Exploring the Thermal and Mechanical Properties of Thermoset-Based Composites Reinforced with New Continuous and Chopped Phosphate Glass Fibers

Abstract

1. Introduction

2. Materials and Methods

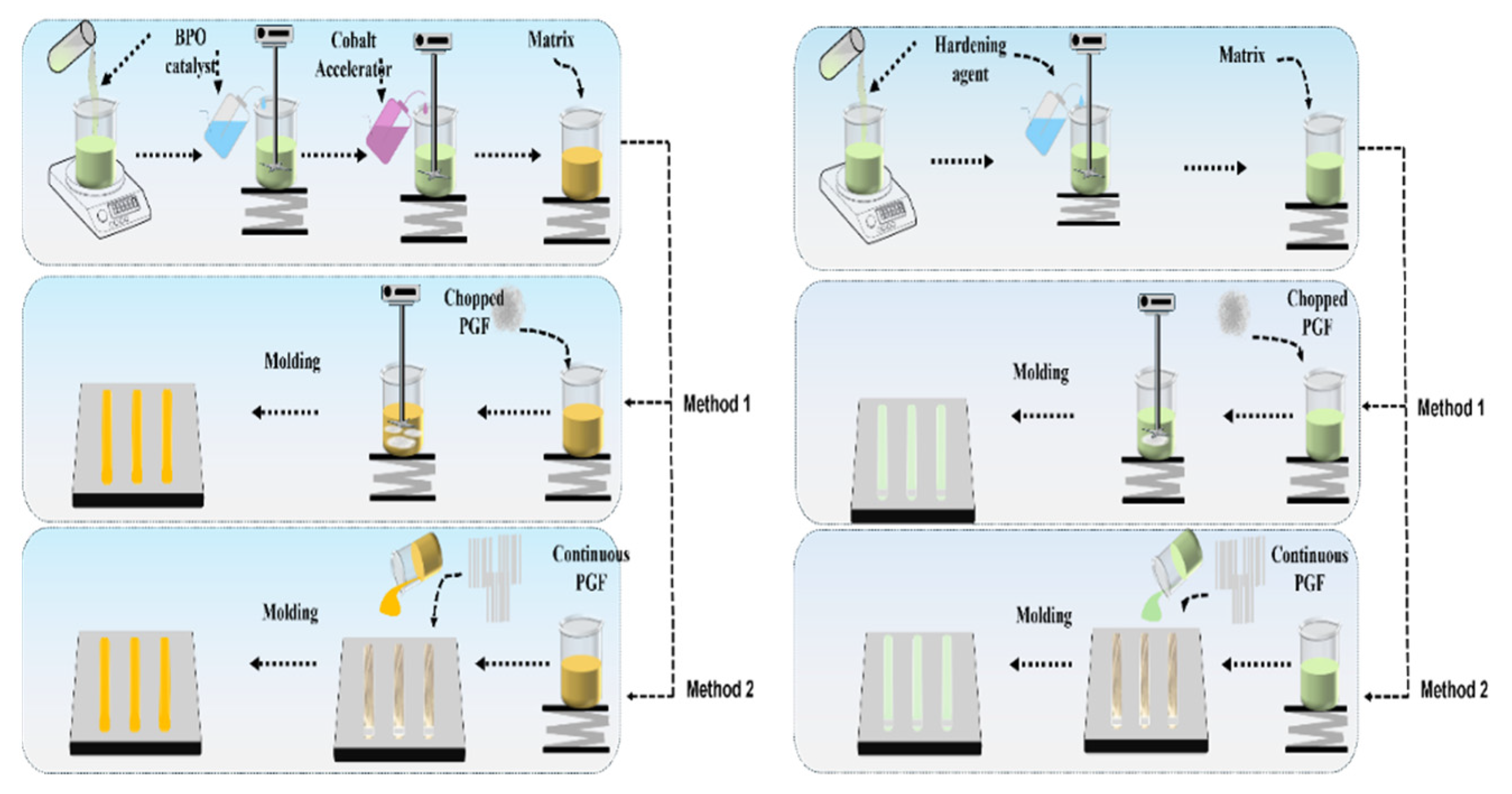

2.1. Process for the Preparation of Composites Reinforced with Phosphate Glass Fibers

2.1.1. Preparation of Phosphate Glass Reinforcement

2.1.2. Matrix Preparation

- Polyester matrix

- b.

