Effects of Helical Tube Electrode Structure on Mixed Machining Product Transfer in Micro-Machining Channel during Tube Electrode High-Speed Electrochemical Discharge Machining

Abstract

:1. Introduction

2. Materials and Methods

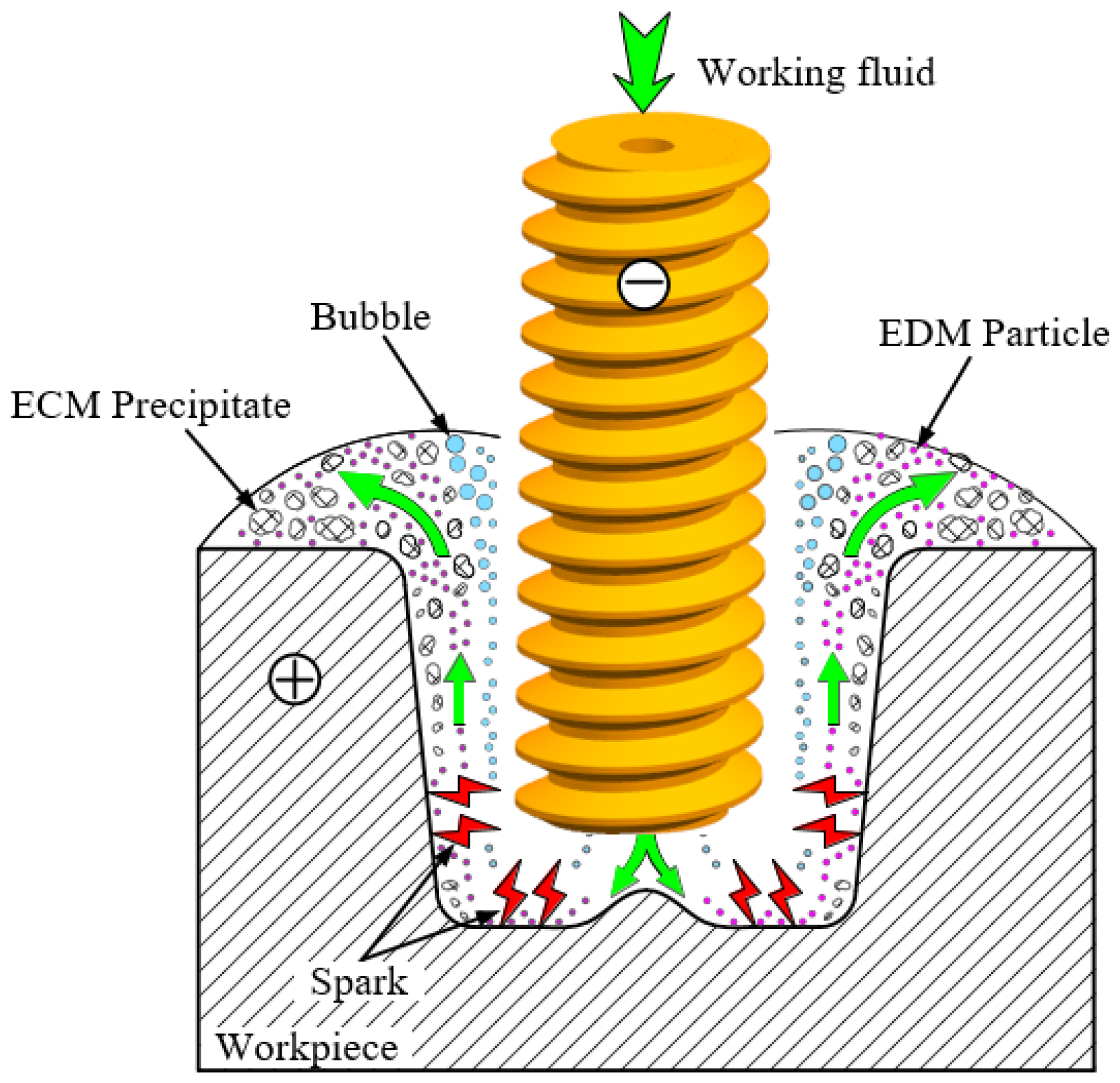

