Wafer Bonding of SiC-AlN at Room Temperature for All-SiC Capacitive Pressure Sensor

Abstract

:1. Introduction

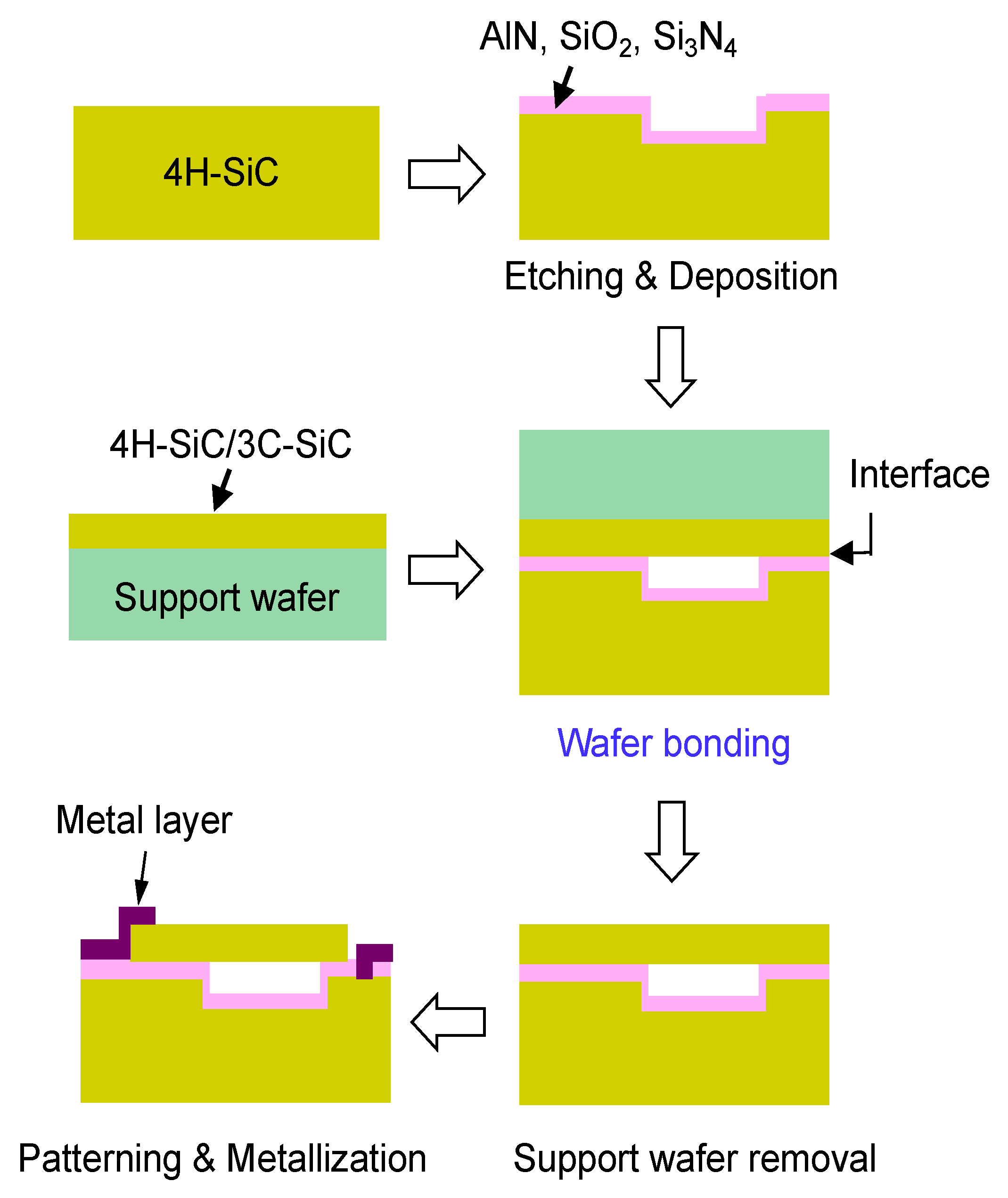

2. Materials and Methods

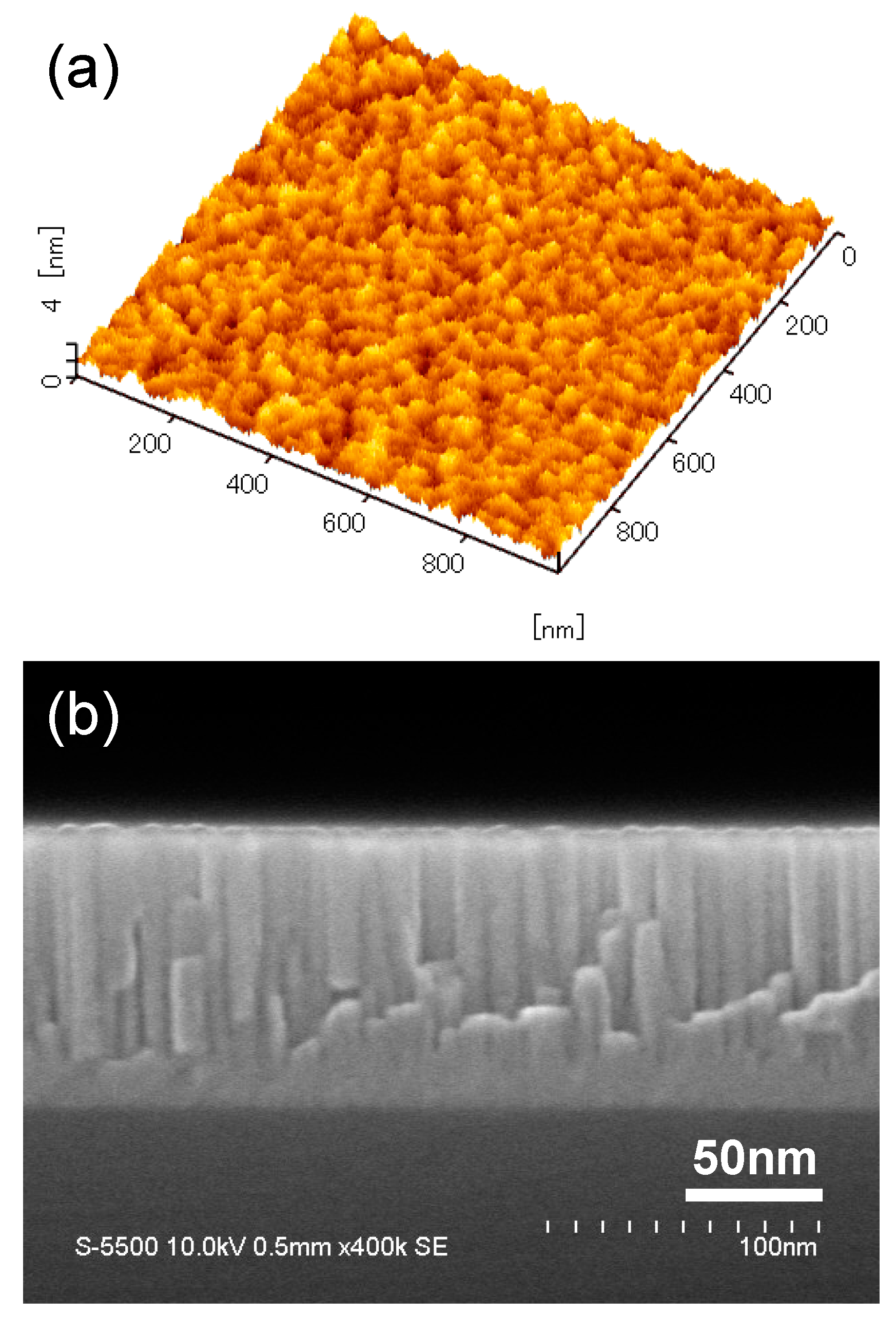

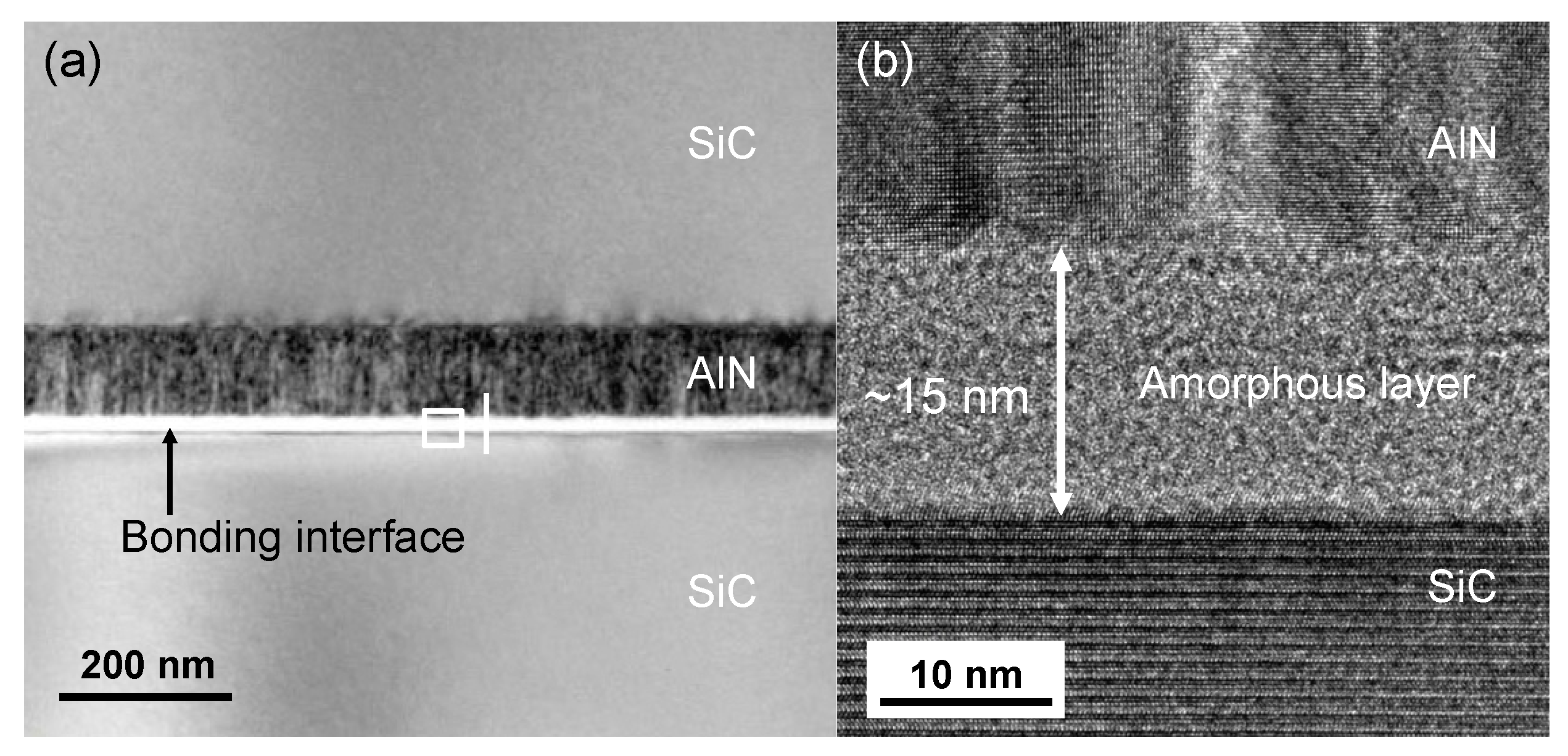

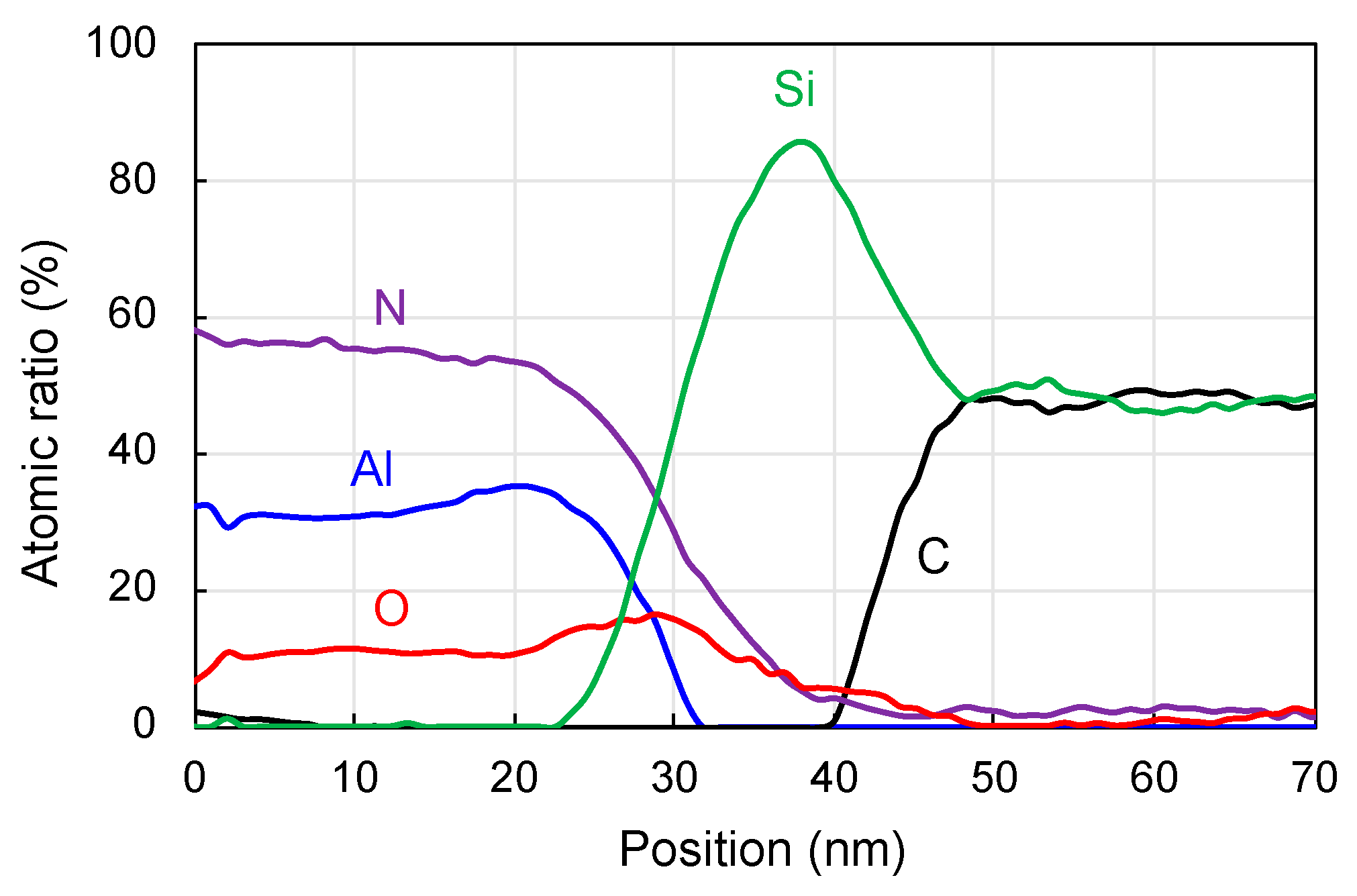

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Phan, H.