Abstract

Sustainable architectural heritage conservation focuses on preserving historical buildings while promoting environmental sustainability. It involves using eco-friendly materials and methods to ensure that the cultural value of these structures is maintained while minimizing their ecological impact. In this paper, the use of the hydroxyapatite (HAp) in various combinations on masonry samples is presented, with the aim of identifying the ideal solution to be applied to an entire historical building in Banloc monument. The new solution has various advantages: compatibility with historical lime mortars (chemical and physical), increased durability under aggressive environmental conditions, non-invasive and reversible, aligning with conservation ethics, bioinspired material that avoids harmful synthetic additives, preservation of esthetics—minimal visual change to treated surfaces, and nanostructural (determined via SEM and AFM) reinforcement to improve cohesion without altering the porosity. An innovative approach involving hydroxiapatite addition to commercial mortars is developed and presented within this paper. Physico-chemical, mechanical studies, and architectural and economic trends will be addressed in this paper. Some specific tests (reduced water absorption, increased adhesion, high mechanical strength, unchanged chromatic aspect, high contact angle, not dangerous freeze–thaw test, reduced carbonation test), will be presented to evidence the capability of hydroxyapatite to be incorporated into green renovation efforts, strengthen the consolidation layer, and focus on its potential uses as an eco-material in building construction and renovation. The methodology employed in evaluating the comparative performance of hydroxyapatite (HAp)-modified mortar versus standard Baumit MPI25 mortar includes a standard error (SE) analysis computed column-wise across performance indicators. To further substantiate the claim of “optimal performance” at 20% HAp addition, independent samples t-tests were performed. The results of the independent samples t-tests were applied to three performance and cost indicators: Application Cost, Annualized Cost, and Efficiency-Cost-Performance (ECP) Index. This validates the claim that HAp-modified mortar offers superior overall performance when considering efficiency, cost, and durability combined.

1. Introduction

The preservation and restoration of historic architectural structures demand not only technical knowledge but also a nuanced understanding of cultural heritage, material authenticity, and regional identity. As a core element in the evolution of built heritage, mortar has served a dual role: structurally binding construction elements and enhancing the visual integrity of facades. Throughout history, lime-based mortars have been valued for their adaptability, breathability, and compatibility with traditional building materials [1]. Although the positive aspects of the lime-based mortars are well-known, it has become easier to use synthetic materials for simplified restoration processes, while the use of the traditional recipes has become an exception. One of the most common issues is the fact that organic treatments are not always compatible with the original support layer, while the inorganic products have proven to have limited positive effects [2,3]. One of the reasons for this tendency is the fact that original lime-based mortars have proven challenging in time, due to their sensitivity to the freeze–thaw cycles, changing temperatures, acid rain, pollution, and exposure to biological and chemical degradation [4], highlighting the need for new innovative mortars that are based on traditional recipes, but are improved in terms of resistance and sustainability.

Contemporary efforts to advance the performance of lime mortars, particularly for use in restoration and conservation, rely heavily on interdisciplinary research that bridges heritage science, materials engineering, and architectural conservation [5]. These innovations seek to address both structural and esthetic challenges while ensuring the long-term durability of historical buildings [6]. Formulations often incorporate pozzolanic or nanostructured additives—such as metakaolin, crushed brick, or hydroxyapatite—that enhance strength, resistance to weathering, and compatibility with aged substrates, thereby meeting modern performance standards without compromising authenticity [7,8,9]. More than just the compatibility of the materials, in the restoration process, it is important to use materials in stable phases, leading to the proposal of using calcium phosphates (ideally HAP) [10], which was proposed at first for the conservation of marble and limestone elements [11]. The integration of scientific diagnostics, experimental modeling, and conservation ethics is essential in tailoring mortar compositions to specific historic contexts [12]. Moreover, to prevent damage caused by changing weather, and biological or chemical actions, architectural conservation science has developed new treatments that are using nanotechnology and implicitly, nanomaterials, but it is important to promote environmentally friendly (nano) materials, such as hydroxyapatite [13].

Built heritage, particularly historical monuments, is currently facing a critical situation worldwide, challenged by a wide range of threats such as climate change, rapid urbanization, armed conflicts, and the pressures of mass tourism. The United Nations Educational, Scientific and Cultural Organization (UNESCO) has warned that over half of the sites inscribed on the World Heritage List are directly or indirectly affected by the consequences of climate change [14]. In the European context, although the continent holds the highest concentration of protected historical monuments, many of these are in an advanced state of degradation, mainly due to insufficient funding, incoherent conservation policies, and fragile legislative frameworks. Recent initiatives such as the “New European Bauhaus” promote sustainable restoration and the integration of cultural heritage into the green transition, advocating for a multidisciplinary and participatory approach [15]. In Romania, the challenges are similar, but often amplified by administrative inefficiencies and chronic underfunding of the heritage sector. According to the National Institute of Heritage [16], a significant portion of the more than 30,000 monuments listed in the National Register of Historical Monuments are in a poor condition.

The rich history of Romania is also characterized by a large number of historical buildings, many of them being classified as regional or national monuments. Although there is a list of architectural and cultural monuments available online, it was last updated 10 years ago, and is considered already outdated [16,17]. Statistically, the number of classified monuments remained almost the same for the last two updates, with only a 2% increase, from 29,547 monuments existing in 2008 to 30,147 in 2015 [17], as presented in Figure 1 [18].

Figure 1.

Number of classified monuments in Romania for each county: (a) in 2008; (b) in 2015 [18].

Despite the existence of some official financing programs (national and European), the funds are very limited. Also, the number of professionals and multidisciplinary teams that are trained to work on monuments and historical buildings is too little in relation to the needs, leading to a small number of buildings that have benefited from any restoration project in the past years.

On-site architectural surveys included the dimensional measurements, structural observations, and photographic documentation of the existing conditions. Particular attention was given to signs of degradation, structural instability, and material decay, especially in vaulted masonry, load-bearing walls, and carpentry elements.

Material sampling and analysis were performed to characterize the original construction materials and identify possible interventions. Laboratory testing focused on mortar composition, binder type, aggregate granulometry, and physical properties relevant to heritage conservation.

Reasoning and Motivation: The application of hydroxyapatite (HAp) in mortars stems from the need to develop durable, compatible, and environmentally friendly materials for the conservation and restoration of historic buildings and monuments. Traditional restoration mortars often suffer from chemical incompatibility with original substrates, poor durability, or unsatisfactory performance under environmental stressors such as moisture, salts, or biological agents.

This method has a high level of innovation due to the following: (i) demonstrating the feasibility of hydroxyapatite as a functional additive or binder in heritage mortars—an area previously underexplored; (ii) providing detailed insight into how HAp interacts with lime and aggregates at the micro- and nano-scale, (iii) quantifying the improvements in mortar performance, such as compressive strength, water absorption, and salt resistance, and (iv) validation of the hypothesis under laboratory conditions. HAp is offering a conservation-grade material that aligns with the key principles of reversibility, compatibility, and durability, potentially reducing the need for frequent interventions. Historic mortars are often lime-based and porous, which makes them susceptible to environmental degradation. Hydroxyapatite is chemically compatible with lime and can be integrated without introducing harmful salts or triggering deleterious reactions.

In essence, the research into hydroxyapatite in mortars is grounded in the intersection of material science, conservation ethics, and bioinspired engineering. The scientific hypothesis is that HAp integration enhances the long-term viability and environmental resistance of mortars used in heritage conservation. This study has opened up new directions for creating durable, chemically compatible, and environmentally friendly restoration materials.

This paper aims to position this context by exploring the architectural, historical, and material characteristics of the Banloc Castle estate in southwestern Romania. Located approximately 48 km from Timișoara and 7 km from Deta, the site occupies a strategic corridor between Romania and Serbia [19]. The major advantage in terms of accessibility is the proximity of the Timișoara and Belgrade airports.

The research integrates historical cartography, archival documentation, and structural assessment to better understand the significance of the Banloc complex, particularly about its historical ownership, socio-economic contributions, and architectural evolution. Of particular interest is the role of noble patronage in shaping the estate’s character and the enduring material legacy embodied in its structural fabric.

An in-depth analysis of the castle’s historical development will be provided with typological transformations, construction techniques, and the current state of preservation. Through this case study, we aim to contribute to the broader discourse on sustainable restoration practices and the adaptive reuse of heritage buildings in Eastern Europe. The Banloc Castle complex has been the subject of multidisciplinary investigations focusing on historical, architectural, structural, and physical–chemical aspects to identify appropriate restoration solutions in line with international conservation principles. Recent studies have also explored the structural vulnerabilities of the castle, particularly in relation to seismic activity, emphasizing the need for tailored consolidation strategies [20]. Furthermore, the adaptive reuse of heritage buildings, as discussed in broader European contexts, highlights the importance of integrating community-driven approaches and sustainable design principles in restoration projects [21,22].

The research methodology employed in this study combines qualitative and quantitative approaches drawn from the fields of architectural conservation, historical analysis, and materials science. A mixed-methods framework was developed to ensure a comprehensive understanding of the site’s historical trajectory, physical condition, and material composition.

This interdisciplinary methodology allows for the integration of historical context with technical evaluation, ensuring that the proposed conservation measures are both contextually grounded and scientifically validated in this paper.