2.1. Improvement of TSECDM of Holes by Using Helical Tube Electrode

2.2. Experimental Setup

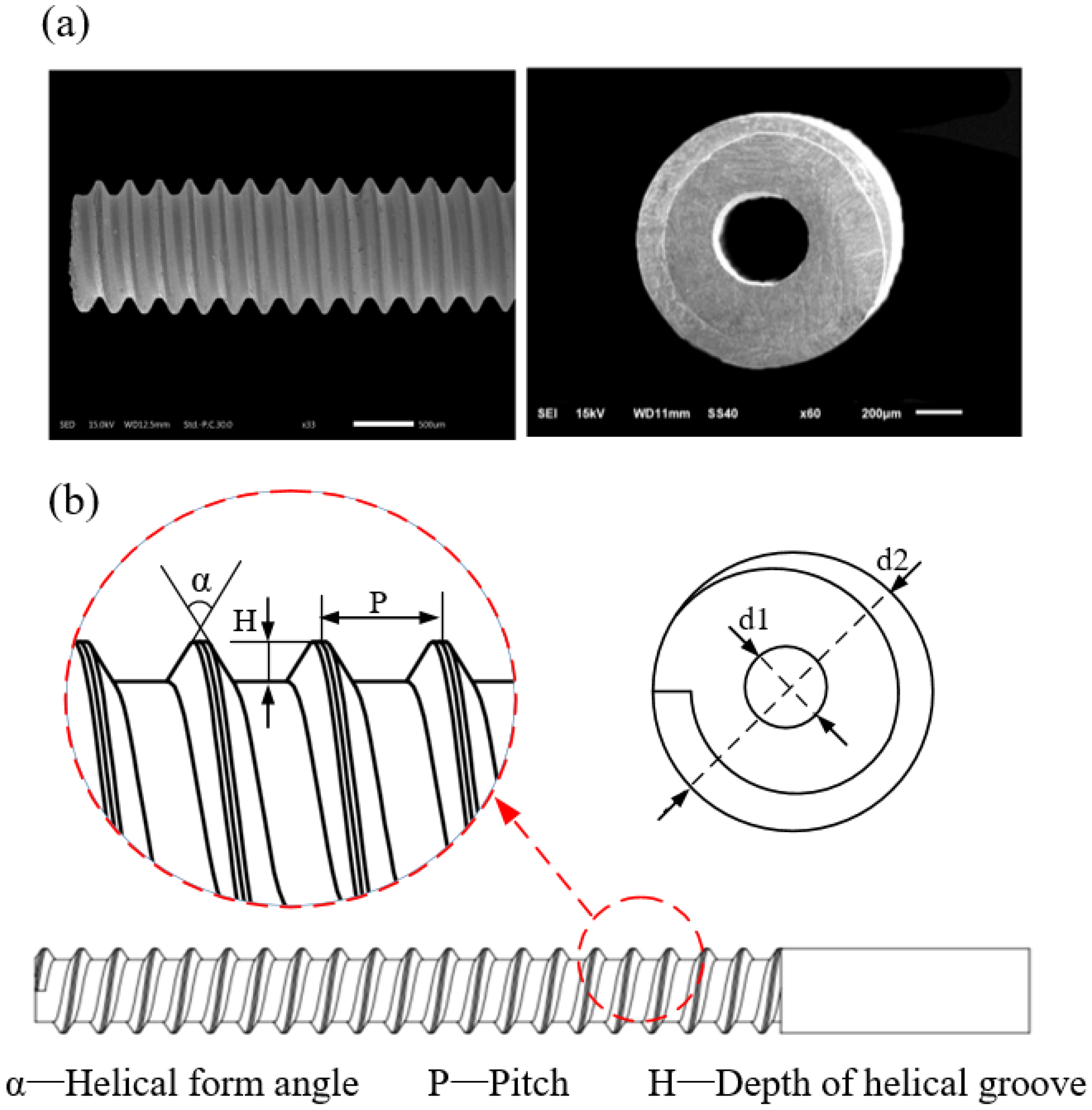

2.2.1. Helical Structure Design of Tube Tool Electrode

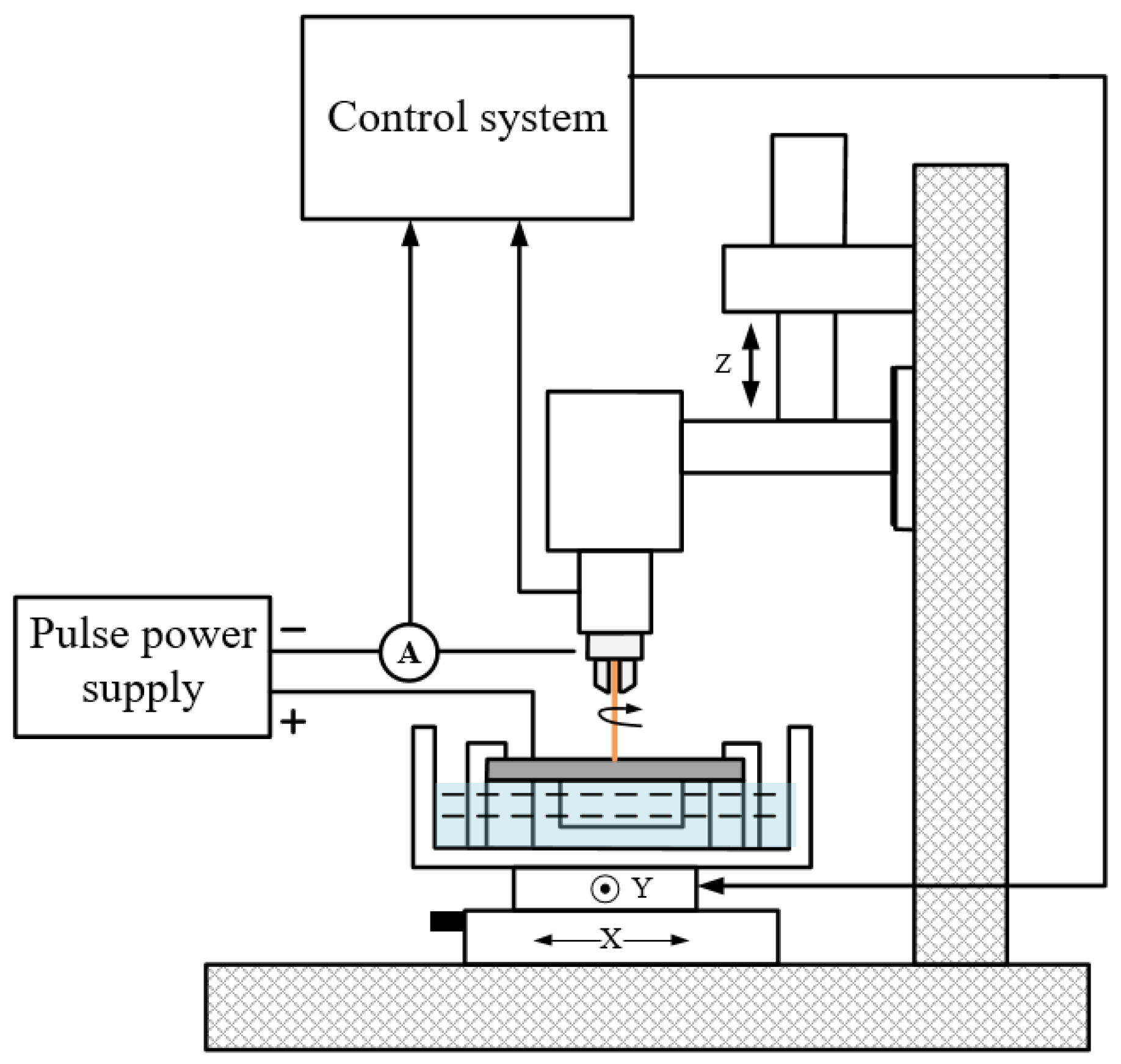

2.2.2. Experimental System

