Hollow CuFe2O4/MgFe2O4 Heterojunction Boost Photocatalytic Oxidation Activity for Organic Pollutants

Abstract

:1. Introduction

2. Results and Discussion

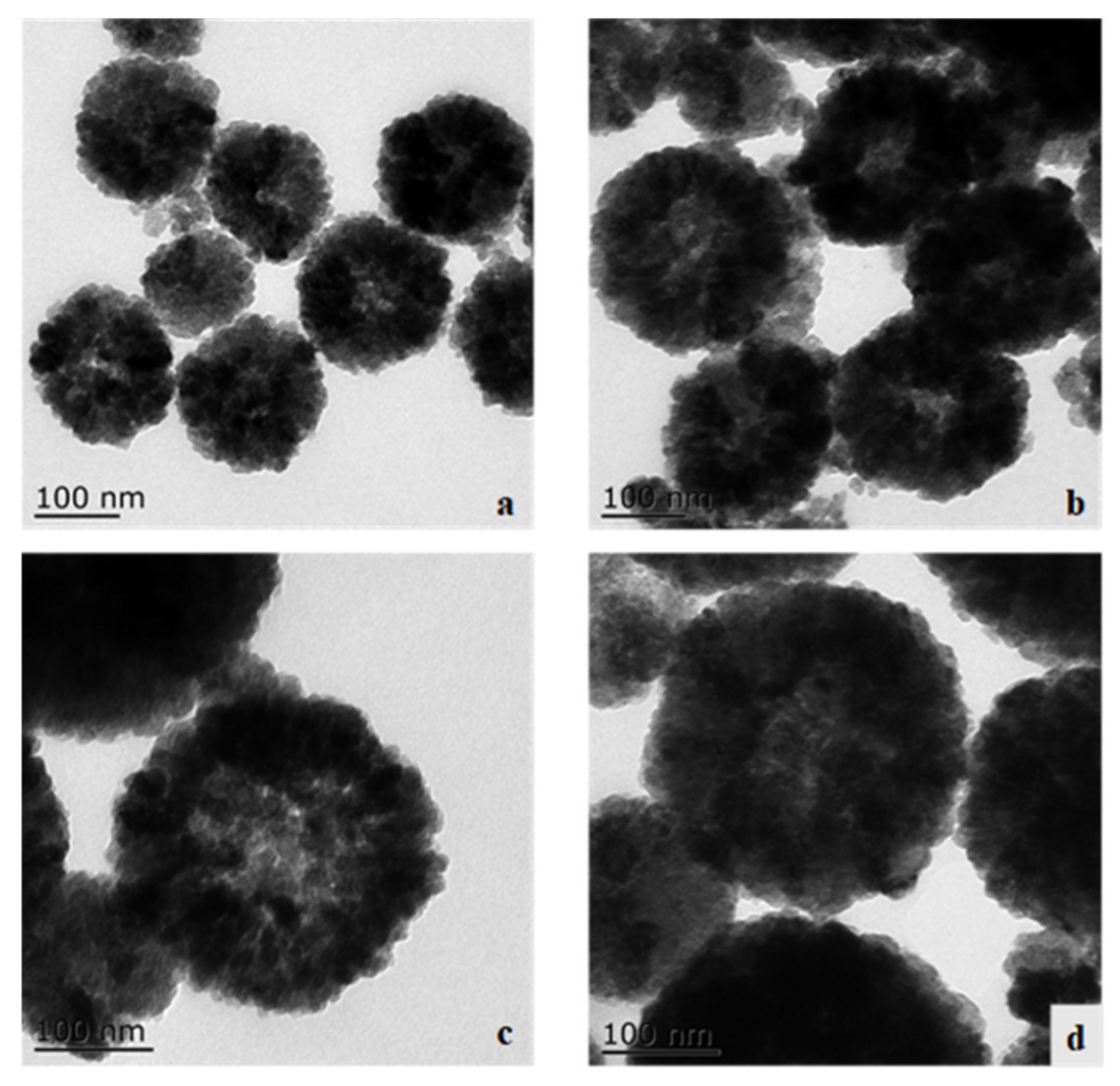

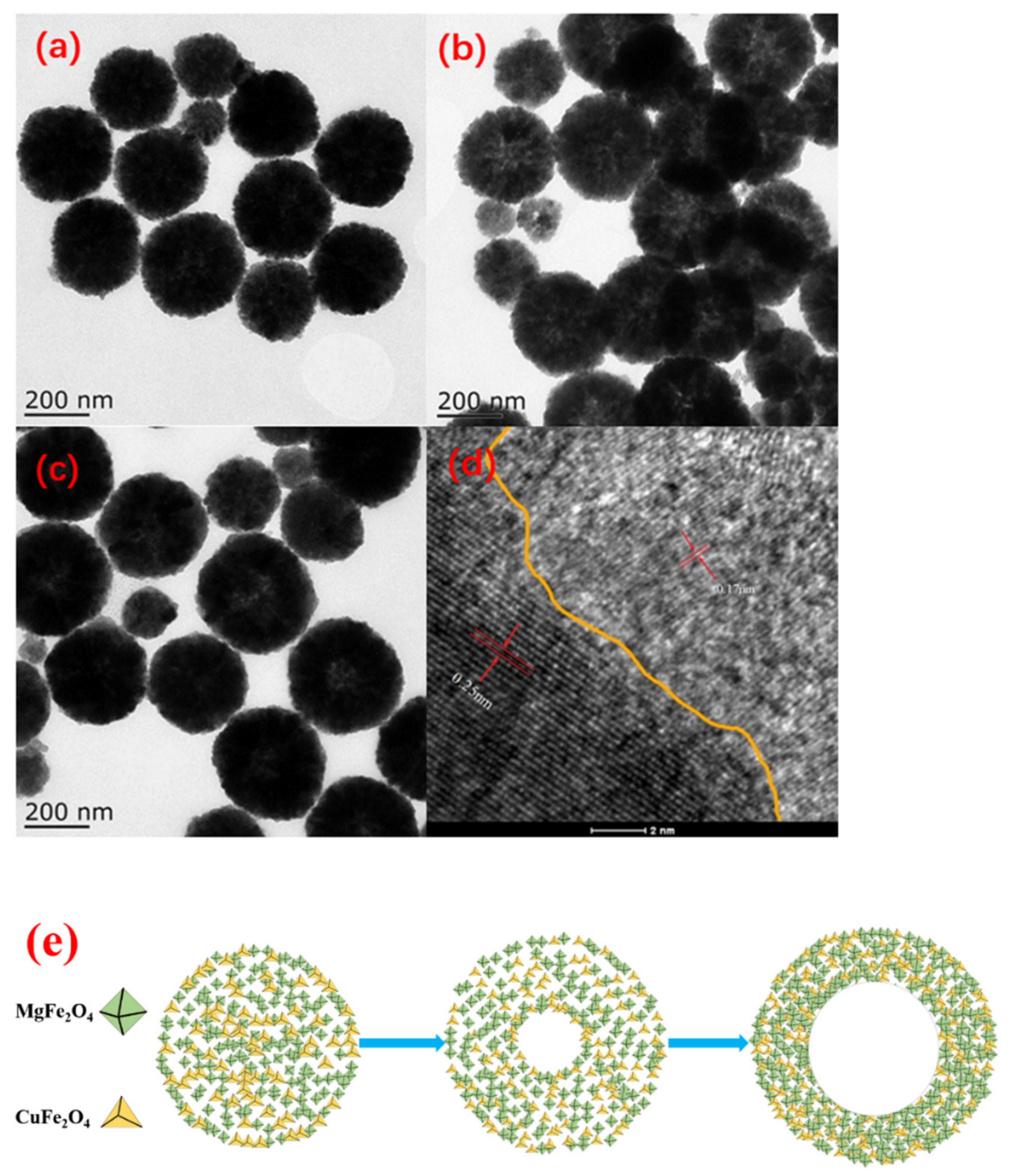

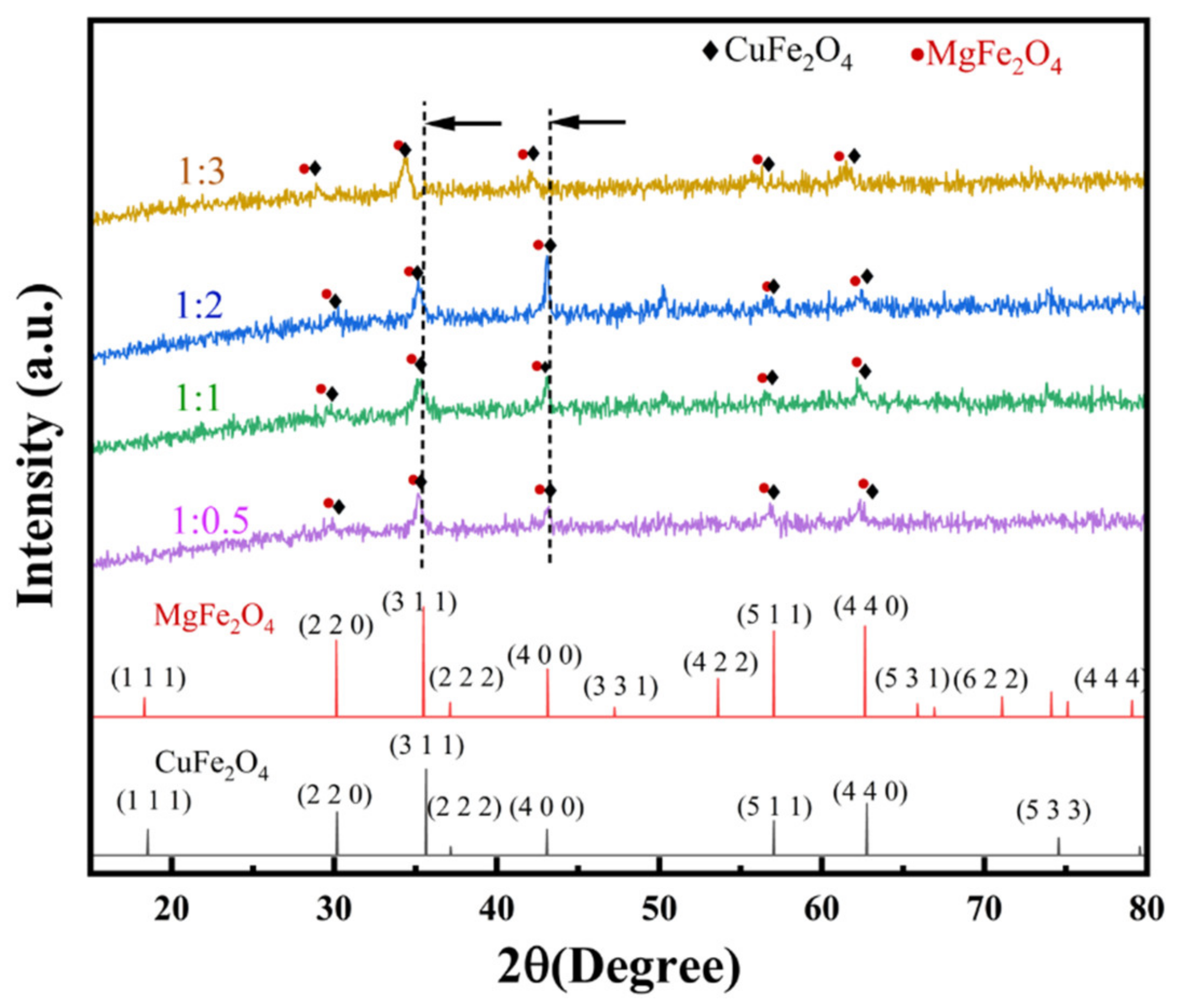

2.1. Fabrication of Hollow CuFe2O4/MgFe2O4 and Its Structure

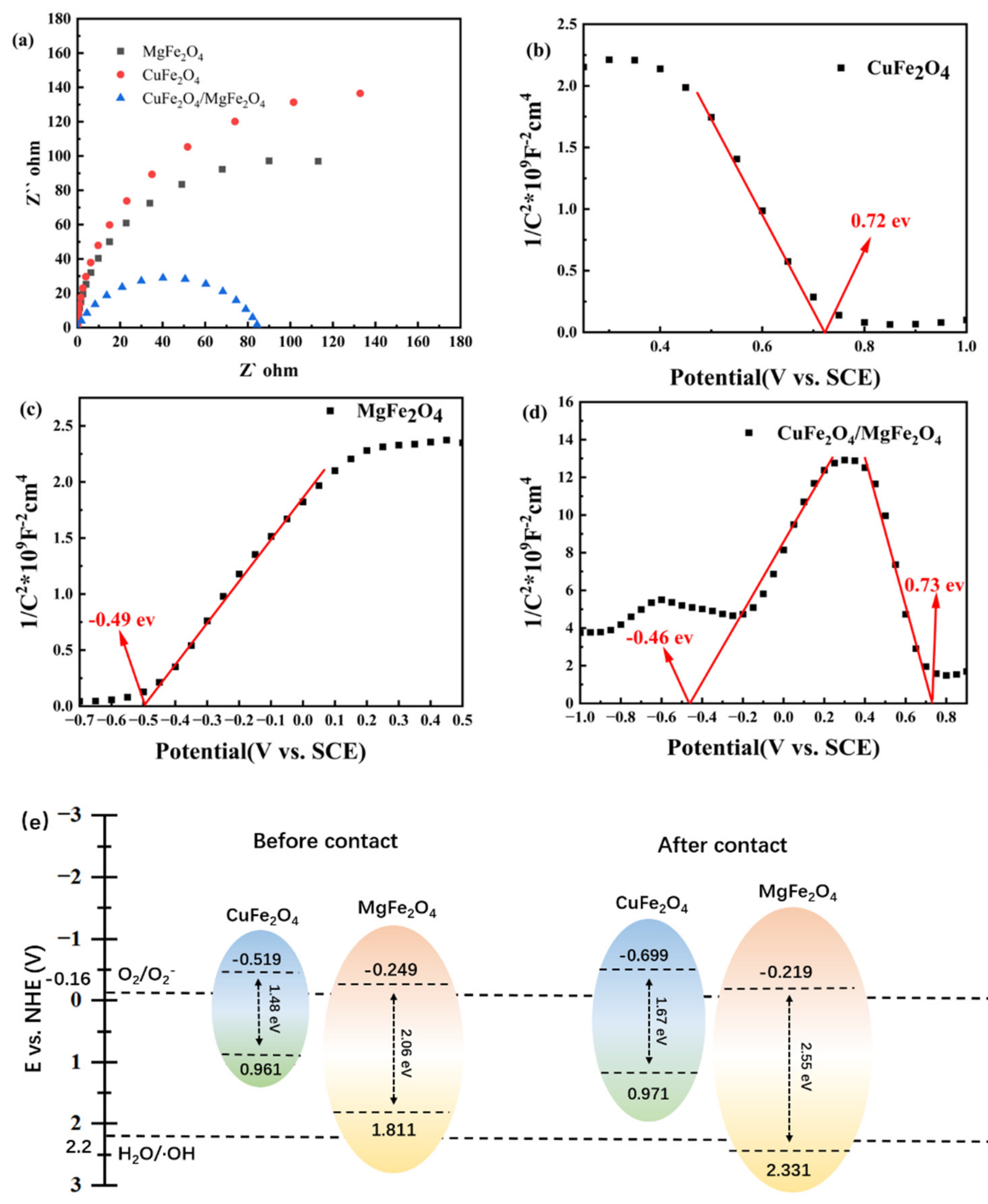

2.2. Optical Properties of the Hollow CuFe2O4/MgFe2O4

2.3. Photocatalytic Experiments of the CuFe2O4/MgFe2O4 Composites

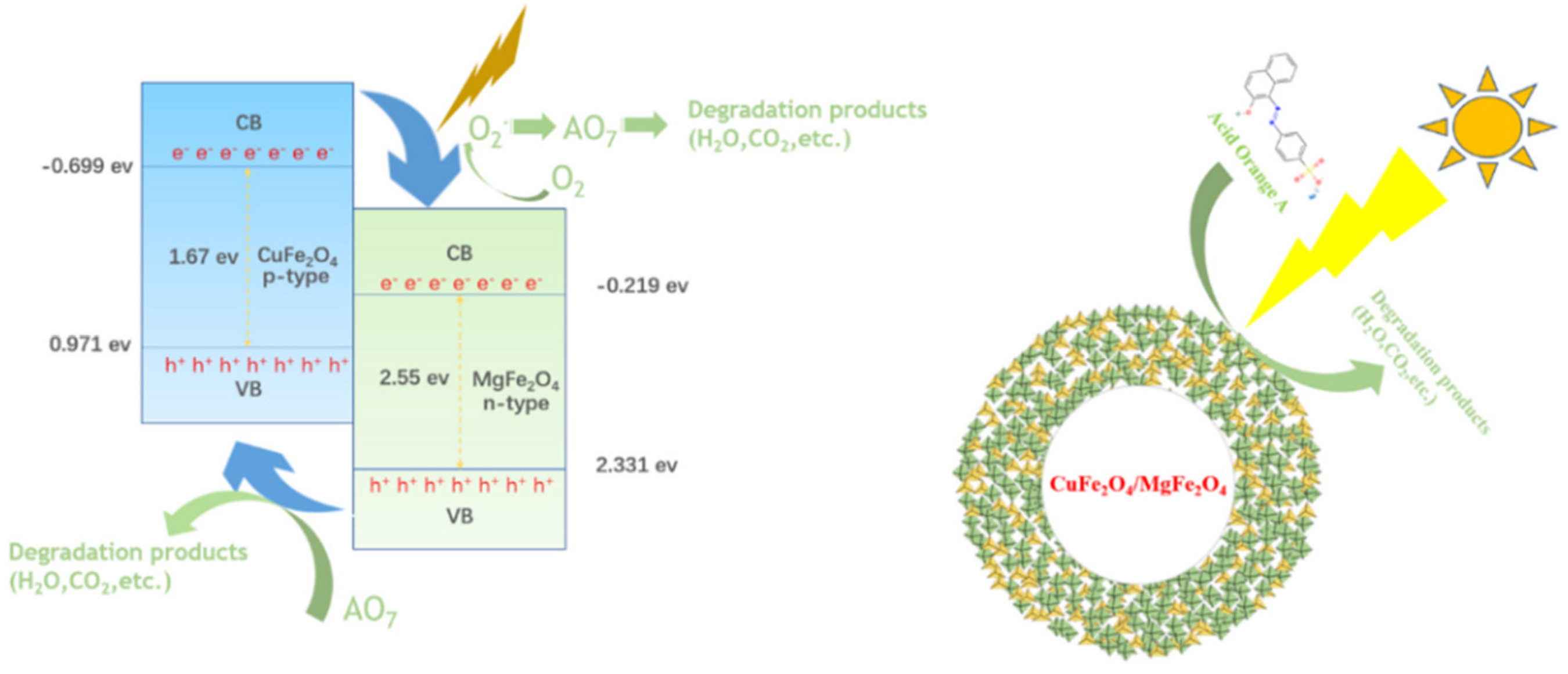

2.4. Mechanism of the Photocatalytic Reaction

