LLDPE-like Polymers Accessible via Ethylene Homopolymerization Using Nitro-Appended 2-(Arylimino)pyridine-nickel Catalysts

Abstract

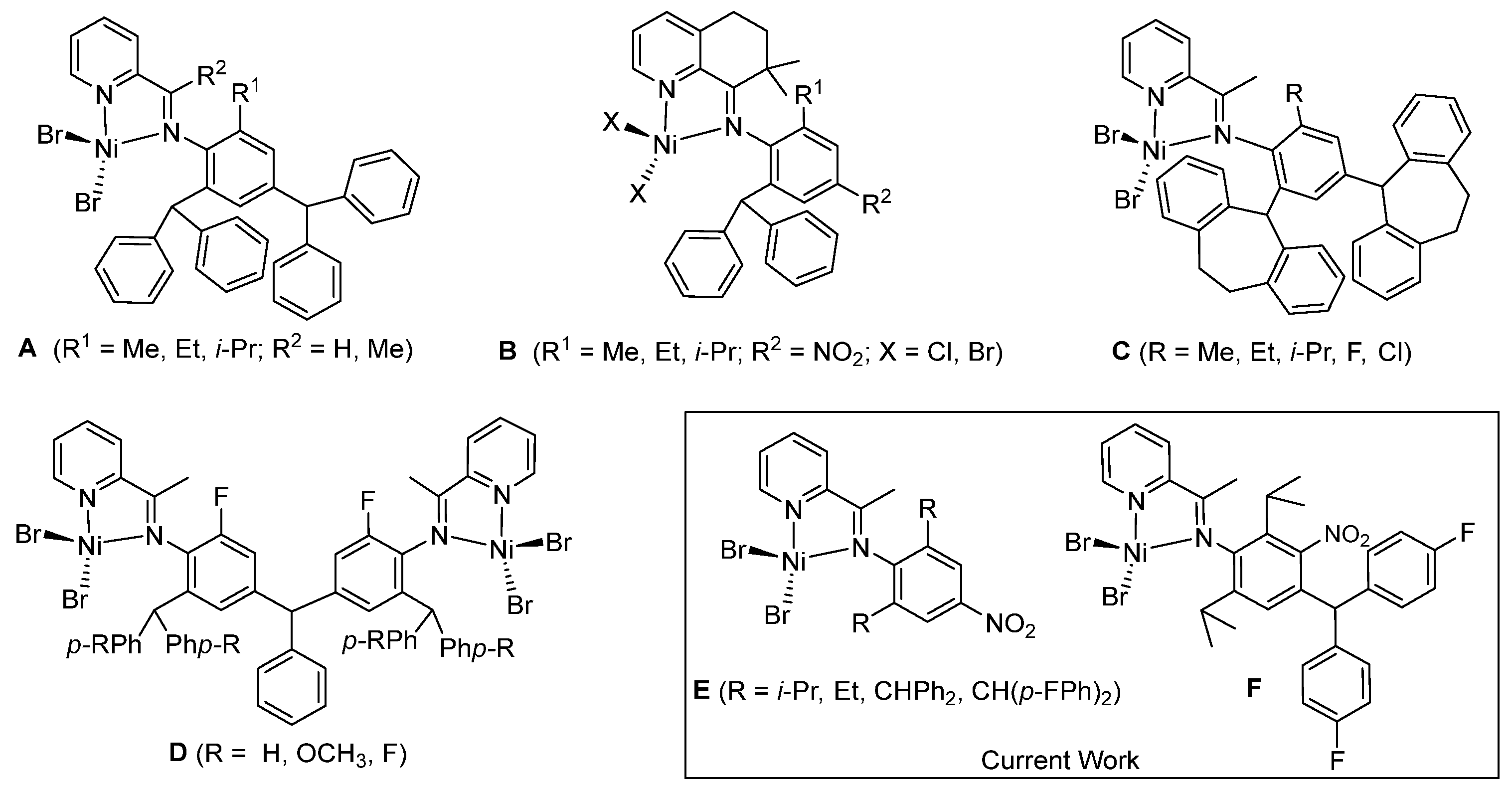

:1. Introduction

2. Results and Discussion

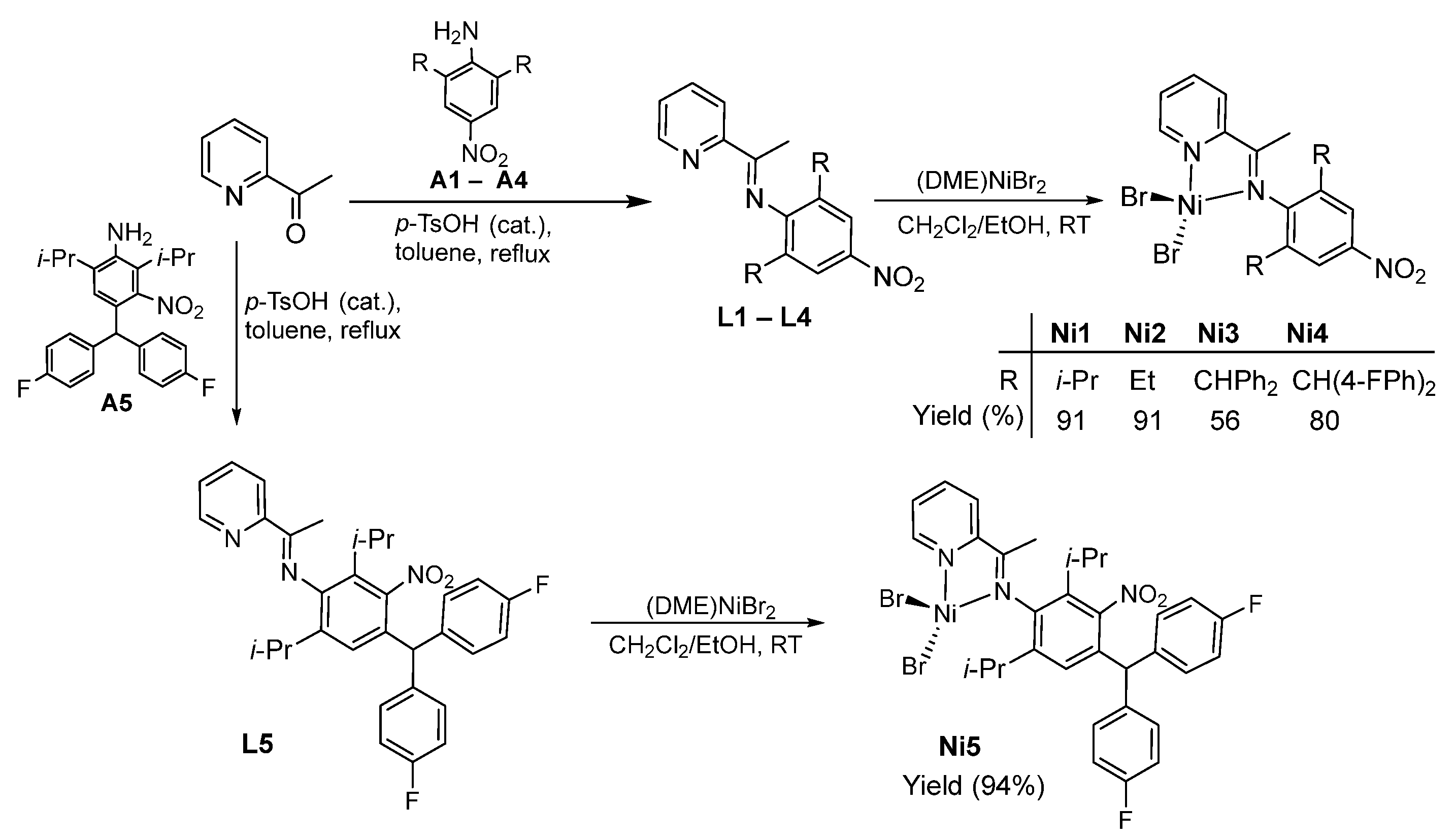

2.1. Synthesis and Characterization of L1–L5 and Their Complexes Ni1–Ni5

2.2. Catalytic Evaluation for Ethylene Polymerization

2.2.1. Co-Catalyst Screening

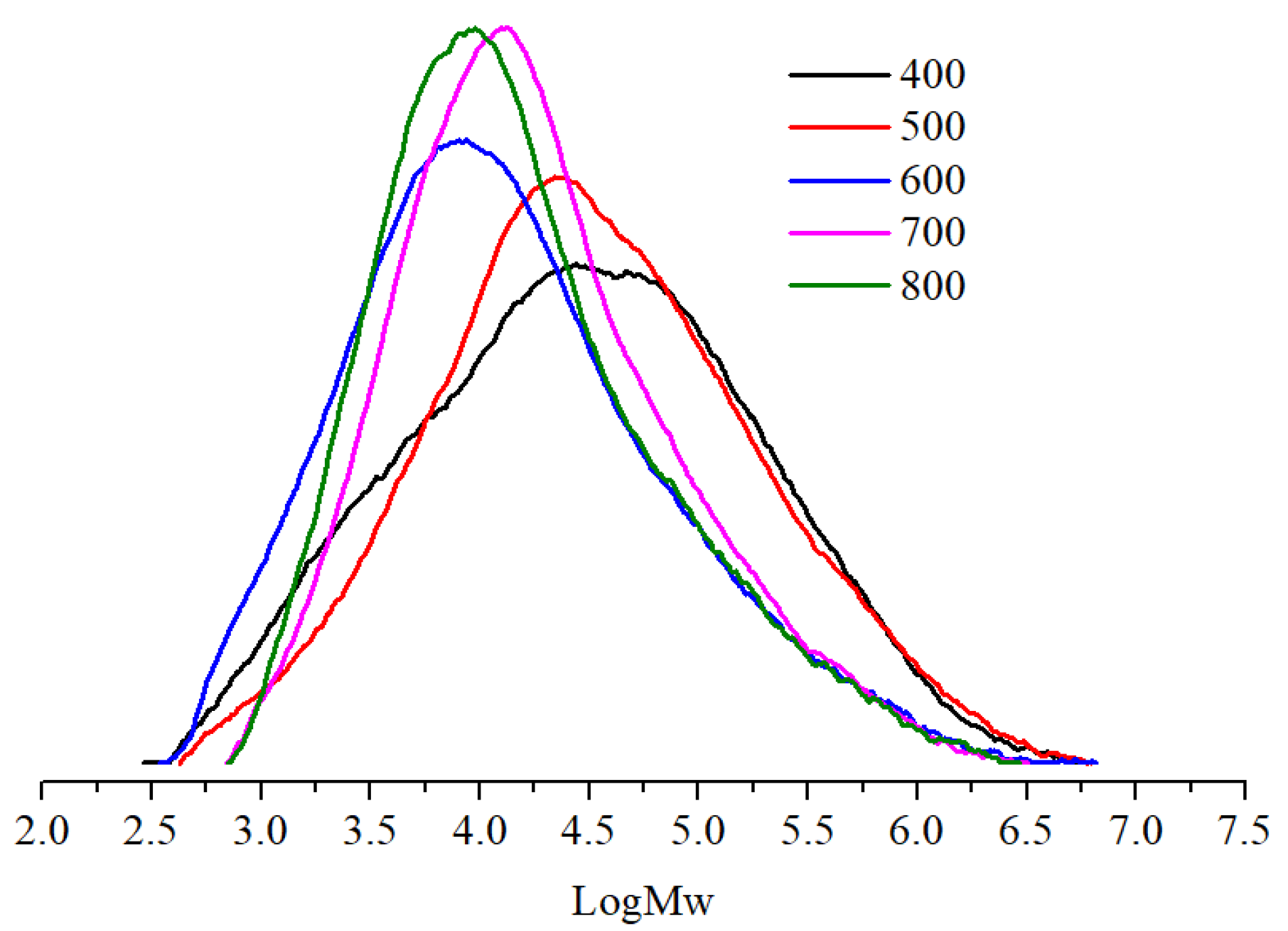

2.2.2. Ethylene Polymerization Using Ni1–Ni5 in the Presence of EtAlCl2

2.2.3. Ethylene Polymerization Using Ni1–Ni5 in the Presence of MMAO

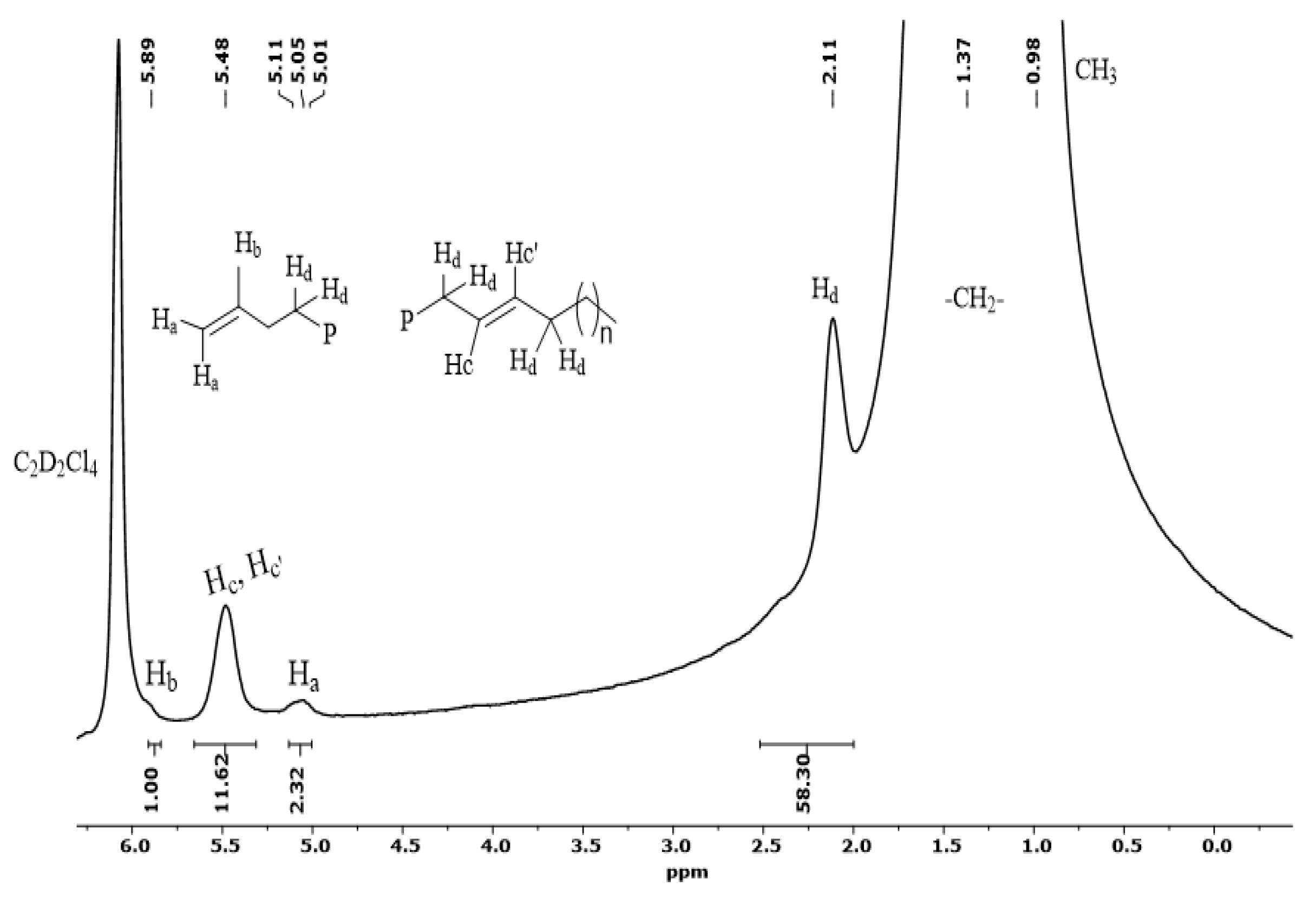

