Peristaltic Pumping of Nanofluids through a Tapered Channel in a Porous Environment: Applications in Blood Flow

Abstract

:1. Introduction

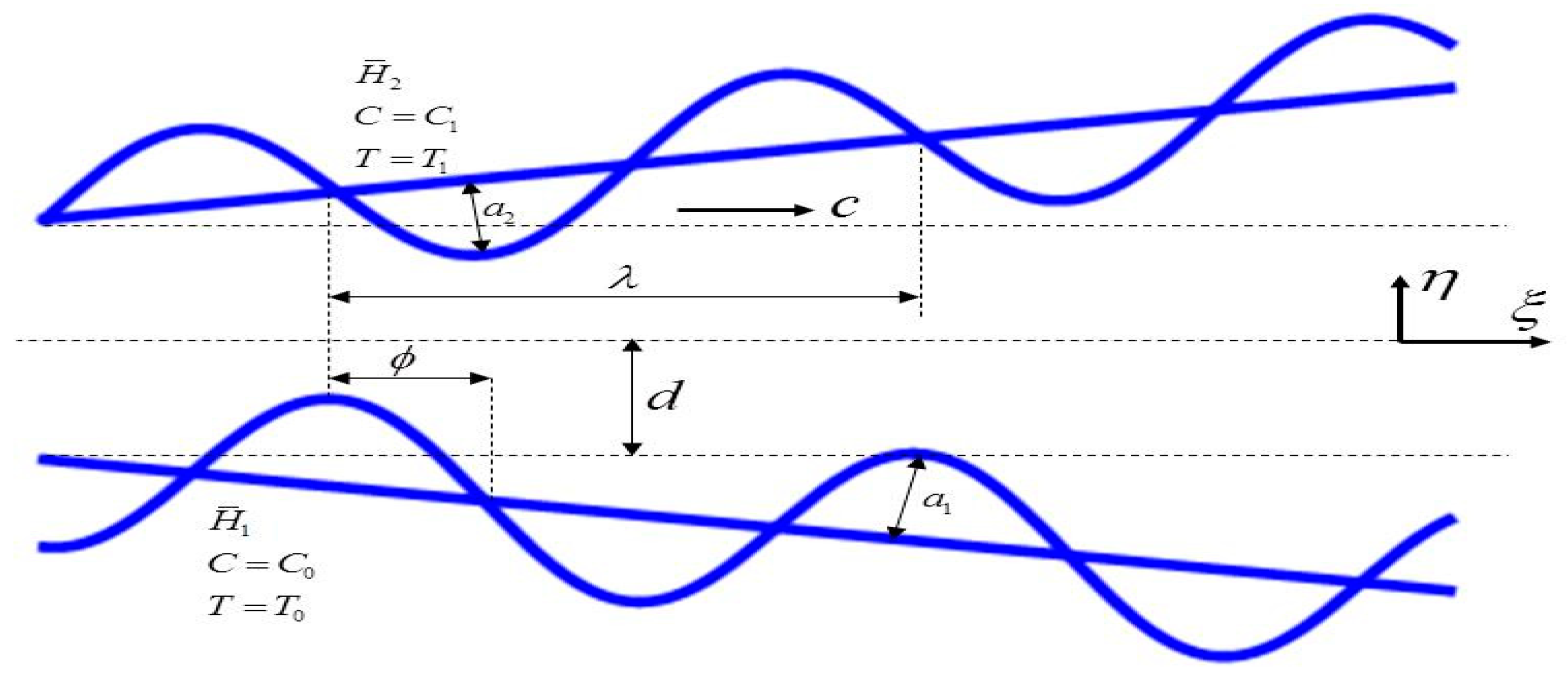

2. Mathematical Formulation

3. Convective Boundary Conditions

4. Non-Dimensional Analysis

5. Analytical Solution

6. Computational Results and Discussion

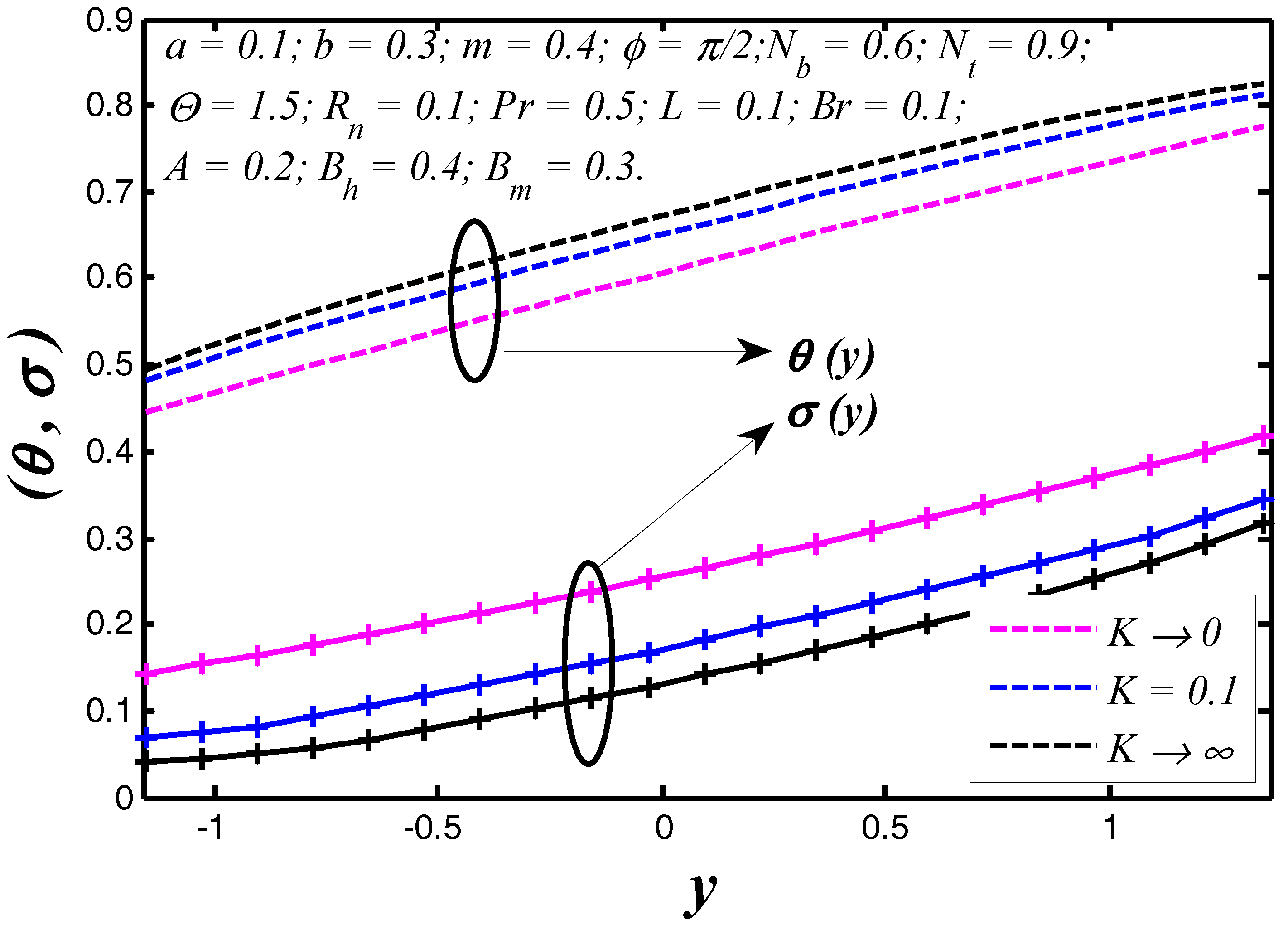

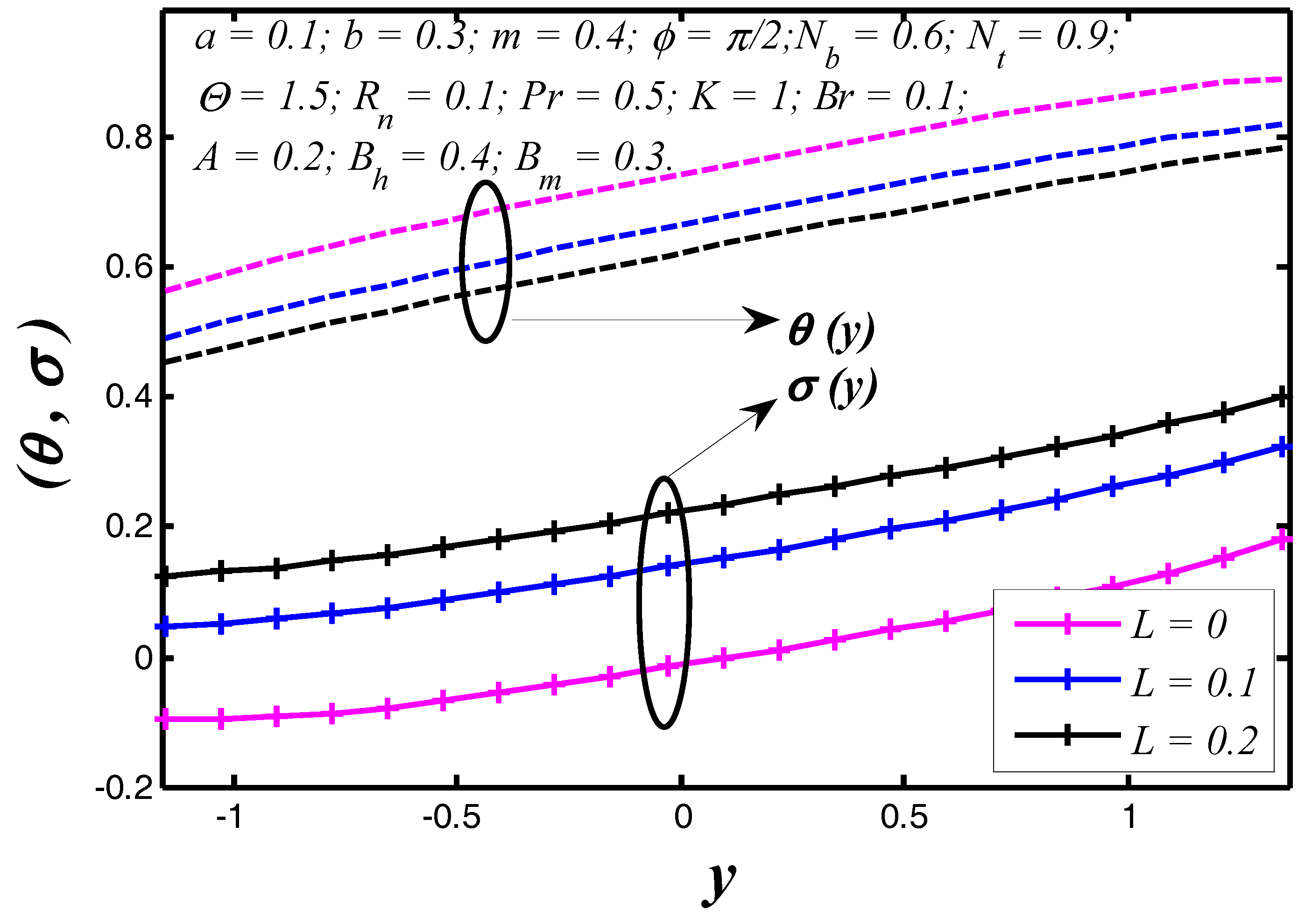

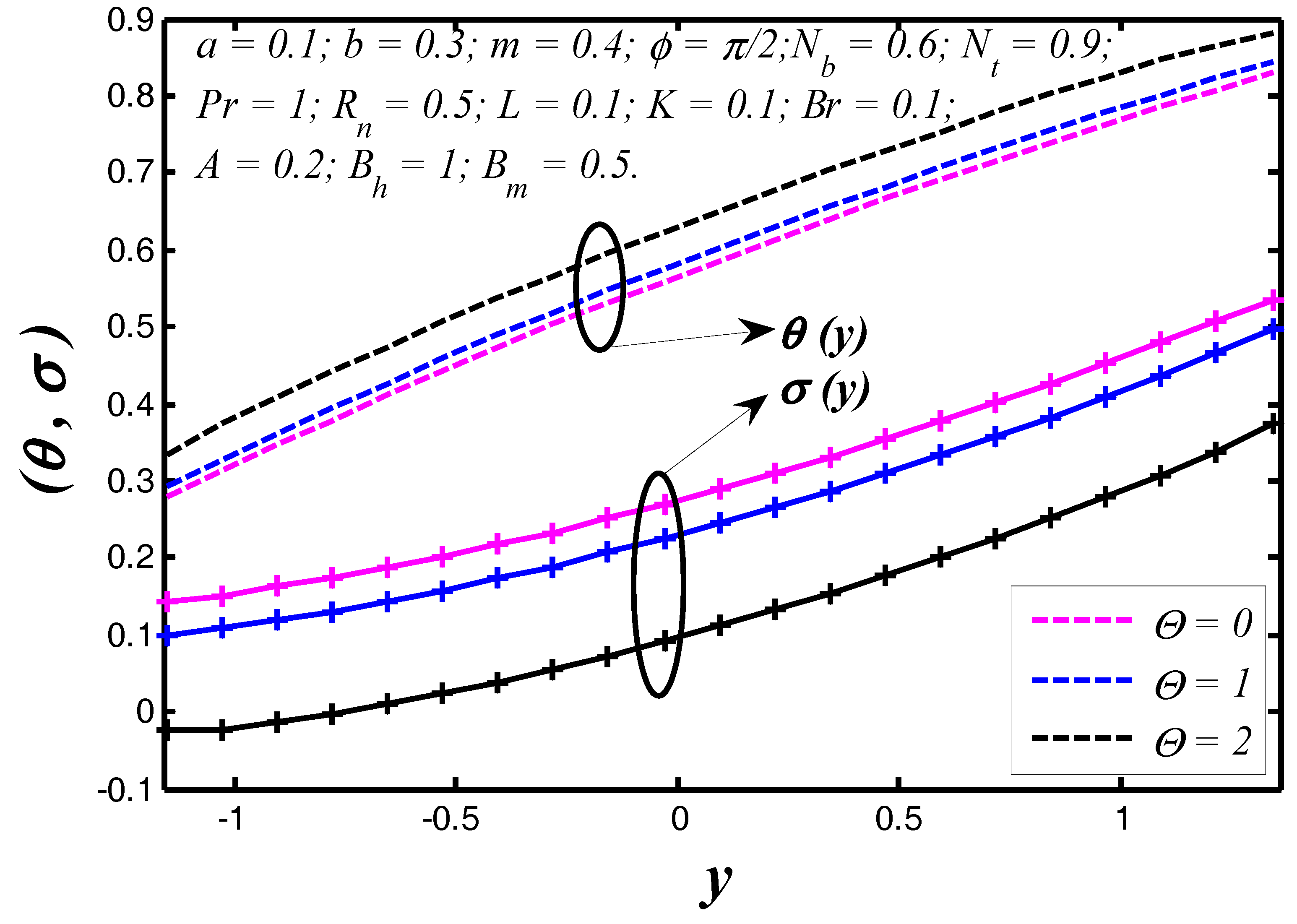

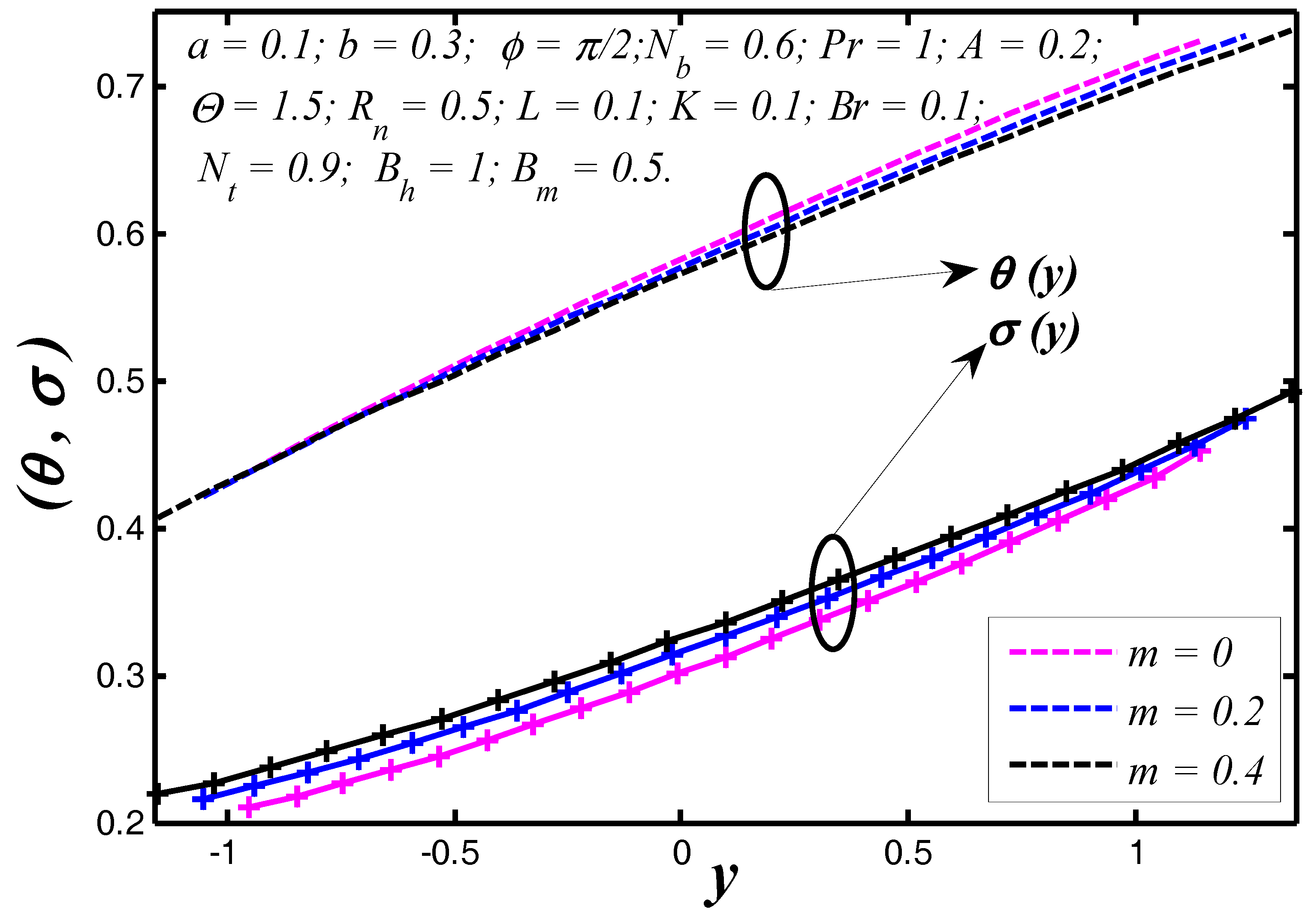

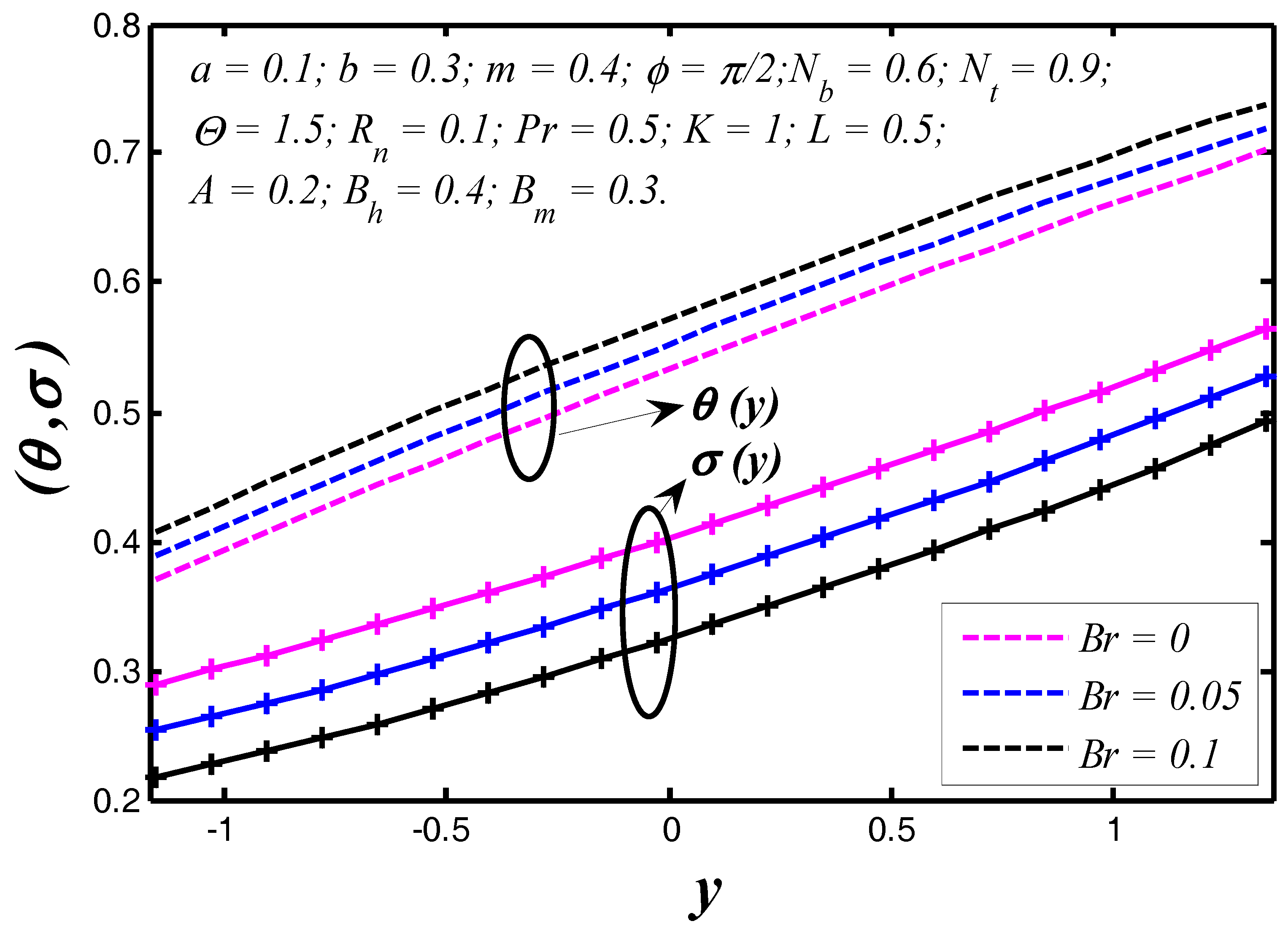

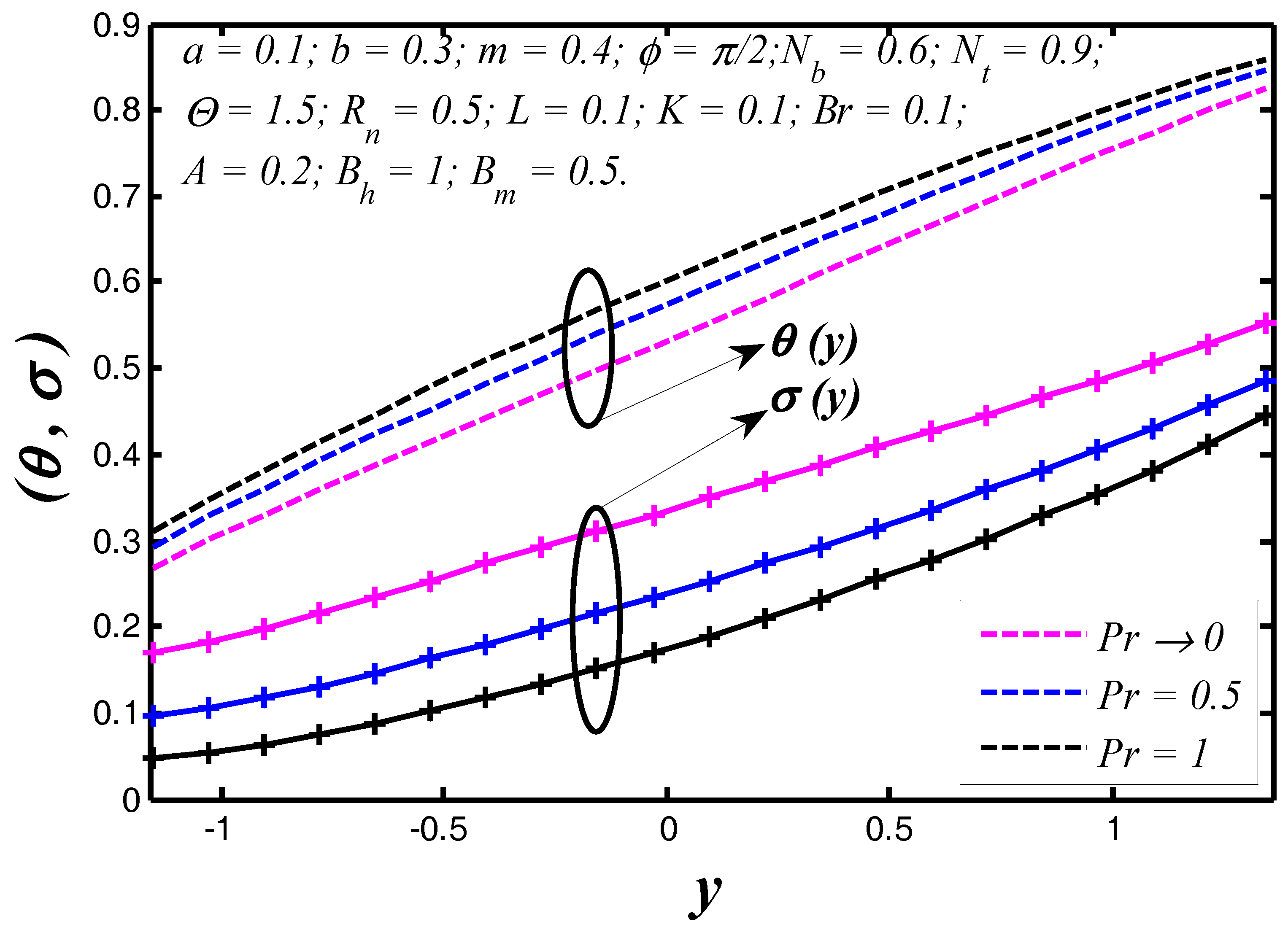

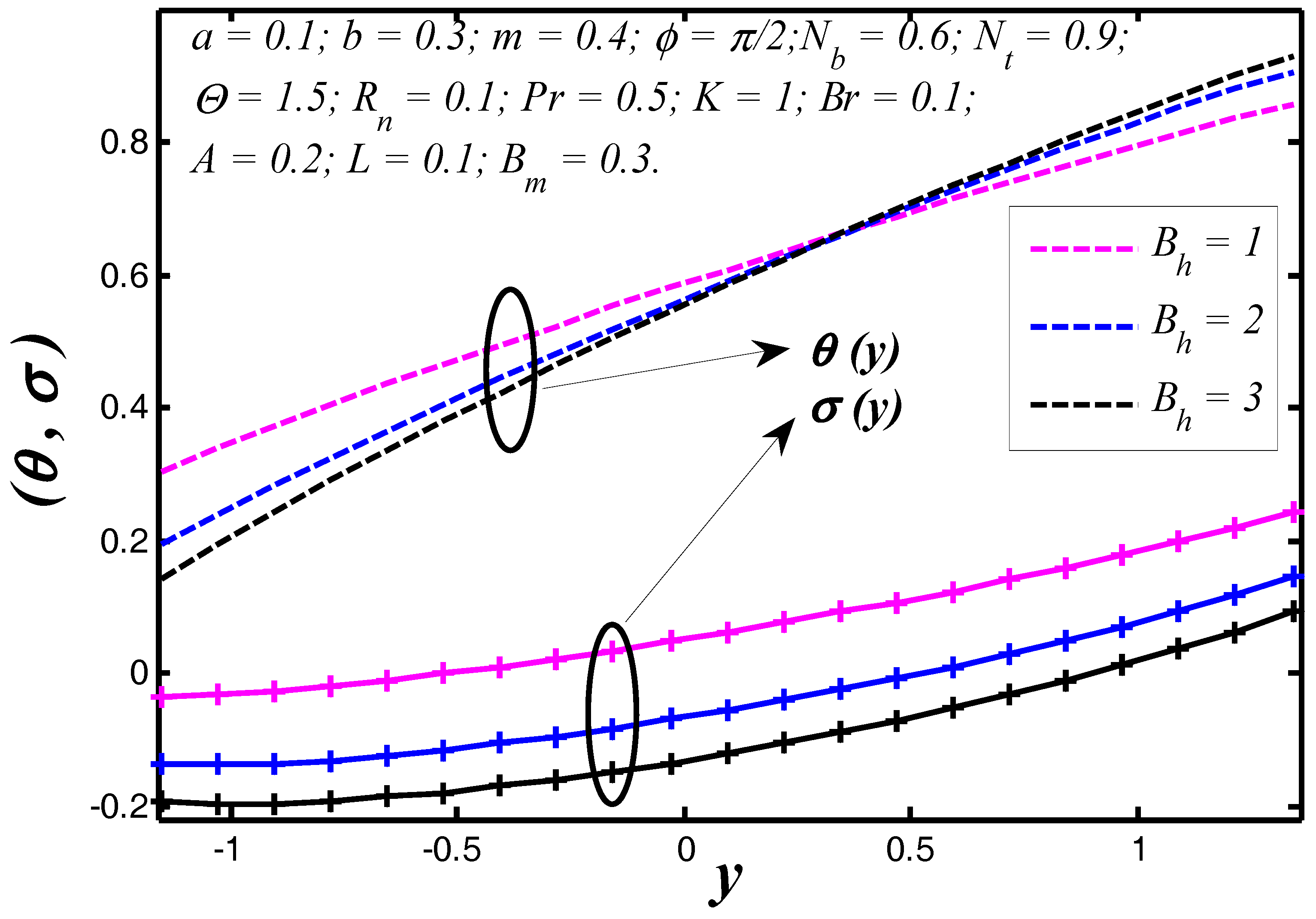

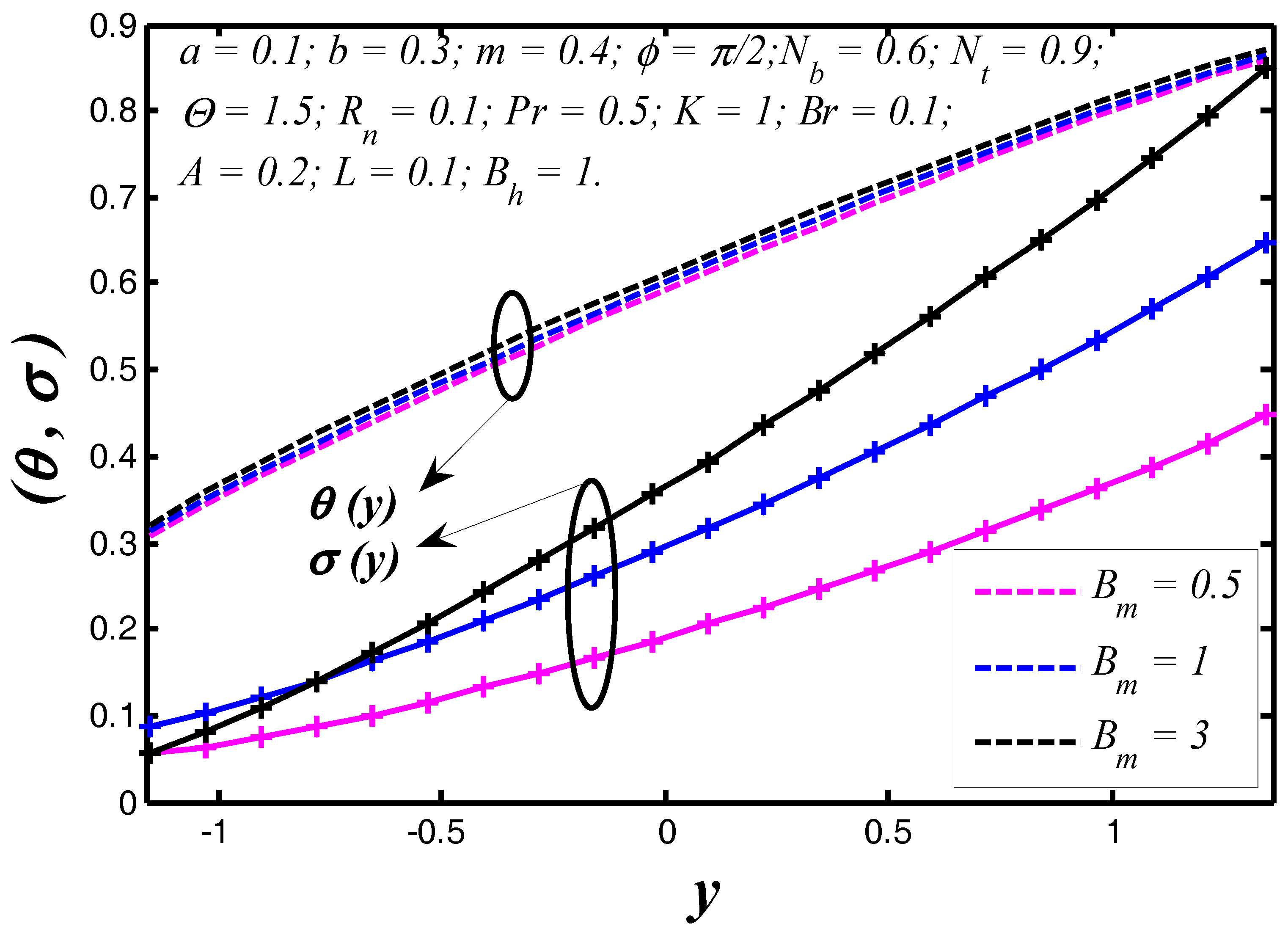

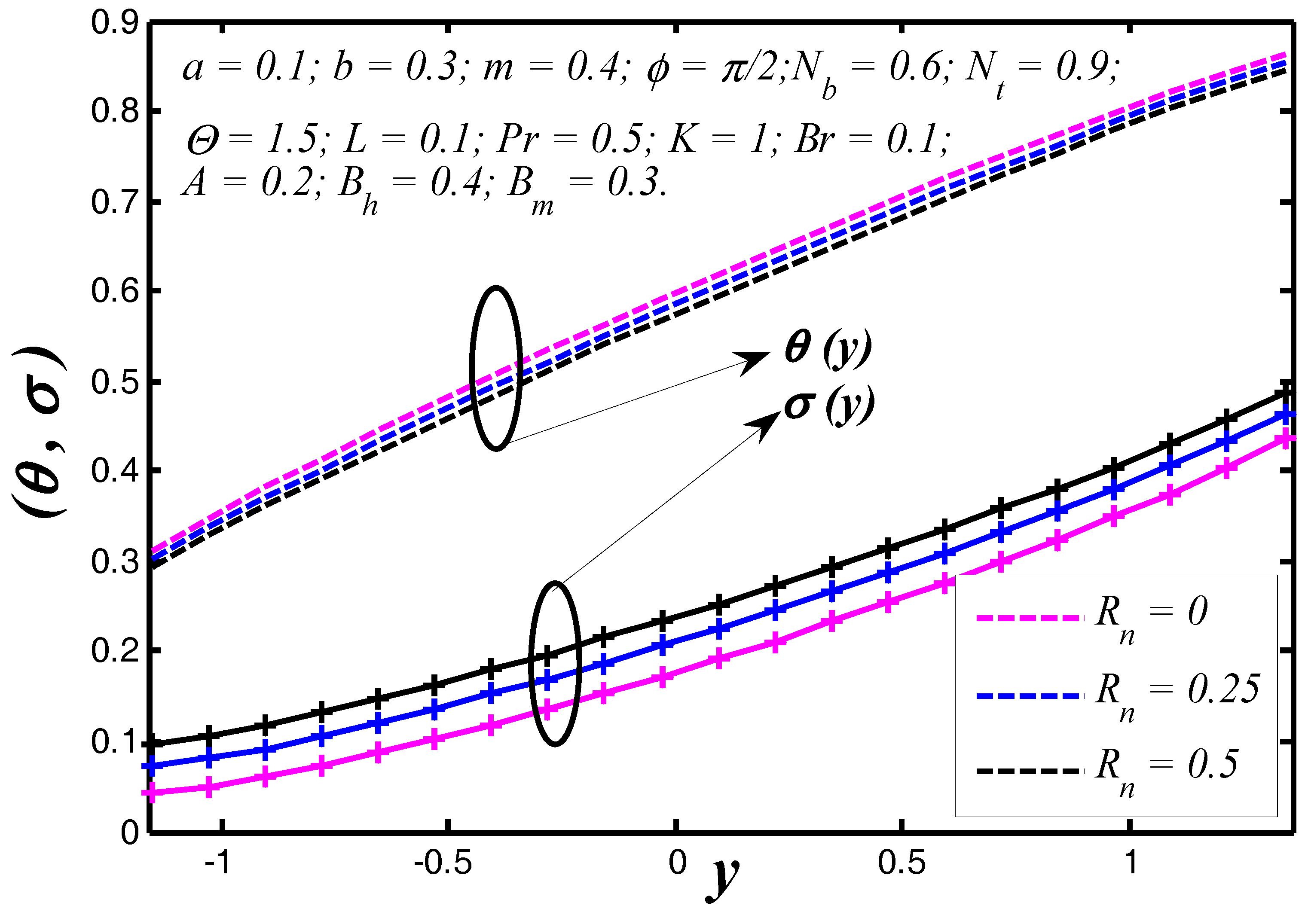

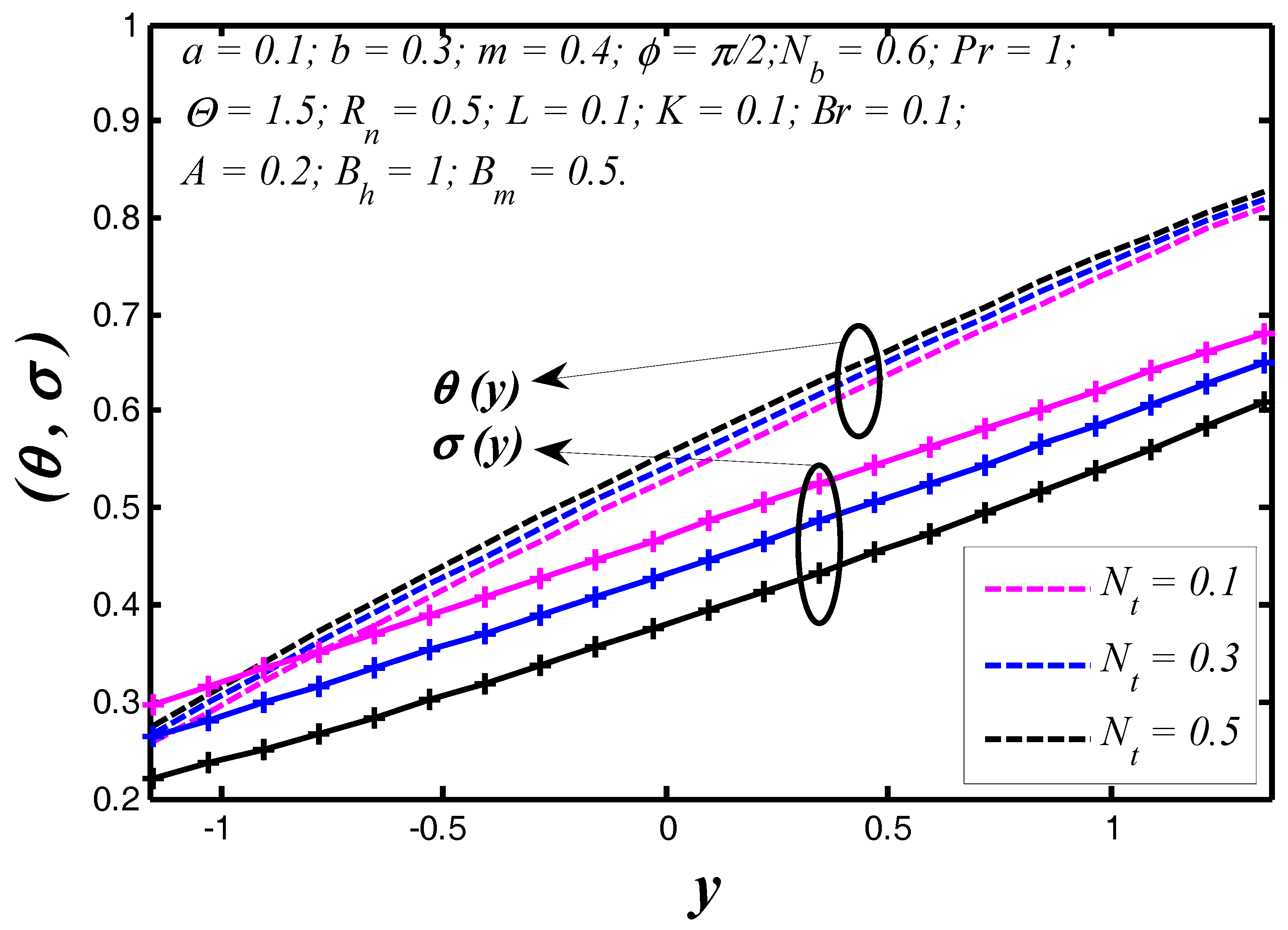

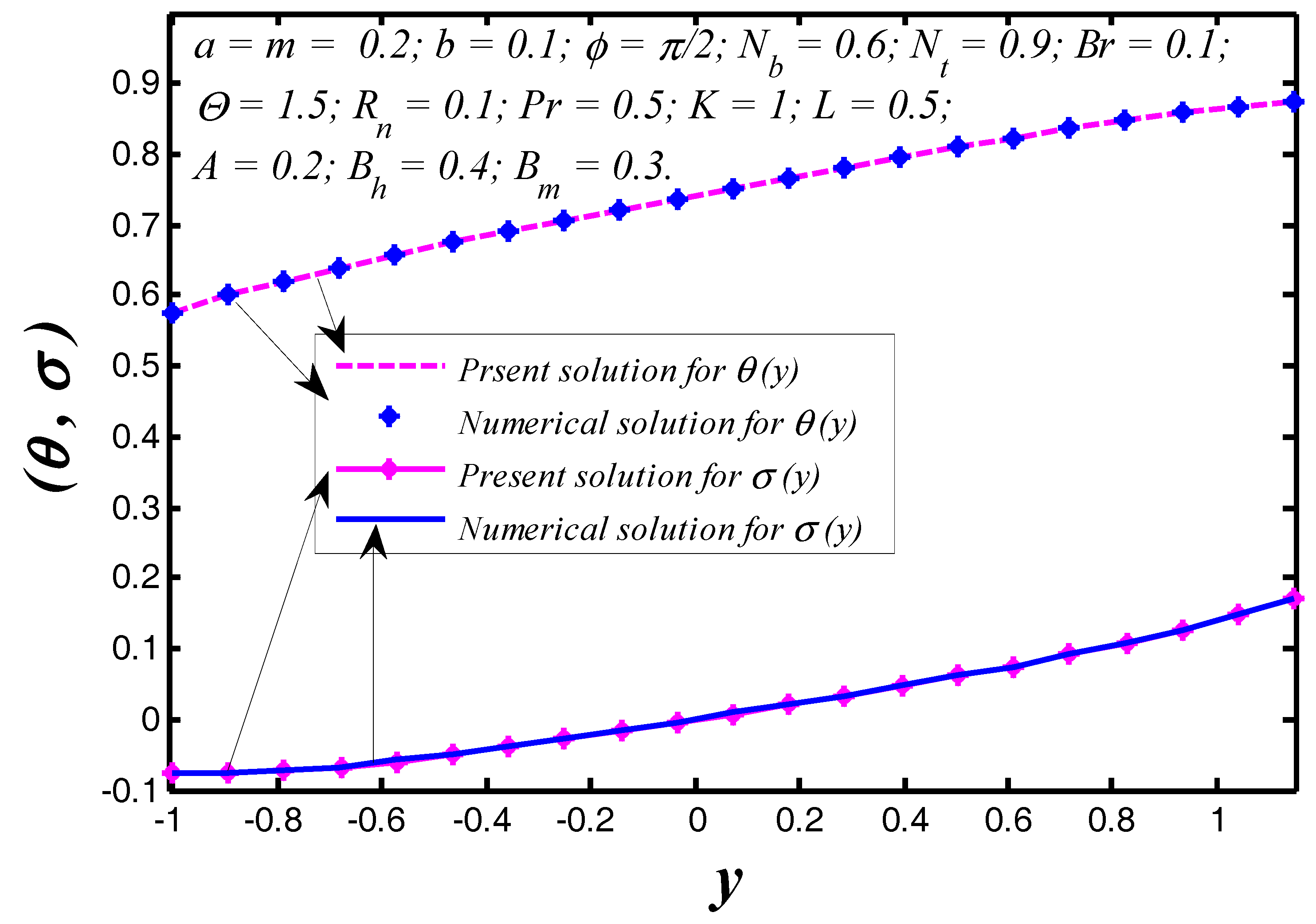

6.1. Thermal and Concentration Profiles

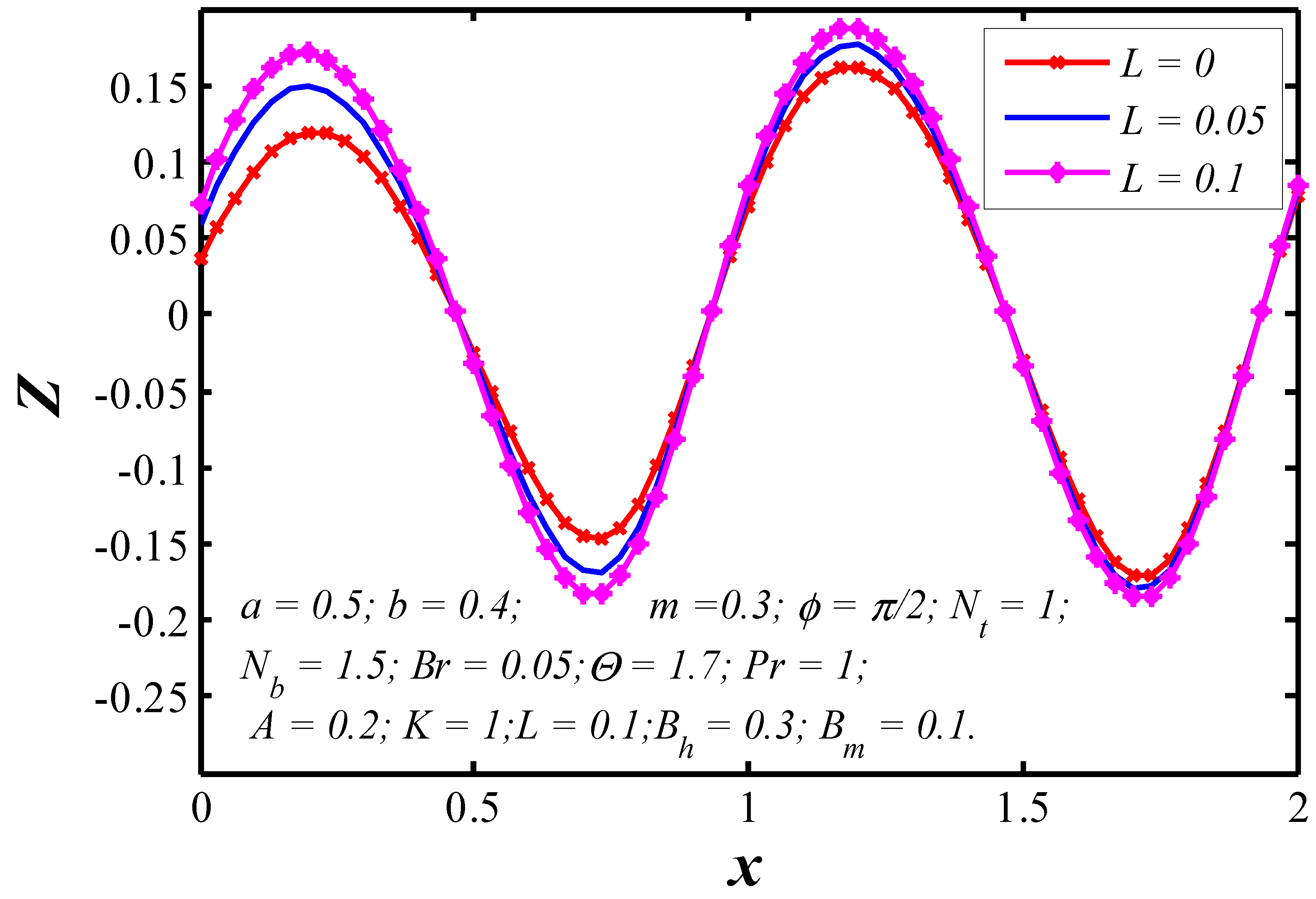

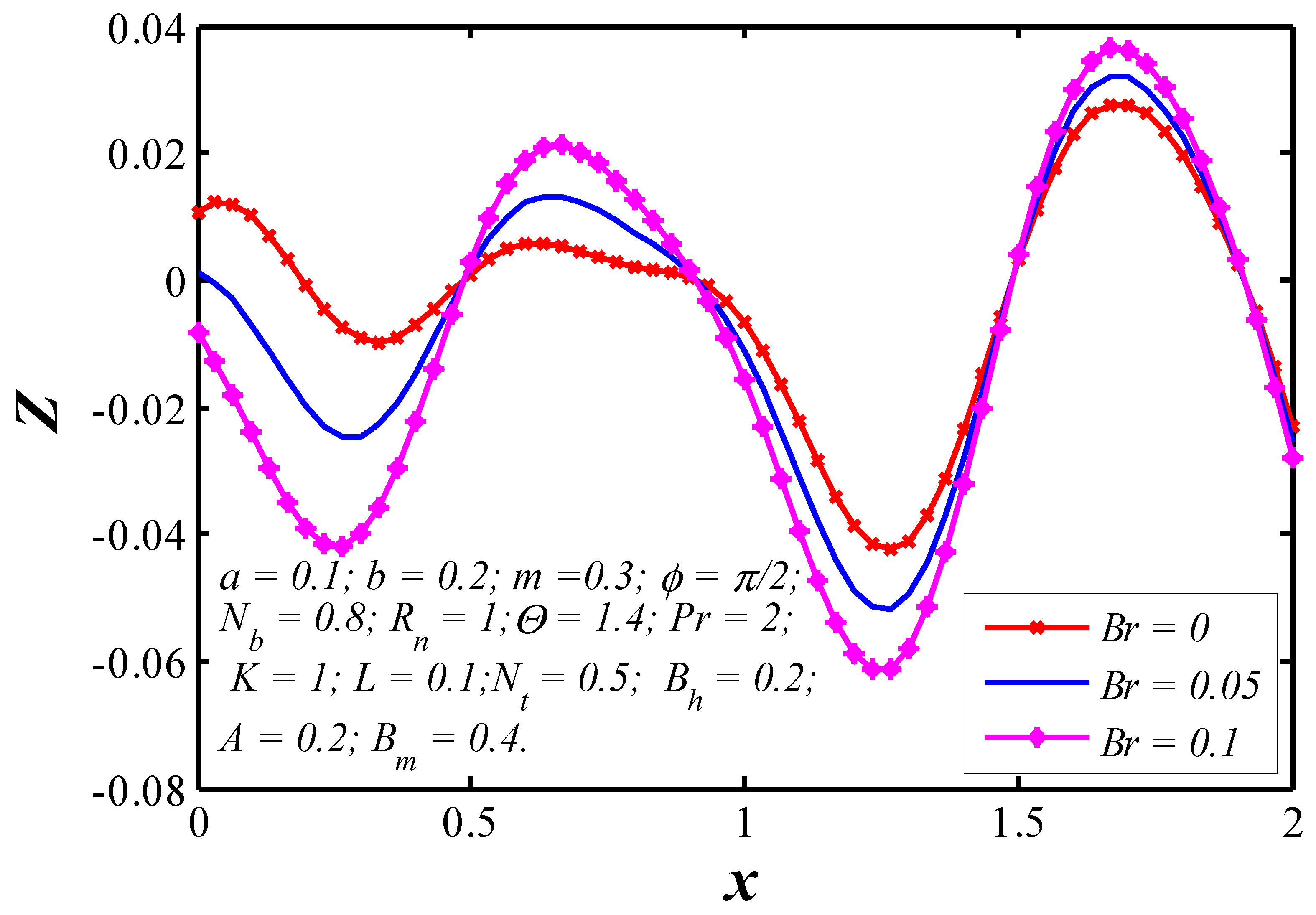

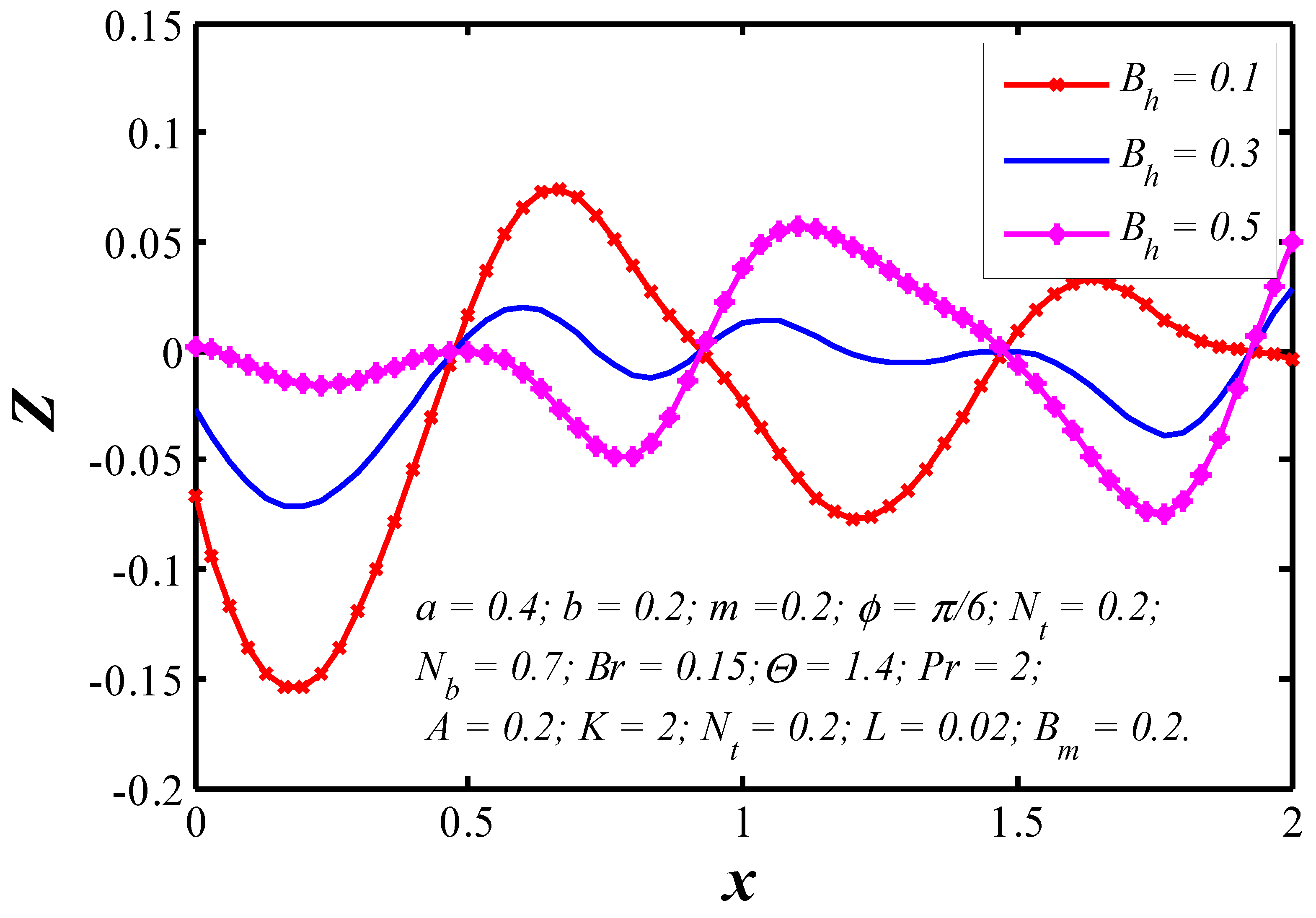

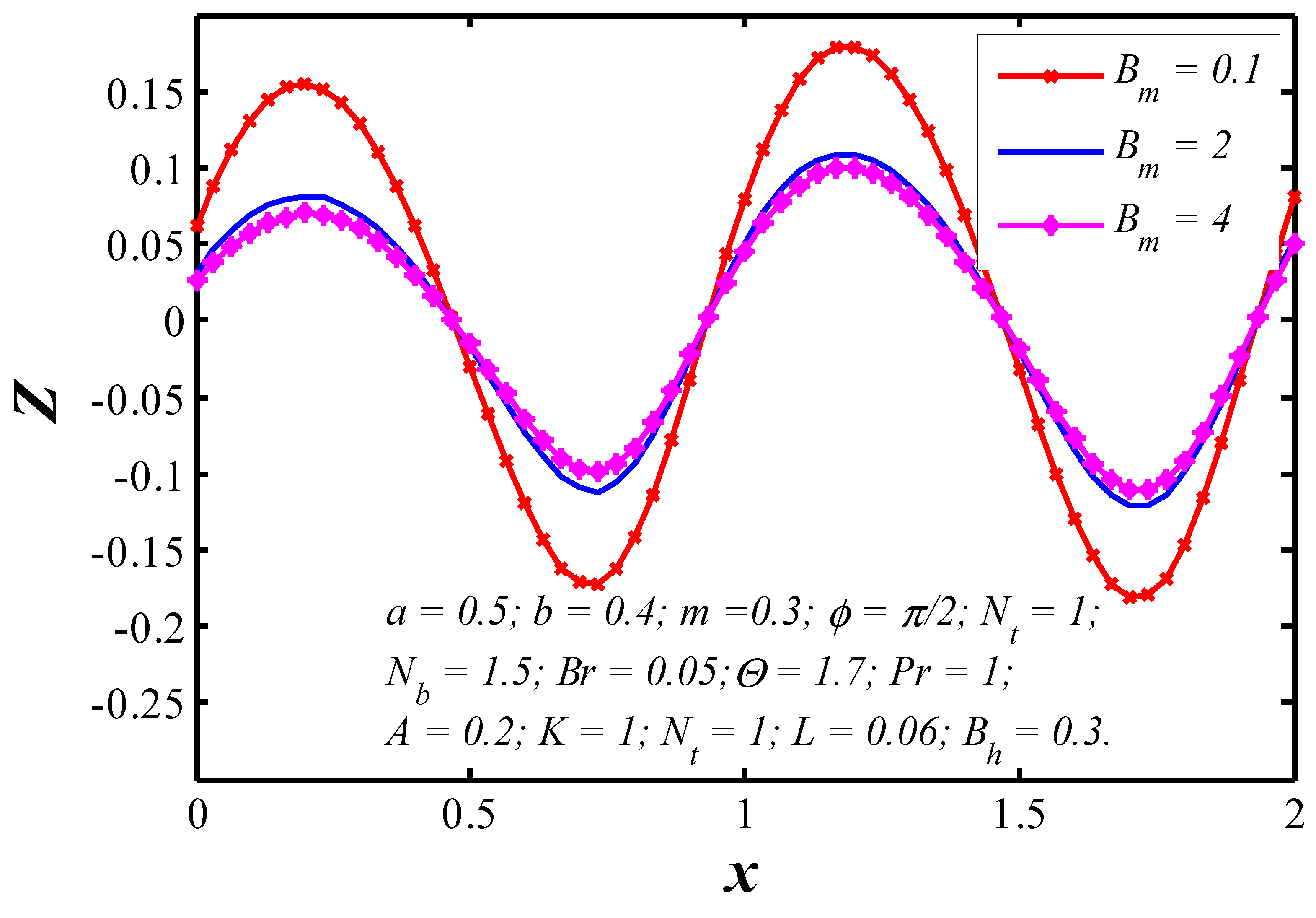

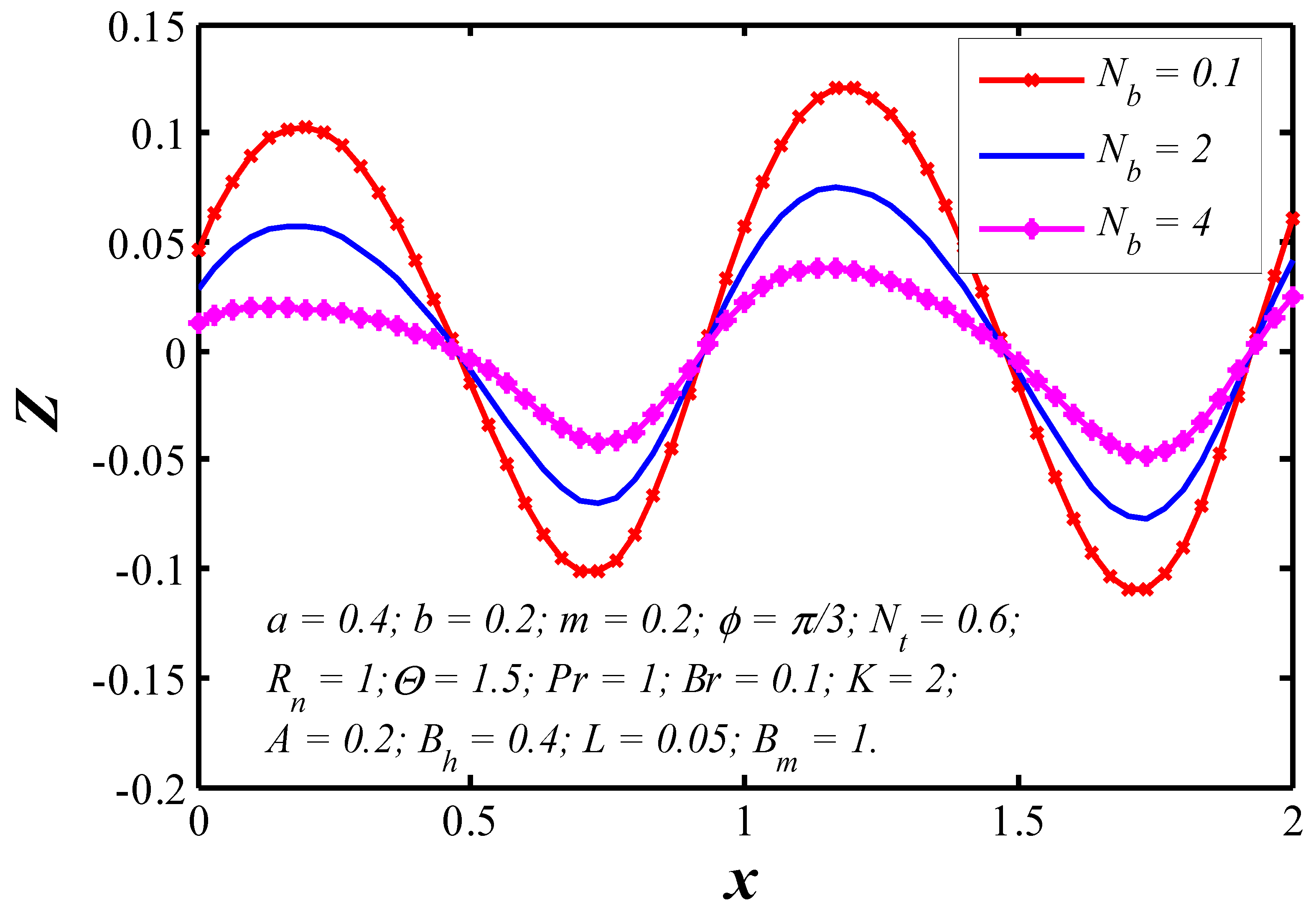

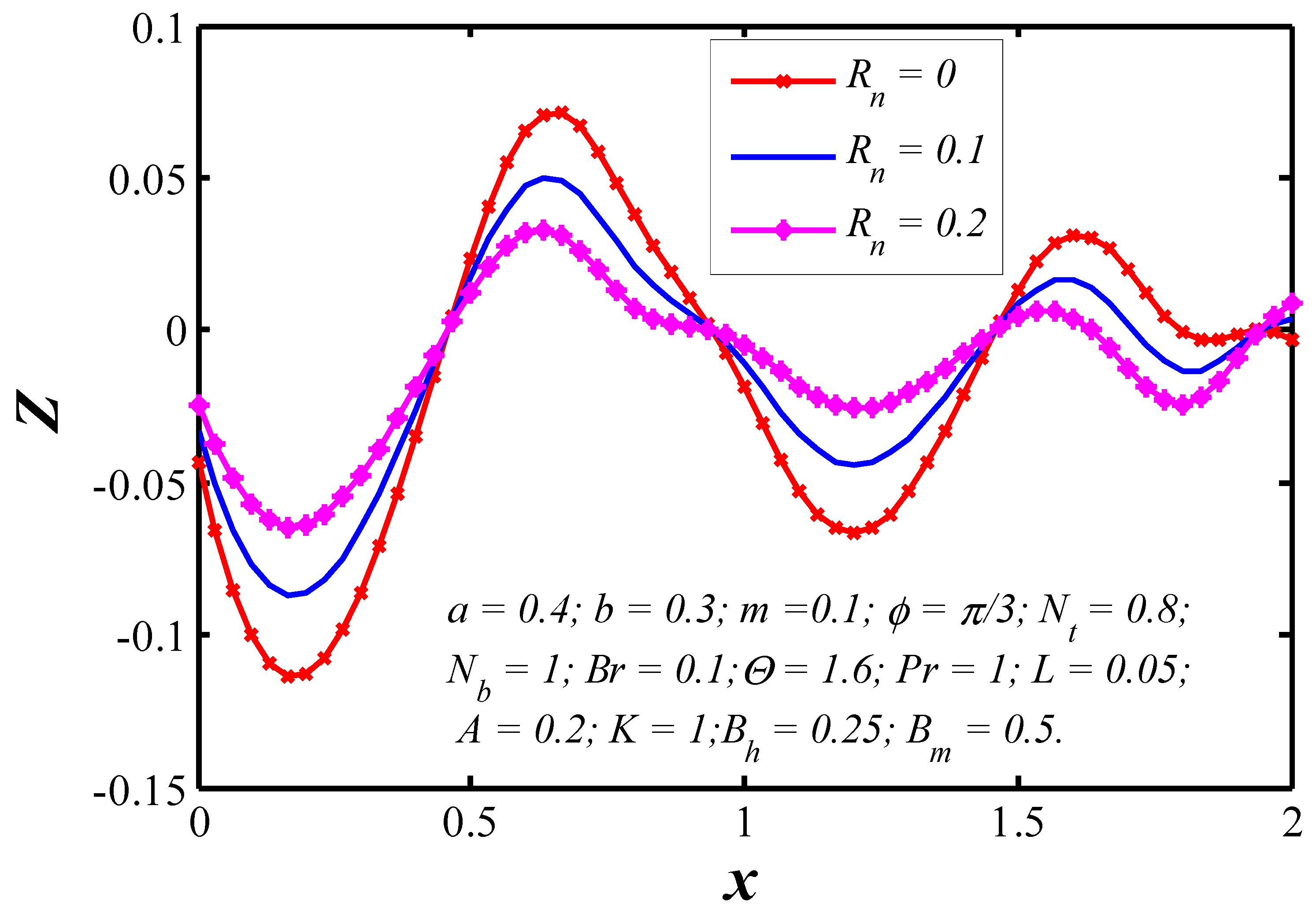

6.2. Nanoparticle Heat Transfer Coefficient

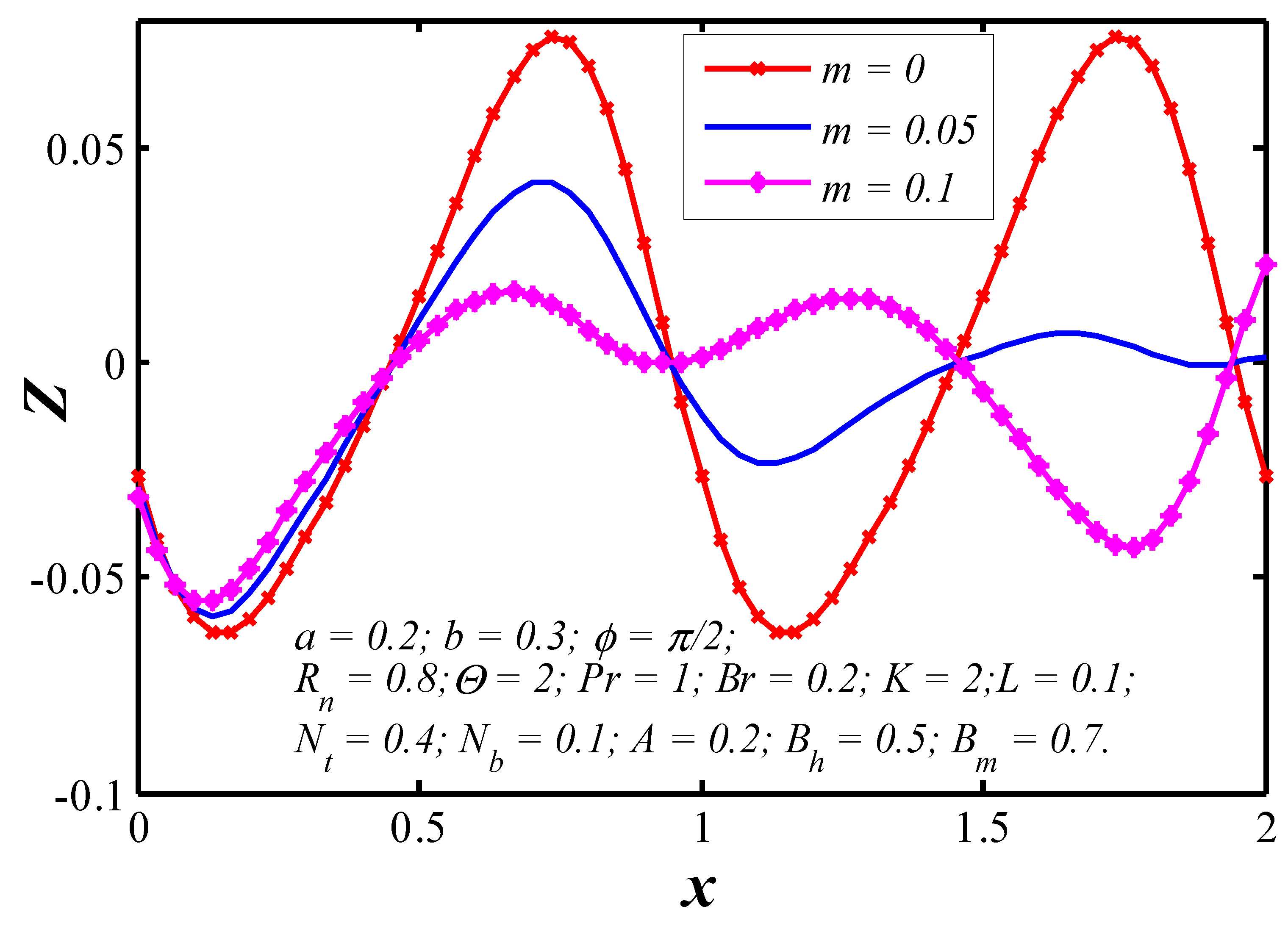

