Design of a Novel Axial Gas Pulses Micromixer and Simulations of its Mixing Abilities via Computational Fluid Dynamics

Abstract

1. Introduction

2. Materials and Methods

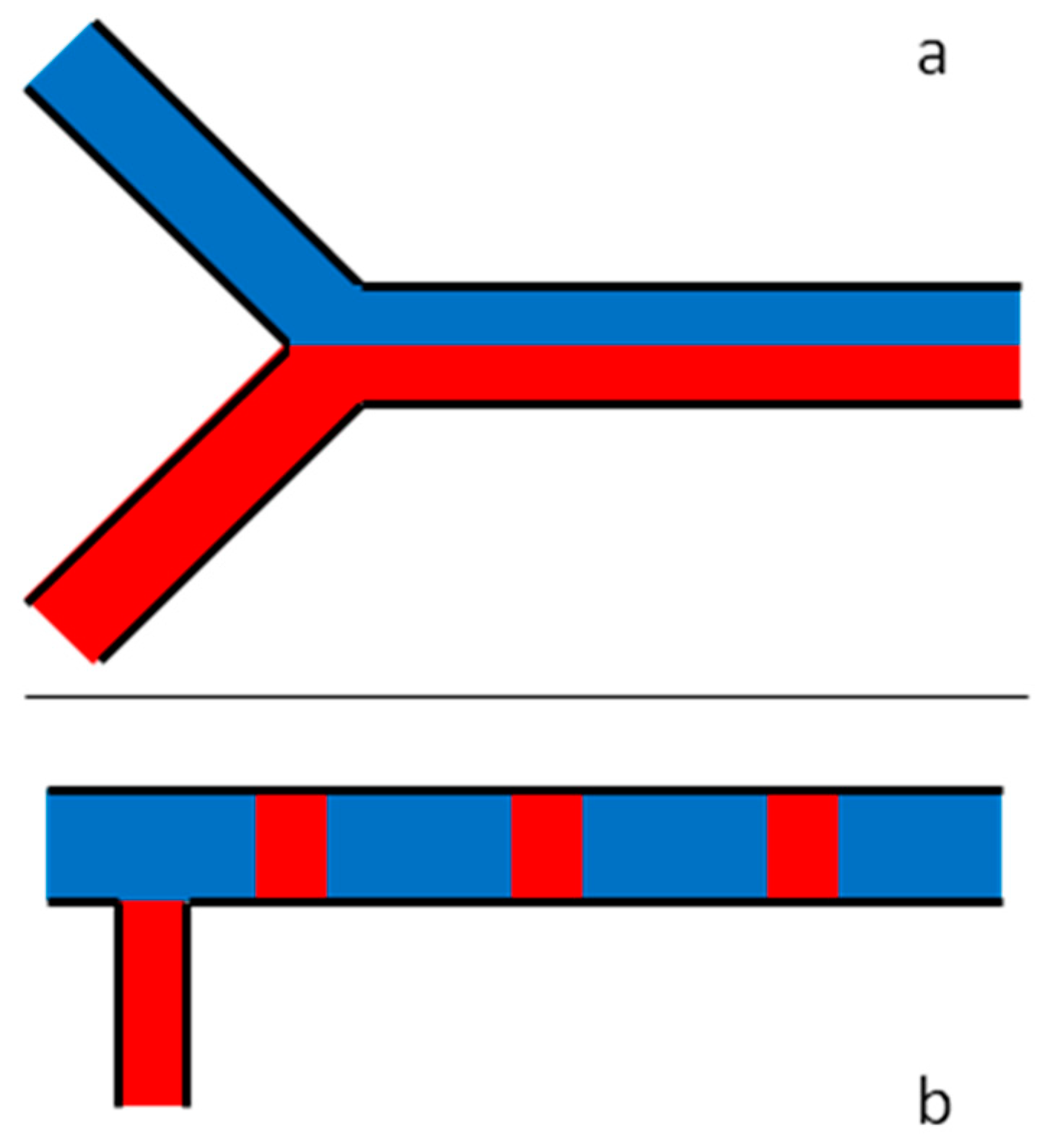

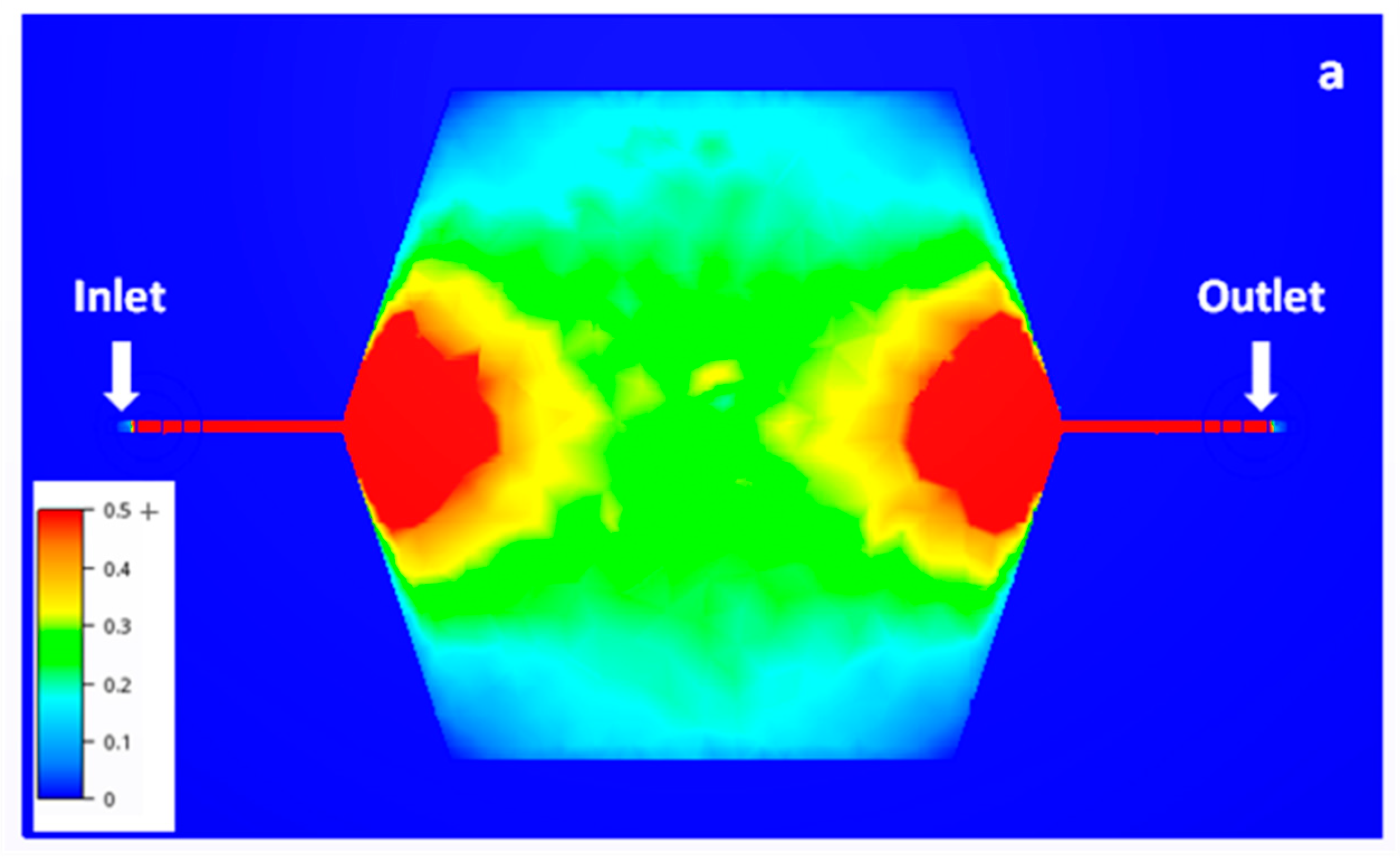

2.1. Design of the Microfluidic Chip

2.1.1. Technical Constraints and Objectives

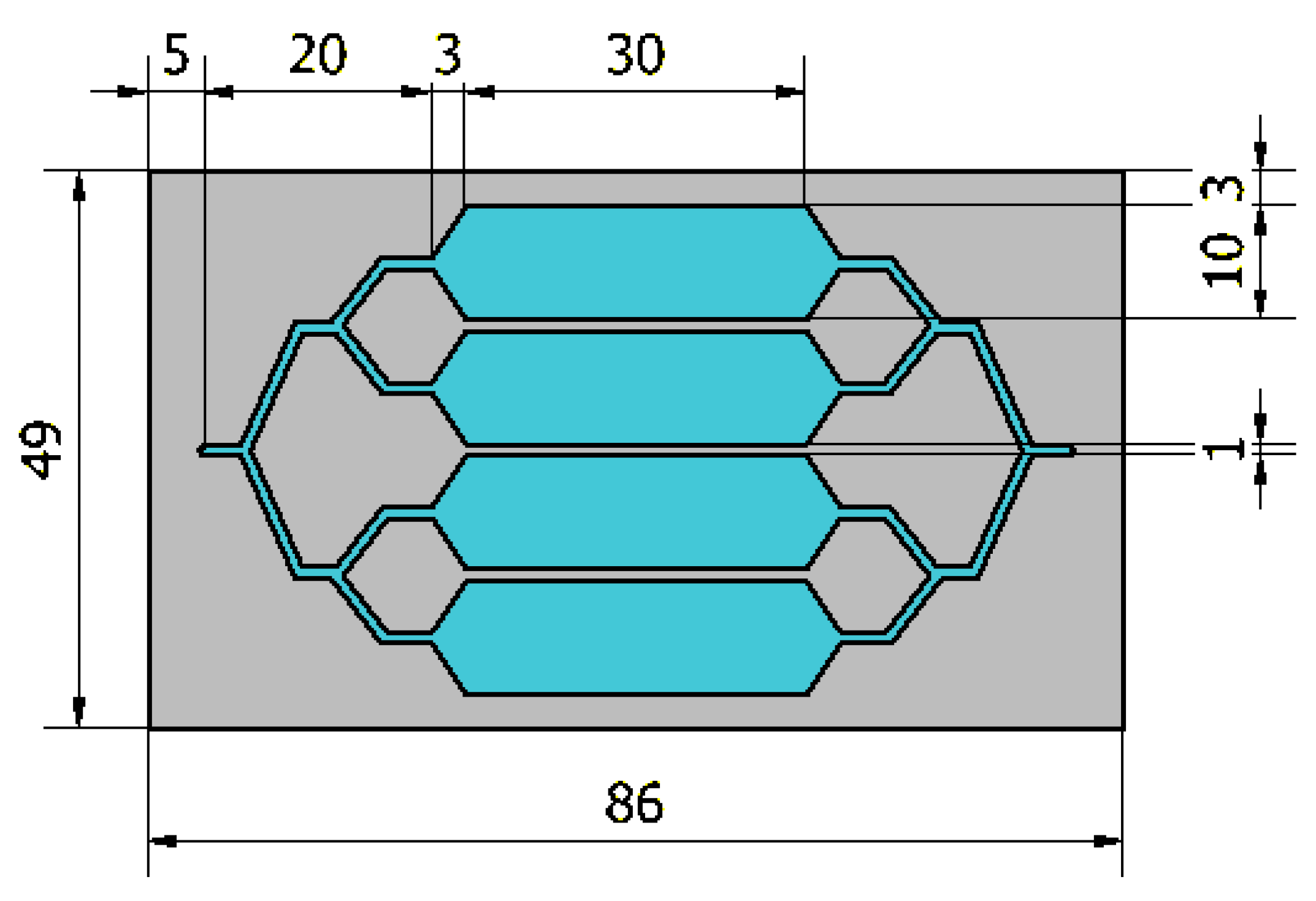

2.1.2. Strategy used to Design and Define the Mixing Microchip Pattern and Size

- -

- 5 mm between the inlet/outlet and the edges of the chip, to leave space for the fluidic connectors;

- -

- 8 mm for every flow division: 4 mm for splitting and 4 mm for redirecting the flow into the right direction;

- -

- 3 mm between channels and the walls of the chip;

- -

- 1 mm between channels.

