Molecular Dynamics Simulations on the Demolding Process for Nanostructures with Different Aspect Ratios in Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Model Constructing

2.2. Force Field and Simulation Procedure

3. Result and Discussion

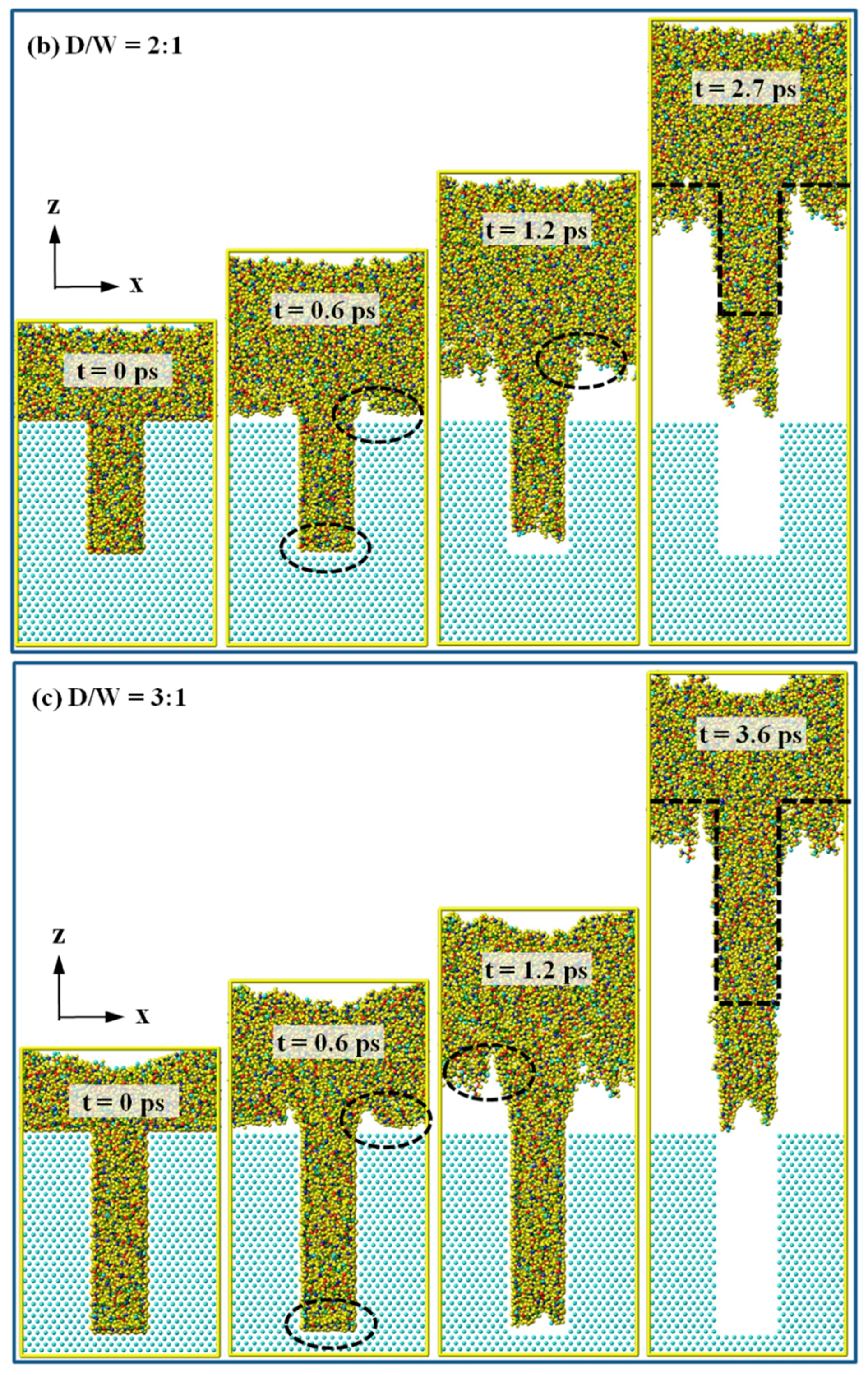

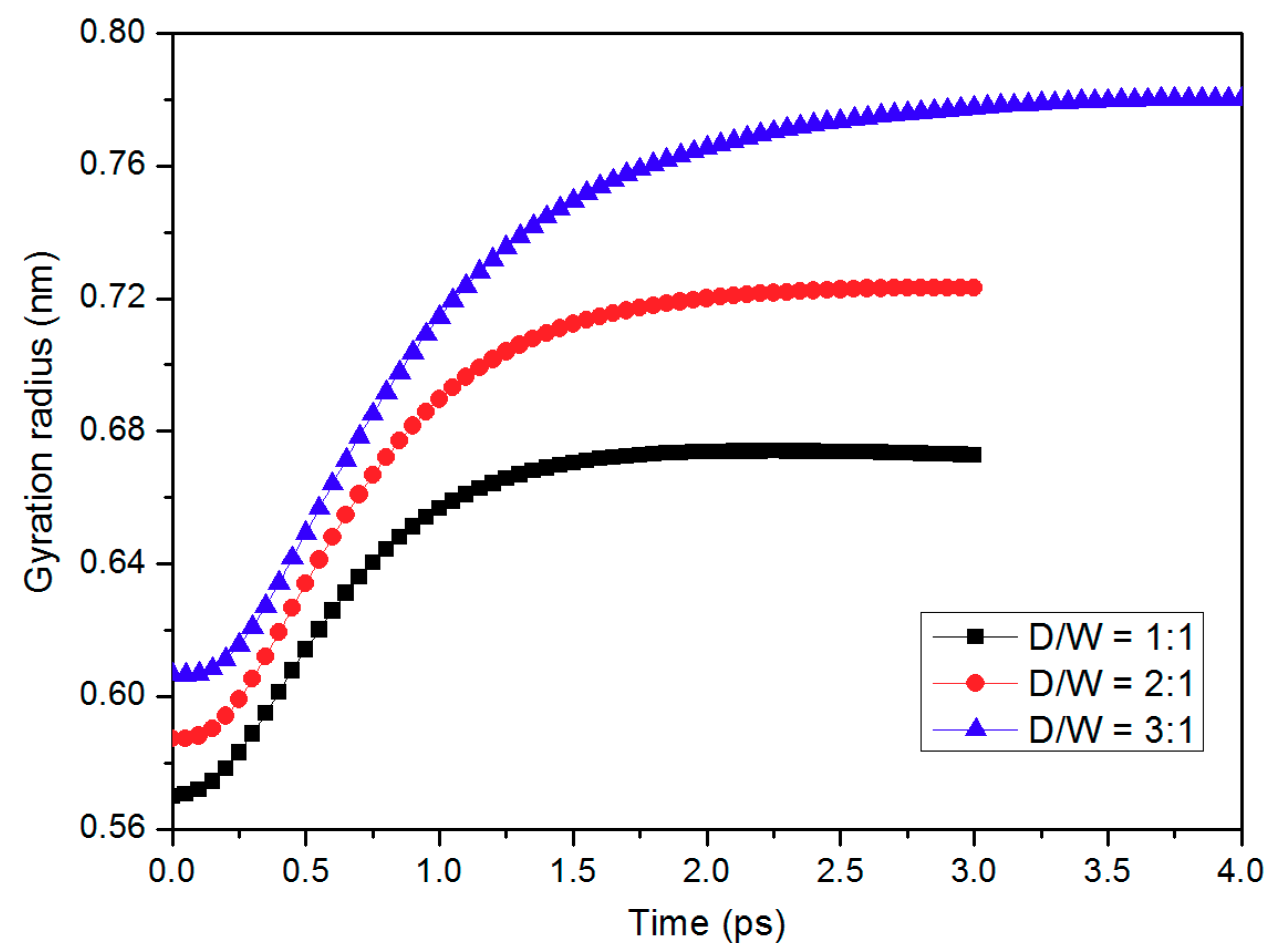

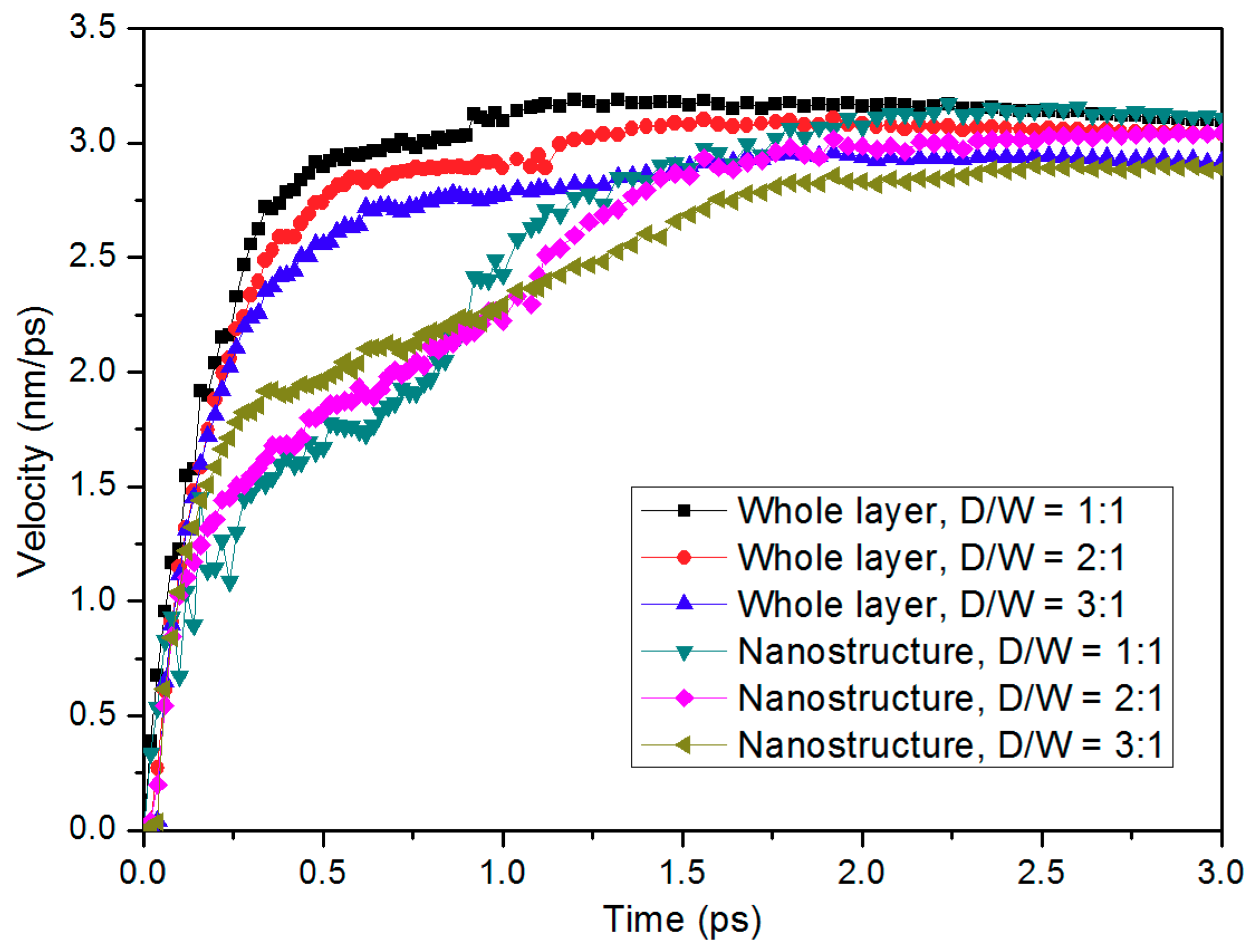

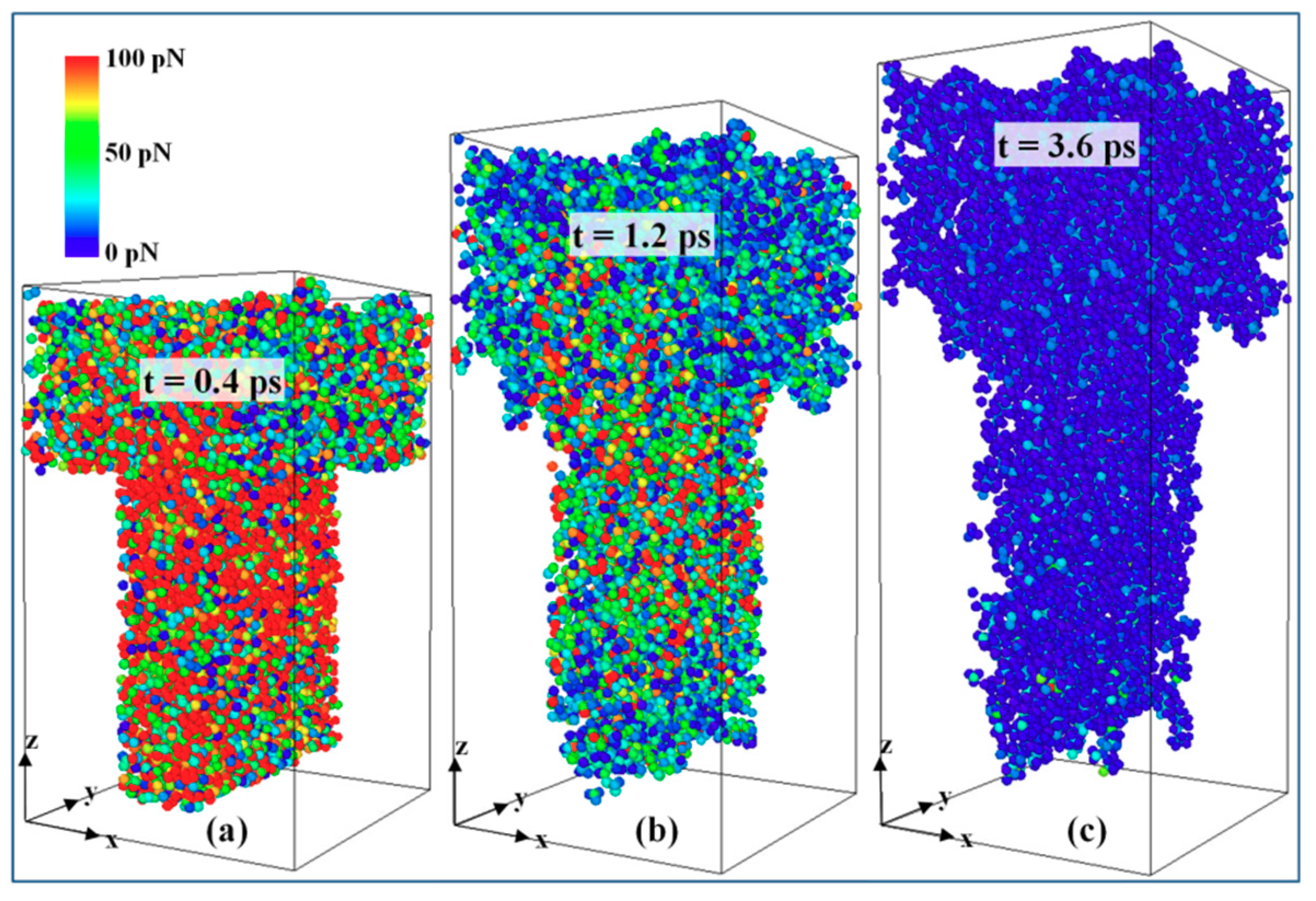

3.1. Investigation on the Conformation Change

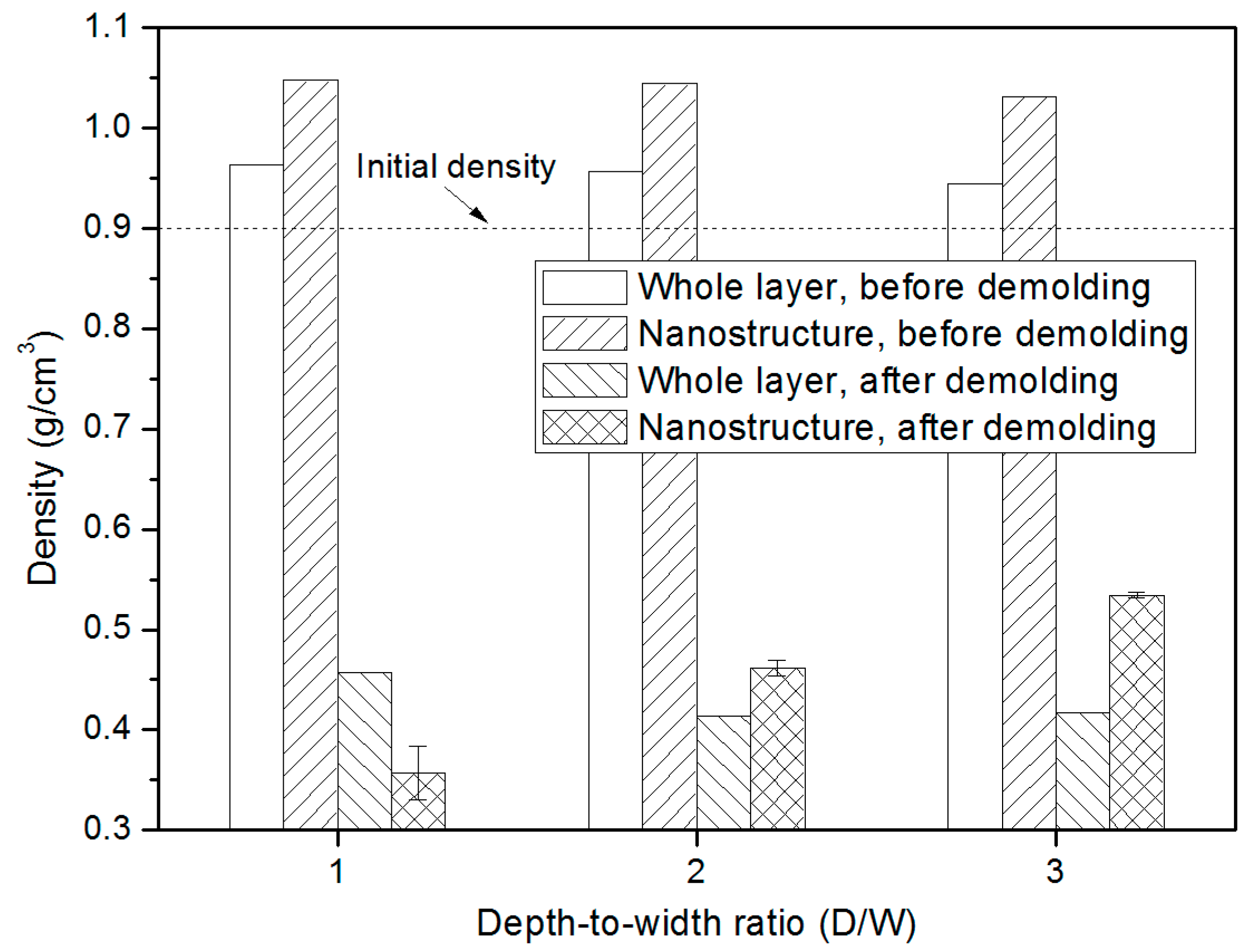

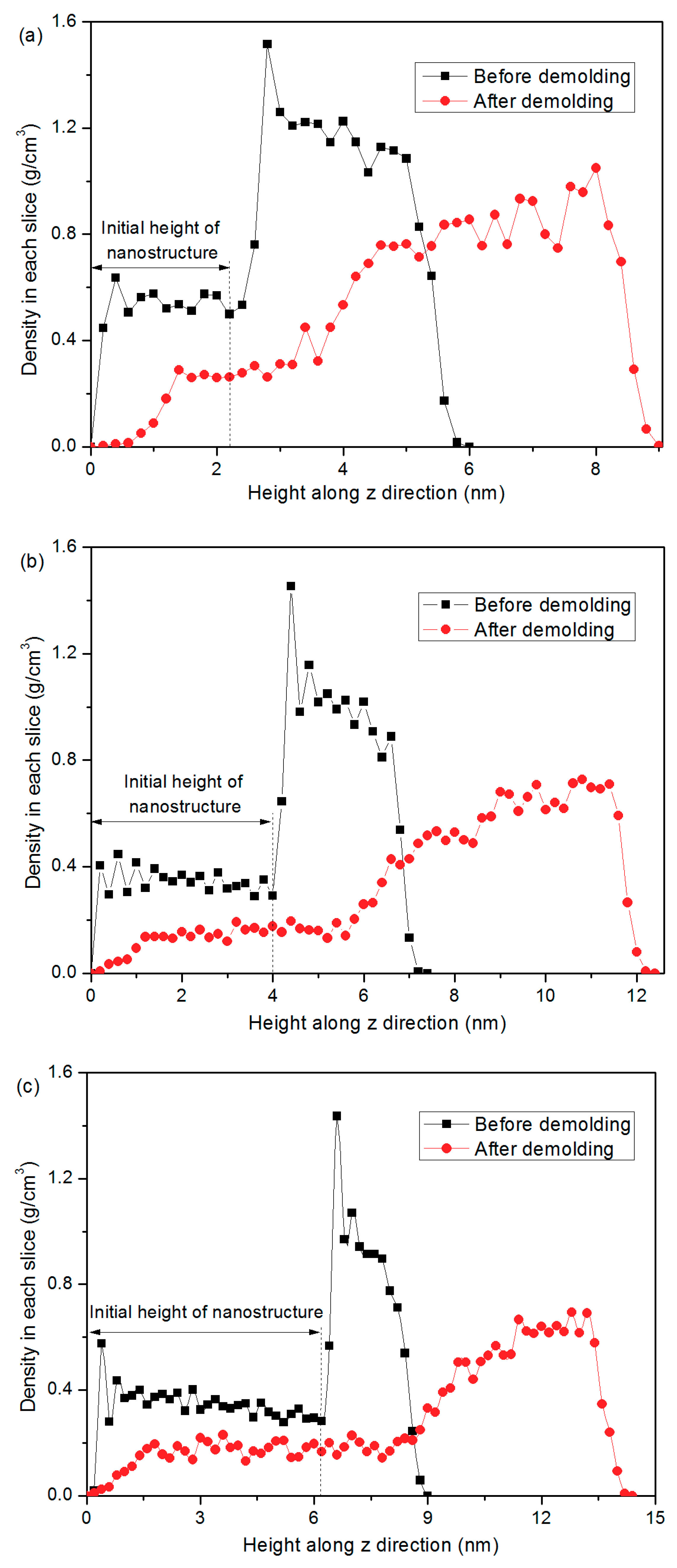