3. Materials and Methods

3.1. Synthesis of CuFe2O4/MgFe2O4

3.2. Catalyst Characterizations

3.3. Photocatalytic Experiments

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lee, M.-Y.; Wang, W.-L.; Du, Y.; Wu, Q.-Y.; Huang, N.; Xu, Z.-B.; Hu, H.-Y. Comparison of UV/H2O2 and UV/PS processes for the treatment of reverse osmosis concentrate from municipal wastewater reclamation. Chem. Eng. J. 2020, 388, 79–88. [Google Scholar] [CrossRef]

- Fu, J.; Xu, Q.; Low, J.; Jiang, C.; Yu, J. Ultrathin 2D/2D WO3/g-C3N4 step-scheme H2-production photocatalyst. Appl. Catal. B-Environ. 2019, 243, 556–565. [Google Scholar] [CrossRef]

- Masuda, Y. Bio-inspired mineralization of nanostructured TiO2 on PET and FTO films with high surface area and high photocatalytic activity. Sci. Rep. 2020, 10, 13499–13504. [Google Scholar] [CrossRef] [PubMed]

- Takanabe, K. Photocatalytic Water Splitting: Quantitative approaches toward photocatalyst by design. ACS Catal. 2017, 7, 8006–8022. [Google Scholar] [CrossRef]

- Alshorifi, F.T.; Alswat, A.A.; Salama, R.S. Gold-selenide quantum dots supported onto cesium ferrite nanocomposites for the efficient degradation of rhodamine B. Heliyon 2022, 8, e09652. [Google Scholar] [CrossRef]

- Ma, Y.; Ma, M.; Yin, X.; Shao, Q.; Lu, N.; Feng, Y.; Lu, Y.; Wujcik, E.K.; Mai, X.; Wang, C.; et al. Tuning polyaniline nanostructures via end group substitutions and their morphology dependent electrochemical performances. Polymer 2018, 156, 128–135. [Google Scholar] [CrossRef]

- Zhang, G.; Zhang, X.; Meng, Y.; Pan, G.; Ni, Z.; Xia, S. Layered double hydroxides-based photocatalysts and visible-light driven photodegradation of organic pollutants: A review. Chem. Eng. J. 2020, 392, 123684–123690. [Google Scholar] [CrossRef]

