Environmental Effects of Moisture and Elevated Temperatures on the Mode I and Mode II Interlaminar Fracture Toughness of a Toughened Epoxy Carbon Fibre Reinforced Polymer

Abstract

1. Introduction

2. Materials, Manufacturing, and Conditioning

2.1. Material Selection

2.2. Specimen Manufacturing

2.3. Conditioning and Preparation

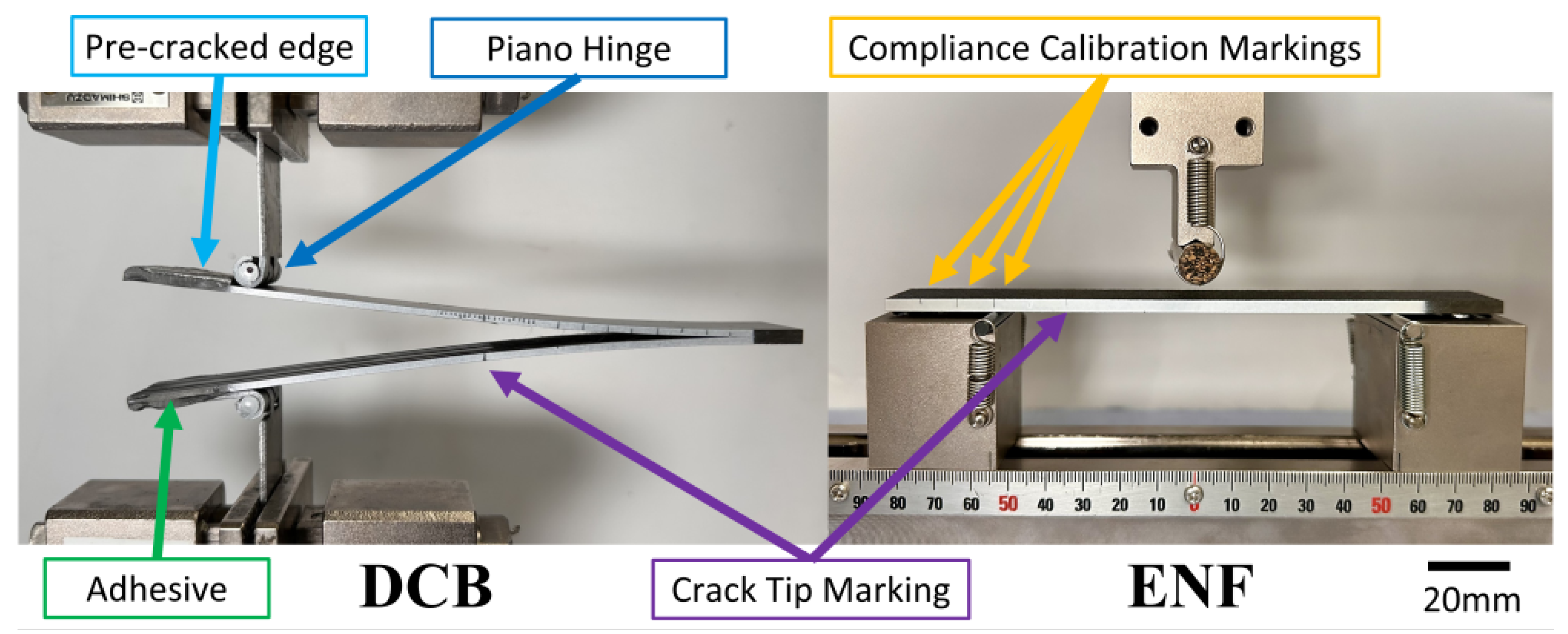

