Design Study for the Construction of Turbo Roundabouts under Constrained Site Conditions

Abstract

:1. Introduction

- −

- A higher capacity by 150–250%, as compared to conventional single- or even double-lane roundabouts. They are also superior to the signalised junctions by eliminating waiting time at traffic lights.

- −

- Traffic safety improvement by eliminating traffic conflicts and intersecting flows in particular. Worth noting is the reduction of fatalities or injuries by approximately 70% as compared to right-of-way intersections and by approximately 50% as compared to signalised intersections or conventional two-lane roundabouts. In addition, turbo-roundabouts reduce the total number of road incidents by 85% and rear-end collisions by 95%.

- −

- Land takes a comparable approach to double-lane approach and exit signalised intersections, accommodating the simultaneous movement of two tractor-trailer units in any direction during one signal cycle.

- −

- Lower future maintenance costs and lower environmental and social costs of the project compared to signalised intersections, with only a slightly higher project cost.

- −

- Vehicles that are about to enter the roundabout through any leg are not obliged to give way to the vehicles navigating through the roundabout on any of the two traffic lanes of the roundabout carriageway.

- −

- Having to give way to vehicles riding on all the three traffic lanes of the roundabout carriageway is complicated and impracticable for many road users. For this reason, larger turbo-roundabouts should be provided with traffic lights as an additional traffic control measure.

- −

- A raised curb installed in the separation lane allocates a specific lane for each vehicle, which shall not change while navigating through the roundabout. There are no traffic conflicts due to weaving or crossing. Turbine roundabouts do not allow driving in circles from any direction.

- −

- Vehicles are gradually shifted from the inside to the outside, following spiral paths without any crossing movements. The smooth path of travel between the raised kerb separation lanes allows driving through the roundabout at a maximum speed of 35 to 40 km/h.

- −

- Dual-lane exits should be provided on the main legs to maximise the roundabout capacity. However, in the case of moderate straight-through traffic, a single exit lane may suffice.

- −

- At each leg, a road user riding in the outer lane must have the option to exit or continue navigating through the turbo-roundabout. A road user driving in the inner lane will have this choice in the next segment.

