Design and Evaluation of an Innovative Thermoelectric-Based Dehumidifier for Greenhouses

Abstract

1. Introduction

2. Materials and Methods

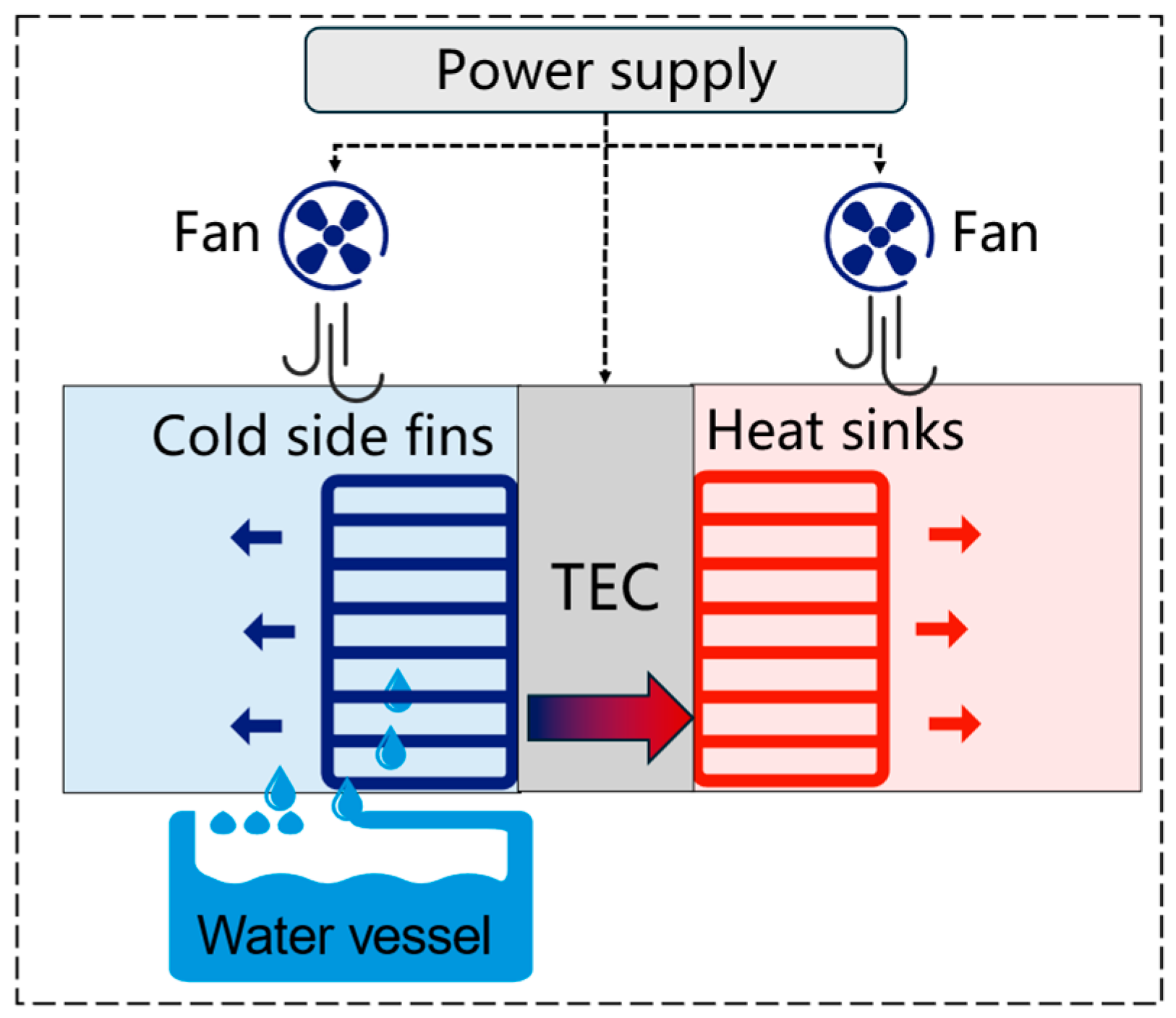

2.1. Structure and Working Principle of TED

2.1.1. Working Principle

2.1.2. Heat Exchanger

2.1.3. TED Cabinet

2.2. Experimental Setup and Process

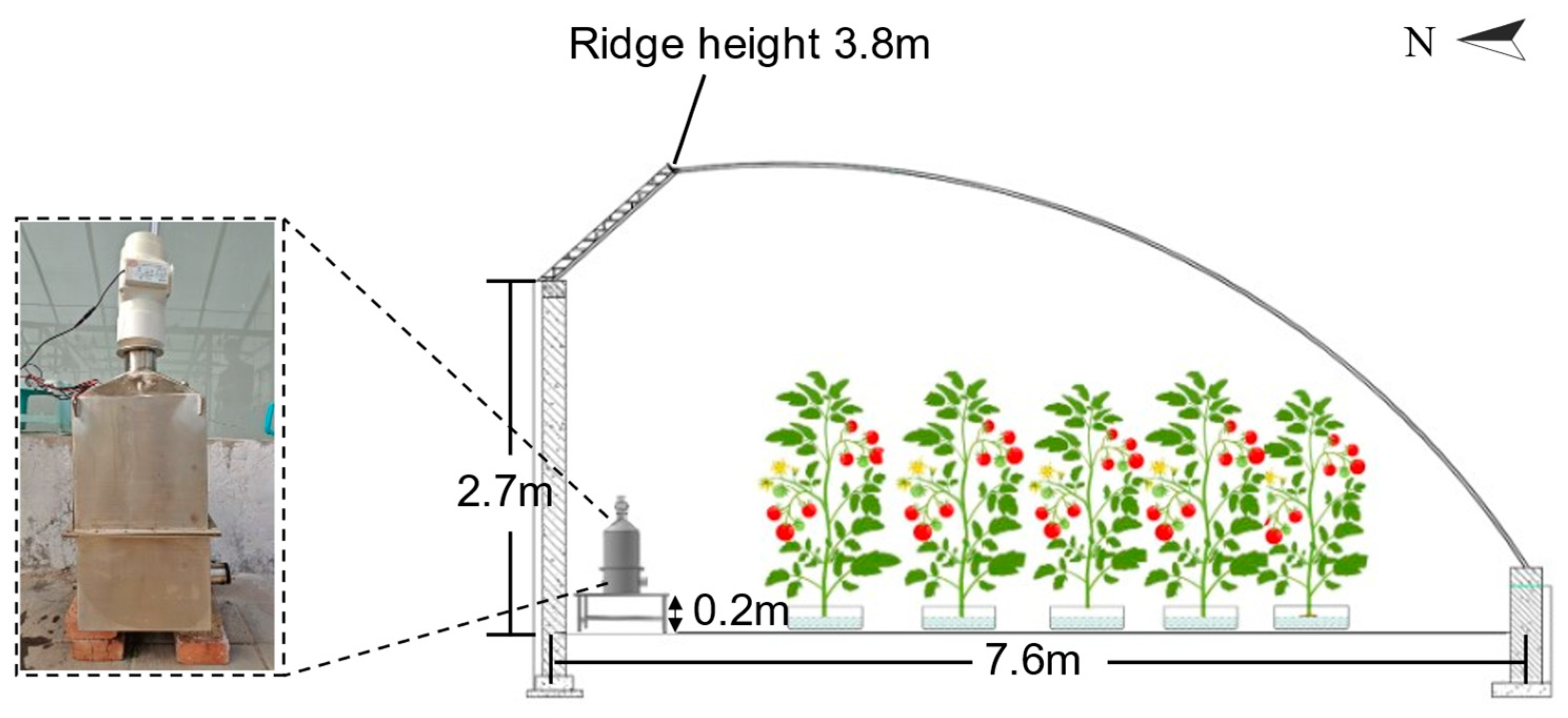

2.2.1. Greenhouse Facilities and Crop Management