3. Experimental Set Up and Applied Test Methods

3.1. Precracking

3.2. Test Procedure

3.3. Hot/Wet Testing

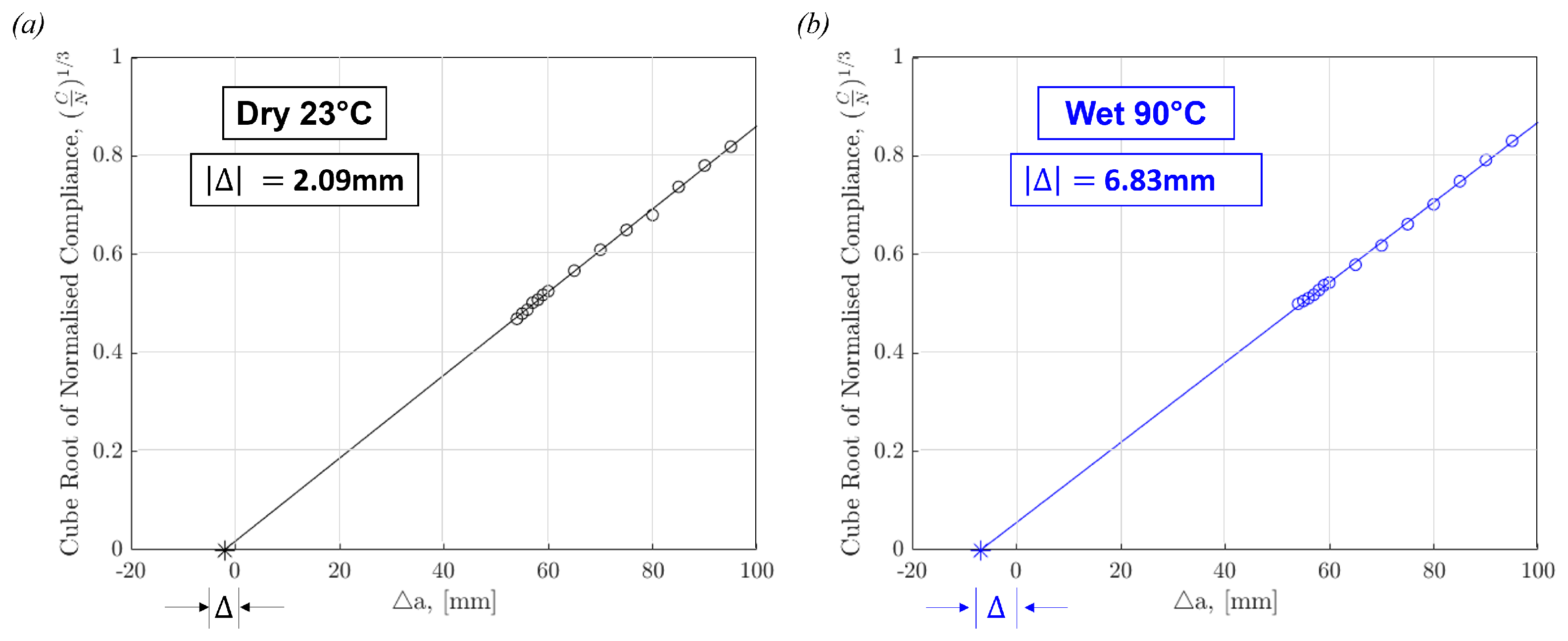

3.4. Data Reduction

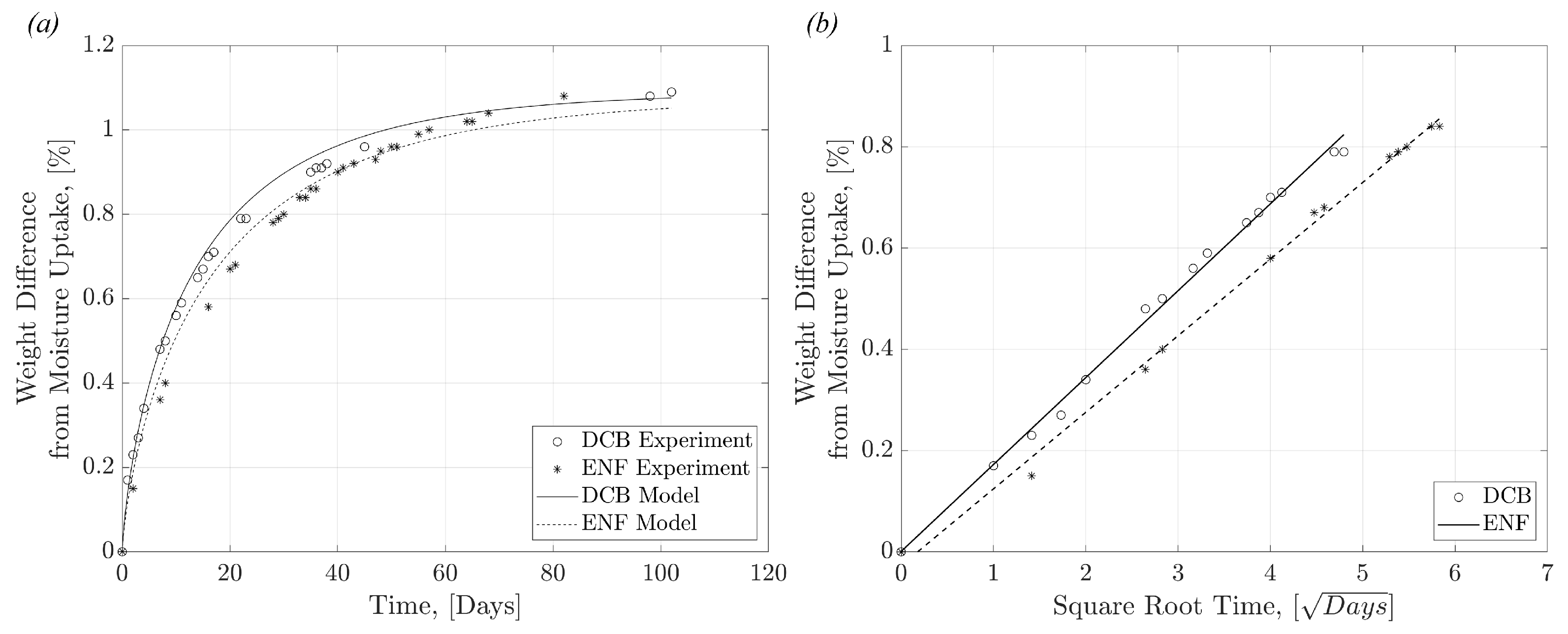

3.5. Moisture Study

3.6. Post-Fracture Analysis

4. Results and Discussion

4.1. Moisture Uptake and Thermal Analysis

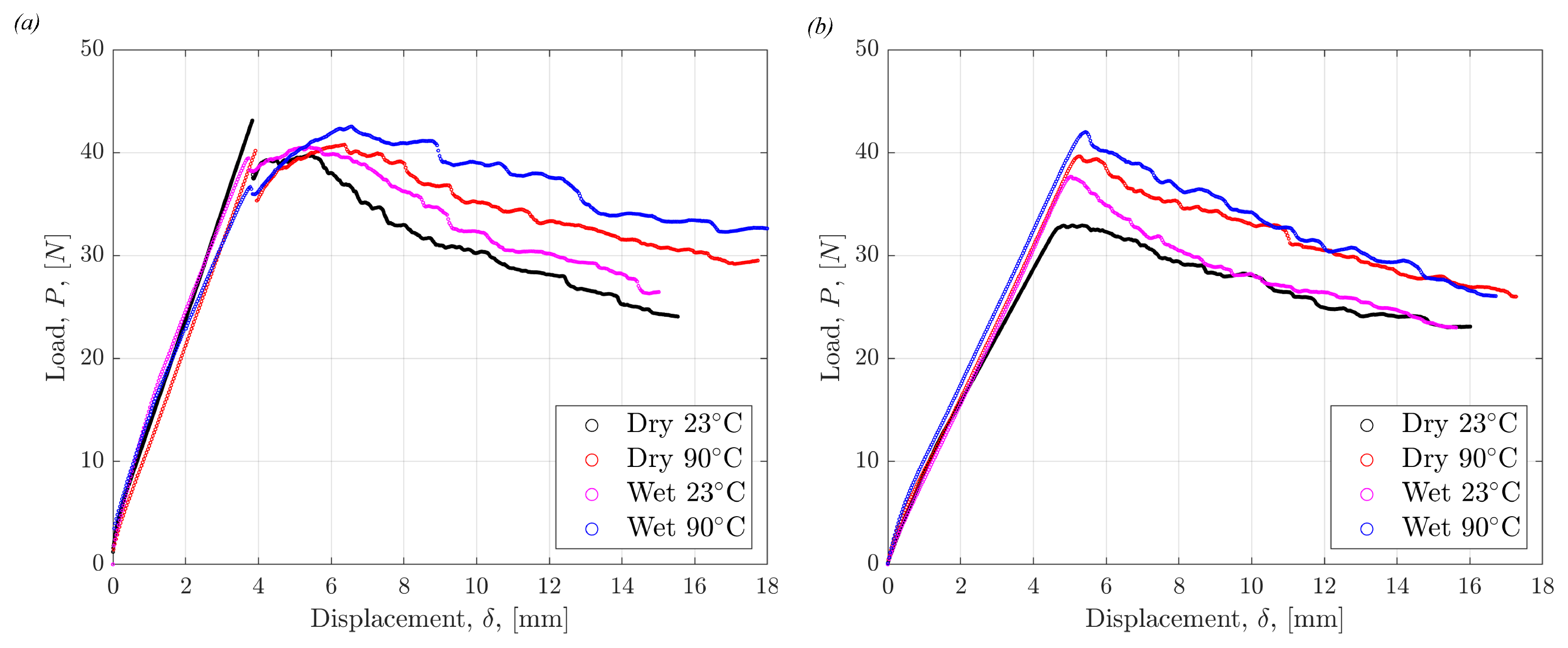