2. Materials and Methods

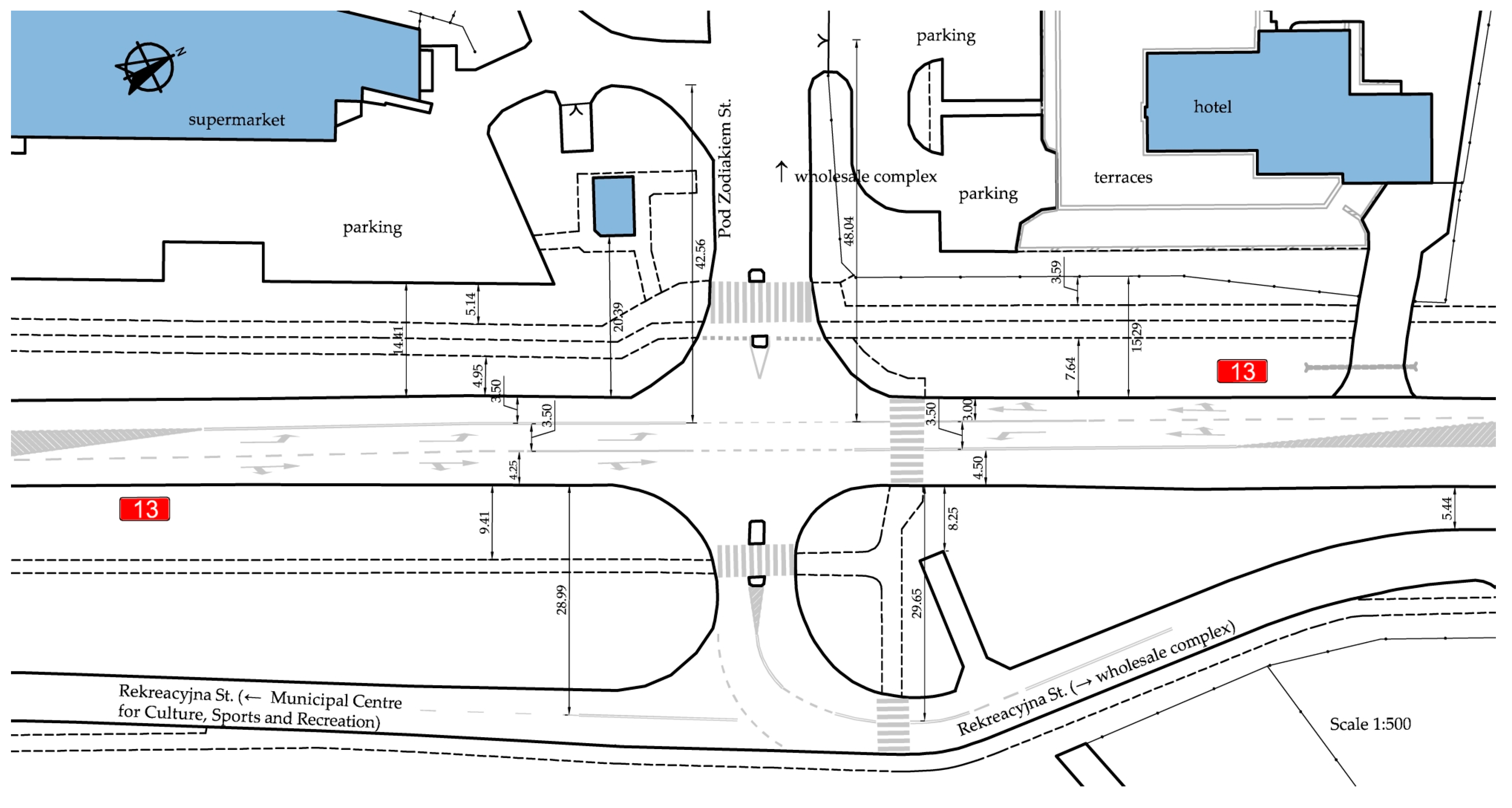

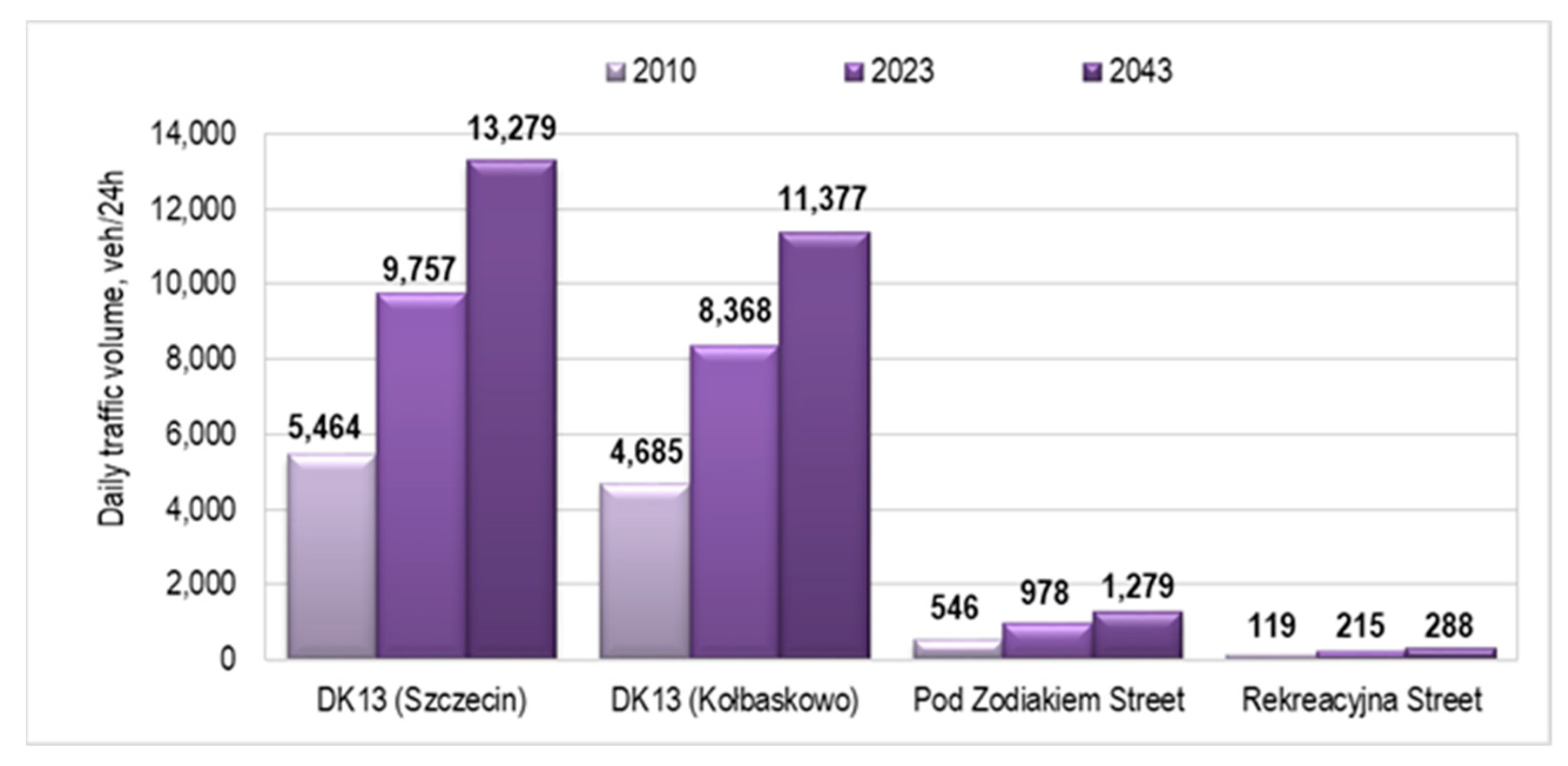

2.1. Study Area

2.2. Design Vehicles and Swept Path

2.3. Standard Turbo Roundabout in a Constrained Site

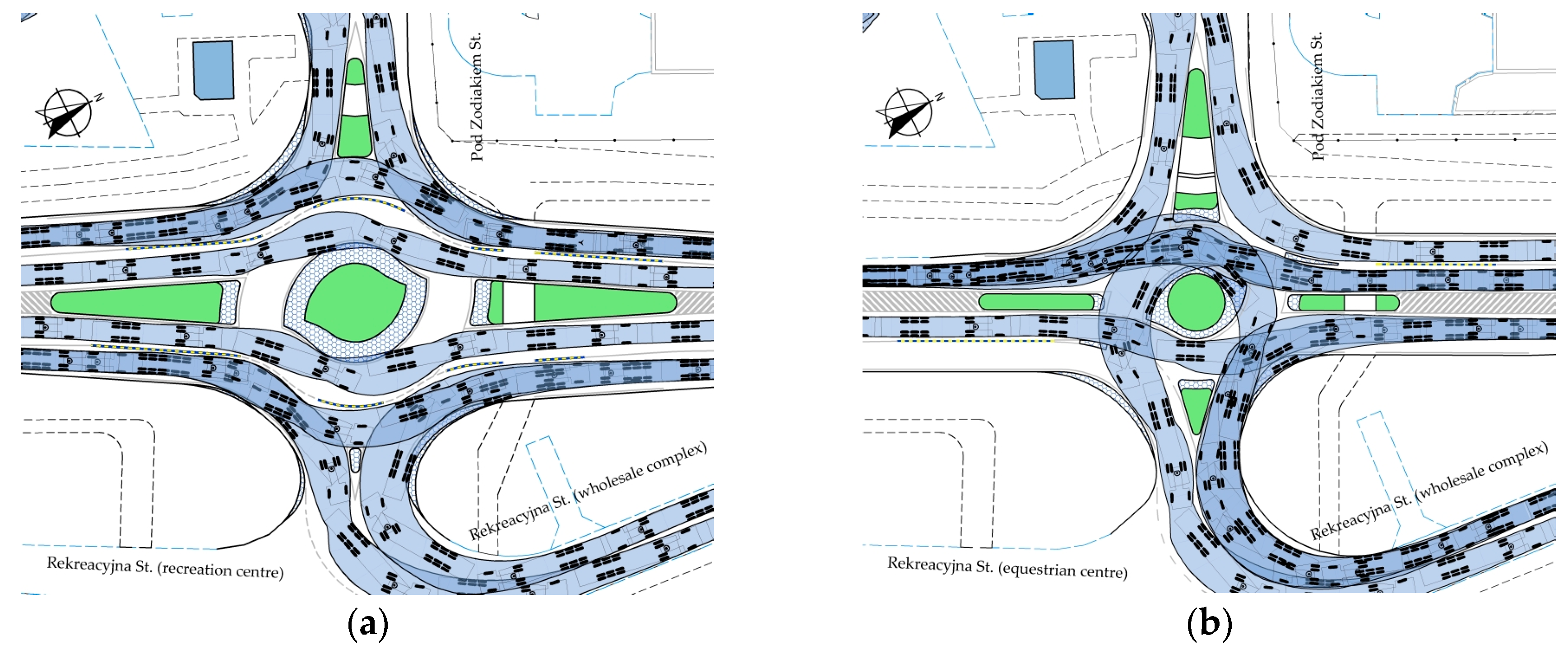

- “flattened” egg turbo-roundabouts,

- elliptical turbo-roundabouts with a central island shape typically for a turbo-roundabout,

- elliptical turbo roundabouts with an elliptical central island.

2.4. Non-Standard Turbo-Roundabout Selection Method for Constrained Areas

- −

- constraints located sideways on the main road, having a determining effect on the limitation of the number of exit lanes on the main road approach legs to one,

- −

- distance of the existing side road constraints, measured along the side road from the main road centreline, having a determining effect on the practicable design of vehicle turn movements and splitter island design (i.e., length and type: nontraversable or traversable),

