recyclable catalyst for the one-pot production of biodiesel from grease via esterification and transesterification. Green Chem. 2014, 16, 1202. [Google Scholar] [CrossRef]

- Erdem, S.; Erdem, B.; Öksüzoğlu, R.M. Magnetic nano-sized solid acid catalyst bearing sulfonic acid groups for biodiesel synthesis. Open Chem. 2018, 16, 923–929. [Google Scholar] [CrossRef]

| Seed (Oil) | Fatty Acid Composition (%) | Reference |

|---|---|---|

| Flaxseed | Linolenic (51.56), palmitic (5.7), stearic (5.6), oleic (20.66), linoleic (15.86), arachidic (0.2), g-linolenic (0.23) and behenic (0.18) acids; SFA (11.69) and UFA (88.31) | [19] |

| Cascabela ovata | Oleic (60), capric (0.5), palmitoleic (0.35), palmitic (19.53), linoleic (6.78), stearic (11.50), oleic (59.30) and arachidic (1.56) acids | [20] |

| Spindletree | Linoleic (49.3), palmitoleic (2.0), palmitic (14.5), oleic (29.8), stearic (3.1), 11-eicosenoic (0.1) and arachidic (0.07) acids, SFA (17.67) and UFA (81.21). | [21] |

| Papaya seed | Oleic (47.7), linoleic (37.3) and palmitic (6.1) acids; UFA (87.5) | [22] |

| Apricot | Palmitic (5.9), stearic (2.51) and behenic (0.66) acids; UFA (89.7) | [22] |

| Soybean | Lauric (14.44), myristic (41.04), palmitic (3.46), stearic (1.5), oleic (14.54), linolenic (5.65) | [23] |

| Coconut | Lauric (7.45), myristic (33.54)), palmitic (2.1), stearic (7.79), oleic (8.58), linolenic (9.2) | [23] |

| Groundnut | Lauric (14.57), palmitic (4.75), stearic (12.07), oleic (12.72), linolenic (5.22) | [23] |

| Linoleic sunflower oil | Palmitic (6.18), stearic (3.98), oleic (21.13), linoleic (66.79) linolenic (<0.20), arachidic (0.20), behenic (0.24) and tetracosanoic acid (0.24); SFA (11.27) and UFA (87.92) | [24] |

| Oleic sunflower | Palmitic (5.20), stearic (3.36), oleic (58.91), linoleic (32.24) linolenic (0.20), arachidic (<0.20), behenic (<0.20) and tetracosanoic acid (<0.20); SFA (8.56) and UFA (91.35) | [24] |

| Canola | Palmitic (4.98), stearic (2.14), oleic (60.86), linoleic (22.42) linolenic (8.11), arachidic (0.88), myristic (0.14) and palmitoleic (0.32) acid | [25] |

| Microorganism (Group) | Specie | Substrate | Reference |

|---|---|---|---|

| Yeast | Rhodotorula graminis | Glucose | [26] |

| Candida tropicalis and Yarrowia lipolytica | Palm oil mill effluent and crude glycerol | [28] | |

| Fungi | Coniochaeta hoffmannii | Carrot pomace | [29] |

| lternaria alternata, Cladosporium cladosporioides, Epicoccum nigrum, Fusarium oxysporum, Aspergillus parasiticus and Emericella nidulans | Sugarcane molasses | [30] | |

| Microalgae | Chlorella minutissima | Inorganic salts | [31] |

| Scenedesmus obliquus and Desmodesmus spp. | Municipal wastewater | [32] | |

| Bacteria | Serratia sp. | Municipal secondary sludge | [33] |

| Bacillus sp. | Sewage sludge | [34] |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ingle, A.P.; Chandel, A.K.; Philippini, R.; Martiniano, S.E.; da Silva, S.S. Advances in Nanocatalysts Mediated Biodiesel Production: A Critical Appraisal. Symmetry 2020, 12, 256. https://doi.org/10.3390/sym12020256

Ingle AP, Chandel AK, Philippini R, Martiniano SE, da Silva SS. Advances in Nanocatalysts Mediated Biodiesel Production: A Critical Appraisal. Symmetry. 2020; 12(2):256. https://doi.org/10.3390/sym12020256

Chicago/Turabian StyleIngle, Avinash P., Anuj K. Chandel, Rafael Philippini, Sabrina Evelin Martiniano, and Silvio Silvério da Silva. 2020. "Advances in Nanocatalysts Mediated Biodiesel Production: A Critical Appraisal" Symmetry 12, no. 2: 256. https://doi.org/10.3390/sym12020256

APA StyleIngle, A. P., Chandel, A. K., Philippini, R., Martiniano, S. E., & da Silva, S. S. (2020). Advances in Nanocatalysts Mediated Biodiesel Production: A Critical Appraisal. Symmetry, 12(2), 256. https://doi.org/10.3390/sym12020256