Bridging Sustainability and Performance: Conceptualizing Net-Zero Integration in Construction Supply Chain Evaluations

Abstract

1. Introduction

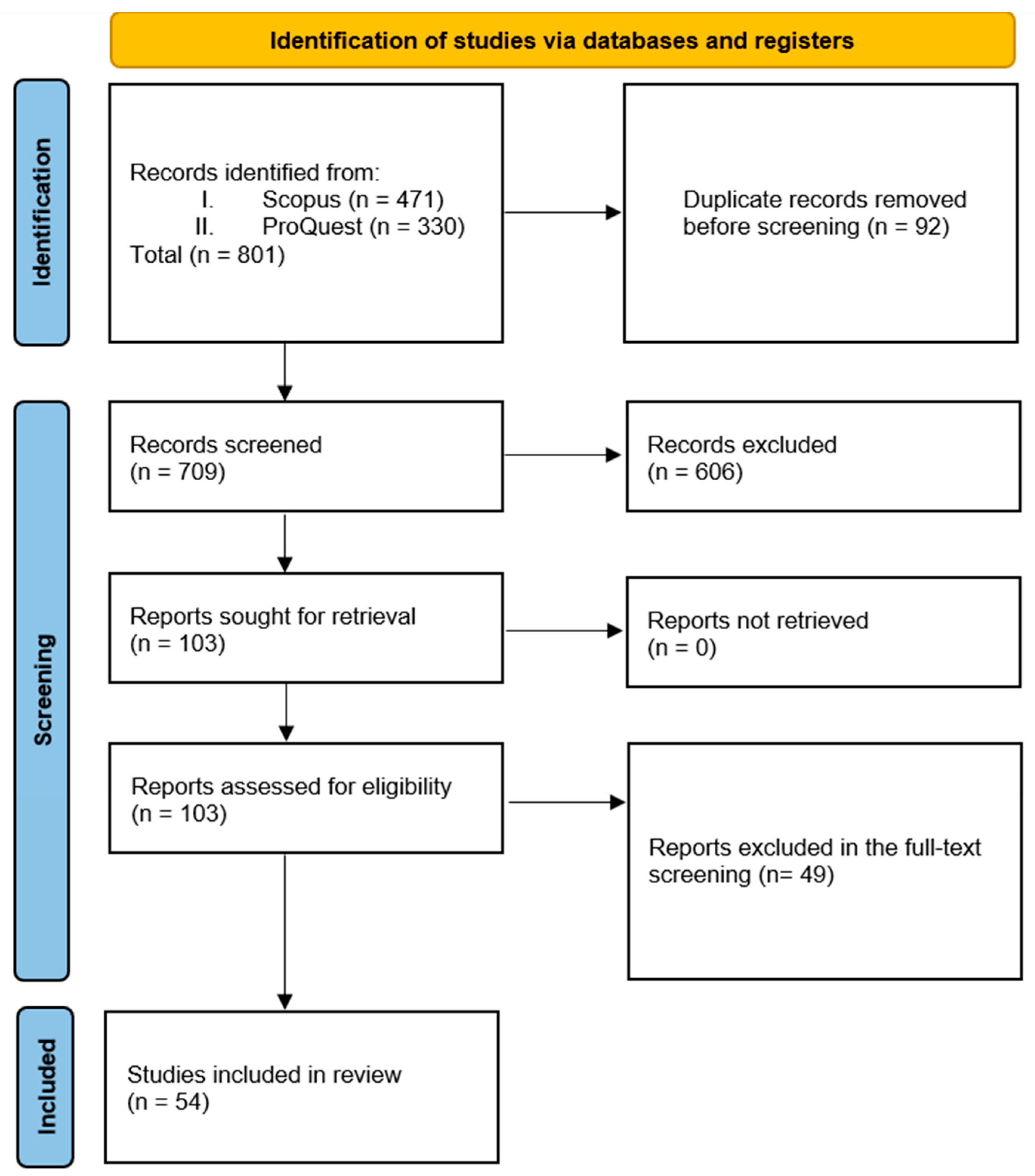

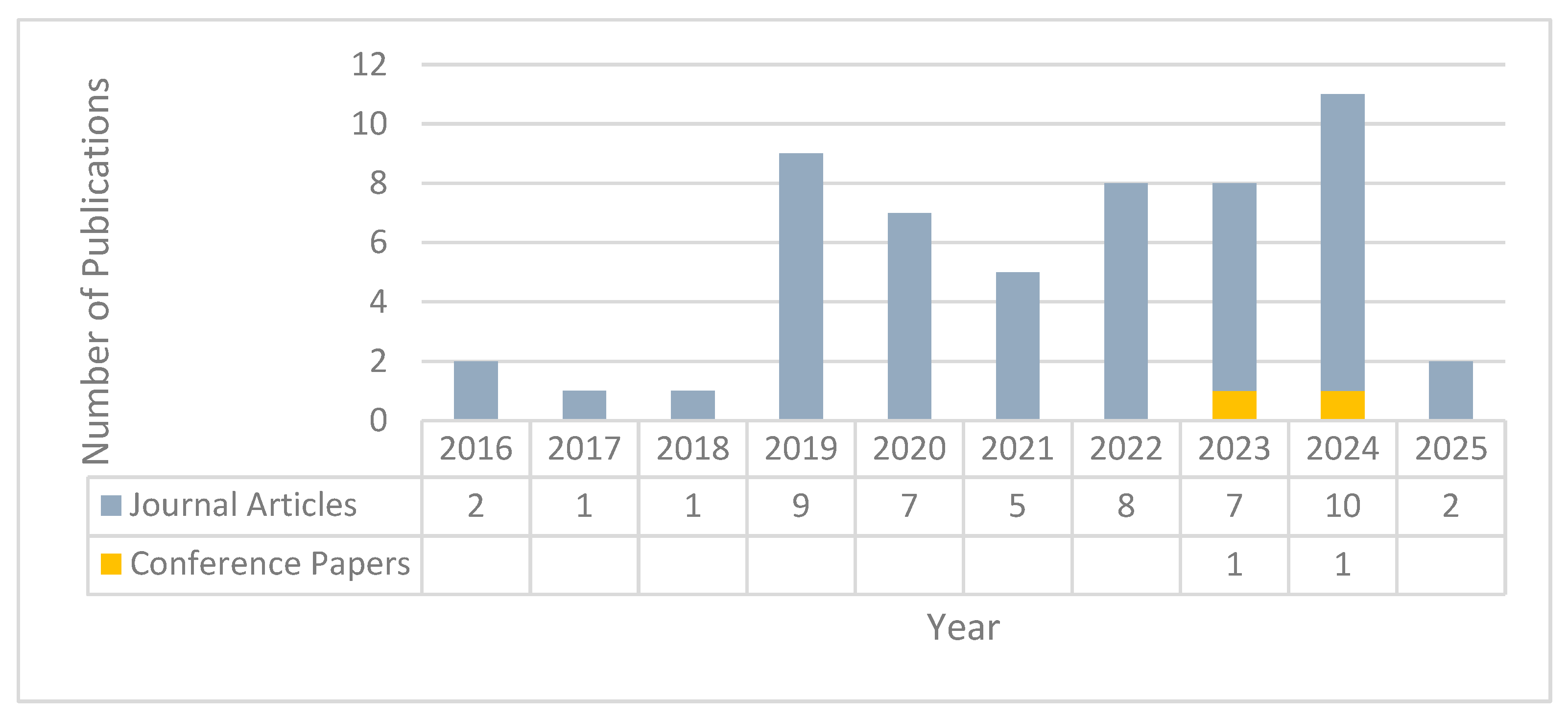

2. Materials and Methods

2.1. Defining the Research Questions

- RQ1: How are the net-zero indicators integrated in the construction material supply chains’ performance evaluation, and what indicators and activities are considered?

