Effect of Flow Length on Pressure and Measurement of PEMFC Temperature by Using Thin-Film Thermocouples

Abstract

1. Introduction

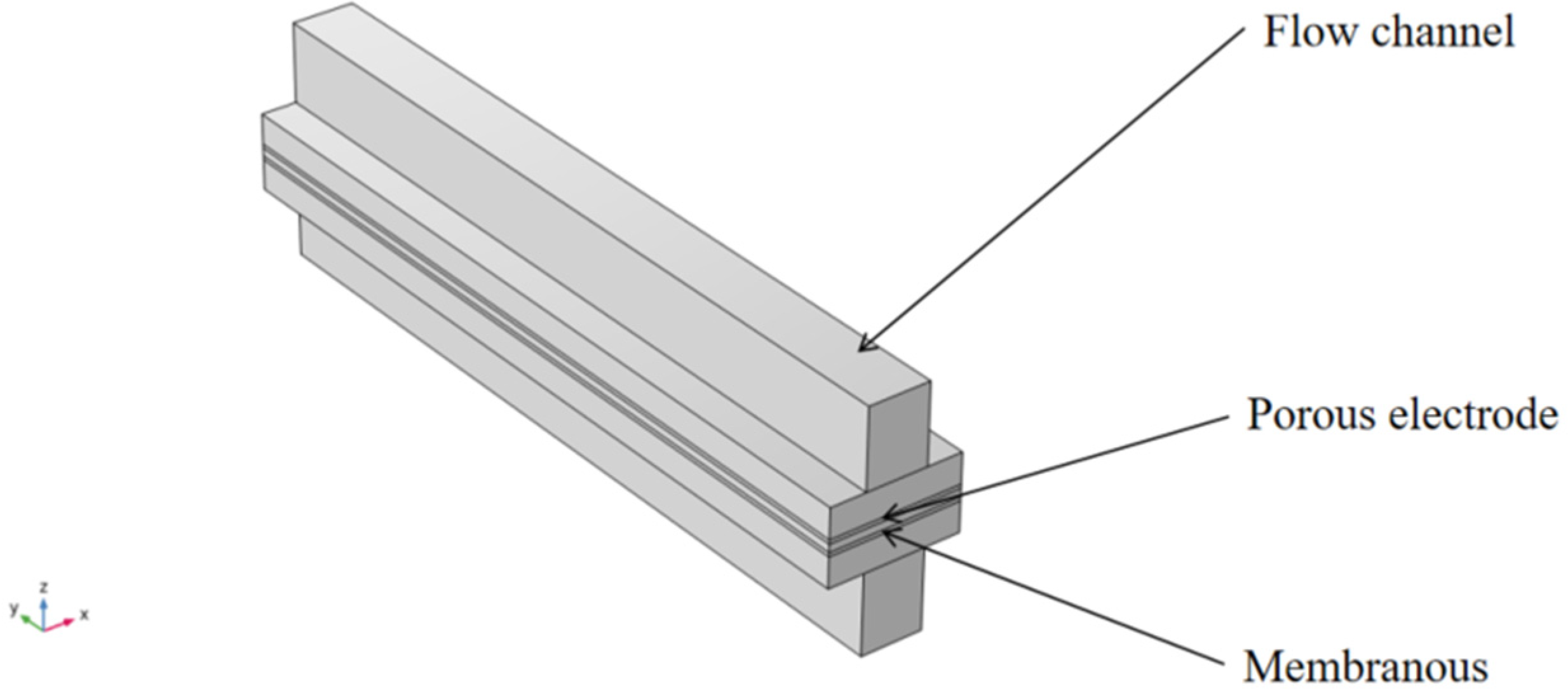

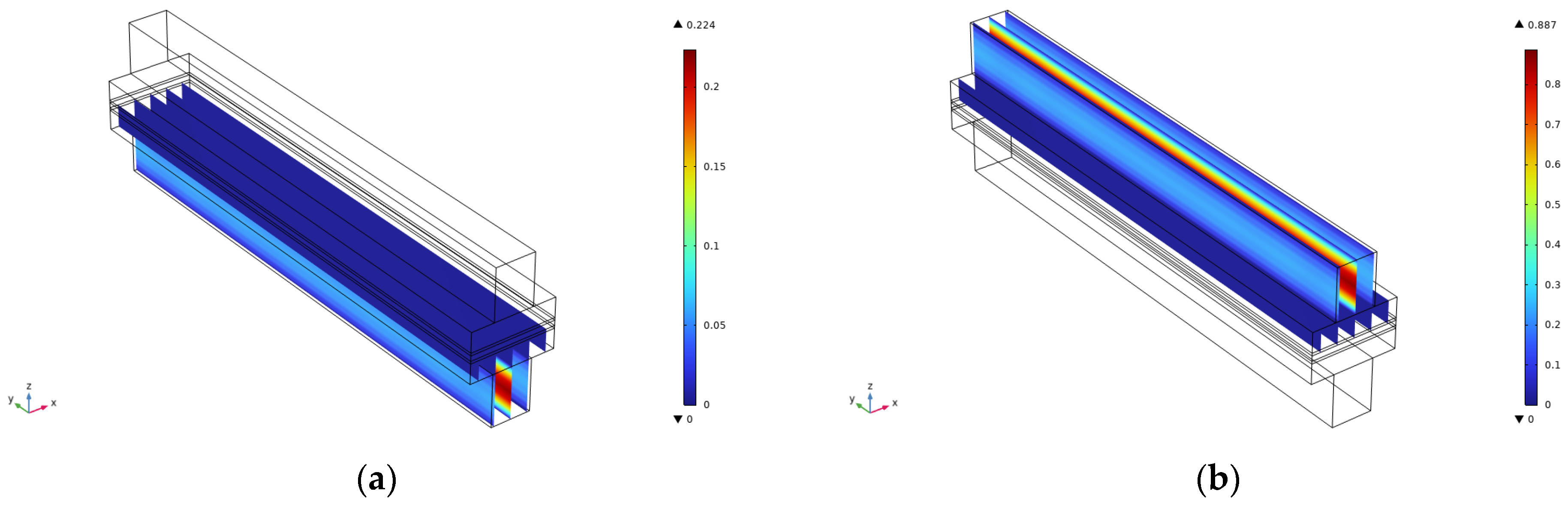

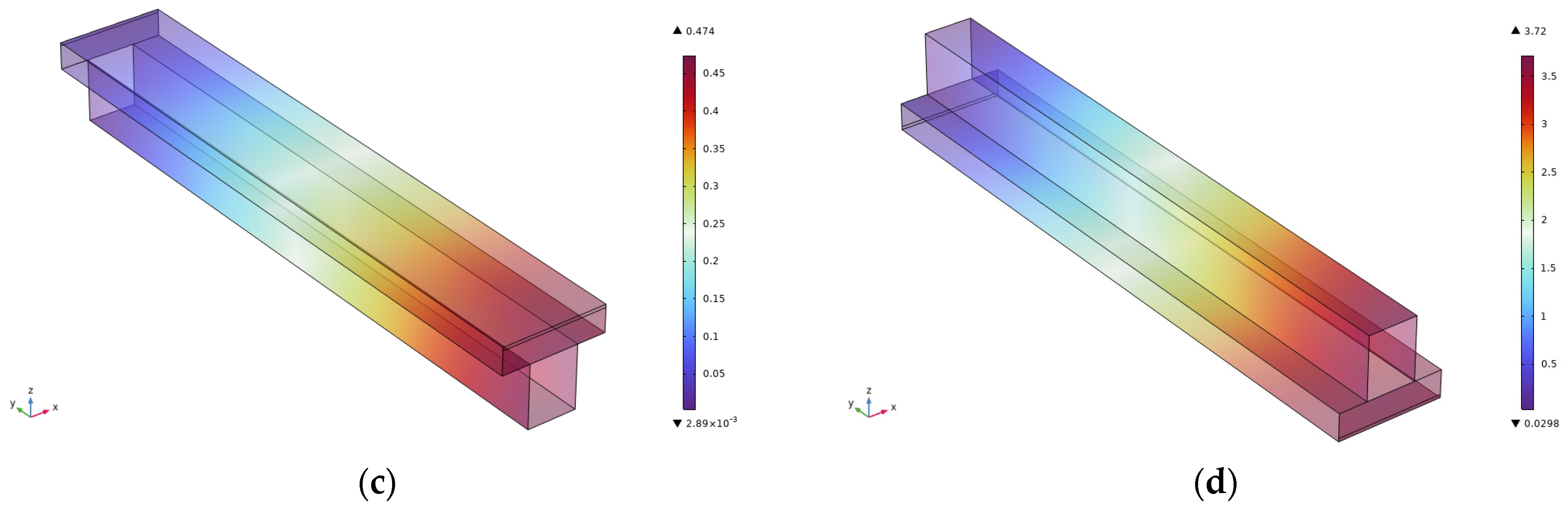

2. Influence of Runner Length on the Velocity as Well as the Pressure of the Bipolar Gas Flow Channel

2.1. Model Definition

2.2. Principles

2.3. Boundary Conditions

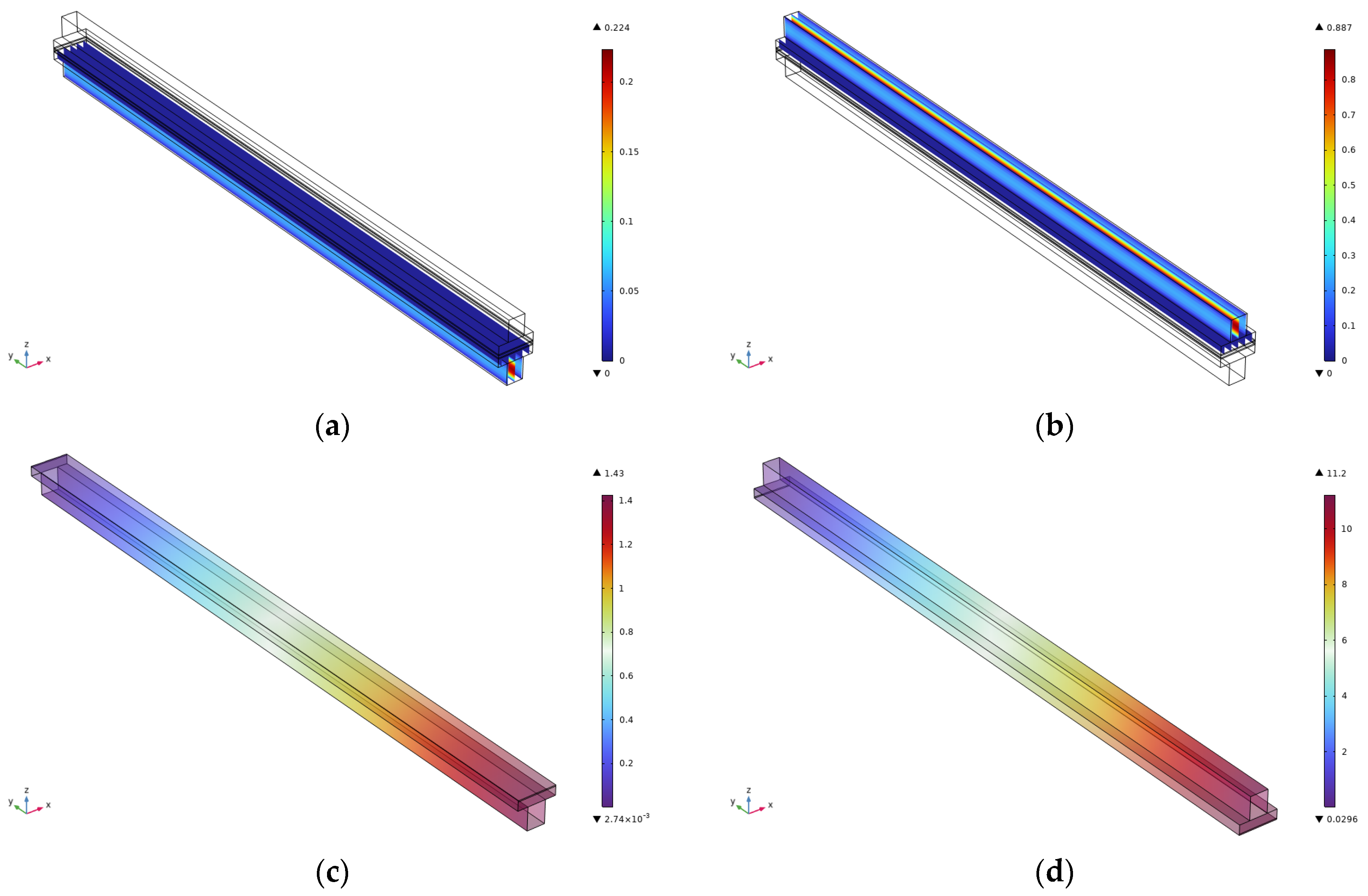

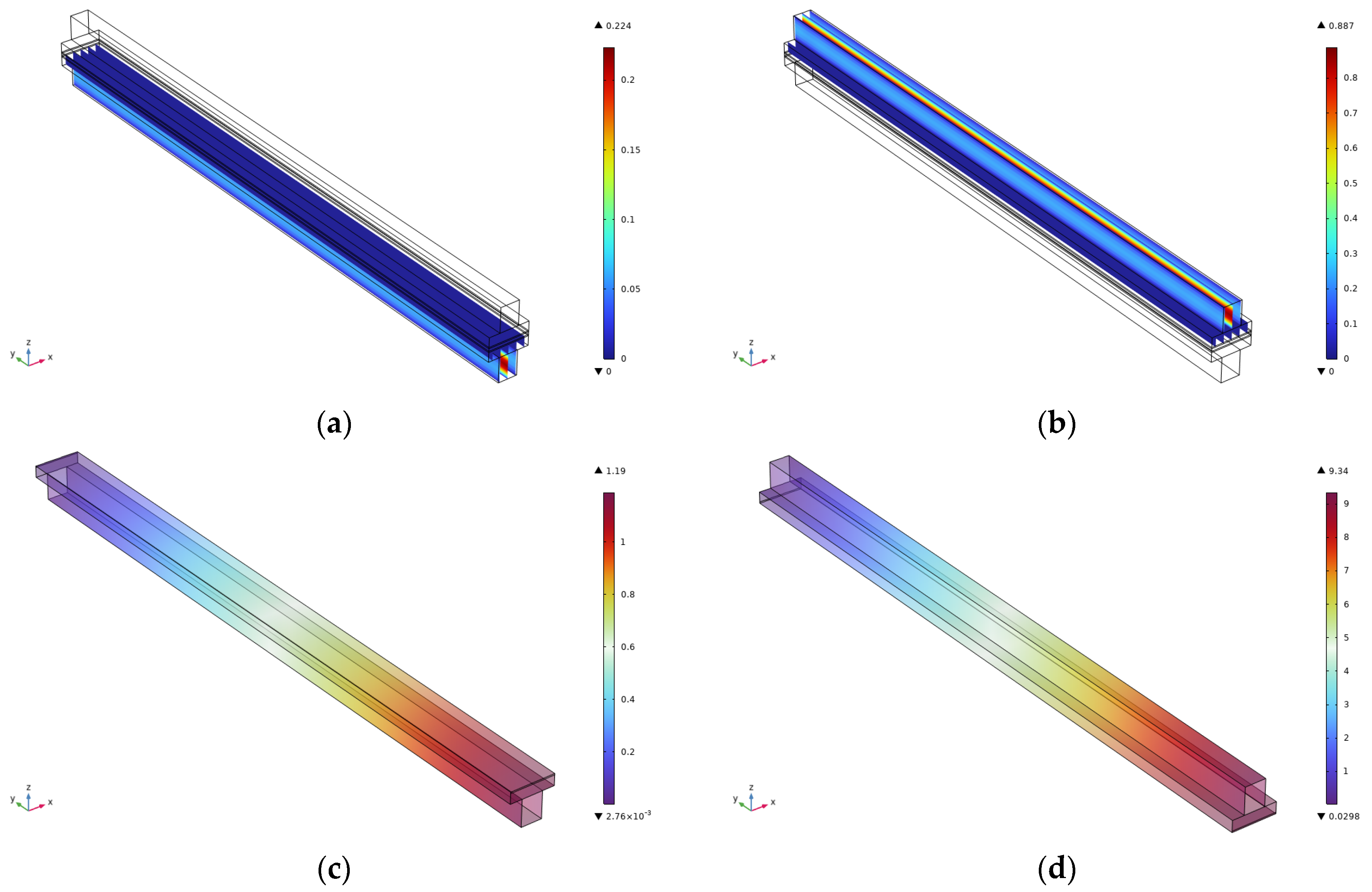

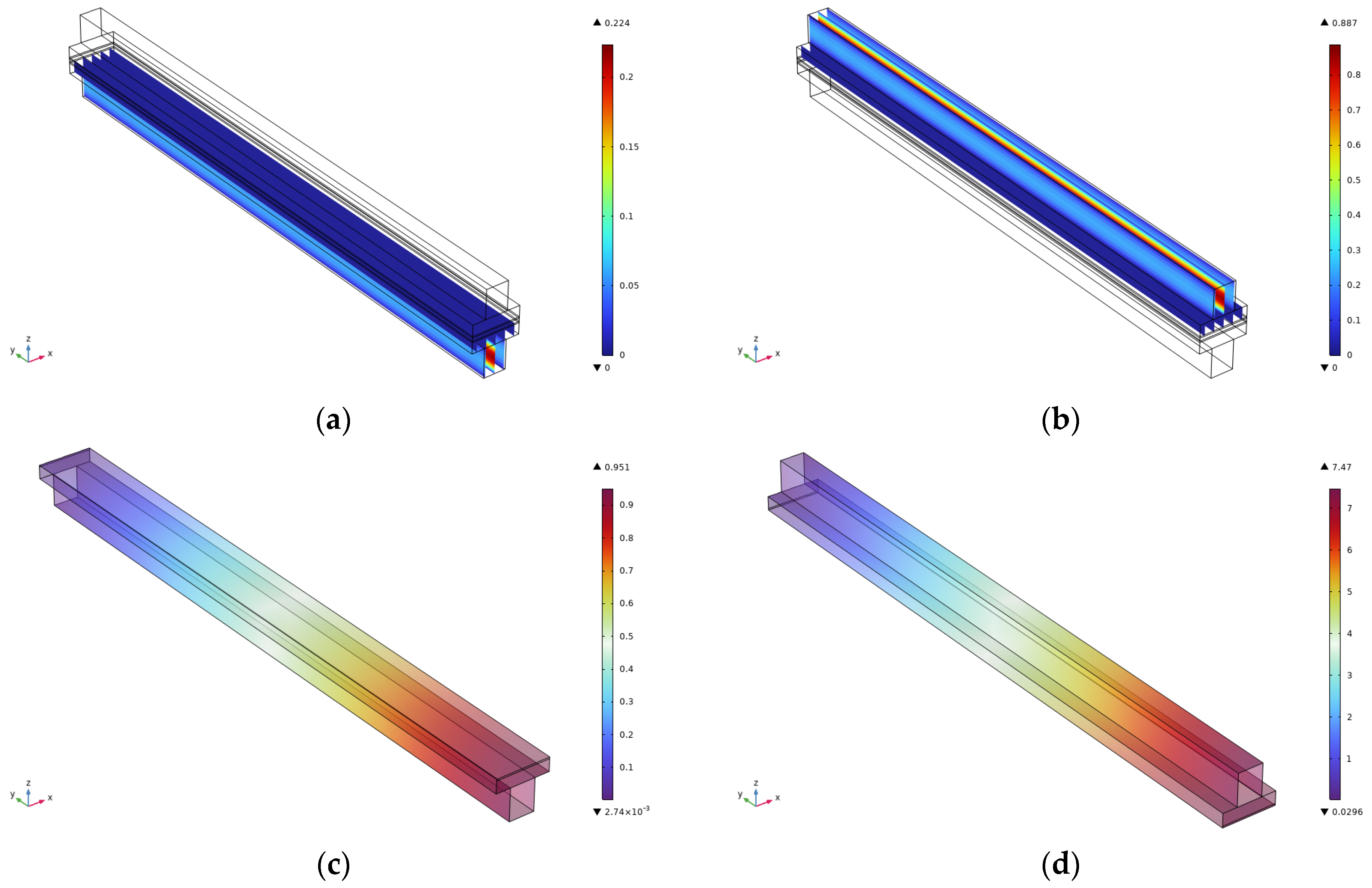

2.4. Results

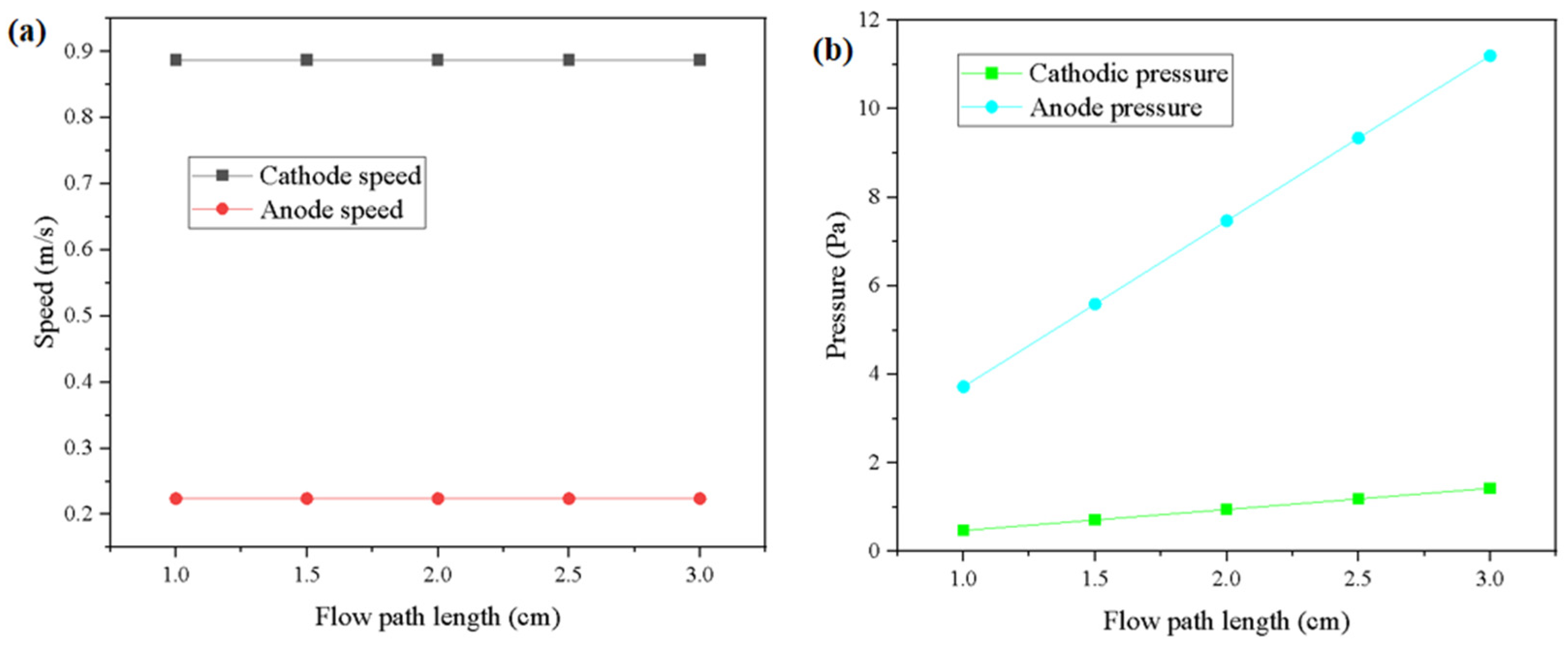

3. Thin-Film Thermocouples for Measuring PEMFC Operating Temperatures

3.1. Principle of the Operation of Thin-Film Thermocouples

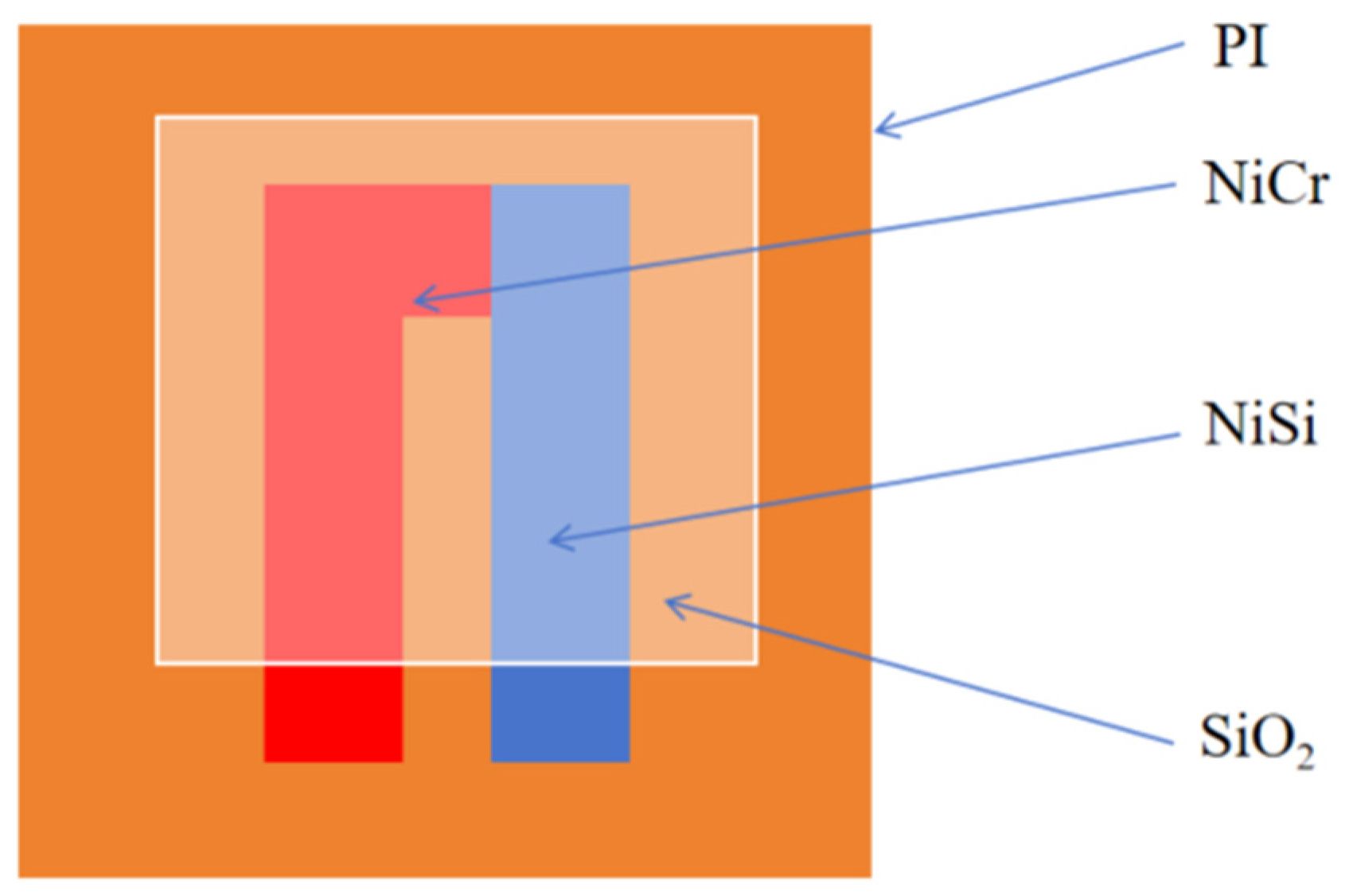

3.2. Thin-Film Thermocouple Structure Design