Even if the use of hydroxiapatite was previously observed mostly in biomedical approaches, the incorporation of such component in existing commercial premixed mortars represents an innovative technological approach, which aims to be suitable for the heritage conservation field. This study explores both the technological testing and application strategy of such material, but also the environmental adaptability of the Hap-enhanced mortars, with an important contribution to the future sustainable approaches in the architectural restoration processes.

2. Historical Context

The Banloc Castle estate holds a layered and multifaceted history, reflective of the broader socio-political transitions in the Banat region. Its origins can be traced back to the 16th century, when it served as the summer residence of the Ottoman Pasha of Timișoara during the period of Turkish control (1552–1717). Following the Habsburg conquest, the site underwent significant transformations aligned with European models of militarized and later aristocratic land development [23].

According to the List of Historical Monuments of Timiș County, the Banloc Castle ensemble is registered under entry no. 154, with the classification code TM-II-a-A-06177, indicating its designation as a Group A Historical Monument, Figure 2. The adjacent Banloc Mansion is listed separately under entry no. 155 (TM-II-a-A-06177.01), and the surrounding park is recorded at entry no. 156 (TM-II-a-A-06177.02) [24].

Figure 2.

Aerial plan of Banloc property (Google Earth).

In 1759, the estate became associated with Ban Draskovich of Croatia, who initiated early structural interventions. However, the most substantial phase of architectural and cultural development occurred under the Karatsonyi family (1783–1922), who converted the estate from a seasonal retreat into a permanent noble residence. The Karatsonyis were deeply engaged in cultural patronage, philanthropy, and estate modernization. Their influence extended beyond architecture to include investments in education, healthcare, and local industry, such as distilleries, mills, and glassworks.

A particularly transformative period came with the acquisition of the property by Princess Elisabeth of Romania (1935–1947). Her stewardship preserved much of the French-inspired garden design, reinstated thoroughbred horses in the stables, and revitalized the manor’s social and cultural life. Known for her artistic sensitivity and charitable works, Princess Elisabeth left a lasting legacy at Banloc, reinforcing its cultural and historical prominence [25].

The estate continued to evolve during its nationalization under the Romanian state (1947–1989), when it was repurposed for public institutions, and more recently under the stewardship of the Romanian Orthodox Archdiocese of Timișoara (1989–2025) [26], which, in April of this year, transferred ownership of the complex to the Timiș County Council.

3. Architectural Analysis

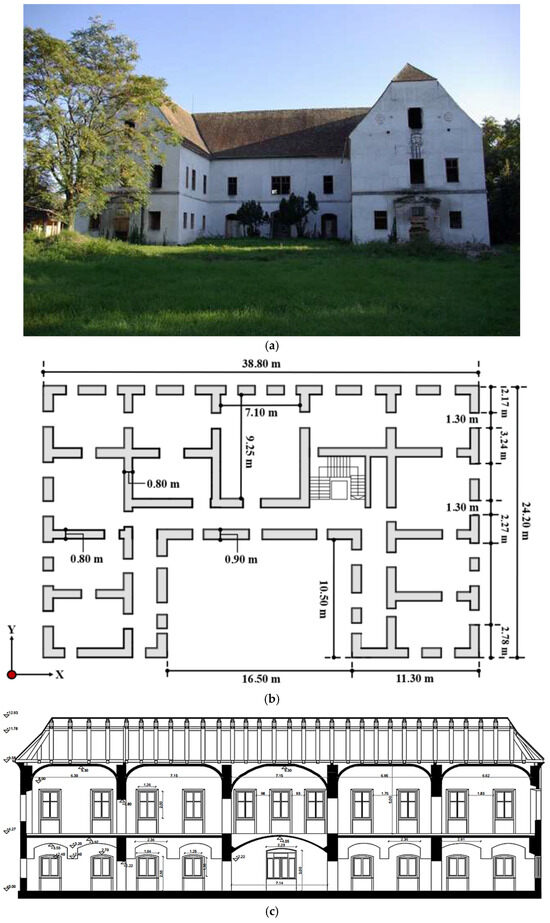

The architectural composition of Banloc Castle exhibits a synthesis of Renaissance form and Baroque elements, reflecting successive construction phases and stylistic adaptations. Initially built in 1759 and later expanded in 1793, the main structure adopts a U-shaped layout centered around a courtyard open to the south. This plan typology was typical of noble residences of the era, facilitating both representative and residential functions.

Constructed primarily of burnt brick masonry, the walls reach thicknesses of approximately 1.25 m, contributing to the structural stability and thermal performance of the building. The load-bearing system is composed entirely of unreinforced masonry walls, with vaulted ceilings present across all levels, including the cellar. Brick vaults are supported by continuous masonry walls and were recently reinforced with U-shaped steel profiles to address deformation and seismic vulnerability.

The building comprises four levels: cellar, ground floor, first floor, and attic. The spatial organization of the ground and first floors follows a clear axial logic. A central hall oriented perpendicular to the southern façade provides circulation between symmetrical rooms in the eastern and western wings. This layout reflects the aristocratic architectural norms of spatial hierarchy, privacy, and symmetry.

The south façade, which originally bore the Karatsonyi family coat of arms in carved stone, is the most architecturally articulated elevation. Although the emblem was removed after 1948, the façade retains its proportional elegance. By contrast, the north façade, once adorned with decorative bas-reliefs including motifs such as a siren, armor helmet, and putti, now suffers from biological deterioration and surface loss.

Fenestration also reflects the building’s historical evolution. The original Baroque-style north-facing windows were transformed into rectangular openings during the post-war communist period (1948–1989), resulting in a loss of stylistic coherence. Wooden window and door joinery are largely missing or severely deteriorated, while interior wall surfaces alternate between exposed brick and fragmented plaster.

Roofing is executed in ceramic tiles over a Baroque-inspired timber truss system. This roof structure was reconstructed following earthquake damage in the 1990s [27]. At present, the roof is in an advanced state of degradation, contributing to interior water infiltration and the acceleration of material decay.

The current state of the building reveals approximately 40% exterior plaster loss, extensive deterioration of oak joinery on the ground level, and complete absence of flooring in multiple rooms. These conditions necessitate both emergency stabilization and long-term conservation planning to preserve the architectural and historical integrity of the ensemble. Built on a “U”-shaped plan, the castle of Banloc is a massive building, with thick walls (approx. 1.25 m) of burnt brick, with the main façade oriented to the south, and to the north with two wings forming a terraced courtyard (Figure 3a) (Court of Honor). The two wings of the castle close the courtyard of honor, closed at times with eighteenth-century ironwork. There were wrought iron floor lamps (one per each corner of the courtyard) and which in their decorative structure specified the year 1793.

Figure 3.

(a) Image of Banloc castle—view from the park, N façade. (b) Ground floor plan. (c) Longitudinal plan.

Ground floor plan of Banloc mansion

Compared to the simplicity of the south façade, the north façade of the castle (facing the park)—especially the two wings that close the courtyard of honor—had several decorative elements: the Baroque windows of the bridge, the high reliefs with well-defined themes (heraldic motifs and themes inspired by Greco-Roman mythology) embedded in the masonry, Figure 3b. In addition to these, important were the eighteenth-century ironwork that closed the courtyard of honor, as well as the wrought iron lamps (one on each corner of the courtyard) and which in their decorative structure had the year 1793 specified.

Interesting from an architectural point of view were the entrances to the basement of the building. Made of resurface, they created a rupture in the plane of the façade and were made up of an architrave that rests on imitations of Doric columns. The wooden gates were provided with eighteenth-century hardware and above them, in the wall, there is a high relief with a different theme for each entrance, depending on the utility that the cellar received, Figure 3c. The entrance to the wine cellar is suggested by the presence of the bunch of grapes that a putto (amoraş) gives to a female character rendered in a seated position, while at the entrance to the wooden cellar there is the representation of the god Pan playing the syrinx (panpipes). Although there are no testimonies in this regard, it seems that the frequent representations of the god Pan (in the park there were at least two statues, the fragments of which are currently at the Banat Museum in Timisoara) are closely related to the name of the locality: Panloch–Panloc–Banloc, a name that would translate as “The place of the master”.

The historical evolution of the Banloc Castle estate can be delineated into six major phases:

- -

- Stage I (1552–1717): Original development during Ottoman control, when the estate served as a seasonal residence for the Pasha of Timișoara.

- -

- Stage II (1759): Architectural and territorial restructuring initiated by Croatian Ban Draskovich.

- -

- Stage III (1783–1922): Major cultural and structural transformation under the Karatsonyi family, marked by noble patronage, philanthropic activity, and estate modernization.

- -

- Stage IV (1935–1947): Renovation and social-cultural revitalization under Princess Elisabeth of Romania.

- -

- Stage V (1947–1989): Refunctionalization and institutional use during the Romanian communist era.

- -

- Stage VI (1989–present): Gradual conservation and consolidation efforts under the Romanian Orthodox Archdiocese of Timișoara.

These six identified stages of transformation reflect not only architectural change but also broader narratives of political power, social responsibility, and cultural identity. Each layer of intervention has left distinct physical and symbolic traces, which now require careful interpretation in the context of restoration and heritage valorization.