- RQ2: What tools and technologies support performance evaluation and carbon tracking?

- RQ3: What are the challenges and enablers of integrating net-zero in construction material supply chain performance evaluation?

- RQ4: What key strategies, theoretical perspectives, and frameworks have been used to evaluate net-zero construction supply chains, and what research gaps remain that could advance net-zero supply chain evaluation?

2.2. Selecting Relevant Studies

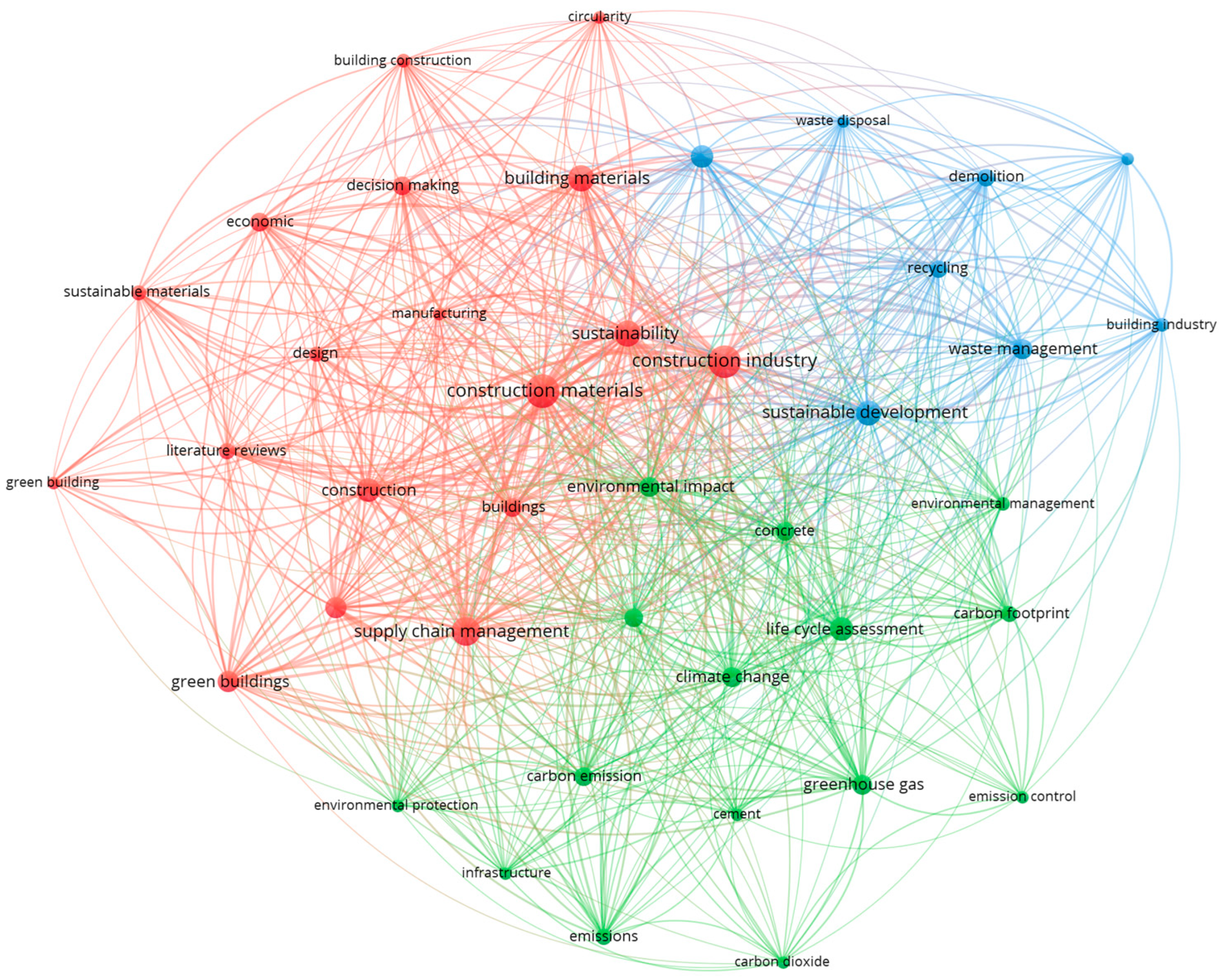

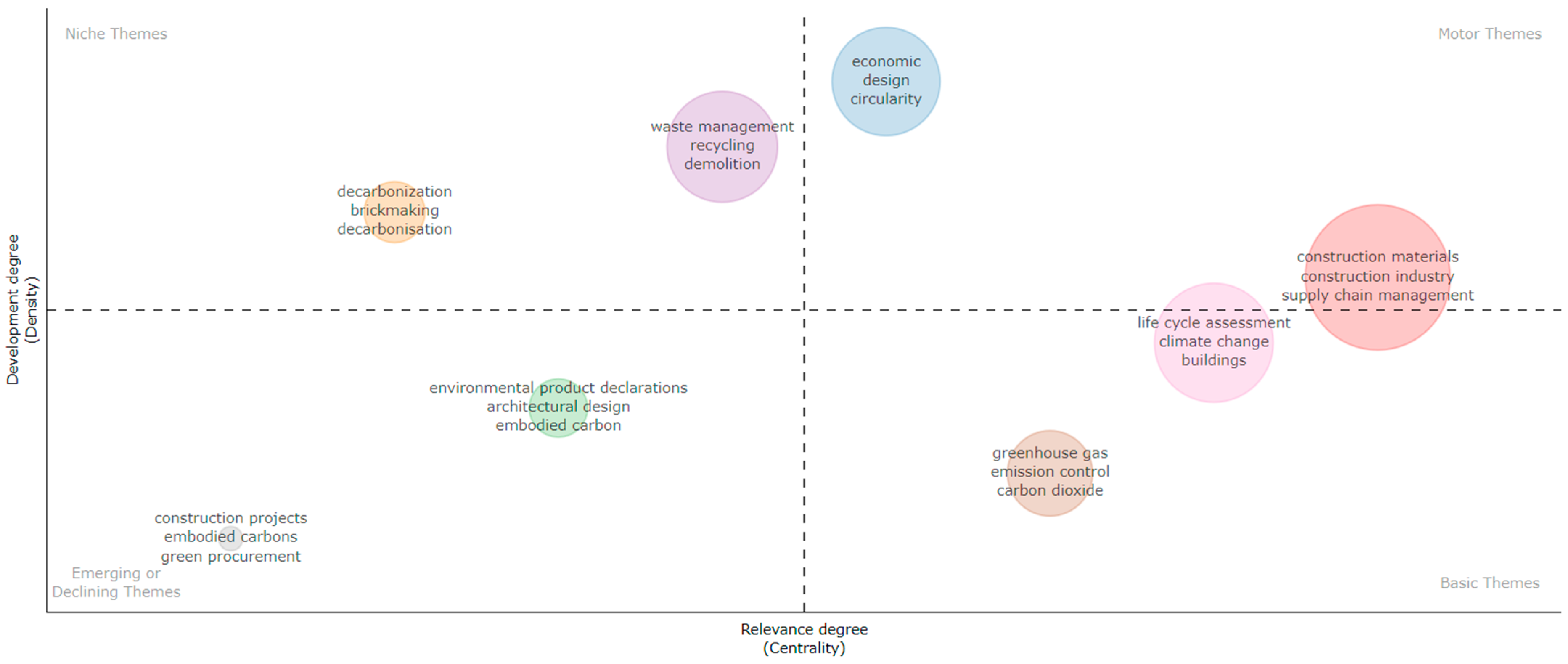

2.3. Analysis and Interpretation

3. Results

3.1. Evaluation of Construction Material Supply Chain Performance

3.2. Application of Tools and Technology

| Tools | References |

|---|---|

| Building Information Modelling (BIM) and Extensions | [5,6,15,16,19,23,24,41,42,45,49,58] |

| Life Cycle Assessment (LCA) Tools | [1,3,5,6,9,10,12,15,23,24,25,26,34,35,36,38,41,47,48,49,50,51,52,53,54,60] |