2.2.2. Experimental Design

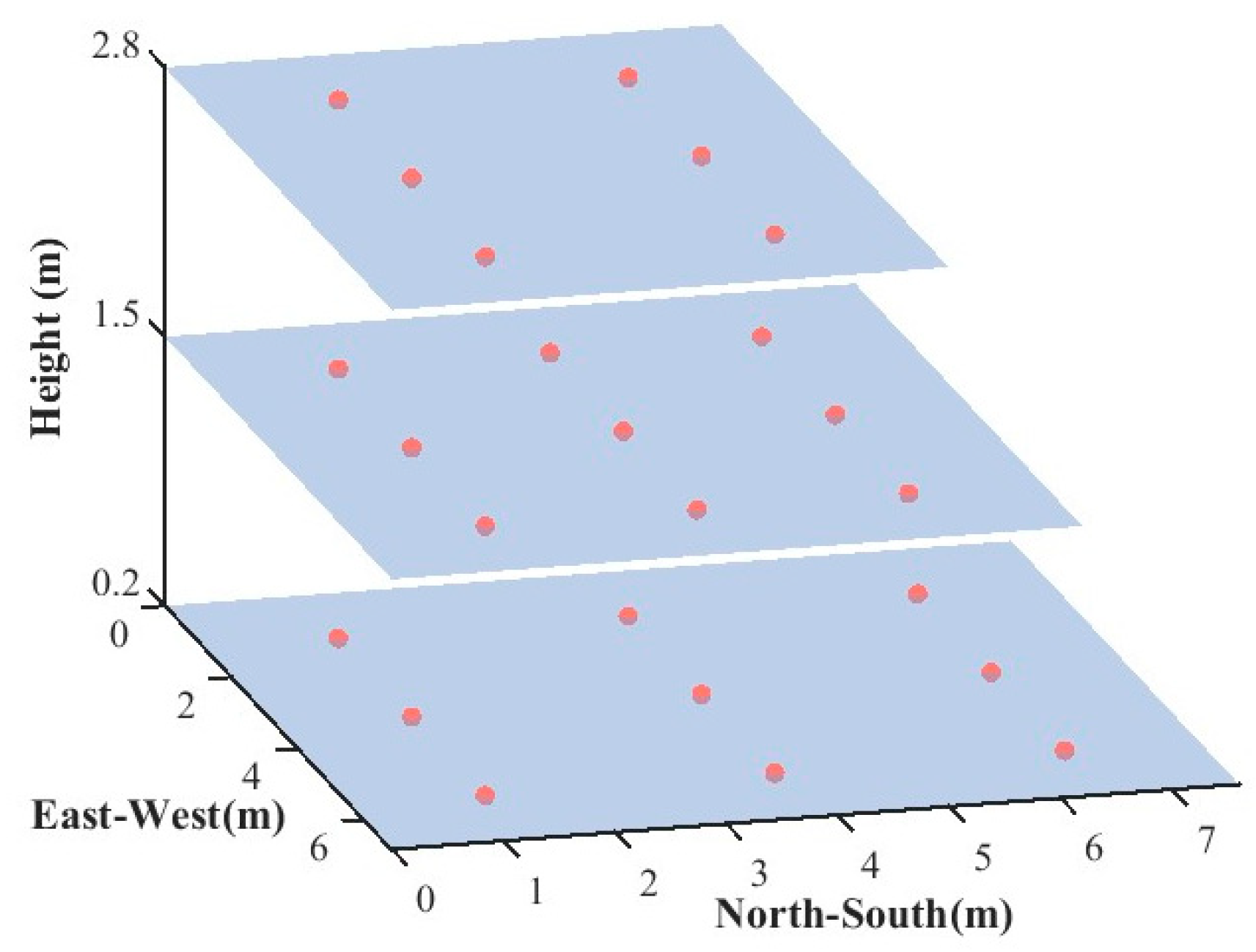

2.2.3. Data Acquisition and Processing

2.2.4. Main Performance Evaluation Index

- (1)

- A higher dehumidification rate indicates enhanced dehumidification effectiveness. The dehumidification rate Vd (g/h) is calculated as follows:where mw,d (g) is the mass of the condensed water vapor; t (h) is the time at which the TED was in operation.