- −

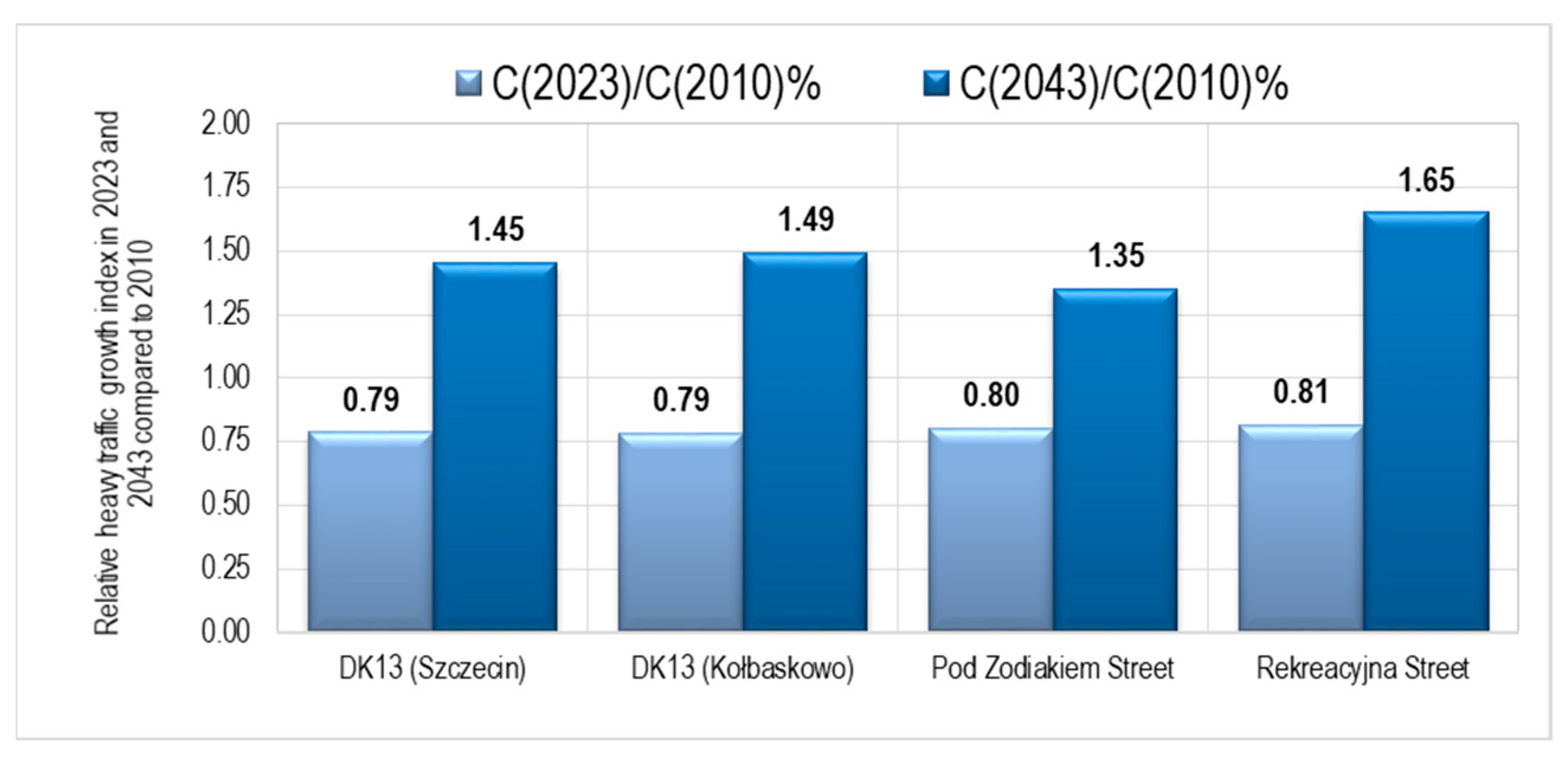

- total current and projected traffic volumes, traffic flow allocation on both roads and traffic composition indicating the expected heavy traffic volume on the turn movements of the analysed legs,

- −

- type of developments around the planned roundabout location.