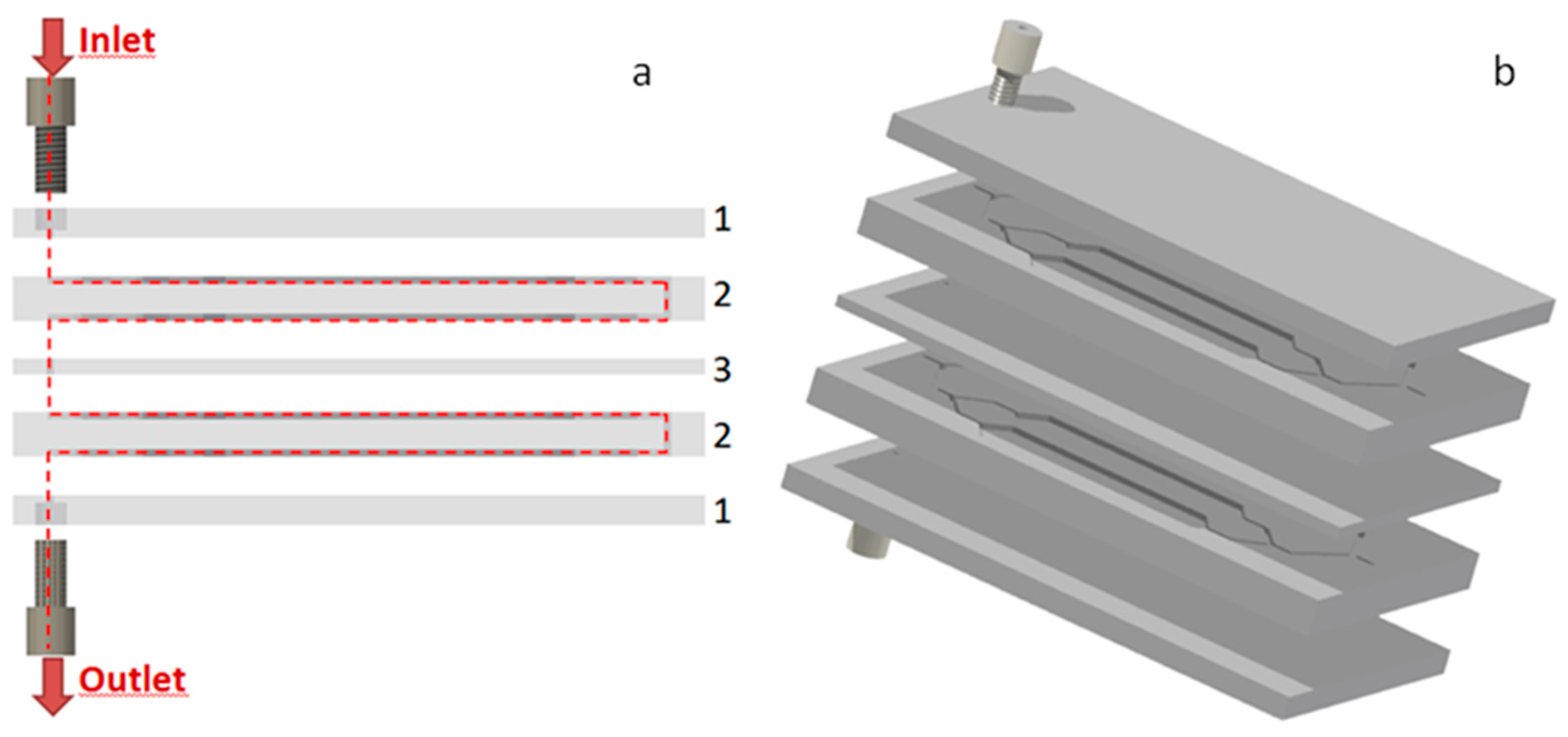

2.1.3. Elaboration of the Multi-Stage Micromixer

2.2. Methodology for Simulation of the Gas Flow and Mixing

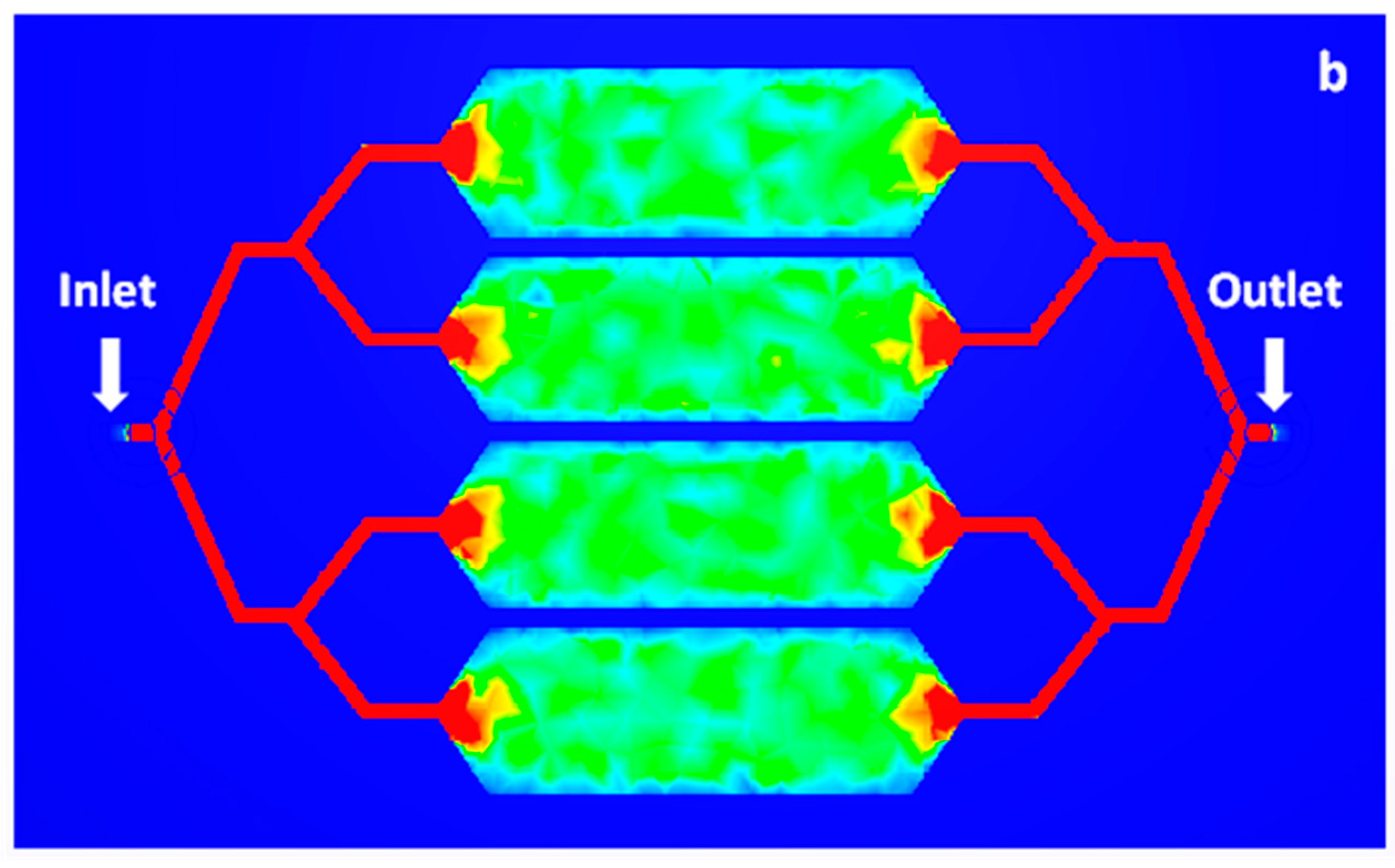

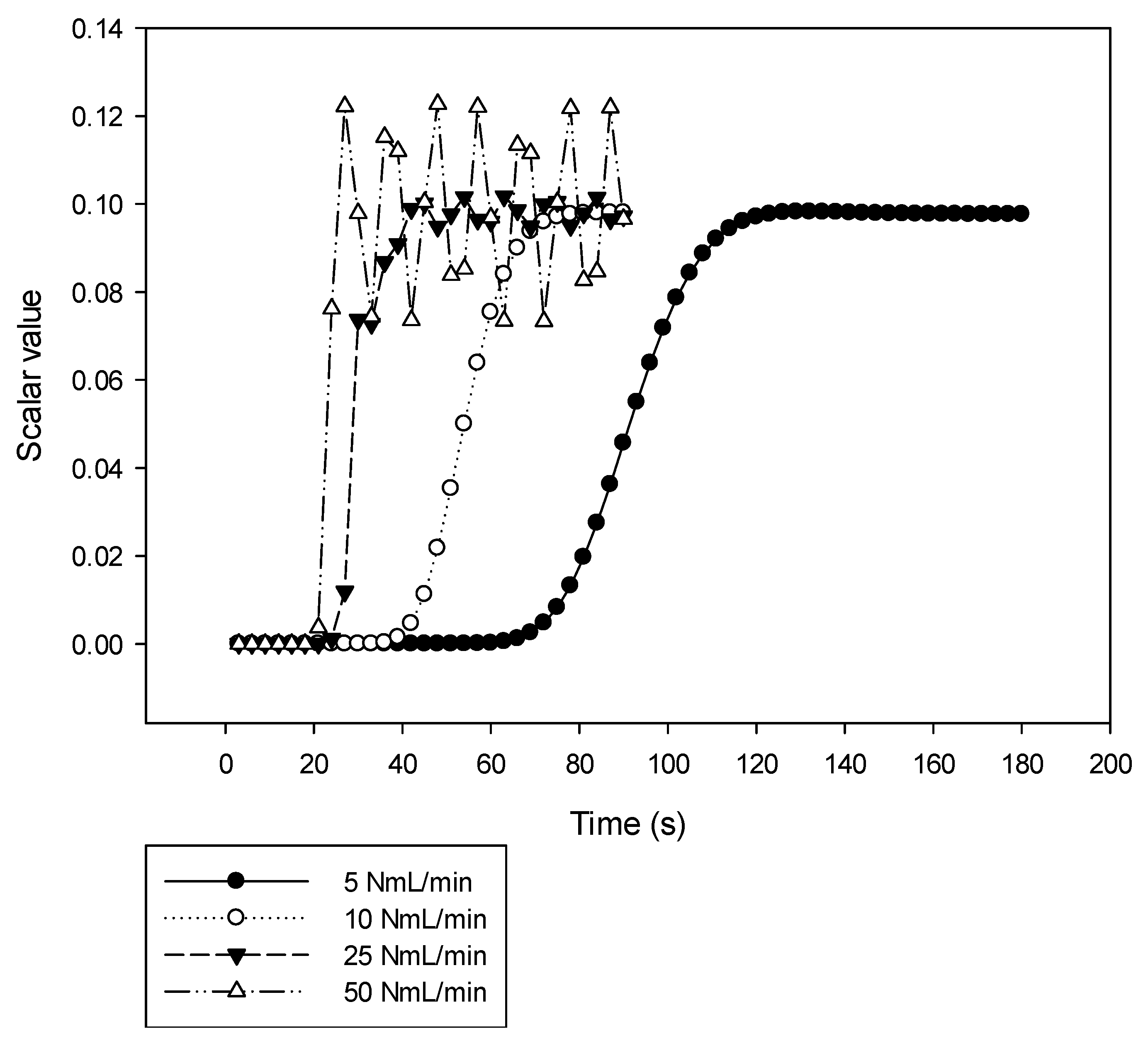

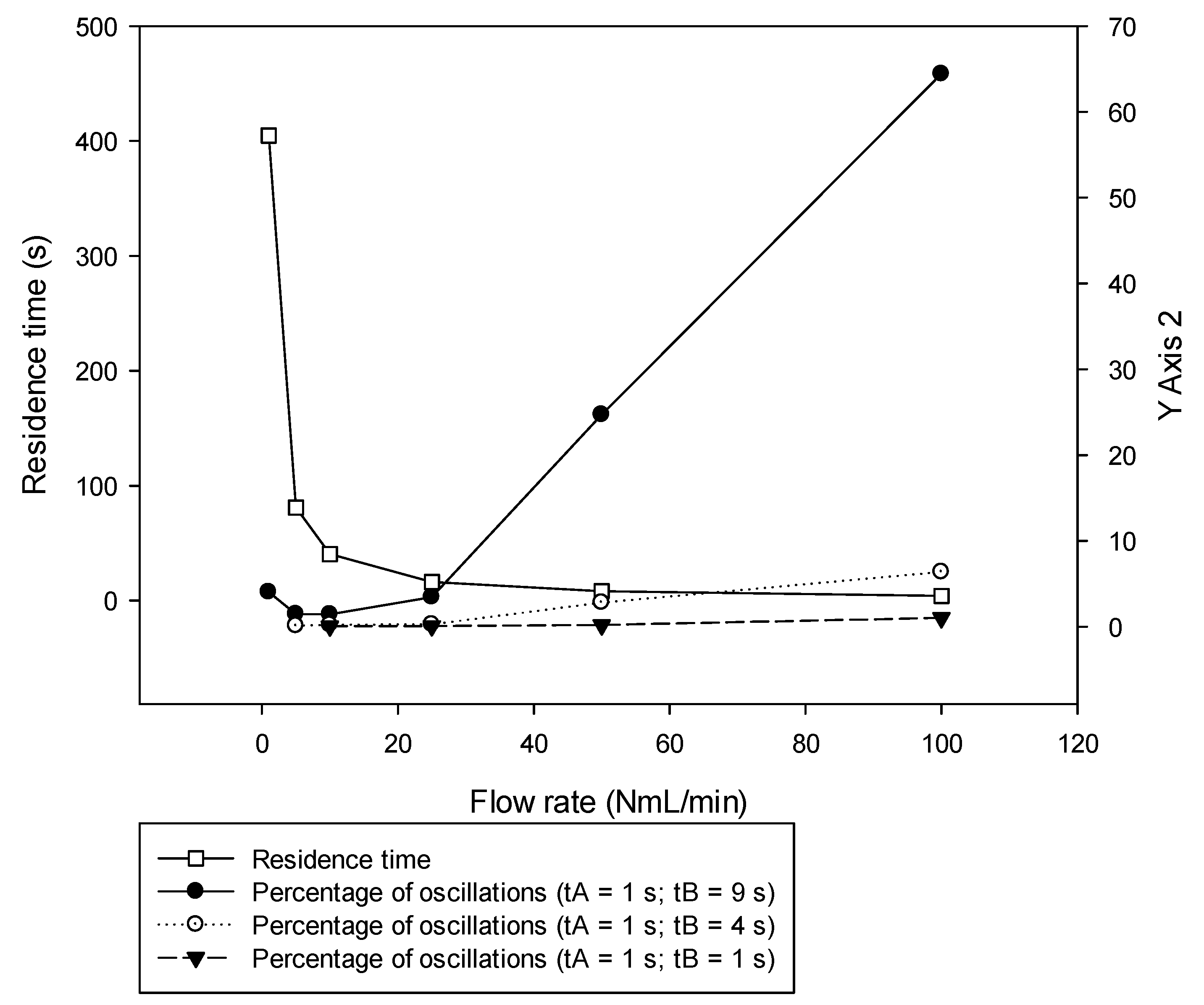

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Robbins, P.A.; Swanson, G.D.; Micco, A.J.; Schubert, W.P. A fast gas-mixing system for breath-to-breath respiratory control studies. J. Appl. Physiol. Respir. Environ. Exerc Physiol. 1982, 52, 1358–1362. [Google Scholar] [CrossRef] [PubMed]

- Dantas, H.V.; Barbosa, M.F.; Moreira, P.N.T.; Galvão, R.K.H.; Araújo, M.C.U. An automatic system for accurate preparation of gas mixtures. Microchem. J. 2015, 119, 123–127. [Google Scholar] [CrossRef]

- Continuous Flow Type Gas Blending Facility Used for Autonomous and System Diving—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S1876610217311748 (accessed on 17 December 2018).

