Energy Prediction Models and Distributed Analysis of the Grinding Process of Sustainable Manufacturing

Abstract

1. Introduction

2. Integrated Energy Prediction Model

2.1. Energy Flow Analysis during Grinding

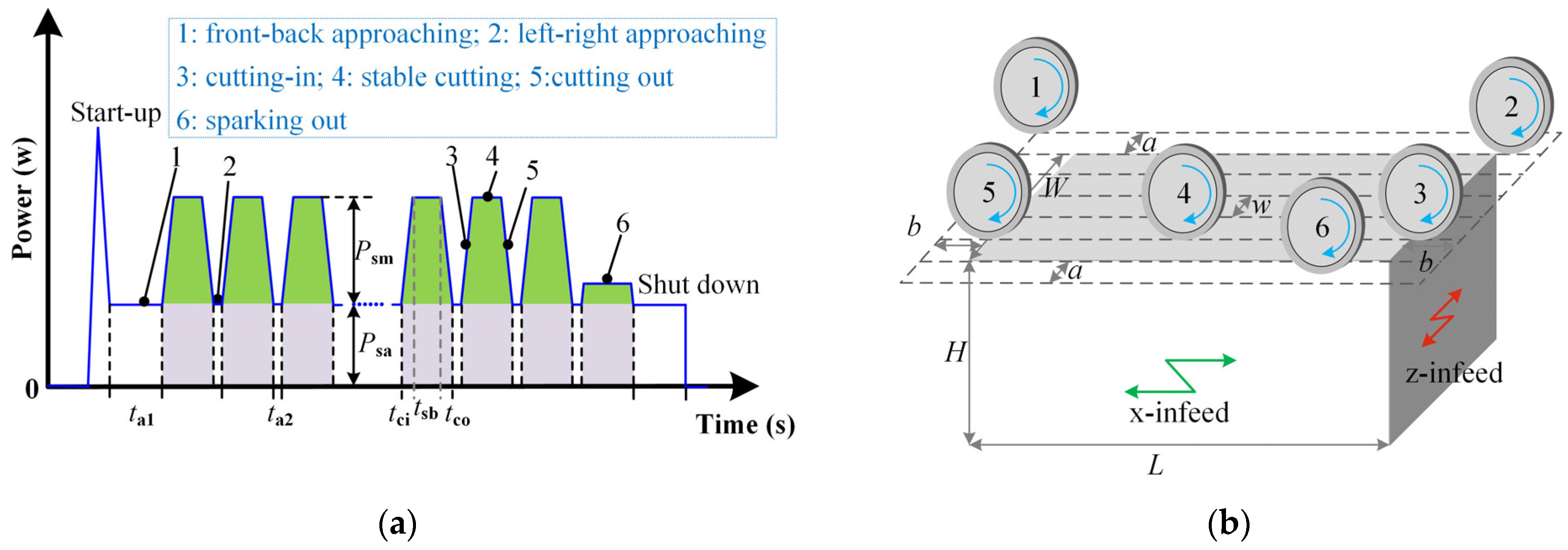

2.2. Energy Modelling of Wheel Air Cutting Rotation and Material Removal

2.3. Energy Modelling of x-Infeed

2.4. Energy Modelling of y- and z-Infeed

2.5. Energy Modelling of the Electric Controller and Cooling System

3. Parameters for Grinding Energy Models

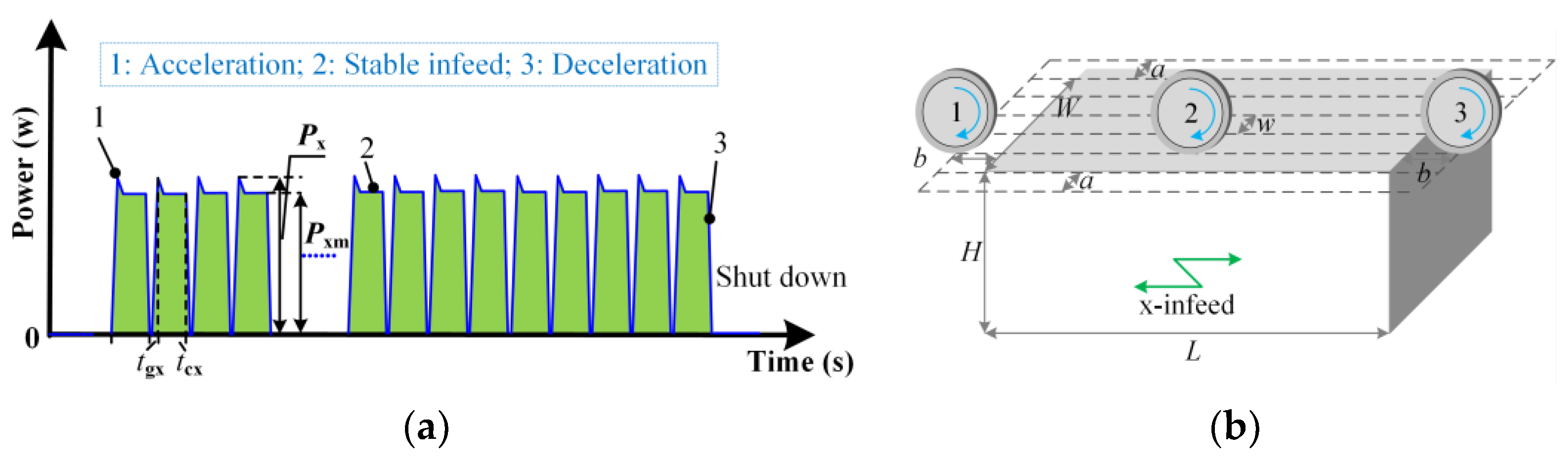

3.1. Grinding Experiment Setup

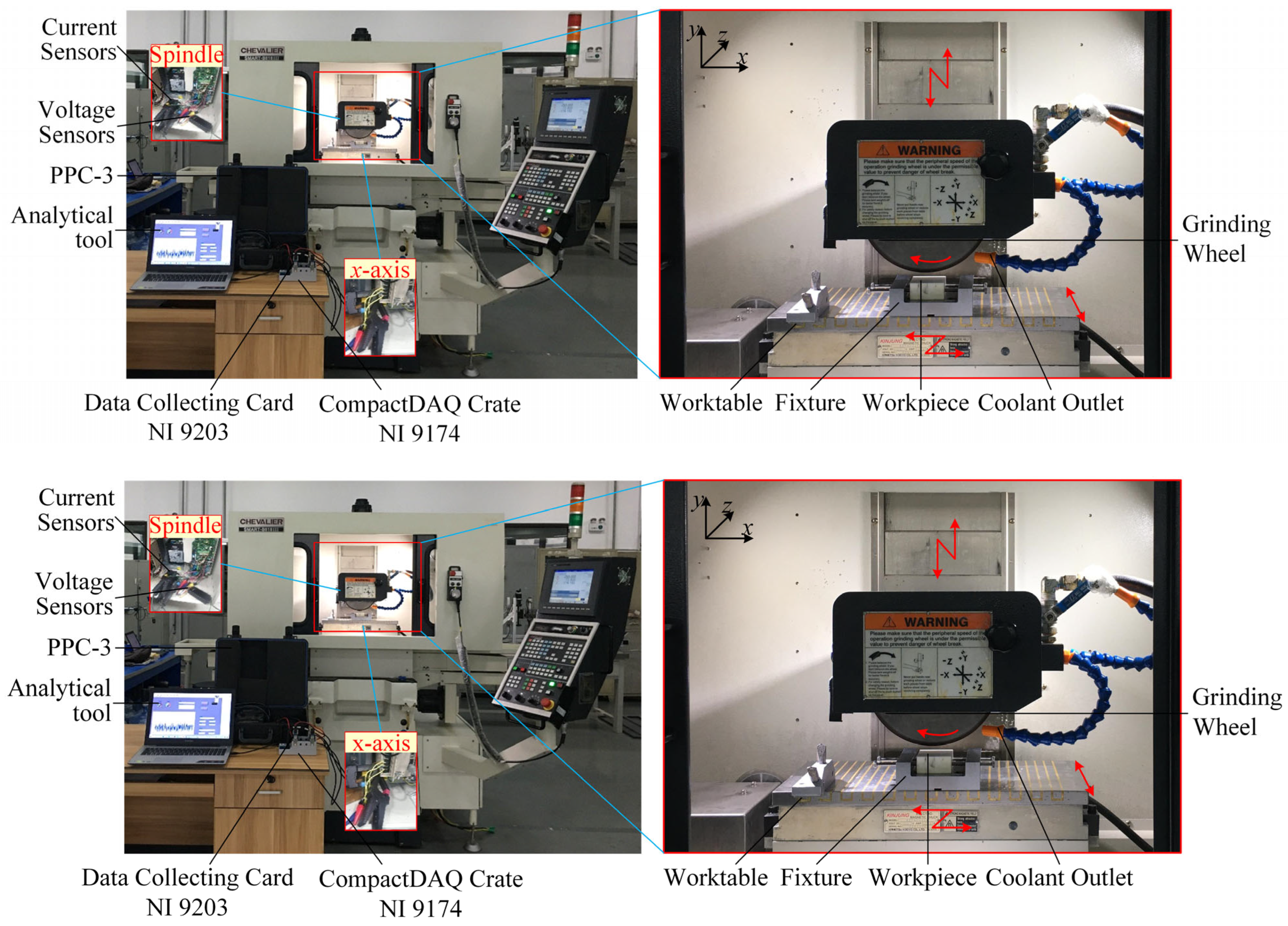

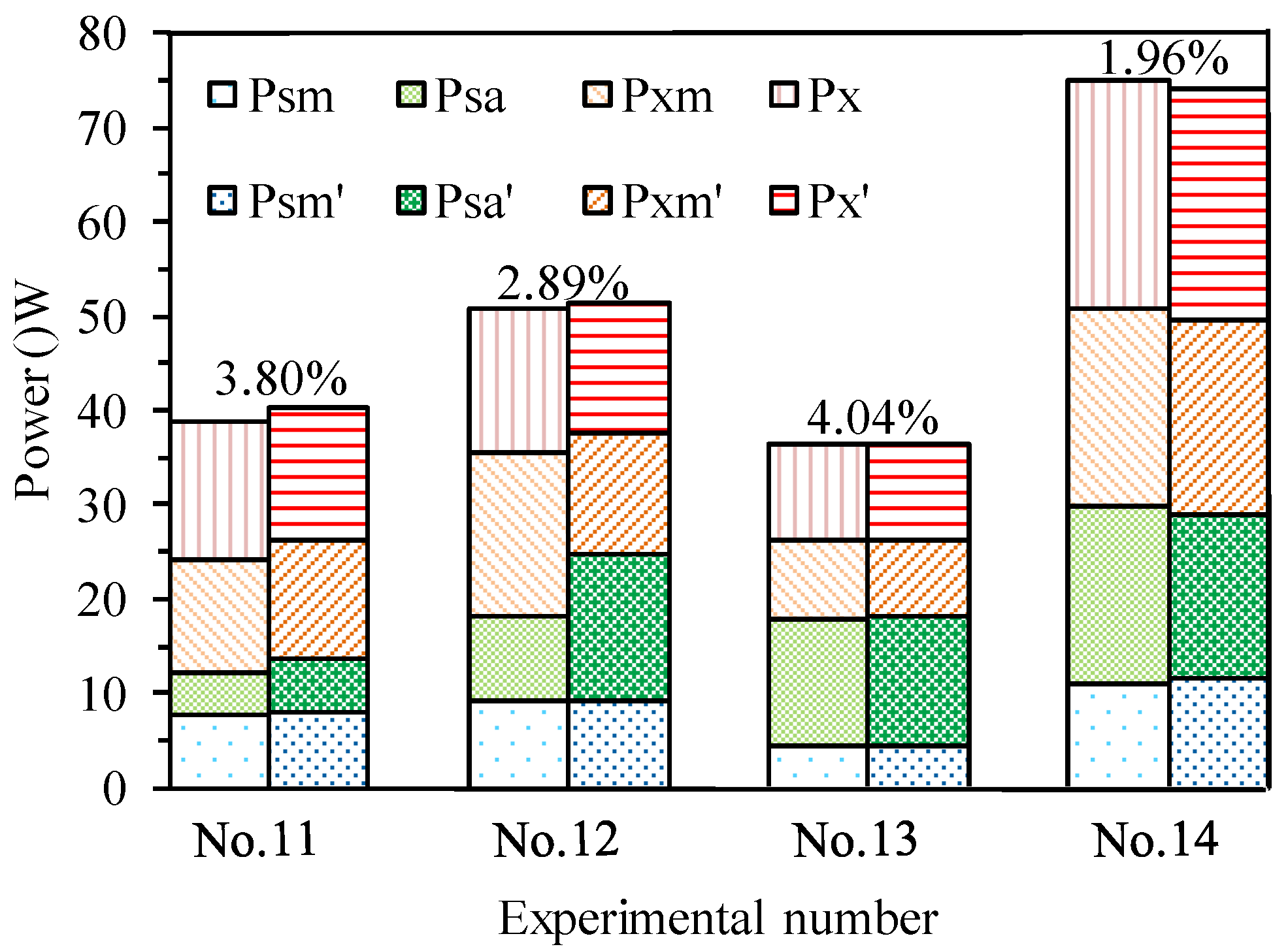

3.2. Experimental Results

3.3. Parameter Studies and Model Verification