- Epoxy matrix

2.1.3. Elaboration of Composite Specimens

2.2. Characterization of Composites Reinforced with Phosphate Glass Fibers

3. Results and Discussion

3.1. Physical Properties

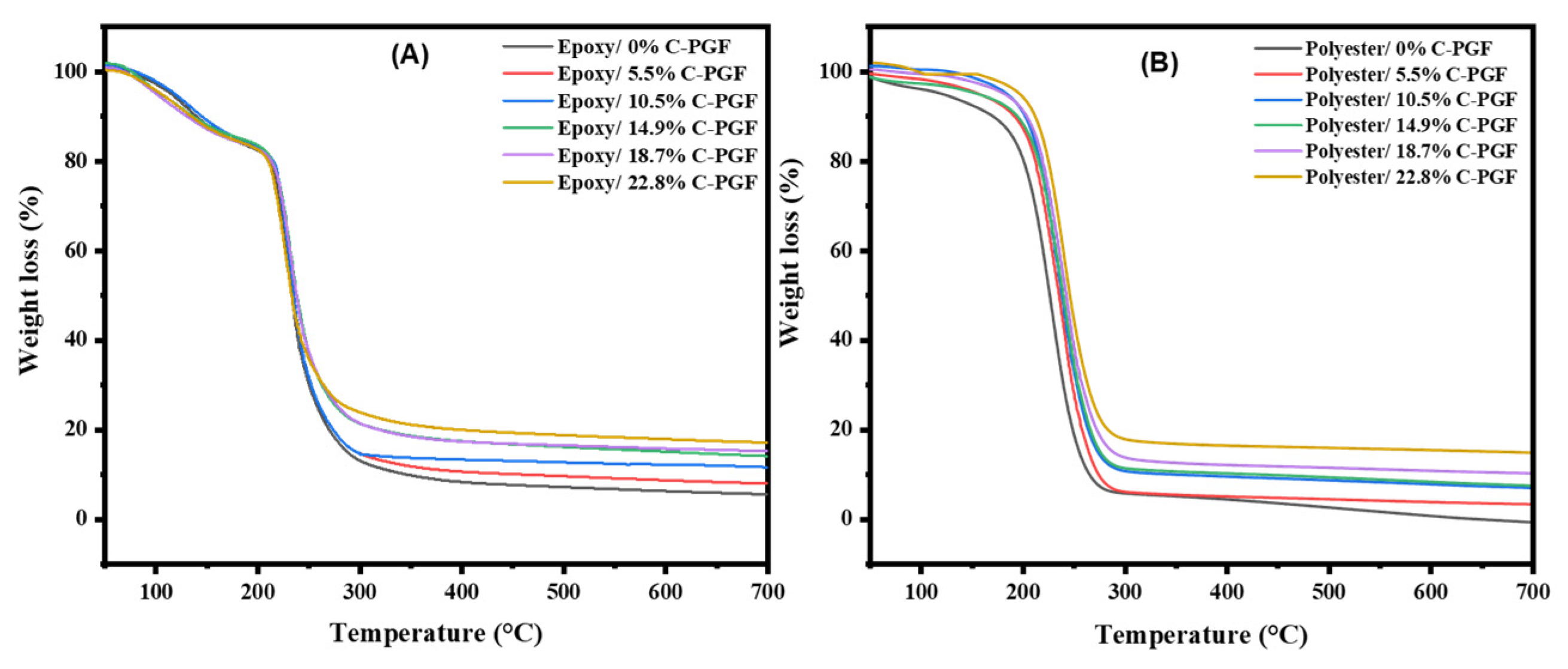

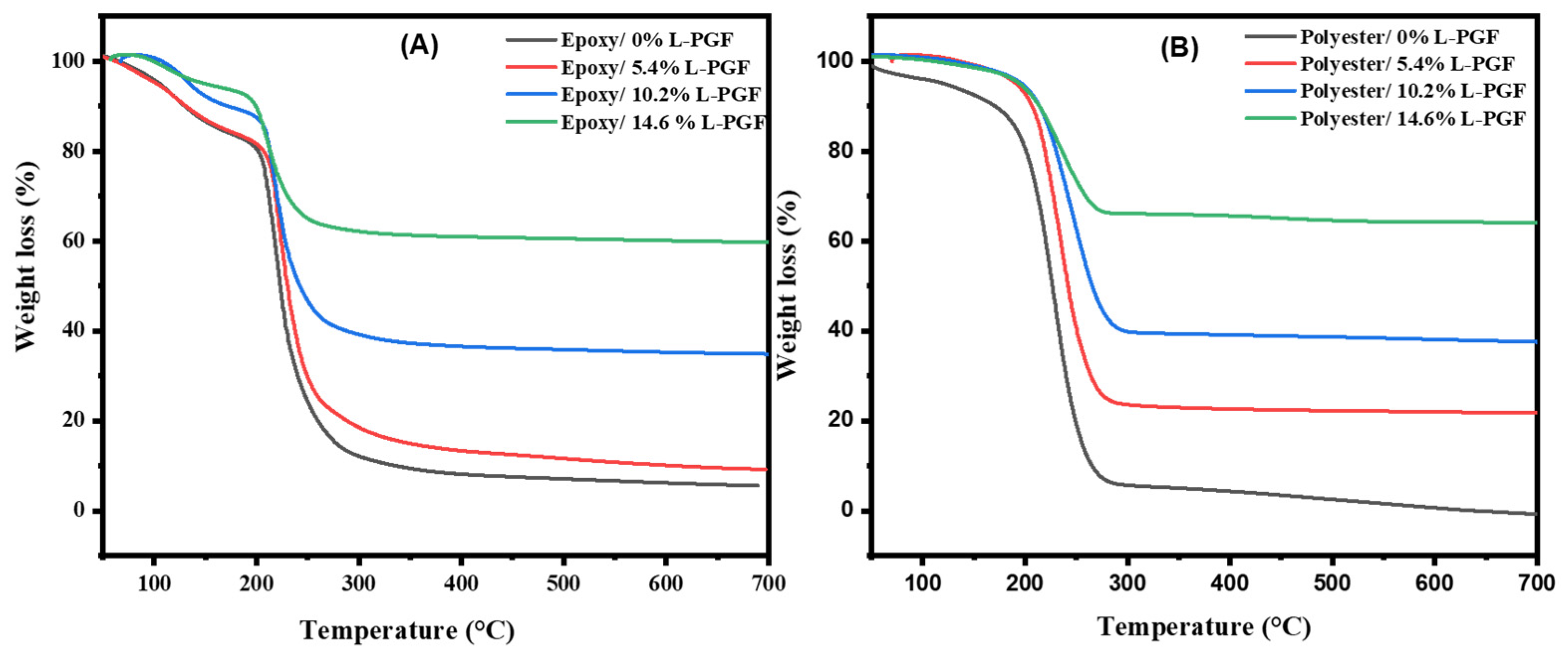

3.2. Thermal Properties