2.2.3. Simulation and Experimental Parameters Setting

2.2.4. Mathematical Model of Flow Field in Machining Gap

3. Results and Discussion

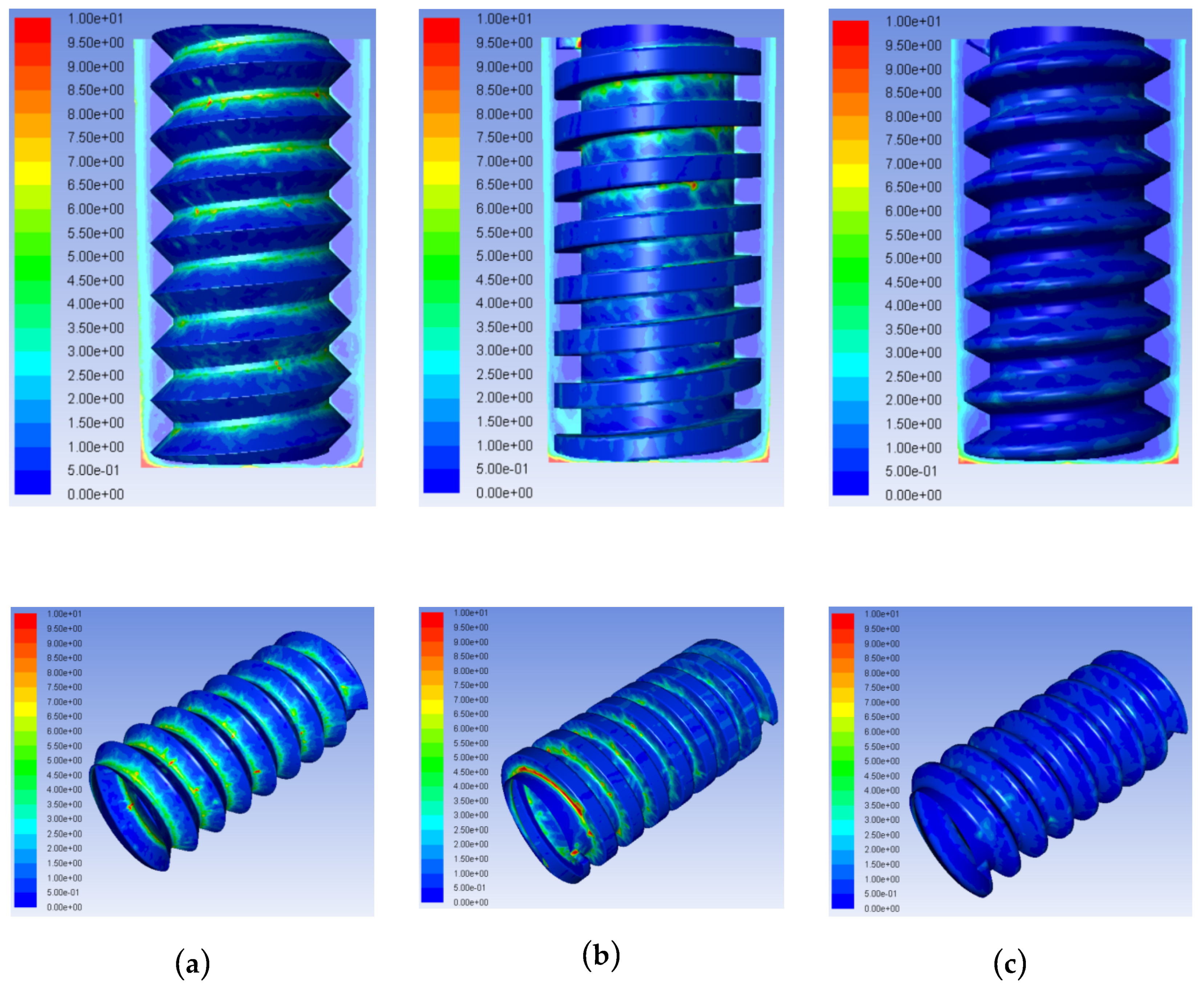

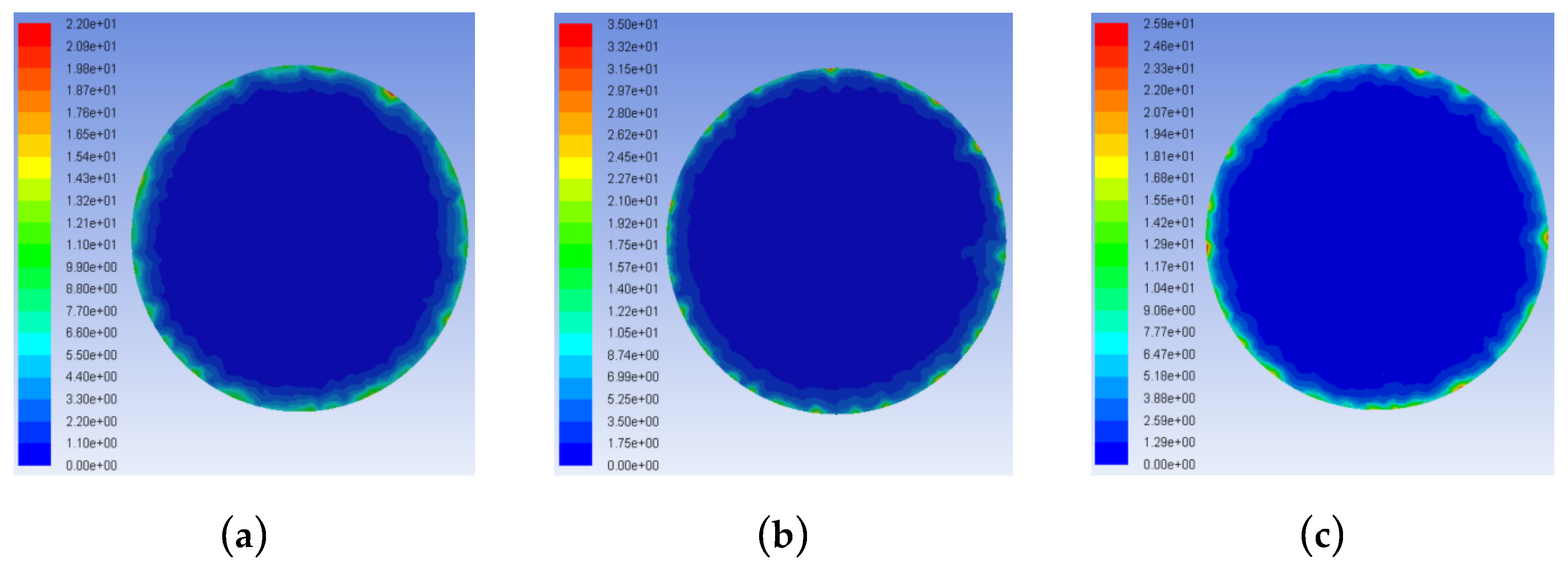

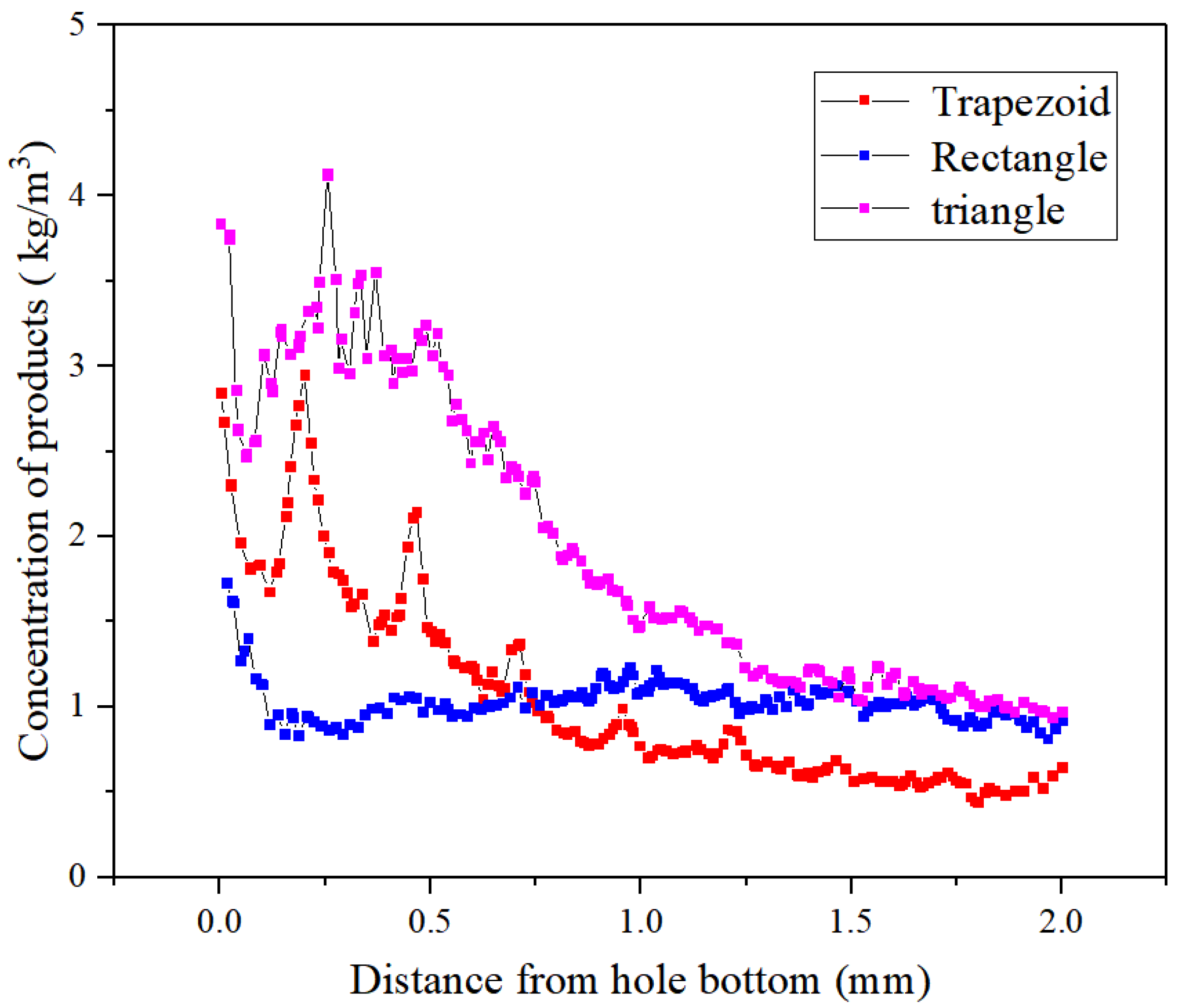