- (2)

- Heat recovery is indirectly deduced by monitoring the volume and temperature changes of the air and calculating the amount of heat required to heat the air. Heat recovery Qheat (kJ) is calculated as follows [29]:where Vair (m3) is the volume of air; ρair (kg/m3) is the density of air, which is usually approximately 1.225 kg/m3; cp,air (J/(kg·°C)) is the specific heat capacity of air, which is usually approximately 1005 J/(kg·°C); ΔT (°C) is the change in the temperature of the air.

- (3)

- When the VPD value is low, the transpiration of crops is weak, which affects the rate at which plants absorb inorganic elements [30]. The VPD requirements vary across crops and growth stages. However, maintaining the VPD in the growing environment above 0.5 kPa meets the growth requirements of most crops [31]. The VPD (kPa) is calculated as follows [32]:where Ta (°C) is the air temperature; HR (%) is the RH.

- (4)

- The SMER represents the ratio of the mass of water removed to the energy consumed during the entire drying process, which reflects the overall performance of the TED. The higher the dehumidification capacity per unit energy consumption of the TED, the greater its energy efficiency. The subsequent assumptions are established for the test: humid air is consistent and comprises two components: dry air and water vapor; the fouling coefficient remains unchanged throughout the test. The SMER (kg/kWh) is calculated using the following equation [12]:where Wd (kWh) is the overall power consumption of the TED.