3.2. Determination of Density and Its Distribution

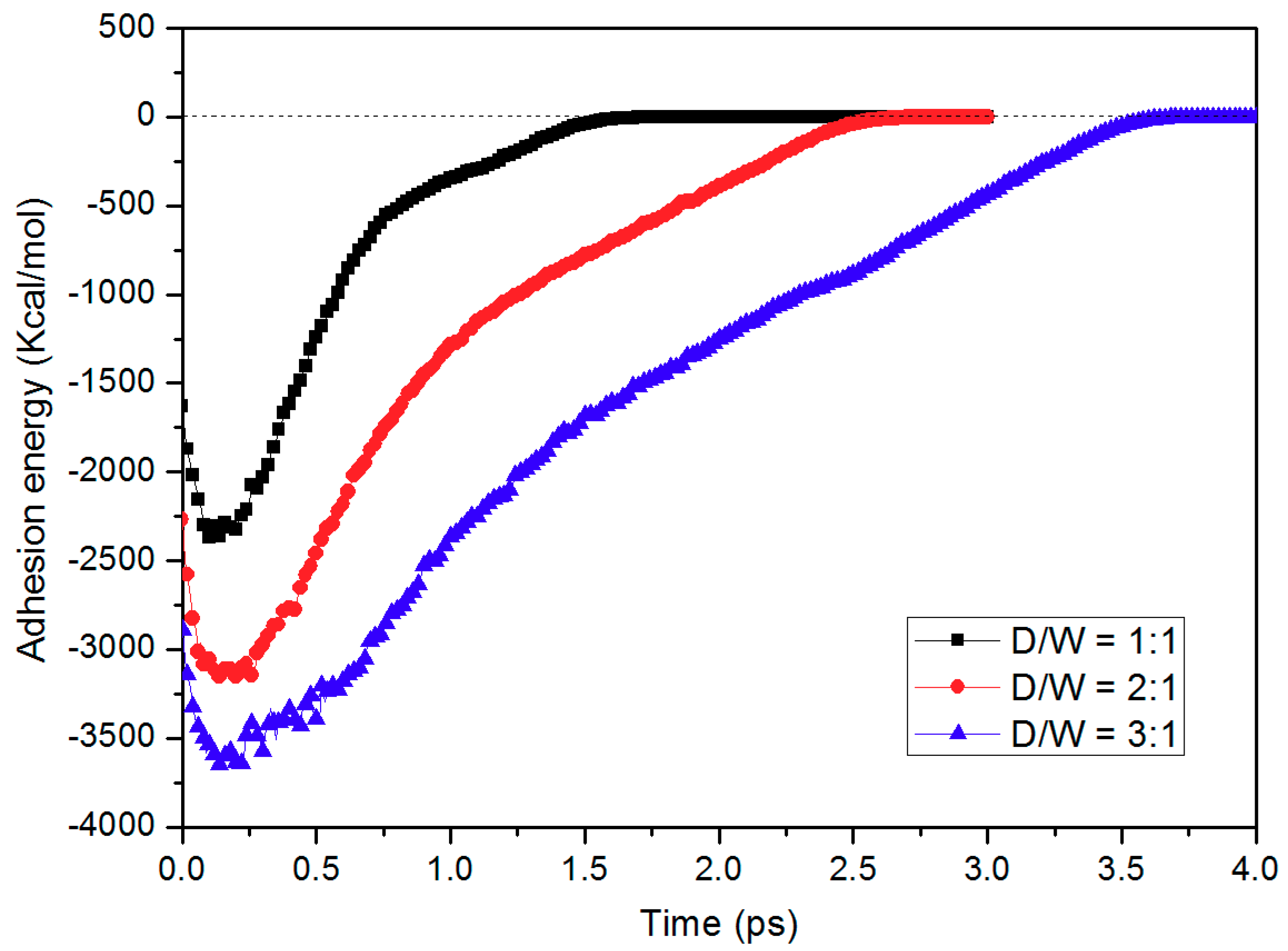

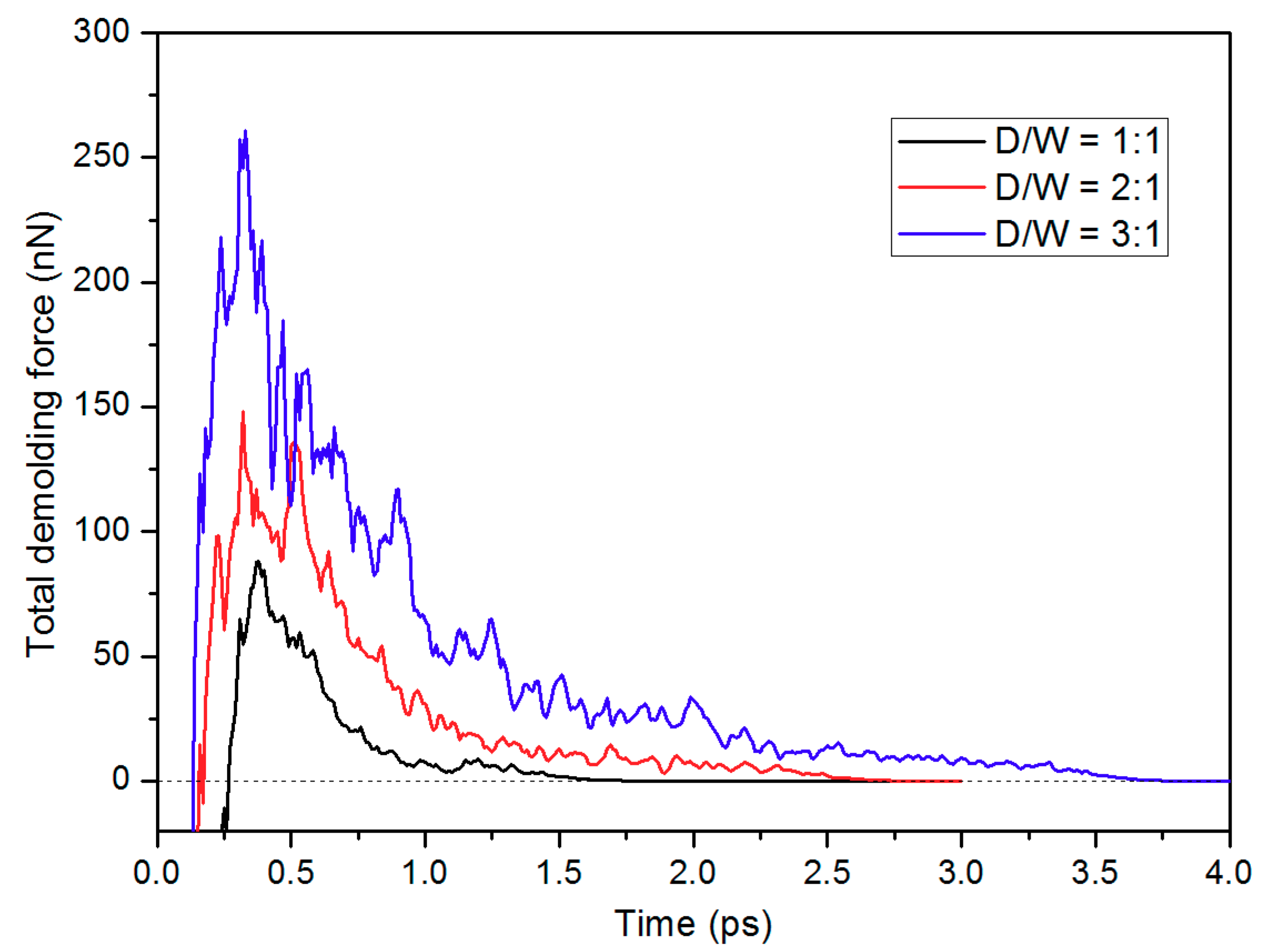

3.3. Determination of Adhesion Energy and Demolding Force

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Stormonth-Darling, J.M.; Pedersen, R.H.; How, C.; Gadegaard, N. Injection moulding of ultra high aspect ratio nanostructures using coated polymer tooling. J. Micromech. Microeng. 2014, 24, 075019. [Google Scholar] [CrossRef]

- Utko, P.; Persson, F.; Kristensen, A.; Larsen, N.B. Injection molded nanofluidic chips: Fabrication method and functional tests using single-molecule DNA experiments. Lab Chip 2011, 11, 303–308. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Xiong, X.; Jiang, B.; Weng, C. Fabrication of high aspect ratio nanopillars and micro/nano combined structures with hydrophobic surface characteristics by injection molding. Appl. Surf. Sci. 2018, 427, 854–860. [Google Scholar] [CrossRef]

- Yanagishita, T.; Kondo, T.; Masuda, H. Preparation of renewable antireflection moth-eye surfaces by nanoimprinting using anodic porous alumina molds. J. Vac. Sci. Technol. B 2018, 36, 031802. [Google Scholar] [CrossRef] [Green Version]

- Park, J.M. Fabrication of various nano-structured nickel stamps using anodic aluminum oxide. Microsyst. Technol. 2014, 20, 2157–2163. [Google Scholar] [CrossRef]

- Weng, C.; Lee, W.B.; To, S. A study of the relevant effects on the maximum residual stress in the precision injection moulding of microlens arrays. J. Micromech. Microeng. 2010, 20, 035033. [Google Scholar] [CrossRef]

- Kimura, F.; Kadoya, S.; Kajihara, Y. Effects of molding conditions on injection molded direct joining using a metal with nano-structured surface. Precis. Eng. 2016, 45, 203–208. [Google Scholar] [CrossRef]

- Saarikoski, I.; Suvanto, M.; Pakkanen, T.A. Modification of polycarbonate surface properties by nano-, micro-, and hierarchical micro–nanostructuring. Appl. Surf. Sci. 2009, 255, 9000–9005. [Google Scholar] [CrossRef]

- Matschuk, M.; Larsen, N.B. Injection molding of high aspect ratio sub-100 nm nanostructures. J. Micromech. Microeng. 2013, 23, 025003. [Google Scholar] [CrossRef]

- Xie, H.; Huang, H.X.; Peng, Y.J. Rapid fabrication of bio-inspired nanostructure with hydrophobicity and antireflectivity on polystyrene surface replicating from cicada wings. Nanoscale 2017, 9, 11951–11958. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Xiong, Y.; Tian, Y. Study of the demolding process—Implications for thermal stress, adhesion and friction control. J. Micromech. Microeng. 2007, 17, 9–19. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, G.; Zhu, X.; Tian, Y. Analysis of the demolding forces during hot embossing. Microsyst. Technol. 2006, 13, 411–415. [Google Scholar] [CrossRef]

- Dirckx, M.E.; Hardt, D.E. Analysis and characterization of demolding of hot embossed polymer microstructures. J. Micromech. Microeng. 2011, 21, 085024. [Google Scholar] [CrossRef]

- Su, Q.; Gilchrist, M.D. Demolding forces for micron-sized features during micro-injection molding. Polym. Eng. Sci. 2016, 56, 810–816. [Google Scholar] [CrossRef]

- Sasaki, T.; Koga, N.; Shirai, K.; Kobayashi, Y.; Toyoshima, A. An experimental study on ejection forces of injection molding. Precis. Eng. 2000, 24, 270–273. [Google Scholar] [CrossRef]