3. Results

3.1. “Flattened” Turbo-Roundabout Featuring a 0.24-m-Wide Separation Lane

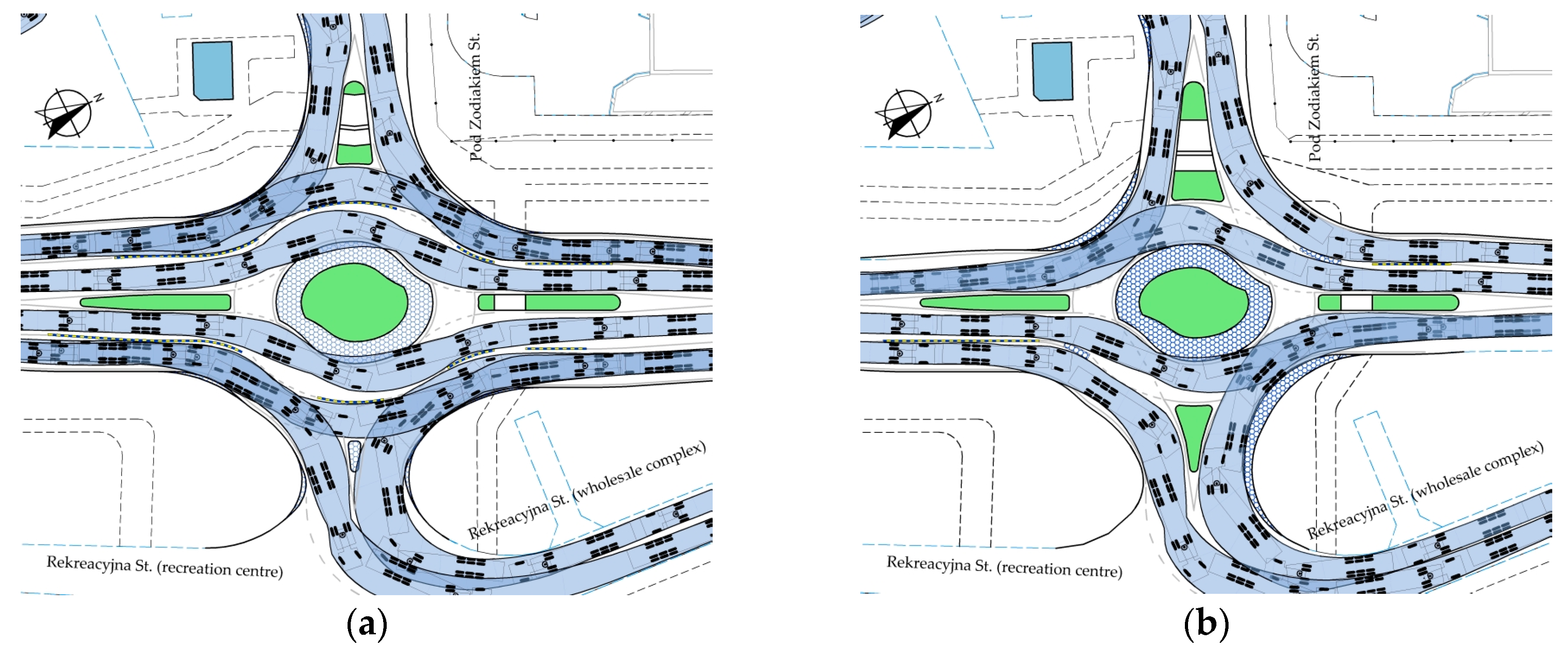

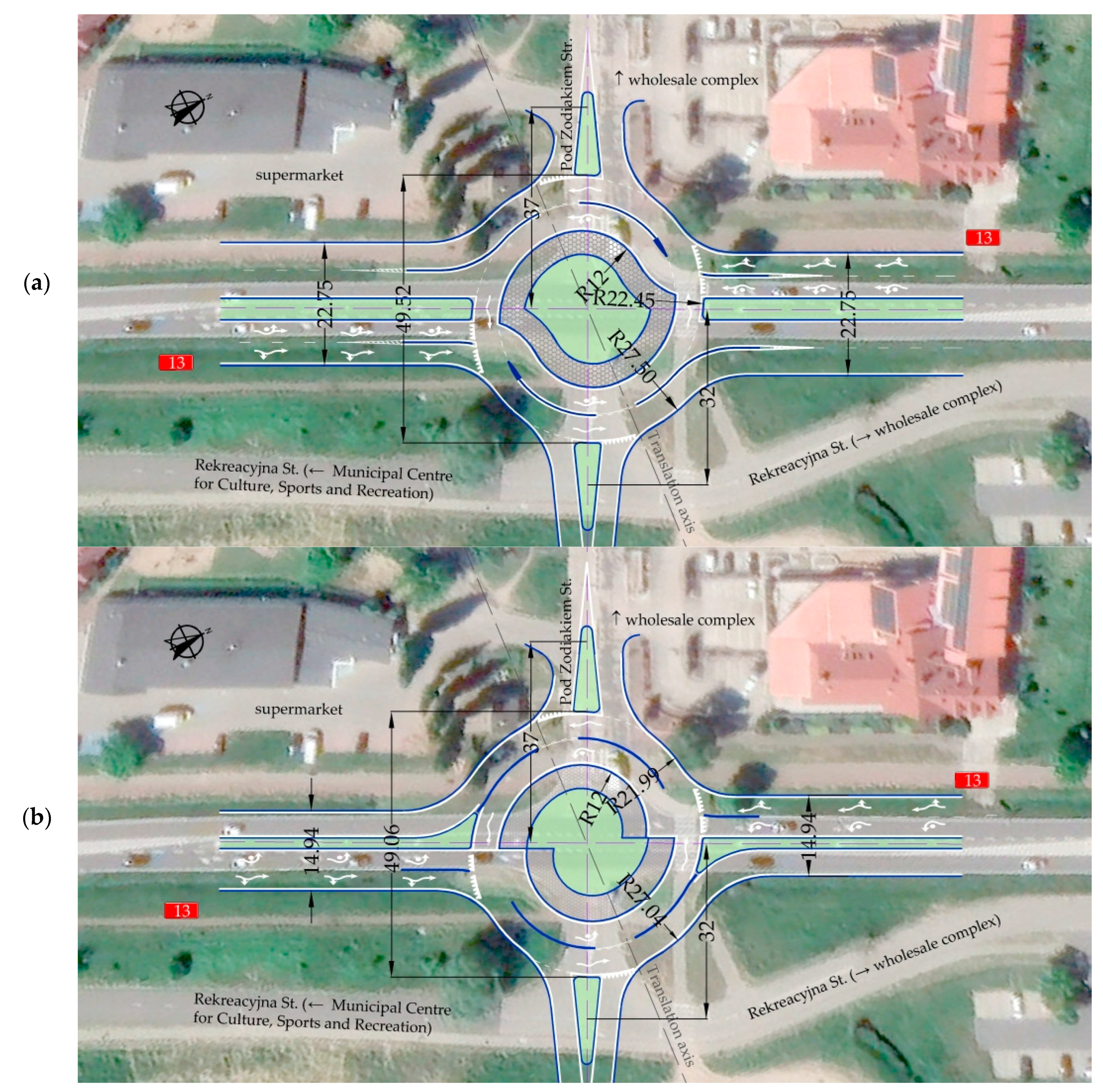

3.2. Elliptical Turbo-Roundabout Featuring a 0.24-m-Wide Separation Lane and a Standard Shape Central Island

3.3. Elliptical Turbo-Roundabout Featuring a 0.2-m-Wide Separation Lane and an Elliptical Central Island

4. Discussion

- (a)

- LUDA low urbanisation degree areas—single family housing estates or woonerf: the side road handles the local traffic composed mainly of the residents’ passenger cars and municipal service vehicles if appropriate,

- (b)

- BA built-up area with a developed community infrastructure, requiring the provision of pedestrian and cycle crossings running through splitter islands on the side approach legs,

- (c)

- CDA highly commercially developed area along the side road, including primarily wholesale complexes, very big warehouses and wholesale markets, resulting in high volumes of articulated trucks on turn movements.

- −

- Dark blue means a good score, i.e., lower cost, bigger pedestrian and cycling amenities, better handling of traffic in the roundabout area by adequate traffic flow allocation: two traffic lanes for the straight movements for high traffic volumes on the main road or a dedicated turn lane for a high, heavy traffic volume for this movement, etc.

- −

- Light blue means the opposite score, i.e., less pedestrian and cyclist amenities, no dedicated right- or left-turn lanes despite a high heavy-traffic volume, etc.

- −

- Blue designates an intermediate score.

- −

- The geometrically related key determinants of the roundabout size in constrained sites include:

- −

- number of straight-through lanes on the roundabout carriageway, G1,

- −

- number of traffic lanes on the main approach legs, G2,

- −

- spacing of splitter islands dividing, measured along the side road, G3.