3.3. Mechanical Properties

3.3.1. Tensile Testing

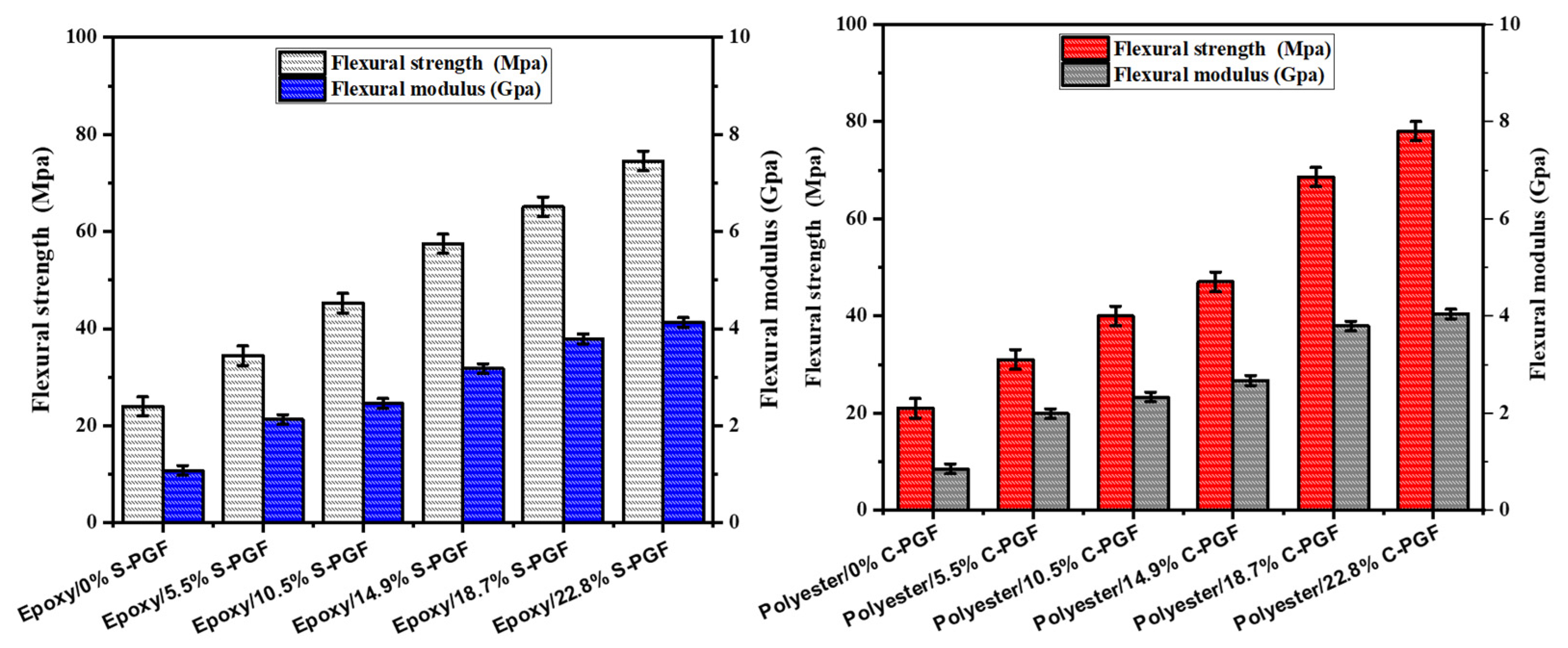

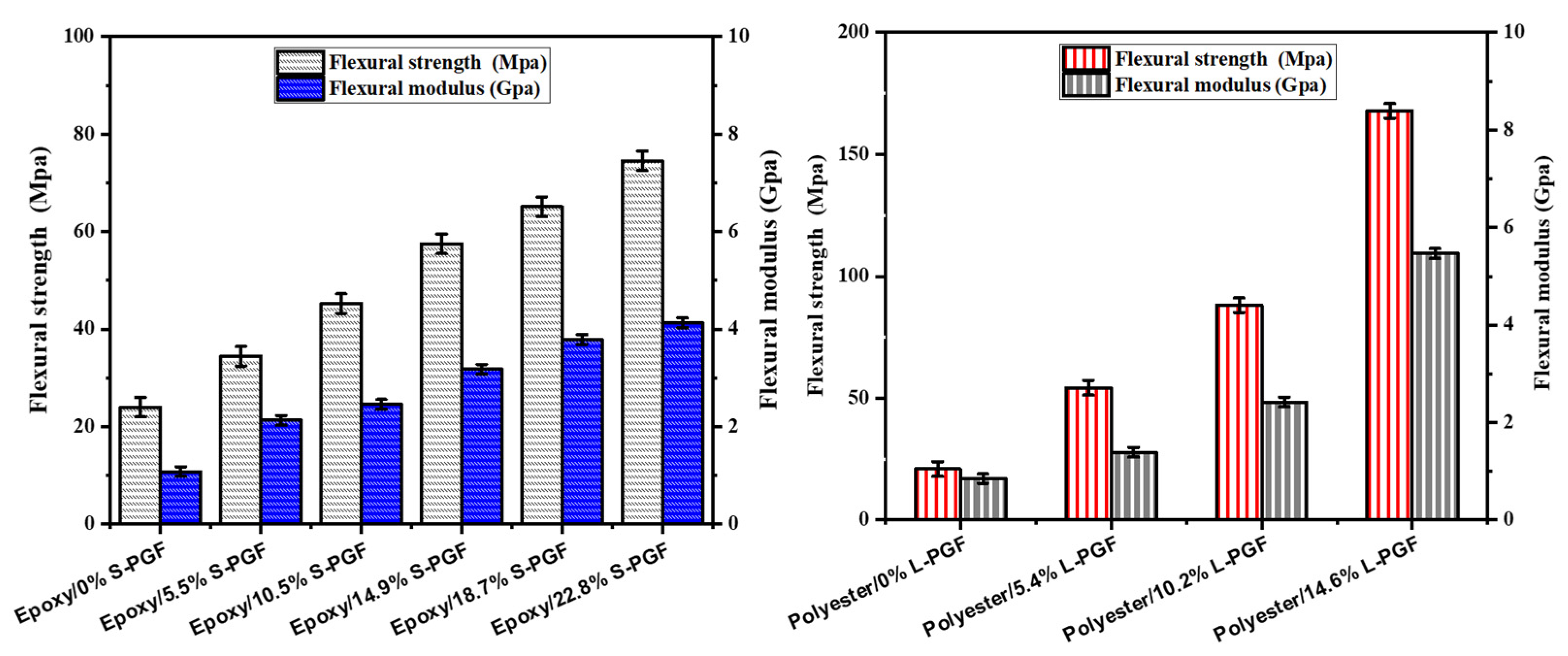

3.3.2. Flexural Testing

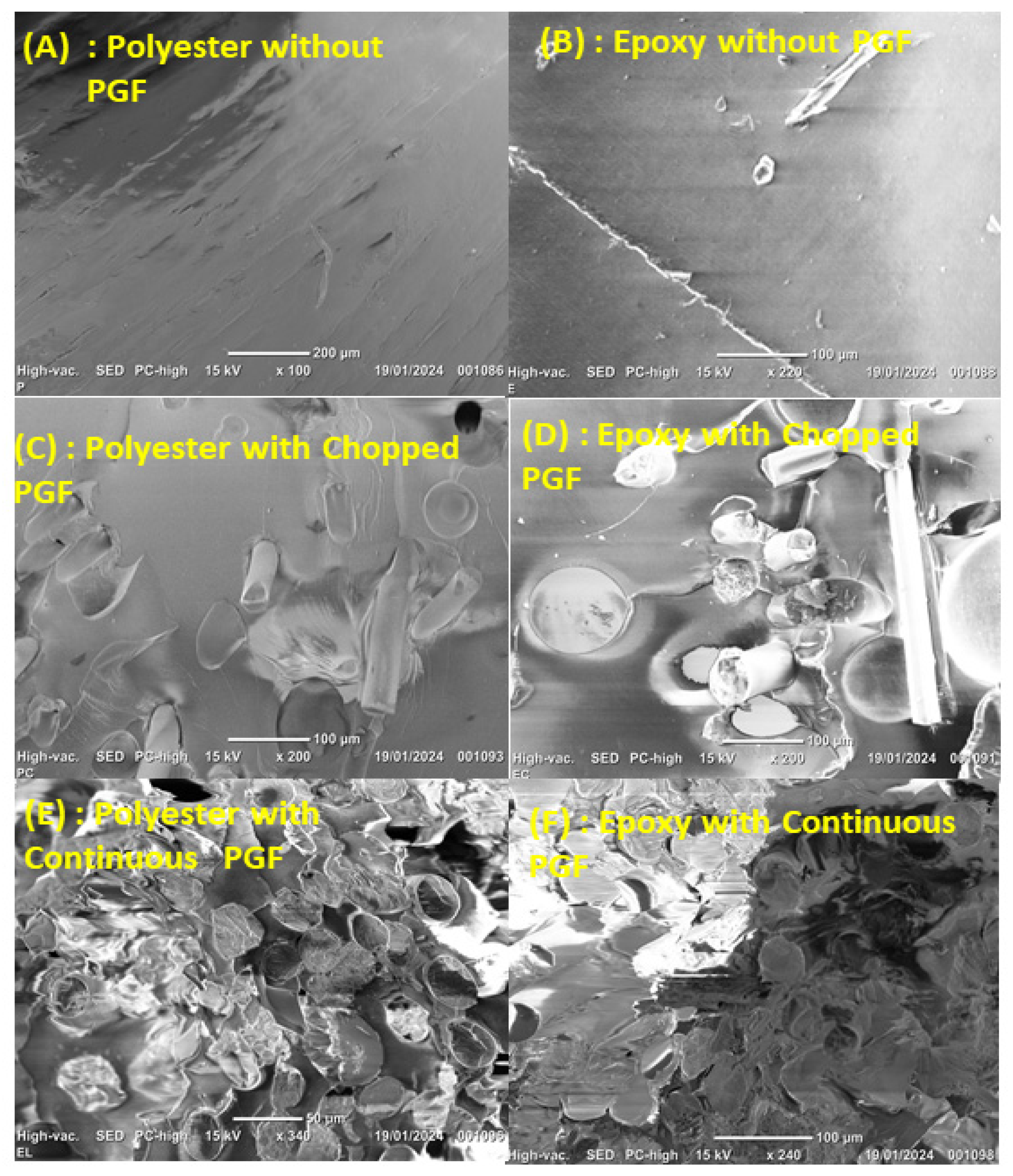

3.4. Morphological Properties

- Polyester without PGF: The fracture surface appears smooth and featureless, typical of brittle failure in unreinforced thermosetting polymers, indicating low energy dissipation.

- Epoxy without PGF: A relatively flat fracture surface with minor surface defects is observed, confirming the limited toughness and absence of reinforcing mechanisms.

