Integrating Prospective LCA in the Development of Automotive Components

Abstract

1. Introduction

2. State of Research

2.1. LCE of Automotive Components

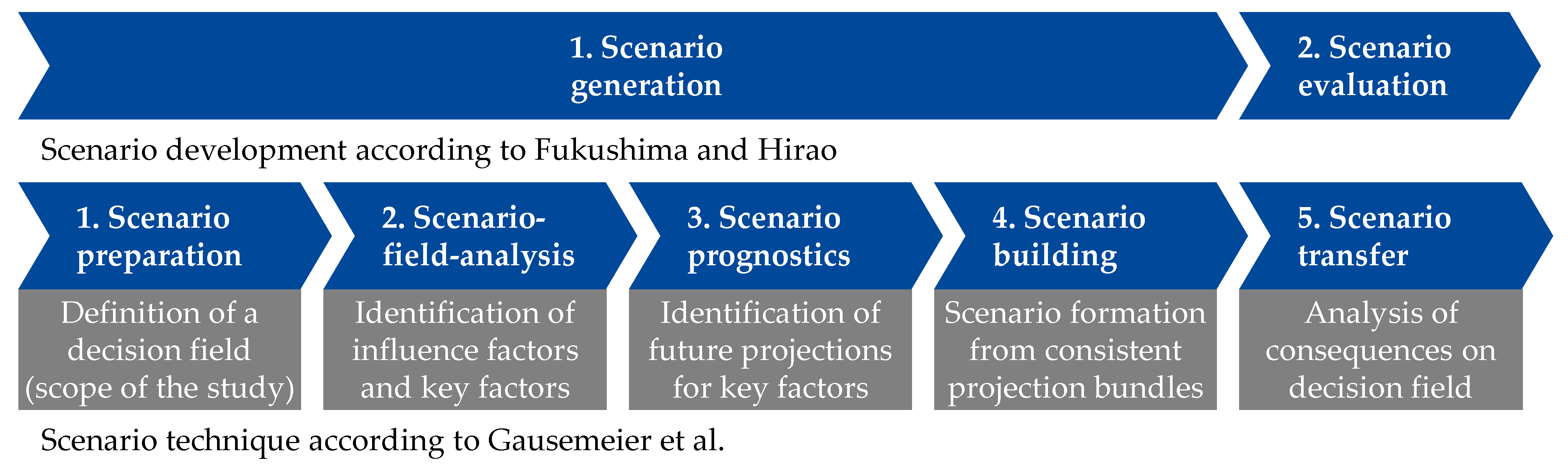

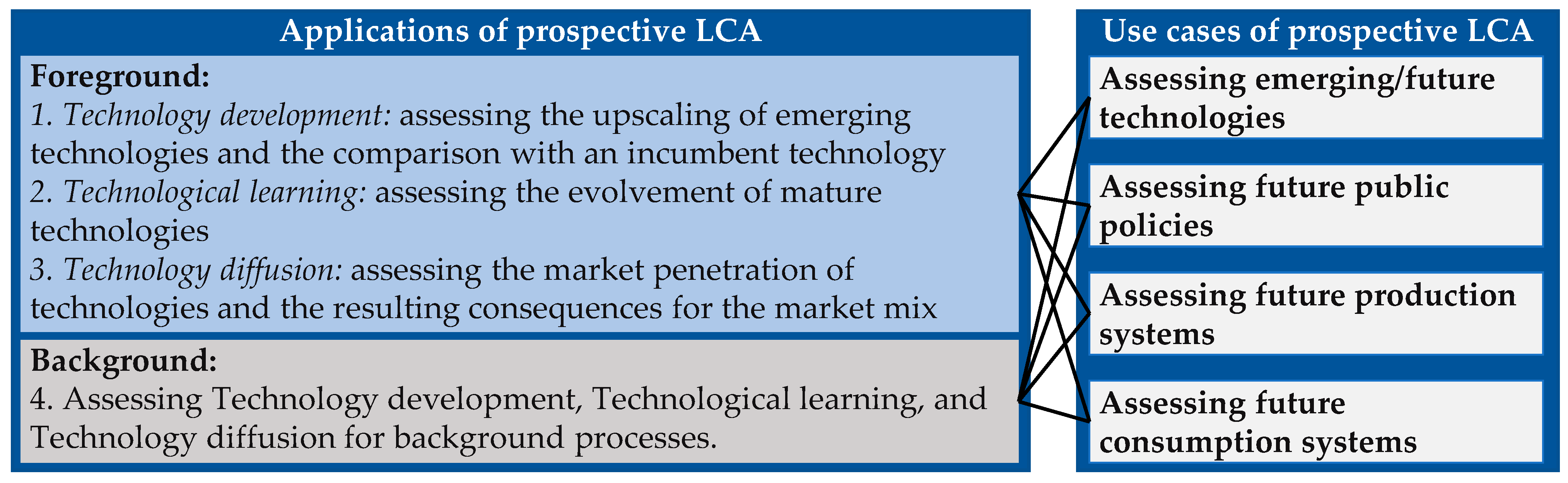

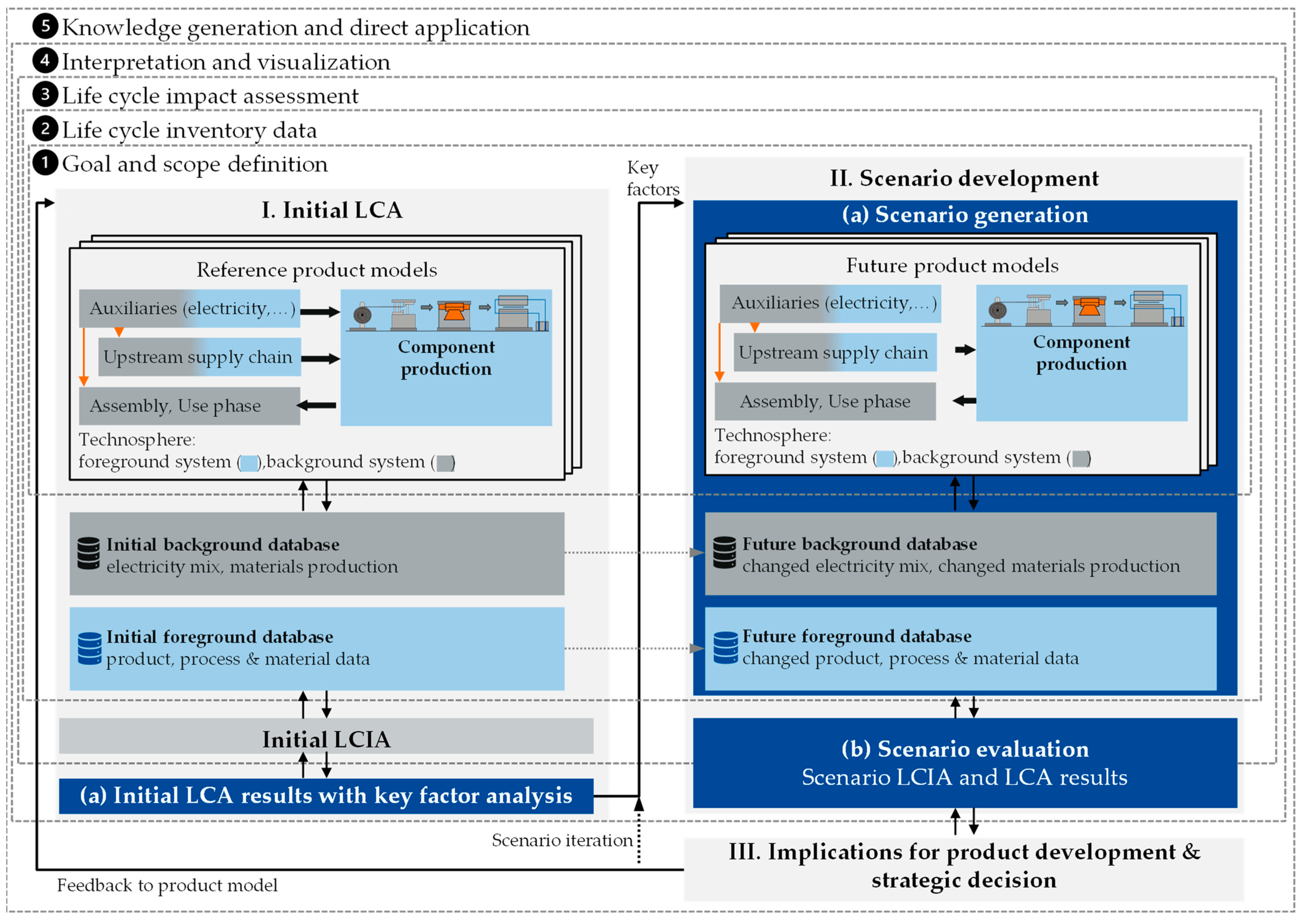

2.2. Prospective LCA