3.3. Thin-Film Thermocouple Process Selection

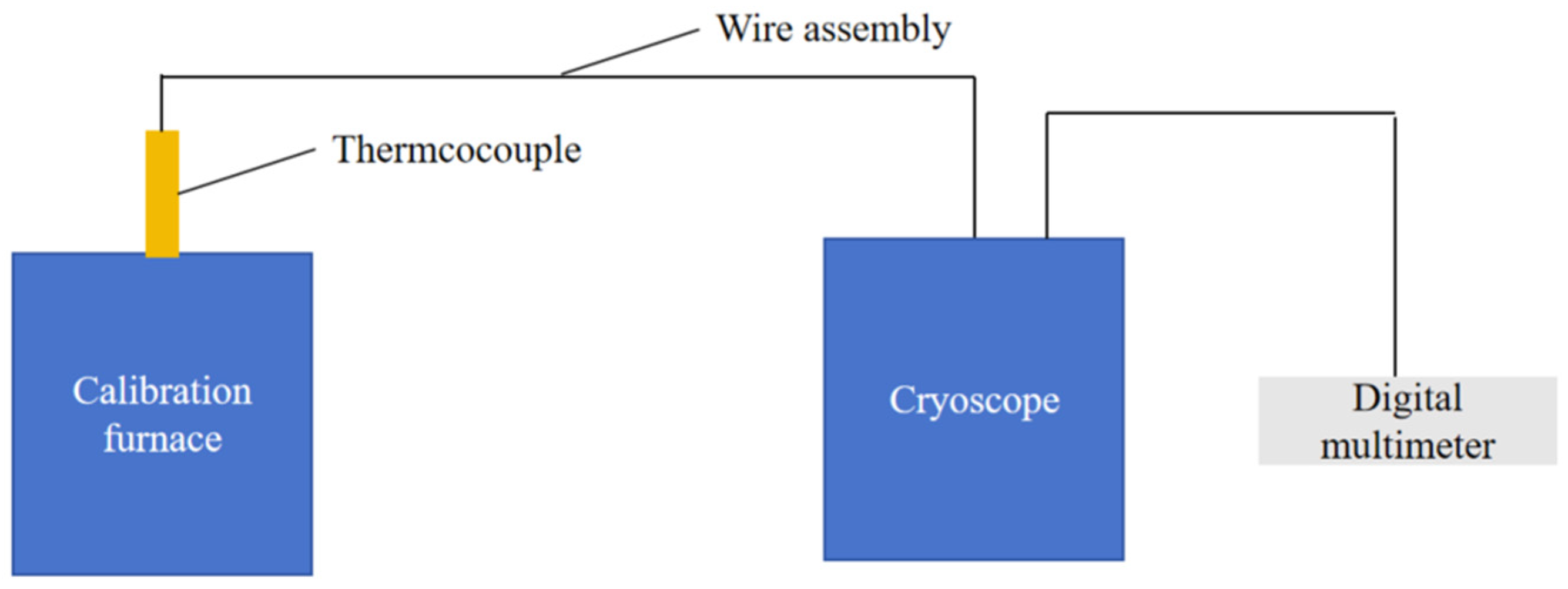

3.4. Thin-Film Thermocouple Calibration

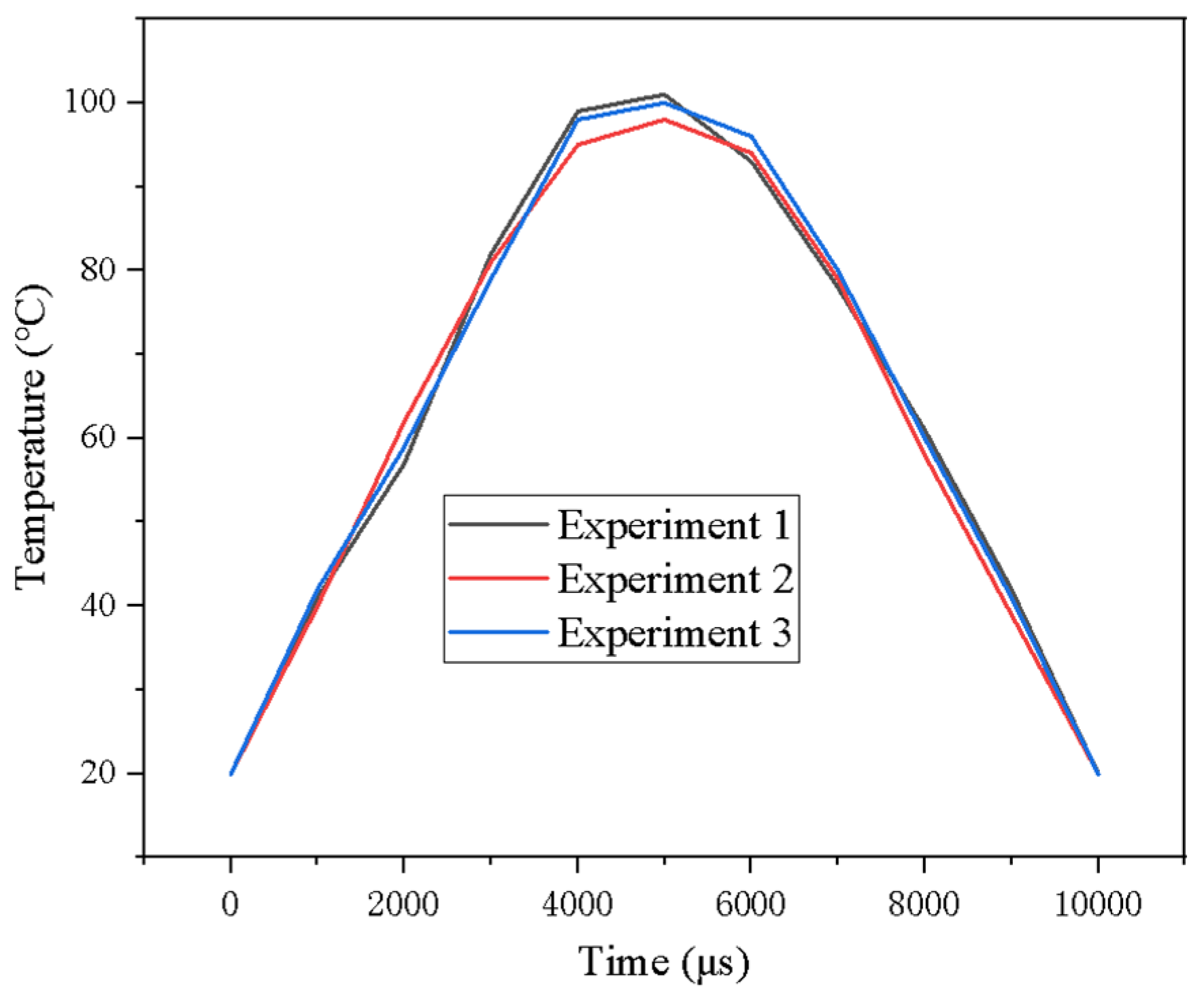

3.5. PEMFC Operating Temperature Measurements

4. Conclusions

- A multiphysics simulation framework was used to reveal the non-linear relationship between flow channel length and internal pressure distribution. The maximum anode pressure increased from 3.72 Pa (at 1 cm) to 11.2 Pa (at 3 cm), while the flow velocity remained nearly constant across all channel lengths, exhibiting stable laminar flow characteristics. It was further demonstrated that shorter channels help suppress concentration polarization and enhance gas–liquid–solid interface mass transfer by minimizing frictional losses and improving permeability coupling within the porous layers.