-P.; Dao, D.V.; Nakamura, K.; Dimitrijev, S.; Nguyen, N.-T. The piezoresistive effect of SiC for MEMS sensors at high temperatures: A review. J. Microelectromech. Syst. 2015, 24, 1663–1677. [Google Scholar] [CrossRef]

- Jones, D.G.; Jog, A.V.; Jamshidi, B.; Myers, D.R.; Chen, L.; Fu, X.; Mehregany, M.; Wijesundara, M.B.J.; Pisano, A.P. A SiC MEMS resonant strain sensor for harsh environment Applications. IEEE Sens. J. 2007, 7, 568–576. [Google Scholar]

- Marsi, N.; Majlis, B.Y.; Mohd-Yasin, F.; Hamzah, A.A. The fabrication of back etching 3C-SiC-on-Si diaphragm employing KOH + IPA in MEMS capacitive pressure sensor. Microsyst. Technol. 2015, 21, 1651–1661. [Google Scholar]

- Young, D.J.; Du, J.; Zorman, C.A.; Ko, W.H. High-temperature single-crystal 3C-SiC capacitive pressure sensor. IEEE Sens. J. 2004, 4, 464–470. [Google Scholar] [CrossRef]

- Du, J.; Ko, W.H.; Mehregany, M.; Zorman, C.A. Poly-SiC capacitive pressure sensors made by wafer bonding. In Proceedings of the IEEE Sensors, Irvine, CA, USA, 30 October–3 November 2005; pp. 1267–1270. [Google Scholar]