2.3. Integration of pLCA in LCE of Automotive Components

3. Materials and Methods

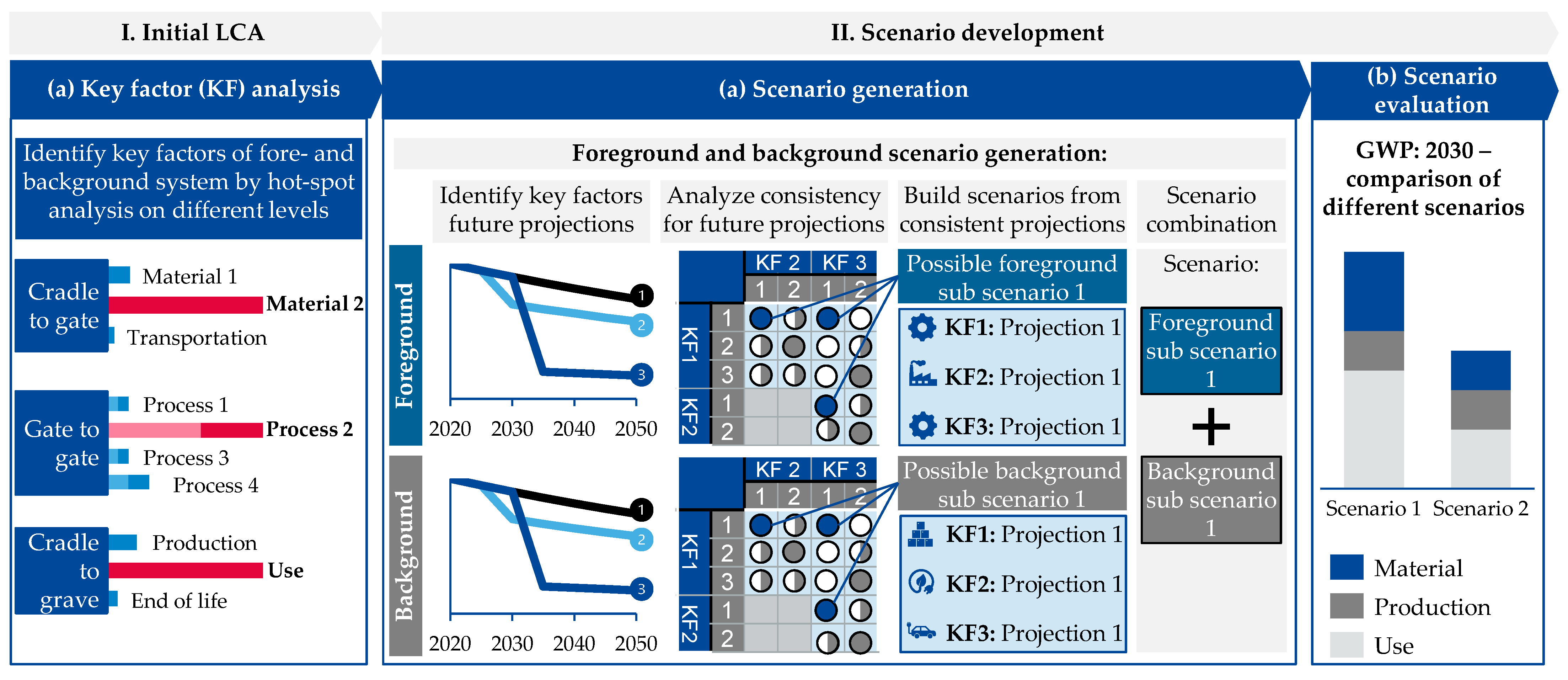

Methodology for Application of Prospective LCA in LCE of Automotive Components

- Cradle-to-Grave: Considering the whole product life cycle to identify general hot spots in the foreground and background systems.

- Gate-to-Gate: Considering the component production at the component producer to identify production processes with high GWP (foreground system).

- Cradle-to-Gate: Considering the upstream supply chain to analyze the contribution of materials and auxiliaries used (background system).