| Environmental Product Declarations (EPDs) | [6,9,12,23,25,45,49] |

| Evaluation and Decision-Making Methods | [2,13,14,32,40,44,48,56,61,67,68] |

| IoT, Sensors, Automation and Integration | [14,15,16,19,37,61] |

| Energy and Emission Modelling | [3,6,12,36,46,51] |

| Standards, Labels and Certifications | [1,19,25,26,55,57,58,59] |

| Databases | [1,5,6,34,35,36,39,49,51,54] |

| Survey and Stakeholder Tools | [2,18,32,42,43,56,57,69] |

| Geographic and Mapping Tools | [16,19,35,37,54] |

| Material and Flow Assessment Tools | [10,15,18,47,68] |

3.3. Challenges and Enablers

3.4. Advancing Net-Zero Supply Chain Evaluation

4. Discussion

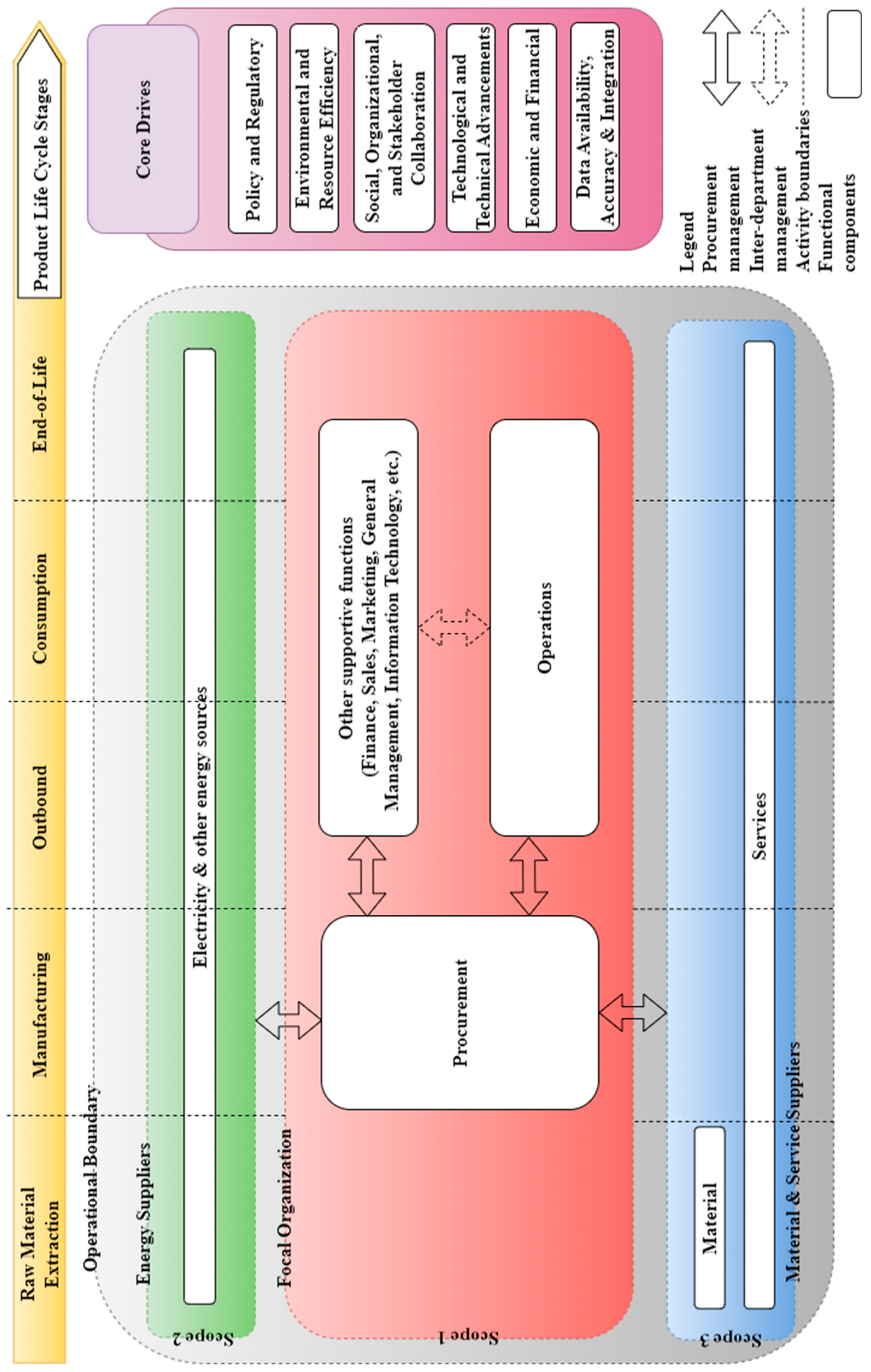

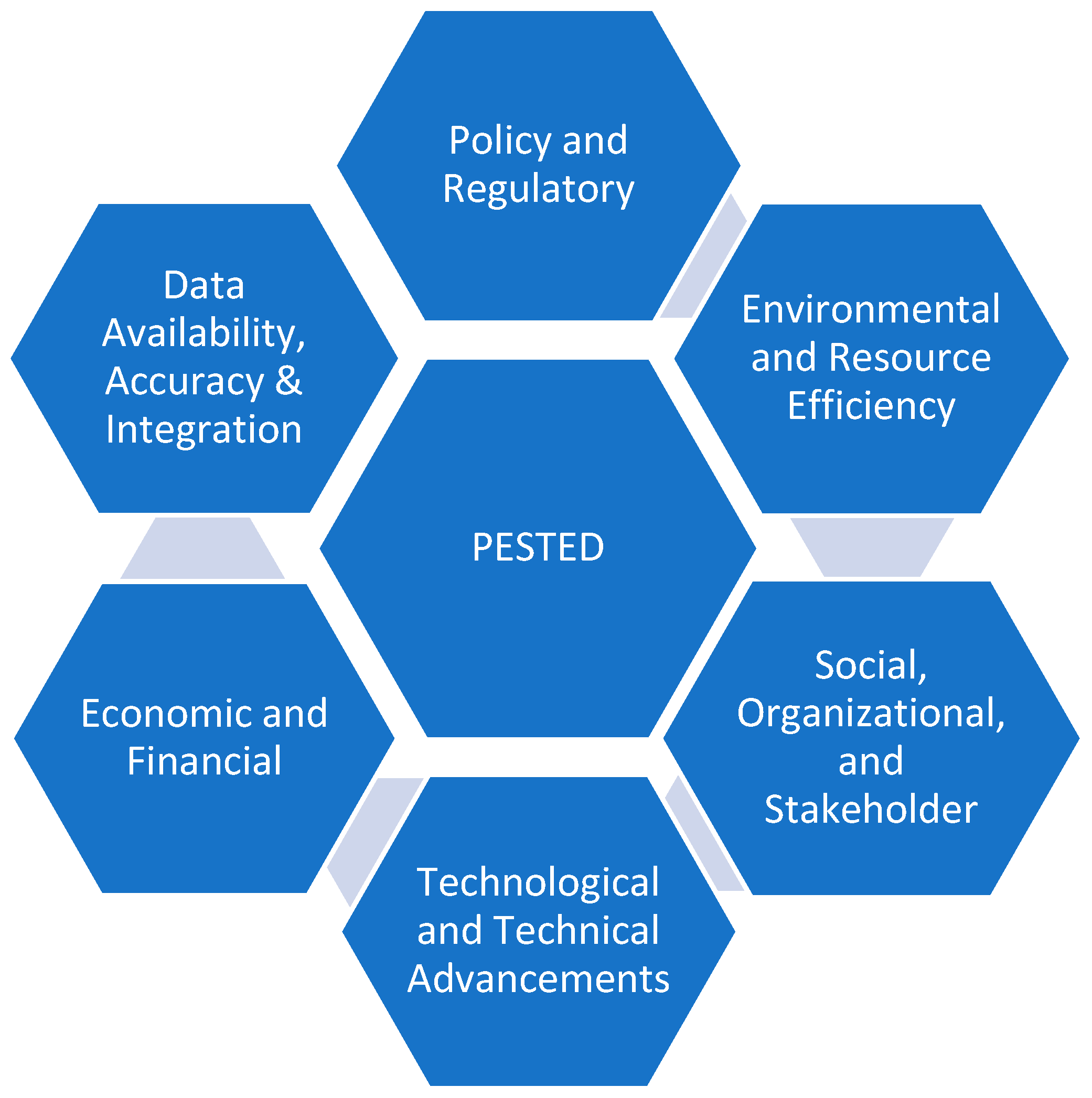

4.1. PESTED Framework

4.2. Conceptual Framework Development

4.3. Future Work

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| BIM | Building Information Modelling |

| CE | Circular Economy |

| EPD | Environmental Product Declarations |

| GHG | Greenhouse Gas |

| GPP | Green Public Procurement |

| GWP | Global Warming Potential |

| ISO | International Organization for Standards |

| LCA | Life Cycle Assessment |

| LEED | Leadership in Energy and Environmental Design |

| MCDM | Multi-Criteria Decision-Making |

| PESTED | Policy and Regulatory, Environmental and Resource Efficiency, Social, Organizational, and Stakeholder Collaboration, Technological and Technical Advancements, Economic and Financial, and Data Availability, Accuracy and Integration |

| PESTLE | Political, Economic, Social, Technological, Legal, and Environmental |

| PRISMA | Preferred Reporting Items for Systematic Reviews and Meta-Analyses |

| RQ | Research Question |

| WMS | Warehouse Management System |

References

- Otero, M.S.; Garnica, T.; Montilla, S.; Conde, M.; Tenorio, J.A. Analysis of Sectoral Environmental Product Declarations as a Data Source for Life Cycle Assessment. Buildings 2023, 13, 3032. [Google Scholar] [CrossRef]

- Shan, M.; Liu, W.Q.; Hwang, B.G.; Lye, J.M. Critical Success Factors for Small Contractors to Conduct Green Building Construction Projects in Singapore: Identification and comparison with large contractors. Environ. Sci. Pollut. Res. 2020, 27, 8310–8322. [Google Scholar] [CrossRef] [PubMed]