The castle has a cellar, ground floor, first floor, and attic. The spatial organization system both on the ground floor and on the first floor is identical and consists, in the center of the main (south) tract, of a dominant room, perpendicular to the façade, which passes through the entire body of the building. At the piano terrena, this hall was formed by building an older vaulted entrance, a fact observed in the masonry of the building. To the left and right of this main hall, there are two rooms—a total of five rooms—and in the east and west wings of the building, another three rooms served by a corridor in each wing. In the dead corners are the stairs, and at the northern ends of the corridors are the bathrooms. A special feature of the castle was given, on the north side, by the two Baroque-inspired windows on the bridge, but which were drastically modified between 1948 and 1989 by transforming them into two square and unstylish openings.

Structural system

With a plan dimension of approximately 40.00 m longitudinally and 25.00 m transversely, the castle is a massive construction, with very thick walls, made of burnt brick. The structure of the building is load-bearing unreinforced masonry, both the foundation and the superstructure; the very thick walls are made of solid brick, there are vaulted ceilings at both the basement, ground floor, and first floor levels, with a massive roof on a wooden structure. The wooden framework is Baroque style, a truss-type structure, rebuilt after the earthquake in 1991. The rooms have a cylindrical vault made of solid brick above the basement, ground floor, and first floor levels (Figure 4).

Figure 4.

The vault from solid bricks with the current state of degradation.

The basement is vaulted, the vaults damaged during the earthquake having been recently rebuilt with solid brick and cement mortar. Cement mortar was injected into the cracks in the masonry. The basement floor is made of reinforced concrete. Every room on the ground floor is vaulted. The vaults in two rooms collapsed during the 1991 earthquake and were completely rebuilt with solid brick and cement mortar. Cement mortar was injected into all visible cracks in the masonry. The interior walls that were collapsed/damaged during the earthquake were rebuilt.

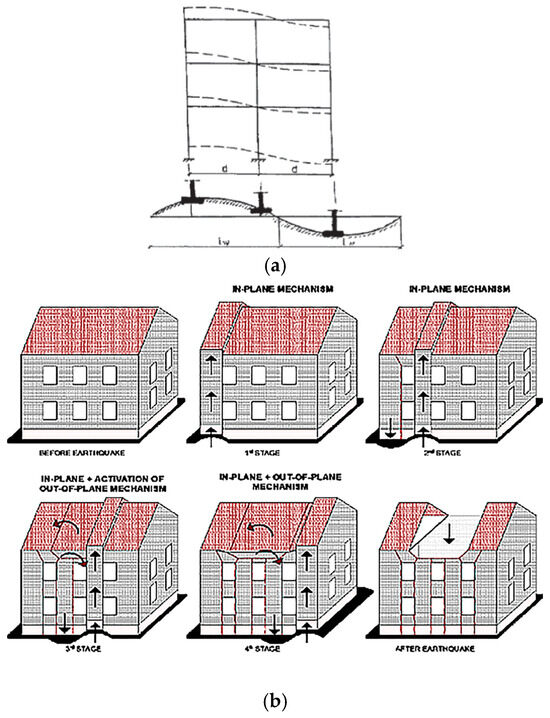

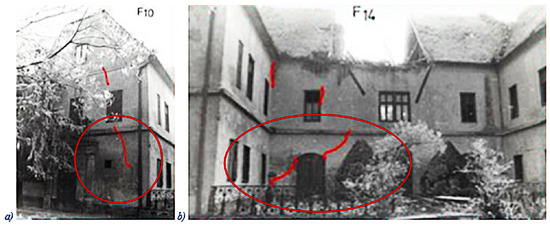

The Banloc castle is located in Banat seismic area, characterized by shallow earthquakes of crustal type, and was affected by the two earthquakes that occurred in July and December 1991. Both earthquakes were characterized by a 0.2–0.3 s short period of short-period vibration, with a powerful first cycle [28]. The damage observed after the earthquake in 1991 was significant, but without affecting the load-bearing capacity of the building. Several cracks were observed in the masonry vaults, with vertical cracks in the masonry walls due to the powerful seismic vertical forces and the partial collapse of the central part of the roof, activating also the out-of-plane overturning failure mechanism of the upper part of the façade masonry wall, as presented in Figure 5 [29]. A part of the observed real damage after the 1991 earthquake is presented in Figure 6 [30].

Figure 5.

The specific failure mechanism of the Banloc castle after the 1991 earthquake: (a) asynchrony of vertical movements specific to shallow earthquakes; (b) in-plane vertical cracking and out-of-plane overturning.

Figure 6.

Real damages observed after 1991 earthquake in Banloc, Romania (a) cracks in the left wing of the building and (b) cracks in the building’s courtyard [25]. Red circles: the most pronounced damages; Red lines: vertical and diagonal cracks after the earthquake; F10 and F14 represent building sectors with the most evidenced damages.

The entire vaulted system has been reinforced and is hanging on U-profile metal rails, anchored in reinforced concrete belts. This system is visible due to the lack of a floor at the floor level. Oak wedges are inserted at the top of the vaults, visible at the floor level, right on the keystone, and cement mortar has been injected into the joints between the bricks to strengthen them. Some of them are moving, and gaps have formed between the bricks. The entrance from the courtyard of honor, on the northern facade, leads to the main hall, the largest on the ground floor, cross-vaulted, with a broken arch, on four repetitive bays, with a single window opening on the main facade. In this main central hall, the vaults were reinforced by injecting mortar; concrete cores and a reinforced concrete slab were poured. The plastered facades show numerous deteriorations. The plaster on the exterior facade is degraded by approximately 40%. The exterior and interior oak woodwork is in an advanced state of degradation, or completely missing at the ground floor level, Figure 6.

All mortar studies were carried out on this building. The sustainable approach requires a high professional level of activity, interdisciplinary teamwork, time to study documentation, and research the building [31,32].

Traditionally, mortar functions as a binding, leveling, and decorative agent in construction, but its mechanical strength can be enhanced by incorporating fillers with finer textures [33]. However, the choice of filler material may also lead to undesirable consequences: for instance, inorganic ash-based fillers can induce shrinkage and reduce mortar workability [34], whereas fibrous materials may decrease the shrinkage rate but can negatively affect the overall performance of the mortar [35].

The identification and development of new mortar formulations are crucial for the effective restoration and maintenance of buildings. In recent years, advanced mortars have been engineered with properties such as super-hydrophobicity, impermeability, and antimicrobial resistance, making them suitable for both indoor and outdoor applications. One example is a mortar composed of Portland cement [36], hydroxyapatite, sand, calcium hydroxide, and water glass, which exhibits low water absorption, antibacterial activity, and good compressive strength. This unique composition provides a durable and long-lasting finish, which is particularly important in high-humidity environments where microbial growth can accelerate degradation and structural damage.

Microbial colonization on and within built structures can lead to serious consequences, including esthetic degradation, internal material decay, and diminished mechanical properties, ultimately increasing maintenance and replacement costs. To address this challenge, the development of antimicrobial mortars has become essential for creating smart and sustainable infrastructures that can effectively resist microbial proliferation, resulting in a healthier, more durable, and cost-efficient built environment. Incorporating antimicrobial agents into mortar composition is a common method of achieving antimicrobial activity.

Hydroxyapatite (HAp) is well known for its consolidation and antimicrobial properties [37,38]. Hydroxyapatite (HAp) is emerging as a sustainable material in the building industry, although its application is still relatively niche compared to traditional materials. Here is how it contributes to sustainable building design, as follows:

- Bio-Based Coatings and Finishes (HAp-based coatings) can be applied to concrete, metals, and glass to enhance durability, corrosion resistance, and bioactivity. These coatings are non-toxic and can extend the lifespan of materials, reducing maintenance and replacement needs.

- Carbon Sequestration and Air Purification (some experimental approaches use HAp’s structure to adsorb pollutants (e.g., CO2, heavy metals, or VOCs) from the air.

This makes it suitable for indoor air quality improvement and carbon-negative material design).

- 3.

- Waste Valorization for Eco-Cement or Concrete Additives (HAp can be synthesized from industrial or agricultural waste (e.g., eggshells, fish bones) and incorporated into cement or composites. This reduces the carbon footprint of cement production by partially replacing Portland cement with biogenic materials.

- 4.

- Thermal and Acoustic Insulation (emerging composites using HAp (with biopolymers or ceramics) are being studied for thermal insulation and acoustic absorption, making buildings more energy efficient).

- 5.

- Fire-Resistant Materials (HAp has a high decomposition temperature and is non-flammable, contributing to fire-safe construction materials when used in composites or coatings).

Mortars incorporating hydroxyapatite (HAp) are an emerging innovation in sustainable and heritage-compatible construction materials. These HAp-enhanced mortars are designed to improve biocompatibility, durability, and sometimes even self-healing or air-purifying properties. The mortars with hydroxyapatite have been used in restoration, bio-construction, or eco-friendly architecture, as follows: as lime-based mortar with hydroxyapatite (for heritage restoration), because it is compatible with historical buildings, breathable, and resistant to microbial growth; as cement–lime mortar with hydroxyapatite (for modern construction or façade repair), for its structural and esthetic application for sustainable buildings, with an enhanced durability and mechanical performance, a lower permeability and microbial colonization and a suitable use for façades, plasters, or thin finishing layers. Also, HAp could be used as a bio-based mortar with hydroxyapatite (for indoor eco-design), because HAp is natural, is a low-toxicity material for indoor use, is excellent for indoor plaster or insulation layers, provides healthy indoor air quality (VOC absorption) and is biodegradable and renewable. Nano-HAp improves binding and surface contact but is costlier, could be derived from natural bones, seashells, or synthesized from calcium phosphate, and pre-mix HAp with water or binder to ensure even distribution.

