Investigations of Shape Deformation Behaviors of the Ferromagnetic Ni–Mn–Ga Alloy/Porous Silicone Rubber Composite towards Actuator Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Alloy Preparations

2.2. Fabrication of Single-Crystal Ni–Mn–Ga Alloys

2.3. Fabrication of Single-Crystal Ni–Mn–Ga Alloys/Polymer Composite Materials

2.4. Measurements

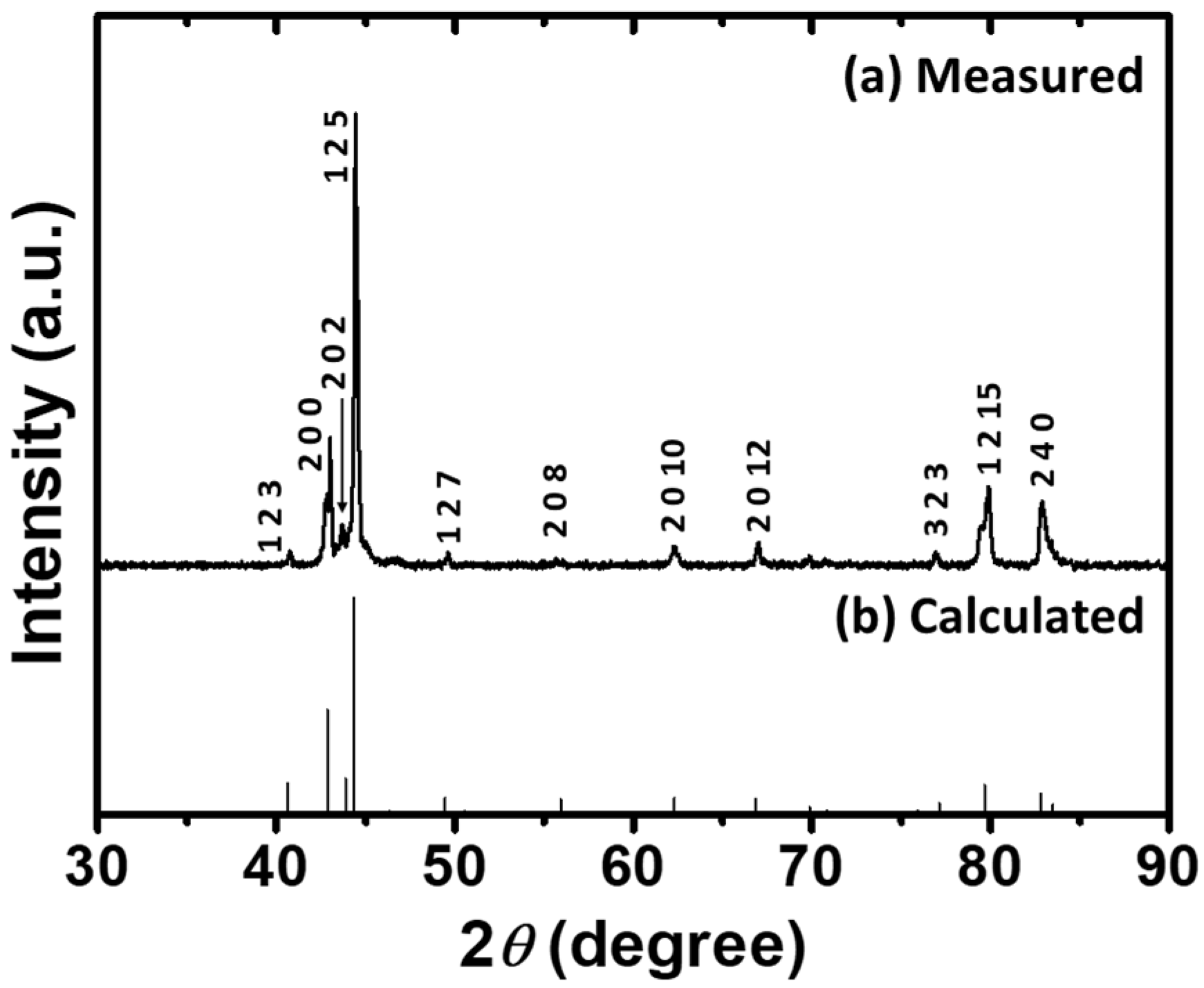

2.4.1. Identification of Phase Constituent

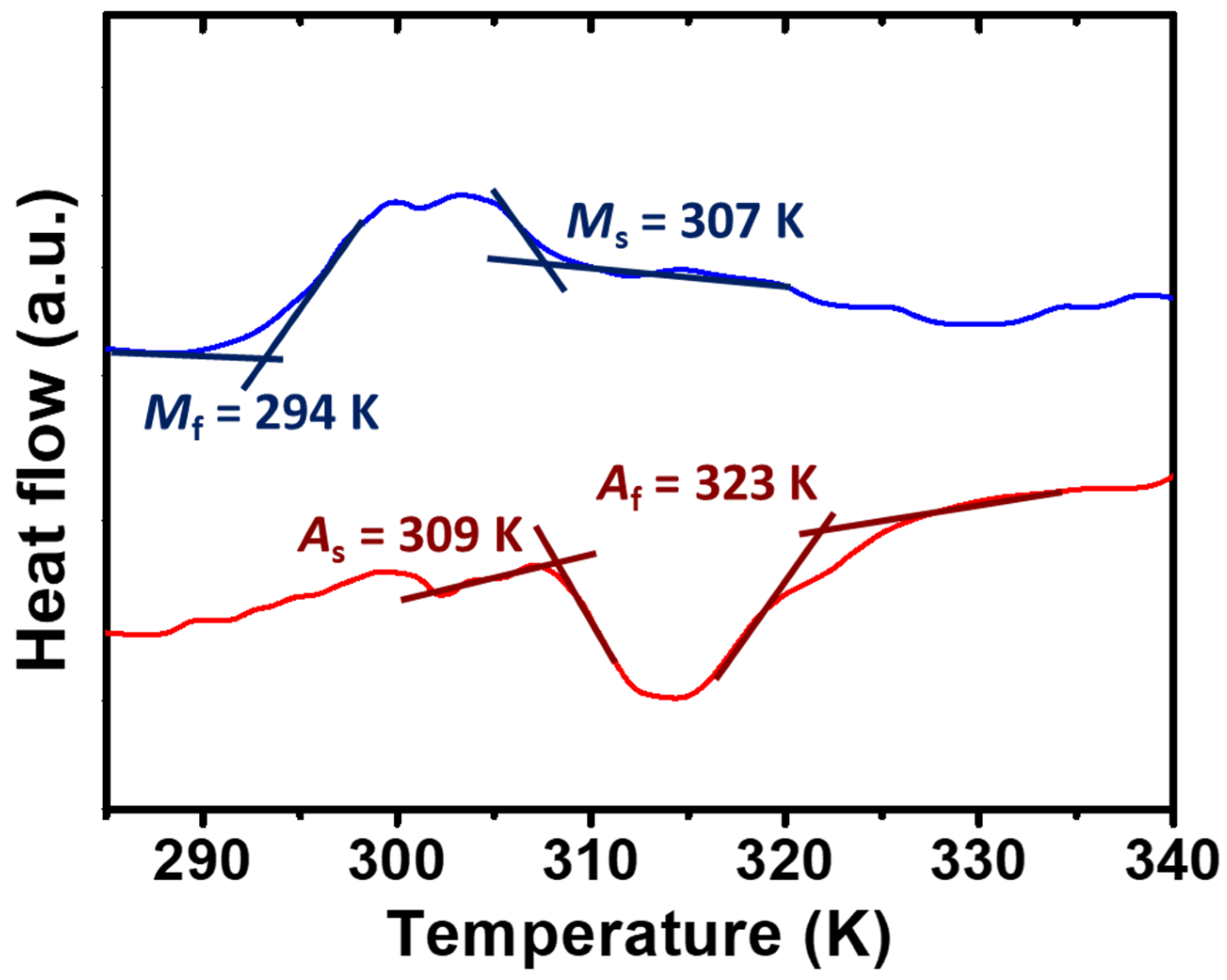

2.4.2. Analysis of Thermal Behaviors