- Tobbala, D.E.; Rashed, A.S.; Salama, R.S.; Ahmed, T.I. Performance enhancement of reinforced concrete exposed to electrochemical magnesium chloride using nano-ferrite zinc-rich epoxy. J. Build. Eng. 2022, 57, 104869–104873. [Google Scholar] [CrossRef]

- Umar, M.; Mahmood, N.; Awan, S.U.; Fatima, S.; Mahmood, A.; Rizwan, S. Rationally designed La and Se co-doped bismuth ferrites with controlled bandgap for visible light photocatalysis. RSC Adv. 2019, 9, 17148–17156. [Google Scholar] [CrossRef]

- An, J.; Zhu, L.; Wang, N.; Song, Z.; Yang, Z.; Du, D.; Tang, H. Photo-Fenton like degradation of tetrabromobisphenol A with grapheneBiFeO3 composite as a catalyst. Chem. Eng. J. 2013, 219, 225–237. [Google Scholar] [CrossRef]

- Li, Z.; Shen, Y.; Yang, C.; Lei, Y.; Guan, Y.; Lin, Y.; Liu, D.; Nan, C.-W. Significant enhancement in the visible light photocatalytic properties of BiFeO3–graphene nanohybrids. J. Mater. Chem. A 2013, 1, 823–829. [Google Scholar] [CrossRef]

- Kazachenko, A.S.; Vasilieva, N.Y.; Fetisova, O.Y.; Sychev, V.V.; Elsuf’ev, E.V.; Malyar, Y.N.; Issaoui, N.; Miroshnikova, A.V.; Borovkova, V.S.; Kazachenko, A.S.; et al. New reactions of betulin with sulfamic acid and ammonium sulfamate in the presence of solid catalysts. Biomass Convers. Biorefinery 2022, 23, 02587–02591. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, Y.; Ai, Q.; Gao, G.; Yuan, L.; Fang, Q.; Tian, X.; Zhang, X.; Egap, E.; Ajayan, P.M.; et al. In situ synthesis of lead-free halide perovskite–COF nanocomposites as photocatalysts for photoinduced polymerization in both organic and aqueous phases. ACS Mater. Lett. 2022, 4, 464–471. [Google Scholar] [CrossRef]

- Bajpai, O.P.; Mandal, S.; Ananthakrishnan, R.; Mandal, P.; Khastgir, D.; Chattopadhyay, S. Structural features, magnetic properties and photocatalytic activity of bismuth ferrite nanoparticles grafted on graphene nanosheets. New J. Chem. 2018, 42, 10712–10723. [Google Scholar] [CrossRef]

- Yin, X.L.; Liu, J.; Jiang, W.J.; Zhang, X.; Hu, J.S.; Wan, L.J. Urchin-like Au@CdS/WO3 micro/nano heterostructure as a visible-light driven photocatalyst for efficient hydrogen generation. Chem. Commun. 2015, 51, 13842–13845. [Google Scholar] [CrossRef]

- Chakraborty, I.; Rakshit, R.; Mandal, K. Synthesis and functionalization of MnFe2O4 nano–hollow spheres for novel optical and catalytic properties. Surf. Interfaces 2017, 7, 106–112. [Google Scholar] [CrossRef]

- Cheng, C.; Zhang, H.; Ren, W.; Dong, W.; Sun, Y. Three dimensional urchin-like ordered hollow TiO2/ZnO nanorods structure as efficient photoelectrochemical anode. Nano Energy 2013, 2, 779–786. [Google Scholar] [CrossRef]

- Cui, X.; Jiang, G.; Zhu, M.; Zhao, Z.; Du, L.; Weng, Y.; Xu, C.; Zhang, D.; Zhang, Q.; Wei, Y.; et al. TiO2/CdS composite hollow spheres with controlled synthesis of platinum on the internal wall for the efficient hydrogen evolution. Int. J. Hydrogen Energy 2013, 38, 9065–9073. [Google Scholar] [CrossRef]

- Amuthan, T.; Sanjeevi, R.; Kannan, G.R.; Sridevi, A. A novel p-CuFe2O4/n-ZnS heterojunction photocatalyst: Co-precipitation synthesis, characterization and improved visible-light driven photocatalytic activity for removal of MB and CV dyes. Phys. B Condens. Matter 2022, 638, 413842–413848. [Google Scholar] [CrossRef]

- Mousavi, M.; Habibi, M.M.; Zhang, G.; Pourhakkak, P.; Moradian, S.; Ghasemi, J.B. In-situ construction of ZnO/Sb2MoO6 nano-heterostructure for efficient visible-light photocatalytic conversion of N2 to NH3. Surf. Interfaces 2022, 30, 101844. [Google Scholar] [CrossRef]

- Wang, Z.; Lin, Z.; Shen, S.; Zhong, W.; Cao, S. Advances in designing heterojunction photocatalytic materials. Chin. J. Catal. 2021, 42, 710–730. [Google Scholar] [CrossRef]

- Jang, J.S.; Kim, H.G.; Lee, J.S. Heterojunction semiconductors: A strategy to develop efficient photocatalytic materials for visible light water splitting. Catal. Today 2012, 185, 270–277. [Google Scholar] [CrossRef]

- Yan, Y.; Zeng, Z.; Huang, M.; Chen, P. Van der waals heterojunctions for catalysis. Mater. Today Adv. 2020, 6, 100059–100063. [Google Scholar] [CrossRef]

- Arimi, A.; Megatif, L.; Granone, L.I.; Dillert, R.; Bahnemann, D.W. Visible-light photocatalytic activity of zinc ferrites. J. Photochem. Photobiol. A-Chem. 2018, 366, 118–126. [Google Scholar] [CrossRef]