- Polyester with chopped PGF (22.8 wt%): The micrograph shows randomly oriented and well-dispersed PGFs within the matrix. However, the presence of voids and visible fiber pull-out suggests partial interfacial bonding and limited stress transfer efficiency.

- Epoxy with chopped PGF (22.8 wt%): Improved fiber dispersion and stronger interfacial adhesion compared to the polyester matrix are evident. Fiber breakage and matrix tearing are observed, indicating a more effective stress transfer and enhanced toughness.

- Polyester with continuous PGF: The fracture surface reveals a well-aligned, unidirectional fiber arrangement, resulting from flow-induced orientation during contact molding. The strong fiber–matrix interface limits fiber pull-out, contributing to better mechanical performance.

- Epoxy with continuous PGF: A highly organized and compact fracture morphology is observed, with tightly packed, oriented fibers. Excellent interfacial bonding is demonstrated by minimal fiber debonding, indicating delayed failure mechanisms and superior mechanical resistance.

4. Conclusions

- The addition of phosphate glass fibers to polyester–epoxy matrices results in a significant increase in composite density, particularly marked with chopped fibers. Epoxy, which is denser than polyester, strongly influences this increase, and continuous fibers contribute to increased density while reducing porosity, thus optimizing mechanical performance without altering structure. On the other hand, chopped fibers, due to their greater surface area, also modify density while influencing material rigidity.

- The studied composites exhibit improved thermal behavior, with initial thermal stability up to approximately 150–230 °C, depending on the fiber content, matrix type, and composite geometry. The incorporation of phosphate glass fibers and fillers, along with optimized structural design, contributed to a reduced rate of thermal degradation and a higher residual mass. These findings underscore the important role of reinforcement and formulation in enhancing thermal resistance and delaying decomposition.

- The addition of phosphate glass fibers to composites based on thermosetting resins, whether polyester or epoxy, significantly improves tensile and flexural strength, with a more marked increase in a continuous geometry than in a cut geometry. Phosphate glass fibers effectively reinforce both types of resin, although epoxy shows superior overall performance, particularly in terms of tensile and flexural strength, stiffness, and durability.

- Scanning electron microscopy (SEM) analysis highlighted the critical role of fiber–matrix compatibility and fiber configuration in determining the mechanical performance of the composites. Composites reinforced with continuous, well-aligned fibers exhibited excellent interfacial adhesion and optimized load transfer, resulting in enhanced mechanical strength. In contrast, chopped fibers, although easier to process, led to more limited improvements, highly dependent on adhesion quality—particularly low in polyester. These findings confirm that combining good fiber wetting with continuous reinforcement is essential to achieving high-performance composite materials.

- The experimental data from tensile strengths and Young’s modulus of s-PGF and L-PGF-reinforced polyester and epoxy composites were evaluated according to the theoretical composite Hirsch model. The results showed a good correlation between the experimental data and theoretical prediction with a high β interaction coefficient in the case of L-PGF-based epoxy composites compared to L-PGF polyester ones.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ishtiaq, S.; Saleem, M.Q.; Naveed, R.; Harris, M.; Khan, S.A. Glass–Carbon–Kevlar fiber reinforced hybrid polymer composite (HPC): Part (A) mechanical and thermal characterization for high GSM laminates. Compos. Part C Open Access 2024, 14, 100468. [Google Scholar] [CrossRef]

- Gonçalves, R.; Martinho, A.; Oliveira, J. Evaluating the potential use of recycled glass fibers for the development of gypsum-based composites. Constr. Build. Mater. 2022, 321, 126320. [Google Scholar] [CrossRef]

- Sajan, S.; Selvaraj, D.P. A review on polymer matrix composite materials and their applications. Mater. Today Proc. 2021, 47, 5493–5498. [Google Scholar] [CrossRef]

- Beardmore, P.; Johnson, C. The potential for composites in structural automotive applications. Compos. Sci. Technol. 1986, 26, 251–281. [Google Scholar] [CrossRef]

- Fuchs, E.R.; Field, F.R.; Roth, R.; Kirchain, R.E. Strategic materials selection in the automobile body: Economic opportunities for polymer composite design. Compos. Sci. Technol. 2008, 68, 1989–2002. [Google Scholar] [CrossRef]

- Mangalgiri, P. Composite materials for aerospace applications. Bull. Mater. Sci. 1999, 22, 657–664. [Google Scholar] [CrossRef]

- Patel, M.; Pardhi, B.; Chopara, S.; Pal, M. Lightweight composite materials for automotive-a review. Carbon 2018, 1, 151. [Google Scholar]

- Mohammadi, H.; Ahmad, Z.; Mazlan, S.A.; Johari, M.A.F.; Siebert, G.; Petru, M.; Coloor, S.S.R. Lightweight glass fiber-reinforced polymer composite for automotive bumper applications: A review. Polymers 2022, 15, 193. [Google Scholar] [CrossRef]

- Saloumi, N.; Daki, I.; El Bouchti, M.; Oumam, M.; Manoun, B.; Yousfi, M.; Hannache, H.; Cherkaoui, O. Development and characterization of phosphate glass fibers and their application in the reinforcement of polyester matrix composites. Materials 2022, 15, 7601. [Google Scholar] [CrossRef]

- Abdouni, I.E.; Krimi, S. Effect of CaO on the structure; durability and bioactivity properties of phosphate Na2O–SrO–TiO2–P2O5 glasses. Mater. Today Proc. 2022, 62, 6305–6311. [Google Scholar] [CrossRef]

- Es-Soufi, H.; Bih, L. Effect of TiO2 on the chemical durability and optical properties of Mo-based phosphate glasses. J. Non-Cryst. Solids 2021, 558, 120655. [Google Scholar] [CrossRef]