2.2.5. Data Analysis

3. Results and Discussion

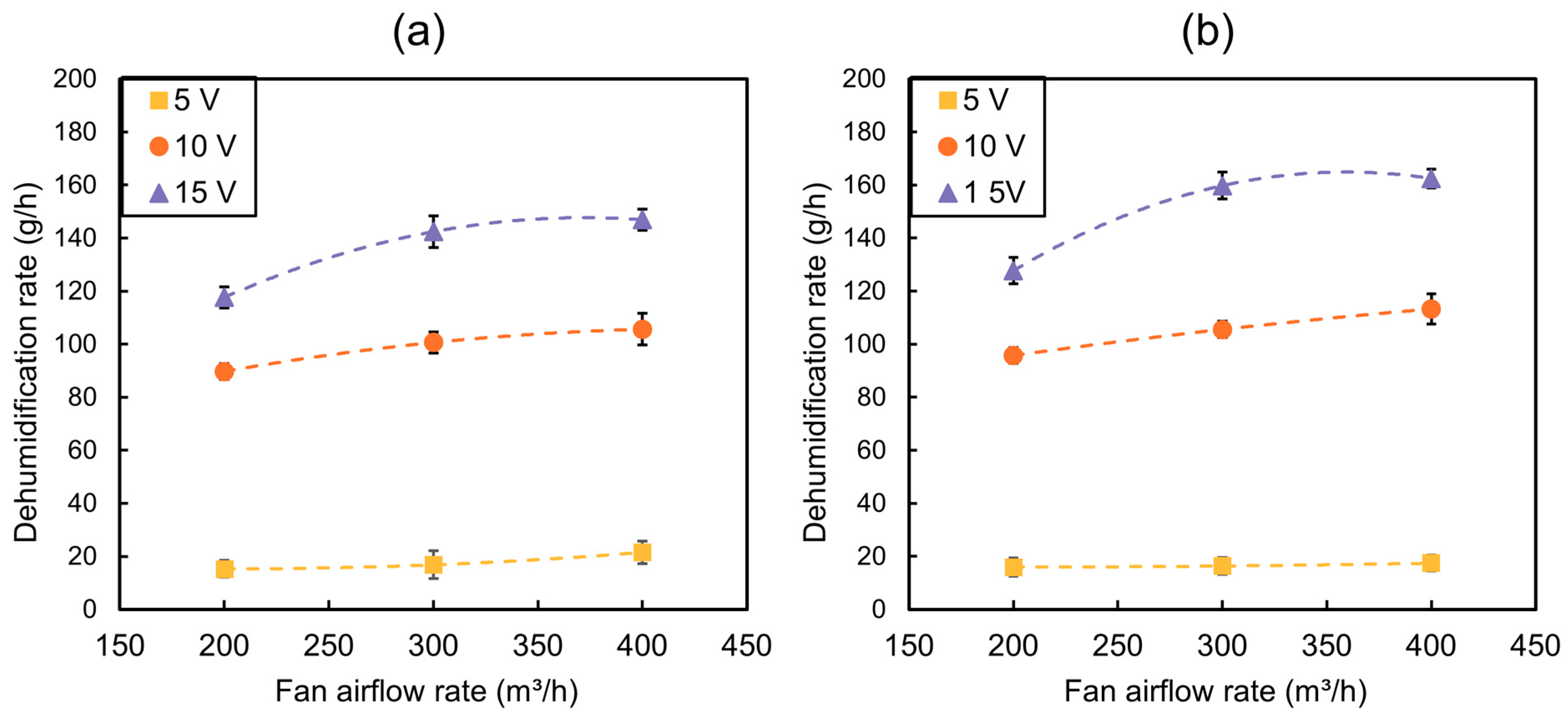

3.1. TED Performance Validation and Optimization in Exp. I

3.1.1. Analysis of Factors Affecting Dehumidification Rate

3.1.2. Analysis of Factors Affecting Heat Recovery Rate

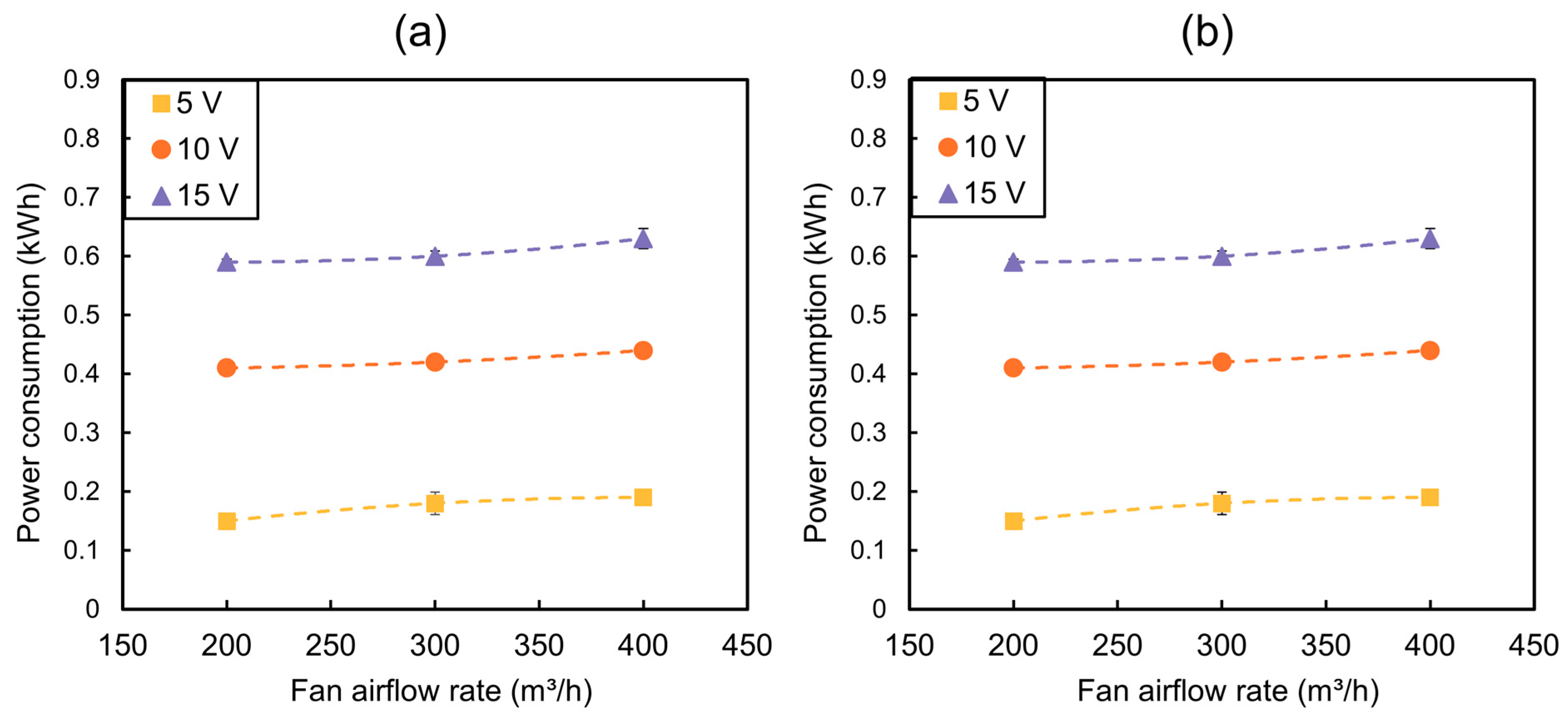

3.1.3. Analysis of Factors Affecting Power Consumption

3.1.4. Comprehensive Evaluation of TED Performance

3.2. TED Effect on Temperature and RH in the CSG During Exp. II

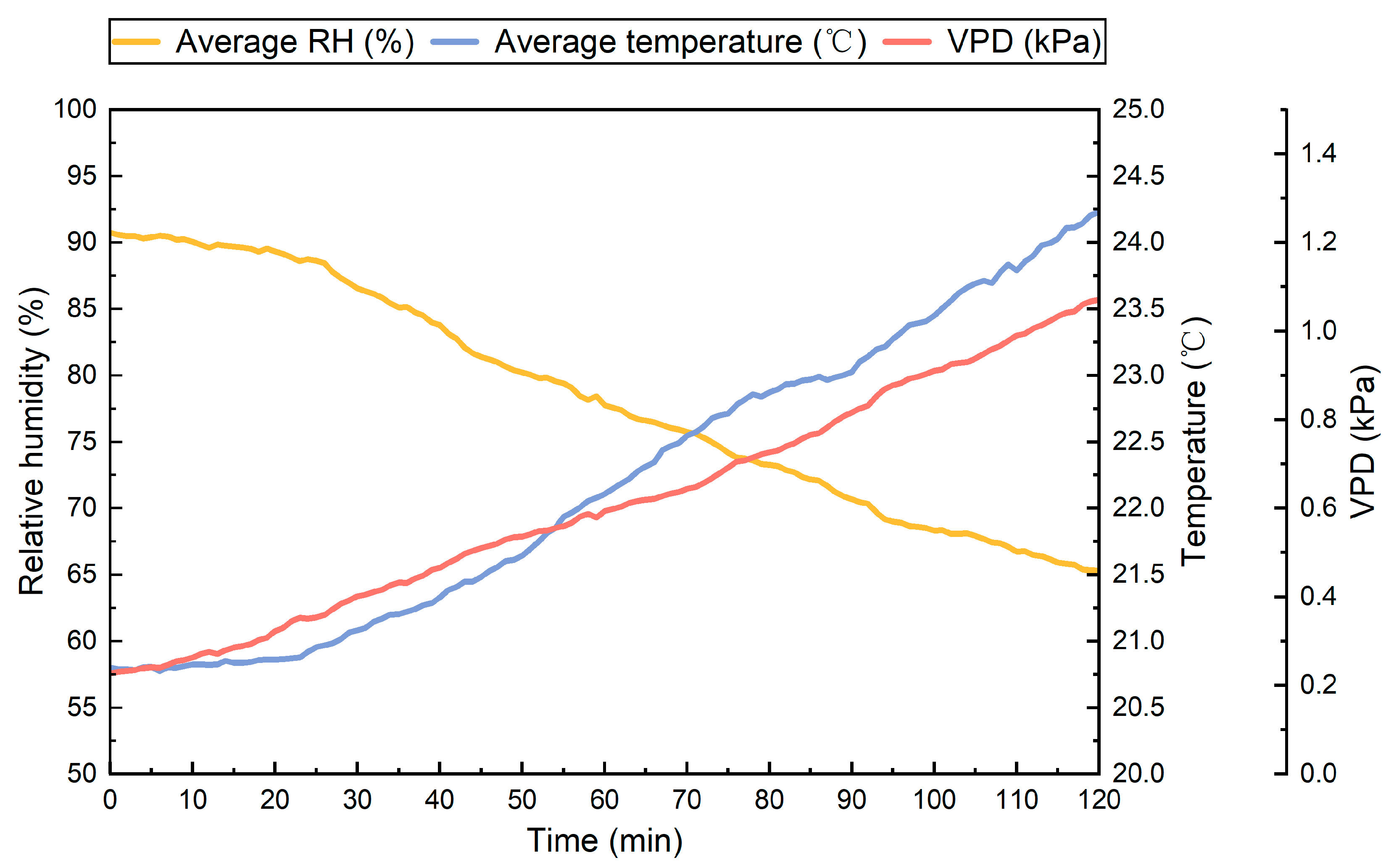

3.2.1. RH, Temperature, and VPD Variations in the CSG

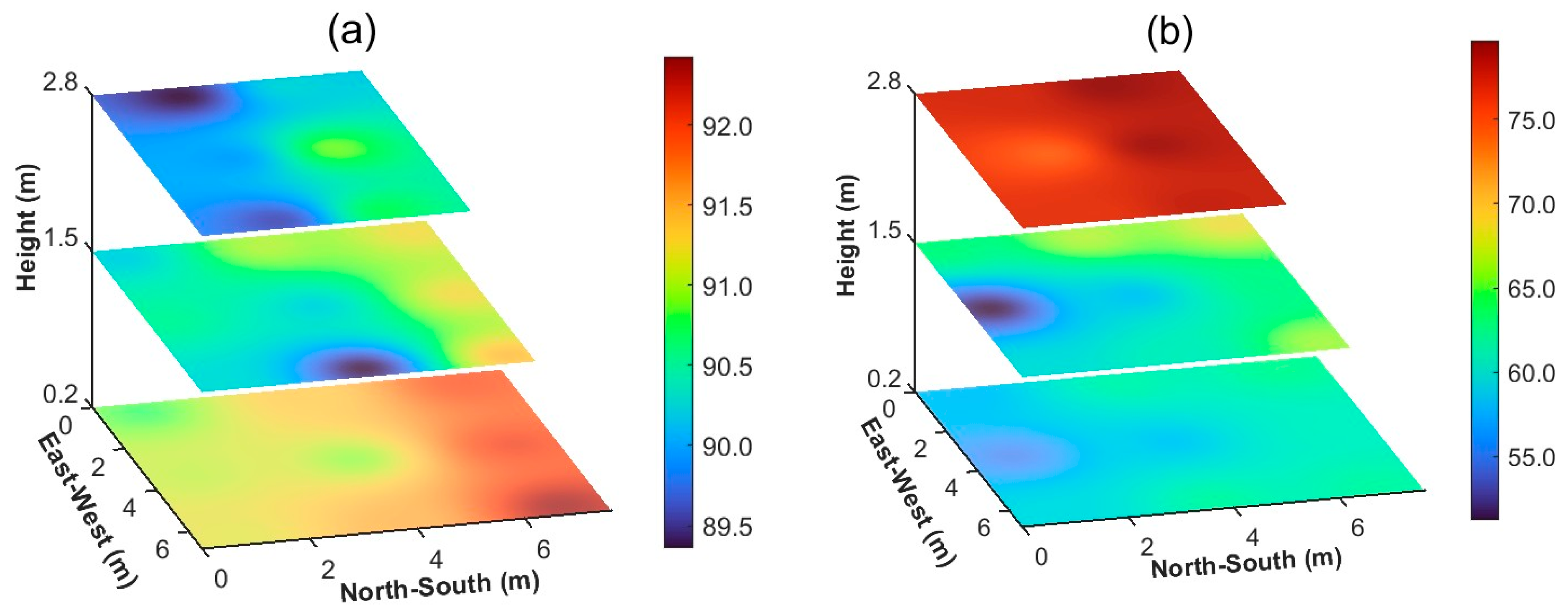

3.2.2. Spatial Variation in RH in the Greenhouse

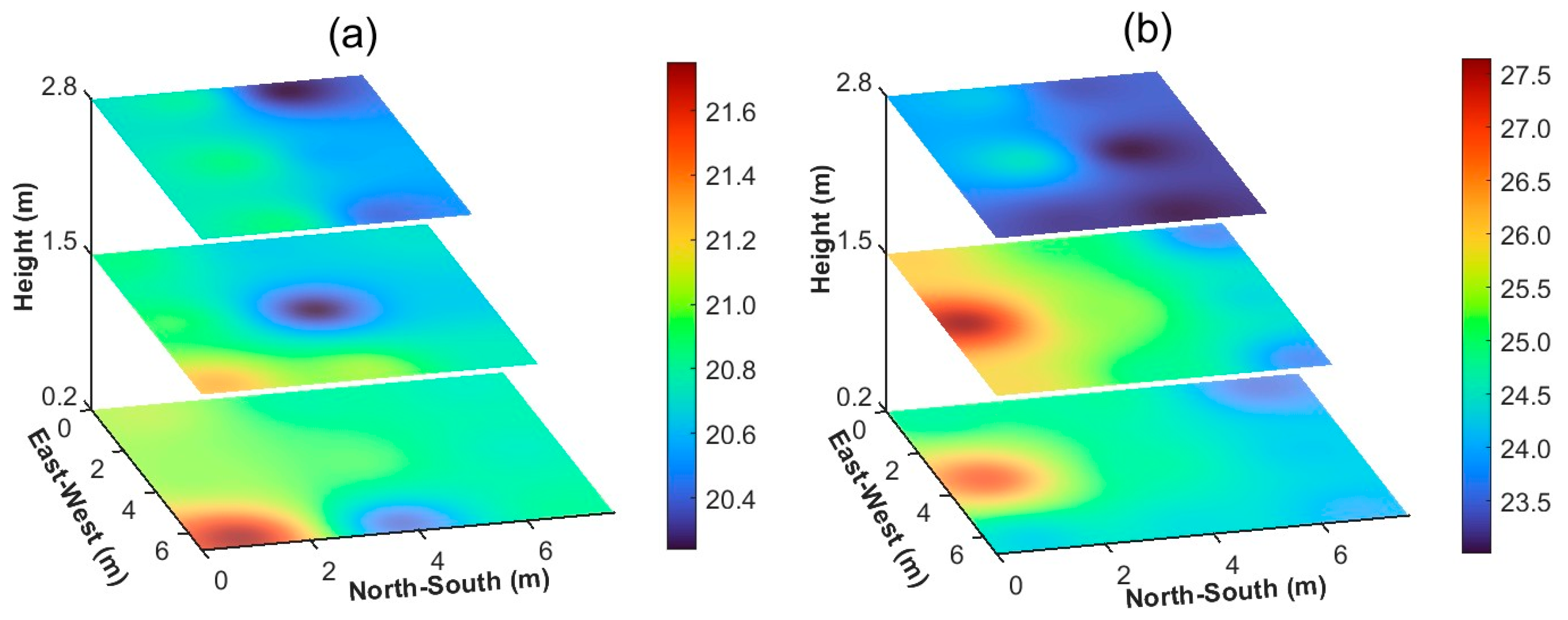

3.2.3. Spatial Variation in Temperature in the Greenhouse

3.3. SMER and Economic Analysis of the TED

3.3.1. SMER Analysis of the TED

3.3.2. Economic Analysis of the TED

3.3.3. Comparative Analysis of TED and Conventional Dehumidification Methods

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rahman, M.S.; Guo, H.; Han, J. Dehumidification requirement modeling and control strategy for greenhouses in cold regions. Comput. Electron. Agric. 2021, 187, 106264. [Google Scholar] [CrossRef]

- Mortensen, L.M. Effects of air humidity on growth, flowering, keeping quality and water relations of four short-day greenhouse species. Sci. Hortic. 2000, 86, 299–310. [Google Scholar] [CrossRef]