Up to now, there are some reports in the literature, reporting new Mortar Recipes for Romanian Architectural Heritage Consolidation [39].

In addition to HAp, other additives could be used: titanium dioxide (TiO2), which provides self-cleaning, air purification, and antibacterial properties; zinc oxide (ZnO), with unique antimicrobial and photocatalytic activity; and silica nanoparticles, which accelerate hydration and enhance strength during early microstructure densification while also improving antibacterial performance [40,41,42,43].

This research paper will present new mortar formulations incorporating hydroxyapatite for the consolidation of Romanian architectural heritage. The study found that mortars with 20% hydroxyapatite content exhibited the optimal mechanical and antimicrobial properties, making them suitable for restoration purposes. The objective was to determine the most effective composition in terms of physical and mechanical properties for potential future use in the restoration and regeneration of architectural heritage. Some investigations will be performed: HAp characterization, its incorporation into the mortars and preparation of some specimens, physical, chemical, and mechanical properties of the newly prepared specimens, and economical aspects for this new solution that uses HAp as a green solution in conservation and restoration.

4. Materials and Methods

Materials

Hydroxyapatite [HAp, Ca10(PO4)6(OH)2] was used in the form of a commercial powder supplied by ACROS ORGANICS, Germany. It was employed for particle dispersion within the mortar specimens. The hydroxyapatite used has a CaO content of 45–60 mass %, a P2O5 content of 30–50 mass %, and a particle size of 50–70 nm.

A total of 60 mortar specimens (5 cm × 5 cm × 5 cm) were prepared using a progressively increasing percentage of hydroxyapatite (HAp), based on a BAUMIT–MPI 25 mortar formulation. BAUMIT MPI25 product is manufactured by Baumit GmbH (Baumit Group, Waldegg, AU) that is an Austrian company that is part of the Wopfinger Baustoffindustrie GmbH group. With its headquarters in Austria, Baumit is a well-established construction materials manufacturer, operating across more than 30 countries in Europe, including Romania.

In the composition of the dry premixed mortar Baumit MPI 25, lime is present in the form of finely ground hydrated lime (Ca(OH)2), with a typical particle size below 90 µm, derived from selected limestones that are calcined and slaked under controlled industrial conditions. This component significantly enhances the workability of the fresh mix by increasing its plasticity and water retention capacity, and it contributes to the mechanical performance of the hardened plaster through its gradual reaction with atmospheric carbon dioxide in the secondary carbonation process, forming calcite crystals that reinforce the matrix [44,45]. Furthermore, lime reduces the risk of shrinkage cracking due to its relatively elastic behavior during drying and setting [46]. Its high alkalinity (pH ≈ 12.5) also provides a natural antiseptic effect, temporarily inhibiting microbial development within the applied layer. In Baumit mortars, lime is used within a matrix based on cement and fine limestone sand (0–1 mm), supplemented with organic additives designed to regulate the setting time and adhesion, in accordance with the manufacturer’s specifications [47].

A consolidation mortar based on cement, lime, a fine aggregate of plaster sand type, hydroxyapatite (commercial), and water was used, in which the dry mortar contains 30…34% mass percent normal Portland cement with a density of 3.16 g/cm3 with the composition: 60–67% CaO, 17–25% SiO2, 3–8% Al2O3, 0.5–6% Fe2O3, 0.1–4% MgO, 1.3–3% SO3, and 0.4–1.3% alkalis, 5…7% matured calcium hydroxide with a density of 2.21 g/cm3, 5…30% mass percent hydroxyapatite with a density of 2.92 g/cm3, CaO content of 52.9 mass%, P2O5 content of 38.9%, average particle size of 50…70 nm, 50–60% fine aggregate of sea sand type with a density of 2.57 g/cm3, and coarse fraction of 0.01–2 mm. After making the mortar and applying it on brick surfaces, B.C.A., an aqueous solution of glass water (calcium silicate) concentration of 3–5% was applied by spraying over it, in 2…3 layers, and then it was left to dry in the open atmosphere, without air currents.

A mixture of mortar, HAp, and water was poured into identical molds to ensure consistency (see Figure 7).

Figure 7.

Appearance of specimens made with HAp (from left to right: control, 10% HAp, 20% Hap, and 30% HAp).

Analytical Techniques and Equipment

Scanning Electron Microscopy coupled with Energy-Dispersive X-ray Spectroscopy (SEM-EDS) provides detailed information regarding the morphology and elemental composition of powders. SEM-EDS analysis was performed using an SU-70 scanning electron microscope (Hitachi, Japan), commonly employed for characterizing micro- and nanomaterials, conducting qualitative and quantitative analyses of samples, and assessing the structural composition across selected surface areas.

Atomic Force Microscopy (AFM) was carried out using an Agilent 550 SPM AFM microscope, described by PicoSPM controlled by a MAC mode module and connected to a PicoScan controller from Agilent Technologies, Tempe, AZ, USA (Molecular Imaging). This technique yields the high-resolution imaging of the surface topography at the atomic scale in the non-contact mode (with a probe-to-sample distance greater than 10 Å).

The colorimetric tests were performed using a Konica Minolta colorimeter, model CR-410 (Konica Minolta, Tokyo, Japan). Chromatic parameters (Lx*, ax*, bx*) were measured in triplicate, according to the CIE L*a*b* system (CIE 1986) [48], both for the control samples (mortars without HAp) and for the 10%, 20%, and 30% HAp compositions. Average values were considered for each specimen. The color differences between the mortar and HAp specimens were calculated, and the total color differences (ΔE*) were determined using Equation (1):

where ΔL* is the difference in lightness between control and HAp samples; Δa* is the chromatic deviation along the red–green axis; Δb* is the chromatic deviation along the yellow–blue axis.

The water absorption test, achieved according to STAS 6200/12-73, involved the total immersion of samples in distilled water for 24 h, after a drying step when the specimens were kept in an oven at 40 °C for 8 h, until reaching constant masses (W1). Following immersion, the samples were wiped and weighed (W2). The value of water absorption was determined using Equation (2):

The water repellency (WR) was determined using a procedure adapted from [49], considering the water drop absorption (WA) and Equations (3) and (4). First, the mortar and Hap samples were dried until a constant mass sample was obtained, for approx. 8 h at 60 °C, and then cooled at room temperature. A total of 1 mL of distillate water from a biuret was dropped onto the specimen’s surface, and the time for the total absorption of the water was measured, in minutes (tn and tx—absorption time into simple and HAp mortars’ surface, respectively).

The freeze–thaw test was conducted, according to STAS 6200/15-83, for the evaluation of the frost susceptibility or gelivity of the specimens. Initially, the samples were dried at 105 ± 5 °C for one hour until they reached a constant mass (m1), defined as the point where the weight difference between two consecutive measurements was less than 0.1% of the previous value. Afterward, the samples were immersed in distilled water for 15 min at room temperature and weighed again (m2). Then, the specimens were arranged on racks in a freezer with a 10–20 mm gap between them to allow for adequate air circulation and constant cooling. They were stored at −18 ± 5 °C for 3 h, then removed and immersed in distilled water at room temperature for thawing. The cycle was closed by thawing the frozen samples in water. The test consisted of 20 complete cycles. The samples were visually analyzed to observe the cracks of other damage that could appear during the test. Using the final weight (m3), the frost resistance expressed by the gelivity coefficient (μg)—Equation (5)—could be evaluated.

The compressive strength test was conducted to estimate the surface hardness and the compressive strength. A Silver Schmidt Hammer (Proceq, type L), with an impact energy of 0.735 Nm and testing range of 10–100 N/mm2, was used, in accordance with ASTM C805. Ten measurements were performed on each specimen, maintaining a minimum 25 mm between testing points and from the sample edges. The hammer was held in a vertical position (90° downward), and the rebound number (Q-value) was measured and reported as an average. The in situ compressive strength was estimated considering the instrument calibration curve, specific constant (2.77) and Equation (6).

The accelerating carbonation test was performed using 3 samples from each type of mortar and HAp mortars that were introduced in a climatic chamber with 2 (v/v) % CO2 for 7, 28, and 56 days. After each period, the carbonation was tested by applying a 1% phenolphthalein solution in ethyl alcohol, as a pH indicator, on the freshly cut surfaces of the samples. Red-purple colored surfaces can be observed if the surfaces are carbonated. Using the ImageJ software (version 1.44), the carbonation depth (mm) can be measured, respectively, the distance between the external surface of the colored zone and the specimen edge [50].

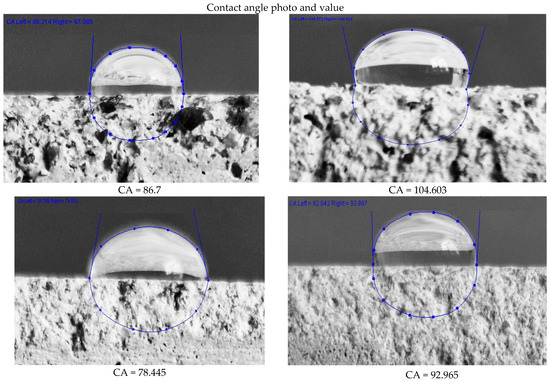

The contact angle was measured for each mortar specimen in order to evaluate the hydrophobic properties of the bone glue coating applied on the samples. The value was obtained by measuring the angle formed by a water droplet with the mortar surface using the DropAnalysis plugin LB-ADSA from ImageJ according to [51]. The test was made at a constant temperature of 21 °C, in duplicate, and reported as an average.