4. Energy Distribution Analysis and Discussion

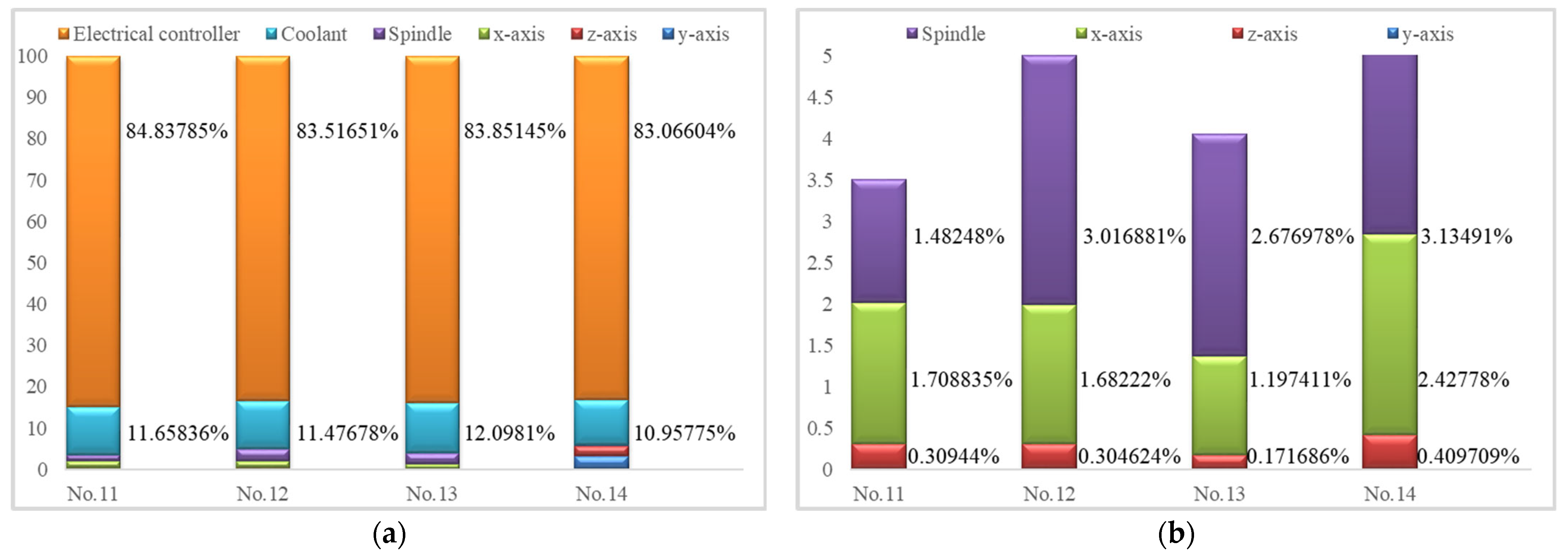

4.1. Energy Distribution Analysis and Discussion of Different Components

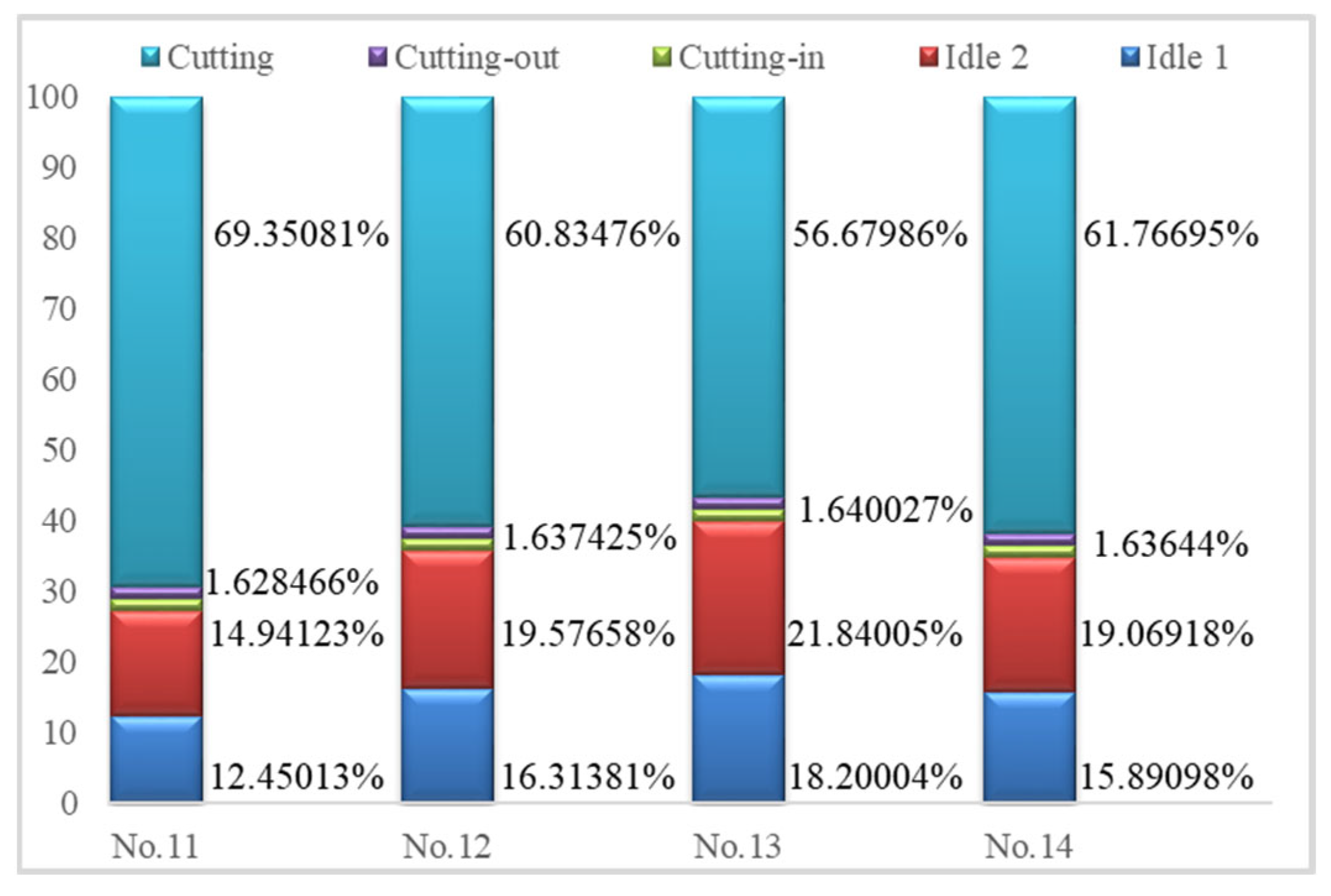

4.2. Energy Distribution Analysis and Discussion of Wheel Spindle in Different Machining Stages

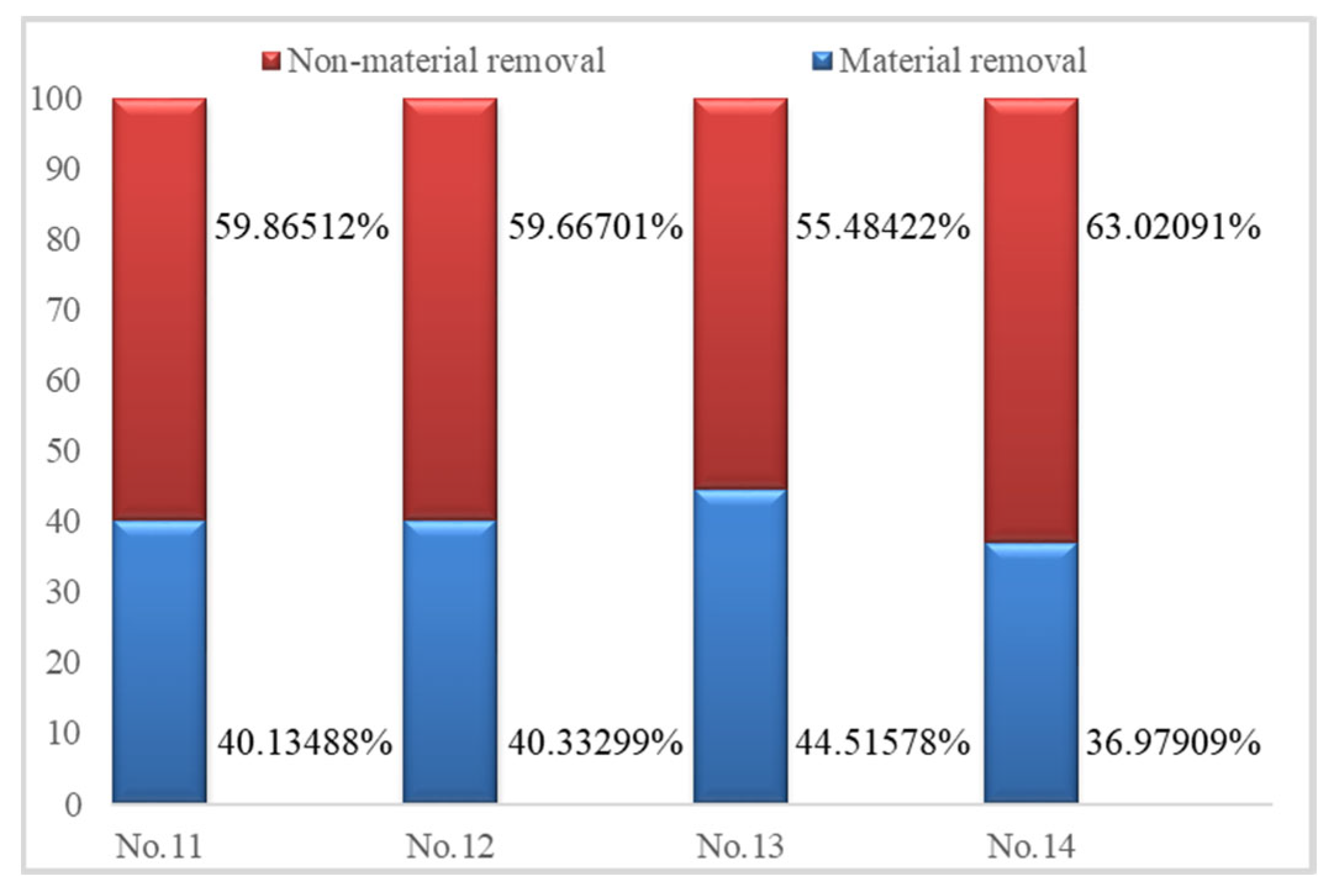

4.3. Energy Efficiency Analysis and Improvement Strategies

5. Conclusions

- (1)

- Predicted power and energy errors compared with measured values were kept within 5%. The integrated energy model is regarded as acceptable for further energy distribution and efficiency analysis.

- (2)