- Fletcher, G.C.; Summers, G.; Corrigan, V.K.; Johanson, M.R.; Hedderley, D. Optimizing Gas Mixtures for Modified Atmosphere Packaging of Fresh King Salmon (Oncorhynchus tshawytscha). J. Aquat. Food Prod. Technol. 2005, 13, 5–28. [Google Scholar] [CrossRef]

- Hood, M.E. Gas Mixing Device for Draught Beer Dispensing. U.S. Patent 2,569,378, 25 Spetember 1951. [Google Scholar]

- Mvola, B.; Kah, P. Effects of shielding gas control: Welded joint properties in GMAW process optimization. Int. J. Adv. Manuf. Technol. 2017, 88, 2369–2387. [Google Scholar] [CrossRef]

- Shmelev, V.M.; Nikolaev, V. Propane conversion in a chemical compression reactor. Russ. J. Phys. Chem. B 2011, 5, 235–243. [Google Scholar] [CrossRef]

- Zethræus, B.; Adams, C.; Berge, N. A simple model for turbulent gas mixing in CFB reactors. Powder Technol. 1992, 69, 101–105. [Google Scholar] [CrossRef]

- Christensen, P.L.; Nielsen, J.; Kann, T. Methods to produce calibration mixtures for anesthetic gas monitors and how to perform volumetric calculations on anesthetic gases. J. Clin. Monit. Comput. 1992, 8, 279–284. [Google Scholar] [CrossRef]

- Martin, N.A.; Goody, B.A.; Wang, J.; Milton, M.J.T. Accurate and adjustable calibration gas flow by switching permeation and diffusion devices. Meas. Sci. Technol. 2012, 23, 105005. [Google Scholar] [CrossRef]

- Rosenberg, E.; Hallama, R.A.; Grasserbauer, M. Development and evaluation of a calibration gas generator for the analysis of volatile organic compounds in air based on the injection method. Fresenius J. Anal. Chem 2001, 371, 798–805. [Google Scholar] [CrossRef]

- Monsé, C.; Broding, H.; Hoffmeyer, F.; Jettkant, B.; Berresheim, H.; Brüning, T.; Bünger, J.; Sucker, K. Use of a Calibration Gas Generator for Irritation Threshold Assessment and As Supplement of Dynamic Dilution Olfactometry. Chem. Sens. 2010, 35, 523–530. [Google Scholar] [CrossRef]