Optical microscopy was achieved by using a Novex Microscope with a magnification of 4–100×, equipped with a digital video camera (EUROMEX, Arnhem, The Netherlands) that allows real-time image acquirement.

Stereomicroscopy used a Euromex StereoBlue binocular stereomicroscope (PeplerOptics, Cheshire, GB), with a maximum magnification of 40×.

5. Results

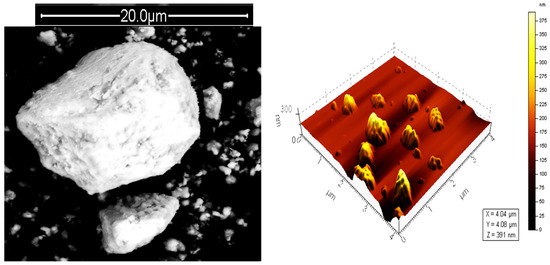

For HAp, some microscopy investigations have been conducted. The obtained images reveal agglomerated particles with a rough, granular surface, exhibiting a cauliflower-like morphology, as previously reported [52]. All these characteristics could be observed via Scanning Electron Microscopy (SEM) and Atomic Force Microscopy (AFM); see Figure 8.

Figure 8.

SEM image (left) and AFM image of HAp powder (right).

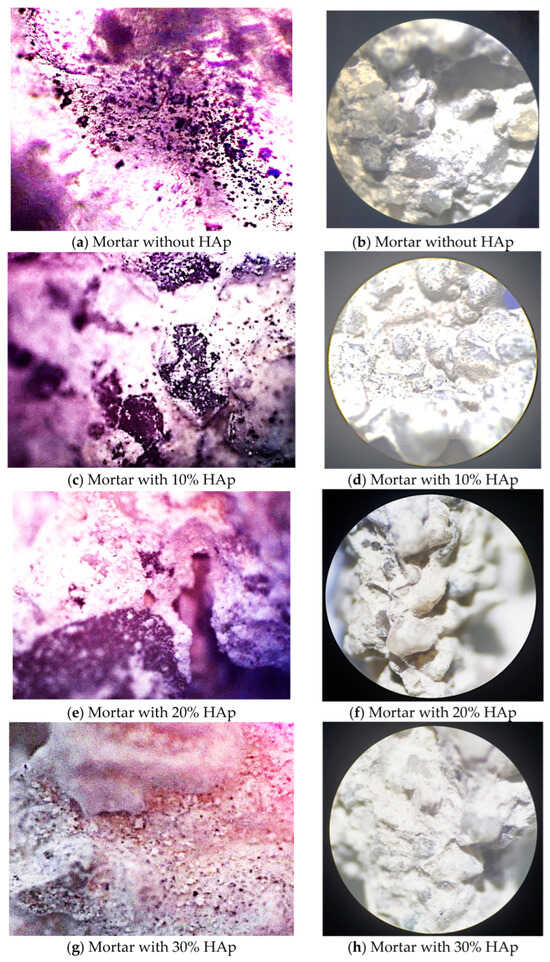

Optical and Stereomicroscopic Analysis of Specimens

The following images illustrate the results obtained through optical microscopy (OM) and stereomicroscopy. Optical microscopy provides insights into the compositional homogeneity of mineral/inorganic materials and is particularly useful in diagnosing mortar degradation, analyzing interfacial transition zones, and identifying reaction products between binders and aggregates [53].

In this study, OM revealed that quartz is the predominant mineral within the aggregates, accounting for approximately 70% of the volume. The grains were polycrystalline with undulatory extinction and irregular surfaces exhibiting crystalline imperfections (Figure 9). The images highlight polycrystalline grains with wavy extinction patterns and heterogeneous surfaces, likely composed of aluminosilicates.

Figure 9.

OM (left) and stereomicroscopy (right) of the mortar samples with different concentrations of HAp.

Stereomicroscopy further revealed the presence of hydroxyapatite (HAp) on the surface of the mortar, which contributes to its enhanced chemical and microbiological stability.

Chromatic parameters

The CIELab 1976 (CIELab 76) color model is one of the most comprehensive systems for describing colors within the visible spectrum. It enables the specification of the widest range of perceptible color shades using its chromatic components, a* and b*. As a result, the CIELab model is often regarded as offering the broadest gamut of reproducible colors visible to the human eye [48].

The CIELab color space is structured as a three-dimensional Cartesian coordinate system with three orthogonal axes: L*, a*, and b*. The L* axis represents lightness (ranging from black to white), the a* axis represents the green to red color range, and the b* axis represents the blue to yellow color range.

In our case, by adding HAp, a lightness is visible in relation to the specimens: L* increases, while a* and b* decrease, as a result of the whitening tendency of the specimens by adding HAp, Table 1.

Table 1.

Chromatic parameters of the studied specimens.

Determination of Specimen Parameters

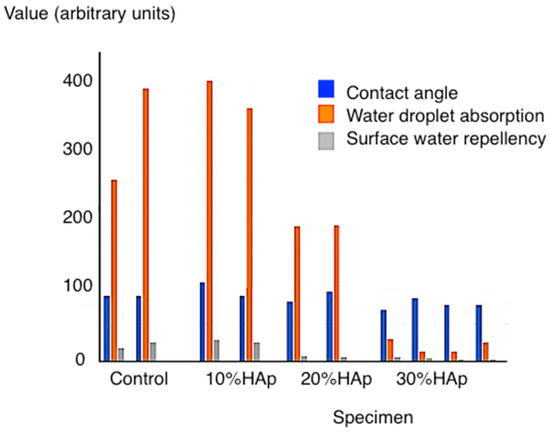

Water droplet absorption (WA) in treated zones, surface water repellency (WR), and the consolidation percentage (%C) were used to assess the amount of detached material and to evaluate the adhesion of a coating to a substrate—an especially important parameter in conservation practice when measuring the consolidation effectiveness of degraded stone.

These values, presented in Table 2, confirmed the best results for the mortar formulation containing 20% HAp.

Table 2.

Measured parameters for samples with various HAp concentrations.

Carbonation Depth Determination

The carbonation depth of HAp-based mortars is illustrated in Figure 10, which shows that as the HAp concentration increases, the carbonation depth decreases. These results are consistent with several studies [49,54], which concluded that the carbonation depth tends to increase with higher amounts of inorganic filler. In contrast, HAp exerts a beneficial influence not only on the compressive strength but also on the carbonation resistance.

Figure 10.

Images of the specimen with HAp 20% (non-tested sample (left) and tested for carbonation depth (right)).

Freeze–Thaw Resistance

The freeze–thaw resistance was evaluated by waterproofing the specimens with bone glue and subjecting them to two test series: one with 10 cycles and the other with 20 cycles.

Freeze–thaw resistance is one of the fundamental parameters to consider when introducing a material into conservation practice. In the cases examined in this study, specimens containing hydroxyapatite (HAp) without and coated with bone glue demonstrated superior freeze–thaw resistance (gelivity).

The consolidating material (HAp) improved the freeze–thaw resistance, with the best gelivity coefficients recorded for HAp additions between 20% and 30%. The observed order of freeze–thaw resistance was as follows:

30% HAp > 20% HAp > 10% HAp

The fact that these specimens withstood 20 freeze–thaw cycles indicates that the new consolidating formulations possess adequate durability and are promising candidates for future conservation studies. The application of a bone glue layer significantly enhanced the freeze–thaw resistance and an improved contact angle of the tested samples, as will be presented further.

Contact Angle Test

In addition to the freeze–thaw tests, contact angle measurements were also performed, both for the control specimens and for the specimens treated with HAp. According to the scientific literature, the greater the contact angle (especially above 100°), the lower the surface’s wettability (i.e., the water impermeability is reduced). In our tests, the highest contact angle values were recorded for specimens containing 20% HAp.

Except for the above experiments, bone clay has been applied on the specimen’s surface to create an impermeable surface; see Figure 11.

Figure 11.

Contact angle (°), water droplet absorption (minutes), and surface water repellency (%) for the specimens treated with HAp.

The use of bone clay in monument surface restoration is an emerging and specialized technique that combines traditional conservation methods with modern material science.

Bone clay refers to a composite material that includes finely ground bone ash (primarily calcium phosphate) mixed with clay minerals. It is typically formulated to match the physical and chemical properties of the original monument materials, such as limestone or marble.

Bone clay is typically composed of bone ash, predominantly with HAp derived from calcined animal bones, clay matrix (usually kaolinite or bentonite, added for plasticity and workability), and optional binders: lime, casein, or synthetic resins to enhance bonding and durability.

The microstructural details of bone clay adhesion and surface integration include interlocking particle morphology, porous microstructure facilitating vapor permeability, and strong interface bonding with calcareous substrates.

From Figure 12, an extraordinary time increase of the contact angle (between 60 and 130) can be observed concomitantly with a water absorption decrease (not higher than 20 s) for the samples treated with bone clay, which is quite convenient for our experiments and the monument surface impermeabilization.

Figure 12.

Images of contact angle for the prepared specimens and their value (drops blue-marked).