- Ding, J.; Jiao, X.; Bai, P.; Hu, Y.; Zhang, J.; Li, J. Effect of vapor pressure deficit on the photosynthesis, growth, and nutrient absorption of tomato seedlings. Sci. Hortic. 2022, 293, 110736. [Google Scholar] [CrossRef]

- Mahmoud, M.; BenRejeb, I.; Punja, Z.K.; Buirs, L.; Jabaji, S. Understanding bud rot development, caused by Botrytis cinerea, on cannabis (Cannabis sativa L.) plants grown under greenhouse conditions. Botany 2023, 101, 200–231. [Google Scholar] [CrossRef]

- Pokhrel, A. Role of individual components of disease triangle in disease development: A review. Plant Pathol. Microbiol. 2021, 12, 573. [Google Scholar]

- Dash, S.P.; Dipankar, P.; Burange, P.S.; Rouse, B.T.; Sarangi, P.P. Climate change: How it impacts the emergence, transmission, resistance and consequences of viral infections in animals and plants. Crit. Rev. Microbiol. 2021, 47, 307–322. [Google Scholar] [CrossRef]

- Amani, M.; Foroushani, S.; Sultan, M.; Bahrami, M. Comprehensive review on dehumidification strategies for agricultural greenhouse applications. Appl. Therm. Eng. 2020, 181, 115979. [Google Scholar] [CrossRef]

- Ghaderi, M.; Reddick, C.; Sorin, M. A systematic heat recovery approach for designing integrated heating, cooling, and ventilation systems for greenhouses. Energies 2023, 16, 5493. [Google Scholar] [CrossRef]