- Laveglia, A.; Ukrainczyk, N.; De Belie, N.; Koenders, E. From Quarry to Carbon Sink: Process-Based LCA Modelling of Lime-Based Construction Materials for Net-Zero and Carbon-Negative Transformation. Green Chem. 2024, 26, 6584–6600. [Google Scholar] [CrossRef]

- Iqbal, M.; Fan, Y.; Ahmad, N.; Ullah, I. Circular Economy Solutions for Net-Zero Carbon in China’s Construction Sector: A strategic evaluation. J. Clean. Prod. 2025, 504, 145398. [Google Scholar] [CrossRef]

- Jalaei, F.; Masoudi, R.; Guest, G. A Framework for Specifying Low-Carbon Construction Materials in Government Procurement: A Case Study for Concrete in a New Building Investment. J. Clean. Prod. 2022, 345, 131056. [Google Scholar] [CrossRef]

- Dalton, T.; Dorignon, L.; Boehme, T.; Kempton, L.; Iyer-Raniga, U.; Oswald, D.; Amirghasemi, M.; Moore, T. Building Materials in a Circular Economy. AHURI Final. Rep. 2023. [Google Scholar] [CrossRef]

- Iqbal, M.; Ma, J.; Ahmad, N.; Ullah, Z.; Hassan, A. Energy-Efficient Supply Chains in Construction Industry: An Analysis of Critical Success Factors Using ISM-MICMAC Approach. Int. J. Green Energy 2023, 20, 265–283. [Google Scholar] [CrossRef]

- Teske, S.; Nagrath, K.; Niklas, S.; Talwar, S.; Atherton, A.; Orbe, J.G.; Assaf, J.; Giurco, D. Scopes 1, 2, and 3 Industry Emissions and Future Pathways. In Achieving the Paris Climate Agreement Goals: Part 2: Science-Based Target Setting for the Finance Industry —Net-Zero Sectoral 1.5 °C Pathways for Real Economy Sectors; Teske, S., Ed.; Springer International Publishing: Cham, Switzerland, 2022; pp. 315–336. ISBN 978-3-030-99177-7. [Google Scholar]

- Kerr, J.; Rayburg, S.; Neave, M.; Rodwell, J. Comparative Analysis of the Global Warming Potential (GWP) of Structural Stone, Concrete and Steel Construction Materials. Sustainability 2022, 14, 9019. [Google Scholar] [CrossRef]

- Laveglia, A.; Ukrainczyk, N.; De Belie, N.; Koenders, E. Decarbonizing the Lime-Based Construction Materials Industry: A Practical Guide for Cradle-to-Gate Life-Cycle Inventory. Sustain. Prod. Consum. 2023, 40, 194–209. [Google Scholar] [CrossRef]