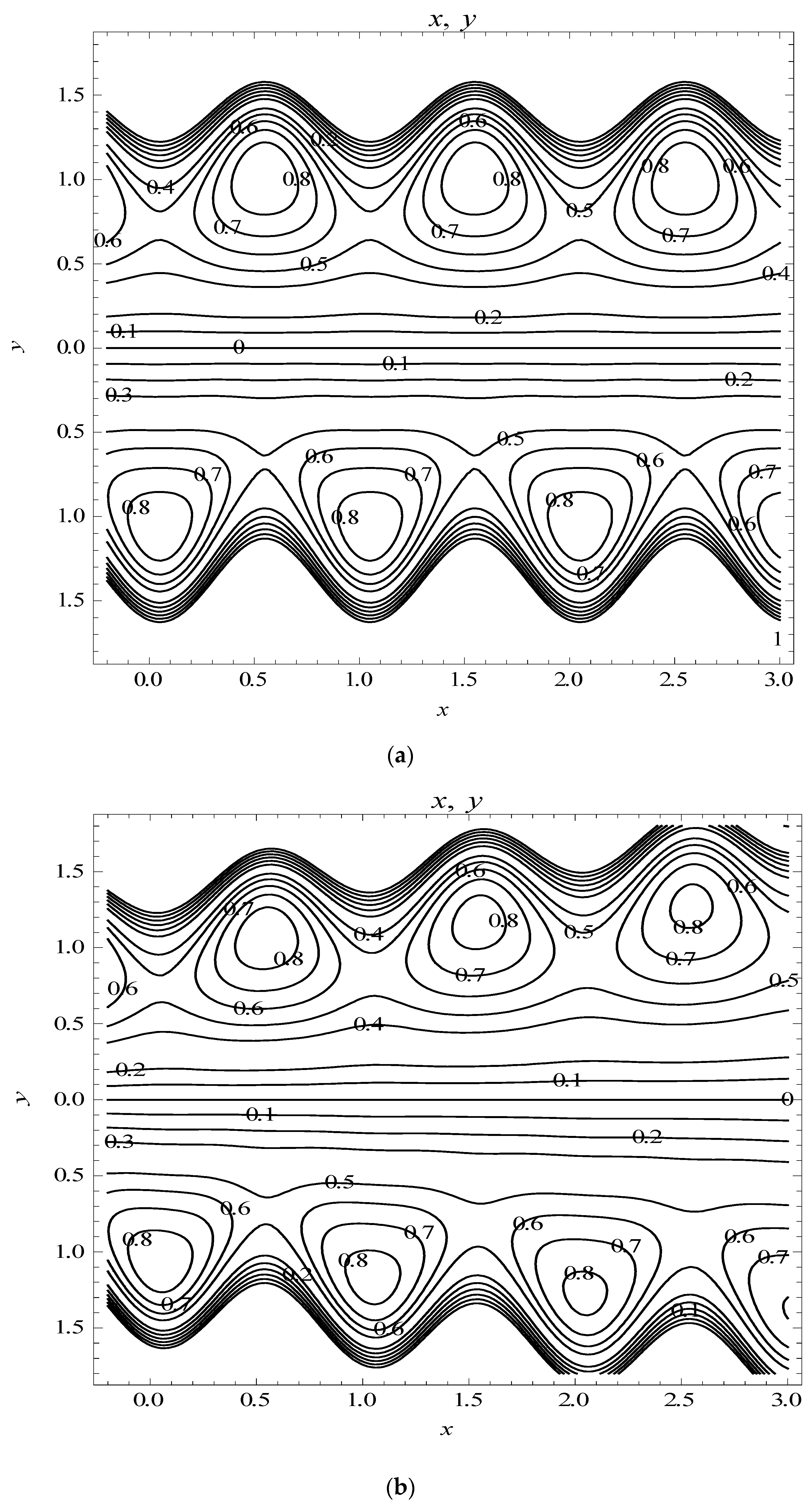

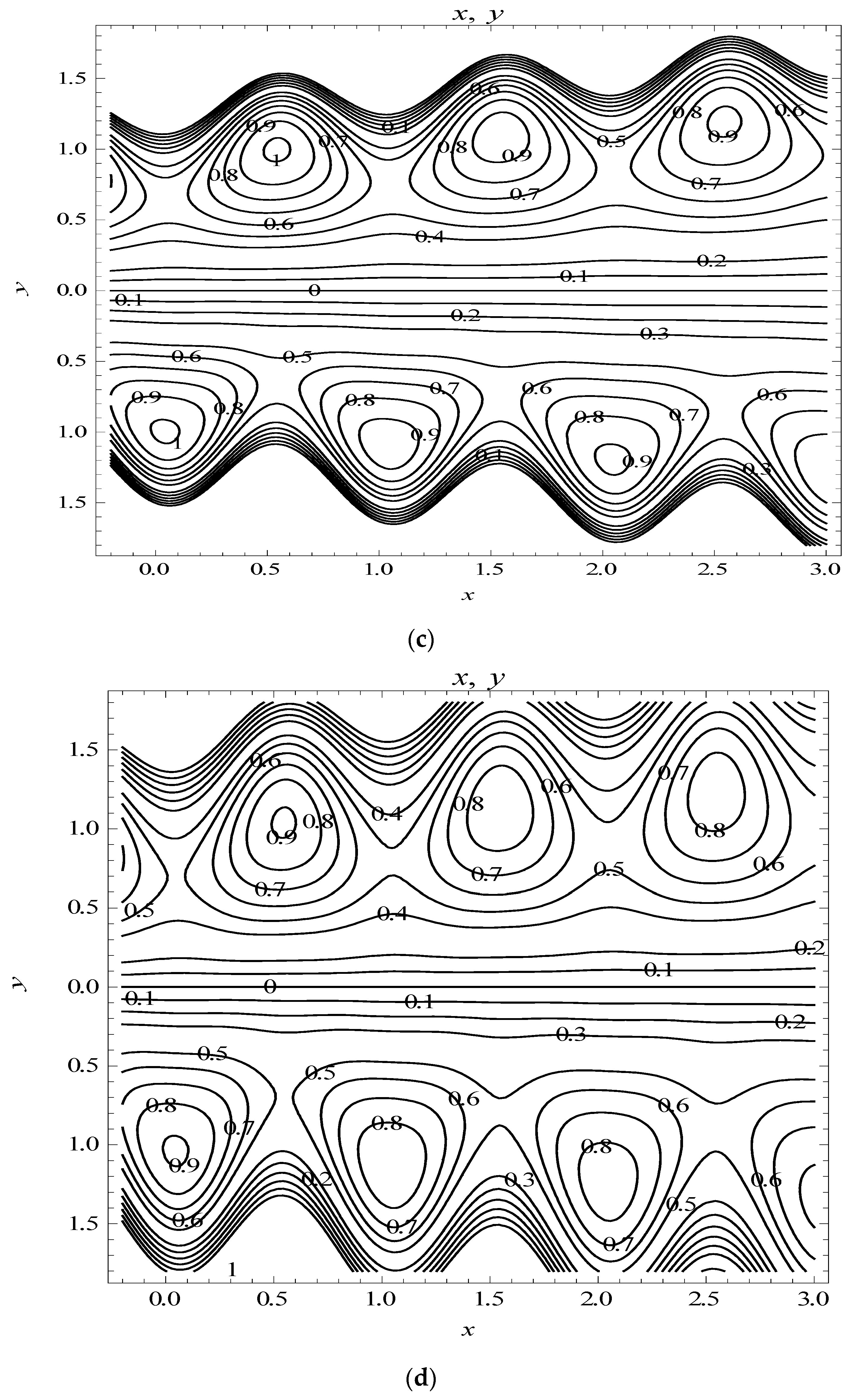

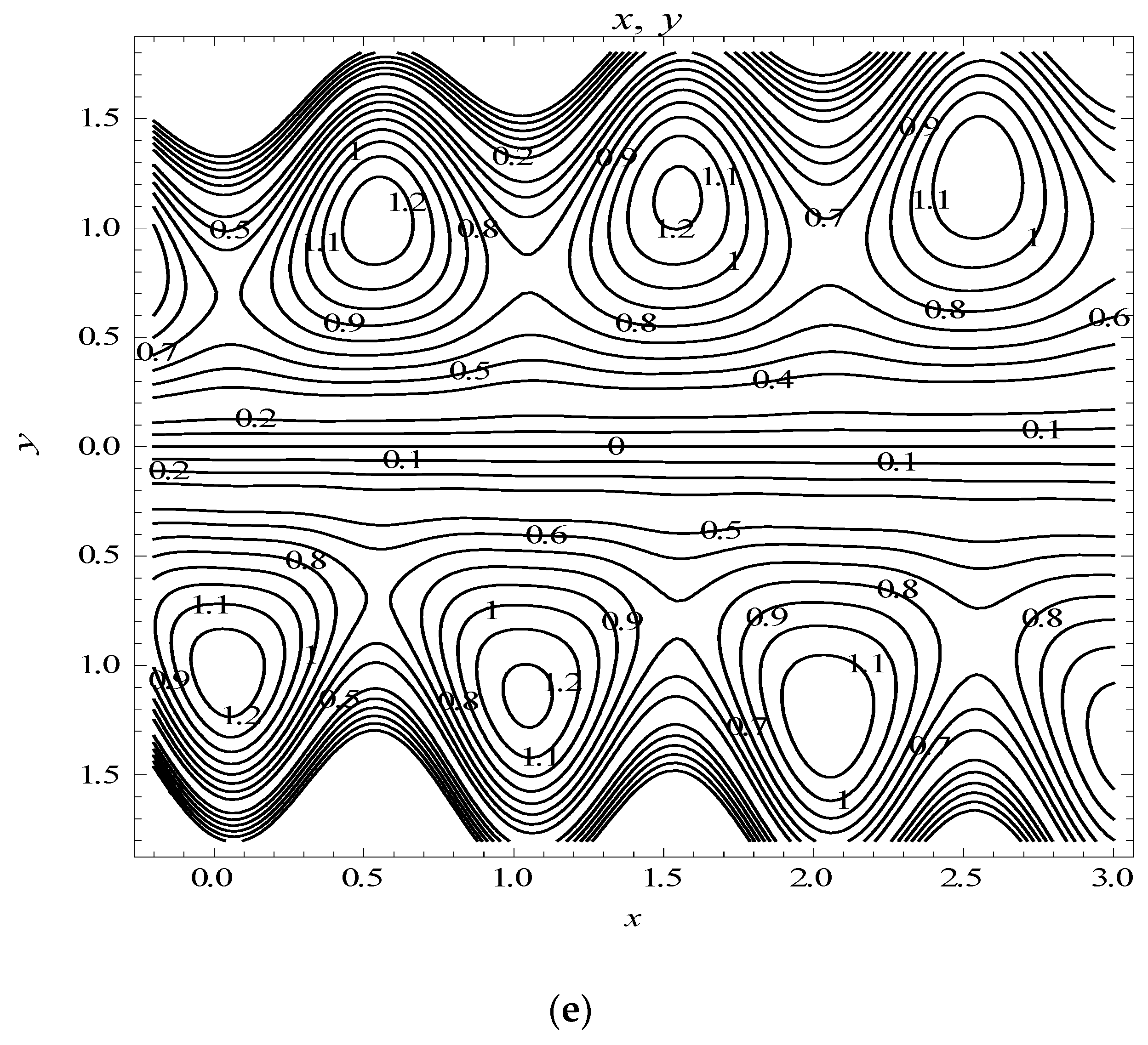

6.3. Trapping

6.4. Validation

7. Conclusions

- Nanoparticle heat transfer between the tapered walls strongly depends on Brinkman number because the tissue presents the chief resistance to heat flow.

- Thermal radiation contains the potential to contribute a significant change in the nanoparticle temperature distribution.

- With increasing the radiation parameter, the nanoparticle temperature and heat transfer coefficient enhance.

- The nanoparticle temperature reduces with enhancing the Prandtl number, however, reverse behavior is noticed for nanoparticle concentration.

- Heat transfer coefficient depends on the flow, thermal and geometrical nature of flow regime.

- The trapping phenomenon also alters with changing the magnitude of slip and permeability parameters.

- The findings of the present models can be utilized to engineer smart peristaltic pumps which can be applicable for transporting drugs and delivery of nanoparticles.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| Symbol | description | Unit |