- Wu, C.-H.; Zorman, C.A.; Mehregany, M. Fabrication and testing of bulk micromachined silicon carbide piezoresistive pressure sensors for high temperature applications. IEEE Sens. J. 2006, 6, 316–324. [Google Scholar]

- Liu, L.; Tang, W.; Zheng, B.; Zhang, H. Fabrication and characterization of SiC thin films. In Proceedings of the 2011 6th IEEE International Conference on Nano/Micro Engineered and Molecular Systems, Kaohsiung, Taiwan, 20–23 February 2011; pp. 146–149. [Google Scholar]

- Xie, S.; Savu, V.; Tang, W.; Vazquez-Mena, O.; Sidler, K.; Zhang, H.; Brugger, J. Robust PECVD SiC membrane made for stencil lithography. Microelectron. Eng. 2011, 88, 2790–2793. [Google Scholar]

- Du, J.; Zorman, C.A. A polycrystalline SiC-on-Si architecture for capacitive pressure sensing applications beyond 400 °C: Process development and device performance. J. Mater. Res. 2013, 28, 120–128. [Google Scholar] [CrossRef]

- Wieczorek, G.; Schellin, B.; Obermeier, E.; Fagnani, G.; Drera, L. SiC based pressure sensor for high-temperature environments. In Proceedings of the 2007 IEEE Sensors, Atlanta, GA, USA, 28–31 October 2007; pp. 748–751. [Google Scholar]

- Okojie, R.S. Stable 600 °C silicon carbide MEMS pressure transducers. In Proceedings of the Sensors and Systems for Space Applications, Orlando, FL, USA, 9–13 April 2007; p. 65550V. [Google Scholar]

- Akiyama, T.; Briand, D.; de Rooij, N.F. Piezoresistive n-type 4H-SiC pressure sensor with membrane formed by mechanical milling. In Proceedings of the 2011 IEEE Sensors, Limerick, Ireland, 28–31 October 2011; pp. 222–225. [Google Scholar]

- Okojie, R.S.; Lukco, D.; Nguyen, V.; Savrun, E. 4H-SiC piezoresistive pressure sensors at 800 °C with observed sensitivity recovery. IEEE Electron Device Lett. 2015, 36, 174–176. [Google Scholar] [CrossRef]

- Chen, L.; Mehregany, M. A silicon carbide capacitive pressure sensor for in-cylinder pressure measurement. Sens. Actuat. A Phys. 2008, 145, 2–8. [Google Scholar]

- Griffin, B.A.; Habermehl, S.D.; Clews, P.J. Development of an aluminum nitride-silicon carbide material set for high-temperature sensor applications. Proceedings of the Sensors for Extreme Harsh Environments 1130A.

- Wang, W.; Liang, J.; Ruan, Y.; Pang, W.; You, Z. Design and fabrication of an surface acoustic wave resonator based on AlN/4H-SiC material for harsh environments. J. Zhejiang Univ. Sci. A 2017, 18, 67–74. [Google Scholar] [CrossRef]

- Lv, H.; Yu, H.; Hu, G. A SiC high-temperature pressure sensor operating in severe condition. TELKOMNIKA Indones. J. Electr. Eng. 2012, 10, 2247–2252. [Google Scholar] [CrossRef]

- Lv, H.J.; Yu, H.Y.; Hou, J.H.; Geng, T. A study of a silicon carbide capacitive pressure sensor applied in harsh environment. Appl. Mech. Mater. 2013, 241, 984–987. [Google Scholar]

- Takagi, H.; Kikuchi, K.; Maeda, R.; Chung, T.R.; Suga, T. Surface activated bonding of silicon wafers at room temperature. Appl. Phys. Lett. 1996, 68, 2222–2224. [Google Scholar]

- Maszara, W.P.; Goetz, G.; Caviglia, A.; McKitterick, J.B. Bonding of silicon wafers for silicon-on-insulator. J. Appl. Phys. 1988, 64, 4943–4950. [Google Scholar] [CrossRef]

- Plößl, A.; Gertrud, K. Wafer direct bonding: tailoring adhesion between brittle materials. Mater. Sci. Eng. R Rep. 1999, 25, 1–88. [Google Scholar] [CrossRef]