2.4.3. Examinations of Elastic Modulus of Various Silicone Rubbers

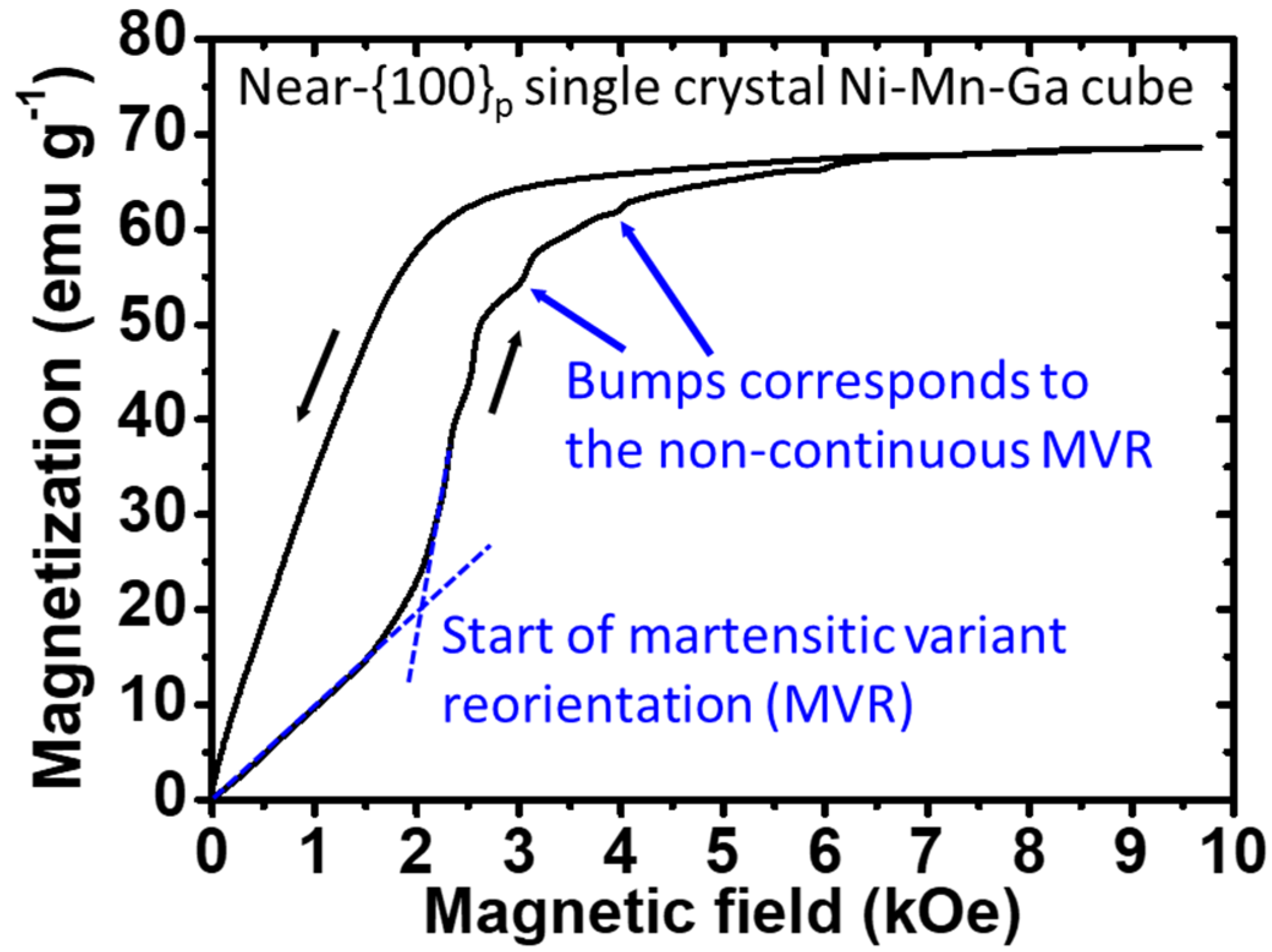

2.4.4. Evaluations of Magnetic Properties

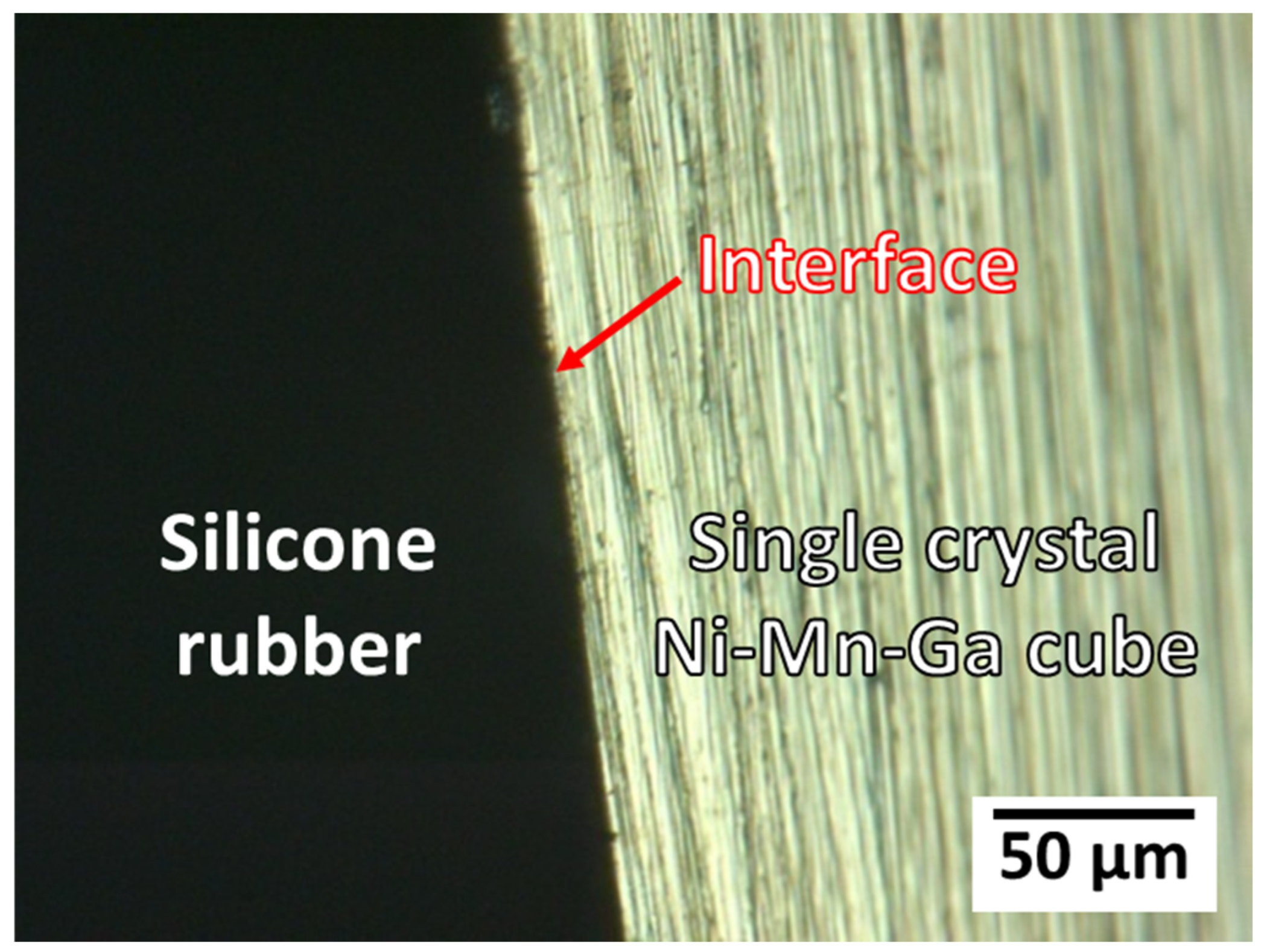

2.4.5. Observations of Microstructure

2.4.6. Analysis of Deformation

3. Results and Discussion

3.1. Identification of Phase Constituent

3.2. Analysis of Thermal Behaviors

3.3. Evaluations of Elastic Modulus

3.4. Observation of Martensitic Variant Reorientation (MVR)