| Dimensional amplitude of the lower and upper walls | m | |

| Wave speed | m/s | |

| Nanoparticle volumetric volume fraction | Kg/m3 | |

| Nanoparticle concentration at the lower and upper walls | Kg/m3 | |

| Brownian diffusion coefficient | m/s | |

| Themophoretic diffusion coefficient | m2/s | |

| Dimensionless half width of the channel | m | |

| Heat transfer coefficient | W/m2K (or) kg/s3K | |

| Mass transfer coefficient | m/s | |

| Permeable of porous medium | H/m | |

| Permeability of the porous wavy wall | Darcy (or) m2 | |

| Thermal conductivity of wavy wall | W/mK | |

| Mass conductivity of wavy wall | W/mK | |

| Dimensional non-uniform parameter | m | |

| Dimensional pressures | Pa (or) N/m2 (or) kg/ms2 | |

| Uni-directional thermal radiative flux | kg/s3 (or) W/m2 | |

| Dimensional time | s | |

| Nanoparticle temperature | K | |

| Mean temperature | K | |

| Temperature at the lower and upper walls | K | |

| Velocity components in the wave frame | m/s | |

| Rectangular coordinates | m | |

| Density of the fluid | Kg/m3 | |

| Density of the particle | Kg/m3 | |

| Dynamic Viscosity | kg/m.s | |