2.2.4. Microstructural Studies of the Polyethylene

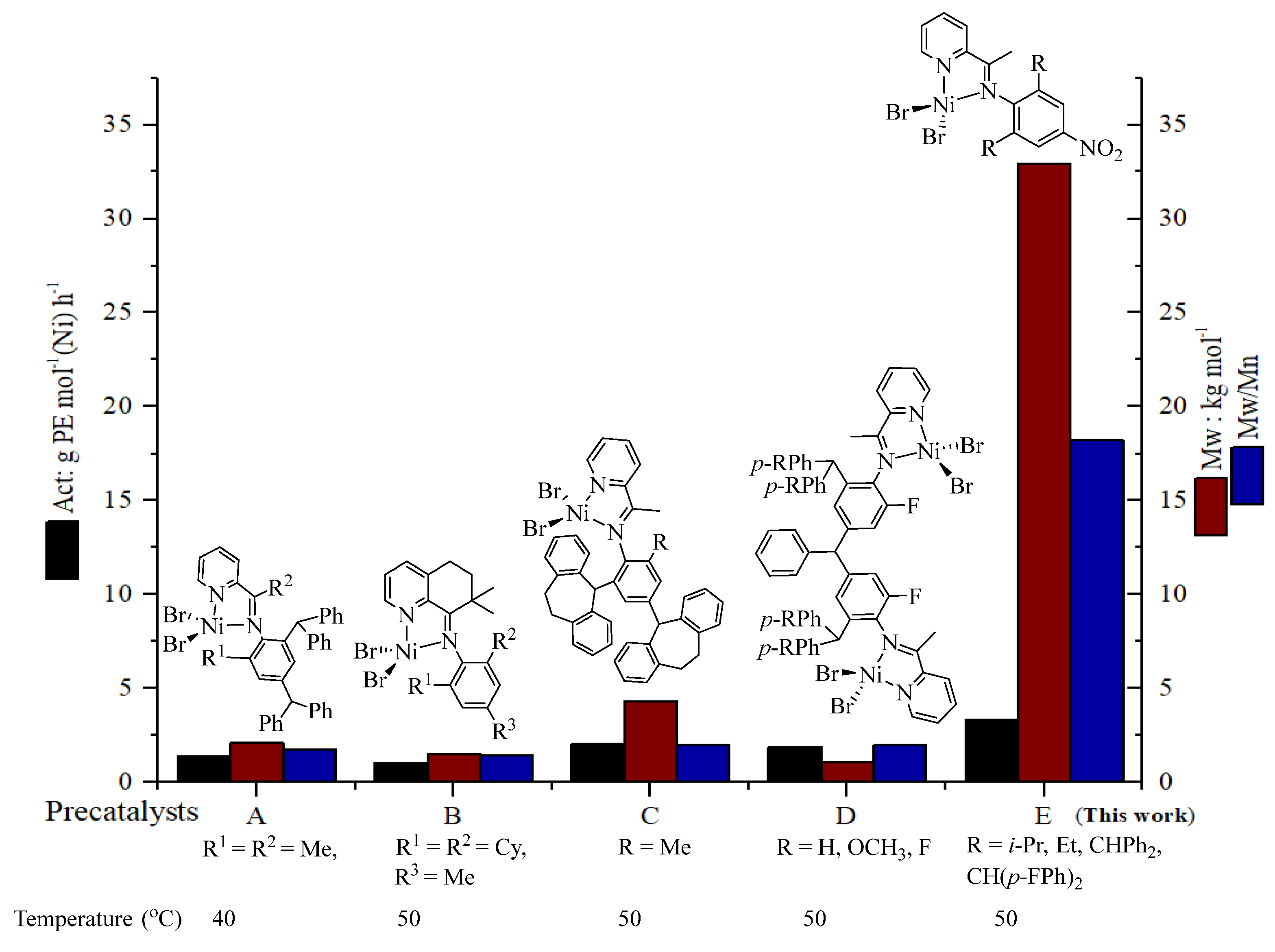

2.2.5. Comparison between Current and Reported Analogues

3. Experimental Section

3.1. General Consideration

3.2. Experimental Procedure for the Synthesis of L1–L5

3.2.1. 2-{(2,6-i-Pr2-4-NO2C6H2)N=CMe}C5H4N (L1)

3.2.2. 2-{(2,6-Et2-4-NO2C6H2)N=CMe}C5H4N (L2)

3.2.3. 2-{(2,6-((C6H5)2CH)2-4-NO2C6H2)N=CMe}C5H4N (L3)

3.2.4. 2-{(2,6-((4-F-C6H4)2CH)2-4-NO2C6H2)N=CMe}C5H4N (L4)

3.2.5. 2-{(2,6-i-Pr2-3-NO2-4-(4-F-C6H4)C6H)=CMe}C5H4N (L5)

3.3. Experimental Procedure for the Synthesis of Ni1–Ni5

3.3.1. [2-{(2,6-i-Pr2-4-NO2C6H2)N=CMe}C5H4N]NiBr2 (Ni1)