4. Results—Case Study

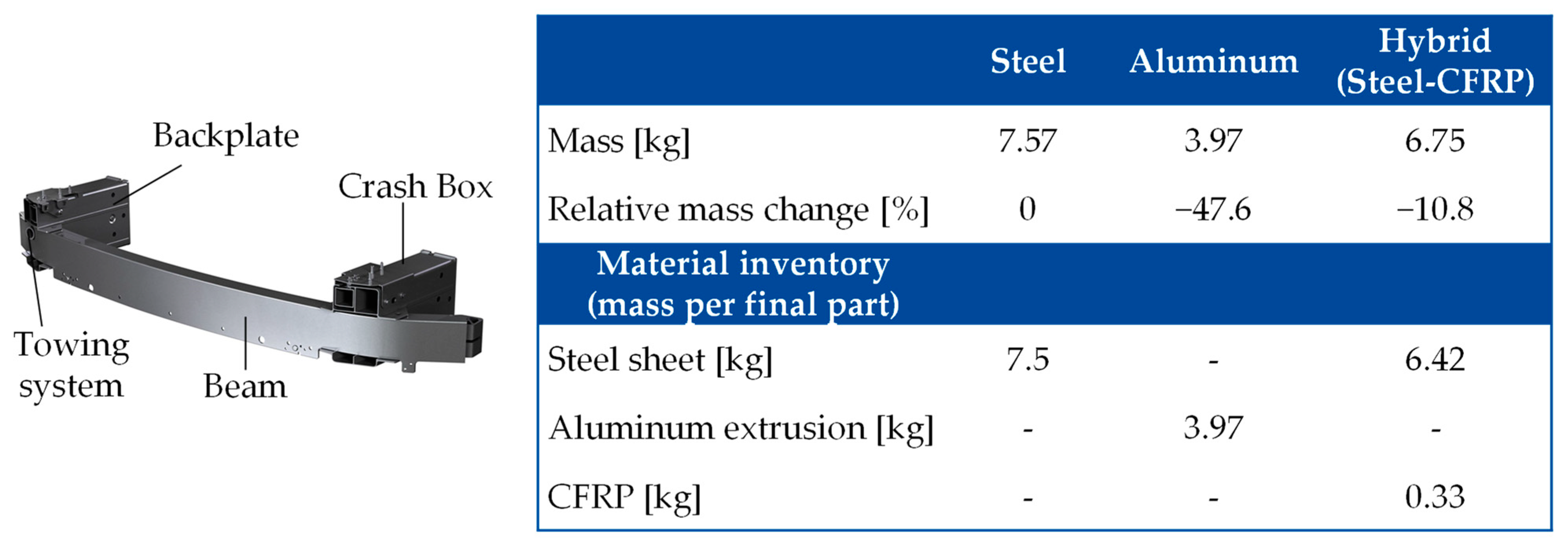

4.1. Goal and Scope Definition

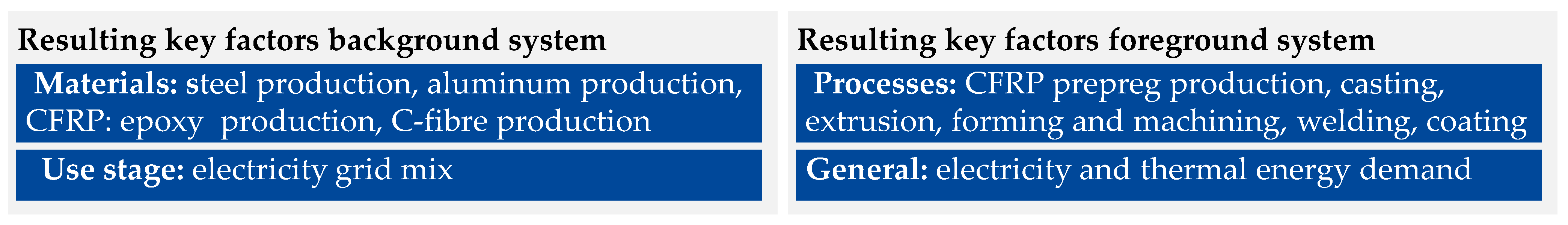

4.2. Initial LCA and Key Factor Analysis

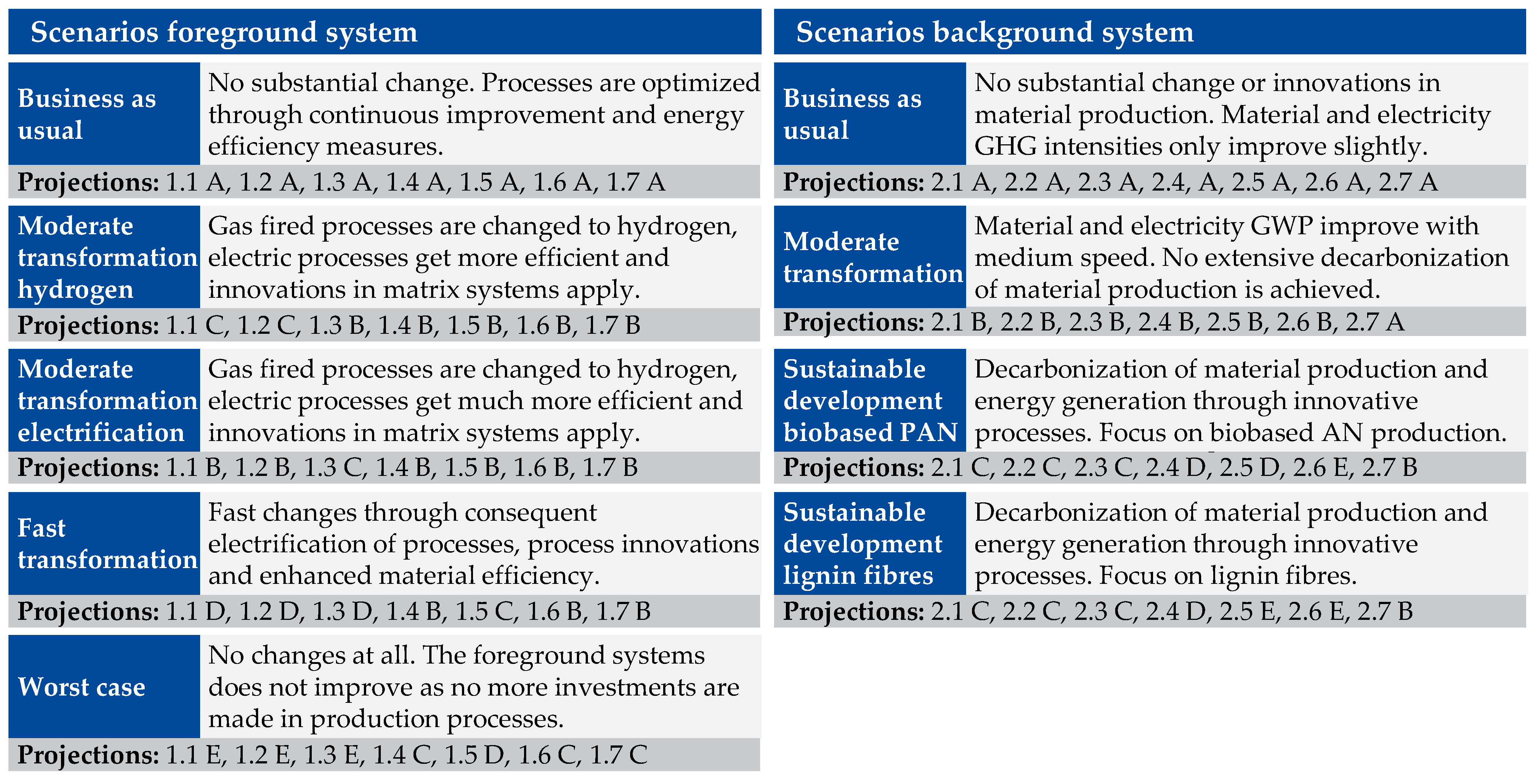

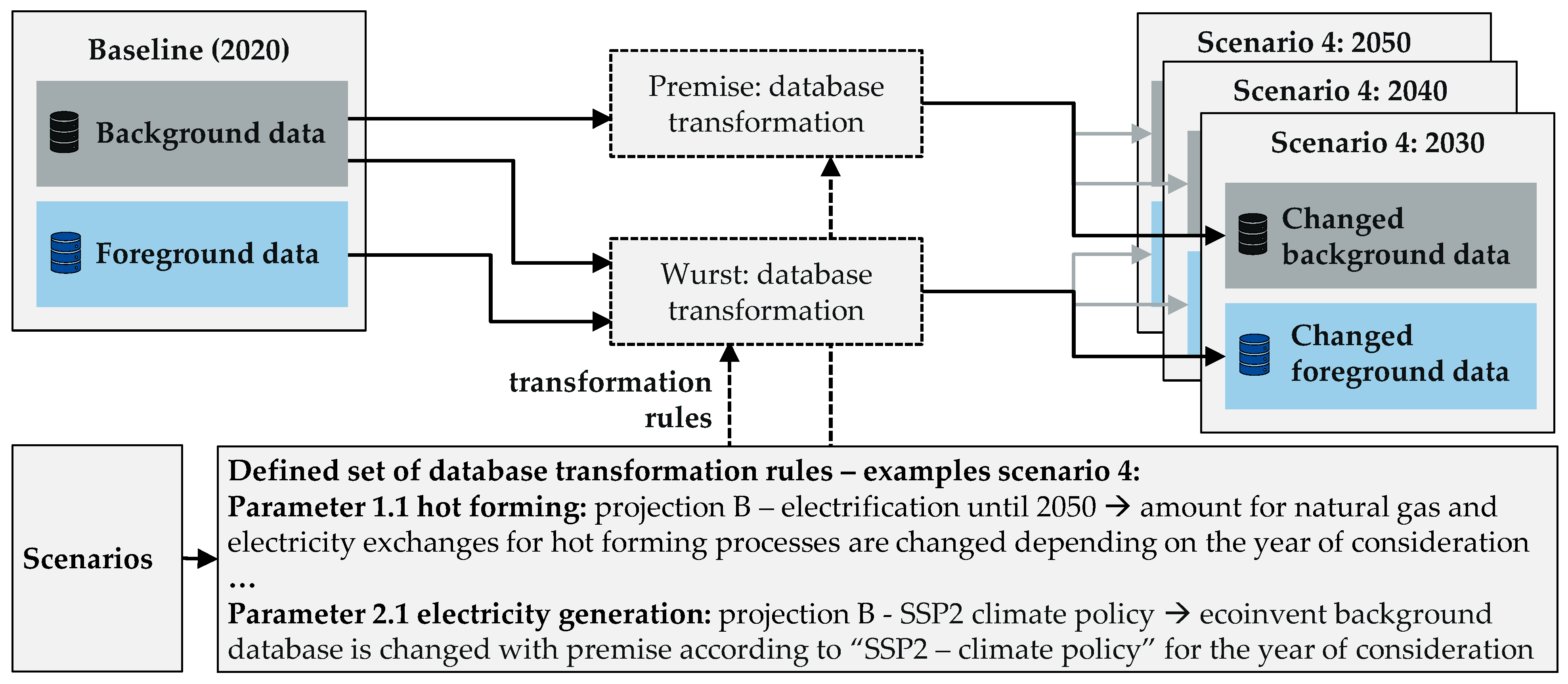

4.3. Scenario Generation

4.3.1. Identification of Future Projections

4.3.2. Consistency Matrix

4.3.3. Scenario Building

4.3.4. Scenario Evaluation

4.4. Implications for Product Development and Strategic Decisions

- Own production: The switch from fossil energy to renewable energy is crucial to reach a reduction in GWP from a gate-to-gate perspective. However, the analysis shows that even a very fast transformation approach from, e.g., natural gas fired processes to electrification, as shown in scenario 5, does not result in a fast decarbonization. Electrification is only useful when sufficient renewable electricity is available to substitute the fossil fuels (scenario 6). Therefore, when deciding for either the electrification of processes or the substitution of fossil fuels by other fuels such as hydrogen, the availability has to be assured. One possibility is to assure availability by investing in the production of renewable electricity or green hydrogen.