- Lenin, N.; Kanna, R.R.; Sakthipandi, K.; Kumar, A.S. Structural, electrical and magnetic properties of NiLaxFe2-xO4 nanoferrites. Mater. Chem. Phys. 2018, 212, 385–393. [Google Scholar] [CrossRef]

- Alshorifi, F.T.; Ali, S.L.; Salama, R.S. Promotional synergistic effect of Cs–Au NPs on the performance of Cs–Au/MgFe2O4 catalysts in catalysis 3,4-Dihydropyrimidin-2(1H)-Ones and degradation of RhB Dye. J. Inorg. Organomet. Polym. Mater. 2022, 8, 02389–02401. [Google Scholar] [CrossRef]

- Kumar, G.M.; Cho, H.D.; Lee, D.J.; Kumar, J.R.; Siva, C.; Ilanchezhiyan, P.; Kim, D.Y.; Kang, T.W. Elevating the charge separation of MgFe2O4 nanostructures by Zn ions for enhanced photocatalytic and photoelectrochemical water splitting. Chemosphere 2021, 283, 131134–131145. [Google Scholar] [CrossRef]

- Kim, H.G.; Borse, P.H.; Jang, J.S.; Jeong, E.D.; Jung, O.-S.; Suh, Y.J.; Lee, J.S. Fabrication of CaFe2O4/MgFe2O4 bulk heterojunction for enhanced visible light photocatalysis. Chem. Commun. 2009, 279, 5889–5891. [Google Scholar] [CrossRef]

- Fan, W.; Li, M.; Bai, H.; Xu, D.; Chen, C.; Li, C.; Ge, Y.; Shi, W. Fabrication of MgFe2O4/MoS2 heterostructure nanowires for photoelectrochemical catalysis. Langmuir 2016, 32, 1629–1636. [Google Scholar] [CrossRef]

- Liu, X.; An, S.; Shi, W.; Yang, Q.; Zhang, L. Microwave-induced catalytic oxidation of malachite green under magnetic Cu-ferrites: New insight into the degradation mechanism and pathway. J. Mol. Catal. A Chem. 2014, 395, 243–250. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, H.; Li, M.; Fan, J.; Zhao, G. Magnetic ordered mesoporous copper ferrite as a heterogeneous Fenton catalyst for the degradation of imidacloprid. Appl. Catal. B-Environ. 2014, 147, 534–545. [Google Scholar] [CrossRef]

- Shen, Y.; Wu, Y.; Xu, H.; Fu, J.; Li, X.; Zhao, Q.; Hou, Y. Facile preparation of sphere-like copper ferrite nanostructures and their enhanced visible-light-induced photocatalytic conversion of benzene. Mater. Res. Bull. 2013, 48, 4216–4222. [Google Scholar] [CrossRef]

- Sharma, R.; Kumar, V.; Bansal, S.; Singhal, S. Assortment of magnetic nanospinels for activation of distinct inorganic oxidants in photo-Fenton’s process. J. Mol. Catal. A-Chem. 2015, 402, 53–63. [Google Scholar] [CrossRef]

- Ilhan, S.; Izotova, S.G.; Komlev, A.A. Synthesis and characterization of MgFe2O4 nanoparticles prepared by hydrothermal decomposition of co-precipitated magnesium and iron hydroxides. Ceram. Int. 2015, 41, 577–585. [Google Scholar] [CrossRef]

- Derbal, A.; Omeiri, S.; Bouguelia, A.; Trari, M. Characterization of new heterosystem CuFeO2/SnO2 application to visible-light induced hydrogen evolution. Int. J. Hydrogen Energy 2008, 33, 4274–4282. [Google Scholar] [CrossRef]

- Fedailaine, M.; Bellal, B.; Berkani, S.; Trari, M.; Abdi, A. Photo-electrochemical characterization of the spinel CuFe2O4: Application to Ni2+ removal under solar light. Environ. Process. 2016, 3, 387–396. [Google Scholar] [CrossRef]

- Dom, R.; Subasri, R.; Radha, K.; Borse, P.H. Synthesis of solar active nanocrystalline ferrite, MFe2O4 (M: Ca, Zn, Mg) photocatalyst by microwave irradiation. Solid State Commun. 2011, 151, 470–473. [Google Scholar] [CrossRef]

- Feizpoor, S.; Habibi-Yangjeh, A.; Vadivel, S. Novel TiO2/Ag2CrO4 nanocomposites: Efficient visible-light-driven photocatalysts with n-n heterojunctions. J. Photochem. Photobiol. A-Chem. 2017, 341, 57–68. [Google Scholar] [CrossRef]

- Gu, X.; Li, C.; Yuan, S.; Ma, M.; Qiang, Y.; Zhu, J. ZnO based heterojunctions and their application in environmental photocatalysis. Nanotechnology 2016, 27, 402001–402013. [Google Scholar] [CrossRef]

- Yan, Y.; Guan, H.; Liu, S.; Jiang, R. Ag3PO4/Fe2O3 composite photocatalysts with an n-n heterojunction semiconductor structure under visible-light irradiation. Ceram. Int. 2014, 40, 9095–9100. [Google Scholar] [CrossRef]

- Zou, X.; Dong, Y.; Zhang, X.; Cui, Y.; Ou, X.; Qi, X. The highly enhanced visible light photocatalytic degradation of gaseous odichlorobenzene through fabricating like-flowers BiPO4/BiOBr p-n heterojunction composites. Appl. Surf. Sci. 2017, 391, 525–534. [Google Scholar] [CrossRef]