3.3.2. [2-{(2,6-Et2-4-NO2C6H2)N=CMe}C5H4N]NiBr2 (Ni2)

3.3.3. [2-{(2,6-((C6H5)2CH)2-4-NO2C6H2)N=CMe}C5H4N]NiBr2 (Ni3)

3.3.4. [2-{(2,6-((4-F-C6H4)2CH)2-4-NO2C6H2)N=CMe}C5H4N]NiBr2 (Ni4)

3.3.5. [2-{(2,6-i-Pr2-3-NO2-4-(4-F-C6H4)2C6H)N=CMe}C5H4N]NiBr2 (Ni5)

3.4. Ethylene Polymerization Evaluation

3.4.1. At PC2H4 = 1 atm

3.4.2. At PC2H4 = 5 or 10 atm

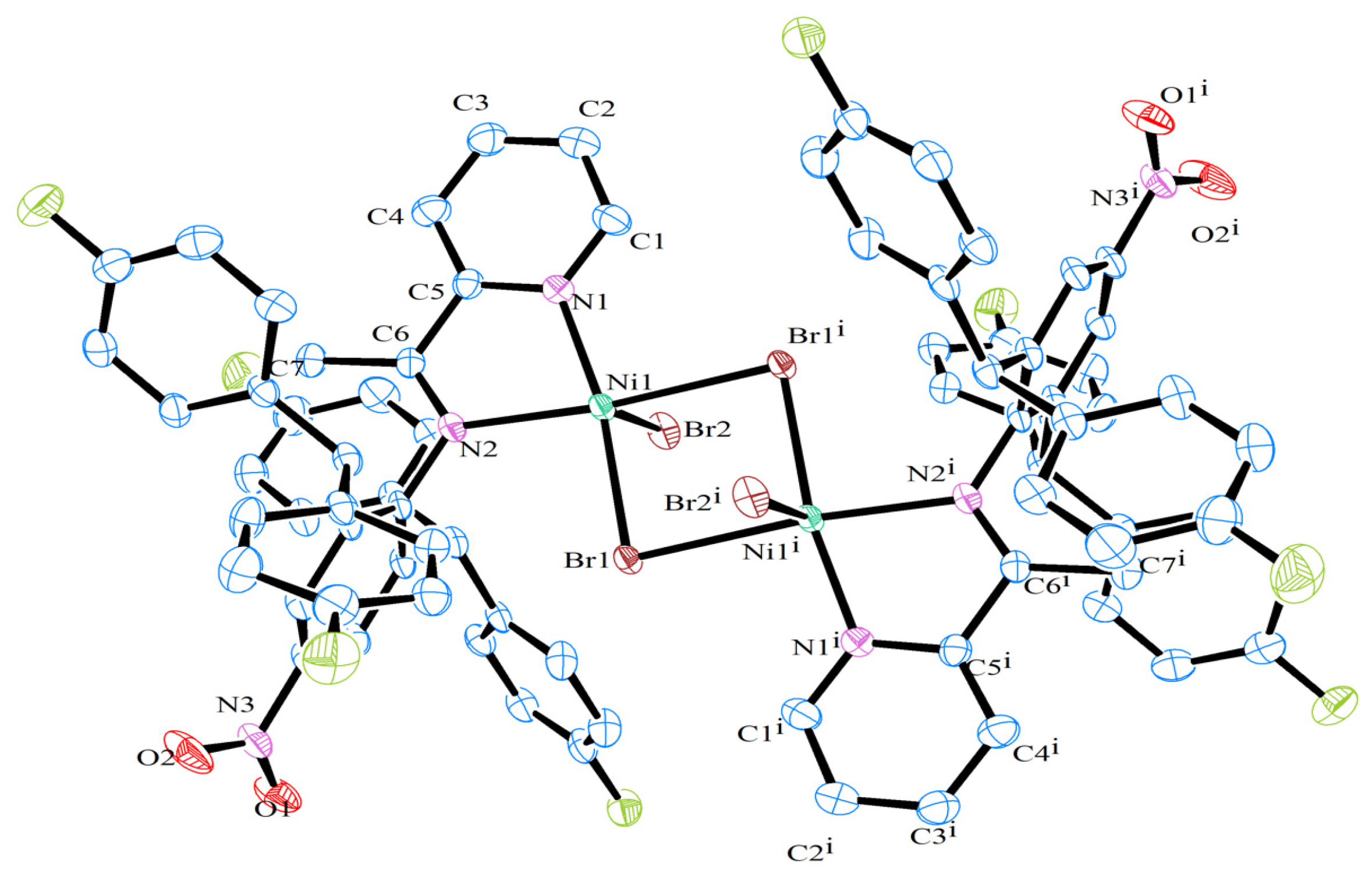

3.5. X-ray Crystallographic Studies

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Johnson, L.K.; Killian, C.M.; Brookhart, M. New Pd(II)- and Ni(II)-Based Catalysts for Polymerization of Ethylene and α-Olefins. J. Am. Chem. Soc. 1995, 117, 6414–6415. [Google Scholar] [CrossRef]