| Thermal conductivity of the fluid | m2/s | |

| Wave length | m |

Dimensionless parameters:

| Slip coefficient at the surface of the porous walls | |

| Blood flow constant | |

| Dimensionless amplitude of the lower and upper walls | |

| Heat transfer Biot number | |

| Mass transfer Biot number | |

| Brinkman number | |

| Eckert number | |

| Dimensionless flow rate | |

| Lower and upper wall boundaries of the micro- asymmetric channel | |

| Dimensionless lower and upper wall shapes in wave frame | |

| Slip parameter | |

| Dimensionless non-uniform parameter | |

| Thermophoresis parameter | |

| Brownian motion parameter | |

| Dimensionless pressure | |

| Prandtl number | |

| R | Reynolds number |

| Thermal radiation | |

| Schmidt number | |

| Dimensionless time | |

| Velocity components in the wave frame | |

| Constant flow rate | |

| Dimensionless rescaled nanoparticle volume fraction | |

| Dimensionless nanoparticle temperature | |

| Stream function | |

| Phase difference | |

| Permeability parameter | |

| Wave number |

Appendix A

References

- Burns, J.C.; Parkes, T. Peristaltic motion. J. Fluid Mech. 1967, 29, 731–743. [Google Scholar] [CrossRef]

- Zien, T.F.; Ostrach, S. A long wave approximation to peristaltic motion. J. Biomech. 1970, 3, 63–75. [Google Scholar] [CrossRef]

- Raju, K.K.; Devanathan, R. Peristaltic motion of a non-Newtonian fluid. Rheol. Acta 1972, 11, 170–178. [Google Scholar] [CrossRef]

- Ellahi, R.; Zeeshan, A.; Hussain, F.; Asadollahi, A. Peristaltic blood flow of couple stress fluid suspended with nanoparticles under the influence of chemical reaction and activation energy. Symmetry 2019, 11, 276. [Google Scholar] [CrossRef]

- Zeeshan, A.; Ijaz, N.; Abbas, T.; Ellahi, R. The sustainable characteristic of Bio-bi-phase flow of peristaltic transport of MHD Jeffery fluid in human body. Sustainability 2018, 10, 2671. [Google Scholar] [CrossRef]

- Hussain, F.; Ellahi, R.; Zeeshan, A.; Vafai, K. Modelling study on heated couple stress fluid peristaltically conveying gold nanoparticles through coaxial tubes: A remedy for gland tumors and arthritis. J. Mol. Liq. 2018, 268, 149–155. [Google Scholar] [CrossRef]