- Zhao, F.; Du, W.; Huang, C.-F. Fabrication and characterization of single-crystal 4H-SiC microactuators for MHz frequency operation and determination of Young’s modulus. Microelectron. Eng. 2014, 129, 53–57. [Google Scholar]

- Singh, A.V.; Chandra, S.; Bose, G. Deposition and characterization of c-axis oriented aluminum nitride films by radio frequency magnetron sputtering without external substrate heating. Thin Solid Films 2011, 519, 5846–5853. [Google Scholar] [CrossRef]

- Thedsakhulwong, A.; Locharoenrat, K.; Thowladda, W. Structure and piezoelectric properties of aluminum nitride thin films on quartz substrates deposited by reactive RF-magnetron sputtering. Adv. Mater. Res. 2013, 699, 308–313. [Google Scholar]

- Jackson, N.; Keeney, L.; Mathewson, A. Flexible-CMOS and biocompatible piezoelectric AlN material for MEMS applications. Smart Mater. Struct. 2013, 22, 115033. [Google Scholar]

- Mu, F.; Iguchi, K.; Nakazawa, H.; Takahashi, Y.; Fujino, M.; Suga, T. Direct wafer bonding of SiC-SiC by SAB for monolithic integration of SiC MEMS and electronics. ECS J. Solid State Sci. Technol. 2016, 5, 451–456. [Google Scholar] [CrossRef]

- Mu, F.; Iguchi, K.; Nakazawa, H.; Takahashi, Y.; Fujino, M.; He, R.; Suga, T. A comparison study: Direct wafer bonding of SiC-SiC by standard surface-activated bonding and modified surface-activated bonding with Si-containing Ar ion beam. Appl. Phys. Express 2016, 9, 081302. [Google Scholar] [CrossRef]

- Mu, F.; Iguchi, K.; Nakazawa, H.; Takahashi, Y.; Fujino, M.; He, R.; Suga, T. Room temperature SiC-SiO2 wafer bonding enhanced by using an intermediate Si nano Layer. ECS J. Solid State Sci. Technol. 2017, 6, 227–230. [Google Scholar] [CrossRef]