- A NiCr/NiSi thin-film thermocouple was successfully fabricated using magnetron sputtering. Static calibration yielded a high Seebeck coefficient of 41.56 μV/°C with excellent linearity and a calibration error below 1.5%. The incorporation of a SiO₂ protective layer significantly improved its stability under the PEMFC’s humid and oxidizing environment. This sensor offers a reliable, minimally intrusive solution for temperature monitoring in high-performance electrochemical systems.

- Dynamic measurements of the PEMFC operating temperature revealed a characteristic thermal response curve—rapid heating to ~100 °C followed by gradual cooling—that was consistent across three repeated experiments, with fluctuation within 5%. These results confirm the sensor’s robustness and suitability for real-time thermal diagnostics in PEMFCs.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Agyekum, E.B.; Ampah, J.D.; Wilberforce, T.; Afrane, S.; Nutakor, C. Research progress, trends, and current state of development on PEMFC-new insights from a bibliometric analysis and characteristics of two decades of research output. Membranes 2022, 12, 1103. [Google Scholar] [CrossRef] [PubMed]

- Baroutaji, A.; Arjunan, A.; Robinson, J.; Wilberforce, T.; Abdelkareem, M.A.; Olabi, A.G. PEMFC poly-generation systems: Developments, merits, and challenges. Sustainability 2021, 13, 11696. [Google Scholar] [CrossRef]

- Chen, H.; Pei, P.; Song, M. Lifetime prediction and the economic lifetime of proton exchange membrane fuel cells. Appl. Energy 2015, 142, 154–163. [Google Scholar] [CrossRef]