- Sagan, J.; Sobotka, A. Analysis of Factors Affecting the Circularity of Building Materials. Materials 2021, 14, 7296. [Google Scholar] [CrossRef]

- Palomar-Torres, A.; Rey-Hernández, J.M.; Rey-Hernández, A.; Rey-Martínez, F.J. Decarbonizing Near-Zero-Energy Buildings to Zero-Emission Buildings: A Holistic Life Cycle Approach to Minimize Embodied and Operational Emissions Through Circular Economy Strategies. Appl. Sci. 2025, 15, 2670. [Google Scholar] [CrossRef]

- Cabral, M.R.; Blanchet, P. Prioritizing Indicators for Material Selection in Prefabricated Wooden Construction. Buildings 2024, 14, 63. [Google Scholar] [CrossRef]

- Xia, W.; Li, B.; Shi, Y. A Prescription for Urban Sustainability Transitions in China: Innovative Partner Selection Management of Green Building Materials Industry in an Integrated Supply Chain. Sustainability 2020, 12, 2581. [Google Scholar] [CrossRef]

- Ott, S.; Rudena, A.; Kies, U.; Wagner, A.; Jancke, O. Digital Twin Framework for Visual Exploration of Material Flows and Carbon Impacts of Engineered Wood Supply Chains from Forest to Buildings. In Proceedings of the World Conference on Timber Engineering (WCTE), Oslo, Norway, 19–22 June 2023; Nyrud, A.Q., Malo, K.A., Nore, K., Alsen, K.W.L., Tulebekova, S., Staehr, E.R., Bergh, G., Wuyts, W., Eds.; Volume 7, pp. 4496–4504. [Google Scholar]

- Junussova, T.; Nadeem, A.; Kim, J.R.; Azhar, S. Key Drivers for BIM-Enabled Materials Management: Insights for a Sustainable Environment. Buildings 2024, 14, 84. [Google Scholar] [CrossRef]

- Li, Q.; Chen, Z.; Li, X.; Brancart, S.; Overend, M. Vertical Perovskite Solar Cell Envelope for the Circular Economy: A Case Study Using Life Cycle Cost Analysis in Europe. J. Clean. Prod. 2024, 467, 143017. [Google Scholar] [CrossRef]

- Egerter, A.; Koehler, J.; Oltean, C.; Hall, D.; Thuesen, C. Circular Economy Maturity: How Circular Are Our Construction Products? IOP Conf. Ser. Earth Environ. Sci. 2024, 1389, 012002. [Google Scholar] [CrossRef]

- Chen, P.H.; Nguyen, T.C. A BIM-WMS Integrated Decision Support Tool for Supply Chain Management in Construction. Autom. Constr. 2019, 98, 289–301. [Google Scholar] [CrossRef]

- Amudjie, J.; Chan, A.P.C.; Darko, A.; Debrah, C.; Agyekum, K. CircularBIM: Future Needs at the Convergence of Building Information Modelling and the Circular Economy. Autom. Constr. 2025, 176, 106250. [Google Scholar] [CrossRef]

- Li, Q.; Monticelli, C.; Kutlu, A.; Zanelli, A. Environmental Performance Analysis of Textile Envelope Integrated Flexible Photovoltaic Using Life Cycle Assessment Approach. J. Build. Eng. 2024, 89, 109348. [Google Scholar] [CrossRef]

- Almulhim, M.S.M.; Hunt, D.V.L.; Rogers, C.D.F. A Resilience and Environmentally Sustainable Assessment Framework (RESAF) for Domestic Building Materials in Saudi Arabia. Sustainability 2020, 12, 3092. [Google Scholar] [CrossRef]

- Göswein, V.; Carvalho, S.; Cerqueira, C.; Lorena, A. Circular Material Passports for Buildings–Providing a Robust Methodology for Promoting Circular Buildings. IOP Conf. Ser. Earth Environ. Sci. 2022, 1122, 012049. [Google Scholar] [CrossRef]

- Finnie, D.A.; Masood, R.; Goldsworthy, S.; Harding, B. Embodied Carbon in New Zealand Commercial Construction. Energies 2024, 17, 2629. [Google Scholar] [CrossRef]

- Assaad, R.H. Examining Low-Carbon Material Initiatives: Existing Policies, Impacts on the Procurement of Projects, Current Challenges, and Potential Solutions to Reduce Embodied Carbon in the Construction Industry. J. Leg. Aff. Dispute Resolut. Eng. Constr. 2024, 16, 04523060. [Google Scholar] [CrossRef]

- Senseney, C.T.; Harvey, J.; Butt, A.A.; Meijer, J. Recommendations for Cradle-to-Gate Environmental Product Declarations (EPD) in ‘Buy Clean’ Procurement Based on CDOT’s Experience. Environ. Res. Infrastruct. Sustain. 2023, 3, 035004. [Google Scholar] [CrossRef]

- Benedetti, A.C.; Costantino, C.; Lobosco, R.; Predari, G.; Gulli, R. Comparative LCA Scenarios for Urban Regeneration of Residential Building Stock. Application to an Existing High-density Urban Block in Bologna. Energy Build. 2025, 329, 115270. [Google Scholar] [CrossRef]

- Calzolari, T.; Genovese, A.; Brint, A. Circular Economy Indicators for Supply Chains: A Systematic Literature Review. Environ. Sustain. Indic. 2022, 13, 100160. [Google Scholar] [CrossRef]

- Daemei, A.B.; Lovreglio, R.; Feng, Z.; Paes, D.; Miller, C. Gamification for Air Quality Education: A Systematic Literature Review. Build. Environ. 2025, 270, 112526. [Google Scholar] [CrossRef]

- Tjebane, M.M.; Musonda, I.; Okoro, C.; Onososen, A. Artificial Intelligence (AI) in Sustainable Construction Management: A Scientometric Review. In Construction in 5D: Deconstruction, Digitalization, Disruption, Disaster, Development; Springer: Cham, Switzerland, 2023; pp. 137–150. ISBN 978-3-030-97748-1. [Google Scholar]

- Baas, J.; Schotten, M.; Plume, A.; Côté, G.; Karimi, R. Scopus as a Curated, High-Quality Bibliometric Data Source for Academic Research in Quantitative Science Studies. Quant. Sci. Stud. 2020, 1, 377–386. [Google Scholar] [CrossRef]

- Litos, L.; Paddea, S.; Salonitis, K.; Jolly, M. A Conceptual Assessment Framework for Sustainability in the Foundation Industries. In Procedia CIRP; Erkoyuncu, J.A., Farsi, M., Addepalli, P., Eds.; Elsevier: Amsterdam, The Netherlands, 2024; Volume 128, pp. 692–697. [Google Scholar]

- Aria, M.; Cuccurullo, C. bibliometrix: An R-tool for comprehensive science mapping analysis. J. Informetr. 2017, 11, 959–975. [Google Scholar] [CrossRef]

- Nouhoun, I.S.; Nshimiyimana, P.; Hema, C.; Messan, A. Development of a Life Cycle Inventory Database for Environmental Impact Assessment of Construction Materials in Burkina Faso. Sustainability 2025, 17, 471. [Google Scholar] [CrossRef]