- More than 90% of electrical energy is wasted on two auxiliary systems: electrical controlling and cooling. Energy-saving chips, lightweight worktable utilization, and minimal lubricant quantity techniques are recommended in the next-generation design of grinders.

- (3)

- Grinding parameters have a larger effect on the energy distribution of both the spindle and the x-axis system. A larger workpiece infeed speed is desired to improve both energy-saving and process efficiency.

- (4)

- Energy efficiency reaches 36–45% (over a general level in machining) due to more grinding strokes; it may increase grinding time. A novel balance between energy efficiency, process time, and surface quality should be studied in depth.

6. Patents

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, M.; Wang, E.Z.; Hou, Y. The relationship between manufacturing growth and CO2 emissions: Does renewable energy consumption matter? Energy 2021, 232, 121032. [Google Scholar] [CrossRef]

- Cosgrove, J.; Duarte, M.-J.R.; Littlewood, J.; Wilgeroth, P. An energy mapping methodology to reduce energy consumption in manufacturing operations. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2018, 232, 1731–1740. [Google Scholar] [CrossRef]

- Park, C.W.; Kwon, K.S.; Kim, W.B.; Min, B.-K.; Park, S.-J.; Sung, I.-H.; Yoon, Y.S.; Lee, K.-S.; Lee, O.-H.; Seok, J. Energy consumption reduction technology in manufacturing—A selective review of policies, standards, and research. Int. J. Precis. Eng. Manuf. 2009, 10, 151–173. [Google Scholar] [CrossRef]

- Moradnazhad, M.; Unver, H.O. Energy efficiency of machining operations: A review. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2017, 231, 1871–1889. [Google Scholar] [CrossRef]

- Camposeco-Gegrete, C.; Calderon-Najera, J.D.D. Sustainable machining as a mean of reducing the environmental impacts related to the energy consumption of the machine tool: A case study of AISI 1045 steel machining. Int. J. Adv. Manuf. Technol. 2019, 102, 27–41. [Google Scholar] [CrossRef]

- Zhou, L.; Li, J.; Li, F.; Meng, Q.; Li, J.; Xu, X. Energy consumption model and energy efficiency of machine tools: A comprehensive literature review. J. Clean. Prod. 2016, 112, 3721–3734. [Google Scholar] [CrossRef]