6. Economic Evaluation

6.1. Hydroxyapatite in Construction: Challenges and Emerging Applications

Hydroxyapatite (HAp) is gaining increasing attention in the construction industry as a bio-based, sustainable material with multifunctional potential. However, its integration into large-scale applications still faces several critical challenges. One of the primary obstacles is cost and scalability: HAp remains significantly more expensive than conventional construction materials. Furthermore, in its pure form, hydroxyapatite lacks the mechanical strength necessary for structural applications, limiting its use to non-load-bearing components unless reinforced. To overcome these limitations, HAp must be carefully incorporated into composite formulations, often alongside polymers, resins, or ceramics, to achieve the desired performance characteristics.

Despite these challenges, hydroxyapatite shows promising potential across a variety of current and emerging applications. It is already being explored in eco-friendly cementitious composites and advanced façade systems, including self-cleaning and anti-corrosive coatings. Innovative uses also include smart surfaces with air-purifying capabilities, which align with indoor environmental quality standards in green buildings. As research continues, HAp is expected to play a growing role in interior finishes designed for sustainability, health, and energy efficiency.

Within the building sector, hydroxyapatite-based solutions are particularly suitable for specific architectural and functional components. These include interior wall cladding for office partitions and wellness rooms, ceiling panels in healthcare environments where VOC (volatile organic compound) control is critical, and exterior ventilated façades enhanced with UV-protective features. Additionally, the use of removable, modular panels containing HAp supports circular construction strategies, allowing for reconfiguration, reuse, and reduced material waste.

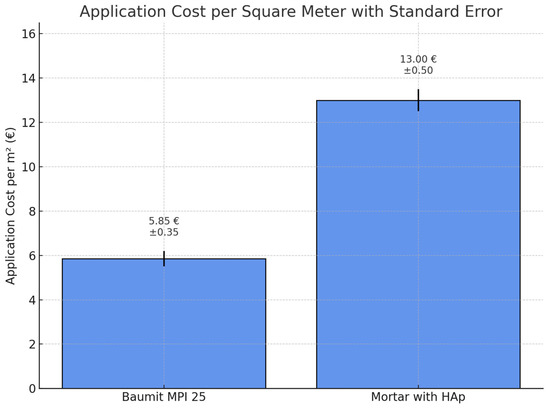

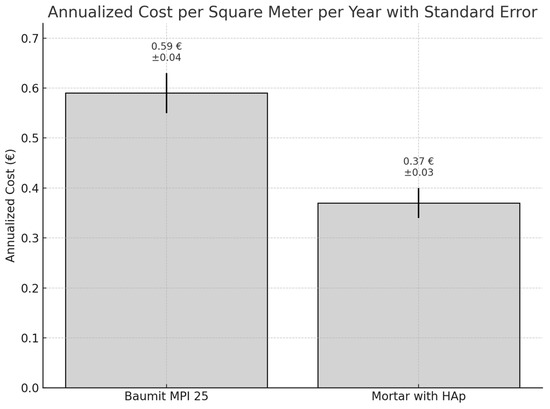

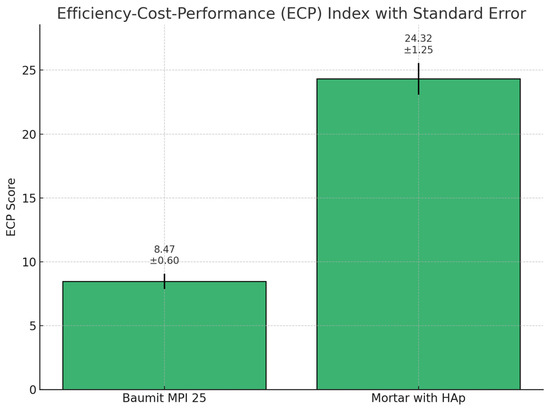

6.2. Comparative Financial Analysis: HAp-Modified Mortar vs. Baumit MPI 25

The table below (Table 3) provides a comparative overview of two mortar types from a financial and performance perspective. Key indicators such as cost per kilogram, application costs per square meter, durability, maintenance needs, performance rating, and an Efficiency-Cost-Performance (ECP) Index are presented.

Table 3.

Financial comparison data.

The standard error (SE) was computed on a column-wise basis, comparing mortar types across each individual indicator. This approach facilitates the quantification of inter-product variability (e.g., in terms of cost, durability, etc.) and supports the isolated assessment of performance metrics, rather than a holistic evaluation of the composite solution [55].

The Global Standard Error (Mean of Individual Standard Errors) represents the arithmetic mean of the standard errors across all numerical columns, providing a general measure of data variability (see Formula (7)).

where SEi is the standard error of each numerical column.

Global Standard Error Summary, mean of Column-wise Standard Errors: 3.92

The standard error (SE) computation across performance indicators for each mortar type serves to quantify the internal variability and coherence of the economic profile characterizing each assessed alternative (Table 4).

Table 4.

Financial comparison data with standard error computation across performance indicators for each mortar type.

Figure 13, Figure 14 and Figure 15 present the comparative financial impact analyses of the two mortar types under investigation: the conventional lime-based mortar and the hydroxyapatite-enhanced variant.

Figure 13.

The initial application cost per square meter is significantly higher for the HAp-modified mortar due to its additive content.

Figure 14.

Annualized costs illustrate that HAp mortar becomes more economical over time because of its extended durability.

Figure 15.

The Efficiency-Cost-Performance (ECP) Index shows a much higher score for HAp, underlining its long-term value.

The methods have unspecified standardization and statistical controls, and include strong statistical analysis (ANOVA, t-tests) to support claims of “optimal” at 20% HAp performance.

The methodology employed in evaluating the comparative performance of hydroxyapatite (HAp) modified mortar versus standard Baumit MPI25 mortar includes a standard error (SE) analysis computed column-wise across performance indicators. This provides an initial form of statistical control by quantifying intra-category variability. To further substantiate the claim of “optimal performance” at 20% HAp addition, independent samples t-tests were conducted. The results of independent samples t-tests were conducted on three performance and cost indicators: application cost, annualized cost, and Efficiency-Cost-Performance (ECP) Index (Table 5). For each metric, simulated samples were generated based on the provided mean and standard error values. The tests determine whether the differences between the two mortar types are statistically significant.

Table 5.

t-test results on three performance and cost indicators: application cost, annualized cost, and Efficiency-Cost-Performance (ECP) Index.

By interpretation of these data, some conclusions could be resumed:

- Application cost (€/m2):

The p-value of 0.054 is slightly above the standard threshold for statistical significance (0.05).

This indicates that although the HAp-modified mortar appears more expensive to apply, the difference is not statistically significant.

A larger sample size might yield a more definitive result.

- 2.

- Annualized cost (€/m2/year):

With a p-value of 0.00296, the annualized cost difference is statistically significant.

This supports the conclusion that HAp-modified mortar is more cost-efficient over the long term, despite its higher initial application cost.

- 3.

- Efficiency-Cost-Performance (ECP) Index:

The ECP index shows a highly significant difference (p = 0.0044).

This validates the claim that HAp-modified mortar offers superior overall performance when considering efficiency, cost, and durability combined.

6.3. Radar Chart Analysis: Hydroxyapatite vs. Standard Mortar

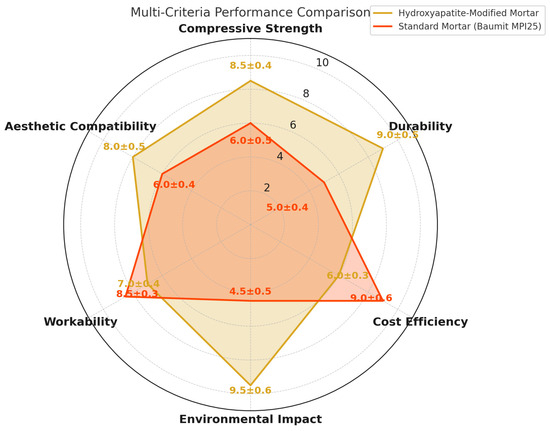

This radar chart presents a multi-criteria comparison between a hydroxyapatite-modified mortar and a traditional Baumit MPI25 mortar [56]. The evaluation covers six performance indicators: compressive strength, durability, cost efficiency, environmental impact, workability, and esthetic compatibility (Figure 16).

Figure 16.

Multi-criteria performance comparison between standard mortar and hydroxyapatite additives mortar.

From the chart, the hydroxyapatite-modified mortar outperforms the standard variant in durability, environmental impact, and esthetic compatibility—criteria critical in heritage conservation. On the other hand, the standard mortar scores better in cost efficiency and workability (Table 6). This visual tool aids in selecting materials not just by economic cost, but by holistic performance suited to sustainable restoration projects.

Table 6.

Multi-criteria evaluation scores.

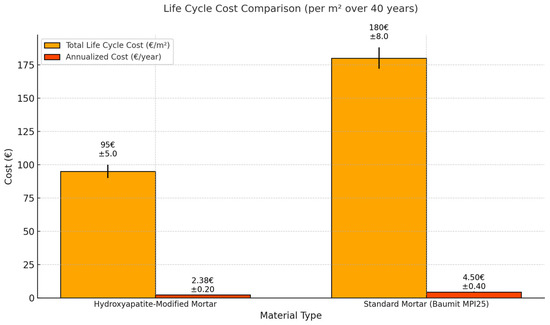

6.4. Life Cycle Cost Analysis

This bar chart from Figure 17 compares both the total and annualized life cycle costs of the hydroxyapatite-modified mortar and the standard Baumit MPI25 mortar over 40 years. The hydroxyapatite mortar, despite a higher initial cost, requires no reapplication, resulting in a lower total cost compared to the standard mortar, which needs to be reapplied every 10 years. The annualized cost of the HAp mortar is thus significantly more favorable for long-term investments.