- Choi, S.U.S.; Eastman, J.A. Enhancing Thermal Conductivity of Fluids with Nanoparticles. In Proceedings of Enhancing Thermal Conductivity of Fluids with Nanoparticles, San Francisco, CA, USA; American Society of Mechanical Engineers, FED: New York, NY, USA, 1995; Volume 231, pp. 99–105. Available online: https://www.osti.gov/biblio/196525-enhancing-thermal-conductivity-fluids-nanoparticles (accessed on 21 June 2019).

- Masuda, H.; Ebata, A.; Teramae, K.; Hishinuma, N. Alteration of thermal conductivity and viscosity of liquids by dispersing ultra-fine particles. Netsu Bussei. 1993, 7, 227–233. [Google Scholar] [CrossRef]

- Buongiorno, J.; Hu, W. Nanofluid Coolants for Advanced Nuclear Power Plants. In Proceedings of the nternational Congress on Advances in Nuclear Power Plants (ICAPP’05), Seoul, Korea, 15–19 May 2005. [Google Scholar]

- Buongiorno, J. Convective transport in nanofluids. J. Heat Transf. 2005, 128, 240–250. [Google Scholar] [CrossRef]

- Akbar, N.S.; Nadeem, S. Endoscopic effects on the peristaltic flow of a nanofluid. Commun. Theor. Phys. 2011, 56, 761–768. [Google Scholar] [CrossRef]

- Akbar, N.S. Peristaltic Sisko nanofluid in an asymmetric channel. Appl. Nanosci. 2014, 4, 663–673. [Google Scholar] [CrossRef]