- Babe, I.B.; Gupta, K.; Chaubey, S.K. Sustainable dry machining of stainless steel with microwave-treated tungsten carbide cutting tools. Micromachines 2023, 14, 1148. [Google Scholar] [CrossRef] [PubMed]

- Tuo, J.; Liu, F.; Liu, P.; Zhang, H.; Cai, W. Energy efficiency evaluation for machining systems through virtual part. Energy 2018, 159, 172–183. [Google Scholar] [CrossRef]

- Li, L.; Zhang, B.; Sun, Z. Research report on green and low-carbon development of superhard material industry. Diam. Abras. Eng. 2023, 43, 10–13. [Google Scholar]

- Liu, P.; Liu, F.; Qiu, H. A novel approach for acquiring the real-time energy efficiency of machine tools. Energy 2017, 121, 524–532. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Tang, W.; Liu, Y.; Zhang, Y.; Jia, S. An investigation into reducing the spindle acceleration energy consumption of machine tools. J. Clean. Prod. 2017, 143, 794–803. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, Z.; He, Y.; Cao, H.; Guo, Y. Energy consumption in machining: Classification, prediction, and reduction strategy. Energy 2017, 133, 142–157. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Jia, S.; Liu, Y. Experimental study on energy consumption of computer numerical control machine tools. J. Clean. Prod. 2016, 112, 3864–3874. [Google Scholar] [CrossRef]

- Shang, Z.; Gao, D.; Jiang, Z.; Lu, Y. Towards less energy intensive heavy-duty machine tools: Power consumption characteristics and energy-saving strategies. Energy 2019, 178, 263–276. [Google Scholar] [CrossRef]

- Liu, P.; Zhang, Z.; Wang, X.; Li, X.; Wang, X.V.; Tuo, J. A generalized method for the inherent energy performance modeling of machine tools. J. Manuf. Syst. 2021, 61, 406–422. [Google Scholar] [CrossRef]

- Feng, C.; Huang, Y.; Wu, Y.; Zhang, J. Feature-based optimization method integrating sequencing and cutting parameters for minimizing energy consumption of CNC machine tools. Int. J. Adv. Manuf. Technol. 2022, 121, 503–515. [Google Scholar] [CrossRef]

- Avram, O.I.; Xirouchakis, P. Evaluating the use phase energy requirements of a machine tool system. J. Clean. Prod. 2011, 19, 699–711. [Google Scholar] [CrossRef]

- Liu, W.; Li, L.; Cai, W.; Li, C.; Li, L.; Chen, X.; Sutherland, J.W. Dynamic characteristics and energy consumption modelling of machine tools based on bond graph theory. Energy 2020, 212, 118767. [Google Scholar] [CrossRef]

- Duflou, J.R.; Sutherland, J.W.; Dornfeld, D.; Herrmann, C.; Jeswiet, J.; Kara, S.; Hauschild, M.Z.; Kellens, K. Towards energy and resource efficient manufacturing: A processes and systems approach. CIRP Ann.-Manuf. Technol. 2012, 61, 587–609. [Google Scholar] [CrossRef]

- Schudeleit, T.; Züst, S.; Wegener, K. Methods for evaluation of energy efficiency of machine tools. Energy 2015, 93, 196470. [Google Scholar] [CrossRef]

- Li, G.; Ding, S. Machining of medical device components. In Metallic Biomaterials Processing and Medical Device Manufacturing; Woodhead Publishing: Sawston, UK, 2020; pp. 137–157. [Google Scholar]

- Li, J.L.R.A. A review on machining and optimization of particle-reinforced metal matrix composites. Int. J. Adv. Manuf. Technol. 2019, 100, 2929–2943. [Google Scholar] [CrossRef]

- Jia, S.; Yuan, Q.; Cai, W.; Li, M.; Li, Z. Energy modeling method of machine-operator system for sustainable machining. Energy Convers. Manag. 2018, 172, 265–276. [Google Scholar] [CrossRef]

- Lv, J.; Tang, R.; Tang, W.; Jia, S.; Liu, Y.; Cao, Y. An investigation into methods for predicting material removal energy consumption in turning. J. Clean. Prod. 2018, 193, 128–139. [Google Scholar] [CrossRef]

- Yip, W.; To, S. Energy consumption modeling of ultra-precision machining and the experimental validation. Energy 2020, 196, 117018. [Google Scholar] [CrossRef]

- Shi, K.; Ren, J.; Wang, S.; Liu, N.; Liu, Z.; Zhang, D.; Lu, W. An improved cutting power-based model for evaluating total energy consumption in general end milling process. J. Clean. Prod. 2019, 231, 1330–1341. [Google Scholar] [CrossRef]

- Shin, S.; Woo, J.; Rachuri, S. Energy efficiency of milling machining: Component modeling and online optimization of cutting parameters. J. Clean. Prod. 2017, 161, 12–29. [Google Scholar] [CrossRef]

- Jia, S.; Cai, W.; Liu, C.; Zhang, Z.; Bai, S.; Wang, Q.; Li, S.; Hu, L. Energy modeling and visualization analysis method of drilling processes in the manufacturing industry. Energy 2021, 228, 120567. [Google Scholar] [CrossRef]

- Xiao, Q.; Li, C.; Tang, Y.; Pan, J.; Yu, J.; Chen, X. Multi-component energy modeling and optimization for sustainable dry gear hobbling. Energy 2019, 187, 115911. [Google Scholar] [CrossRef]