- −

- spacing of splitter islands on the main road approach legs, which, upon exceeding a certain limit, may require reconstruction of the bus stops, as may be located, for example, near the analysed intersection, or longer pedestrian travel distances to these bus stops, C1; this increases the cost as a result (Figure 11a and Figure 17),

- −

- the spacing of splitter islands on the main road approach legs increases the pedestrian travel distances to the pedestrian crossings and the nearby parking areas, S2, at the main approach legs, resulting in longer pedestrian crossings and longer accesses to nearby C2 car parks; this increases the cost as a result (Figure 11a and Figure 17),

- −

- spacing of splitter islands on the side legs, which, upon exceeding a certain limit in a constrained site, may preclude provision of a cycle crossing through the side road, C3, and thus the roundabout type may get the lowest score and may be discouraged for highly urbanised areas featuring a highly developed cycling infrastructure (Figure 11a and Figure 17),

- −

- requirement of mountable apron areas over pedestrian crossing width C4, causing disturbance to pedestrian traffic, especially for people on wheelchairs, and thus this roundabout type may get the lowest score and may be discouraged for highly urbanised areas featuring a highly developed community infrastructure,

- −

- requirement for traversable parts at the beginning of splitter islands C5, which increases the travel distance to pedestrian crossings and possibly affects traffic safety, thus resulting in a lower score given for this roundabout.

- −

- the required number of straight-through traffic lanes on the roundabout carriageway has a considerable effect on the roundabout capacity when dealing with high traffic volumes carried by the main road, TE1,

- −

- the number of main road exit lanes has a considerable effect on the roundabout capacity when dealing with high traffic volumes carried by the main road, TE2,

- −

- distance to adjacent junctions on the main road requires provision of additional traffic lanes before them, which, in the case of close proximity of such junctions, has a considerable bearing on the carriageway division into traffic lanes on the approach to the analysed roundabout and the installation of appropriate road surface markings, TE3,

- −

- high left-turning traffic volume, requires, for example, the provision of a dedicated traffic lane on the roundabout carriageway TE4,

- −

- high right-turning traffic volume, requires, for example, the provision of a dedicated traffic lane on the roundabout carriageway TE5.

5. Conclusions

- −

- The currently available turbo-roundabout design guidelines do not include turbo blocks that could be used for designing such roundabouts where site constraints are an issue.

- −

- The proposed turbo blocks for designing six types of turbo roundabouts of different shapes and roundabout carriageway divisions offer new turbo roundabout design options for constrained sites.

- −

- Based on predetermined criteria and determinants, three turbo roundabout types were recommended for constrained site projects, with the final choice depending on the adjacent land characteristics:

- In low urbanisation degree areas LUDA (single family neighbourhoods or woonerf) with negligible heavy traffic volume and most severe site constraints, a “flattened” turbo roundabout featuring one lane on the main road approach leg should be the option of choice.

- In built-up areas featuring well-developed community infrastructure, BA requires pedestrian and cycle crossings to run through splitter islands on the side legs. With less severe site constraints and a considerable share of heavy traffic on the left- and right-turn movements, the option of choice is an elliptical turbo roundabout with an elliptical central island and one exit lane on the main road approach leg.

- In areas with rapidly growing commercial developments, a CDA along a side road featuring an elliptical roundabout featuring an elliptical central island and two lanes on the main road approach leg should be considered.

- −

- As the authors plan to continue the research with capacity analyses for different traffic flow allocations, new findings and roundabout selection guidelines may be expected.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

| Approach | Left Turning | Straight Through | Right Turning | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P | HGV | TSU | B | P | HGV | TSU | B | P | HGV | TSU | B | |

| Volume of traffic by vehicle in hours 14–15 | ||||||||||||

| A | 29 | – | 3 | – | 469 | 31 | 112 | 4 | 96 | 3 | 6 | – |

| B | 64 | – | 4 | – | 394 | 24 | 130 | 4 | 42 | 2 | 4 | – |

| C | 98 | 1 | 1 | – | 4 | – | – | – | 102 | – | 4 | – |

| D | 24 | 2 | – | – | – | – | – | – | 97 | – | 2 | – |

| Volume of traffic by vehicle in hours 5–6 | ||||||||||||

| A | 38 | – | 20 | – | 240 | 33 | 88 | 1 | 55 | 5 | 24 | – |

| B | 48 | 3 | 25 | – | 280 | 18 | 92 | 1 | 22 | 4 | 35 | – |

| C | 32 | – | 28 | – | – | – | – | – | 18 | – | 18 | – |

| D | 17 | – | 7 | – | – | – | – | – | 42 | 8 | 27 | – |

Appendix C

Appendix D

| Main Elements of a Transverse Cross-Section of the Roundabout | Mathematical Designation | Radius and Measurement in m | |||