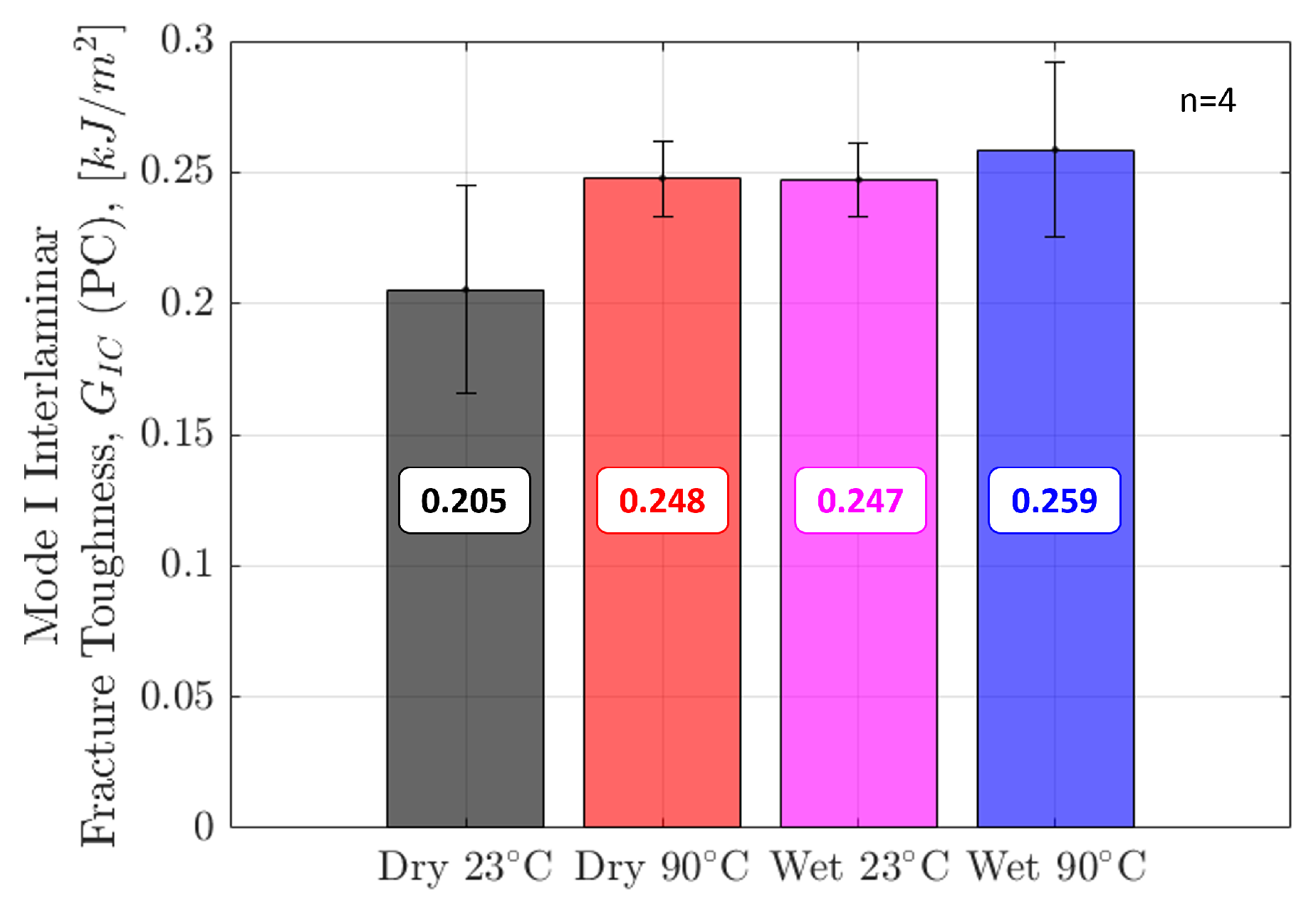

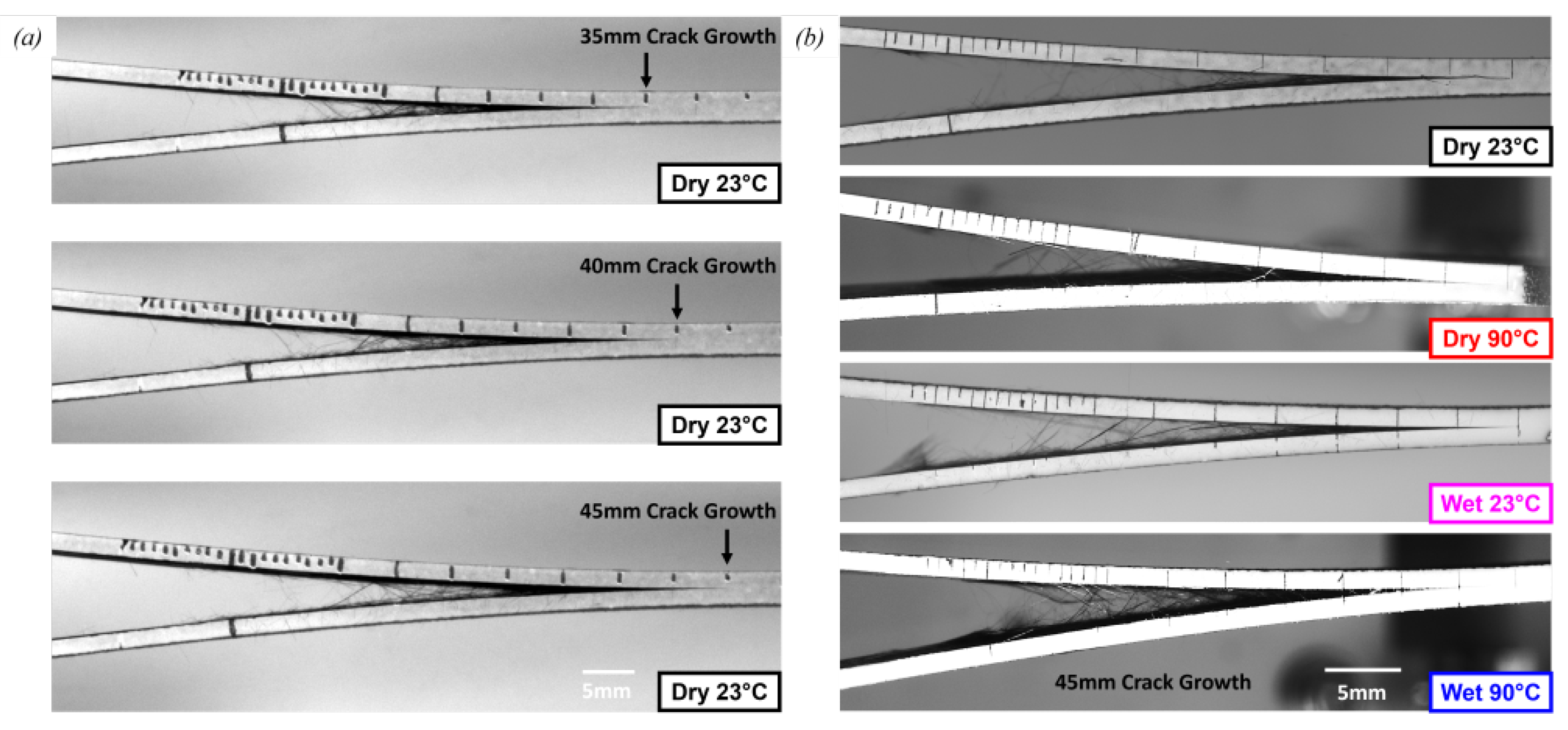

4.2. Mode I Interlaminar Fracture

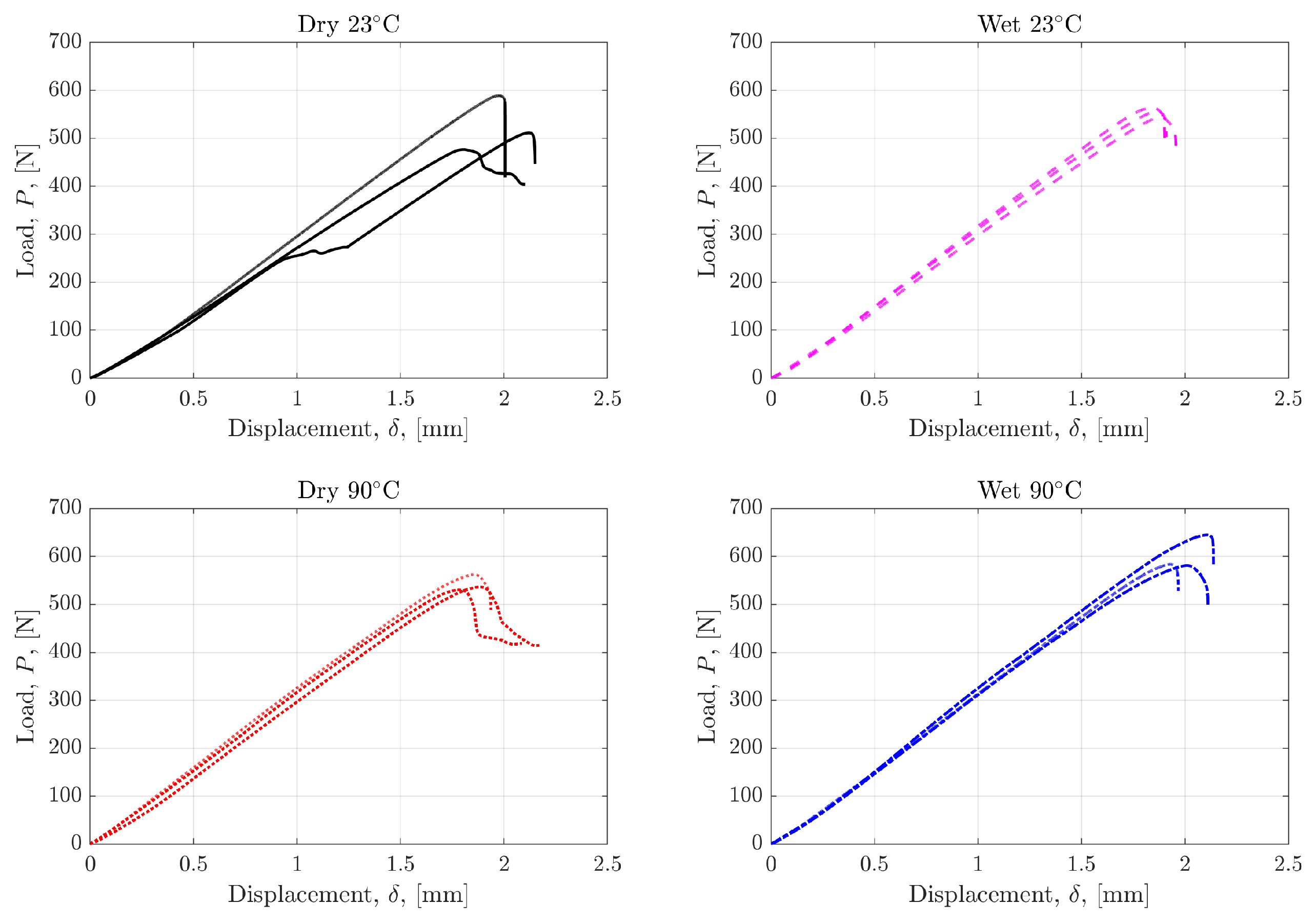

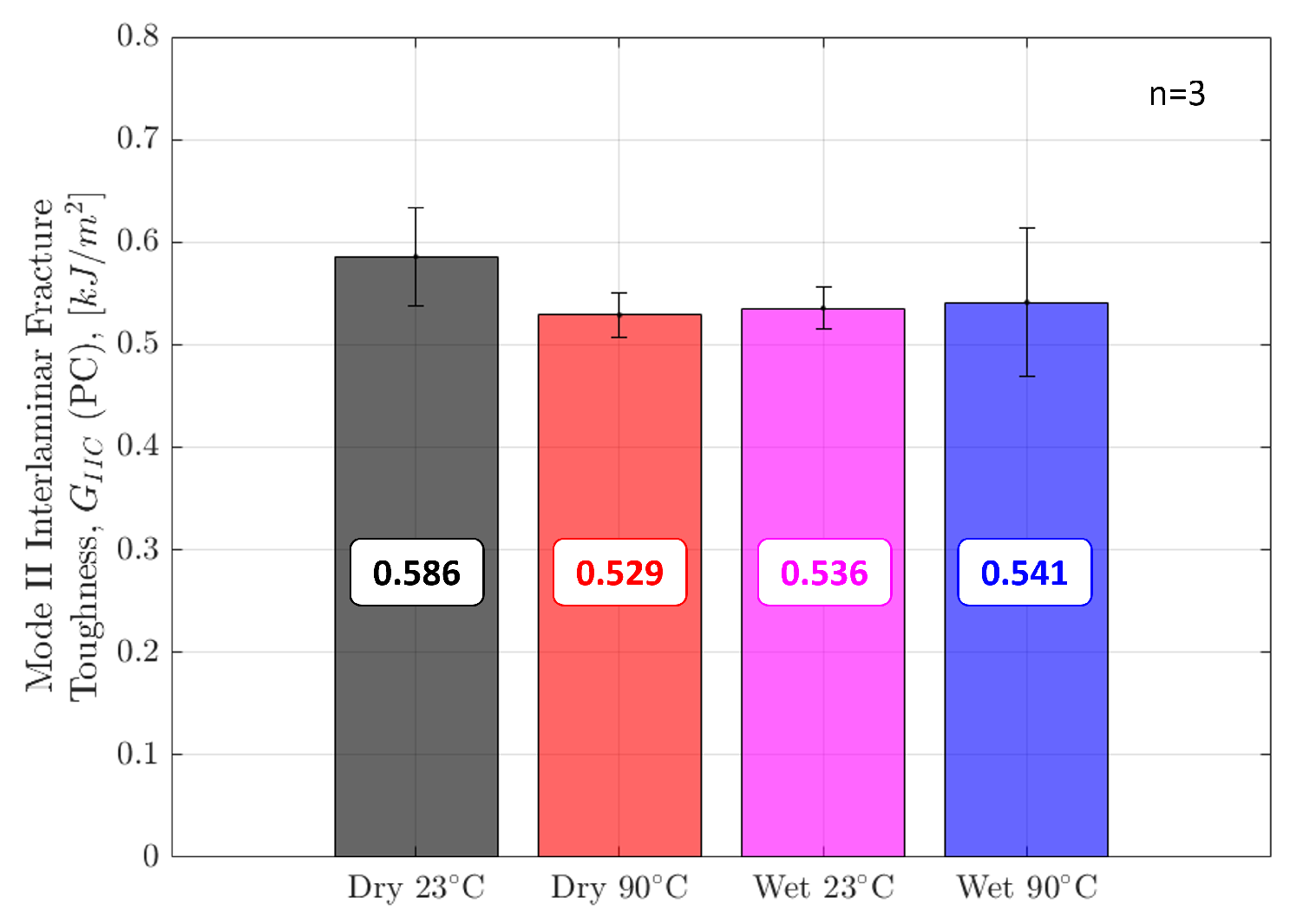

4.3. Mode II Interlaminar Fracture

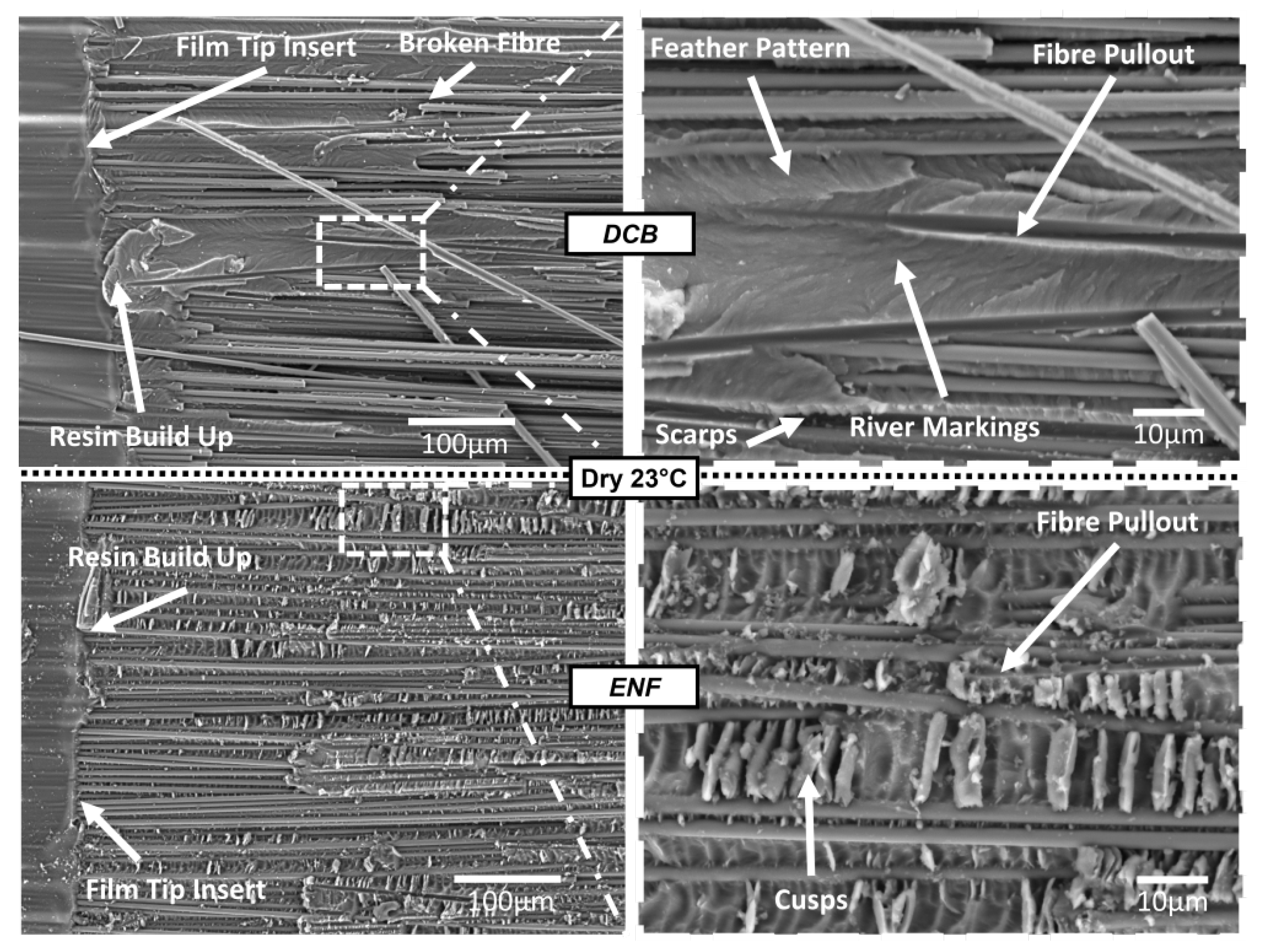

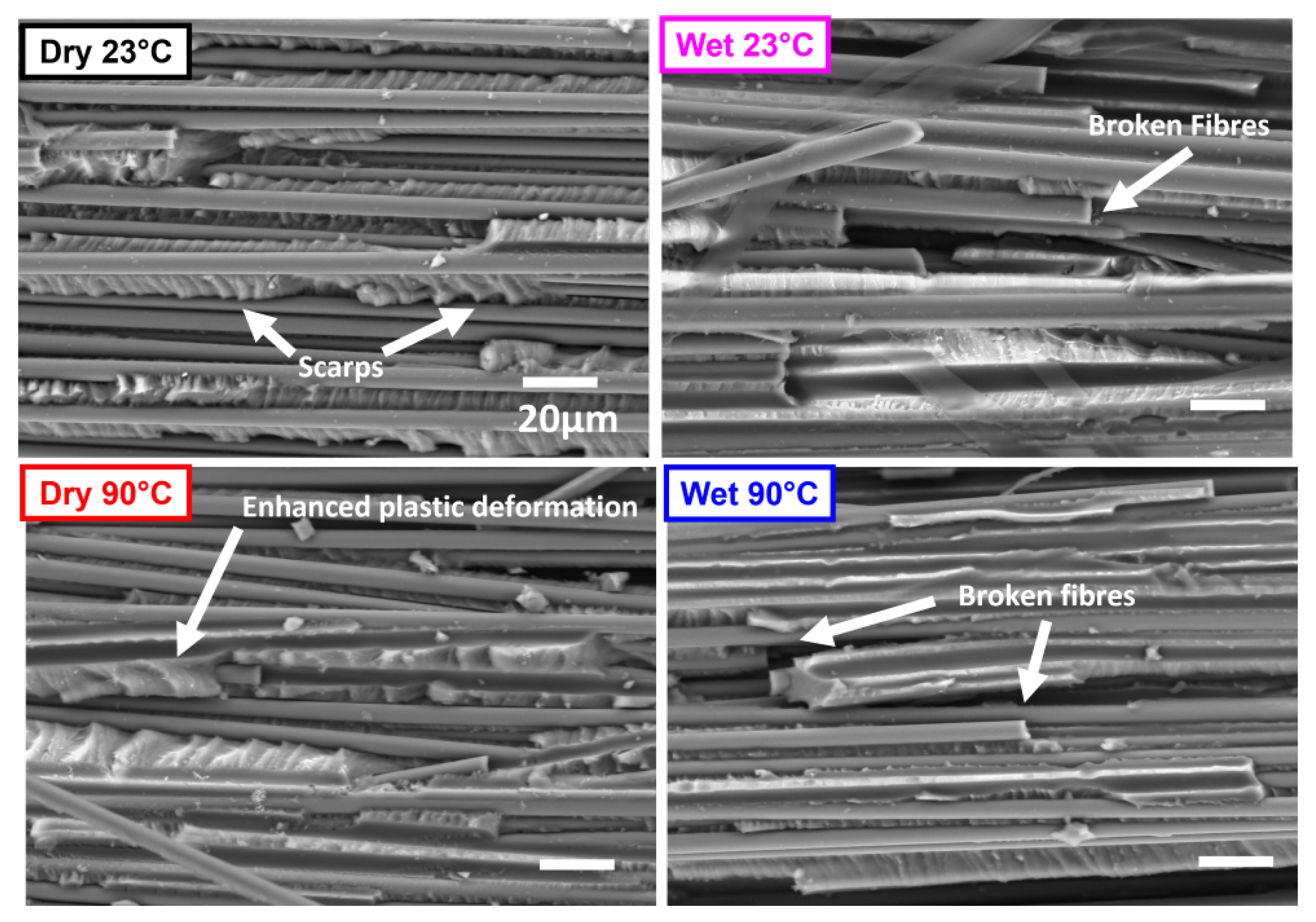

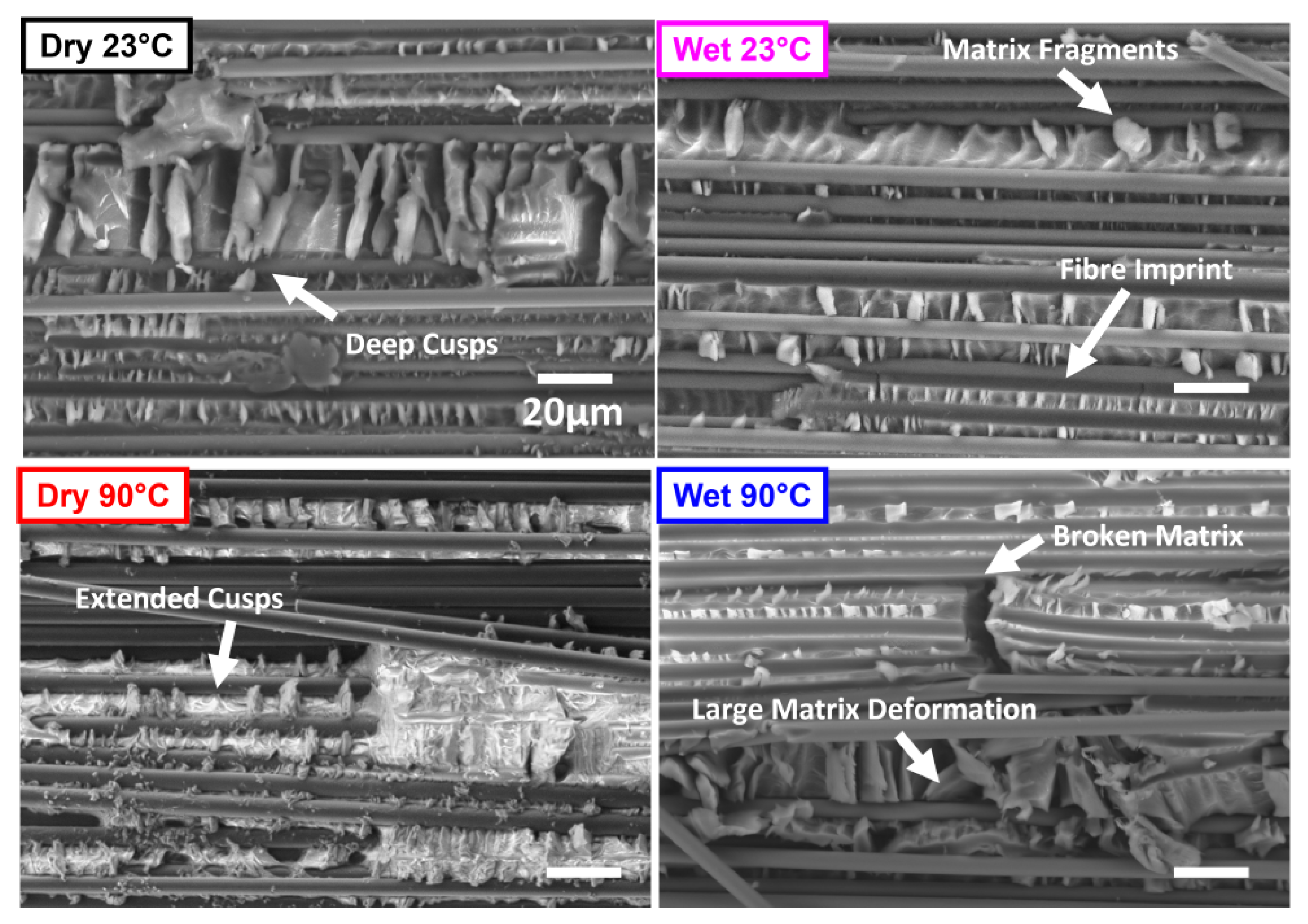

4.4. Fractographic Analysis

5. Conclusions

- IM7/8552 has been shown to exhibit a Fickian Response to moisture uptake. A maximum moisture content of ≈1.1% was achieved after ≈100 days of conditioning in 70 °C/85% relative humidity.

- The glass transition temperature of the material decreased by 13% (-onset, Storage Modulus), 15% (-peak, Loss Modulus) and 17% (-peak, Tan Delta) in ‘Wet’ specimens compared to ‘Dry’, characterised by DMA.

- Mode I initiation and propagation interlaminar fracture toughness values were calculated using DCB specimens, and R-curves were plotted to show the increase in fracture toughness as delamination increased. Mode I toughness was highest in the ‘hot/wet’ (Wet 90 °C) specimens, where toughness values were on average 26% higher than Dry 23 °C specimens.

- Temperature was more dominant than moisture in increasing Mode I fracture toughness as delamination progressed, as evidenced by the R-curves. This is due to matrix softening, resulting in more compliant specimens and an increase in the ductile behaviour of the composite. Fibre bridging and pull-out are also enhanced, further arresting crack growth.