- Bazgaou, A.; Fatnassi, H.; Bouharroud, R.; Ezzaeri, K.; Gourdo, L.; Wifaya, A.; Demrati, H.; Elame, F.; Carreño-Ortega, Á.; Bekkaoui, A.; et al. Effect of active solar heating system on microclimate, development, yield and fruit quality in greenhouse tomato production. Renew. Energy 2021, 165, 237–250. [Google Scholar] [CrossRef]

- Sultan, M.; El-Sharkawy, I.I.; Miyazaki, T.; Saha, B.B.; Koyama, S. An overview of solid desiccant dehumidification and air conditioning systems. Renew. Sustain. Energy Rev. 2015, 46, 16–29. [Google Scholar] [CrossRef]

- Chasseriaux, G.; Travers, A.; Ternoy, M. Heat pumps for reducing humidity in plastics greenhouses. Plasticulture 1987, 73, 29–40. [Google Scholar]

- Cámara-Zapata, J.M.; Sánchez-Molina, J.A.; Rodríguez, F.; López, J.C. Evaluation of a dehumidifier in a mild weather greenhouse. Appl. Therm. Eng. 2019, 146, 92–103. [Google Scholar] [CrossRef]

- Islam, M.N.; Iqbal, M.Z.; Ali, M.; Gulandaz, M.A.; Kabir, M.S.N.; Jang, S.H.; Chung, S.O. Evaluation of a 0.7 kw suspension-type dehumidifier module in a closed chamber and in a small greenhouse. Sustainability 2023, 15, 5236. [Google Scholar] [CrossRef]

- Jani, D.B.; Mishra, M.; Sahoo, P.K. Solid desiccant air conditioning—A state of the art review. Renew. Sustain. Energy Rev. 2016, 60, 1451–1469. [Google Scholar] [CrossRef]

- Liang, K.; Li, Z.; Chen, M.; Jiang, H. Comparisons between heat pipe, thermoelectric system, and vapour compression refrigeration system for electronics cooling. Appl. Therm. Eng. 2019, 146, 260–267. [Google Scholar] [CrossRef]