- Makhkhas, Y.; Benchekroun, D.; Lassri, H.; Sajieddine, M. Effect of transition oxides on thermal and magnetic properties of phosphate materials. Mater. Today Proc. 2022, 66, 484–488. [Google Scholar] [CrossRef]

- Eddine, O.J.; Wakrim, H.; El Bouchti, M.; Boukhriss, A.; Cherkaoui, O.; Hannache, H.; Gmouh, S. Mechanical, structural, and chemical properties of unmodified and iron-modified phosphate glass fibers based on natural phosphate and kaolin clay. Mater. Chem. Phys. 2020, 255, 123573. [Google Scholar] [CrossRef]

- Morampudi, P.; Namala, K.K.; Gajjela, Y.K.; Barath, M.; Prudhvi, G. Review on glass fiber reinforced polymer composites. Mater. Today Proc. 2021, 43, 314–319. [Google Scholar] [CrossRef]

- Yang, X.; He, M.; He, Y.; Ou, Z. The synergistic enhancement of bending and compression properties of glass fiber reinforced phosphate activated metakaolin geopolymer. Case Study Constr. Mater. 2025, 22, e04527. [Google Scholar] [CrossRef]

- Rashid, A.B.; Haque, M.; Islam, S.M.; Labib, K.R.U. Nanotechnology-enhanced fiber-reinforced polymer composites: Recent advancements on processing techniques and applications. Heliyon 2024, 10, e24692. [Google Scholar] [CrossRef]

- Yalçın, Ç.; Bolat, B.; Ergene, K.; Arakılınç, U.; Yavaş, Ç.; Öz, Y.; Ercetin, A.; Maraş, S.; Der, O. Effect of drilling parameters and tool diameter on delamination and thrust force in the drilling of high-performance glass/epoxy composites for aerospace structures with a new design drill. Polymers 2024, 16, 3011. [Google Scholar] [CrossRef]

- Wu, Y.; Song, Y.; Wu, D.; Mao, X.; Yang, X.; Jiang, S.; Zhang, C.; Guo, R. Recent progress in modifications; properties; and practical applications of glass fiber. Molecules 2023, 28, 2466. [Google Scholar] [CrossRef]

- Mani, P.; Gupta, A.; Krishnamoorthy, S. Comparative study of epoxy and polyester resin-based polymer concretes. Int. J. Adhes. Adhes. 1987, 7, 157–163. [Google Scholar] [CrossRef]

- Daki, I.; Saloumi, N.; Assamadi, C.; Ouafik, A.; Mansouri, S.; Yousfi, M.; Gérard, J.-F.; Duchet-Rumeau, J.; Oumam, M.; Cherkaoui, O.; et al. Synthesis and characterization of new continuous phosphate glass fibers intended for structural engineering applications: Structure/property relationships. Materialia 2024, 38, 102260. [Google Scholar] [CrossRef]

- ISO 527; Plastiques—Determination of Tensile Properties. 2019. Available online: https://www.iso.org/fr/standard/75824.html (accessed on 5 June 2025).

- ISO 14125; Fibre-Reinforced Plastic Composites—Determination of Flexural Properties. 1998. Available online: https://www.iso.org/obp/ui/#iso:std:iso:14125:ed-1:v1:en (accessed on 5 June 2025).

- Nikam, D.; Milani, A.S. Effect of fiber orientation on the stresses generated in dental crowns made of glass fiber composites. Compos. Struct. 2022, 279, 114790. [Google Scholar] [CrossRef]

- Melo, P.; Tarrant, E.; Swift, T.; Townshend, A.; German, M.; Ferreira, A.M.; Gentile, P.; Dalgarno, K. Short phosphate glass fiber-PLLA composite to promote bone mineralization. Mater. Sci. Eng. C 2019, 104, 109929. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Prasad, L.; Patel, V.K.; Kumar, V.; Kumar, A.; Yadav, A.; Winczek, J. Physical and mechanical properties of natural leaf fiber-reinforced epoxy polyester composites. Polymers 2021, 13, 1369. [Google Scholar] [CrossRef]

- Chen, Z.; Liu, X.; Lü, R.; Li, T. Mechanical and tribological properties of PA66/PPS blend. III. Reinforced with GF. J. Appl. Polym. Sci. 2006, 102, 523–529. [Google Scholar] [CrossRef]

- Budai, Z.; Sulyok, Z.; Vargha, V. Glass-fibre reinforced composite materials based on unsaturated polyester resins. J. Therm. Anal. Calorim. 2012, 109, 1533–1544. [Google Scholar] [CrossRef]

- Hameed, N.; Sreekumar, P.; Francis, B.; Yang, W.; Thomas, S. Morphology; dynamic mechanical and thermal studies on poly (styrene-co-acrylonitrile) modified epoxy resin/glass fibre composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2422–2432. [Google Scholar] [CrossRef]

- Zu, Q.; Solvang, M.; Li, H. Fiberglass Science and Technology; Springer Nature: Cham, Switzeland, 2021. [Google Scholar]

- Torabizadeh, M.A. Tensile, compressive and shear properties of unidirectional glass/epoxy composites subjected to mechanical loading and low temperature services. Indian J. Eng. Mater. Sci. 2013, 20, 299–309. [Google Scholar]

- Alam, S.; Habib, F.; Irfan, M.; Iqbal, W.; Khalid, K. Effect of orientation of glass fiber on mechanical properties of GRP composites. J. Chem. Soc. Pak. 2010, 32, 265–269. [Google Scholar]