- Gates, D.P.; Svejda, S.A.; Oñate, E.; Killian, C.M.; Johnson, L.K.; White, P.S.; Brookhart, M. Synthesis of Branched Polyethylene Using (α-Diimine) nickel(II) Catalysts: Influence of Temperature, Ethylene Pressure, and Ligand Structure on Polymer Properties. Macromolecules 2000, 33, 2320–2334. [Google Scholar] [CrossRef]

- Killian, C.M.; Johnson, L.K.; Brookhart, M. Preparation of Linear α-Olefins Using Cationic Nickel(II) α-Diimine Catalysts. Organometallics 1997, 16, 2005–2007. [Google Scholar] [CrossRef]

- Mahmood, Q.; Sun, W.-H. N,N-chelated nickel catalysts for highly branched polyolefin elastomers: A survey. Soc. Open Sci. 2018, 5, 180367. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Ma, Y.; Hu, X.; Solan, G.A.; Sun, Y.; Sun, W.-H. Molecular Weight Control of Polyethylene Waxes using a Constrained Imino Cyclopenta[b]pyridyl-Nickel Catalyst. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 3494–3505. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, F.; Qu, M.; Yue, E.; Oleynik, I.V.; Oleynik, I.I.; Zeng, Y.; Liang, T.; Li, K.; Zhang, W.; et al. Targeting polyethylene waxes: 9-(2-Cycloalkylphenylimino)-5,6,7,8-tetrahydrocycloheptapyridylnickel halides and their ethylene polymerization. RSC Adv. 2015, 5, 77913–77921. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, W.; Mahmood, Q.; Zhang, R.; Sun, Y.; Sun, W.-H. Vinyl/Vinylene functionalized highly branched polyethylene waxes obtained using electronically controlled cyclohexyl-fused pyridinylimine-nickel precatalysts. Polym. Chem. 2018, 56, 1269–1281. [Google Scholar] [CrossRef]

- Guo, L.; Zhu, D.; Zhang, W.; Zada, M.; Solan, G.A.; Hao, X.; Sun, W.-H. Remote dibenzocycloheptyl-substitution of an iminotrihydroquinoline-nickel catalyst as a route to narrowly dispersed branched polyethylene waxes with alkene functionality. Eur. Polym. J. 2018, 107, 315–328. [Google Scholar] [CrossRef]

- Wang, S.; Sun, W.-H.; Redshaw, C. Recent progress on nickel-based systems for ethylene oligo-/polymerization catalysis. J. Organomet. Chem. 2014, 751, 717–741. [Google Scholar] [CrossRef]

- Makaryan, I.; Sedov, I. State of the Global Market of Bimodal Polyethylenes and the Basic Technologies for Their Production. Russ. J. Gen. Chem. 2021, 91, 571–581. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, Q.; Solan, G.A.; Sun, W.-H. Recent advances in Ni-mediated ethylene chain growth: Nimine-donor ligand effects on catalytic activity, thermal stability and oligo-/polymer structure. Coord. Chem. Rev. 2017, 350, 68–83. [Google Scholar] [CrossRef]

- Brown, L.A.; Anderson, W.C.; Mitchell, N.E., Jr.; Gmernicki, K.R.; Long, B.K. High Temperature, Living polymerization of ethylene by a sterically-demanding nickel (II) α-diimine catalyst. Polymers 2018, 10, 41. [Google Scholar] [CrossRef]

- Hu, X.; Kang, X.; Jian, Z. Suppression of Chain Transfer at High Temperature in Catalytic Olefin Polymerization. Angew. Chem. Int. Ed. 2022, 61, e202207363. [Google Scholar] [CrossRef]

- Liang, T.; Goudari, S.B.; Chen, C. A simple and versatile nickel platform for the generation of branched high molecular weight polyolefins. Nat. Commun. 2020, 11, 372. [Google Scholar] [CrossRef]

- Wang, S.; Du, S.; Zhang, W.; Asuha, S.; Sun, W.-H. Nickel(II) Complexes Bearing 4-Arylimino-1,2,3-trihydroacridines: Synthesis, Characterization, and Ethylene Oligomerization. ChemistryOpen 2015, 4, 328–334. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, W.; Du, S.; Asuha, S.; Flisak, Z.; Sun, W.-H. Propyl substituted 4-arylimino-1,2,3-trihydroacridylnickel complexes: Their synthesis, characterization and catalytic behavior toward ethylene. J. Organomet. Chem. 2015, 798, 408–413. [Google Scholar] [CrossRef]

- Huang, F.; Sun, Z.; Du, S.; Yue, E.; Ba, J.; Hu, X.; Liang, T.; Galland, G.B.; Sun, W.-H. Ring-tension adjusted ethylene polymerization by aryliminocycloheptapyridyl nickel complexes. Dalton Trans. 2015, 44, 14281–14292. [Google Scholar] [CrossRef]

- Antonov, A.A.; Semikolenova, N.V.; Talsi, E.P.; Matsko, M.A.; Zakharov, V.A.; Bryliakov, K.P. 2-Iminopyridine nickel(II) complexes bearing electron-withdrawing groups in the ligand core: Synthesis, characterization, ethylene oligo- and polymerization behavior. J. Organomet. Chem. 2016, 822, 241–249. [Google Scholar] [CrossRef]

- Kumar, K.; Godeto, T.; Darkwa, J. Tandem ethylene dimerization and Friedel-Crafts alkylation of toluene catalyzed by homo- and heterogeneous nickel(II) and palladium(II) pre-catalysts. J. Organomet. Chem. 2016, 818, 137–144. [Google Scholar] [CrossRef]

- Obuah, C.; Jordaan, J.H.L.; Darkwa, J. (Ferrocenylpyrazolyl)nicke(II)-catalysed ethylene oligomerization. Catal. Sci. Technol. 2016, 6, 4814–4823. [Google Scholar] [CrossRef]

- Song, S.; Li, Y.; Redshaw, C.; Wang, F.; Sun, W.-H. 2-(1-Aryliminoethylidene)quinolylnickel(II) dibromides: Synthesis, characterization and ethylene dimerization capability. J. Organomet. Chem. 2011, 696, 3772–3778. [Google Scholar] [CrossRef]

- Huang, C.; Zeng, Y.; Flisak, Z.; Zhao, Z.; Liang, T.; Sun, W.-H. 2-Substituted 8-(2-benzhydrylarylimino)-5,6,7–trihydro-quinoline-N,N’ nickel dichlorides: Synthesis, characterization and catalytic behavior towards ethylene. J. Polym. Sci. Part A Polym. Chem. 2017, 55, 2071–2083. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, X.; Sun, W.-H.; Redshaw, C. Synthesis, Characterization, and Ethylene Polymerization Behavior of 8-(Nitroarylamino)-5,6,7-trihydroquinolylnickel Dichlorides: Influence of the Nitro Group and Impurities on Catalytic Activity. ACS Catal. 2011, 1, 1213–1220. [Google Scholar] [CrossRef]

- Yue, E.; Zeng, Y.; Zhang, W.; Huang, F.; Cao, X.-P.; Liang, T.; Sun, W.-H. Tailoring polyethylenes through constraining geometry of nickel complex: Synthesis, characterization and ethylene polymerization of 8-(2-benzhydrylnaphthylimino)- 5,6,7-trihydroquinolylnickel halides. Inorg. Chim. Acta. 2016, 442, 178–186. [Google Scholar] [CrossRef]

- Huang, C.; Zhang, Y.; Liang, T.; Zhao, Z.; Hu, X.; Sun, W.-H. Rigid geometry 8-arylimino-7,7-dimethyl-5,6-dihydroquinolyl nickel bromides: Single-site active species towards ethylene polymerization. New J. Chem. 2016, 40, 9329–9336. [Google Scholar] [CrossRef]

- Hou, X.; Liang, T.; Sun, W.-H.; Redshaw, C.; Chen, X. Tailoring Polymers Through Interplay of Ligands Within Precatalysts: 8-(Nitro/Benzhydryl-Arylimino)-7,7-Dimethyl-5,6-Dihydroquinolylnickel Halides in Ethylene Polymerization. J. Organomet. Chem. 2012, 708–709, 98–105. [Google Scholar] [CrossRef]