- Wang, L.; Chu, T.; Yuan, S. Advances and future perspectives in thermoelectric cooling technology. Energy Convers. Manag. 2025, 332, 119621. [Google Scholar] [CrossRef]

- Liu, W.D.; Yin, L.C.; Li, L. Grain boundary re-crystallization and sub-nano regions leading to high plateau figure of merit for Bi2Te3 nanoflakes. Energy Environ. Sci. 2023, 16, 5123–5135. [Google Scholar] [CrossRef]

- Zaferani, S.H.; Sams, M.W.; Ghomashchi, R.; Chen, Z.G. Thermoelectric coolers as thermal management systems for medical applications: Design, optimization, and advancement. Nano Energy 2021, 90, 106572. [Google Scholar] [CrossRef]

- Casallas, I.; Pérez, M.; Fajardo, A. Experimental parameter tuning of a portable water generator system based on a thermoelectric cooler. Electronics 2021, 10, 141. [Google Scholar] [CrossRef]

- Muñoz-García, M.A.; Moreda, G.P.; Raga-Arroyo, M.P.; Marín-González, O. Water harvesting for young trees using Peltier modules powered by photovoltaic solar energy. Comput. Electron. Agric. 2013, 93, 60–67. [Google Scholar] [CrossRef]

- Sanaye, S.; Shourabi, A.; Borzuei, D. Sustainable water production with an innovative thermoelectric-based atmospheric water harvesting system. Energy Rep. 2023, 10, 1339–1355. [Google Scholar] [CrossRef]

- John, J.; Zafar, H.R.; Francis, J.; James, A.; Tharian, M.G.; Mathew, M.J. Design and optimization of an atmospheric water generator using thermoelectric cooling modules. Mater. Today Proc. 2022, 56, 2563–2567. [Google Scholar] [CrossRef]

- Casallas, I.; Fajardo, A.; Paez-Rueda, C.I. Towards indoor hydroponic fodder sustainability with a low-cost atmospheric water generator. Comput. Electron. Agric. 2024, 218, 108666. [Google Scholar] [CrossRef]

- Wang, M.; Liu, E.; Jin, T.; Zafar, S.U.; Mei, X.; Fauconnier, M.L.; De Clerck, C. Towards a better understanding of atmospheric water harvesting (AWH) technology. Water Res. 2024, 250, 121052. [Google Scholar] [CrossRef]

- Historical Weather in Beijing in December 2023. Available online: https://tianqi.eastday.com/lishi/beijing/202312 (accessed on 5 January 2025).

- Yu, S.; Guo, Y.; Li, H.; Bai, L.; Piao, X.; Lian, M. Selection of nutrient solution concentration for ex vitro rooting of Spathiphyllum kochii in hydroponic cultivation based on radar chart analysis. Agric. Sci. J. Yanbian Univ. 2023, 45, 18–24. [Google Scholar]

- Eltaweel, M.; Heggy, A.H.; Yaseen, Z.M.; Alawi, O.A.; Falah, M.W.; Hussein, O.A.; Abdelrazek, A.H. Application of the ANOVA method in the optimization of a thermoelectric cooler-based dehumidification. Energy Rep. 2022, 8, 10533–10545. [Google Scholar] [CrossRef]

- Seo, Y.M.; Ha, M.Y.; Park, S.H.; Lee, G.H.; Kim, Y.S.; Park, Y.G. A numerical study on the performance of the thermoelectric module with different heat sink shapes. Appl. Therm. Eng. 2018, 128, 1082–1094. [Google Scholar] [CrossRef]

- Jouhara, H.; Khordehgah, N.; Almahmoud, S.; Delpech, B.; Chauhan, A.; Tassou, S.A. Waste heat recovery technologies and applications. Therm. Sci. Eng. Prog. 2018, 6, 268–289. [Google Scholar] [CrossRef]

- Noh, H.; Lee, J. The effect of vapor pressure deficit regulation on the growth of tomato plants grown in different planting environments. Appl. Sci. 2022, 12, 3667. [Google Scholar] [CrossRef]

- Balliu, A.; Zheng, Y.; Sallaku, G.; Fernández, J.A.; Gruda, N.S.; Tuzel, Y. Environmental and cultivation factors affect the morphology, architecture and performance of root systems in soilless grown plants. Horticulturae 2021, 7, 243. [Google Scholar] [CrossRef]

- Yuan, R.R.; Huang, X.L.; Hao, L. Spatio–temporal variation of vapor pressure deficit and impact factors in China in the past 40 years. Clim. Environ. Res. 2021, 26, 413–424. [Google Scholar]

- Wang, S.; Hou, L.; Lee, J.; Bu, X. Evaluating wheel loader operating conditions based on radar chart. Autom. Constr. 2017, 84, 42–49. [Google Scholar]

- Shourideh, A.H.; Ajram, W.B.; Al Lami, J.; Haggag, S.; Mansouri, A. A comprehensive study of an atmospheric water generator using Peltier effect. Therm. Sci. Eng. Prog. 2018, 6, 14–26. [Google Scholar] [CrossRef]

- Shahrokhi, F.; Esmaeili, A. Optimizing relative humidity based on the heat transfer terms of the thermoelectric atmospheric water generator (AWG). Innov. Des. Alex. Eng. J. 2023, 67, 143–152. [Google Scholar] [CrossRef]

- Enescu, D.; Virjoghe, E.O. A review on thermoelectric cooling parameters and performance. Renew. Sustain. Energy Rev. 2014, 38, 903–916. [Google Scholar] [CrossRef]

- Heggy, A.H.; Abdel-Rehim, A.A. Optimization of a thermoelectric cooler-based system for dehumidification applications in terms of heat dissipation and water collection. Energy Convers. Manag. 2022, 258, 115550. [Google Scholar] [CrossRef]

- Reliability of Thermoelectric Cooling Modules. Available online: https://thermal.ferrotec.com/technology/thermoelectric-reference-guide/thermalref10/ (accessed on 5 January 2025).