3.4.1. MVR Behaviors of the Single-Crystal Ni–Mn–Ga Cubes

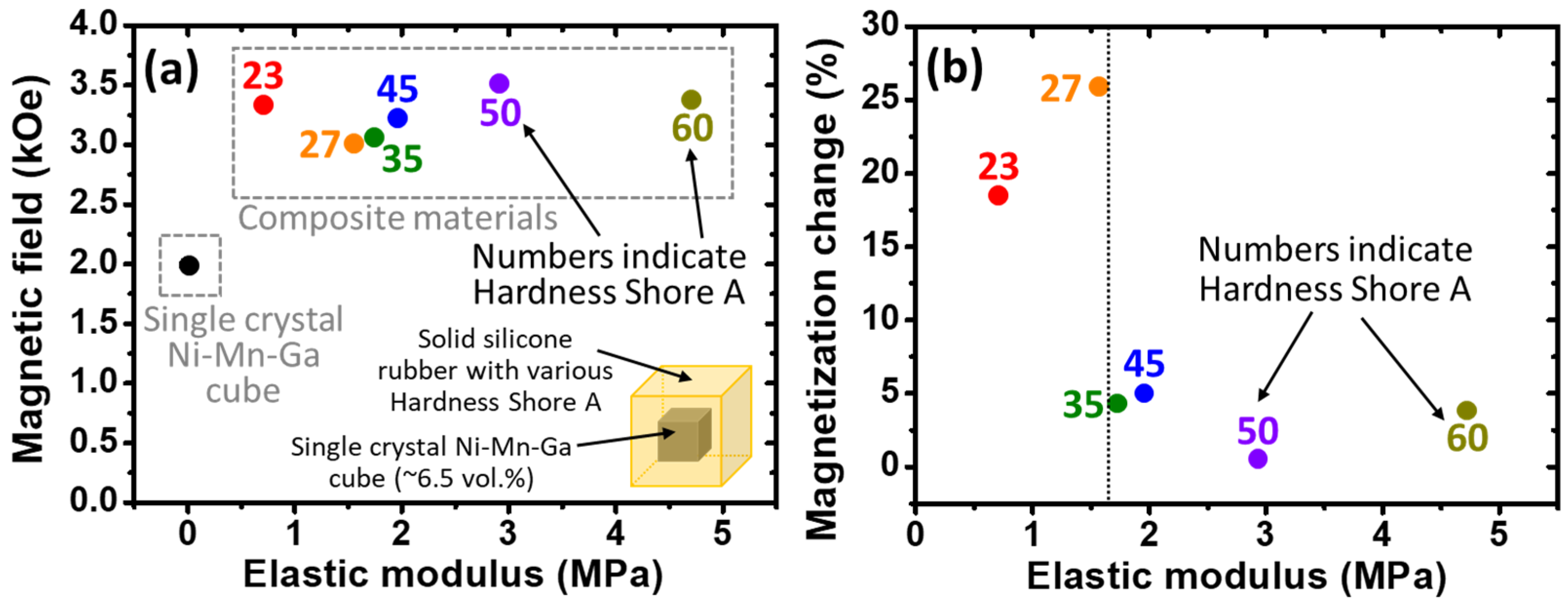

3.4.2. MVR Behaviors of the Single-Crystal Ni–Mn–Ga Cubes/Solid Silicone Rubber

3.4.3. MVR Behaviors of the Single-Crystal Ni–Mn–Ga Cubes/Porous Silicone Rubber

3.4.4. Effect of PFP Configuration on the MVR of the Single-Crystal Ni–Mn–Ga Cube

3.5. Quantitively Analysis of MVR

3.6. Comparison between the Solid and the Porous Structures of Silicone Matrix

3.7. Factors That Affect the MVR of the Single-Crystal Ni–Mn–Ga Alloy

3.7.1. Back Stress from the Silicone Rubber Matrix

3.7.2. Volume Fraction of the Composite Materials

3.8. Deformation of the Composite Material

4. Conclusions

- According to the phase identification and the thermal analysis, the Ni–Mn–Ga cube was confirmed to be in the near-{100}p single-crystal 5M-martensite phase with a ferromagnetism.

- The higher the Hardness Shore A of the silicone rubber (i.e., from 23 to 60 of the Hardness Shore A), the higher the elastic modulus that was found, as expected.