- Torabi, S.; Fazeli, N. A rapid quantitative method for determination of short chain branching content and branching distribution index in LLDPEs by DSC. Polym. Test. 2009, 28, 866–870. [Google Scholar] [CrossRef]

- Wang, B.; Daugulis, O.; Brookhart, M. Ethylene Polymerization with Ni(II) Diimine Complexes Generated from 8-Halo-1-naphthylamines: The Role of Equilibrating Syn/Anti Diastereomers in Determining Polymer Properties. Organometallics 2019, 38, 4658–4668. [Google Scholar] [CrossRef]

- Meinhard, D.; Wegner, M.; Kipiani, G.; Hearley, A.; Reuter, P.; Fischer, S.; Marti, O.; Rieger, B. New Nickel(II) Diimine Complexes and the Control of Polyethylene Microstructure by Catalyst Design. J. Am. Chem. Soc. 2007, 129, 9182–9191. [Google Scholar] [CrossRef]

- Yue, E.; Zhang, L.; Xing, Q.; Cao, X.-P.; Hao, X.; Redshaw, C.; Sun, W.-H. 2-(1-(2-Benzhydrylnaphthylimino)ethyl)-pyridylnickel halides: Synthesis, characterization, and ethylene polymerization behavior. Dalton Trans. 2014, 43, 423–431. [Google Scholar] [CrossRef] [Green Version]

- Gao, R.; Sun, W.-H.; Redshaw, C. Nickel complex pre-catalysts in ethylene polymerization: New approaches to elastomeric materials. Catal. Sci. Technol. 2013, 3, 1172–1179. [Google Scholar] [CrossRef]

- Sun, W.-H.; Song, S.; Li, B.; Redshaw, C.; Hao, X.; Li, Y.-S.; Wang, F. Ethylene polymerization by 2-iminopyridylnickel halide complexes: Synthesis, characterization and catalytic influence of the benzhydryl group. Dalton Trans. 2012, 41, 11999–12010. [Google Scholar] [CrossRef] [PubMed]

- Sun, Z.; Yue, E.; Qu, M.; Oleynik, I.V.; Oleynik, I.I.; Li, K.; Liang, T.; Zhang, W.; Sun, W.-H. 8-(2-Cycloalkylphenylimino)-5,6,7-trihydroquinolylnickel halides: Polymerizing ethylene to highly branched and lower molecular weight polyethylenes. Inorg. Chem. Front. 2015, 2, 223–227. [Google Scholar] [CrossRef]

- Zada, M.; Vignesh, A.; Guo, L.; Zhang, R.; Zhang, W.; Ma, Y.; Sun, Y.; Sun, W.-H. Sterically and Electronically Modified Aryliminopyridyl-Nickel Bromide Precatalysts for an Access to Branched Polyethylene with Vinyl/Vinylene End Groups. ACS Omega 2020, 5, 10610–10625. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, W.; Liu, T.; Ye, Z.; Liang, T.; Sun, W.-H. Fluorinated Sterically Bulky Mononuclear and Binuclear 2-Iminopyridylnickel Halides for Ethylene Polymerization: Effects of Ligand Frameworks and Remote Substituents. ACS Omega 2021, 6, 30157–30172. [Google Scholar] [CrossRef]

- Zai, S.; Liu, F.; Gao, H.; Li, C.; Zhou, G.; Cheng, S.; Guo, L.; Zhang, L.; Zhu, F.; Wu, Q. Longstanding living polymerization of ethylene: Substituent effect on bridging carbon of 2-pyridinemethanamine nickel catalysts. Chem. Commun. 2010, 46, 4321–4323. [Google Scholar] [CrossRef]

- Zhang, Y.; Kang, X.; Jian, Z. Visualizing group II intron dynamics between the first and second steps of splicing. Nat. Commun. 2022, 13, 2837. [Google Scholar]

- Chen, Y.; Du, S.; Huang, C.; Solan, G.A.; Hao, X.; Sun, W.-H. Catalytic oligomerization and polymerization of ethylene with complexes of iron triad metals: Influence of metal nature and new prospects. Polym. Chem. 2017, 55, 1971–1983. [Google Scholar] [CrossRef]

- Mahmood, Q.; Zeng, Y.; Wang, X.; Sun, Y.; Sun, W.H. Advancing polyethylene properties by incorporating—NO2 moiety in 1,2-bis(arylimino)acenaphthylylnickel precatalysts: Synthesis, characterization and ethylene polymerization. Dalton Trans. 2017, 46, 6934–6947. [Google Scholar] [CrossRef]

- Katla, V.; Yue, E.; Rajendran, N.M.; Liang, T.; Sun, W.-H. Synthesis, characterization and ethylene polymerization of 1-(2,6-dimethyl-4-fluorenylphenylimino)-2-aryliminoacenaphthyl nickel bromides. C. R. Chim. 2016, 19, 604–613. [Google Scholar] [CrossRef]

- Wang, K.; Shen, M.; Sun, W.-H. Synthesis, characterization and ethylene oligomerization of nickel complexes bearing N-(2-(1H-benzo[d]imidazol-2-yl)quinolin-8-yl)benzamide derivatives. Dalton Trans. 2009, 4085–4095. [Google Scholar] [CrossRef] [PubMed]

- Mahmood, Q.; Zeng, Y.; Yue, E.; Solan, G.A.; Liang, T.; Sun, W.-H. Ultra-high molecular weight elastomeric polyethylene using an electronically and sterically enhanced nickel catalyst. Polym. Chem. 2017, 8, 6416–6430. [Google Scholar] [CrossRef]

- Kulkarni, N.V.; Elkin, T.; Tumaniskii, B.; Botoshansky, M.; Shimon, L.J.; Eisen, M.S. Asymmetric Bis (formamidinate) Group 4 Complexes: Synthesis, Structure and Their Reactivity in the Polymerization of α-Olefins. Organometallics 2014, 33, 3119–3136. [Google Scholar] [CrossRef]

- Elkin, T.; Kulkarni, N.V.; Tumanskii, B.; Botoshansky, M.; Shimon, L.J.; Eisen, M.S. Synthesis and structure of Group 4 symmetric amidinate complexes and their reactivity in the polymerization of α-olefins. Organometallics 2013, 32, 6337–6352. [Google Scholar] [CrossRef]

- Liu, H.; Zhao, W.; Yu, J.; Yang, W.; Hao, X.; Redshaw, C.; Chen, L.; Sun, W.-H. Synthesis, characterization and ethylene polymerization behavior of nickel dihalide complexes bearing bulky unsymmetrical α-diimine ligands. Catal. Sci. Technol. 2012, 2, 415–422. [Google Scholar] [CrossRef]

- Zubkevich, S.V.; Tuskaev, V.A.; Gagieva, S.C.; Bulychev, B.M. Balancing High Thermal Stability with High Activity in Diaryliminoacenaphthene-Nickel(II) Catalysts for Ethylene Polymerization. Russ. Chem. Rev. 2022, 91, RCR5021. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, M.; Ma, Y.; Ye, Z.; Liang, T.; Sun, W.-H. Highly active and thermostable camphyl α-diimine–nickel (II) catalysts for ethylene polymerization: Effects of N-aryl substituting groups on catalytic properties and branching structures of polyethylene. Appl. Organomet. Chem. 2022, 36, e6606. [Google Scholar] [CrossRef]

- Matsko, M.A.; Semikolenova, N.V.; Zakharov, V.A.; Soshnikov, I.E.; Shundrina, I.K.; Sun, W.-H. Formation of branched polyethylenes by ethylene homopolymerization using LNiBr2 homo- and heterogeneous precatalysts: Interpretation of the polymer structures in comparison with commercial LLDPE. J. Appl. Polym. Sci. 2021, 138, 50436. [Google Scholar] [CrossRef]

- Wagner, M.H.; Kheirandish, S.; Yamaguchi, M. Quantitative analysis of melt elongational behavior of LLDPE/LDPE blends. Rheol. Acta 2004, 44, 198–218. [Google Scholar] [CrossRef]

- Delgadillo-Velázquez, O.; Hatzikiriakos, S.; Sentmanat, M. Thermo-rheological properties of LLDPE/LDPE blends. Rheol. Acta 2008, 47, 19–31. [Google Scholar] [CrossRef]

- Wu, R.; Wang, Y.; Zhang, R.; Guo, C.-Y.; Flisak, Z.; Sun, Y.; Sun, W.-H. Finely tuned nickel complexes as highly active catalysts affording branched polyethylene of high molecular weight: 1-(2,6-Dibenzhydryl-4-methoxyphenylimino)-2-(arylimino) acenaphthylenenickel halides. Polymer 2018, 153, 574–586. [Google Scholar] [CrossRef]