- Pérez Ballesta, P.; Baldan, A.; Cancelinha, J. Atmosphere Generation System for the Preparation of Ambient Air Volatile Organic Compound Standard Mixtures. Anal. Chem. 1999, 71, 2241–2245. [Google Scholar] [CrossRef] [PubMed]

- Ricker, N.L.; Muller, C.J.; Craig, I.K. Fuel gas blending benchmark for economic performance evaluation of advanced control and state estimation. J. Process. Control. 2012, 22, 968–974. [Google Scholar] [CrossRef]

- Safdar, M.; Jänis, J.; Sánchez, S. Microfluidic fuel cells for energy generation. Lab Chip 2016, 16, 2754–2758. [Google Scholar] [CrossRef]

- Seong, G.H.; Crooks, R.M. Efficient Mixing and Reactions within Microfluidic Channels Using Microbead-Supported Catalysts. J. Am. Chem. Soc. 2002, 124, 13360–13361. [Google Scholar] [CrossRef] [PubMed]

- Shang, L.; Cheng, Y.; Zhao, Y. Emerging Droplet Microfluidics. Chem. Rev. 2017, 117, 7964–8040. [Google Scholar] [CrossRef] [PubMed]

- Zhu, P.; Wang, L. Passive and active droplet generation with microfluidics: A review. Lab. Chip 2016, 17, 34–75. [Google Scholar] [CrossRef]

- Christopher, G.F.; Anna, S.L. Microfluidic methods for generating continuous droplet streams. J. Phys. D Appl. Phys. 2007, 40, R319. [Google Scholar] [CrossRef]

- Baroud, C.N.; Willaime, H. Multiphase flows in microfluidics. C. R. Phys. 2004, 5, 547–555. [Google Scholar] [CrossRef]

- Zhao, C.-X.; Middelberg, A.P.J. Two-phase microfluidic flows. Chem. Eng. Sci. 2011, 66, 1394–1411. [Google Scholar] [CrossRef]

- Lee, C.-Y.; Chang, C.-L.; Wang, Y.-N.; Fu, L.-M. Microfluidic Mixing: A Review. Int. J. Mol. Sci. 2011, 12, 3263–3287. [Google Scholar] [CrossRef]

- Suh, Y.K.; Kang, S. A Review on Mixing in Microfluidics. Micromachines 2010, 1, 82–111. [Google Scholar] [CrossRef]

- Haas-Santo, K.; Pfeifer, P.; Schubert, K.; Zech, T.; Hönicke, D. Experimental evaluation of gas mixing with a static microstructure mixer. Chem. Eng. Sci. 2005, 60, 2955–2962. [Google Scholar] [CrossRef]

- Polinkovsky, M.; Gutierrez, E.; Levchenko, A.; Groisman, A. Fine temporal control of the medium gas content and acidity and on-chip generation of series of oxygen concentrations for cell cultures. Lab. Chip 2009, 9, 1073–1084. [Google Scholar] [CrossRef] [PubMed]

- Adler, M.; Polinkovsky, M.; Gutierrez, E.; Groisman, A. Generation of oxygen gradients with arbitrary shapes in a microfluidic device. Lab Chip 2010, 10, 388–391. [Google Scholar] [CrossRef] [PubMed]

- Lo, J.F.; Sinkala, E.; Eddington, D.T. Oxygen gradients for open well cellular cultures via microfluidic substrates. Lab Chip 2010, 10, 2394–2401. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.-Y.; Wan, S.-A.; Hu, Y.-H. Oxygen and nitrogen gases mixing in T-type micromixers visualized and quantitatively characterized using pressure-sensitive paint. Int. J. Heat Mass Transf. 2017, 111, 520–531. [Google Scholar] [CrossRef]

- Tesař, V.R.; Tippetts, J.; Low, Y.-Y. Oscillator Mixer for Chemical Microreactors. In Proceedings of the 9th International Symposium on Flow Visualization, Edinburgh, UK, 22–25 August 2000. [Google Scholar]

- Wilke, C.R.; Lee, C.Y. Estimation of Diffusion Coefficients for Gases and Vapors. Ind. Eng. Chem. 1955, 47, 1253–1257. [Google Scholar] [CrossRef]

- Squires, T.M.; Quake, S.R. Microfluidics: Fluid physics at the nanoliter scale. Rev. Mod. Phys. 2005, 77, 977–1026. [Google Scholar] [CrossRef]

- Faanes, A.; Skogestad, S. A systematic approach to the design of buffer tanks. Comput. Chem. Eng. 2000, 24, 1395–1401. [Google Scholar] [CrossRef]

- Tsao, C.-W. Polymer Microfluidics: Simple, Low-Cost Fabrication Process Bridging Academic Lab Research to Commercialized Production. Micromachines 2016, 7, 225. [Google Scholar] [CrossRef]

- Cussler, E.L. Diffusion: Mass Transfer in Fluid Systems, 2nd ed.; Cambridge University Press: New York, NY, USA, 1997; ISBN 978-0-521-45078-2. [Google Scholar]

- (PDF) Adsorption of Low-Concentration Formaldehyde from Air by Silver and Copper Nano-Particles Attached on Bamboo-Based Activated Carbon. Available online: https://www.researchgate.net/publication/271305127_Adsorption_of_Low-Concentration_Formaldehyde_from_Air_by_Silver_and_Copper_Nano-Particles_Attached_on_Bamboo-Based_Activated_Carbon (accessed on 8 January 2019).