- Igourzal, A.; Auger, F.; Olivier, J.-C.; Retière, C. Improving the operation of multi-stack PEM fuel cell systems to increase efficiency, durability and lifespan while reducing ageing. Energy Convers. Manag. 2024, 314, 118630. [Google Scholar] [CrossRef]

- Qin, W.; Dong, F.; Zhang, S.; Xu, S. Effect of multi-channel shape design on dynamic behavior of liquid water in PEMFC. Int. J. Hydrog. Energy 2024, 50, 1465–1483. [Google Scholar] [CrossRef]

- Jung, D.Y.; Song, D.K.; Kim, J.S.; Lee, S.H.; Min, G.W.; Son, J.H.; Cho, G.Y. Numerical Investigation of Effects of Obstacles in Flow Channels and Depth of Flow Channels for PEMFCs. Sustainability 2024, 16, 10144. [Google Scholar] [CrossRef]

- Chen, W.; Yin, Y.; Liu, Y. Numerical Analysis and Optimization of Secondary Flow Channels in a PEMFC Cooling Plate. J. Mar. Sci. Eng. 2025, 13, 764. [Google Scholar] [CrossRef]

- Brakni, O.; Kerkoub, Y.; Amrouche, F.; Mohammedi, A.; Ziari, Y.K. CFD investigation of the effect of flow field channel design based on constriction and enlargement configurations on PEMFC performance. Fuel 2024, 357, 129920. [Google Scholar] [CrossRef]

- Chen, J.H.; He, P.; Cai, S.J.; He, Z.H.; Zhu, H.N.; Yu, Z.Y.; Yang, L.Z.; Tao, W.Q. Modeling and temperature control of a water-cooled PEMFC system using intelligent algorithms. Appl. Energy 2024, 372, 123790. [Google Scholar] [CrossRef]

- Wang, Y.; Sun, Z.Y.; Yang, L. Optimizing temperature distribution in a PEMFC stack: A computational study on cooling plate and coolant dynamics. Int. J. Hydrog. Energy 2025, 97, 88–103. [Google Scholar] [CrossRef]

- Arat, H.T.; Çeper, B.A. Investigation of instantaneous temperature variations in hydrogen PEM fuel cell stack under cold climate conditions. Int. J. Hydrog. Energy 2025, 107, 539–547. [Google Scholar] [CrossRef]

- Yin, J.; Wang, X.; Zhou, Q.; Zhao, Z.; Deng, S.; Cui, Y.; Wang, H. Determination of optimal temperature range and prediction of tool life to ensure hole quality during continuous drilling of CFRP composites. J. Manuf. Process. 2025, 141, 1535–1550. [Google Scholar] [CrossRef]

- Lee, S.K.; Ito, K.; Sasaki, K. Temperature measurement in through-plane direction in PEFC with a fabricated in-line thermocouple and supporter. ECS Trans. 2009, 25, 495. [Google Scholar] [CrossRef]

- Ali, S.T.; Lebæk, J.; Nielsen, L.P.; Mathiasen, C.; Møller, P.; Kær, S.K. Thin film thermocouples for in situ membrane electrode assembly temperature measurements in a polybenzimidazole-based high temperature proton exchange membrane unit cell. J. Power Sources 2010, 195, 4835–4841. [Google Scholar] [CrossRef]