|---|---|---|---|---|---|

| Fastest path speed for a passenger car in km/h | v | 37–41 | 37–39 | ||

| Mini roundabout | Small roundabout | ||||

| Figure 7a and Figure A4 | Figure 7b | ||||

| Lane divider between driving lanes | 0.70 | 0.24 | 0.70 | 0.24 | |

| Radii | |||||

| Inner radius of the inner lane | R1 | 10.50 | 10.50 | 12.00 | 12.00 |

| Outside radius of the inner lane | R2 | 15.85 | 15.65 | 17.15 | 16.95 |

| Inner radius of the outside lane | R3 | 16.15 | 15.89 | 17.45 | 17.19 |

| Outside radius of the outside lane | R4 | 21.15 | 20.69 | 22.45 | 21.99 |

| Curve lane divider entry | Rt | 12 | 12 | 12 | 12 |

| Curve lane divider exit | Ra | 14 | 14 | 14 | 14 |

| Widths | |||||

| Overrun area (truck apron) width | 5.00 | 5.00 | 5.00 | 5.00 | |

| Width, inside lane | bu | 4.70 | 4.70 | 4.50 | 4.50 |

| Width, outside lane | bv | 4.35 | 4.35 | 4.35 | 4.35 |

| Shift of inner arc centres along the translation axis(stakeout: R2, R3, R4) | ∆v | 5.75 | 5.75 | 5.35 | 5.35 |

| Shift of outer arc centres along the translation axis(stakeout: R0, R1) | ∆u | 5.05 | 5.05 | 5.05 | 5.05 |

Appendix E

References

- Overkamp, D.P.; van der Wijk, W. Roundabouts—Application and Design, A Practical Manual; Royal Haskoning DHV, Dutch Ministry of Transport, Public Works and Water Management, Partners for Roads: Hague, The Netherlands, 2009. [Google Scholar]

- Fortuijn, L.G.H. Turborotonde En Turboplein: Ontwerp, Capaciteit En Veiligheid. Trail Thesis series T 2013/1. Ph.D. Thesis, Trail Research School, Dissertation of Delft University of Technology, Delf, The Netherlands, January 2013. [Google Scholar]

- CROW. Turborotondes; CROW Publication No. 257; CROW: Hague, The Netherlands, 2008. [Google Scholar]

- Fortuijn, L.; Salomons, A.M. Capacity Increase through connectivity for the i-Roundabout and i-Turbo roundabout. In Proceedings of the 2020 Forum on Integrated and Sustainable Transportation Systems (FISTS), Delft, The Netherlands, 3–5 November 2020. [Google Scholar] [CrossRef]

- Gallelli, V.; Vaiana, R. Safety improvements by converting a standard roundabout with unbalanced flow distribution into an egg turbo roundabout: Simulation approach to a case study. Sustainability 2019, 11, 466. [Google Scholar] [CrossRef]

- Liu, Q.; Deng, J.; Shen, Y.; Wang, W.; Zhang, Z.; Lu, L. Safety and Efficiency Analysis of Turbo Roundabout with Simulations Based on the Lujiazui Roundabout in Shanghai. Sustainability 2020, 12, 7479. [Google Scholar] [CrossRef]

- Ciampa, D.; Diomedi, M.; Giglio, F.; Olita, S.; Petruccelli, U.; Restaino, C. Effectiveness of unconventional roundabouts in the design of suburban intersections. Eur. Transp. Trasp. Eur. 2020, 80, 1–16. [Google Scholar] [CrossRef]

- Silva, A.B.; Mariano, P.; Silva, J.P. Performance assessment of turbo-roundabouts in corridors. Transp. Res. Procedia 2015, 10, 124–133. [Google Scholar] [CrossRef]

- CROW. Eenheid in Rotondes; CROW Publication: Ede No. 126; CROW: Hague, The Netherlands, 1998. [Google Scholar]

- De Baan, D. Aantal ‘Gespotte’ Turborotondes. Available online: https://www.dirkdebaan.nl/types.html (accessed on 2 July 2023).

- Google Earth. Available online: http://www.earth.google.com (accessed on 2 July 2023).

- Tollazzi, T. “Turbo” Krožišča: Krožna Križišča s Spiralnim Potekom Krožnega Vozišča; Ministrstvo za Promet, Direkcija Republike Slovenije za Ceste: Ljubljana, Slovenia, 2008.

- Tollazzi, T.; Mauro, R.; Guerrieri, M.; Rencelj, M. Comparative analysis of four new alternative types of roundabouts: “turbo”, “flower”, “target” and “four-flyover” roundabout. Period. Polytech. Civ. Eng. 2015, 60, 51–60. [Google Scholar] [CrossRef]

- Tollazzi, T. Alternative Types of Roundabouts. An Informational Guide; Springer Tracts on Transportation and Traffic STTT; Springer: Berlin/Heidelberg, Germany, 2015; Volume 6. [Google Scholar] [CrossRef]

- Tollazzi, T. Experiences with Alternative Types of Roundabouts in Slovenia. In Proceedings of the Conference European Road Assessment (EuroRAP), Brussels, Belgium, 3–5 January 2020; Available online: https://eurorap.org/wp-content/uploads/2020/01/3-5-Tollazzi-Konferenca-o-prometni-varnosti-2016.pdf (accessed on 2 July 2023).