- Wang, X.; Fan, L.; Yuan, Y.; Du, S.; Sun, Y.; Solan, G.A.; Guo, C.-Y.; Sun, W.-H. Raising the N-aryl fluoride content in unsymmetrical diaryliminoacenaphthylenes as a route to highly active nickel(II) catalysts in ethylene polymerization. Dalton Trans. 2016, 45, 18313–18323. [Google Scholar] [CrossRef] [PubMed]

- Gao, M.; Du, S.; Ban, Q.; Xing, Q.; Sun, W.-H. Ethylene polymerization by 2,3-diiminobutylnickel bromide pre-catalysts bearing remote benzhydryl substituents. J. Organomet. Chem. 2015, 798, 401–407. [Google Scholar] [CrossRef]

- Jie, S.; Zhang, D.; Zhang, T.; Sun, W.-H.; Chen, J.; Ren, Q.; Liu, D.; Zheng, G.; Chen, W. Bridged bis-pyridinylimino dinickel(II) complexes: Syntheses, characterization, ethylene oligomerization and polymerization. J. Organomet. Chem. 2005, 690, 1739–1749. [Google Scholar] [CrossRef]

- Bahuleyan, B.K.; Lee, U.; Ha, C.-S.; Kim, I. Ethylene oligomerization/polymerization over a series of iminopyridyl Ni (II) bimetallic catalysts modulated electronically and sterically. Appl. Catal. Part A Chem. 2008, 351, 36–44. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Tomkovic, T.; Liu, G.; Doufas, A.A.; Hatzikiriakos, S.G. Melt fracture of linear low-density polyethylenes: Die geometry and molecular weight characteristics. Phys. Flu. 2018, 30, 053103. [Google Scholar] [CrossRef]

- Zhang, S.; Sun, W.-H.; Kuang, X.; Vystorop, I.; Yi, J. Unsymmetric bimetal (II) complexes: Synthesis, structures and catalytic behaviors toward ethylene. J. Organomet. Chem. 2007, 692, 5307–5316. [Google Scholar] [CrossRef]

- Busico, V.; Cipullo, R.; Friederichs, N.; Linssen, H.; Segre, A.; Van Axel Castelli, V.; van der Velden, G. 1H NMR Analysis of Chain Unsaturations in Ethene/1-Octene Copolymers Prepared with Metallocene Catalysts at High Temperature. Macromolecules 2005, 38, 6988–6996. [Google Scholar] [CrossRef]

- Grant, D.M.; Paul, E.G. Carbon-13 Magnetic Resonance. II. Chemical Shift Data for the Alkanes. J. Am. Chem. Soc. 1964, 86, 2984–2990. [Google Scholar] [CrossRef]

- Lindeman, L.P.; Adama, J.Q. Carbon-13 Nuclear Magnetic Resonance Spectrometry Chemical Shifts for the Paraffins through C9. Anal. Chem. 1971, 43, 1245–1252. [Google Scholar] [CrossRef]

- McCord, E.F.; McLain, S.J.; Nelson, L.T.; Ittel, S.D.; Tempel, D.; Killian, C.M.; Johnson, L.K.; Brookhart, M. 13C NMR Analysis of α-Olefin Enchainment in Poly(α-olefins) Produced with Nickel and Palladium α-Diimine Catalysts. Macromolecules 2007, 40, 410–420. [Google Scholar] [CrossRef]

- Liao, H.; Gao, J.; Zhong, L.; Gao, H.-Y.; Wu, Q. Regioselective Polymerizations of α-Olefins with an α-Diamine Nickel Catalyst. Chin. J. Polym. Sci. 2019, 37, 959–965. [Google Scholar]

- Budzelaar, P.H. Mechanisms of branch formation in metal-catalyzed ethene polymerization. Comput. Mol. Sci. 2012, 2, 221–241. [Google Scholar] [CrossRef]

- Subramanyam, U.; Rajamohanan, P.; Sivaram, S.A. A study of the structure of poly(hexene-1) prepared by nickel(α-diimine)/MAO catalyst using high resolution NMR spectroscopy. Polymer 2004, 45, 4063–4076. [Google Scholar] [CrossRef]

- Albeladi, A.; Soares, J.B.; Mehdiabadi, S. Comparing Long-Chain Branching Mechanisms for Ethylene Polymerization with Metallocenes and Other Single-Site Catalysts: What Simulated Microstructures Can Teach Us. Macromol. React. Eng. 2019, 13, 1800059. [Google Scholar] [CrossRef]

- Yu, J.; Hu, X.; Zeng, Y.; Zhang, L.; Ni, C.; Hao, X.; Sun, W.-H. Synthesis, characterization and ethylene oligomerization behaviour of N-(2-substituted-5,6,7-trihydroquinolin-8-ylidene)aryl-aminonickel dichlorides. New J. Chem. 2011, 35, 178–183. [Google Scholar] [CrossRef]

- Song, S.; Xiao, T.; Liang, T.; Wang, F.; Redshaw, C.; Sun, W.-H. Synthesis, characterization and ethylene oligomerization behaviour of 8-(1-aryliminoethylidene)quinaldinylnickel dihalides. Catal. Sci. Technol. 2011, 1, 69–75. [Google Scholar] [CrossRef]

- Gao, R.; Zhang, M.; Liang, T.; Wang, F.; Sun, W.-H. Nickel (II) Complexes Chelated by 2-Arylimino-6-benzoxazolylpyridine: Syntheses, Characterization, and Ethylene Oligomerization. Organometallics 2008, 27, 5641–5648. [Google Scholar] [CrossRef]

- Dolomanov, O.V.; Bourhis, L.J.; Gildea, R.J.; Howard, J.A.K.; Puschmann, H. OLEX2 A Complete Structure Solution, Refinement and Analysis Program. J. Appl. Cryst. 2009, 42, 339–341. [Google Scholar] [CrossRef]

- Sheldrick, G.M. SHELXT—Integrated space-group and crystal structure determination. Acta Cryst. 2015, A71, 3–8. [Google Scholar] [CrossRef]

- Sheldrick, G.M. Crystal structure refinement with SHELXL. Acta Cryst. 2015, C71, 3–8. [Google Scholar]

- Spek, A.L. Structure validation in chemical crystallography. Acta Cryst. 2009, D65, 148–155. [Google Scholar] [CrossRef] [PubMed]

- Van der Sluis, P.; Spek, A. BYPASS: An Effective Method for the Refinement of Crystal Structures Containing Disordered Solvent Regions. Acta Cryst. 1990, A46, 194–201. [Google Scholar] [CrossRef]

- Farrugia, L.J. ORTEP-3 for Windows—A version of ORTEP-III with a Graphical User Interface (GUI). J. Appl. Crystallogr. 1997, 30, 565. [Google Scholar] [CrossRef]

- Muller, T.E.; Hultzsch, K.C.; Yus, M.; Foubelo, F.; Tada, M. Hydroamination: Direct Addition of Amines to Alkenes and Alkynes. Chem. Rev. 2008, 108, 3795–3892. [Google Scholar] [CrossRef] [PubMed]

- Meiries, S.; Speck, K.; Cordes, D.B.; Slawin, A.M.; Nolan, S.P. [Pd(IPr*OMe)(acac)Cl]: Tuning the N-Heterocyclic Carbene in Catalytic C−N Bond Formation. Organometallics 2013, 32, 330–339. [Google Scholar] [CrossRef]

- Zhang, R.; Wang, Z.; Ma, Y.; Solan, G.A.; Sun, Y.; Sun, W.-H. Plastomeric-like polyethylenes achievable using thermally robust N,N′-nickel catalysts appended with electron withdrawing difluorobenzhydryl and nitro groups. Dalton Trans. 2019, 48, 1878–1891. [Google Scholar] [CrossRef]