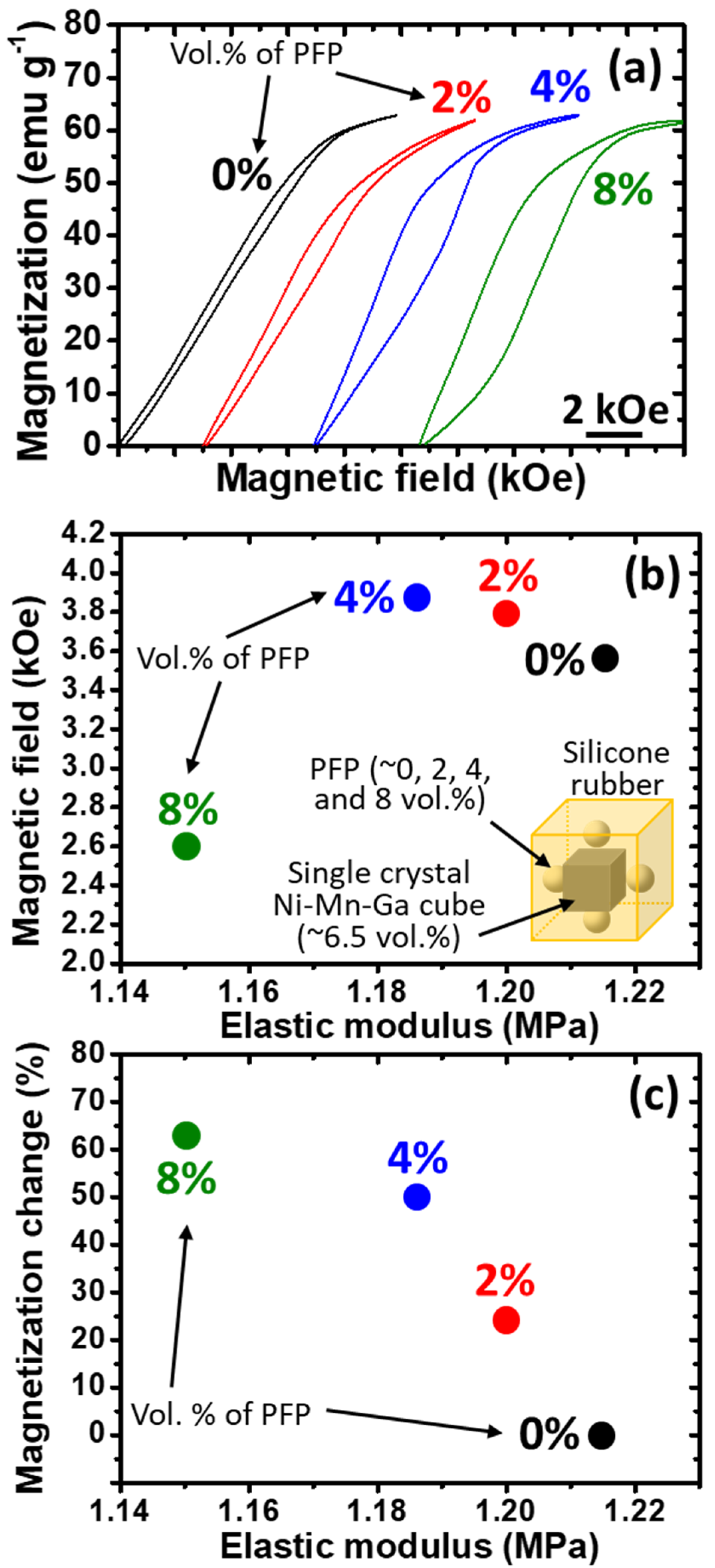

- With the introduction of pores to the silicone rubber by utilizing the PFP, the elastic modulus of the porous silicone rubber was successfully reduced in a good trend.

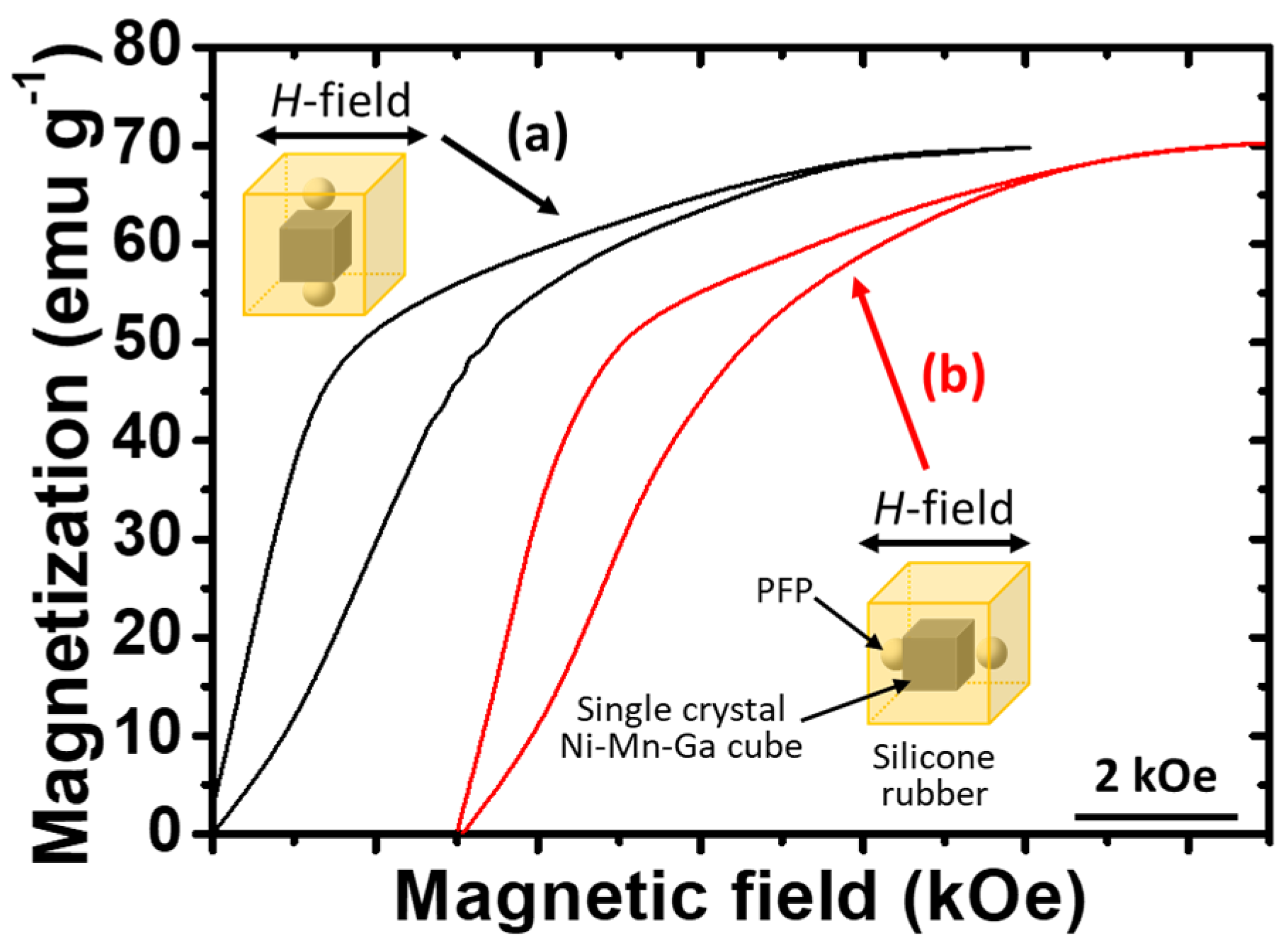

- The obvious magnetic field-induced MVR of the single-crystal Ni–Mn–Ga cube was found in its M-H curve, and the observed necessary H-field required for the commencement of the MVR of the 5M-martensite Ni–Mn–Ga alloy at around 2 kOe corresponds well with the results in the literature.