- Gauf, A.; Navarro, C.; Balch, G.; Hargreaves, L.R.; Khakoo, M.A.; Winstead, C.; McKoy, V. Low-energy elastic electron scattering by acetaldehyde. Phys. Rev. A 2014, 89, 022708. [Google Scholar] [CrossRef]

- Weng, Y.; Qiu, S.; Ma, L.; Liu, Q.; Ding, M.; Zhang, Q.; Zhang, Q.; Wang, T. Jet-Fuel Range Hydrocarbons from Biomass-Derived Sorbitol over Ni-HZSM-5/SBA-15 Catalyst. Catalysts 2015, 5, 2147–2160. [Google Scholar] [CrossRef]

| Short Description/Technology Used | Approach | Applications | Type of Heterogeneity | Total Flow Rate (NmL·min−1) | Mixing Time (s) | Microchip Design | Reference |

|---|---|---|---|---|---|---|---|

| Fluids collision inducing oscillations for mixing liquids or gases | Experimental (liquids) | Fuel technology | Radial | - | - | Fixed | Tesař et al., 2000 [24] |

| Multilamination by using V-shaped microstructures | Experimental | Chemical reaction engineering | Radial | 1000–10,000 | 6 × 10−4 | Modular | Haas-Santo et al., 2005 [25] |

| Microchannels network generating discrete concentrations of O2 in N2 | Experimental | Biotechnology, cell culture | Radial | 16.2 | 4 | Fixed | Polinkovsky et al., 2009 [26] |

| Mixing of 9 gas flows at different O2 concentrations to create O2 concentration gradients | Experimental | Cell culture | Radial | 108 | 24 | Fixed | Adler et al., 2009 [27] |

| Diffusion between parallel flow channels through PDMS layer to create an O2 concentration gradient | Experimental | Cell culture | Radial | 80 | 20 | Modular | Lo et al., 2010 [28] |

| Splitting of the flow between inlet and outlet chambers, followed by a buffer tank | Modelling | Calibration gases generation | Axial | - | 120 | Fixed | Martin et al., 2012 [10] |

| Basic T-shaped mixer | Experimental | Microcombuster, fuel technology | Radial | 5–250 | 3.7 × 10−3 | Modular | Huang et al., 2017 [29] |