- Galland, G.B.; de Souza, R.F.; Mauler, R.S.; Nunes, F.F. 13C NMR determination of the composition of linear low-density polyethylene obtained with [η3-methallyl-nickel-diimine] PF6 complex. Macromolecules 1999, 32, 1620–1625. [Google Scholar] [CrossRef]

| (L3)NiBr2(H2O)2 (Molecule A) | [(L3)NiBr(H2O)3]Br (Molecule B) | ||

|---|---|---|---|

| Bond lengths (Å) | |||

| Ni(1)–N(1) | 2.065(2) | Ni(2)–N(4) | 2.043(2) |

| Ni(1)–N(2) | 2.149(2) | Ni(2)–N(5) | 2.123(2) |

| Ni(1)-Br(1) | 2.5280(5) | Ni(2)-Br(3) | 2.5290(5) |

| Ni(1)–O(1) | 2.1298(19) | Ni(2)–O(5) | 2.1004(19) |

| Ni(1)–Br(2) | 2.5634(5) | Ni(2)–O(6) | 2.055(2) |

| Ni(1)–O(2) | 2.139(2) | Ni(2)–O(7) | 2.113(3) |

| N(2)–C(6) | 1.291(3) | N(5)–C(45) | 1.293(3) |

| N(1)–C(5) | 1.347(3) | N(4)–C(44) | 1.351(3) |

| N(3)–O(3) | 1.225(4) | N(6)–O(8) | 1.219(4) |

| N(3)–O(4) | 1.217(4) | N(6)–O(9) | 1.223(4) |

| Bond angles (°) | |||

| N(1)–Ni(1)–N(2) | 78.08(8) | N(4)–Ni(2)–N(5) | 78.95(8) |

| N(1)–Ni(1)–Br(1) | 171.24(6) | N(4)–Ni(2)–Br(3) | 170.45(6) |

| N(1)–Ni(1)–Br(2) | 92.21(6) | N(4)-Ni(2)–O(5) | 90.86(8) |

| N(1)–Ni(1)–O(1) | 92.30(8) | N(4)–Ni(1)–O(6) | 93.78(9) |

| N(1)–Ni(1)–O(2) | 86.37(9) | N(4)–Ni(1)–O(7) | 87.96(9) |

| N(2)–Ni(1)–Br(1) | 94.40(6) | N(5)–Ni(2)–Br(3) | 91.83(6) |

| N(2)–Ni(1)–Br(2) | 100.33(6) | N(5)–Ni(2)–O(6) | 172.00(8) |

| N(2)–Ni(1)–O(1) | 170.34(8) | N(5)–Ni(2)–O(7) | 96.92(8) |

| O(1)–Ni(1)–Br(1) | 95.11(6) | O(6)–Ni(2)–Br(3) | 95.57(8) |

| O(1)–Ni(1)–Br(2) | 80.81(6) | O(6)–Ni(2)–O(5) | 83.01(8) |

| O(1)–Ni(1)-O(2) | 84.72(8) | O(6)–Ni(2)–O(7) | 85.05(8) |

| O(2)–Ni(1)–Br(1) | 89.65(6) | O(7)–Ni(2)–Br(3) | 90.75(6) |

| O(2)–Ni(1)–Br(2) | 165.39(6) | O(7)–Ni(2)–O(5) | 168.90(8) |

| Br(1)–Ni(1)–Br(2) | 93.583(16) | Br(3)–Ni(2)–O(5) | 92.19(6) |

| O(3)–N(3)–O(4) | 123.9(3) | O(8)–N(6)–O(9) | 123.2(3) |

| C(6)–N(2)–C(8) | 118.4(2) | C(45)–N(5)–C(47) | 120.9(2) |

| Ni4 | Ni5 | |

|---|---|---|

| Bond lengths (Å) | ||

| Ni(1)–N(1) | 2.037(4) | 2.048(2) |

| Ni(1)–N(2) | 2.151(3) | 2.0518(17) |

| Br(1)–Ni(1) | 2.5100(8) | 2.4863(4) |

| Br(1)–Ni(1i) | 2.6049(7) | 2.5562(3) |

| Br(2)–Ni(1) | 2.5573(8) | 2.4167(4) |

| N(2)–C(8) | 1.442(5) | 1.445(2) |

| N(2)–C(6) | 1.283(3) | 1.287(3) |

| N(1)–C(5) | 1.353(6) | 1.344(3) |

| Bond angles (°) | ||

| Ni(1)–Br(1)–Ni(1i) | 87.52(3) | 94.984(14) |

| Br(1)–Ni(1)–Br(1i) | 92.48(3) | 85.017 (14) |

| Br(1)–Ni(1)–Br(2) | 94.08(3) | 138.298(17) |

| Br(2)–Ni(1)–Br(1i) | 85.35(2) | 95.917(2) |

| N(2)–Ni(1)–Br(1) | 92.88(10) | 116.3(5) |

| N(2)–Ni(1)–Br(1i) | 173.89(10) | 100.31(5) |

| N(2)–Ni(1)–Br(2) | 97.19(9) | 104.58(5) |

| N(1)–Ni(1)–Br(1) | 170.52(11) | 91.13 (6) |

| N(1)–Ni(1)–Br(1i) | 95.90(10) | 175.47 (6) |

| N(1)–Ni(1)–Br(2) | 91.01(11) | 88.55(6) |

| N(1)–Ni(1)–N(2) | 78.54(14) | 79.25 (7) |

| C(6)–N(2)–Ni(1) | 113.9(3) | 115.09(14) |

| C(8)–N(2)–Ni(1) | 125.9(3) | 124.87(13) |

| Run | Co-Cat. | Al:Ni | Activity b | Mwc | Mw/Mnc | Tm (°C) d |

|---|---|---|---|---|---|---|

| 1 | MAO | 2000 | 1.9 | 78.9 | 21.6 | 67.8, 121.4 |

| 2 | MMAO | 2000 | 2.1 | 7.2 | 3.4 | 93.4, 110.6 |

| 3 | EASC | 600 | 1.8 | 130.4 | 28.5 | 118.8 |

| 4 | Et2AlCl | 600 | 0.2 | 63.2 | 14.5 | 125.3 |

| 5 | EtAlCl2 | 600 | 3.8 | 61.5 | 12.9 | 125.9 |

| Run | Precat. | T (°C) | t (min) | Al:Ni | Activity b | Mwc | Mw/Mnc | Ri d | Rt e | Tm (°C) f |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Ni4 | 30 | 30 | 400 | 0.9 | 129.5 | 17.7 | 64.8 | 248.4 | 119.3 |