- Mode II initiation fracture toughness values were calculated using ENF specimens. Mode II toughness was highest in Dry 23 °C specimens, reducing by 8% in ‘Wet 90 °C’. ENF specimens tested in ‘hot/wet’ conditions had the largest scatter.

- Temperature and moisture contributed to an increase in Mode I interlaminar fracture toughness and a decrease in Mode II interlaminar fracture toughness.

- The strong influence of the resin build-up in the film tip region is displayed using SEM images, highlighting the importance of precracking before testing.

- Mode I fracture contains matrix features including feather patterns, river markings and scarps. Mode II fracture is identified by matrix cusps. Both types of fracture demonstrate evidence of broken fibres and fibre pull-out.

- Blunt fracture behaviour was noted in Dry 23 °C specimens, demonstrated by sharp, highly concentrated scarps (Mode I) and deep, sharp cusps (Mode II).

- Extended matrix deformation with smoother, drawn-out features was observed in high-temperature tests. Clean fibres with less resin residue pointed to a degraded fibre-matrix interface caused by moisture in ‘Wet’ specimens

- ‘hot/wet’ conditions resulted in a ductile, soft, plasticised matrix with broken fibres, large local deformations and deposited matrix fragments.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pilato, L.A.; Michno, M.J. Advanced Composite Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 1994. [Google Scholar]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials, 4th ed.; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Toulitsis, A.; Fielden-Stewart, Z.; Lopez, M.Y.R.; Hamerton, I. Phenolic Triazine Silicon Polymer Resin Blends. U.S. Patent US11840627B2, 12 December 2023. [Google Scholar]

- Salunke, A.; Sasidharan, S.; Cherukattu Gopinathapanicker, J.; Kandasubramanian, B.; Anand, A. Cyanate Ester—Epoxy Blends for Structural and Functional Composites. Ind. Eng. Chem. Res. 2021, 60, 3260–3277. [Google Scholar] [CrossRef]

- Barroeta Robles, J.; Hubert, P. Material characterization of cyanate ester material for structures with high dimensional stability requirements. Compos. Part A Appl. Sci. Manuf. 2023, 175, 107747. [Google Scholar] [CrossRef]

- Moulishwar Reddy, A.; Kandasubramanian, B.; Rath, S.K. Cyanate ester blends and composites to improve dielectric, mechanical, and thermal performance for functional applications. Polym. Bull. 2023, 81, 3781–3836. [Google Scholar] [CrossRef]

- Mouritz, A.P. Introduction to Aerospace Materials; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Potter, R.T.; Purslow, D. The environmental degradation of notched CFRP in compression. Composites 1983, 14, 206–225. [Google Scholar] [CrossRef]

- Aceti, P.; Carminati, L.; Bettini, P.; Sala, G. Hygrothermal ageing of composite structures. Part 1: Technical review. Compos. Struct. 2023, 319, 117076. [Google Scholar] [CrossRef]

- Shetty, K.; Bojja, R.; Srihari, S. Effect of hygrothermal aging on the mechanical properties of IMA/M21E aircraft-grade CFRP composite. Adv. Compos. Lett. 2020, 29, 2633366X20926520. [Google Scholar] [CrossRef]

- Rocha, I.B.C.M.; Raijmaekers, S.; Nijssen, R.P.L.; van der Meer, F.P.; Sluys, L.J. Hygrothermal ageing behaviour of a glass/epoxy composite used in wind turbine blades. Compos. Struct. 2017, 174, 110–122. [Google Scholar] [CrossRef]

- Wisnom, M.R.; Swolfs, Y.; París, F. 2.03—Measuring the Mechanical Properties of Composites and the Factors Affecting Them. In Comprehensive Mechanics of Materials, 1st ed.; Silberschmidt, V., Ed.; Elsevier: Oxford, UK, 2024; pp. 57–102. [Google Scholar] [CrossRef]

- Sela, N.; Ishai, O. Interlaminar fracture toughness and toughening of laminated composite materials: A review. Composites 1989, 20, 423–435. [Google Scholar] [CrossRef]

- ASTM D5528/D5528M-21; Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 1994.

- ASTM D7905/D7905M-19e1; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2014.

- Asp, L. The effects of moisture and temperature on the interlaminar delamination toughness of a carbon/epoxy composite. Compos. Sci. Technol. 1998, 58, 967–977. [Google Scholar] [CrossRef]

- Boni, L.; Fanteria, D.; Lazzeri, L.; Panettieri, E.; Mariani, U.; Rigamonti, M. Influence of environment conditioning on the interlaminar fracture toughness of a graphite/epoxy unidirectional material. Compos. Part B Eng. 2018, 153, 97–107. [Google Scholar] [CrossRef]

- Garg, A.; Ishai, O. Hygrothermal influence on delamination behavior of graphite/epoxy laminates. Eng. Fract. Mech. 1985, 22, 413–427. [Google Scholar] [CrossRef]

- Selzer, R.; Friedrich, K. Inluence of water up-take on interlaminar fracture properties of carbon fibre-reinforced polymer composites. J. Mater. Sci. 1995, 30, 334–338. [Google Scholar] [CrossRef]

- Coronado, P.; Argüelles, A.; Viña, J.; Mollón, V.; Viña, I. Influence of temperature on a carbon–fibre epoxy composite subjected to static and fatigue loading under mode-I delamination. Int. J. Solids Struct. 2012, 49, 2934–2940. [Google Scholar] [CrossRef]

- De Cássia Mendonça Sales, R.; Rossi Dias Endo, B.L.; Donadon, M.V. Influence of Temperature on Interlaminar Fracture Toughness of a Carbon Fiber-Epoxy Composite Material. Adv. Mater. Res. 2016, 1135, 35–51. [Google Scholar] [CrossRef]

- Cao, J.; Gu, J.; Dang, Z.; Zhang, C. On temperature-dependent fiber bridging in mode I delamination of unidirectional composite laminates. Compos. Part A Appl. Sci. Manuf. 2023, 171, 107581. [Google Scholar] [CrossRef]

- Russell, A.J.; Street, K.N. Moisture and Temperature Effects on the Mixed-Mode Delamination Fracture of Unidirectional Graphite/Epoxy; ASTM STP 876; ASTM International: West Conshohocken, PA, USA, 1985. [Google Scholar]

- Almansour, F.A.; Dhakal, H.N.; Zhang, Z.Y. Effect of water absorption on Mode I interlaminar fracture toughness of flax/basalt reinforced vinyl ester hybrid composites. Compos. Struct. 2017, 168, 813–825. [Google Scholar] [CrossRef]

- Johar, M.; Chong, W.W.F.; Kang, H.S.; Wong, K.J. Effects of moisture absorption on the different modes of carbon/epoxy composites delamination. Polym. Degrad. Stab. 2019, 165, 117–125. [Google Scholar] [CrossRef]

- Hunston, D.L.; Bascom, W.D. Effects of Lay-Up, Temperature, and Loading Rate in Double Cantilever Beam Tests of Interlaminar Crack Growth. Compos. Technol. Res. 1983, 5, 118–119. [Google Scholar] [CrossRef]

- Bascom, W.D.; Bitner, J.L.; Moulton, R.J.; Siebert, A.R. The interlaminar fracture of organic-matrix, woven reinforcement composites. Composites 1980, 11, 9–18. [Google Scholar] [CrossRef]

- Wong, K.J.; Johar, M.; Koloor, S.S.R.; Petrů, M.; Tamin, M.N. Moisture Absorption Effects on Mode II Delamination of Carbon/Epoxy Composites. Polymers 2020, 12, 2162. [Google Scholar] [CrossRef]

- HEXCEL. HexTow Laminate Properties in HexPly® 8552|Hexcel. 2025. Available online: https://www.hexcel.com/Products/Resources/1664/hextow-laminate-properties-in-hexply-8552 (accessed on 16 May 2025).