- Horiuchi, Y.; Araki, T.; Sugimoto, T. Developments of MEMS-Based Thermocouple Array for Sensing Effects of a Flow Channel on PEMFC Local Temperature Distribution. In Proceedings of the ASME 2013 11th International Conference on Nanochannels, Microchannels, and Minichannels, Sapporo, Japan, 16–19 June 2013. [Google Scholar]

- Xu, J.; Xiao, S.; Xu, X.; Xu, X. Numerical study of carbon monoxide poisoning effect on high temperature PEMFCs based on an elementary reaction kinetics coupled electrochemical reaction model. Appl. Energy 2022, 318, 119214. [Google Scholar] [CrossRef]

- Zhang, M.; Liu, Y.; Li, J.; Wu, C.; Liu, Y.; Wei, P.; Zhao, W.; Cai, K. Screen printing Ag2Se/carbon nanocomposite films for flexible thermoelectric applications. Carbon 2024, 229, 119480. [Google Scholar] [CrossRef]

- Mehrzad, A.; Verdian, A.; Sarabi-Jamab, M. Smart nano-inks based on natural food colorant for screen-printing of dynamic shelf life of shrimp. Food Chem. 2024, 447, 138963. [Google Scholar] [CrossRef]

- Guo, W.; Chen, J.; Ma, T.; Chen, Z.; Li, M.; Zeng, H.; Lu, J. Direct photolithography patterning of quantum dot-polymer. Adv. Funct. Mater. 2024, 34, 2310338. [Google Scholar] [CrossRef]

- Gao, L.; Liang, Y.; Song, L.; Yin, D.; Qi, J.; Chen, J.; Liu, Z.; Yu, J.; Liu, J.; Zhang, H.; et al. Thin-film lithium niobate electro-optic isolator fabricated by photolithography assisted chemo-mechanical etching. Opt. Lett. 2024, 49, 614–617. [Google Scholar] [CrossRef]

- Wakamatsu, T.; Isobe, Y.; Takane, H.; Kaneko, K.; Tanaka, K. Ge doping of α-Ga2O3 thin films via mist chemical vapor deposition and their application in Schottky barrier diodes. J. Appl. Phys. 2024, 135, 155705. [Google Scholar] [CrossRef]

- Gleason, K.K. Designing organic and hybrid surfaces and devices with initiated chemical vapor deposition (iCVD). Adv. Mater. 2024, 36, 2306665. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Guo, S.; E, M.; Liu, H.; Liu, Z.; Ding, W.; Li, D.; Cui, Y. Self-powered rapid response flexible pressure sensor for wearable application. Adv. Eng. Mater. 2023, 25, 2201678. [Google Scholar] [CrossRef]

- Mingfeng, E.; Cui, Y.; Guo, S.; Liu, H.; Ding, W.; Yin, J. Novel lead-connection technology for thin-film temperature sensors with arbitrary electrode lengths. Meas. Sci. Technol. 2023, 34, 065113. [Google Scholar]

- Liu, Z.; Yang, Y.; Sun, Y.; Guo, T.; Shen, K.; Cheng, Y.; Wang, B.; Hu, K.; Zhang, C.; Hao, G.; et al. Measurement and analysis of surface temperature gradients on magnetron sputtered thin film growth studied using NiCr/NiSi thin film thermocouples. Small 2025, 21, 2404829. [Google Scholar] [CrossRef]

- Wang, H.; Cui, Y.; Mingfeng, E.; Sun, Y.; Ma, F.; Ding, W.; Yin, J. Nanosecond-level second-order characteristics in dynamic calibration of thin film thermocouples by short-pulse laser. Measurement 2024, 238, 115165. [Google Scholar] [CrossRef]

| Experimental Parameters | NiCr Membrane | NiSi Membrane | SiO2 Membrane |

|---|---|---|---|

| Target material | NiCr target | NiSi target | SiO2 target |

| Target-base distance | 120 mm | 120 m | 120 mm |

| Working gas | Ar | Ar | Ar/O2 |

| Working pressure | 0.7 Pa | 0.7 Pa | 0.6 Pa |

| Flow | 20 sccm | 20 sccm | 20/5 sccm |

| Inversion time | 1 μs | 1 μs | 1 μs |

| Pulse frequency | 100 kHz | 100 kHz | 100 kHz |

| Sputtering power density | 1.9 W cm−2 | 1.9 W cm−2 | 0.83–5.00 Wcm−2 |

| Deposition time | 35 min | 41 min | 3.5 h |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, H.; Liu, Z.; Li, X.; Wang, X.; Zhang, M.; Zhang, S.; Wang, Z.; Ding, W. Effect of Flow Length on Pressure and Measurement of PEMFC Temperature by Using Thin-Film Thermocouples. Micromachines 2025, 16, 535. https://doi.org/10.3390/mi16050535

Guo H, Liu Z, Li X, Wang X, Zhang M, Zhang S, Wang Z, Ding W. Effect of Flow Length on Pressure and Measurement of PEMFC Temperature by Using Thin-Film Thermocouples. Micromachines. 2025; 16(5):535. https://doi.org/10.3390/mi16050535

Chicago/Turabian StyleGuo, Huijin, Zhihui Liu, Xingyu Li, Xingshu Wang, Maopeng Zhang, Shiqi Zhang, Zixi Wang, and Wanyu Ding. 2025. "Effect of Flow Length on Pressure and Measurement of PEMFC Temperature by Using Thin-Film Thermocouples" Micromachines 16, no. 5: 535. https://doi.org/10.3390/mi16050535

APA StyleGuo, H., Liu, Z., Li, X., Wang, X., Zhang, M., Zhang, S., Wang, Z., & Ding, W. (2025). Effect of Flow Length on Pressure and Measurement of PEMFC Temperature by Using Thin-Film Thermocouples. Micromachines, 16(5), 535. https://doi.org/10.3390/mi16050535