- The elastic modulus of the solid silicone rubber matrix hardly affected the necessary H-field required for the commencement of the MVR of the single-crystal Ni–Mn–Ga cube. However, the accumulated magnetization change depended on the elastic modulus of the solid silicone rubber matrix.

- Both the necessary H-field required for the commencement of the MVR of the single-crystal Ni–Mn–Ga cube and the accumulated magnetization change are dependent on the elastic modulus of the porous silicone rubber matrix.

- The configurations (vertical or parallel to the external H-field applied) of the pores in the composites used had a limited effect on the magnetic properties of the composite materials.

- The displacement of around 22 to 25 μm of the composite materials could be obtained by taking advantage of the composite materials.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.; Zhang, L. Magnetic Actuation Systems for Miniature Robots: A Review. Adv. Intell. Syst. 2020, 2, 2000082. [Google Scholar] [CrossRef]

- Veale, A.J.; Xie, S.Q. Towards compliant and wearable robotic orthoses: A review of current and emerging actuator technologies. Med. Eng. Phys. 2016, 38, 317–325. [Google Scholar] [CrossRef] [PubMed]

- Kovacs, G.; Lochmatter, P.; Wissler, M. An arm wrestling robot driven by dielectric elastomer actuators. Smart Mater. Struct. 2007, 16, S306–S317. [Google Scholar] [CrossRef]

- Hollerbach, J.M.; Hunter, I.W.; Ballantyne, J. A comparative analysis of actuator technologies for robotics. Robot. Rev. 1991, 2, 299–342. [Google Scholar]

- Wang, L.; Yang, Y.; Chen, Y.; Majidi, C.; Iida, F.; Askounis, E.; Pei, Q. Controllable and reversible tuning of material rigidity for robot applications. Mater. Today 2018, 21, 563–576. [Google Scholar] [CrossRef]

- Kanner, O.Y.; Shilo, D.; Sheng, J.; James, R.D.; Ganor, Y. Ferromagnetic shape memory flapper for remotely actuated propulsion systems. Smart Mater. Struct. 2013, 22, 085030. [Google Scholar] [CrossRef]

- Riccardi, L.; Naso, D.; Janocha, H.; Turchiano, B. A precise positioning actuator based on feedback-controlled magnetic shape memory alloys. Mechatronics 2012, 22, 568–576. [Google Scholar] [CrossRef]

- Faran, E.; Shilo, D. The kinetic relation for twin wall motion in NiMnGa. J. Mech. Phys. Solids 2011, 59, 975–987. [Google Scholar] [CrossRef]

- Karaca, H.E.; Karaman, I.; Basaran, B.; Chumlyakov, Y.I.; Maier, H.J. Magnetic field and stress induced martensite reorientation in NiMnGa ferromagnetic shape memory alloy single crystals. Acta Mater. 2006, 54, 233–245. [Google Scholar] [CrossRef]

- Karaca, H.E.; Karaman, I.; Basaran, B.; Ren, Y.; Chumlyakov, Y.I.; Maier, H.J. Magnetic Field-Induced Phase Transformation in NiMnCoIn Magnetic Shape-Memory Alloys—A New Actuation Mechanism with Large Work Output. Adv. Funct. Mater. 2009, 19, 983–998. [Google Scholar] [CrossRef]

- Karaca, H.E.; Karaman, I.; Basaran, B.; Lagoudas, D.C.; Chumlyakov, Y.I.; Maier, H.J. On the stress-assisted magnetic-field-induced phase transformation in Ni2MnGa ferromagnetic shape memory alloys. Acta Mater. 2007, 55, 4253–4269. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Wuttig, M.; Craciunescu, C.; Li, J. Phase Transformations in Ferromagnetic NiMnGa Shape Memory Films. Mater. Trans. 2000, 41, 933–937. [Google Scholar] [CrossRef]

- Karaman, I.; Basaran, B.; Karaca, H.E.; Karsilayan, A.I.; Chumlyakov, Y.I. Energy harvesting using martensite variant reorientation mechanism in a NiMnGa magnetic shape memory alloy. Appl. Phys. Lett. 2007, 90, 172505. [Google Scholar] [CrossRef]

- Jiang, C.; Liang, T.; Xu, H.; Zhang, M.; Wu, G. Superhigh strains by variant reorientation in the nonmodulated ferromagnetic NiMnGa alloys. Appl. Phys. Lett. 2002, 81, 2818–2820. [Google Scholar] [CrossRef]

- Heczko, O.; Sozinov, A.; Ullakko, K. Giant field-induced reversible strain in magnetic shape memory NiMnGa alloy. IEEE Trans. Magn. 2000, 36, 3266–3268. [Google Scholar] [CrossRef]

- Karaca, H.E.; Basaran, B.; Karaman, I.; Chumlyakov, Y.I. Stress-induced martensite to austenite phase transformation in Ni2MnGa magnetic shape memory alloys. Smart Mater. Struct. 2012, 21, 045011. [Google Scholar] [CrossRef]

- Arndt, M.; Griebel, M.; Novák, V.; Roubíček, T.; Šittner, P. Martensitic transformation in NiMnGa single crystals: Numerical simulation and experiments. Int. J. Plast. 2006, 2, 1943–1961. [Google Scholar] [CrossRef]

- Pagounis, E.; Szczerba, M.J.; Chulist, R.; Laufenberg, M. Large magnetic field-induced work output in a NiMnGa seven-layered modulated martensite. Appl. Phys. Lett. 2015, 107, 152407. [Google Scholar] [CrossRef]