- Barako, M.T.; Park, W.; Marconnet, A.M.; Asheghi, M.; Goodson, K.E. Thermal Cycling, Mechanical Degradation, and the Effective Figure of Merit of a Thermoelectric Module. J. Electron. Mater. 2013, 42, 372–381. [Google Scholar] [CrossRef]

- Zheng, Y.; Tan, X.Y.; Wan, X. Thermal stability and mechanical response of Bi2Te3-based materials for thermoelectric applications. ACS Appl. Energy Mater. 2019, 3, 2078–2089. [Google Scholar] [CrossRef]

| Type | Maximum Current | Maximum Voltage | Dimensions | Maximum Temperature Difference |

|---|---|---|---|---|

| TEC1-12706 | 6 A | 15.4 V | 40 mm × 40 mm | 66 °C |

| Height | Mean ± Standard Deviation | ||

|---|---|---|---|

| 0 min | 60 min | 120 min | |

| 0.2 m | 91.5 ± 0.6 a | 73.5 ± 3.8 b | 60.3 ± 2.8 b |

| 1.5 m | 90.6 ± 0.7 b | 75.1 ± 5.1 b | 62.1 ± 5.3 b |

| 2.8 m | 90.1 ± 0.6 b | 85.8 ± 3.0 a | 77.6 ± 2.0 a |

| Average | 90.8 ± 0.8 | 78.1 ± 6.5 | 65.3 ± 8.2 |

| Height | Mean ± Standard Deviation | ||

|---|---|---|---|

| 0 min | 60 min | 120 min | |

| 0.2 m | 20.9 ± 0.4 a | 21.9 ± 1.1 a | 24.7 ± 1.0 a |

| 1.5 m | 20.8 ± 0.3 a | 22.1 ± 1.3 a | 25.2 ± 1.3 a |

| 2.8 m | 20.6 ± 0.3 a | 21.0 ± 0.5 a | 23.6 ± 0.6 b |

| Average | 20.8 ± 0.3 | 21.7 ± 1.1 | 24.6 ± 1.2 |

| Reference | Dimensions (m × m × m) | Number of TECs | Produced Water Rate (g/h) | SMER (kg/kWh) |

|---|---|---|---|---|

| Enescu et al. (2014) [36] | 0.18 × 0.10 × 0.02 | 1 | 24.58 | unknown |

| Shourideh et al. (2018) [34] | 0.44 × 0.34 × 0.17 | 4 | 30.00 | 0.50 |

| Heggy et al. (2022) [37] | unknown | 18 | 96 | unknown |

| Casallas et al. (2024) [23] | 0.10 × 0.07 × 0.07 | 1 | 3.01 | 0.31 |

| Our device (2025) | 0.27 × 0.27 × 0.55 | 4 | 156.7 | 0.52 |

| Component | Lifetime (Year) | Cost (USD/each) | Quantity | Cost for 10 Years (USD) |

|---|---|---|---|---|

| Heat exchanger (Excluding TECs) | 15 | 8.23 | 4 | 32.92 |

| TECs | 10 | 1.65 | 8 | 13.2 |

| Duct fan | 10 | 16.02 | 1 | 16.02 |

| Pump | 10 | 2.68 | 1 | 2.68 |

| Cabinet | 20 | 41.25 | 1 | 41.25 |

| Auxiliary components | 10 | 6.88 | ─ | 6.88 |

| Total | ─ | ─ | ─ | 112.95 |

| Power Consumption (kW) | Days of Operation Per Year (d) | Hours of Operation Per Day (h/d) | Price of Electricity (USD/kWh) | Total Electricity Cost (USD) |

|---|---|---|---|---|

| 0.305 | 90 | 6 | 0.0858 | 14.13 |

| Content | Cost (USD/Year) |

|---|---|

| Annual electricity consumption | 14.13 |

| Annual depreciation expense | 12.30 |

| Annual fixed cost | 6.8 |

| Total annual operating cost | 33.23 |

| Method | Advantages | Disadvantages |

|---|---|---|

| Ventilation | Simple, low-cost, easy to operate | Significant heat loss in winter; causes temperature drop |

| Heating | Prevents frost damage; increases air temperature | No absolute moisture removal; high energy consumption |

| Desiccant | High dehumidification efficiency at low temperatures | Needs frequent material regeneration; additional maintenance required |

| Heat Pump | High dehumidification efficiency; energy-saving | High initial investment; complex maintenance |

| TED | Combines dehumidification and heating; compact and low-cost | Lower dehumidification capacity compared to heat pumps |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Liu, T.; Cai, Y.; Wang, D.; Wei, X.; Hai, Y.; Shi, R.; Guo, W. Design and Evaluation of an Innovative Thermoelectric-Based Dehumidifier for Greenhouses. Agronomy 2025, 15, 1194. https://doi.org/10.3390/agronomy15051194

Han X, Liu T, Cai Y, Wang D, Wei X, Hai Y, Shi R, Guo W. Design and Evaluation of an Innovative Thermoelectric-Based Dehumidifier for Greenhouses. Agronomy. 2025; 15(5):1194. https://doi.org/10.3390/agronomy15051194

Chicago/Turabian StyleHan, Xiaobei, Tianxiang Liu, Yuliang Cai, Dequn Wang, Xiaoming Wei, Yunrui Hai, Rongchao Shi, and Wenzhong Guo. 2025. "Design and Evaluation of an Innovative Thermoelectric-Based Dehumidifier for Greenhouses" Agronomy 15, no. 5: 1194. https://doi.org/10.3390/agronomy15051194

APA StyleHan, X., Liu, T., Cai, Y., Wang, D., Wei, X., Hai, Y., Shi, R., & Guo, W. (2025). Design and Evaluation of an Innovative Thermoelectric-Based Dehumidifier for Greenhouses. Agronomy, 15(5), 1194. https://doi.org/10.3390/agronomy15051194