- Tripathi, D.; Beg, O.A. A study on peristaltic flow of nanofluids: Application in drug delivery systems. Int. J. Heat Mass Transf. 2014, 70, 61–70. [Google Scholar] [CrossRef]

- Akbar, N.S.; Nadeem, S.; Khan, Z.H. Numerical simulation of peristaltic flow of a Carreau nanofluid in an asymmetric channel. Alexandria Eng. J. 2013, 53, 191–197. [Google Scholar] [CrossRef]

- Bég, O.A.; Tripathi, D. Mathematica simulation of peristaltic pumping with double-diffusive convection in nanofluids: A bio-nano-engineering model. Proc. Inst. Mech. Eng. Part N J Nanoeng. Nanosyst. 2012, 225, 99–114. [Google Scholar] [CrossRef]

- Akbar, N.S.; Tripathi, D.; Bég, A.O. Modeling nanoparticle geometry effects on peristaltic pumping of medical magnetohydrodynamic nanofluids with heat transfer. J. Mechan. Med. Bio. 2016, 16, 1650088. [Google Scholar] [CrossRef]

- Reddy, M.G.; Makinde, O.D. Magnetohydrodynamic peristaltic transport of Jeffrey nanofluid in an asymmetric channel. J. Mol. Liq. 2016, 223, 1242–1248. [Google Scholar] [CrossRef]

- Akbar, N.S.; Huda, A.B.; Tripathi, D. Thermally developing MHD peristaltic transport of nanofluids with velocity and thermal slip effects. Eur. Phys. J. Plus. 2016, 131, 332. [Google Scholar] [CrossRef]