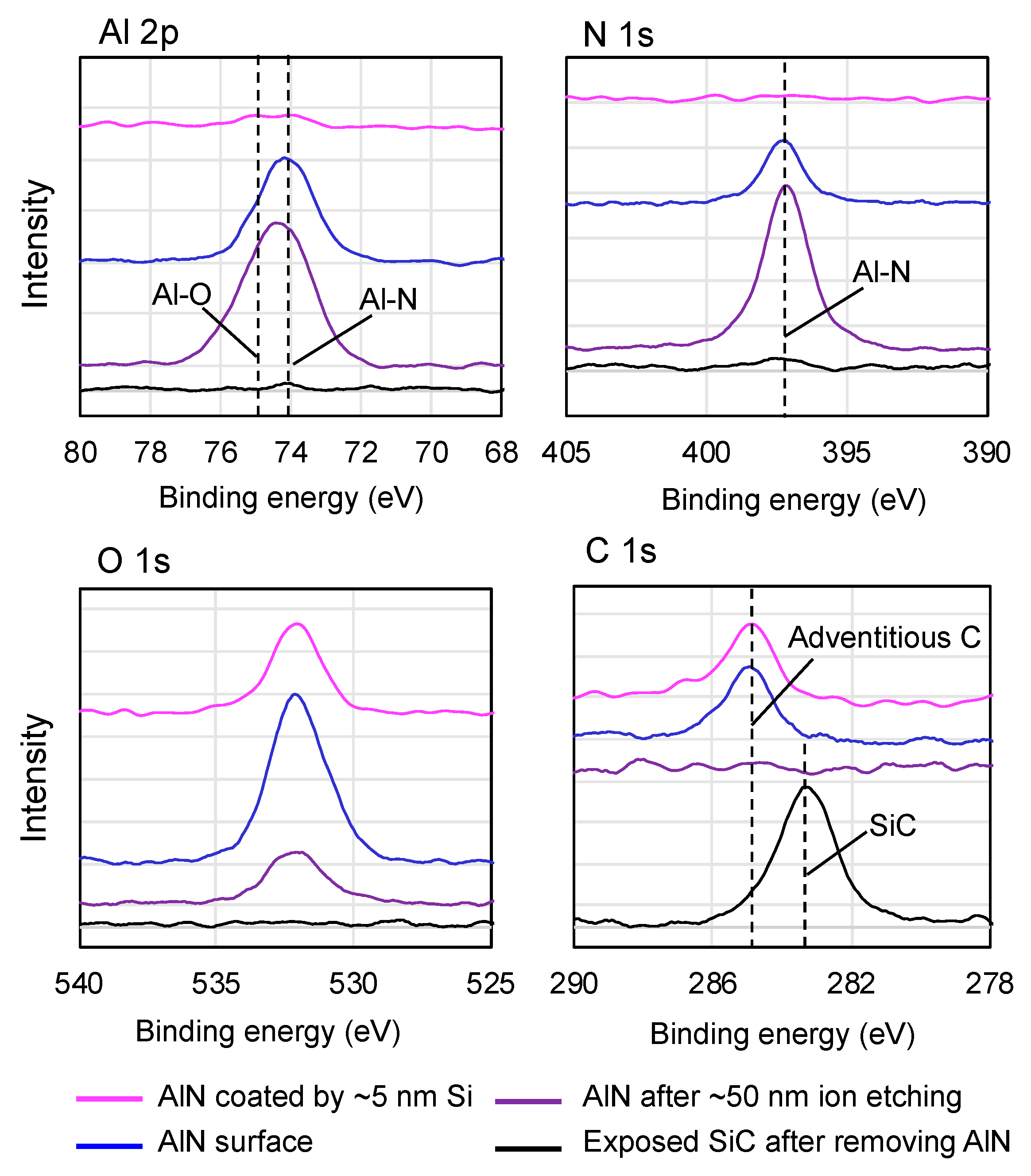

- Taylor, J.A.; Rabalais, J.W. Reaction of N2+ beams with aluminum surfaces. J. Chem. Phys. 1981, 75, 1735–1745. [Google Scholar] [CrossRef]

- Di Castro, V.; Polzonetti, G.; Contini, G.; Cozza, C.; Paponetti, B. XPS study of MnO2 minerals treated by bioleaching. Surf. Interface Anal. 1990, 16, 571–574. [Google Scholar] [CrossRef]

- Asahara, R.; Nozaki, M.; Yamada, T.; Ito, J.; Nakazawa, S.; Ishida, M.; Ueda, T.; Yoshigoe, A.; Hosoi, T.; Shimura, T.; et al. Effect of nitrogen incorporation into Al-based gate insulators in AlON/AlGaN/GaN metal–oxide–semiconductor structures. Appl. Phys. Express 2016, 9, 101002. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mu, F.; Xu, Y.; Shin, S.; Wang, Y.; Xu, H.; Shang, H.; Sun, Y.; Yue, L.; Tsuyuki, T.; Suga, T.; et al. Wafer Bonding of SiC-AlN at Room Temperature for All-SiC Capacitive Pressure Sensor. Micromachines 2019, 10, 635. https://doi.org/10.3390/mi10100635

Mu F, Xu Y, Shin S, Wang Y, Xu H, Shang H, Sun Y, Yue L, Tsuyuki T, Suga T, et al. Wafer Bonding of SiC-AlN at Room Temperature for All-SiC Capacitive Pressure Sensor. Micromachines. 2019; 10(10):635. https://doi.org/10.3390/mi10100635

Chicago/Turabian StyleMu, Fengwen, Yang Xu, Seongbin Shin, Yinghui Wang, Hengyu Xu, Haiping Shang, Yechao Sun, Lei Yue, Tatsurou Tsuyuki, Tadatomo Suga, and et al. 2019. "Wafer Bonding of SiC-AlN at Room Temperature for All-SiC Capacitive Pressure Sensor" Micromachines 10, no. 10: 635. https://doi.org/10.3390/mi10100635

APA StyleMu, F., Xu, Y., Shin, S., Wang, Y., Xu, H., Shang, H., Sun, Y., Yue, L., Tsuyuki, T., Suga, T., Wang, W., & Chen, D. (2019). Wafer Bonding of SiC-AlN at Room Temperature for All-SiC Capacitive Pressure Sensor. Micromachines, 10(10), 635. https://doi.org/10.3390/mi10100635