- Ogbonna, V.; Popoola, A.; Popoola, O.; Adeosun, S. A review on corrosion; mechanical; and electrical properties of glass fiber-reinforced epoxy composites for high-voltage insulator core rod applications: Challenges and recommendations. Polym. Bull. 2022, 79, 6857–6884. [Google Scholar] [CrossRef]

- Mohan, N.; Natarajan, S.; KumareshBabu, S.; Siddaramaiah. Investigation on sliding wear behaviour and mechanical properties of jatropha oil cake-filled glass-epoxy composites. J. Am. Oil Chem. Soc. 2011, 88, 111–117. [Google Scholar] [CrossRef]

- Godara, A.; Raabe, D. Influence of fiber orientation on global mechanical behavior and mesoscale strain localization in a short glass-fiber-reinforced epoxy polymer composite during tensile deformation investigated using digital image correlation. Compos. Sci. Technol. 2007, 67, 2417–2427. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A. Modeling and evaluation of tensile properties of randomly oriented banana/epoxy composite. J. Reinf. Plast. Compos. 2011, 30, 1957–1967. [Google Scholar] [CrossRef]

- Qureshi, J. A review of fibre reinforced polymer structures. Fibers 2022, 10, 27. [Google Scholar] [CrossRef]

- Joseph, P.; Mathew, G.; Joseph, K.; Thomas, S.; Pradeep, P. Mechanical properties of short sisal fiber-reinforced polypropylene composites: Comparison of experimental data with theoretical predictions. J. Appl. Polym. Sci. 2003, 88, 602–611. [Google Scholar] [CrossRef]

- Kretsis, G. A review of the tensile; compressive; flexural and shear properties of hybrid fibre-reinforced plastics. Composites 1987, 18, 13–23. [Google Scholar] [CrossRef]

- Sreekumar, P.; Joseph, K.; Unnikrishnan, G.; Thomas, S. A comparative study on mechanical properties of sisal-leaf fibre-reinforced polyester composites prepared by resin transfer and compression moulding techniques. Compos. Sci. Technol. 2007, 67, 453–461. [Google Scholar] [CrossRef]

- Iba, H.; Chang, T.; Kagawa, Y. Optically transparent continuous glass fibre-reinforced epoxy matrix composite: Fabrication; optical and mechanical properties. Compos. Sci. Technol. 2002, 62, 2043–2052. [Google Scholar] [CrossRef]

- Dkier, M.; Yousfi, M.; Lamnawar, K.; Maazouz, A. Chemo-rheological studies and monitoring of high-Tg reactive polyphtalamides towards a fast innovative RTM processing of fiber-reinforced thermoplastic composites. Eur. Polym. J. 2019, 120, 109227–109242. [Google Scholar] [CrossRef]

- Rijsdijk, H.; Contant, M.; Peijs, A. Continuous-glass-fibre-reinforced polypropylene composites: I. Influence of maleic-anhydride-modified polypropylene on mechanical properties. Compos. Sci. Technol. 1993, 48, 161–172. [Google Scholar] [CrossRef]

| Properties | Value |

|---|---|

| Density (g/cm3) | 2.8 |

| Tg (°C) | 538 |

| Tc (°C) | 655 |

| Young’s modulus (GPa) | 140 |

| Tensile strength (MPa) | 2668 |

| Samples | Mass Fraction (%) | Composite Density (g/cm3) | Volume Fraction (%) | Thickness (mm) |

|---|---|---|---|---|

| Polyester/0% S-PGF | 0 | 1.60 | 0 | 5.0 |

| Polyester/5.5% S-PGF | 5.5 | 1.64 | 3.2 | 5.0 |

| Polyester/10.5% S-PGF | 10.5 | 1.68 | 6.3 | 5.0 |

| Polyester/14.9% S-PGF | 14.9 | 1.71 | 9.1 | 5.0 |

| Polyester/18.7% S-PGF | 18.7 | 1.74 | 11.6 | 5.0 |

| Polyester/22.8% S-PGF | 22.8 | 1.77 | 14.4 | 5.0 |

| Polyester/5.4% L-PGF | 5.4 | 1.64 | 3.2 | 5.0 |

| Polyester/10.2% L-PGF | 10.2 | 1.67 | 6.1 | 5.0 |

| Polyester/14.6% L-PGF | 14.6 | 1.71 | 8.9 | 5.0 |

| Samples | Mass Fraction (%) | Composite Density (g/cm3) | Volume Fraction (%) | Thickness (mm) |