- Grabowski, R. Turbo-roundabouts as an alternative to standard roundabouts with the circular centre island. Roads Bridges Drog. Mosty 2012, 11, 215–231. [Google Scholar]

- Leonardi, S.; Distefano, N. Turbo-Roundabouts as an Instrument for Improving the Efficiency and Safety in Urban Area: An Italian Case Study. Sustainability 2023, 15, 3223. [Google Scholar] [CrossRef]

- Guerrieri, M.; Tollazzi, T. Analysis of Kinematic Parameters and Driver Behavior at Turbo Roundabouts. J. Transp. Eng. Part A Syst. 2018, 144, 04018020. [Google Scholar] [CrossRef]

- Vasconcelos, L.; Silva, A.B.; Seco, A.M.; Fernandes, P.; Coelho, M.C. Turboroundabouts: Multicriterion Assessment of Intersection Capacity, Safety, and Emissions. J. Transp. Res. Rec. 2014, 2402, 28–37. [Google Scholar] [CrossRef]

- Vasconcelos, L.; Silva, A.B.; Seco, A.M. Capacity of normal and turbo-roundabouts: Comparative analysis. Proc. Inst. Civ. Eng. Transp. 2014, 167, 88–99. [Google Scholar] [CrossRef]

- Pitlova, E.; Kocianova, A. Case Study: Capacity Characteristics Comparison of Single-lane Roundabout and Turbo-roundabouts. Procedia Eng. 2017, 192, 701–706. [Google Scholar] [CrossRef]

- Šarić, A.; Lovrić, I. Multi-lane Roundabout Capacity Evaluation. Front. Built Environ. Sec. Transp. Transit Syst. 2017, 3, 42. [Google Scholar] [CrossRef]

- Kocianova, A. Capacity Limits of Basic Turbo-Roundabouts. Commun. Sci. Lett. Univ. Zilina 2016, 18, 90–98. [Google Scholar] [CrossRef]

- Gallelli, V.; Perri, G.; Vaiana, R. Operational and safety management at intersections: Can the turbo-roundabout be an effective alternative to conventional solutions? Sustainability 2021, 13, 5103. [Google Scholar] [CrossRef]

- Urząd Miasta Przestrzenny Plan Zagospodarowania Przestrzennego Miasta, Urząd Miasta w Szczecinie. 2022. Available online: https://bip.um.szczecin.pl/chapter_11424.asp (accessed on 19 May 2022).

- GDDKiA. Generalny Pomiar Ruchu GPR 2020/2021. Available online: https://www.gov.pl/web/gddkia/generalny-pomiar-ruchu-20202021 (accessed on 25 May 2023).

- Rozporządzenie Ministra Infrastruktury z dnia 24 czerwca 2022 r. w sprawie przepisów techniczno-budowlanych dotyczących dróg publicznych. Dziennik Ustaw 2022. Warszawa, z dnia 20 lipca 2022 r., poz. 1518. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=WDU20220001518 (accessed on 25 May 2023).

- Bąk, R.; Gaca, S.; Ostrowski, K.; Tracz, M.; Woźniak, K. Wytyczne Projektowania Skrzyżowań Drogowych WR-D-31-3. Ronda; Ministerstwo Infrastruktury: Warszawa, Poland, 2022. [Google Scholar]

- Corriere, F.; Guerrieri, M. Performance analysis of basic turbo-roundabouts in urban context. Procedia Soc. Behav. Sci. 2012, 53, 622–632. [Google Scholar] [CrossRef]

- Chan, S. Radial, left or right offset alignment and roundabout vehicle speeds. Roundabouts Now 2017, 3, 24–27. [Google Scholar]

- Chan, S.; Livingston, R. Design Vehicle’s Influence to the Geometric Design of Turbo Roundabouts. Teach America. Retrieved 17 October 2017. 2015. Available online: http://teachamerica.com/RAB14ppr147_Chan.pdf (accessed on 25 April 2021).

- Campbell, D.; Jurisich, I.; Dunn, R. Improved Multi-Lane Roundabout Designs for Urban Areas; Research Report 476; NZ Transport Agency: Wellington, New Zealand, 2012. [Google Scholar]

- Džambas, T.; Ahac, S.; Dragčević, V. Design of turbo roundabouts based on the rules of vehicle movement geometry. J. Transp. Eng. 2016, 142, 05016004. [Google Scholar] [CrossRef]

- Džambas, T.; Dragčević, V.; Korlaet, Ž. Optimizing geometric design of standard turboroundabouts. KSCE J. Civ. Eng. 2020, 24, 3034–3049. [Google Scholar] [CrossRef]

- Severino, A.; Pappalardo, G.; Trubia, S. Safety evaluation of turbo roundabout considering autonomous vehicles operation. Arch. Civ. Eng. 2021, LXVII, 439–460. [Google Scholar] [CrossRef]

shows the Cartesian quadrants.

shows the Cartesian quadrants.

shows the Cartesian quadrants.

shows the Cartesian quadrants.

| Design Vehicle Data | Vehicle Details | |||||||

|---|---|---|---|---|---|---|---|---|

| L | MABS 1 | L2 | F | WB | B2 | WB2 | ||

| DV1 |  | 16.50 | 70 | 13.43 | 1.62 | 4.81 | 3.92 | 6.15 |

| DV2 |  | 9.90 | – | – | 1.53 | 4.77 | – | – |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sołowczuk, A.; Majer, S. Design Study for the Construction of Turbo Roundabouts under Constrained Site Conditions. Sustainability 2023, 15, 13220. https://doi.org/10.3390/su151713220

Sołowczuk A, Majer S. Design Study for the Construction of Turbo Roundabouts under Constrained Site Conditions. Sustainability. 2023; 15(17):13220. https://doi.org/10.3390/su151713220

Chicago/Turabian StyleSołowczuk, Alicja, and Stanisław Majer. 2023. "Design Study for the Construction of Turbo Roundabouts under Constrained Site Conditions" Sustainability 15, no. 17: 13220. https://doi.org/10.3390/su151713220

APA StyleSołowczuk, A., & Majer, S. (2023). Design Study for the Construction of Turbo Roundabouts under Constrained Site Conditions. Sustainability, 15(17), 13220. https://doi.org/10.3390/su151713220