- Wang, W.H.; Hu, F.X.; Chen, J.L.; Li, Y.X.; Wang, Z.; Gao, Z.Y.; Zheng, Y.F.; Zhao, L.C.; Wu, G.H.; Zan, W.S. Magnetic properties and structural phase transformations of NiMnGa alloys. IEEE Trans. Magn. 2001, 37, 2715–2717. [Google Scholar] [CrossRef]

- Stephan, J.M.; Pagounis, E.; Laufenberg, M.; Paul, O.; Ruther, P. A Novel Concept for Strain Sensing Based on the Ferromagnetic Shape Memory Alloy NiMnGa. IEEE Sens. J. 2011, 11, 2683–2689. [Google Scholar] [CrossRef]

- Wuttig, M.; Li, J.; Craciunescu, C. A new ferromagnetic shape memory alloy system. Scr. Mater. 2001, 44, 2393–2397. [Google Scholar] [CrossRef]

- Chernenko, V.A. Compositional instability of β-phase in Ni-Mn-Ga alloys. Scr. Mater. 1999, 40, 523–527. [Google Scholar] [CrossRef]

- Glock, S.; Zhang, X.X.; Kucza, N.J.; Müllner, P.; Michaud, V. Structural, physical and damping properties of melt-spun Ni–Mn–Ga wire-epoxy composites. Compos. Part A Appl. Sci. Manuf. 2014, 63, 68–75. [Google Scholar] [CrossRef]

- Dunand, D.C.; Müllner, P. Size Effects on Magnetic Actuation in Ni-Mn-Ga Shape-Memory Alloys. Adv. Mater. 2011, 23, 216–232. [Google Scholar] [CrossRef]

- Witherspoon, C.; Zheng, P.; Chmielus, M.; Dunand, D.C.; Müllner, P. Effect of porosity on the magneto-mechanical behavior of polycrystalline magnetic shape-memory Ni–Mn–Ga foams. Acta Mater. 2015, 92, 64–71. [Google Scholar] [CrossRef]

- Qian, M.F.; Zhang, X.X.; Wei, L.S.; Geng, L.; Peng, H.X. Structural, Magnetic and Mechanical Properties of Oligocrystalline Ni-Mn-Ga Shape Memory Microwires. Mater. Today Proc. 2015, 2, S577–S581. [Google Scholar] [CrossRef]

- Scheerbaum, N.; Lai, Y.W.; Leisegang, T.; Thomas, M.; Liu, J.; Khlopkov, K.; McCord, J.; Fähler, S.; Träger, R.; Meyer, D.C.; et al. Constraint-dependent twin variant distribution in Ni2MnGa single crystal, polycrystals and thin film: An EBSD study. Acta Mater. 2010, 58, 4629–4638. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Sratong-on, P.; Tahara, M.; Chernenko, V.; Hosoda, H. Aging behavior of Ni-Mn-Ga/silicone particulate composites exhibiting large recoverable magnetostrain. Scr. Mater. 2023, 227, 115277. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Sratong-on, P.; Chang, T.-F.M.; Tahara, M.; Sone, M.; Chernenko, V.; Hosoda, H. Bi-doping engineering of Ni-Mn-Ga polycrystals and resulting grain particles for smart Ni-Mn-Ga/polymer composites. J. Mater. Res. Technol. 2023, 23, 131–142. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Sratong-on, P.; Tahara, M.; Chernenko, V.; Hosoda, H. Large magnetostrains of Ni-Mn-Ga/silicone composite containing system of oriented 5M and 7M martensitic particles. Scr. Mater. 2022, 207, 114265. [Google Scholar] [CrossRef]

- Han, D.K.; Chiu, W.-T.; Tahara, M.; Chernenko, V.; Lanceros-Mendez, S.; Hosoda, H. Framework of magnetostrain responsive Ni–Mn–Ga microparticles driving magnetic field induced out-of-plane actuation of laminate composite. Sci. Rep. 2003, 13, 7160. [Google Scholar] [CrossRef]

- Wang, Z.L.; Zheng, P.; Nie, Z.H.; Ren, Y.; Wang, Y.D.; Müllner, P.; Dunand, D.C. Superelasticity by reversible variants reorientation in a Ni–Mn–Ga microwire with bamboo grains. Acta Mater. 2015, 99, 373–381. [Google Scholar] [CrossRef]

- Chmielus, M.; Rolfs, K.; Wimpory, R.; Reimers, W.; Müllner, P.; Schneider, R. Effects of surface roughness and training on the twinning stress of Ni–Mn–Ga single crystals. Acta Mater. 2010, 58, 3952–3962. [Google Scholar] [CrossRef]

- Sratong-On, P.; Chernenko, V.A.; Feuchtwanger, J.; Hosoda, H. Magnetic field-induced rubber-like behavior in Ni-Mn-Ga particles/polymer composite. Sci. Rep. 2019, 9, 3443. [Google Scholar] [CrossRef] [PubMed]

- Chiu, W.-T.; Goto, A.; Tahara, M.; Inamura, T.; Hosoda, H. Investigation of the martensite variant reorientation of the single crystal Ni-Mn-Ga alloy via training processes and a modification with a silicone rubber. Mater. Chem. Phys. 2023, 297, 127390. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Goto, A.; Tahara, M.; Inamura, T.; Hosoda, H. Effects of volume fraction between single crystal Ni-Mn-Ga ferromagnetic shape memory alloy and silicone rubber on the martensite variant reorientation. J. Alloys Compd. 2022, 926, 166862. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Okuno, M.; Tahara, M.; Inamura, T.; Hosoda, H. Fundamental Investigations of the Deformation Behavior of Single-Crystal Ni-Mn-Ga Alloys and Their Polymer Composites via the Introduction of Various Fields. Appl. Sci. 2023, 13, 8475. [Google Scholar] [CrossRef]