- Nadeem, S.; Riaz, A.; Ellahi, R.; Akbar, N.S.; Zeeshan, A. Heat and mass transfer analysis of peristaltic flow of nanofluid in a vertical rectangular duct by using the optimized series solution and genetic algorithm. J. Comput. Theor. Nanosci. 2014, 11, 1133–1149. [Google Scholar] [CrossRef]

- Ellahi, R.; Riaz, A.; Nadeem, S. A theoretical study of Prandtl nanofluid in a rectangular duct through peristaltic transport. Appl. Nanosci. 2014, 4, 753–760. [Google Scholar] [CrossRef]

- Ellahi, R.; Bhatti, M.M.; Riaz, A.; Sheikholeslami, M. Effects of magnetohydrodynamics on peristaltic flow of Jeffrey fluid in a rectangular duct through a porous medium. J. Por. Med. 2014, 17, 143–157. [Google Scholar] [CrossRef]

- Kothandapani, M.; Prakash, J. Influence of heat source, thermal radiation and inclined magnetic field on peristaltic flow of a hyperbolic tangent nanofluid in a tapered asymmetric channel. IEEE Trans. NanoBiosci. 2015, 14, 385–392. [Google Scholar] [CrossRef]

- Nadeem, S.; Riaz, A.; Ellahi, R.; Akbar, N.S. Effects of heat and mass transfer on peristaltic flow of a nanofluid between eccentric cylinders. Appl. Nanosci. 2014, 4, 393–404. [Google Scholar] [CrossRef]

- Prakash, J.; Sharma, A.; Tripathi, D. Thermal radiation effects on electroosmosis modulated peristaltic transport of ionic nanoliquids in biomicrofluidics channel. J. Mol. Liq. 2018, 249, 843–855. [Google Scholar] [CrossRef]

- Tripathi, D.; Shashi, B.; Bég, O.A.; Akbar, N.S. Transient peristaltic diffusion of nanofluids: A model of micropumps in medical engineering. J. Hydrodyn. 2018, 30, 1001–1011. [Google Scholar] [CrossRef]

- Tripathi, D.; Sharma, A.; Bég, O.A. Joule heating and buoyancy effects in electro-osmotic peristaltic transport of aqueous nanofluids through a microchannel with complex wave propagation. Adv. Powder Technol. 2018, 29, 639–653. [Google Scholar] [CrossRef]

- Prakash, J.; Siva, E.P.; Tripathi, D.; Kuharat, S.; Bég, O.A. Peristaltic pumping of magnetic nanofluids with thermal radiation and temperature-dependent viscosity effects: Modelling a solar magneto-biomimetic nanopump. Renew. Energ. 2019, 133, 1308–1326. [Google Scholar] [CrossRef]

- Prakash, J.; Tripathi, D. Electroosmotic flow of Williamson ionic nanoliquids in a tapered microfluidic channel in presence of thermal radiation and peristalsis. J. Mol. Liq. 2018, 256, 352–371. [Google Scholar] [CrossRef]

- Prakash, J.; Jhorar, R.; Tripathi, D.; Azese, M.N. Electroosmotic flow of pseudoplastic nanoliquids via peristaltic pumping. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 61. [Google Scholar] [CrossRef]

- Mosayebidorcheh, S.; Hatami, M. Analytical investigation of peristaltic nanofluid flow and heat transfer in an asymmetric wavy wall channel (Part I: Straight channel). Int. J. Heat Mass Transf. 2018, 126, 790–799. [Google Scholar] [CrossRef]

- Abbasi, F.M.; Gul, M.; Shehzad, S.A. Hall effects on peristalsis of boron nitride-ethylene glycol nanofluid with temperature dependent thermal conductivity. Physica E Low Dimens. Syst Nanostruct. 2018, 99, 275–284. [Google Scholar] [CrossRef]

- Ranjit, N.K.; Shit, G.C.; Tripathi, D. Joule heating and zeta potential effects on peristaltic blood flow through porous micro vessels altered by electrohydrodynamic. Microvasc. Res. 2018, 117, 74–89. [Google Scholar] [CrossRef]

- Sadiq, M.A. MHD stagnation point flow of nanofluid on a plate with anisotropic slip. Symmetry 2019, 11, 132. [Google Scholar] [CrossRef]

- Ellahi, R. The effects of MHD and temperature dependent viscosity on the flow of non-Newtonian nanofluid in a pipe: Analytical solutions. Appl. Math. Model. 2013, 37, 1451–1457. [Google Scholar] [CrossRef]

- Zeeshan, A.; Shehzad, N.; Abbas, A.; Ellahi, R. Effects of radiative electro-magnetohydrodynamics diminishing internal energy of pressure-driven flow of titanium dioxide-water nanofluid due to entropy generation. Entropy 2019, 21, 236. [Google Scholar] [CrossRef]

- Hussain, F.; Ellahi, R.; Zeeshan, A. Mathematical models of electro magnetohydrodynamic multiphase flows synthesis with nanosized hafnium particles. Appl. Sci. 2018, 8, 275. [Google Scholar] [CrossRef]

- Ellahi, R.; Zeeshan, A.; Hussain, F.; Abbas, T. Study of shiny film coating on multi-fluid flows of a rotating disk suspended with nano-sized silver and gold particles: A comparative analysis. Coatings 2018, 8, 422. [Google Scholar] [CrossRef]

- Harvey, R.W.; Metge, D.W.; Kinner, N.; Mayberry, N. Physiological considerations in applying laboratory-determined buoyant densities to predictions of bacterial and protozoan transport in groundwater, Results of in-situ and laboratory tests. Enviorn. Sci. Technol. 1997, 31, 289–295. [Google Scholar] [CrossRef]

- Mishra, M.; Rao, A.R. Peristaltic transport in a channel with a porous peripheral layer: Model of a flow in gastrointestinal tract. J. Biomech. 2005, 38, 779–789. [Google Scholar] [CrossRef]

- Mekheimer, K.S. Nonlinear peristaltic transport through a porous medium in an inclined planar channel. J. Por. Med. 2003, 6, 13. [Google Scholar] [CrossRef]

- Siddiqui, A.M.; Ansari, A.R. A note on the swimming problem of a singly flagellated microorganism in a fluid flowing through a porous medium. J. Porous Med. 2005, 8, 551–556. [Google Scholar] [CrossRef]

- Wernert, V.; Schäf, O.; Ghobarkar, H.; Denoyel, R. Adsorption properties of zeolites for artificial kidney applications. Microporous Mesoporous Mat. 2005, 83, 101–113. [Google Scholar] [CrossRef]

- Jafari, A.; Zamankhan, P.; Mousavi, S.M.; Kolari, P. Numerical investigation of blood flow part II: In capillaries. Commun. Nonlinear Sci. Numeri. Simulat. 2009, 14, 1396–1402. [Google Scholar] [CrossRef]

- Goerke, A.R.; Leung, J.; Wickramasinghe, S.R. Mass and momentum transfer in blood oxygenators. Che. Eng. Sci. 2002, 57, 2035–2046. [Google Scholar] [CrossRef]

- Mneina, S.S.; Martens, G.O. Linear phase matched filter design with causal real symmetric impulse response. AEU Int. J. Electron. Commun. 2009, 63, 83–91. [Google Scholar] [CrossRef]

- Andoh, Y.H.; Lips, B. Prediction of porous walls thermal protection by effusion or transpiration cooling. An analytical approach. Appl. Thermal. Eng. 2003, 23, 1947–1958. [Google Scholar] [CrossRef]

- Runstedtler, A. On themodified Stefan–Maxwell equation for isothermal multi component gaseous diffusion. Chemical Eng. Sci. 2006, 61, 5021–5029. [Google Scholar] [CrossRef]

- Uddin, M.J.; Khan, W.A.; Ismail, A.I.M. Free convection boundary layer flow from a heated upward facing horizontal flat plate embedded in a porous medium filled by a nanofluid with convective boundary condition. Transp. Porous Med. 2012, 92, 867–881. [Google Scholar] [CrossRef]

- Chamkha, A.J.; Abbasbandy, S.; Rashad, A.M.; Vajravelu, K. Radiation effects on mixed convection over a wedge embedded in a porous medium filled with a nanofluid. Transp. Porous Med. 2011, 91, 261–279. [Google Scholar] [CrossRef]

- Kuznetsov, A.V.; Nield, D.A. Effect of local thermal non-equilibrium on the onset of convection in a porous medium layer saturated by a nanofluid. Transp. Porous Med. 2010, 83, 425–436. [Google Scholar] [CrossRef]

- Akbar, N.S. Double-diffusive natural convective peristaltic flow of a Jeffrey nanofluid in a porous channel. Heat Trans. Res. 2014, 45, 293–307. [Google Scholar] [CrossRef]

- Nadeem, S.; Riaz, A.; Ellahi, R.; Akbar, N.S. Mathematical model for the peristaltic flow of nanofluid through eccentric tubes comprising porous medium. Appl. Nanosci. 2014, 4, 733–743. [Google Scholar] [CrossRef]

- Bhatti, M.M.; Zeeshan, A.; Ellahi, R.; Shit, G.C. Mathematical modeling of heat and mass transfer effects on MHD peristaltic propulsion of two-phase flow through a Darcy-Brinkman-Forchheimer porous medium. Adv. Powder Technol. 2018, 29, 1189–1197. [Google Scholar] [CrossRef]

- Alamri, S.Z.; Ellahi, R.; Shehzad, N.; Zeeshan, A. Convective radiative plane Poiseuille flow of nanofluid through porous medium with slip: An application of Stefan blowing. J. Mol. Liq. 2019, 273, 292–304. [Google Scholar] [CrossRef]

- Shehzad, N.; Zeeshan, A.; Ellahi, R.; Rashidid, S. Modelling study on internal energy loss due to entropy generation for non-Darcy Poiseuille flow of silver-water nanofluid: An application of purification. Entropy 2018, 20, 851. [Google Scholar] [CrossRef]

- Kothandapani, M.; Prakash, J. The peristaltic transport of Carreau nanofluids under effect of a magnetic field in a tapered asymmetric channel: Application of the cancer therapy. J. Mech. Med. Bio. 2015, 15, 1550030. [Google Scholar] [CrossRef]

- Hayat, T.; Abbasi, F.M.; Al-Yami, M.; Monaquel, S. Slip and Joule heating effects in mixed convection peristaltic transport of nanofluid with Soret and Dufour effects. J. Mol. Liq. 2014, 194, 93–99. [Google Scholar] [CrossRef]

- Kothandapani, M.; Prakash, J. Effects of thermal radiation parameter and magnetic field on the peristaltic motion of Williamson nanofluids in a tapered asymmetric channel. Int. J. Heat Mass Transf. 2015, 51, 234–245. [Google Scholar] [CrossRef]

- Hayat, T.; Yasmin, H.; Ahmad, B.; Chen, B. Simultaneous effects of convective conditions and nanoparticles on peristaltic motion. J. Mol. Liq. 2014, 193, 74–82. [Google Scholar] [CrossRef]

- Makinde, O.D. Thermal stability of a reactive viscous flow through a porous-saturated channel with convective boundary conditions. Appl. Therm. Eng. 2009, 29, 1773–1777. [Google Scholar] [CrossRef]

- Parti, M. Mass transfer Biot numbers. Periodica Polytechnica Mech. Eng. 1994, 38, 109–122. [Google Scholar]

- Kikuchi, Y. Effect of leukocytes and platelets on blood flow through a parallel array of microchannels: Micro-and Macroflow relation and rheological measures of leukocytes and platelate acivities. Microvasc. Res. 1995, 50, 288–300. [Google Scholar] [CrossRef]

- Mishra, M.; Rao, A.R. Peristaltic transport of a Newtonian fluid in an asymmetric channel. Z. Angew. Math. Phys. 2003, 54, 532–550. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Prakash, J.; Tripathi, D.; Tiwari, A.K.; Sait, S.M.; Ellahi, R. Peristaltic Pumping of Nanofluids through a Tapered Channel in a Porous Environment: Applications in Blood Flow. Symmetry 2019, 11, 868. https://doi.org/10.3390/sym11070868

Prakash J, Tripathi D, Tiwari AK, Sait SM, Ellahi R. Peristaltic Pumping of Nanofluids through a Tapered Channel in a Porous Environment: Applications in Blood Flow. Symmetry. 2019; 11(7):868. https://doi.org/10.3390/sym11070868

Chicago/Turabian StylePrakash, J., Dharmendra Tripathi, Abhishek Kumar Tiwari, Sadiq M. Sait, and Rahmat Ellahi. 2019. "Peristaltic Pumping of Nanofluids through a Tapered Channel in a Porous Environment: Applications in Blood Flow" Symmetry 11, no. 7: 868. https://doi.org/10.3390/sym11070868

APA StylePrakash, J., Tripathi, D., Tiwari, A. K., Sait, S. M., & Ellahi, R. (2019). Peristaltic Pumping of Nanofluids through a Tapered Channel in a Porous Environment: Applications in Blood Flow. Symmetry, 11(7), 868. https://doi.org/10.3390/sym11070868