- Hossain, M.U.; Sohail, A.; Ng, S.T. Developing a GHG-based Methodological Approach to Support the Sourcing of Sustainable Construction Materials and Products. Resour. Conserv. Recycl. 2019, 145, 160–169. [Google Scholar] [CrossRef]

- Padilla-Rivera, A.; Amor, B.; Blanchet, P. Evaluating the Link between Low Carbon Reductions Strategies and Its Performance in the Context of Climate Change: A Carbon Footprint of a Wood-Frame Residential Building in Quebec, Canada. Sustainability 2018, 10, 2715. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W.; Chi, B.; Yuan, H.; Hao, J. Procurement Innovation for a Circular Economy of Construction and Demolition Waste: Lessons learnt from Suzhou, China. Waste Manag. 2019, 99, 12–21. [Google Scholar] [CrossRef]

- Liu, J.; Chai, Y.; Zheng, J.; Dai, J.; Wang, Z. Optimizing City-Scale Demolition Waste Supply Chain Under Different Carbon Policies. Environ. Sci. Pollut. Res. 2024, 31, 25787–25804. [Google Scholar] [CrossRef]

- Mercader-Moyano, P.; Camporeale, P.E.; López-López, J. A Construction and Demolition Waste Management Model Applied to Social Housing to Trigger Post-Pandemic Economic Recovery in Mexico. Waste Manag. Res. 2022, 40, 1027–1038. [Google Scholar] [CrossRef]

- Long, H.; Liu, H.; Li, X.; Chen, L. An Evolutionary Game Theory Study for Construction and Demolition Waste Recycling Considering Green Development Performance under the Chinese Government’s Reward–Penalty Mechanism. Int. J. Environ. Res. Public. Health 2020, 17, 6303. [Google Scholar] [CrossRef]

- Maury-Ramírez, A.; Illera-Perozo, D.; Mesa, J.A. Circular Economy in the Construction Sector: A Case Study of Santiago de Cali (Colombia). Sustainability 2022, 14, 1923. [Google Scholar] [CrossRef]

- Yao, L.; Jing, K.T.; Zelong, H.; Yee, H.C.; Zilin, Z.; Siyao, C.; Zihao, D. The Integration of BIM In the Application of Green Building Materials in Construction Projects. J. Adv. Res. Appl. Sci. Eng. Technol. 2023, 33, 508–516. [Google Scholar] [CrossRef]

- Zhu, J.; Xu, J. Driving Factors of Green Supply Chain Management in Building Materials Enterprises. IOP Conf. Ser. Earth Environ. Sci. 2019, 295, 012063. [Google Scholar] [CrossRef]

- Zhang, L.; Yang, W.; Yuan, Y.; Zhou, R. An Integrated Carbon Policy-Based Interactive Strategy for Carbon Reduction and Economic Development in a Construction Material Supply Chain. Sustainability 2017, 9, 2107. [Google Scholar] [CrossRef]

- Göswein, V.; Carvalho, S.; Lorena, A.; Fernandes, J.; Ferrão, P. Bridging the Gap–A Database Tool for BIM-Based Circularity Assessment. IOP Conf. Ser. Earth Environ. Sci. 2022, 1078, 012099. [Google Scholar] [CrossRef]

- Al-Nuaimi, S.; Banawi, A.A.; Al-Ghamdi, S.G. Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar. Sustainability 2019, 11, 6000. [Google Scholar] [CrossRef]

- Meglin, R.; Kytzia, S.; Habert, G. Regional Circular Economy of Building Materials: Environmental and Economic Assessment Combining Material Flow Analysis, Input-Output Analyses, and Life Cycle Assessment. J. Ind. Ecol. 2022, 26, 562–576. [Google Scholar] [CrossRef]

- AzariJafari, H.; Guest, G.; Kirchain, R.; Gregory, J.; Amor, B. Towards Comparable Environmental Product Declarations of Construction Materials: Insights from a Probabilistic Comparative LCA approach. Build. Environ. 2021, 190, 107542. [Google Scholar] [CrossRef]

- Rangelov, M.; Dylla, H.; Mukherjee, A.; Sivaneswaran, N. Use of Environmental Product Declarations (EPDs) of Pavement Materials in the United States of America (U.S.A.) to Ensure Environmental Impact Reductions. J. Clean. Prod. 2021, 283, 124619. [Google Scholar] [CrossRef]

- Waldman, B.; Huang, M.; Simonen, K. Embodied Carbon in Construction Materials: A Framework for Quantifying Data Quality in EPDs. Build. Cities 2020, 1, 625–636. [Google Scholar] [CrossRef]

- Pálenský, D.; Lupíšek, A. Carbon Benchmark for Czech Residential Buildings Based on Climate Goals Set by the Paris Agreement for 2030. Sustainability 2019, 11, 6085. [Google Scholar] [CrossRef]

- Kim, A.; Miller, S.A. Meeting Industrial Decarbonization Goals: A Case Study of and Roadmap to a Net-Zero Emissions Cement Industry in California. Environ. Res. Lett. 2023, 18, 104019. [Google Scholar] [CrossRef]

- Karlsson, I.; Rootzén, J.; Toktarova, A.; Odenberger, M.; Johnsson, F.; Göransson, L. Roadmap for Decarbonization of the Building and Construction Industry—A Supply Chain Analysis Including Primary Production of Steel and Cement. Energies 2020, 13, 4136. [Google Scholar] [CrossRef]

- Rondinel-Oviedo, D.R.; Keena, N. Evaluating Environmental Impacts of Concrete in Lima: Bridging the Gap between Quantitative LCA results and local contexts. IOP Conf. Ser. Earth Environ. Sci. 2024, 1363, 012069. [Google Scholar] [CrossRef]

- Handayani, N.U.; Rinawati, D.I.; Wibowo, M.A.; Gabriella, T.; Ulkhaq, M.M. The Driver and Barrier of Implementation Green Supply Chain Management (GSCM) in Construction Projects. IOP Conf. Ser. Mater. Sci. Eng. 2019, 673, 012045. [Google Scholar] [CrossRef]

- Le, T.T. The Effect of Green Supply Chain Management Practices on Sustainability Performance in Vietnamese Construction Materials Manufacturing Enterprises. Uncertain Supply Chain Manag. 2020, 8, 43–54. [Google Scholar] [CrossRef]

- Siew, R. Are We Ready for Circular Economy? Towards Zero Waste in Construction. Sustain. Build. 2019, 4, 2. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Chan, J.K.S.; Wadu, M.J. Facilitating Effective Green Procurement in Construction Projects: An Empirical Study of the Enablers. J. Clean. Prod. 2016, 135, 859–871. [Google Scholar] [CrossRef]

- Yousif, Y.; Misnan, M.S.; Ismail, M.Z. The Influence of Labelled Green Building Materials on the Performance of Green Construction Projects. IOP Conf. Ser. Earth Environ. Sci. 2023, 1274, 012028. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Lo, I.M.C.; Cheng, J.C.P. Comparative Environmental Evaluation of Aggregate Production from Recycled Waste Materials and Virgin Sources by LCA. Resour. Conserv. Recycl. 2016, 109, 67–77. [Google Scholar] [CrossRef]

- Singh, A.K.; Kumar, V.R.P. Integrating Blockchain Technology Success Factors in the Supply Chain of Circular Economy-Driven Construction Materials: An Environmentally Sustainable Paradigm. J. Clean. Prod. 2024, 460, 142577. [Google Scholar] [CrossRef]

- ISO 20400:2017; Sustainable Procurement—Guidance. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/obp/ui/en/#iso:std:63026:en (accessed on 18 June 2025).