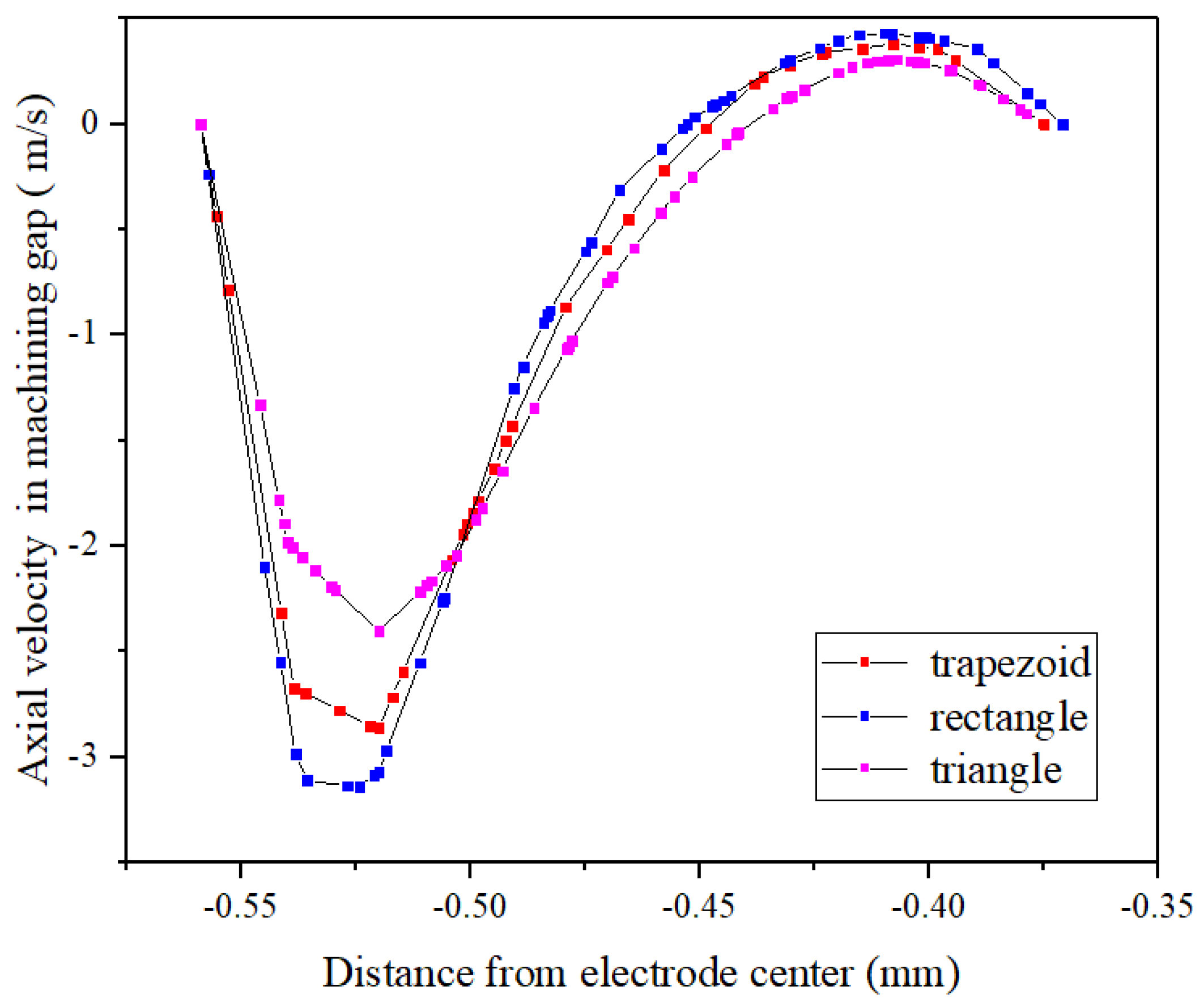

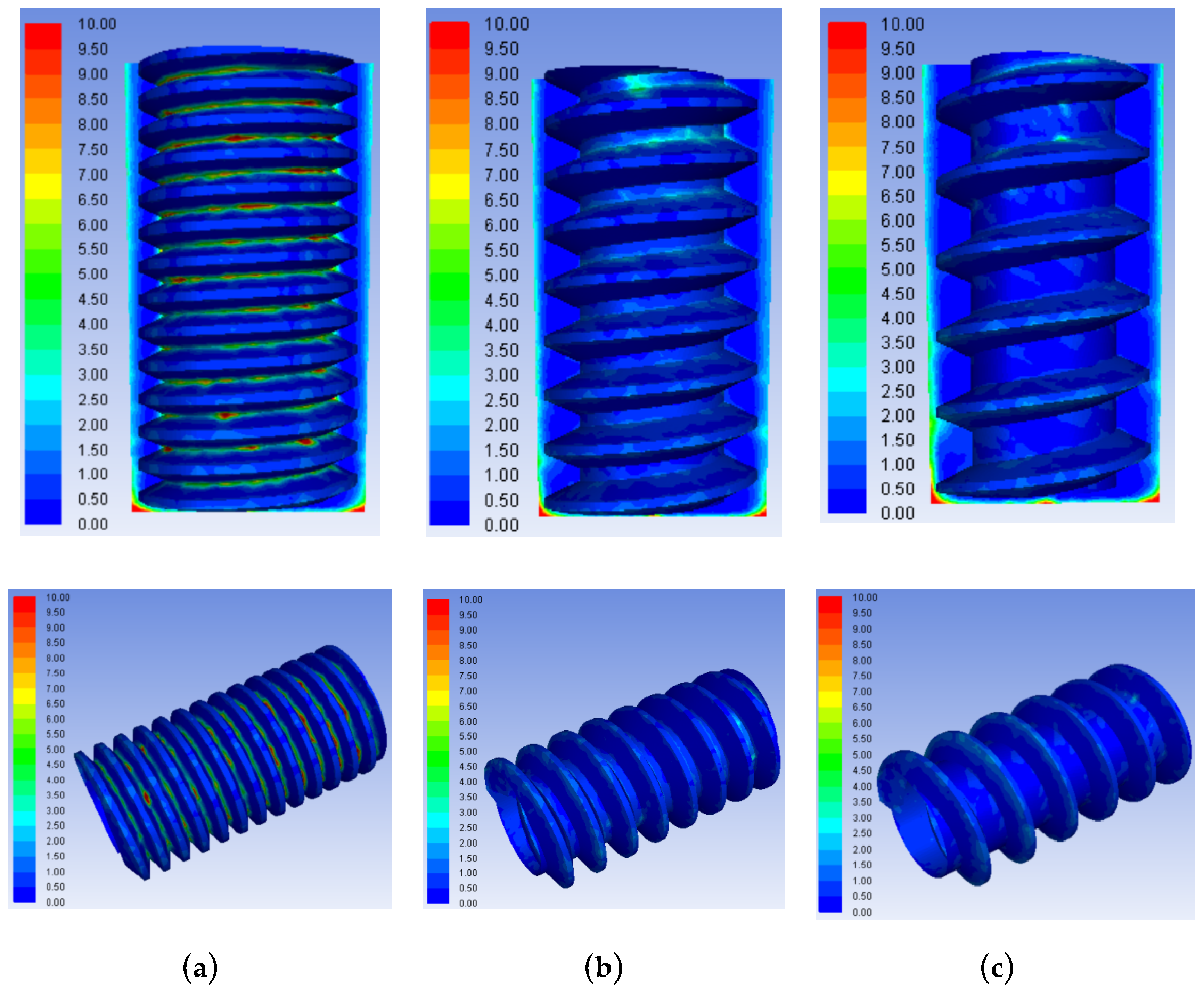

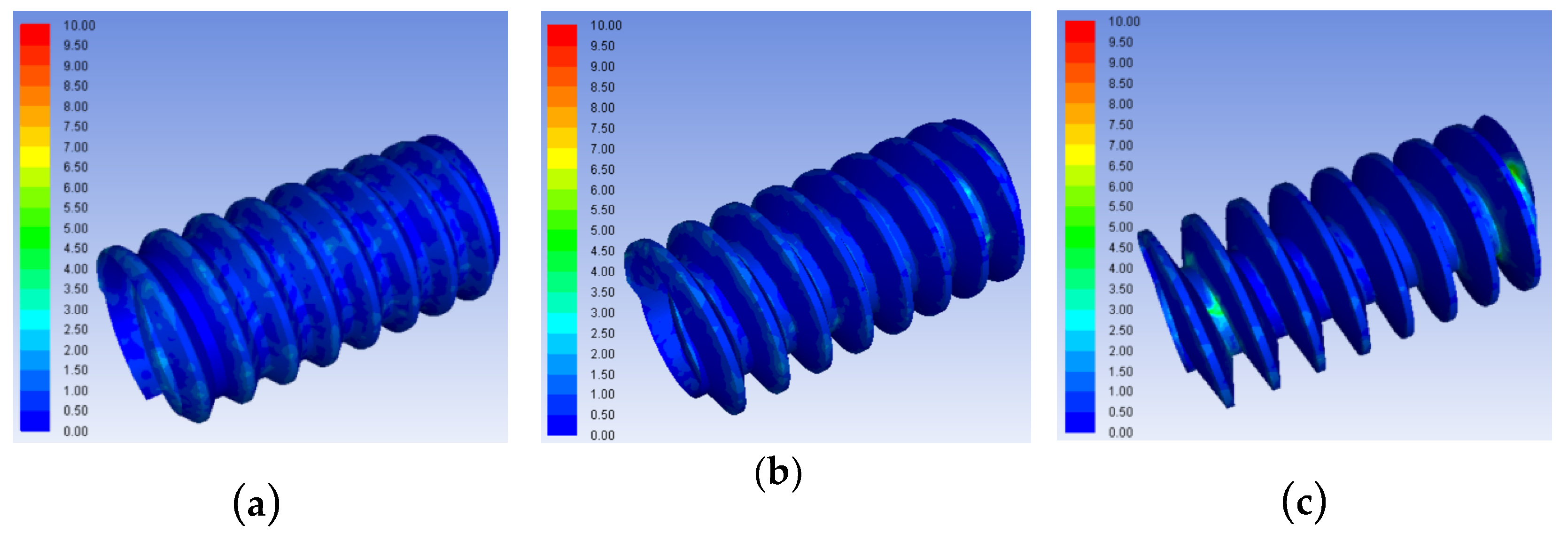

3.1. Concentration Distributions of Hybrid Products in the Small Machining Gap Using Tube Electrodes with Different Helical Structures