- Wang, X.; Feng, J.; Bai, Y.; Zhang, Q.; Yin, Y. Synthesis, Properties, and Applications of Hollow Micro-/Nanostructures. Chem. Rev. 2016, 116, 10983–11060. [Google Scholar] [CrossRef]

- Gabal, M.A.; Al-luhaibi, R.S.; Al Angari, Y.M. Mn-Zn nano-crystalline ferrites synthesized from spent Zn-C batteries using novel gelatin method. J. Hazard. Mater. 2013, 246, 227–233. [Google Scholar] [CrossRef]

- Sharma, R.; Bansal, S.; Singhal, S. Tailoring the photo-Fenton activity of spinel ferrites (MFe2O4) by incorporating different cations (M = Cu, Zn, Ni and Co) in the structure. RSC Adv. 2015, 5, 6006–6018. [Google Scholar] [CrossRef]

- Yin, Y.; Liu, W.; Huo, N.; Yang, S. High rate capability and long cycle stability of Fe2O3/MgFe2O4 anode material synthesized by gelcast processing. Chem. Eng. J. 2017, 307, 999–1007. [Google Scholar] [CrossRef]

- Zhang, L.; Ghimire, P.; Phuriragpitikhon, J.; Jiang, B.; Goncalves, A.A.S.; Jaroniec, M. Facile formation of metallic bismuth/bismuth oxide heterojunction on porous carbon with enhanced photocatalytic activity. J. Colloid Interface Sci. 2018, 513, 82–91. [Google Scholar] [CrossRef]

- Wen, X.-J.; Niu, C.-G.; Zhang, L.; Liang, C.; Zeng, G.-M. An in depth mechanism insight of the degradation of multiple refractory pollutants via a novel SrTiO3/BiOI heterojunction photocatalysts. J. Catal. 2017, 356, 283–299. [Google Scholar] [CrossRef]

- Huu, H.T.; Thi, M.D.N.; Nguyen, V.P.; Thi, L.N.; Phan, T.T.T.; Hoang, Q.D.; Luc, H.H.; Kim, S.J.; Vo, V. One-pot synthesis of S-scheme MoS2/g-C3N4 heterojunction as effective visible light photocatalyst. Sci. Rep. 2021, 11, 14787. [Google Scholar] [CrossRef]

- Wen, X.-J.; Niu, C.-G.; Zhang, L.; Liang, C.; Zeng, G.-M. A novel Ag2O/CeO2 heterojunction photocatalysts for photocatalytic degradation of enrofloxacin: Possible degradation pathways, mineralization activity and an in depth mechanism insight. Appl. Catal. B-Environ. 2018, 221, 701–714. [Google Scholar] [CrossRef]

- Barros, V.P.; Assis, M.D. Iron porphyrins as biomimetical models for disperse azo dye oxidation. J. Braz. Chem. Soc. 2013, 24, 830–836. [Google Scholar] [CrossRef]

- Wu, F.; Deng, N.S.; Hua, H.L. Degradation mechanism of azo dye C.I. reactive red 2 by iron powder reduction and photooxidation in aqueous solutions. Chemosphere 2000, 41, 1233–1238. [Google Scholar] [CrossRef]

- Zhang, S.J.; Yu, H.Q.; Li, Q.R. Radiolytic degradation of Acid Orange 7: A mechanistic study. Chemosphere 2005, 61, 1003–1011. [Google Scholar] [CrossRef]

- Li, X.; Hou, Y.; Zhao, Q.; Wang, L. A general, one-step and template-free synthesis of sphere-like zinc ferrite nanostructures with enhanced photocatalytic activity for dye degradation. J. Colloid Interface Sci. 2011, 358, 102–108. [Google Scholar] [CrossRef]

- Xing, X.; Qu, H.; Shao, R.; Wang, Q.; Xie, H. Mechanism and kinetics of dye desorption from dye-loaded carbon (XC-72) with alcohol-water system as desorbent. Water Sci. Technol. 2017, 76, 1243–1250. [Google Scholar] [CrossRef]

- Stylidi, M.; Kondarides, D.I.; Verykios, X.E. Visible light-induced photocatalytic degradation of Acid Orange 7 in aqueous TiO2 suspensions. Appl. Catal. B-Environ. 2004, 47, 189–201. [Google Scholar] [CrossRef]

- Liang, S.; Zhu, S.; Chen, Y.; Wu, W.; Wang, X.; Wu, L. Rapid template-free synthesis and photocatalytic performance of visible light-activated SnNb2O6 nanosheets. J. Mater. Chem. 2012, 22, 2670–2678. [Google Scholar] [CrossRef]

- Su, M.; He, C.; Sharma, V.K.; Abou Asi, M.; Xia, D.; Li, X.-Z.; Deng, H.; Xiong, Y. Mesoporous zinc ferrite: Synthesis, characterization, and photocatalytic activity with H2O2/visible light. J. Hazard. Mater. 2012, 211, 95–103. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, W.; Niu, J.; Chen, Y. Mechanism of photogenerated reactive oxygen species and correlation with the antibacterial properties of engineered metal-oxide nanoparticles. ACS Nano 2012, 6, 5164–5173. [Google Scholar] [CrossRef]