- Han, Y.; Liu, C.; Yu, M.; Jiang, L.; Zhu, W.; Qian, L.; Beaucamp, A. Material removal characteristics in submerged pulsating air jet polishing process. Int. J. Mech. Sci. 2023, 257, 108534. [Google Scholar] [CrossRef]

- Han, Y.; Zhu, W.L.; Zhang, L.; Beaucamp, A. Region adaptive scheduling for time-dependent processes with optimal use of machine dynamics. Int. J. Mach. Tools Manuf. 2020, 156, 103589. [Google Scholar] [CrossRef]

- Tian, Y.; Liu, F.; Wang, Y.; Wu, H. Development of portable power monitoring system and grinding analytical tool. J. Manuf. Process. 2017, 27, 188–197. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; Tian, Y.; Liu, Y.; Zhang, K. Methods of grinding power signal acquisition and dynamic power monitoring database establishment. Diam. Abras. Eng. 2022, 3, 356–363. [Google Scholar]

- Yoon, H.-S.; Kim, E.-S.; Kim, M.-S.; Lee, J.-Y.; Lee, G.-B.; Ahn, S.-H. Towards greener machine tools-A review on energy saving strategies and technologies. Renew. Sustain. Energy Rev. 2015, 48, 870–891. [Google Scholar] [CrossRef]

- Dogra, M.; Sharma, V.S.; Dureja, J.S.; Gill, S.S. Environment-friendly technological advancements to enhance the sustainability in surface grinding- A review. J. Clean. Prod. 2018, 197, 218–231. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Yu, T.; Zhao, J. Assessment and optimization of grinding process on AISI 1045 steel in terms of green manufacturing using orthogonal experimental design and grey relational analysis. J. Clean. Prod. 2020, 253, 119896. [Google Scholar] [CrossRef]

- Deng, Z.; Lv, L.; Li, S.; Wan, L.; Liu, W.; Yan, C.; Zhang, H. Study on the model of high efficiency and low carbon for grinding parameters optimization and its application. J. Clean. Prod. 2016, 137, 1672–1681. [Google Scholar] [CrossRef]

- Wu, W.; Li, C.; Yang, M.; Zhang, Y.; Jia, D.; Hou, Y.; Li, R.; Cao, H.; Han, Z. Specific energy and G ratio of grinding cemented carbide under different cooling and lubrication conditions. Int. J. Adv. Manuf. Technol. 2019, 105, 67–82. [Google Scholar] [CrossRef]

- Sinha, M.K.; Ghosh, S.; Paruchuri, V.R. Modelling of specific grinding energy for Inconel 718 superalloy. Proc. Inst. Mech. Eng. Part B-J. Eng. Manuf. 2017, 233, 443–460. [Google Scholar] [CrossRef]

- Wang, J.; Tian, Y.; Hu, X.; Li, Y.; Zhang, K.; Liu, Y. Predictive modelling and Pareto optimization for energy efficient grinding based on aANN-embedded NSGA II algorithm. J. Clean. Prod. 2021, 327, 129479. [Google Scholar] [CrossRef]

- Zhang, K.; Tian, Y.; Cong, J.; Liu, Y.; Yan, N.; Lu, T. Reduction grinding energy consumption by modified particle swarm optimization based on dynamic inertia weight. Diam. Abras. Eng. 2021, 41, 71–75. [Google Scholar]

- Wang, J.; Tian, Y.; Hu, X.; Han, J.; Liu, B. Integrated assessment and optimization of dual environmental and production objectives in grinding. Energy 2023, 272, 127046. [Google Scholar] [CrossRef]

- Zhang, K. Research on Intelligent Monitoring and Process Decision-Making Optimization of Grinding Power and Energy Consumption. Master’s Thesis, Shandong University of Technology, Zibo, China, 2021. [Google Scholar]