3.2. Optimization of Main Geometric Parameters for Trapezoidal Helical Tube Electrode

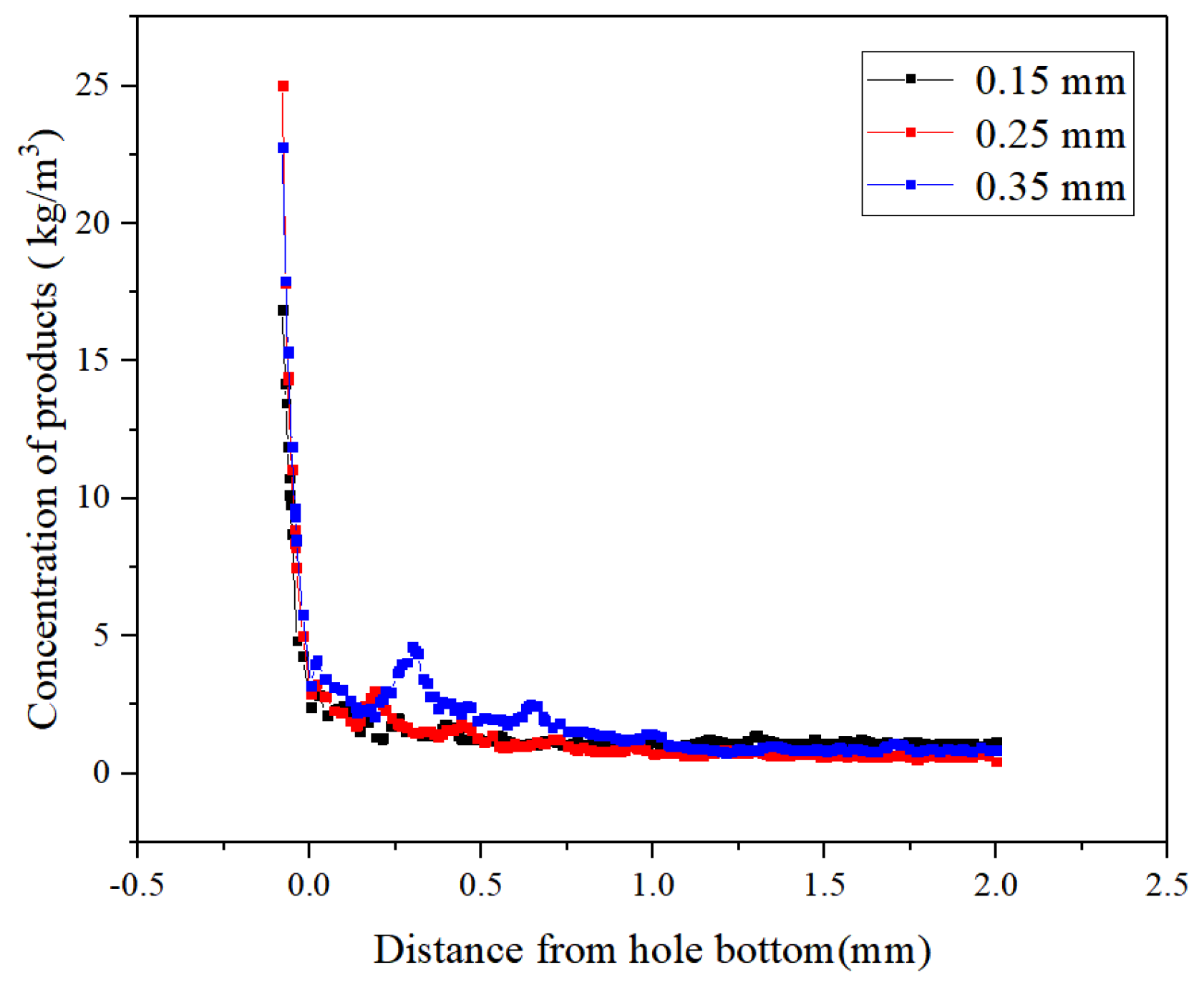

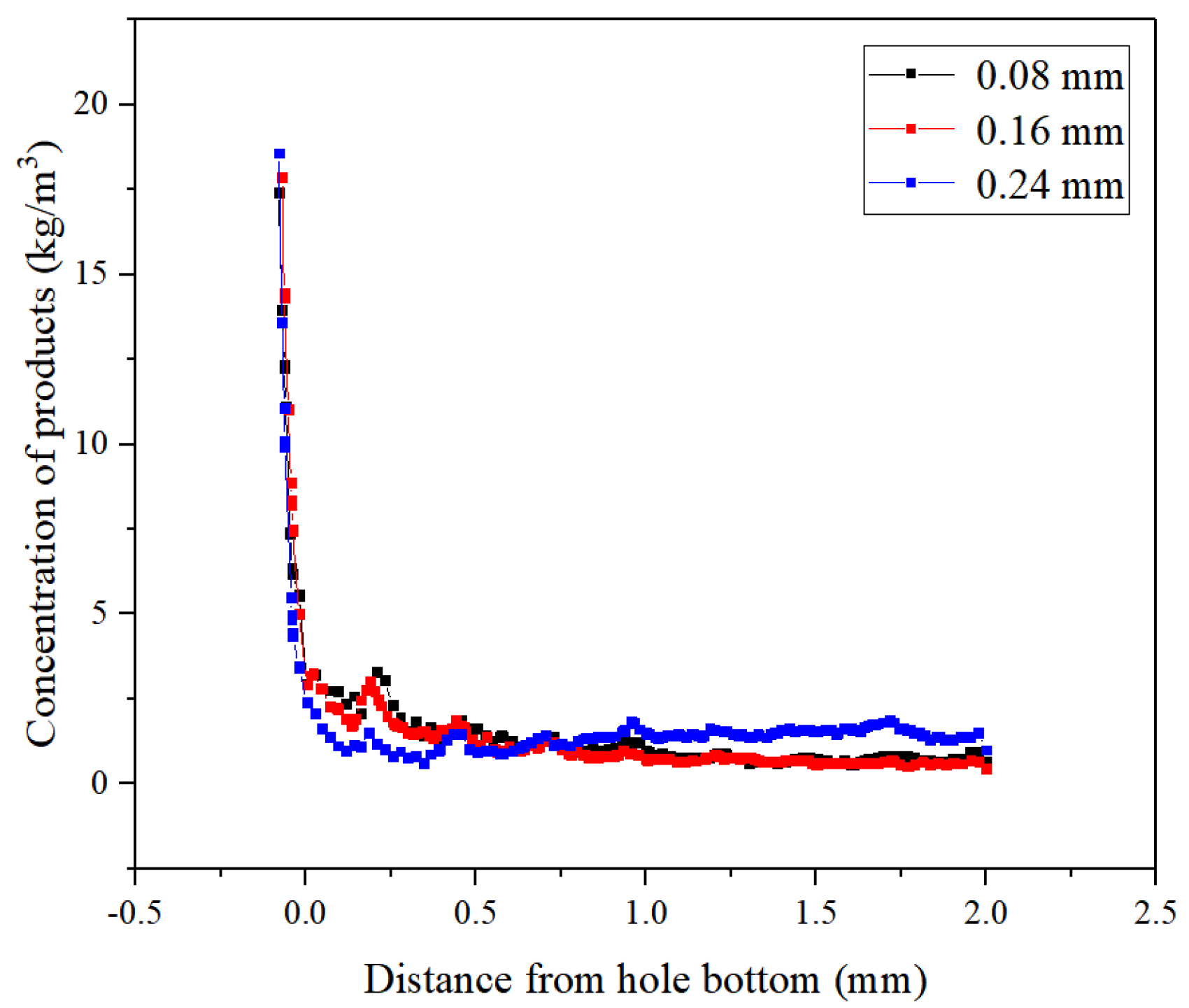

3.2.1. Effect of Helical Pitch on Product Concentration Distribution in the Machining Gap

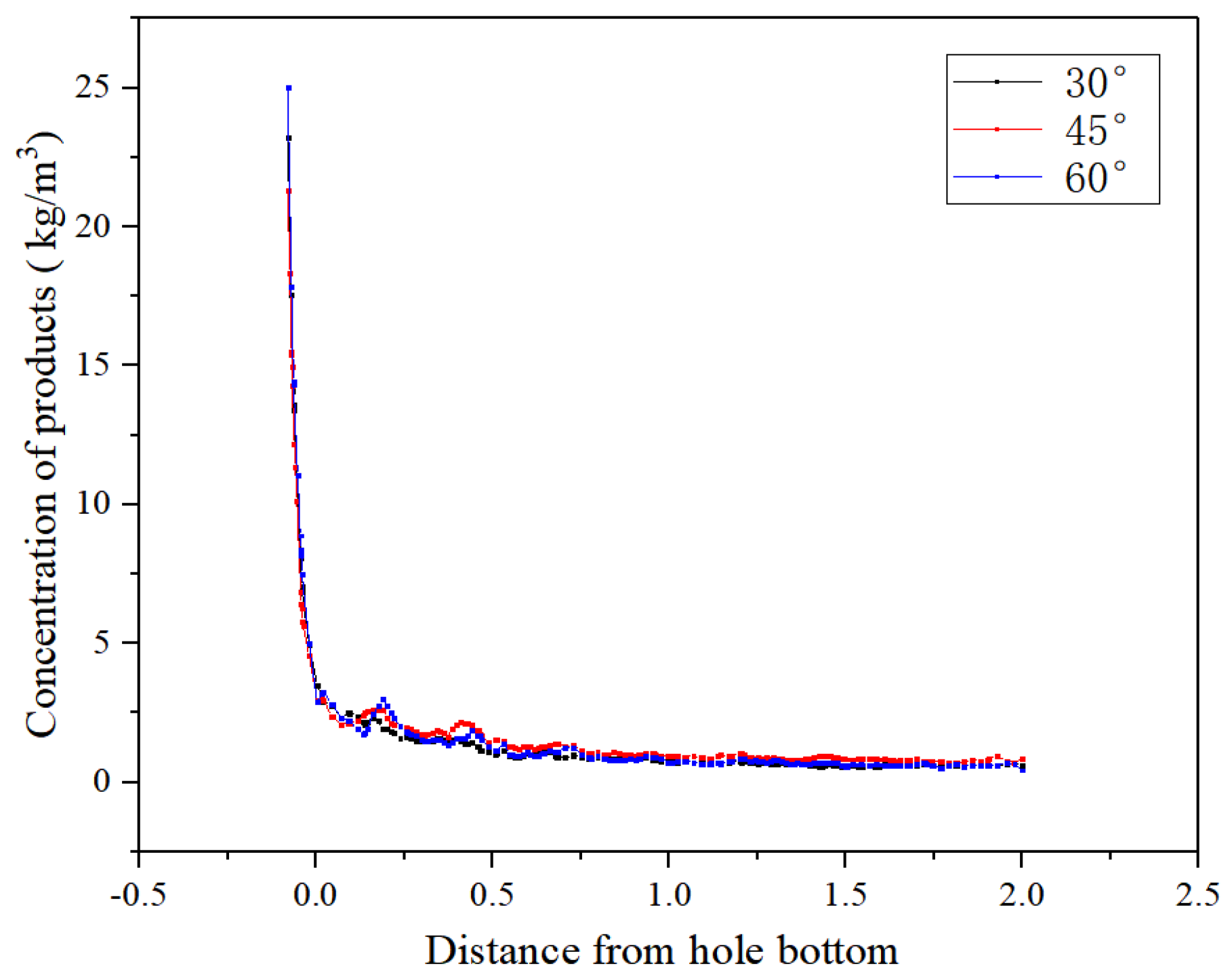

3.2.2. Effect of Thread Form Angle on Product Concentration Distribution in Machining Gap