Figure 17.

Total and annualized life cycle cost comparison.

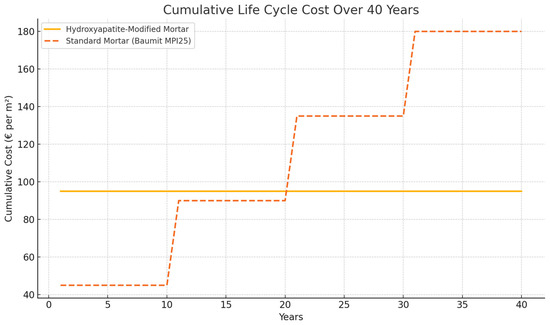

The cumulative cost chart in Figure 18 further illustrates the economic advantage of hydroxyapatite-modified mortar over time [57]. Its cost remains constant after the initial application, whereas the standard mortar incurs spikes in cost every 10 years. This visual emphasizes the value of long-lasting materials in sustainable restoration, minimizing disruptions and future expenses.

Figure 18.

Cumulative life cycle cost over time.

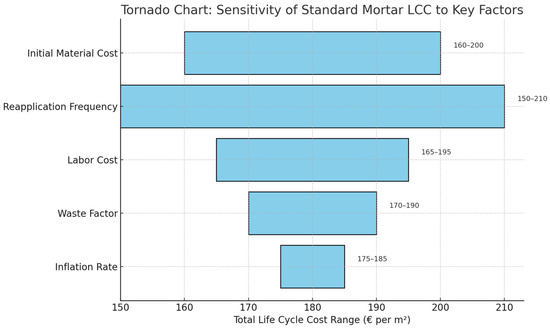

6.5. Sensitivity Analysis: Tornado Chart

The Tornado Chart (Figure 19), illustrates the sensitivity of the total life cycle cost of the standard Baumit MPI25 mortar to key economic and technical variables. Among these, the reapplication frequency and initial material cost exert the greatest influence on the overall cost. A higher frequency of maintenance or price fluctuations can significantly increase expenses over a 40-year period. Conversely, stable costs and efficient material use can mitigate this impact. Such sensitivity analysis is crucial for identifying risk areas in restoration budgeting and long-term material planning.

Figure 19.

Sensitivity of standard mortar life cycle cost.

This document presents a comprehensive financial analysis comparing a hydroxyapatite-modified mortar with a traditional Baumit MPI25 mortar, specifically in the context of sustainable heritage restoration [58]. The evaluation incorporates multiple decision-making criteria, long-term cost assessments, and sensitivity studies—offering a nuanced view of the economic and performance implications over a 40-year lifecycle.

The hydroxyapatite-based mortar, although more expensive at the outset, demonstrates superior longevity and environmental benefits, which are particularly valuable in the preservation of high-value historical assets. The graphics and evaluations herein are intended to guide restoration specialists, architects, and heritage managers in choosing cost-effective and performance-driven solutions for durable conservation [59].

6.6. Interpretation and Importance of Financial Analysis in Sustainable Restoration

This analysis underlines the critical importance of looking beyond the initial material costs when planning sustainable restoration interventions. Although the HAp-modified mortar presents a higher upfront investment, it outperforms traditional mortar in both durability and reduced maintenance needs. The annualized cost and ECP index reinforce that choosing higher-quality, longer-lasting materials leads to more efficient spending over time.

- The Efficiency-Cost-Performance (ECP) Index and cost comparisons are sound but involve some rationalizing of assumptions. Some estimation was used for durability years, and where the “performance score” comes from is presented below.

The Efficiency-Cost-Performance (ECP) Index was constructed to evaluate the comparative advantages of hydroxyapatite (HAp)-modified mortar relative to a conventional product, using normalized criteria relevant to restoration performance.

- Durability Estimate: A durability of 10 years was assigned to the standard mortar, reflecting typical service intervals for such materials in restoration contexts. The HAp-modified mortar was assigned a durability of 40 years, based on its chemical stability, improved resistance to environmental degradation, and laboratory-observed long-term performance indicators.

- Performance Score Source: The performance scores used in the ECP index and related radar chart were derived through a multi-criteria assessment approach, incorporating six indicators: compressive strength, durability, cost efficiency, environmental impact, esthetic compatibility, and workability. Each indicator was assessed on a scale from 1 to 10, allowing comparative visualization in the radar diagram.

- ECP Index Scale: Unlike the radar chart, the ECP Index is a composite numerical value that integrates the weighted performance scores with cost-related data. As such, it is not constrained to a 1–10 scale, and in this study ranged between 1 and 25. This scale reflects a combined evaluation of efficiency, durability, and cost per unit performance, offering a comprehensive representation of material suitability.

Such data-driven evaluations are not only vital for technical decision making but also enhance transparency and funding justification, especially for projects eligible under European Union heritage conservation grants. Interdisciplinary collaboration between material scientists, conservation architects, and economists is essential in delivering sustainable outcomes grounded in measurable value.

6.7. Qualitative Value Considerations

Beyond economic metrics, the integration of HAp into restoration mortars provides qualitative benefits that are critical in heritage conservation. These include enhanced material compatibility, reduced intervention frequency, and the preservation of authenticity in historic materials. Such advantages have been highlighted in recent studies that demonstrate the chemical and mechanical compatibility of hydroxyapatite with carbonate stone substrates [60]. These factors are particularly valuable in UNESCO sites, listed buildings, or structures of national significance, where long-term material integrity and cultural value outweigh short-term financial costs.

7. Discussion

One of the most challenging aspects in the restoration process is finding appropriate materials that are compatible with the original layers, but at the same time are better in terms of resistance, sustainability, durability, etc. Especially when it comes to masonry heritage buildings, one of the most affected materials is the mortar, highlighting the need to develop new, innovative mortars as alternatives to the traditional ones.

A higher contact angle (CA) corresponds to a lower water absorption (WA). Untreated control samples without a bone glue coating exhibited very low CA values and relatively high WA values.

Lime-based mortars demonstrated significantly greater durability compared to those without lime. This observation reaffirms the traditional formulations used by Roman Empire craftsmen, who combined hydroxyapatite with quicklime. Over time, in the presence of atmospheric carbon dioxide, the lime transformed into calcium carbonate, which, together with hydroxyapatite, formed a volumetric mass capable of filling voids and cracks within masonry structures. This self-healing property makes the formulation particularly valuable for long-term preservation [61,62,63,64,65,66].

Based on our findings, we propose the following final recipe for consolidating historic surfaces: lime-based mortar mixed with 20% hydroxyapatite, and, under specific conditions, coated with bone glue.

The study presents new mortar compositions that could serve as viable alternatives to traditional mortars in restoring historical buildings. The addition of hydroxyapatite yielded the following results:

- HAp is similar to that synthesized in the labs [67] was homogeneously mixed into the mortar matrix, as confirmed by both optical microscopy and stereomicroscopy.

- The critical concentration of HAp was determined to be 20%, at which point the mortar exhibited the lowest peeling rate, the highest consolidation effectiveness, best compressive strength, lowest droplet water absorption, and greatest surface water repellency.

The sustainable restoration of architectural heritage is a growing priority in Europe, especially as historical buildings face increased environmental pressure. This research explores the integration of hydroxyapatite (HAp) into lime mortars, evaluating the resulting material properties in relation to conservation criteria. The project aligns with European green policy frameworks and emphasizes both material compatibility and long-term performance.

The study examined traditional lime mortars modified with hydroxyapatite synthesized via wet chemical methods. A base mortar mix was prepared using hydrated lime (CL-90), fine siliceous sand, and water. HAp was introduced in varying concentrations (2.04 g/kg) to assess its influence on physical and mechanical performance. All the specimens were cast in prismatic molds and cured under laboratory-controlled conditions for 28 days.

The mortars were analyzed using a suite of advanced techniques: X-ray diffraction (XRD) for phase identification, scanning electron microscopy (SEM) for morphological analysis, Fourier-transform infrared spectroscopy (FTIR), and mechanical testing (compressive and flexural strength) [52]. Capillary water absorption and porosity measurements were also conducted according to EN standards.

The addition of hydroxyapatite significantly reduced the capillary water absorption and increased the mechanical strength. SEM images revealed a denser and more cohesive microstructure in HAp-modified samples, with reduced pore connectivity. XRD and FTIR confirmed the formation of additional calcium phosphate phases that contribute to long-term consolidation. Mechanical testing showed an average increase of 28.6% in compressive strength for HAp-enriched mortars.

In our mortars enhanced with additives like hydroxyapatite (HAp), it is common to see performance (e.g., mechanical strength, durability, or porosity reduction) peak at an optimal concentration (e.g., 20%), then decline beyond that point (e.g., 30%).

In order to explain this behavior, the following factors could be taken into account:

Particle Packing and Pore Refinement (Percolation and Microstructure Densification). Up to ~20% HAp, fine HAp particles could be observed filling the voids between larger particles in the mortar matrix, improving the packing density, reducing the porosity, and enhancing the mechanical interlocking. This leads to better compressive strength, water resistance, and durability. When small particles occupy interstitial spaces efficiently, the composite matrix becomes denser and more coherent. There could be an optimized particle packing and percolation thresholds. Beyond ~20% (e.g., at 30% HAp), excess HAp can disrupt the matrix continuity, introducing more interfaces and creating regions of poor bonding. It may lead to the agglomeration of HAp (leading to weak zones), increase in internal stresses due to incompatible stiffness, and higher water demand due to an increased surface area, negatively affecting the workability and hydration. Overfilling disrupts the packing efficiency, leading to a poor dispersion and phase separation.