|---|---|---|---|---|

| Epoxy/0% S-PGF | 0 | 1.70 | 0 | 5.0 |

| Epoxy/5.5% S-PGF | 5.5 | 1.74 | 3.4 | 5.0 |

| Epoxy/10.5% S-PGF | 10.5 | 1.77 | 6.6 | 5.0 |

| Epoxy/14.9% S-PGF | 14.9 | 1.81 | 9.6 | 5.0 |

| Epoxy/18.7% S-PGF | 18.7 | 1.84 | 12.3 | 5.0 |

| Epoxy/22.8% S-PGF | 22.8 | 1.87 | 15.2 | 5.0 |

| Epoxy/5.4% L-PGF | 5.4 | 1.74 | 3.4 | 5.0 |

| Epoxy/10.2% L-PGF | 10.2 | 1.77 | 6.4 | 5.0 |

| Epoxy/14.6% L-PGF | 14.6 | 1.80 | 9.4 | 5.0 |

| Samples | Tmax | Residue (%) at Tmax |

|---|---|---|

| Epoxy/0% S-PGF | 183 | 5 |

| Epoxy/5.5% S-PGF | 229 | 7 |

| Epoxy/10.5% S-PGF | 233 | 11 |

| Epoxy/14.9% S-PGF | 233 | 14 |

| Epoxy/18.7% S-PGF | 234 | 15 |

| Epoxy/22.8% S-PGF | 235 | 18 |

| Polyester/0% S-PGF | 187 | 0 |

| Polyester/5.5% S-PGF | 228 | 3 |

| Polyester/10.5% S-PGF | 235 | 7 |

| Polyester/14.9% S-PGF | 237 | 7 |

| Polyester/18.7% S-PGF | 239 | 10 |

| Polyester/22.8% S-PGF | 329 | 14.5 |

| Samples | Tmax | Residue (%) at Tmax |

|---|---|---|

| Epoxy/0% L-PGF | 183 | 5 |

| Epoxy/5.4% L-PGF | 233 | 21 |

| Epoxy/10.2% L-PGF | 233 | 37 |

| Epoxy/14.6% L-PGF | 244 | 64 |

| Polyester/0% L-PGF | 187 | 0 |

| Polyester/5.4% L-PGF | 228 | 9 |

| Polyester/10.2% L-PGF | 228 | 34 |

| Polyester/14.6% L-PGF | 231 | 59 |

| Resin | Choice of Geometry | Vf | Tensile Strength (MPa) | Tensile Modulus (MPa) | Flexural Strength (MPa) | Flexural Modulus (MPa) | Ref. |

|---|---|---|---|---|---|---|---|

| Polyester | GFRP virgin | - | 64.4 | 7200 | - | - | [29] |

| GFRP Chopped Strand | 0.30 | - | 124 | - | 159 | [26] | |

| GFRP woven carpet | - | 220 | 7000 | - | - | [30] | |

| Chopped strands + vertical rovings | - | 103.5 | - | - | - | [31] | |

| PGFRP chopped | 15.2 | 71.3 | 5120 | 78.1 | 404 | Present Study | |

| PGFRP continuous | 9.4 | 145.7 | 11,550 | 167.9 | 547 | Present Study | |

| Epoxy | GFRP Randomly oriented | 0.5 | 179.4 | 6700 | 297.8 | - | [32] |

| GFRP Unidirectional | 0.55 | 784.9 | - | - | - | [30] | |

| Woven FRP | 0.60 | 311.0 | 18,610 | - | - | [33] | |

| GFRP woven + (35% by weight short borosilicate) | - | 355.0 | 43,700 | - | - | [34] | |

| PGFRP chopped | 15.2 | 75.9 | 7570 | 74.6 | 413 | Present Study | |

| PGFRP continuous | 9.4 | 187.9 | 15,930 | 218.0 | 786 | Present Study |

| Configuration | Fiber Orientation | Fiber/Matrix Adhesion | Expected Mechanical Properties |

|---|---|---|---|

| Neat matrices | None | – | High brittleness, low toughness |

| Chopped PGF | Random | Moderate (polyester), good (epoxy) | Moderate toughness, limited improvement in strength |

| Continuous PGF | Unidirectional | Strong (especially with epoxy) | High modulus, improved tensile strength, delayed crack propagation |

| PGF-Reinforced Composites | Fitting from Tensile Moduli Data | Fitting from Tensile Strength Data | ||||

|---|---|---|---|---|---|---|

| β Coefficient | R2 | Error | β Coefficient | R2 | Error | |

| Polyester/S-PGF | 0.18 | 0.96 | 0.01 | 0.12 | 0.97 | 0.01 |

| Polyester/L-PGF | 0.89 | 0.99 | 0.04 | 0.46 | 0.96 | 0.05 |

| Epoxy/S-PGF | 0.22 | 0.98 | 0.01 | 0.11 | 0.98 | 0.01 |

| Epoxy/L-PGF | 0.99 | 0.99 | 0.06 | 0.61 | 0.99 | 0.03 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Daki, I.; Saloumi, N.; Yousfi, M.; Parajua-sejil, C.; Truchot, V.; Gérard, J.-F.; Cherkaoui, O.; Hannache, H.; El Bouchti, M.; Oumam, M. Exploring the Thermal and Mechanical Properties of Thermoset-Based Composites Reinforced with New Continuous and Chopped Phosphate Glass Fibers. Polymers 2025, 17, 1627. https://doi.org/10.3390/polym17121627

Daki I, Saloumi N, Yousfi M, Parajua-sejil C, Truchot V, Gérard J-F, Cherkaoui O, Hannache H, El Bouchti M, Oumam M. Exploring the Thermal and Mechanical Properties of Thermoset-Based Composites Reinforced with New Continuous and Chopped Phosphate Glass Fibers. Polymers. 2025; 17(12):1627. https://doi.org/10.3390/polym17121627

Chicago/Turabian StyleDaki, Iliass, Nezha Saloumi, Mohamed Yousfi, Caroline Parajua-sejil, Vivien Truchot, Jean-François Gérard, Omar Cherkaoui, Hassan Hannache, Mehdi El Bouchti, and Mina Oumam. 2025. "Exploring the Thermal and Mechanical Properties of Thermoset-Based Composites Reinforced with New Continuous and Chopped Phosphate Glass Fibers" Polymers 17, no. 12: 1627. https://doi.org/10.3390/polym17121627

APA StyleDaki, I., Saloumi, N., Yousfi, M., Parajua-sejil, C., Truchot, V., Gérard, J.-F., Cherkaoui, O., Hannache, H., El Bouchti, M., & Oumam, M. (2025). Exploring the Thermal and Mechanical Properties of Thermoset-Based Composites Reinforced with New Continuous and Chopped Phosphate Glass Fibers. Polymers, 17(12), 1627. https://doi.org/10.3390/polym17121627