- Materials: The three main aspects of material efficiency, usage of secondary materials, and usage of sustainably produced materials have been analyzed in the context of this study to reduce the GWP from the materials used in the products. The highest potential was reached in scenarios 6 and 7, where all three aspects where applied. The first aspect is material efficiency. The efficient usage of materials in the production can reduce the GWP significantly, especially when it comes to production processes with high material losses or very GHG intensive materials like FRP. The development of material efficient production technologies is therefore one central aspect for companies. The second aspect is the usage of recycled materials to produce automotive components. The recycled materials for all materials in this study have a lower GWP than the virgin materials. Aiming at a circular economy, the recycled content should therefore be increased as far as possible without losing physical properties or the weakening the crash performance of the component. The third aspect is the sustainable production of virgin materials. Due to the increasing demand for raw materials globally, not all products can be produced with secondary materials. A certain amount of virgin material is still needed. Therefore, this virgin material needs to be produced as sustainably as possible. Investments in new technologies and partnerships with suppliers of these materials are therefore possible steps for component producers.

5. Discussion

6. Conclusions

- The methodology is suitable for usage in the automotive industry and provides a practical way to consider future developments in product and strategy development;

- The main advantage of the methodology is the possibility to develop different consistent future scenarios for the foreground and background systems, to analyze their influence on the GWP of the products under study, and to derive implications for future product and decarbonization strategy developments from the results;

- Scenario consistency is improved through the integration of a structured consistency analysis but remains a limitation through the unavoidable usage of data from different sources.