Also, the interface Transition Zone (ITZ) behavior between mortar components and HAp should be taken into account. HAp interacts with the binder (lime or cement) to form a chemically and mechanically integrated interfacial zone. At optimal concentration (~20%), the ITZ is strengthened. At a higher loading (~30%), interface saturation occurs, leading to incomplete bonding, weak ITZ formation, and microcrack propagation under stress.

It is a critical interfacial saturation; beyond a threshold, more additive does not enhance bonding; instead, it creates flaws.

Nucleation and Growth during Setting. HAp can act as a nucleation site for binder hydration products (e.g., C-S-H in cement or carbonates in lime mortars). Moderate amounts (e.g., 20%) boost hydration and carbonation. Excess (30%) may consume water, delay hydration, act as an inert filler beyond a certain concentration, and create localized zones with uneven hydration.

Nucleation site saturation. Once the system has enough sites, adding more no longer benefits growth and may hinder it.

Mechanical Percolation Threshold. There is a percolation limit at which added phases like HAp begin to form a continuous network. Below the threshold (~20%), HAp reinforces the matrix. Beyond it (~30%), HAp may start to form weak, brittle paths within the mortar, leading to a reduced mechanical ductility, and premature crack initiation. Too many rigid inclusions can reduce composite toughness and increase brittleness.

Rheology and Workability Effects. Fine HAp particles increase the surface area, raising water demand and altering rheological behavior. At higher loadings, poor workability affects homogeneous mixing, air entrapment, and setting kinetics. This rheological instability explains why excessive additives disrupt the optimal water-to-binder ratio and microstructure evolution.

The observed peak at ~20% HAp and drop at ~30% are a result of competing physical mechanisms. Initially, HAp enhances packing, bonding, and the microstructure. Beyond a threshold, it introduces discontinuities, weak zones, agglomeration, and hydration interference. These trends reflect universal principles in composite material design: optimal dispersion, interfacial engineering, and load transfer are maximized only within a narrow compositional window.

Regarding the mechanisms of interaction between hydroxyapatite and lime/cement phases, such as whether HAp influences carbonation or pore microstructure, and whether HAp forms secondary phases with lime (e.g., calcium phosphate carbonates), it can be mentioned that the hydroxyapatite (HAp, Ca10(PO4)6(OH)2) is largely chemically inert in traditional lime or cement matrices under normal conditions. Generally, no significant chemical reactions occur between hydroxyapatite and lime or Portland cement. HAp is thermodynamically stable and does not readily react with Ca(OH)2 or with common cement hydration products (C-S-H, portlandite) under ambient conditions. Even without chemical reactivity, HAp acts as a microstructural “glue”, strengthening interfaces, filling shrinkage cracks, and improving the overall mechanical strength (compressive strength, cohesion) in heritage mortars. However, some minor ion exchange or local transformations may occur under certain pH, temperature, or CO2 environments. Under CO2-rich and humid conditions, some superficial transformation of HAp may occur, leading to carbonate apatite or dicalcium phosphate carbonate (CaHPO4·CaCO3). HAp can also slightly stabilize the local pH, helping to maintain the alkaline environment necessary for lime carbonation. In principle, HAp could have a filling effect, reduce porosity and fill voids, increasing the compaction density, leading to pore refinement, reducing permeability, improving durability, decreasing water absorption, and improving adhesion via good anchoring in the calcite matrix. In conclusion, HAp contributes to more compact interfacial areas, lower total porosity, and a finer average pore diameter [68,69,70,71,72,73,74,75].

While the application of hydroxyapatite in mortar formulations and conservation treatments has demonstrated promising results in terms of improved mechanical properties, environmental resistance, and compatibility with historic materials, several limitations must be considered: scalability and standardization, meaning that most studies are conducted at laboratory scale, under controlled conditions; difficult to scale up for large architectural surfaces, validation, and the development of standardized treatment protocols, especially across diverse climatic and material contexts, cost and material availability, interaction with certain substrates (e.g., silicate-based materials or those with high soluble salts) which may not be fully predictable or beneficial, and esthetic and surface texture concerns, which may alter the surface appearance or glossiness, potentially deviating from the original material character.

By addressing these limitations, hydroxyapatite has the potential to become a standard conservation material that aligns both with scientific rigor and heritage preservation ethics.

These limitations highlight the importance of continued research, pilot-scale field testing, and cross-disciplinary collaboration to ensure that HAp-based mortars are both scientifically sound and culturally responsible in conservation practice.

This study confirms the potential of hydroxyapatite as a performance-enhancing additive in lime mortars for heritage conservation. Its benefits include improved mechanical strength, water resistance, and compatibility with historical materials. However, the substantial financial implications require a careful evaluation of its applicability based on the project priorities, making it particularly suitable for high-value heritage assets where durability and historical fidelity are paramount.

8. Conclusions

This research demonstrates that hydroxyapatite (HAp) can play a pivotal role in enhancing the performance of lime mortars as an innovative way used in the sustainable conservation of architectural heritage. In this paper we demonstrated the utility of this compound, through chemical, physical, and mechanical investigations, which demonstrated that the integration of HAp significantly improves the compressive strength, reduces the water absorption, increases the adhesion, increases the consolidation percentage with no altered chromatic parameters, and contributes to a more cohesive and durable microstructure—qualities essential in extending the service life of restoration materials. Moreover, the application of a bone clay layer improves the water absorption aspect even more and the durability of the material under freeze–thaw and carbonation conditions, that are specific to the investigated case study.

Although the financial implications are substantial when evaluated through conventional cost analysis, alternative metrics, such as cost per year of durability, cost per square meter restored, and performance-to-cost ratio, highlight the long-term economic viability of HAp-based mortars. This approach is in line with recent research advocating for multi-criteria cost–benefit evaluation in sustainable restoration planning.

Known for the improved mechanical properties, environmental resistance, and compatibility with historic materials, several limitations for HAp could be met in some conditions: scalability and standardization, meaning that most studies are conducted at laboratory scale, under controlled conditions; difficult to scale up for large architectural surfaces, validation and the development of standardized treatment protocols, especially across diverse climatic and material contexts, cost and material availability, interaction with certain substrates (e.g., silicate-based materials or those with high soluble salts) which may not be fully predictable or beneficial, and esthetic and surface texture concerns, which may alter the surface appearance or glossiness, potentially deviating from the original material character. These limitations highlight the importance of continued research, pilot-scale field testing, and cross-disciplinary collaboration to ensure that HAp-based mortars are both scientifically sound and culturally responsible in conservation practice.

Physico-chemical, mechanical studies, and architectural and economic trends have been addressed in this paper. Some specific tests (reduced water absorption, increased adhesion, high mechanical strength, unchanged chromatic aspect, high contact angle, not dangerous freeze–thaw test, reduced carbonation test) have been presented to evidence the capability of hydroxyapatite to be incorporated into green renovation efforts, strengthen the consolidation layer, and focus on its potential uses as an eco-material in building construction and renovation. HAp has a filler effect, reduces the porosity, and fills voids, increasing the packing density, leads to pore refinement, reduces the permeability, improves the durability, decreases the water absorption, and improves the adhesion via anchoring well within the calcitic matrix. The methodology employed in evaluating the comparative performance of hydroxyapatite (HAp)-modified mortar versus standard Baumit MPI25 mortar includes a standard error (SE) analysis computed column-wise across performance indicators. To further substantiate the claim of “optimal performance” at 20% HAp addition, independent samples t-tests were conducted. The results of independent samples t-tests were conducted on three performance and cost indicators: application cost, annualized cost, and Efficiency-Cost-Performance (ECP) Index. This validates the claim that HAp-modified mortar offers superior overall performance when considering efficiency, cost, and durability combined. The results indicate that the proposed materials represent an appropriate approach for a more sustainable conservation intervention in the heritage restoration field. In conclusion, hydroxyapatite represents a forward-looking material for sustainable construction.

Author Contributions

Conceptualization, R.-M.I., A.M. and I.O.; methodology, R.-M.I., A.M. and I.O.; software, A.M., O.-C.B. and M.L.M.; validation, R.-M.I., A.M. and I.O.; formal analysis, M.L.M. and O.-C.B.; investigation, R.-M.I., A.M., I.O., L.I., N.I. and R.M.G.; resources, R.-M.I., A.M. and I.O.; data curation, R.-M.I., A.M. and I.O.; writing—original draft preparation, R.-M.I., A.M. and I.O.; writing—review and editing, R.-M.I., A.M. and I.O.; visualization, R.-M.I., A.M. and I.O.; supervision, R.-M.I., A.M. and I.O.; project administration, R.-M.I., A.M. and I.O.; funding acquisition, I.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author due to the protection of patentable data.

Acknowledgments

This work was supported by a grant from the Romanian Ministry of Education and Research, National Authority for Scientific Research (ANC), Nucleu project PN 23.06.02.01—InteGral.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Iedu, I. Banloc Monograph; Artpress Publishing House: Timișoara, Romania, 2001. [Google Scholar]