- Hussain, S.; Hussain, S.; Waleed, A.; Tavakoli, M.M.; Wang, Z.; Yang, S.; Fan, Z.; Nadeem, M.A. Fabrication of CuFe2O4/alpha-Fe2O3 composite thin films on FTO coated glass and 3-D nanospike structures for efficient photoelectrochemical water splitting. ACS Appl. Mater. Interfaces 2016, 8, 35315–35322. [Google Scholar] [CrossRef]

- Nasr, C.; Vinodgopal, K.; Fisher, L.; Hotchandani, S.; Chattopadhyay, A.K.; Kamat, P.V. Environmental photochemistry on semiconductor surfaces. Visible light induced degradation of a textile diazo dye, naphthol blue black, on TiO2 nanoparticles. J. Phys. Chem. 1996, 100, 8436–8442. [Google Scholar] [CrossRef]

- Wen, X.-J.; Niu, C.-G.; Huang, D.-W.; Zhang, L.; Liang, C.; Zeng, G.-M. Study of the photocatalytic degradation pathway of norfloxacin and mineralization activity using a novel ternary Ag/AgCl-CeO2 photocatalyst. J. Catal. 2017, 355, 73–86. [Google Scholar] [CrossRef]

- Bechambi, O.; Jlaiel, L.; Najjar, W.; Sayadi, S. Photocatalytic degradation of bisphenol A in the presence of Ce-ZnO: Evolution of kinetics, toxicity and photodegradation mechanism. Mater. Chem. Phys. 2016, 173, 95–105. [Google Scholar] [CrossRef]

- Zhang, J.; Yan, M.; Sun, G.; Li, X.; Liu, K. Visible-light photo-Fenton catalytic MgFe2O4 spinel: Reaction sintering synthesis and DFT study. J. Alloy. Compd. 2021, 889, 161673–161684. [Google Scholar] [CrossRef]

- Hao, X.; Hu, Z.; Xiang, D.; Jin, Z. Construction of CdS@Cu2-xS core–shell p-n heterojunction with enhanced charge separation for wide spectrum photocatalytic H2 evolution. Mol. Catal. 2022, 528, 112417–112431. [Google Scholar] [CrossRef]

- Huang, T.; Mao, S.; Yu, J.; Wen, Z.; Lu, G.; Chen, J. Effects of N and F doping on structure and photocatalytic properties of anatase TiO2 nanoparticles. RSC Adv. 2013, 3, 16657–16664. [Google Scholar] [CrossRef]

- Baliarsingh, N.; Parida, K.M.; Pradhan, G.C. Effects of Co, Ni, Cu, and Zn on Photophysical and Photocatalytic Properties of Carbonate Intercalated MII/Cr LDHs for Enhanced Photodegradation of Methyl Orange. Ind. Eng. Chem. Res. 2014, 53, 3834–3841. [Google Scholar] [CrossRef]

- Yan, S.; Wang, B.; Shi, Y.; Yang, F.; Hu, D.; Xu, X.; Wu, J. Hydrothermal synthesis of CdS nanoparticle/functionalized graphene sheet nanocomposites for visible-light photocatalytic degradation of methyl orange. Appl. Surf. Sci. 2013, 285, 840–845. [Google Scholar] [CrossRef]

- Chen, Q.; Wu, L.; Zhao, X.; Yang, X.-J. Fabrication of Zn-Ti layered double oxide nanosheets with ZnO/ZnTiO3 heterojunction for enhanced photocatalytic degradation of MO, RhB and MB. J. Mol. Liq. 2022, 353, 118794. [Google Scholar] [CrossRef]

- Xu, M.L.; Jiang, X.J.; Li, J.R.; Wang, F.J.; Li, K.; Cheng, X. Self-Assembly of a 3D Hollow BiOBr@Bi-MOF Heterostructure with Enhanced Photocatalytic Degradation of Dyes. ACS Appl. Mater. Interfaces 2021, 13, 56171–56180. [Google Scholar] [CrossRef]

- Ma, M.; Yang, Y.; Chen, Y.; Jiang, J.; Ma, Y.; Wang, Z.; Huang, W.; Wang, S.; Liu, M.; Ma, D.; et al. Fabrication of hollow flower-like magnetic Fe3O4/C/MnO2/C3N4 composite with enhanced photocatalytic activity. Sci. Rep. 2021, 11, 2597. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Z.; Cai, W.; Rong, S.; Qu, H.; Xie, H. Hollow CuFe2O4/MgFe2O4 Heterojunction Boost Photocatalytic Oxidation Activity for Organic Pollutants. Catalysts 2022, 12, 910. https://doi.org/10.3390/catal12080910

Zhang Z, Cai W, Rong S, Qu H, Xie H. Hollow CuFe2O4/MgFe2O4 Heterojunction Boost Photocatalytic Oxidation Activity for Organic Pollutants. Catalysts. 2022; 12(8):910. https://doi.org/10.3390/catal12080910

Chicago/Turabian StyleZhang, Zhicheng, Wei Cai, Shaopeng Rong, Hongxia Qu, and Huifang Xie. 2022. "Hollow CuFe2O4/MgFe2O4 Heterojunction Boost Photocatalytic Oxidation Activity for Organic Pollutants" Catalysts 12, no. 8: 910. https://doi.org/10.3390/catal12080910

APA StyleZhang, Z., Cai, W., Rong, S., Qu, H., & Xie, H. (2022). Hollow CuFe2O4/MgFe2O4 Heterojunction Boost Photocatalytic Oxidation Activity for Organic Pollutants. Catalysts, 12(8), 910. https://doi.org/10.3390/catal12080910