- A significant reduction of the GWP is possible in seven out of eight future scenarios for all product variants under study considering a time period from 2020 to 2050;

- The main levers for the decarbonization and therefore the main implications for companies are (1) the decarbonization of the own production through the efficient usage of renewable energy, and (2) the decarbonization of the upstream supply chain through the usage of sustainable materials such as secondary materials or materials produced with low GWP, and (3) the decarbonization of the use stage through the usage of renewable electricity;

- For the example under study and the made assumptions, most scenarios show an advantage for the GWP of the steel variant compared to the other design variants. However, it is important to note that the results are specific to the assumptions made, and different results may be obtained for different products or applications.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- EC–European Commission. Regulation (EU) 2021/1119 of the European Parliament and of the Council of 30 June 2021 establishing the framework for achieving climate neutrality and amending Regulations (EC) No 401/2009 and (EU) 2018/1999 (‘European Climate Law’): (EU) 2021/1119. Off. J. Eur. Union 2021, 243, 1–17. [Google Scholar]

- Nidumolu, R.; Prahalad, C.K.; Rangaswami, M.R. Why sustainability is now the key driver of innovation. IEEE Eng. Manag. Rev. 2015, 43, 85–91. [Google Scholar] [CrossRef]

- Lee, H. (Ed.) Synthesis Report of the IPCC Sixth Assessment Report (AR6): Longer Report; IPCC WMO: Geneva, Switzerland, 2023. [Google Scholar]

- Reimer, L.; Kaluza, A.; Cerdas, F.; Meschke, J.; Vietor, T.; Herrmann, C. Design of Eco-Efficient Body Parts for Electric Vehicles Considering Life Cycle Environmental Information. Sustainability 2020, 12, 5838. [Google Scholar] [CrossRef]

- Hirz, M.; Nguyen, T.T. Life-Cycle CO2-Equivalent Emissions of Cars Driven by Conventional and Electric Propulsion Systems. World Electr. Veh. J. 2022, 13, 61. [Google Scholar] [CrossRef]

- Egede, P. Environmental Assessment of Lightweight Electric Vehicles, 1st ed.; Springer International Publishing: Cham, Switzerland, 2017; ISBN 9783319402772. [Google Scholar]

- Koffler, C.; Rohde-Brandenburger, K. On the calculation of fuel savings through lightweight design in automotive life cycle assessments. Int. J. Life Cycle Assess. 2010, 15, 128–135. [Google Scholar] [CrossRef]

- Luk, J.M.; Kim, H.C.; de Kleine, R.; Wallington, T.J.; MacLean, H.L. Review of the Fuel Saving, Life Cycle GHG Emission, and Ownership Cost Impacts of Lightweighting Vehicles with Different Powertrains. Environ. Sci. Technol. 2017, 51, 8215–8228. [Google Scholar] [CrossRef]

- Kim, H.C.; Wallington, T.J. Life Cycle Assessment of Vehicle Lightweighting: A Physics-Based Model to Estimate Use-Phase Fuel Consumption of Electrified Vehicles. Environ. Sci. Technol. 2016, 50, 11226–11233. [Google Scholar] [CrossRef]

- Del Pero, F.; Berzi, L.; Antonacci, A.; Delogu, M. Automotive Lightweight Design: Simulation Modeling of Mass-Related Consumption for Electric Vehicles. Machines 2020, 8, 51. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Hu, G.; Yang, M. Lightweight Research in Engineering: A Review. Appl. Sci. 2019, 9, 5322. [Google Scholar] [CrossRef]

- Herrmann, C.; Dewulf, W.; Hauschild, M.; Kaluza, A.; Kara, S.; Skerlos, S. Life cycle engineering of lightweight structures. CIRP Ann. 2018, 67, 651–672. [Google Scholar] [CrossRef]

- Haraldsson, J.; Johansson, M.T. Effects on primary energy use, greenhouse gas emissions and related costs from improving energy end-use efficiency in the electrolysis in primary Aluminium production. Energy Effic. 2020, 13, 1299–1314. [Google Scholar] [CrossRef]

- Nunez, P.; Jones, S. Cradle to gate: Life cycle impact of primary Aluminium production. Int. J. Life Cycle Assess. 2016, 21, 1594–1604. [Google Scholar] [CrossRef]

- Hohmann, A. Ökobilanzielle Untersuchung von Herstellungsverfahren für CFK-Strukturen zur Identifikation von Optimierungspotentialen: Systematische Methodik zur Abschätzung der Umweltwirkungen von Fertigungsprozessketten. Ph.D. Dissertation, Technische Universität München, Munich, Germany, 2019. [Google Scholar]

- Arnold, U.; de Palmenaer, A.; Brück, T.; Kuse, K. Energy-Efficient Carbon Fiber Production with Concentrated Solar Power: Process Design and Techno-economic Analysis. Ind. Eng. Chem. Res. 2018, 57, 7934–7945. [Google Scholar] [CrossRef]

- Dér, A.; Dilger, N.; Kaluza, A.; Creighton, C.; Kara, S.; Varley, R.; Herrmann, C.; Thiede, S. Modelling and analysis of the energy intensity in polyacrylonitrile (PAN) precursor and carbon fibre manufacturing. J. Clean. Prod. 2021, 303, 127105. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Standardization Organization: Geneva, Switzerland, 2006.