- ISO 44001:2017; Collaborative Business Relationship Management Systems—Requirements and Framework. ISO: Geneva, Switzerland, 2017. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:44001:ed-1:v1:en (accessed on 18 June 2025).

- Hoang, N.H.; Ishigaki, T.; Kubota, R.; Tong, T.K.; Nguyen, T.T.; Nguyen, H.G.; Yamada, M.; Kawamoto, K. Financial and Economic Evaluation of Construction and Demolition Waste Recycling in Hanoi, Vietnam. Waste Manag. 2021, 131, 294–304. [Google Scholar] [CrossRef]

- EN 15804; Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. European Norm: Brussels, Belgium, 2020.

- Van Gulck, L.; Wastiels, L.; Steeman, M. How to Evaluate Circularity through an LCA Study Based on the Standards EN 15804 and EN 15978. Int. J. Life Cycle Assess. 2022, 27, 1249–1266. [Google Scholar] [CrossRef]

- Yin, S.; Zhao, Y. An Agent-Based Evolutionary System Model of the Transformation from Building Material Industry (BMI) to Green Intelligent BMI under Supply Chain Management. Humanit. Soc. Sci. Commun. 2024, 11, 468. [Google Scholar] [CrossRef]

- Marinelli, S.; Butturi, M.A.; Rimini, B.; Gamberini, R.; Sellitto, M.A. Estimating the Circularity Performance of an Emerging Industrial Symbiosis Network: The Case of Recycled Plastic Fibers in Reinforced Concrete. Sustainability 2021, 13, 10257. [Google Scholar] [CrossRef]

- Andersen, B.H.; Komkova, A. Circular Economic Modelling: Barriers and Opportunities in Turning Circular within the Construction Sector. E3S Web Conf. 2022, 349, 01009. [Google Scholar] [CrossRef]

- Dalirazar, S.; Sabzi, Z. Strategic Analysis of Barriers and Solutions to Development of Sustainable Buildings Using PESTLE Technique. Int. J. Constr. Manag. 2023, 23, 167–181. [Google Scholar] [CrossRef]

- Pan, W.; Chen, L.; Zhan, W. PESTEL Analysis of Construction Productivity Enhancement Strategies: A Case Study of Three Economies. J. Manag. Eng. 2019, 35, 05018013. [Google Scholar] [CrossRef]

- Gong, Q.; Wu, J.; Jiang, Z.; Hu, M.; Chen, J.; Cao, Z. An Integrated Design Method for Remanufacturing Scheme Considering Carbon Emission and Customer Demands. J. Clean. Prod. 2024, 476, 143681. [Google Scholar] [CrossRef]

- Iqbal, M.; Waqas, M.; Ahmad, N.; Hussain, K.; Hussain, J. Green Supply Chain Management as a Pathway to Sustainable Operations in the Post-COVID-19 Era: Investigating Challenges in the Chinese Scenario. Bus. Process Manag. J. 2024, 30, 1065–1087. [Google Scholar] [CrossRef]

- Hettiarachchi, I.; Rotimi, J.O.B.; Shahzad, W.M.; Kahandawa, R. Conceptual Framework for Reducing Carbon Footprint in Construction Material Supply Chains. In Proceedings of the New Zealand Built Environment Symposium, Auckland, New Zealand, 12–13 February 2025. [Google Scholar]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneva, Switzerland, 2006. Available online: https://www.iso.org/obp/ui#iso:std:iso:14040:ed-2:v1:en (accessed on 3 October 2024).

- Onat, N.C.; Kucukvar, M. Carbon Footprint of Construction Industry: A Global Review and Supply Chain Analysis. Renew. Sustain. Energy Rev. 2020, 124, 109783. [Google Scholar] [CrossRef]

- Li, Q.; Long, L.; Li, X.; Yang, G.; Bian, C.; Zhao, B.; Chen, X.; Chen, B.M. Life Cycle Cost Analysis of Circular Photovoltaic Façade in Dense Urban Environment Using 3D Modeling. Renew. Energy 2025, 238, 121914. [Google Scholar] [CrossRef]

- Honic, M.; Kovacic, I.; Rechberger, H. Improving the Recycling Potential of Buildings through Material Passports (MP): An Austrian Case Study. J. Clean. Prod. 2019, 217, 787–797. [Google Scholar] [CrossRef]

- Neves, A.; Godina, R.; Azevedo, S.G.; Matias, J.C.O. A Comprehensive Review of Industrial Symbiosis. J. Clean. Prod. 2020, 247, 119113. [Google Scholar] [CrossRef]

- Komakech, R.; Ombati, T.; Kikwatha, R.; Wainaina, M. Resource-Based View Theory and Its Applications in Supply Chain Management: A Systematic Literature Review. Manag. Sci. Lett. 2025, 15, 261–272. [Google Scholar] [CrossRef]

- Yuning, M.; Taozhen, H.; Saleem, N.; Hassan, A.H. Institutional Pressure and Low Carbon Innovation Policy: The Role of EMS, Environmental Interpretations and Governance Heterogeneity. Front. Environ. Sci. 2024, 12, 1385062. [Google Scholar] [CrossRef]

- Yang, G.; Zhou, X.; Gao, C.; Chen, X.; Chen, B.M. Learnable Cost Metric-Based Multi-View Stereo for Point Cloud Reconstruction. IEEE Trans. Ind. Electron. 2024, 71, 11519–11528. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, Y.; Lee, S.; Shin, M. UAV-Based Automated 3D Modeling Framework Using Deep Learning for Building Energy Modeling. Sustain. Cities Soc. 2024, 101, 105169. [Google Scholar] [CrossRef]