- Masato, D.; Sorgato, M.; Parenti, P.; Annoni, M.; Lucchetta, G. Impact of deep cores surface topography generated by micro milling on the demolding force in micro injection molding. J. Mater. Process. Technol. 2017, 246, 211–223. [Google Scholar] [CrossRef]

- Song, Q.; Ji, Y.; Li, S.; Wang, X.; He, L. Adsorption behavior of polymer chain with different topology structure at the polymer-nanoparticle interface. Polymers 2018, 10, 590. [Google Scholar] [CrossRef] [PubMed]

- Hirai, Y.; Konishi, T.; Yoshikawa, T.; Yoshida, S. Simulation and experimental study of polymer deformation in nanoimprint lithography. J. Vac. Sci. Technol. B 2004, 22, 3288. [Google Scholar] [CrossRef]

- Yang, S.; Yu, S.; Cho, M. Influence of mold and substrate material combinations on nanoimprint lithography process: Md simulation approach. Appl. Surf. Sci. 2014, 301, 189–198. [Google Scholar] [CrossRef]

- Takai, R.; Yasuda, M.; Tochino, T.; Kawata, H.; Hirai, Y. Computational study of the demolding process in nanoimprint lithography. J. Vac. Sci. Technol. B 2014, 32, 06FG02. [Google Scholar] [CrossRef]

- Kang, J.-H.; Kim, K.-S.; Kim, K.-W. Molecular dynamics study of pattern transfer in nanoimprint lithography. Tribol. Lett. 2007, 25, 93–102. [Google Scholar] [CrossRef]

- Carrillo, J.M.; Dobrynin, A.V. Molecular dynamics simulations of nanoimprinting lithography. Langmuir 2009, 25, 13244–13249. [Google Scholar] [CrossRef] [PubMed]

- Pina-Estany, J.; García-Granada, A.A. Molecular dynamics simulation method applied to nanocavities replication via injection moulding. Int. Commun. Heat Mass Transf. 2017, 87, 1–5. [Google Scholar] [CrossRef]

- Zhou, M.; Jiang, B.; Weng, C. Molecular dynamics study on polymer filling into nano-cavity by injection molding. Comput. Mater. Sci. 2016, 120, 36–42. [Google Scholar] [CrossRef]

- Dai, C.-F.; Chang, R.-Y. Molecular dynamics simulation of thread break-up and formation of droplets in nanoejection system. Mol. Simulat. 2009, 35, 334–341. [Google Scholar] [CrossRef]

- Lin, H.-Y.; Chang, C.-H.; Young, W.-B. Experimental and analytical study on filling of nano structures in micro injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1477–1486. [Google Scholar] [CrossRef]

- Zhou, M.; Xiong, X.; Drummer, D.; Jiang, B. Molecular dynamics simulation and experimental investigation of the geometrical morphology development of injection-molded nanopillars on polymethylmethacrylate surface. Comput. Mater. Sci. 2018, 149, 208–216. [Google Scholar] [CrossRef]

- Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Kim, S.; Lee, D.E.; Lee, W.I. Molecular dynamic simulation on the effect of polymer molecular size in thermal nanoimprint lithographic (t-nil) process. Tribol. Lett. 2013, 49, 421–430. [Google Scholar] [CrossRef]

- Prathab, B.; Subramanian, V.; Aminabhavi, T.M. Molecular dynamics simulations to investigate polymer–polymer and polymer–metal oxide interactions. Polymer 2007, 48, 409–416. [Google Scholar] [CrossRef]

- Kisin, S.; Božović Vukić, J.; van der Varst, P.G.; de With, G.; Koning, C.E. Estimating the polymer−metal work of adhesion from molecular dynamics simulations. Chem. Mater. 2007, 19, 903–907. [Google Scholar] [CrossRef]

- Liu, F.; Hu, N.; Ning, H.; Liu, Y.; Li, Y.; Wu, L. Molecular dynamics simulation on interfacial mechanical properties of polymer nanocomposites with wrinkled graphene. Comput. Mater. Sci. 2015, 108, 160–167. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Weng, C.; Yang, D.; Zhou, M. Molecular Dynamics Simulations on the Demolding Process for Nanostructures with Different Aspect Ratios in Injection Molding. Micromachines 2019, 10, 636. https://doi.org/10.3390/mi10100636

Weng C, Yang D, Zhou M. Molecular Dynamics Simulations on the Demolding Process for Nanostructures with Different Aspect Ratios in Injection Molding. Micromachines. 2019; 10(10):636. https://doi.org/10.3390/mi10100636

Chicago/Turabian StyleWeng, Can, Dongjiao Yang, and Mingyong Zhou. 2019. "Molecular Dynamics Simulations on the Demolding Process for Nanostructures with Different Aspect Ratios in Injection Molding" Micromachines 10, no. 10: 636. https://doi.org/10.3390/mi10100636