- HEXCEL. HexPly® 8552 Product Data Sheet. 2023. Available online: https://www.scribd.com/document/664965816/HexPly-8552 (accessed on 16 May 2025).

- HEXCEL. HexTow® IM7 Carbon Fiber Product Data Sheet. 2023. Available online: https://www.hexcel.com/Resources/DataSheets/Carbon-Fiber (accessed on 16 May 2025).

- Syensqo. CYCOM® 977-2 AND 977-2A Technical Data Sheet. 2024. Available online: https://www.syensqo.com/en/product/cycom-977-2 (accessed on 16 May 2025).

- Syensqo. Carbon Fiber—Product Catalog. 2025. Available online: https://www.syensqo.com/en/chemical-categories/our-composite-materials-solutions/carbon-fiber/product-catalog (accessed on 16 May 2025).

- ASTM D5229/D5229M-20; Test Method for Moisture Absorption Properties and Equilibrium Conditioning of Polymer Matrix Composite Materials. D30 Committee: West Conshohocken, PA, USA, 2020. [CrossRef]

- Shen, C.H.; Springer, G.S. Moisture Absorption and Desorption of Composite Materials. J. Compos. Mater. 1976, 10, 2–20. [Google Scholar] [CrossRef]

- EN 6032:2015; Aerospace Series—Fibre Reinforced Plastics—Test Method—Determination of the Glass Transition Temperatures. British Standards Institution: London, UK, 2015.

- Katafiasz, T.; Greenhalgh, E.; Allegri, G.; Pinho, S.; Robinson, P. The influence of temperature and moisture on the mode I fracture toughness and associated fracture morphology of a highly toughened aerospace CFRP. Compos. Part A Appl. Sci. Manuf. 2021, 142, 106241. [Google Scholar] [CrossRef]

- Purslow, D. Composites fractography without an SEM—The failure analysis of a CFRP I-beam. Composites 1984, 15, 43–48. [Google Scholar] [CrossRef]

- Marlett, K.; Ng, Y.; Tomblin, J. Hexcel 8552 IM7 Unidirectional Prepreg 190 gsm & 35% RC Qualification Material Property Data Report; Test Report CAM-RP-2009-015, Rev. A; National Center for Advanced Materials Performance: Wichita, KS, USA, 2011; pp. 1–238. [Google Scholar]

- Xian, G.; Zhou, P.; Li, C.; Dong, S.; Du, H.; Tian, J.; Guo, R.; Peng, Z.; Zhang, Z.; He, T. Mechanical properties evaluation of glass fiber reinforced thermoplastic composite plate under combined bending loading and water immersion. Constr. Build. Mater. 2024, 440, 137470. [Google Scholar] [CrossRef]

- Mamalis, D.; Floreani, C.; Ó Brádaigh, C.M. Influence of hygrothermal ageing on the mechanical properties of unidirectional carbon fibre reinforced powder epoxy composites. Compos. Part B Eng. 2021, 225, 109281. [Google Scholar] [CrossRef]

- Alessi, S.; Conduruta, D.; Pitarresi, G.; Dispenza, C.; Spadaro, G. Accelerated ageing due to moisture absorption of thermally cured epoxy resin/polyethersulphone blends. Thermal, mechanical and morphological behaviour. Polym. Degrad. Stab. 2011, 96, 642–648. [Google Scholar] [CrossRef]

- Alessi, S.; Pitarresi, G.; Spadaro, G. Effect of hydrothermal ageing on the thermal and delamination fracture behaviour of CFRP composites. Compos. Part B Eng. 2014, 67, 145–153. [Google Scholar] [CrossRef]

- Czabaj, M.W.; Ratcliffe, J.G. Comparison of intralaminar and interlaminar mode I fracture toughnesses of a unidirectional IM7/8552 carbon/epoxy composite. Compos. Sci. Technol. 2013, 89, 15–23. [Google Scholar] [CrossRef]

| Tensile Strength | Tensile Modulus | Tensile Strain | Short Beam Shear Strength | Compressive Strength | Compressive Modulus |

|---|---|---|---|---|---|

| 2723 MPa | 164 GPa | 1.62% | 137 MPa | 1689 MPa | 150 GPa |

| Specimen | D, [mm2/Day] | , [%] |

|---|---|---|

| DCB | 1.09 | |

| ENF | 1.08 |

| Condition | -Onset [°C] (Storage Modulus) | -Peak [°C] (Loss Modulus) | -Peak [°C] (Tan Delta) |

|---|---|---|---|

| Dry | 202 | 213 | 229 |

| Wet | 175 | 182 | 189 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Williams, A.; Hamerton, I.; Allegri, G. Environmental Effects of Moisture and Elevated Temperatures on the Mode I and Mode II Interlaminar Fracture Toughness of a Toughened Epoxy Carbon Fibre Reinforced Polymer. Polymers 2025, 17, 1503. https://doi.org/10.3390/polym17111503

Williams A, Hamerton I, Allegri G. Environmental Effects of Moisture and Elevated Temperatures on the Mode I and Mode II Interlaminar Fracture Toughness of a Toughened Epoxy Carbon Fibre Reinforced Polymer. Polymers. 2025; 17(11):1503. https://doi.org/10.3390/polym17111503

Chicago/Turabian StyleWilliams, Anna, Ian Hamerton, and Giuliano Allegri. 2025. "Environmental Effects of Moisture and Elevated Temperatures on the Mode I and Mode II Interlaminar Fracture Toughness of a Toughened Epoxy Carbon Fibre Reinforced Polymer" Polymers 17, no. 11: 1503. https://doi.org/10.3390/polym17111503

APA StyleWilliams, A., Hamerton, I., & Allegri, G. (2025). Environmental Effects of Moisture and Elevated Temperatures on the Mode I and Mode II Interlaminar Fracture Toughness of a Toughened Epoxy Carbon Fibre Reinforced Polymer. Polymers, 17(11), 1503. https://doi.org/10.3390/polym17111503