- Li, Q.; Zhao, B.; Wang, X.; Yang, G.; Chang, Y.; Chen, X.; Chen, B.M. Autonomous Building Material Stock Estimation Using 3D Modeling and Multilayer Perceptron. Sustain. Cities Soc. 2025, 130, 106522. [Google Scholar] [CrossRef]

| Stage | Criteria | Decision |

|---|---|---|

| Searching | Journal articles, conference papers, and reports | Inclusion |

| When specified keywords (e.g., net-zero, supply chain, construction materials, decarbonization, performance) are present in the title, abstract, or keywords. | Inclusion | |

| Duplicated studies among identified sources. | Exclusion | |

| Books, review papers, and editorials | Exclusion | |

| Title and Abstract Screening | Studies focus on construction material supply chains relevant to decarbonization or carbon performance evaluation. | Inclusion |

| Studies discuss performance assessment, lifecycle carbon emissions, or net-zero strategies in construction. | Inclusion | |

| Studies not related to material supply chains or net-zero performance | Exclusion | |

| Full-Text Screening | Studies provide conceptual, methodological, or empirical insight into evaluating carbon performance or decarbonization in supply chains. | Inclusion |

| Studies lack clear discussion on carbon metrics, emission scopes, or performance frameworks. | Exclusion | |

| Studies without a substantial focus on construction materials | Exclusion |

| Category | Indicator | References |

|---|---|---|

| Policy and Regulatory | Material sourcing | [19] |

| Legal compliance | [43] | |

| Industry standards | [13,44] | |

| Environmental and Resource Efficiency | Global Warming Potential (GWP) | [1,5,6,9,12,25,26,34,45,46,47,48,49] |

| Embodied Carbon (EC) | [5,6,24,45,48,50] | |

| Energy consumption | [3,10,26,51,52,53] | |

| CO2 emissions | [3,10,35,36,44,46,52,54] | |

| Material recovery | [11] | |

| Recycling | [43] | |

| Reuse rates | [45] | |

| Material efficiency (e.g., recycling, reuse, eco-concretes) | [41] | |

| Waste reduction | [16,55,56] | |

| Cradle-to-gate (A1–A3) emissions | [6,22] | |

| Full lifecycle emissions | [5,15,41,44,45] | |

| Material composition | [16,43,50] | |

| Environmental footprints (e.g., carbon intensity) | [16,43,50] | |

| Waste segregation | [11,57] | |

| Waste recovery | [11] | |

| Recycled material output | [37] | |

| Social, Organizational, and Stakeholder Collaboration | Green supplier/customer integration | [14] |

| Stakeholder collaboration | [58] | |

| Social impact indicators | [42,56,59] | |

| Technological and Technical Advancements | Material substitution | [18] |

| Design for disassembly | [18,23] | |

| R&D investment | [14] | |

| Green design | [43] | |

| Durability of materials | [11,18] | |

| Material Performance indicators (e.g., material properties, durability, fire resistance, environmental certifications) | [1,60] | |

| Waste processing capacity | [38] | |

| Economic and Financial | Warehousing, Logistics and Transportation costs | [37,38] |

| Economic drivers (e.g., market costs, cost savings, ROI, financial analysis, market performance) | [13,32,37,38] |

| Category | Challenges | Enablers | References |

|---|---|---|---|

| Policy and Regulatory | Ambiguous laws Weak enforcement Fragmented standards Ineffective subsidies Corruption risks Misaligned policies (e.g., neglecting net-zero) | Policy support (e.g., carbon tax, GPP) Government subsidies Regulatory protection Policy incentives Legislative mandates Industry standards Harmonization of practices | Challenges: [3,11,13,25,26,37,38,41,43,51,56,58,68] Enablers: [1,10,13,14,22,23,32,38,39,40,51,54,58,60,68] |

| Environmental and Resource Efficiency | High emissions Pollution regulations Landfill scarcity Informal waste practices Limited CE impact Geopolitical disruptions | Use of recycled materials Resource efficiency Waste management Renewable energy Energy optimization Eco-friendly transport Sustainable sourcing | Challenges: [10,12,22,39,40,46,51,52,54,60] Enablers: [10,12,15,18,22,24,51,54,56,58,68] |

| Social, Organizational, and Stakeholder Collaboration | Low awareness Resistance to change Industry fragmentation Lack of skilled labour Client reluctance Poor collaboration | Stakeholder collaboration Public–private partnerships Industry consensus Community engagement Shared knowledge platforms Capacity building | Challenges: [2,16,18,24,25,26,32,36,37,39,41,43,50,55,58,59] Enablers: [2,3,13,14,15,23,38,41,67,68] |

| Technological and Technical Advancements | Immature/inefficient technology Scalability Infrastructure gaps Testing/data process limitations Slow implementation | Use of modern technologies BIM integration R&D investments Innovative construction methods Digital tools Real-time monitoring Energy-efficient solutions | Challenges: [3,15,19,22,47,48,51,52,53,57,59,61,68] Enablers: [12,15,19,24,36,43,47,54,58,64,69] |

| Economic and Financial | High costs (production, treatment, data, green materials) Low demand, Financial fragility Infrastructure investment barriers | Financial incentives Government funding Investment in infrastructure Cost-effective supply chains Tax incentives Support for green products Investment in R&D | Challenges: [2,3,24,25,32,37,38,41,42,43,46,47,49,64,67,69] Enablers: [11,12,25,35,41,44,56,57,59,60,64,67,69] |

| Data Availability, Accuracy and Integration | Lack of standardization Data accuracy Interoperability issues Inconsistent/hypothetical data Dataset quality Subjective judgments | Data integration of BIM and other digital tools like WMS Real-time data Standardized data exchange Harmonized EPDs Better data availability | Challenges: [1,5,6,9,15,18,23,25,34,36,45,47,48,49,50,53,54,61] Enablers: [6,15,16,19,23,25,36,42,45,50,54] |

| PESTED Dimension | PESTLE Focus | Comparison |

|---|---|---|

| Policy and Regulatory | Political drivers Legal compliance | Combines policy and legal instruments into one actionable lens for supply-chain governance and incentives |

| Economic and Financial | Cost and market forces | Unchanged; emphasizes capital flows, carbon-pricing signals, and life cycle cost trade-offs |

| Social, Organizational and Stakeholder Collaboration | Demographics and culture | Expanded to Social, organizational and stakeholder collaboration to capture multi-actor coordination essential for circular, low-carbon practices |

| Technological and Technical Advancements | R&D and innovation | Refined as technological -and technical advancements to include digital construction platforms (BIM, IoT) and low-carbon material technologies |

| Environmental and Resource Efficiency | Natural resources and emissions | Recast as environmental -and resource efficiency to align with circular-economy metrics |

| Data Availability, Accuracy and Integration | - | data availability, accuracy &and integration (new): highlights data quality, interoperability, and transparency as critical enablers of net-zero verification |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hettiarachchi, I.; Rotimi, J.O.B.; Shahzad, W.M.; Kahandawa, R. Bridging Sustainability and Performance: Conceptualizing Net-Zero Integration in Construction Supply Chain Evaluations. Sustainability 2025, 17, 5814. https://doi.org/10.3390/su17135814

Hettiarachchi I, Rotimi JOB, Shahzad WM, Kahandawa R. Bridging Sustainability and Performance: Conceptualizing Net-Zero Integration in Construction Supply Chain Evaluations. Sustainability. 2025; 17(13):5814. https://doi.org/10.3390/su17135814

Chicago/Turabian StyleHettiarachchi, Isuru, James Olabode Bamidele Rotimi, Wajiha Mohsin Shahzad, and Ravindu Kahandawa. 2025. "Bridging Sustainability and Performance: Conceptualizing Net-Zero Integration in Construction Supply Chain Evaluations" Sustainability 17, no. 13: 5814. https://doi.org/10.3390/su17135814

APA StyleHettiarachchi, I., Rotimi, J. O. B., Shahzad, W. M., & Kahandawa, R. (2025). Bridging Sustainability and Performance: Conceptualizing Net-Zero Integration in Construction Supply Chain Evaluations. Sustainability, 17(13), 5814. https://doi.org/10.3390/su17135814