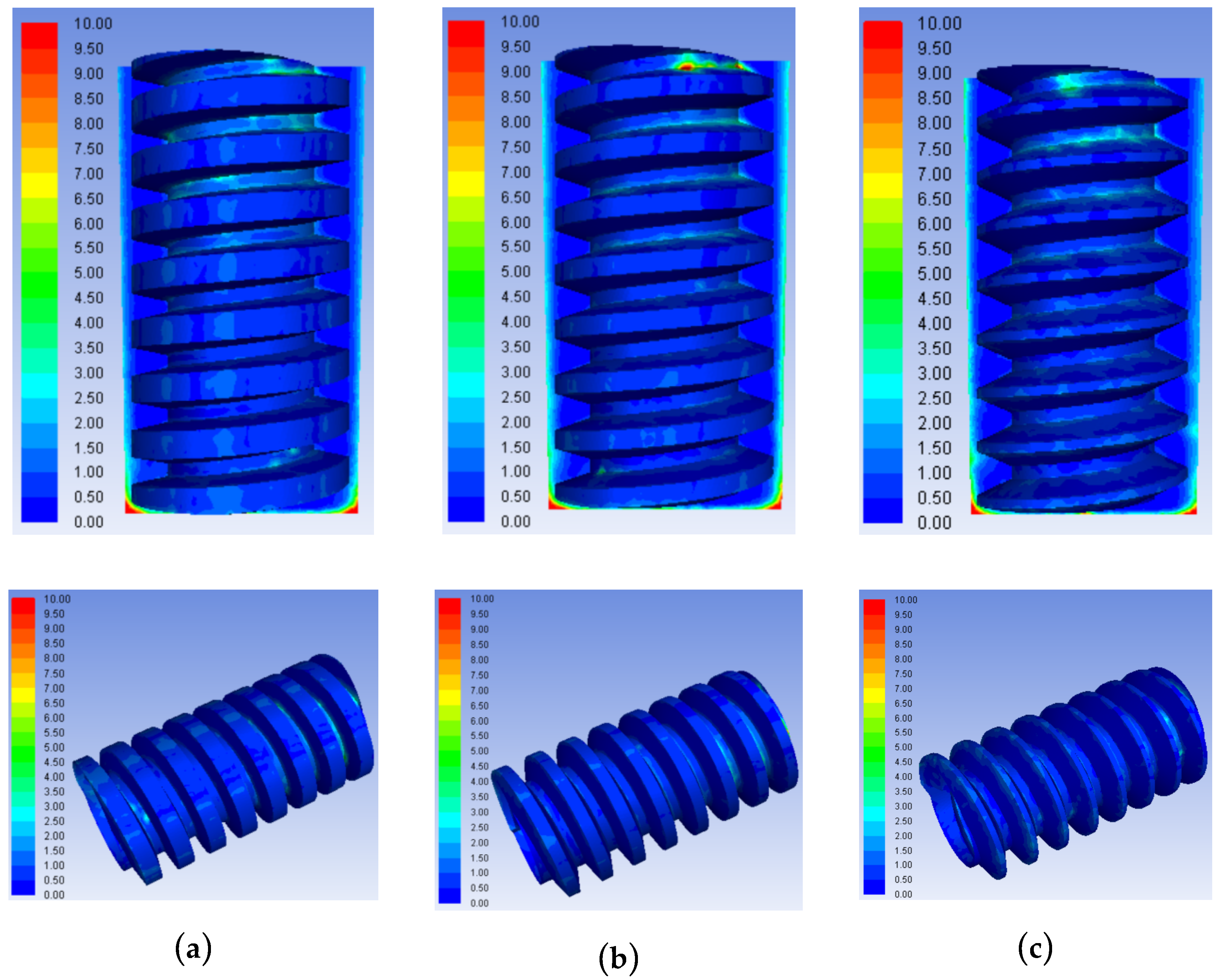

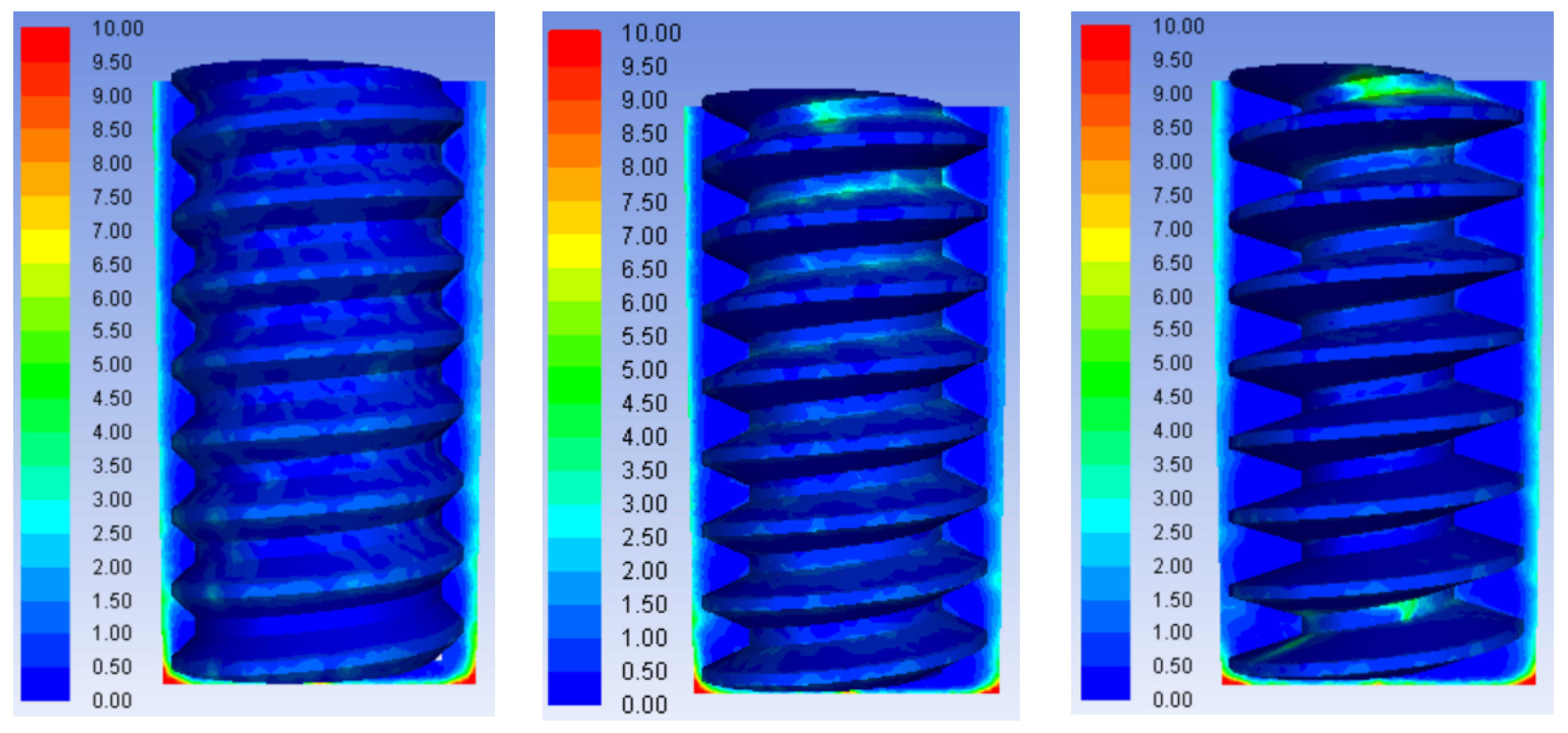

3.2.3. Effect of Depth of Helical Groove on Flow Field in Machining Gap

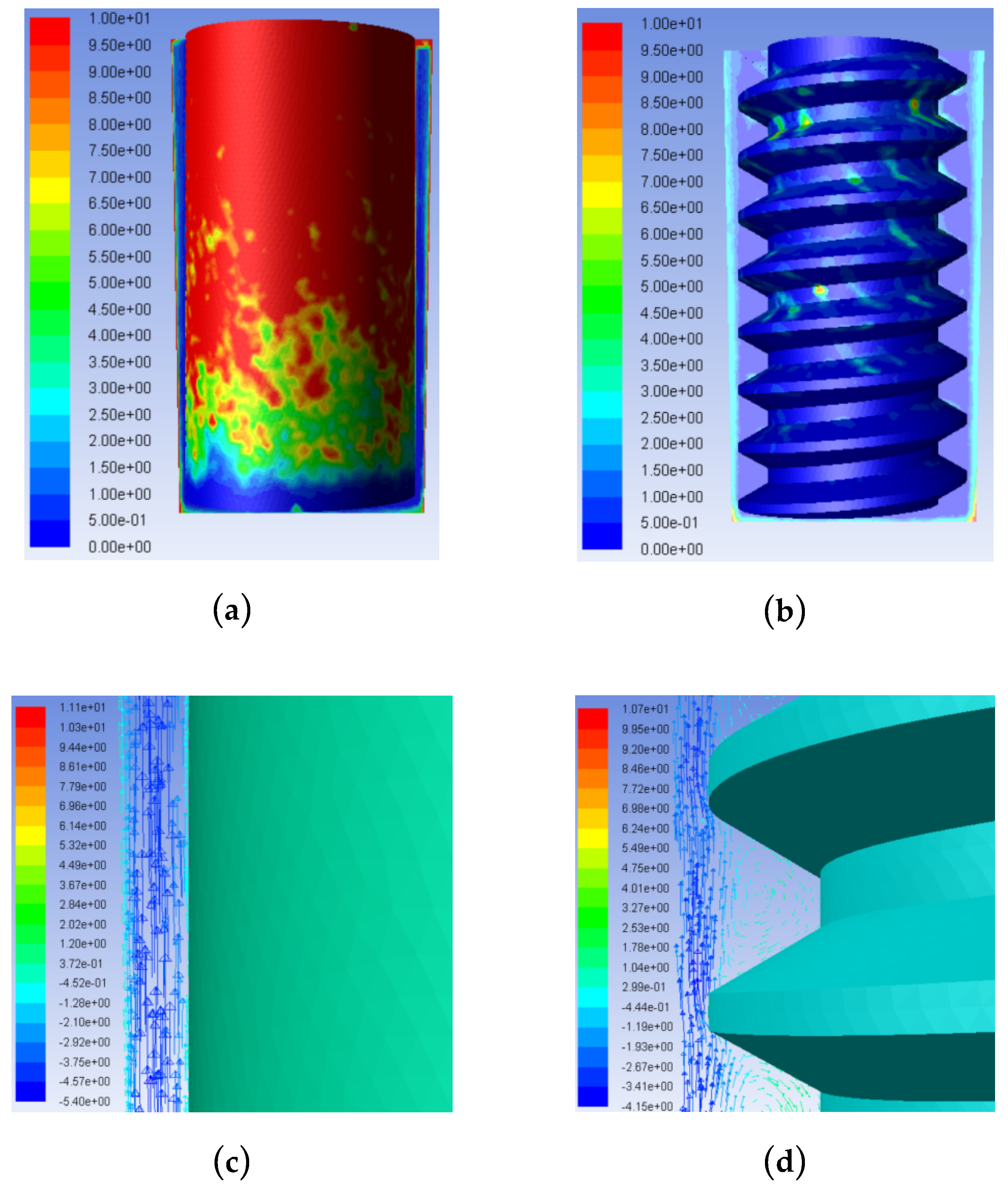

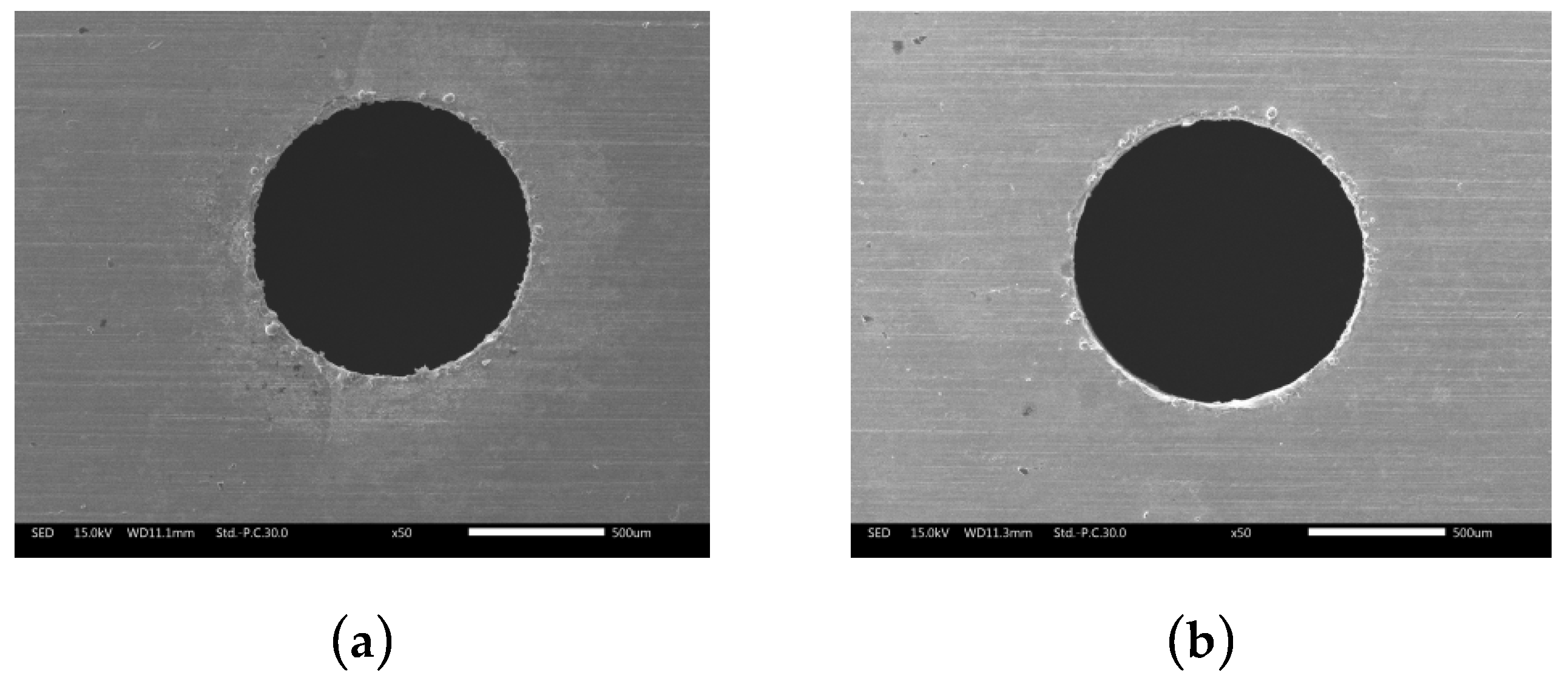

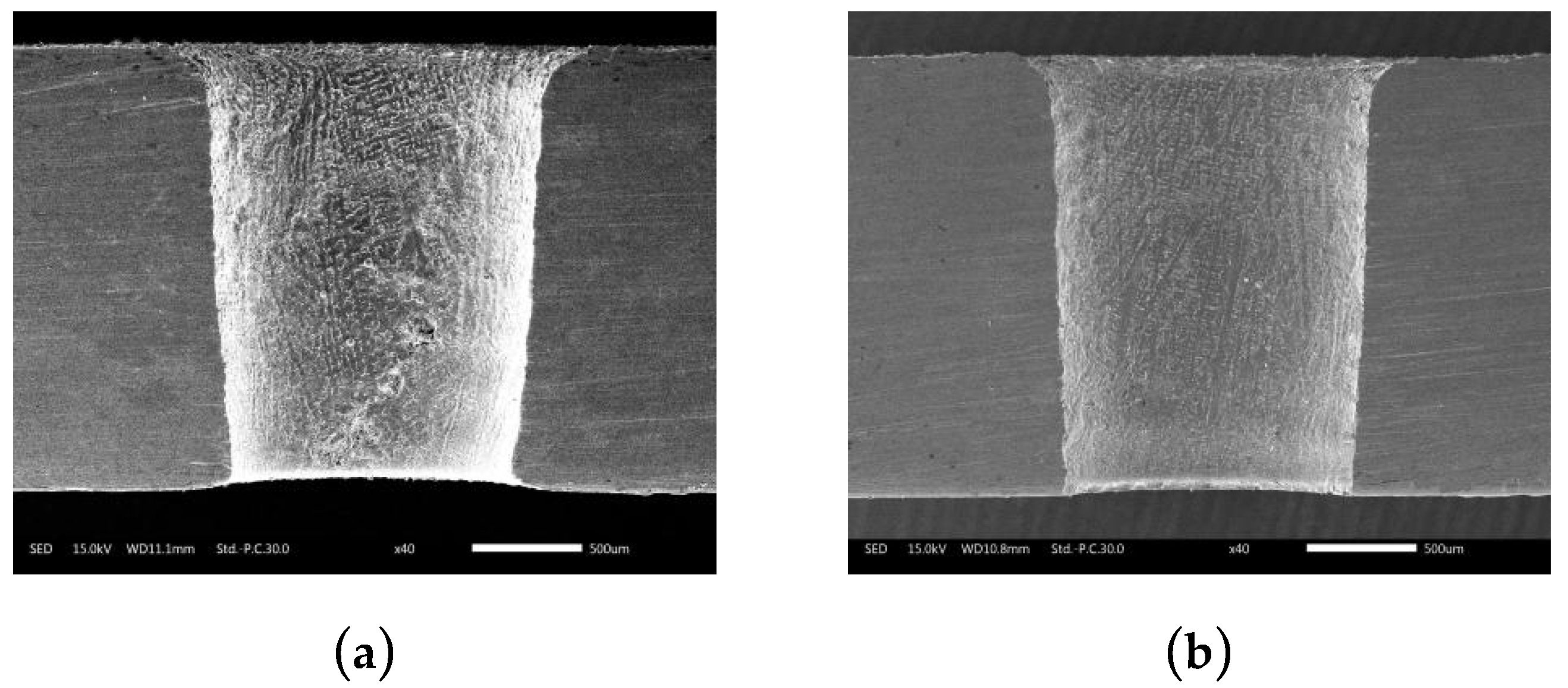

3.3. Comparison of Flow Field Simulations and Experiments Using Trapezoidal Helical and Cylindrical Tube Electrodes

4. Conclusions

- Flow-field simulations of tube electrodes with different helical structures show that, compared to triangular and rectangular helical structures, less product aggregation in the helical grooves occurs using a trapezoidal helical electrode, which is most beneficial for product removal.