| 2 | Ni4 | 30 | 30 | 500 | 2.8 | 137.7 | 14.2 | 197.5 | 570.0 | 126.0 |

| 3 | Ni4 | 30 | 30 | 600 | 3.8 | 61.5 | 12.9 | 268.8 | 1576.1 | 125.9 |

| 4 | Ni4 | 30 | 30 | 700 | 3.2 | 61.0 | 7.6 | 228.2 | 796.0 | 123.3 |

| 5 | Ni4 | 30 | 30 | 800 | 3.1 | 57.1 | 8.3 | 218.9 | 895.0 | 122.4 |

| 6 | Ni4 | 20 | 30 | 600 | 3.1 | 63.3 | 9.9 | 223.9 | 982.2 | 121.0 |

| 7 | Ni4 | 40 | 30 | 600 | 3.5 | 45.1 | 16.8 | 252.4 | 2632.9 | 124.1 |

| 8 | Ni4 | 50 | 30 | 600 | 3.4 | 32.9 | 18.2 | 245.3 | 3822.2 | 123.7 |

| 9 | Ni4 | 60 | 30 | 600 | 3.0 | 30.9 | 20.5 | 213.2 | 3978.1 | 119.3 |

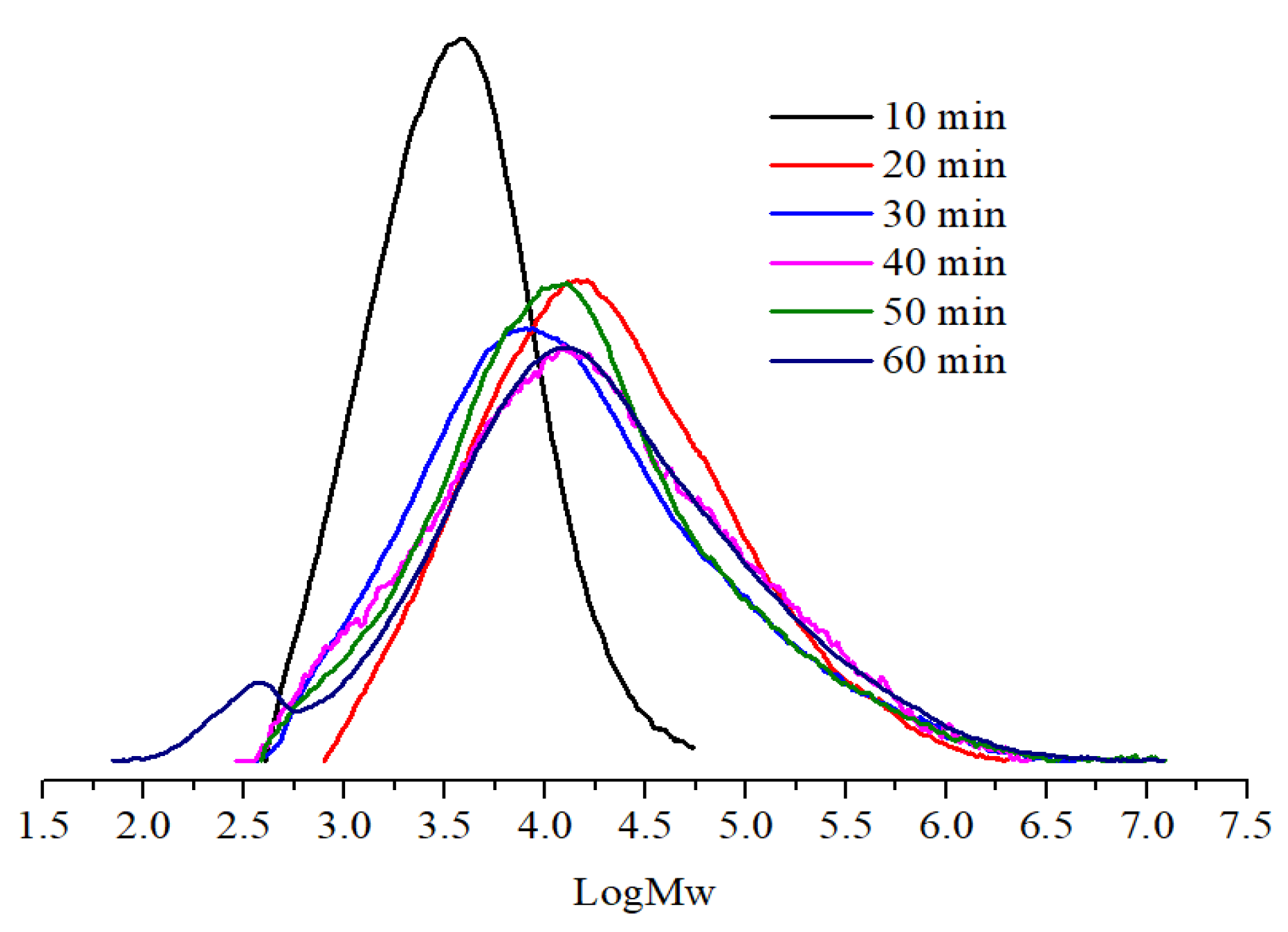

| 10 | Ni4 | 30 | 10 | 600 | 2.7 | 53.0 | 2.2 | 190.8 | 2247.2 | 124.5 |

| 11 | Ni4 | 30 | 20 | 600 | 2.9 | 56.3 | 6.5 | 205.6 | 671.3 | 121.9 |

| 12 | Ni4 | 30 | 40 | 600 | 3.7 | 67.3 | 13.3 | 259.1 | 1435.9 | 124.5 |

| 13 | Ni4 | 30 | 50 | 600 | 3.5 | 69.6 | 12.9 | 252.6 | 1316.5 | 124.8 |

| 14 | Ni4 | 30 | 60 | 600 | 3.1 | 81.6 | 24.4 | 223.9 | 1878.0 | 124.6 |

| 15 g | Ni4 | 30 | 30 | 600 | 2.1 | 32.2 | 5.6 | 149.0 | 727.0 | 124.0 |

| 16 h | Ni4 | 30 | 30 | 600 | - | - | - | - | - | - |

| 17 | Ni1 | 30 | 30 | 600 | 3.1 | 13.1 | 12.7 | 220.3 | 5965.2 | 118.6 |

| 18 | Ni2 | 30 | 30 | 600 | 4.7 | 22.5 | 7.9 | 337.2 | 3331.0 | 117.8 |

| 19 | Ni3 | 30 | 30 | 600 | 2.6 | 7.4 | 8.9 | 188.2 | 6346.2 | 123.2 |

| 20 | Ni5 | 30 | 30 | 600 | 4.6 | 23.3 | 22.2 | 329.4 | 8833.7 | 120.3 |

| Run | Precat. | T (°C) | t (min) | Al:Ni | Activity b | Mwc | Mw/Mnc | Ri d | Rt e | Tm (°C) f |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Ni4 | 30 | 30 | 1250 | 1.6 | 8.2 | 4.1 | 114.1 | 1600.0 | 84.8, 114.4 |

| 2 | Ni4 | 30 | 30 | 1500 | 2.0 | 10.1 | 4.5 | 143.3 | 1782.2 | 91.8, 113.3 |

| 3 | Ni4 | 30 | 30 | 1750 | 2.4 | 8.5 | 5.1 | 171.8 | 2880.0 | 84.8, 114.5 |

| 4 | Ni4 | 30 | 30 | 2000 | 2.1 | 7.2 | 3.4 | 152.6 | 1983.3 | 93.4, 110.6 |

| 5 | Ni4 | 30 | 30 | 2250 | 1.6 | 6.0 | 2.9 | 116.2 | 1559.1 | 86.9, 114.1 |

| 6 | Ni4 | 20 | 30 | 1750 | 1.2 | 21.6 | 8.9 | 88.4 | 1020.2 | 101.5, 114.0 |

| 7 | Ni4 | 40 | 30 | 1750 | 2.2 | 7.6 | 5.5 | 153.3 | 3185.2 | 76.4, 115.4 |

| 8 | Ni4 | 50 | 30 | 1750 | 0.9 | 3.9 | 4.2 | 61.3 | 1937.7 | 61.1, 119.8 |

| 9 | Ni4 | 30 | 10 | 1750 | 1.6 | 6.2 | 3.3 | 111.1 | 1722.6 | 82.3, 113.9 |

| 10 | Ni4 | 30 | 20 | 1750 | 1.7 | 6.5 | 3.4 | 119.9 | 1163.5 | 85.5, 113.1 |

| 11 | Ni4 | 30 | 40 | 1750 | 1.9 | 9.6 | 4.3 | 136.2 | 1702.1 | 93.9, 112.3 |

| 12 | Ni4 | 30 | 50 | 1750 | 1.8 | 10.3 | 5.5 | 140.9 | 1974.1 | 92.3, 111.8 |

| 13 | Ni4 | 30 | 60 | 1750 | 1.6 | 11.4 | 5.3 | 233.9 | 1487.7 | 95.1, 113.5 |

| 14 g | Ni4 | 30 | 30 | 1750 | 0.8 | 5.5 | 2.8 | 57.8 | 814.5 | 70.9, 121.4 |

| 15 h | Ni4 | 30 | 30 | 1750 | trace | - | - | - | - | - |

| 16 | Ni1 | 30 | 30 | 1750 | 0.7 | 7.0 | 5.0 | 50.6 | 1014.3 | 85.3, 117.0 |

| 17 | Ni2 | 30 | 30 | 1750 | 2.7 | 2.6 | 2.4 | 178.2 | 4984.6 | 82.9, 112.1 |

| 18 | Ni3 | 30 | 30 | 1750 | 1.5 | 10.0 | 3.7 | 108.4 | 1125.1 | 90.2, 105.7 |

| 19 | Ni5 | 30 | 30 | 1750 | 1.0 | 1.5 | 7.2 | 73.4 | 9903.8 | 69.0, 125.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sage, D.D.; Zhang, Q.; Liu, M.; Solan, G.A.; Sun, Y.; Sun, W.-H. LLDPE-like Polymers Accessible via Ethylene Homopolymerization Using Nitro-Appended 2-(Arylimino)pyridine-nickel Catalysts. Catalysts 2022, 12, 961. https://doi.org/10.3390/catal12090961

Sage DD, Zhang Q, Liu M, Solan GA, Sun Y, Sun W-H. LLDPE-like Polymers Accessible via Ethylene Homopolymerization Using Nitro-Appended 2-(Arylimino)pyridine-nickel Catalysts. Catalysts. 2022; 12(9):961. https://doi.org/10.3390/catal12090961

Chicago/Turabian StyleSage, Desalegn Demise, Qiuyue Zhang, Ming Liu, Gregory A. Solan, Yang Sun, and Wen-Hua Sun. 2022. "LLDPE-like Polymers Accessible via Ethylene Homopolymerization Using Nitro-Appended 2-(Arylimino)pyridine-nickel Catalysts" Catalysts 12, no. 9: 961. https://doi.org/10.3390/catal12090961

APA StyleSage, D. D., Zhang, Q., Liu, M., Solan, G. A., Sun, Y., & Sun, W.-H. (2022). LLDPE-like Polymers Accessible via Ethylene Homopolymerization Using Nitro-Appended 2-(Arylimino)pyridine-nickel Catalysts. Catalysts, 12(9), 961. https://doi.org/10.3390/catal12090961