- Chiu, W.-T.; Okuno, M.; Tahara, M.; Inamura, T.; Hosoda, H. Investigations of the Crystallographic Orientation on the Martensite Variant Reorientation of the Single-Crystal Ni-Mn-Ga Cube and Its Composites for Actuator Applications. Actuators 2023, 12, 211. [Google Scholar] [CrossRef]

- Sratong-on, P.; Chernenko, V.; Hosoda, H. Influence of internal stress on magnetostrain effect in Ni–Mn–Ga/polymer composite. Results Mater. 2019, 2, 100037. [Google Scholar] [CrossRef]

- Righi, L.; Albertini, F.; Pareti, L.; Paoluzi, A.; Calestani, G. Commensurate and incommensurate “5M” modulated crystal structures in Ni–Mn–Ga martensitic phases. Acta Mater. 2007, 55, 5237–5245. [Google Scholar] [CrossRef]

- Jiang, C.; Muhammad, Y.; Deng, L.; Wu, W.; Xu, H. Composition dependence on the martensitic structures of the Mn-rich NiMnGa alloys. Acta Mater. 2004, 52, 2779–2785. [Google Scholar] [CrossRef]

- Okamoto, N.; Fukuda, T.; Kakeshita, T. Magnetocrystalline anisotropy and twinning stress in Ni-Mn-Ga ferromagnetic shape memory alloys. J. Phys. Conf. Ser. 2006, 51, 315–318. [Google Scholar] [CrossRef]

- Heczko, O.; Straka, L.; Novak, V.; Fähler, S. Magnetic anisotropy of nonmodulated Ni–Mn–Ga martensite revisited. J. Appl. Phys. 2010, 107, 09A914. [Google Scholar] [CrossRef]

- Mandal, K.; Pal, D.; Scheerbaum, N.; Lyubina, J.; Gutfleisch, O. Effect of pressure on the magnetocaloric properties of nickel-rich Ni–Mn–Ga Heusler alloys. J. Appl. Phys. 2009, 105, 073509. [Google Scholar] [CrossRef]

- Fukuda, T.; Kakeshita, T. Magnetic Field-Induced Strain in Ferromagnetic Shape Memory Alloys Fe-31.2Pd, Fe3Pt, and Ni2MnGa. In Disorder and Strain-Induced Complexity in Functional Materials; Springer Series in Materials Science; Kakeshita, T., Fukuda, T., Saxena, A., Planes, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2011; Volume 148. [Google Scholar] [CrossRef]

- Straka, L.; Heczko, O. Magnetic anisotropy in Ni–Mn–Ga martensites. J. Appl. Phys. 2023, 93, 8636–8638. [Google Scholar] [CrossRef]

| (a) Silicone rubbers and the corresponding curing agent catalyst used in this study | ||||||

| Serial umber | M4400 | M8520 | SLJ3220 | M8012 | M8017 | M4470 |

| Hardness Shore A | 23 | 27 | 35 | 45 | 50 | 60 |

| Curing agent catalyst | T40 | T40 | T47 | T40 | T40 | T40 |

| Silicone:Catalyst (wt.%) | 100:3 | 100:4 | 100:4 | 100:4 | 100:4 | 100:3 |

| (b) Volume percentage of the M8017 silicone rubber (Hardness Shore A = 50) and the PFP | ||||||

| M8017 silicone rubber (vol.%) | 100 | 90 | 80 | 70 | 60 | 50 |

| PFP (vol.%) | 0 | 10 | 20 | 30 | 40 | 50 |

| Factor | Commencement of Magnetic Field-Induced MVR | Accumulated Magnetization Change | Reference |

|---|---|---|---|

| (a) Elastic modulus (solid) | X | O | This study |

| (b) Elastic modulus (porous) | O | O | This study |

| (c) Volume fraction of Ni–Mn–Ga alloy | O | O | [36,37] |

| Silicone Rubber Type | Elastic Modulus (MPa) | Displacement (μm) | Deformation (%) |

|---|---|---|---|

| (a) M8520 (Hardness Shore A = 27) | 1.56 | 22 | 0.60 |

| (b) M8012 (Hardness Shore A = 45) | 1.95 | 25 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chiu, W.-T.; Watanabe, Y.; Tahara, M.; Inamura, T.; Hosoda, H. Investigations of Shape Deformation Behaviors of the Ferromagnetic Ni–Mn–Ga Alloy/Porous Silicone Rubber Composite towards Actuator Applications. Micromachines 2023, 14, 1604. https://doi.org/10.3390/mi14081604

Chiu W-T, Watanabe Y, Tahara M, Inamura T, Hosoda H. Investigations of Shape Deformation Behaviors of the Ferromagnetic Ni–Mn–Ga Alloy/Porous Silicone Rubber Composite towards Actuator Applications. Micromachines. 2023; 14(8):1604. https://doi.org/10.3390/mi14081604

Chicago/Turabian StyleChiu, Wan-Ting, Yui Watanabe, Masaki Tahara, Tomonari Inamura, and Hideki Hosoda. 2023. "Investigations of Shape Deformation Behaviors of the Ferromagnetic Ni–Mn–Ga Alloy/Porous Silicone Rubber Composite towards Actuator Applications" Micromachines 14, no. 8: 1604. https://doi.org/10.3390/mi14081604

APA StyleChiu, W.-T., Watanabe, Y., Tahara, M., Inamura, T., & Hosoda, H. (2023). Investigations of Shape Deformation Behaviors of the Ferromagnetic Ni–Mn–Ga Alloy/Porous Silicone Rubber Composite towards Actuator Applications. Micromachines, 14(8), 1604. https://doi.org/10.3390/mi14081604