| Factors | Parameters |

|---|---|

| Machining mode | Plane grinding |

| Workpiece material | SiO2f/SiO2 ceramics |

| Coolant | Water-based |

| Workpiece size (mm) | 50 (L) × 50 (W) × 25 (H) |

| Grinding wheel geometry (mm) | 100 (R) × 10 (Wd) |

| Grinding width, w (mm) | 5 |

| Material removal, d (μm) | 12, 24, 36, 48 |

| Distance, a (mm) | 5 |

| Distance, b (mm) | 10 |

| Workpiece infeed speed, vw (m/min) | 1, 2, 3, 4 |

| Depth of cut, ap (μm) | 3, 6, 9, 12 |

| Wheel speed, vs (m/s) | 15, 20, 25, 30 |

| No. | Pe (W) | Pc (W) | Py (W) | Pz (W) |

|---|---|---|---|---|

| 1 | 443.623 | 65.781 | 0.923 | 16.017 |

| 2 | 438.888 | 67.520 | 0.947 | 16.889 |

| 3 | 438.900 | 66.580 | 0.947 | 14.581 |

| 4 | 436.142 | 67.143 | 0.997 | 16.330 |

| 5 | 431.938 | 68.081 | 0.889 | 16.255 |

| Average | 437.898 | 67.021 | 0.941 | 16.014 |

| No. | vs (m/s) | vw (m/min) | ap (μm) | Psm (W) | Psa (W) | Pxm (W) | Px (W) |

|---|---|---|---|---|---|---|---|

| 1 | 30 | 4 | 12 | 19.77 | 21.61 | 31.92 | 38.63 |

| 2 | 25 | 4 | 12 | 15.58 | 16.17 | 31.63 | 38.28 |

| 3 | 20 | 4 | 12 | 14.97 | 7.73 | 31.63 | 38.53 |

| 4 | 15 | 4 | 12 | 10.65 | 4.77 | 31.58 | 38.52 |

| 5 | 30 | 1 | 12 | 10.16 | 21.96 | 8.32 | 10.27 |

| 6 | 30 | 2 | 12 | 10.70 | 24.41 | 11.90 | 13.81 |

| 7 | 30 | 3 | 12 | 15.09 | 22.91 | 21.51 | 24.43 |

| 8 | 30 | 4 | 9 | 17.90 | 21.30 | 31.33 | 39.86 |

| 9 | 30 | 4 | 6 | 12.60 | 22.81 | 31.82 | 38.30 |

| 10 | 30 | 4 | 3 | 7.72 | 22.34 | 31.75 | 38.94 |

| Power | Coefficients | |||

|---|---|---|---|---|

| Psa | Asa | Bsa | ||

| −13.9620 | 1.1792 | |||

| Psm | λ | α | Β | χ |

| 0.1216 | −0.1986 | 0.6083 | 0.6014 | |

| Pxm | Ax | Bx | Cx | |

| 6.3500 | 0.1100 | 1.5500 | ||

| Px | η | ξ | Ψ | ω |

| 17.22 | −13.33 | 6.947 | −0.5679 | |

| No. | Grinding Parameters | Measured Values | Predicted Values | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| vs (m/s) | vw (m/min) | ap (μm) | Psm (W) | Psa (W) | Pxm (W) | Px (W) | Psm′ (W) | Psa′ (W) | Pxm′ (W) | Px′ (W) | |

| 11 | 16.7 | 2 | 12 | 7.73 | 4.36 | 12.19 | 14.43 | 7.88 | 5.73 | 12.77 | 13.80 |

| 12 | 25 | 2 | 9 | 9.20 | 17.25 | 12.54 | 13.81 | 9.16 | 15.52 | 12.77 | 13.80 |

| 13 | 23.4 | 1 | 6 | 4.50 | 13.43 | 8.23 | 10.27 | 4.47 | 13.63 | 8.01 | 10.27 |

| 14 | 26.7 | 3 | 8 | 11.10 | 18.67 | 20.96 | 24.19 | 11.52 | 17.52 | 20.63 | 24.41 |

| No. | Es (J) | Ex (J) | Ey (J) | Ez (J) | Ee (J) | Ec (J) | Etotal (J) |

|---|---|---|---|---|---|---|---|

| 11 | 1104.487 | 1273.128 | 2.256 | 230.544 | 63,206.49 | 8685.792 | 74,502.69 |

| 12 | 2283.218 | 1273.128 | 2.256 | 230.544 | 63,206.49 | 8685.792 | 75,681.42 |

| 13 | 3594.717 | 1607.916 | 2.256 | 230.544 | 112,601.6 | 16,245.65 | 134,282.7 |

| 14 | 1764.019 | 1366.116 | 2.256 | 230.544 | 46,741.446 | 6165.84 | 56,270.221 |

| No. | Ea1 (J) | Ea2 (J) | Eci (J) | Eco (J) | Ecu (J) | Esm (J) | Es (J) |

|---|---|---|---|---|---|---|---|

| 11 | 137.52 | 165.024 | 17.9862 | 17.9862 | 765.9708 | 801.9432 | 1104.4872 |

| 12 | 372.48 | 446.976 | 37.386 | 37.386 | 1388.9904 | 1463.7624 | 2283.2184 |

| 13 | 654.24 | 785.088 | 58.95434 | 58.95434 | 2037.4808 | 2155.38948 | 3594.71748 |

| 14 | 280.32 | 336.384 | 28.8672 | 28.8672 | 1089.5808 | 1147.3152 | 1764.0192 |

| No. | Emrr (J) | En-mrr (J) | Etotal (J) |

|---|---|---|---|

| 11 | 29,901.564 | 44,601.1292 | 74,502.6932 |

| 12 | 30,524.5836 | 45,156.8408 | 75,681.4244 |

| 13 | 59,776.98504 | 74,505.70244 | 134,282.6875 |

| 14 | 20,808.2168 | 35,462.0044 | 56,270.2212 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Y.; Wang, J.; Hu, X.; Song, X.; Han, J.; Wang, J. Energy Prediction Models and Distributed Analysis of the Grinding Process of Sustainable Manufacturing. Micromachines 2023, 14, 1603. https://doi.org/10.3390/mi14081603

Tian Y, Wang J, Hu X, Song X, Han J, Wang J. Energy Prediction Models and Distributed Analysis of the Grinding Process of Sustainable Manufacturing. Micromachines. 2023; 14(8):1603. https://doi.org/10.3390/mi14081603

Chicago/Turabian StyleTian, Yebing, Jinling Wang, Xintao Hu, Xiaomei Song, Jinguo Han, and Jinhui Wang. 2023. "Energy Prediction Models and Distributed Analysis of the Grinding Process of Sustainable Manufacturing" Micromachines 14, no. 8: 1603. https://doi.org/10.3390/mi14081603

APA StyleTian, Y., Wang, J., Hu, X., Song, X., Han, J., & Wang, J. (2023). Energy Prediction Models and Distributed Analysis of the Grinding Process of Sustainable Manufacturing. Micromachines, 14(8), 1603. https://doi.org/10.3390/mi14081603