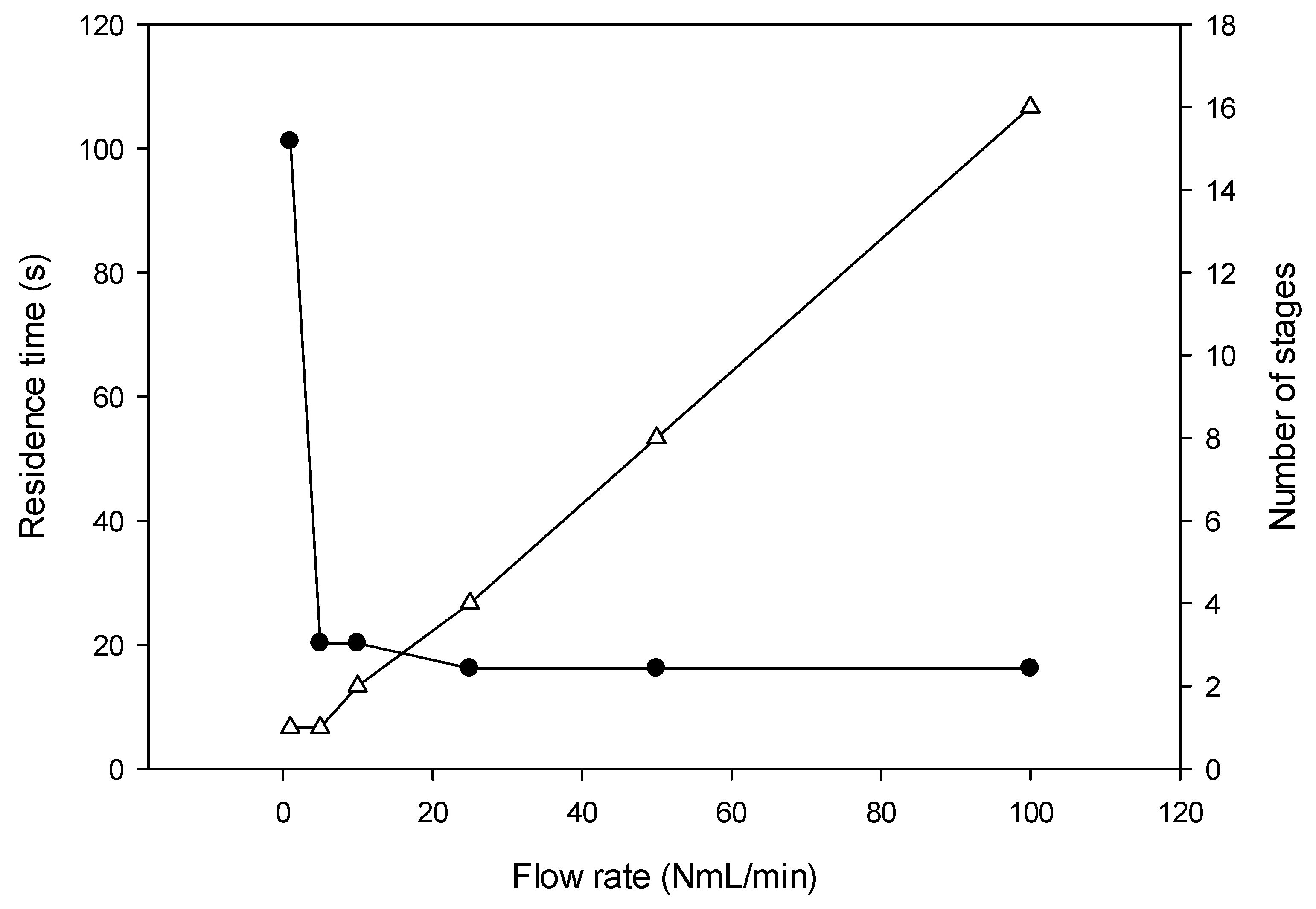

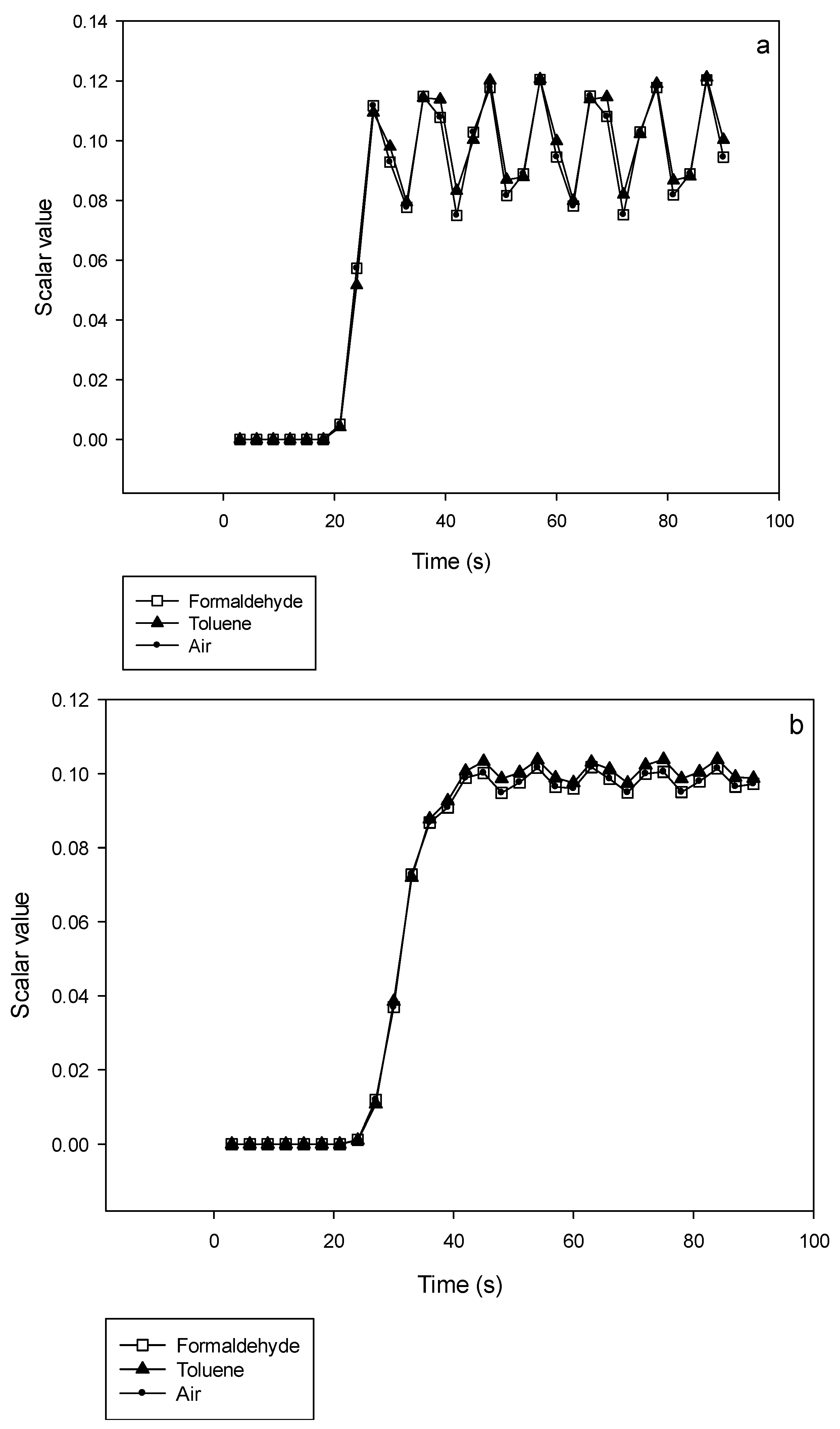

| Multistage mixing microchips for pulsed gas flow | Modelling | Gas mixture generation | Axial | 1–100 | 20 | Modular | This work |

| Gas | Molecular Weight (g·mol−1) | Kinetic Diameter σ (Å) | Diffusion Coefficient in Air (cm²·s−1) |

|---|---|---|---|

| Air | 28.97 | 3.71 [8] | 0.178 |

| Formaldehyde (HCHO) | 30.03 | 3.73 [35] | 0.176 |

| Acetaldehyde (CH3CHO) | 44.05 | 7.27 [36] | 0.074 |

| Benzene (C6H6) | 78.11 | 5.85 [37] | 0.089 |

| Toluene (C7H8) | 92.14 | 5.85 [37] | 0.087 |

| Ethylbenzene | 106.17 | 6.00 [37] | 0.083 |

| p-Xylene | 106.16 | 5.85 [37] | 0.086 |

| m-Xylene | 106.16 | 6.80 [37] | 0.071 |

| o-Xylene | 106.16 | 6.80 [37] | 0.071 |

| Naphthalene | 128.17 | 6.20 [37] | 0.078 |

| Flow Rate (NmL·min−1) | 1 | 5 | 10 | 25 | 50 | 100 | Total Volume (mL) |

|---|---|---|---|---|---|---|---|

| Number of Stages | |||||||

| 1 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 1.686 |

| 2 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 3.372 |

| 3 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 5.058 |

| 4 | ✓ | ✓ | ✓ | ✓ | ✓ | ✓ | 6.744 |

| 8 | ✕ | ✕ | ✕ | ✓ | ✓ | ✓ | 13.488 |

| 16 | ✕ | ✕ | ✕ | ✕ | ✓ | ✓ | 26.976 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Noël, F.; Serra, C.A.; Le Calvé, S. Design of a Novel Axial Gas Pulses Micromixer and Simulations of its Mixing Abilities via Computational Fluid Dynamics. Micromachines 2019, 10, 205. https://doi.org/10.3390/mi10030205

Noël F, Serra CA, Le Calvé S. Design of a Novel Axial Gas Pulses Micromixer and Simulations of its Mixing Abilities via Computational Fluid Dynamics. Micromachines. 2019; 10(3):205. https://doi.org/10.3390/mi10030205

Chicago/Turabian StyleNoël, Florian, Christophe A. Serra, and Stéphane Le Calvé. 2019. "Design of a Novel Axial Gas Pulses Micromixer and Simulations of its Mixing Abilities via Computational Fluid Dynamics" Micromachines 10, no. 3: 205. https://doi.org/10.3390/mi10030205

APA StyleNoël, F., Serra, C. A., & Le Calvé, S. (2019). Design of a Novel Axial Gas Pulses Micromixer and Simulations of its Mixing Abilities via Computational Fluid Dynamics. Micromachines, 10(3), 205. https://doi.org/10.3390/mi10030205