- Through the simulation and optimization of the main geometric parameters of the trapezoidal helical structure, the optimal groove depth is 0.08 mm, the pitch is 0.25 mm, and the tooth angle is 60°.

- The flow field simulation of the machining gap between the trapezoidal helical electrode and the cylindrical electrode shows that the trapezoidal helix is more beneficial for product removal. The simulation results are supported by experimental data on machined holes.

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| ux, uy, uz | velocity components in the X, Y, Z directions (m/s) |

| t | fluid flow time (s) |

| ρ | fluid density (kg/m3) |

| , , | viscous stress component on the micro-element surface (Pa) |

| fx, fy, fz | unit mass force in the X, Y, Z directions (m/s2) |

| velocity of working fluid (m/s) | |

| velocity of particles produced by discharging (m/s) | |

| density of the processed products (kg/m3) | |

| μ | dynamic viscosity of working fluid (Pa·s) |

| ρ | fluid density (kg/m3) |

| dp | diameter of particles produced by discharging (m) |

| Re | Reynolds number |

| CD | drag coefficient |

| gravitational acceleration (m/s2) | |

| F | additional forces (N) |

References

- Bunker, R.S. A review of shaped hole turbine film-cooling technology. J. Heat Transf. 2005, 127, 441–453. [Google Scholar] [CrossRef]

- Bilgi, D.S.; Jain, V.K.; Shekhar, R.; Mehrotra, S. Electrochemical deep hole drilling in super alloy for turbine application. J. Mater. Process. Technol. 2004, 149, 445–452. [Google Scholar] [CrossRef]

- Singh, H. Experimental study of distribution of energy during EDM process for utilization in thermal models. Int. J. Heat Mass Transf. 2012, 55, 5053–5064. [Google Scholar] [CrossRef]

- Bamberg, E.; Heamawatanachai, S. Orbital electrode actuation to improve efficiency of drilling micro-holes by micro-EDM. J. Mater. Process. Technol. 2009, 209, 1826–1834. [Google Scholar] [CrossRef]

- Abbas, N.M. A review on current research trends in electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2007, 47, 1214–1228. [Google Scholar] [CrossRef]

- Goodlet, A.; Koshy, P. Real-time evaluation of gap flushing in electrical discharge machining. CIRP Ann. 2015, 64, 241–244. [Google Scholar] [CrossRef]

- Kumagai, S.; Sato, N.; Takeda, K. Combination of capacitance and conductive working fluid to speed up the fabrication of a narrow, deep hole in electrical discharge machining using a dielectric-encased wire electrode. Int. J. Mach. Tools Manuf. 2006, 46, 1536–1546. [Google Scholar] [CrossRef]

- Chen, S.L.; Lin, M.H.; Huang, G.X.; Wang, C.C. Research of the recast layer on implant surface modified by micro-current electrical discharge machining using deionized water mixed with titanium powder as dielectric solvent. Appl. Surf. Sci. 2014, 311, 47–53. [Google Scholar] [CrossRef]

- Wong, Y.S.; Lim, L.C.; Lee, L.C. Effects of flushing on electro-discharge machined surfaces. J. Mater. Process. Technol. 1995, 48, 299–305. [Google Scholar] [CrossRef]

- Liu, Y.; Li, M.; Niu, J.; Lu, S.; Jiang, Y. Fabrication of Taper Free Micro-Holes Utilizing a Combined Rotating Helical Electrode and Short Voltage Pulse by ECM. Micromachines 2019, 10, 28. [Google Scholar] [CrossRef]

- Wang, W.; Zhu, D.; Qu, N.; Huang, S.; Fang, X. Electrochemical drilling with vacuum extraction of electrolyte. J. Mater. Process. Technol. 2010, 210, 238–244. [Google Scholar] [CrossRef]

- Yang, C.K.; Wu, K.L.; Hung, J.C.; Lee, S.M.; Lin, L.C.; Yan, B.H. Enhancement of ECDM efficiency and accuracy by spherical tool electrode. Int. J. Mach. Tools Manuf. 2011, 51, 528–535. [Google Scholar] [CrossRef]

- Hung, J.C.; Lin, J.K.; Yan, B.H.; Liu, H.S.; Ho, P.H. Using a helical micro-tool in micro-EDM combined with ultrasonic vibration for micro-hole machining. J. Micromech. Microeng. 2006, 16, 2705. [Google Scholar] [CrossRef]

- Nastasi, R.; Koshy, P. Analysis and performance of slotted tools in electrical discharge drilling. CIRP Ann. 2014, 63, 205–208. [Google Scholar] [CrossRef]

- Plaza, S.; Sanchez, J.A.; Perez, E.; Gil, R.; Izquierdo, B.; Ortega, N.; Pombo, I. Experimental study on micro EDM-drilling of Ti6Al4V using helical electrode. Precis. Eng. 2014, 38, 821–827. [Google Scholar] [CrossRef]

- Hung, J.; Liu, H.; Chang, Y.; Hung, K.; Liu, S. Development of helical electrode insulation layer for electrochemical microdrilling. Procedia CIRP 2013, 6, 373–377. [Google Scholar] [CrossRef]

- Fang, X.L.; Zhang, P.F.; Zeng, Y.B.; Qu, N.S.; Zhu, D. Enhancement of performance of wire electrochemical micromachining using a rotary helical electrode. J. Mater. Process. Technol. 2016, 227, 129–137. [Google Scholar]

- Tang, J.P. ANSYS 16.0; Posts and Telecom Press: Beijing, China, 2016; pp. 18–19. [Google Scholar]

- Morsi, S.A.; Alexander, A.J. An investigation of particle trajectories in two-phase flow systems. J. Fluid Mech. 1972, 55, 193–208. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| External diameter of helical tube electrode (μm) | 1000 |

| Internal diameter of helical tube electrode (μm) | 300 |

| Flushing pressure (m/s) | 8 |

| Rotation of helical tube electrode (r/min) | 600 |

| Particle diameter (μm) | 5–50 |

| Parameter | Value |

|---|---|

| Thickness of workpiece (mm) | 2 |

| Working fluid concentration of NaNO3 (g/L) | 4.5 |

| Flushing pressure (MPa) | 3.5 |

| Rotation of helical tube electrode (r/min) | 300 |

| Pulse duration (μs) | 12 |

| Pulse interval (μs) | 12 |

| Peak current (A) | 14 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, C.; Wang, Y.; Ji, L.; Tang, J.; Ni, Q. Effects of Helical Tube Electrode Structure on Mixed Machining Product Transfer in Micro-Machining Channel during Tube Electrode High-Speed Electrochemical Discharge Machining. Micromachines 2019, 10, 634. https://doi.org/10.3390/mi10100634

Zhang Y, Wang C, Wang Y, Ji L, Tang J, Ni Q. Effects of Helical Tube Electrode Structure on Mixed Machining Product Transfer in Micro-Machining Channel during Tube Electrode High-Speed Electrochemical Discharge Machining. Micromachines. 2019; 10(10):634. https://doi.org/10.3390/mi10100634

Chicago/Turabian StyleZhang, Yan, Chen Wang, Yu Wang, Lei Ji, Jian Tang, and Qin Ni. 2019. "Effects of Helical Tube Electrode Structure on Mixed Machining Product Transfer in Micro-Machining Channel during Tube Electrode High-Speed Electrochemical Discharge Machining" Micromachines 10, no. 10: 634. https://doi.org/10.3390/mi10100634

APA StyleZhang, Y., Wang, C., Wang, Y., Ji, L., Tang, J., & Ni, Q. (2019). Effects of Helical Tube Electrode Structure on Mixed Machining Product Transfer in Micro-Machining Channel during Tube Electrode High-Speed Electrochemical Discharge Machining. Micromachines, 10(10), 634. https://doi.org/10.3390/mi10100634