- Hauschild, M.Z.; Herrmann, C.; Kara, S. An Integrated Framework for Life Cycle Engineering. Procedia CIRP 2017, 61, 2–9. [Google Scholar] [CrossRef]

- Kara, S.; Herrmann, C.; Hauschild, M. Operationalization of life cycle engineering. Resour. Conserv. Recycl. 2023, 190, 106836. [Google Scholar] [CrossRef]

- Cerdas, F. Integrated Computational Life Cycle Engineering for Traction Batteries; Springer: Cham, Switzerland, 2022; ISBN 978-3-030-82933-9. [Google Scholar]

- Arvidsson, R.; Tillman, A.-M.; Sandén, B.A.; Janssen, M.; Nordelöf, A.; Kushnir, D.; Molander, S. Environmental Assessment of Emerging Technologies: Recommendations for Prospective LCA. J. Ind. Ecol. 2018, 22, 1286–1294. [Google Scholar] [CrossRef]

- Weber, J. Automotive Development Processes; Springer: Berlin/Heidelberg, Germany, 2009; ISBN 978-3-642-01252-5. [Google Scholar]

- Pfeifer, F.; Dietrich, A.; Marten, T.; Tröster, T.; Nacke, B. Investigation on Inductive Heating of Sheet Metal for an Industrial Hot Stamping Process. In Hot Sheet Metal Forming of High-Performance Steel, Proceedings of the CHS2: 7th International Conference, Luleå, Sweden, 2–5 June 2019; Oldenburg, M., Hardell, J., Casellas, D., Eds.; Verlag Wissenschaftliche Scripten: Auerbach, Germany, 2019; pp. 585–593. ISBN 9783957351043. [Google Scholar]

- Dürr Aktiengesellschaft. Sustainability in the Paint Shop. Available online: https://www.durr.com/en/company/sustainability/sustainability-in-the-paint-shop (accessed on 18 September 2022).

- Koroma, M.S.; Brown, N.; Cardellini, G.; Messagie, M. Prospective Environmental Impacts of Passenger Cars under Different Energy and Steel Production Scenarios. Energies 2020, 13, 6236. [Google Scholar] [CrossRef]

- International Energy Agency. Iron and Steel Technology Roadmap; OECD: Paris, France, 2020; ISBN 9789264441149. [Google Scholar]

- International Aluminium Institute. 1.5 Degrees Scenario: A Model to Drive Emissions Reduction; International Aluminium Institute: London, UK, 2021. [Google Scholar]

- European Aluminium. Vision 2050: European Aluminium’s Contribution to EU’s Mid-Century Low-Carbon Roadmap; European Aluminium: Woluwe-Saint-Pierre, Belgium, 2018. [Google Scholar]

- Hermansson, F.; Heimersson, S.; Janssen, M.; Svanström, M. Can carbon fiber composites have a lower environmental impact than fiberglass? Resour. Conserv. Recycl. 2022, 181, 106234. [Google Scholar] [CrossRef]

- Hohmann, A.; Frank, J. Environmental friendly fiber reinforced plastics (FRP) for high performance applications: Assessment of the global warming potential (GWP) and related levers. In Proceedings of the Composites and Sustainability by Composites United, Virtual, Composites United Switzerland, Winterthur, Switzerland, 29 June–1 July 2021. [Google Scholar]

- Mendoza Beltran, A.; Cox, B.; Mutel, C.; Vuuren, D.P.; Font Vivanco, D.; Deetman, S.; Edelenbosch, O.Y.; Guinée, J.; Tukker, A. When the Background Matters: Using Scenarios from Integrated Assessment Models in Prospective Life Cycle Assessment. J. Ind. Ecol. 2020, 24, 64–79. [Google Scholar] [CrossRef]

- Buyle, M.; Audenaert, A.; Billen, P.; Boonen, K.; Van Passel, S. The Future of Ex-Ante LCA? Lessons Learned and Practical Recommendations. Sustainability 2019, 11, 5456. [Google Scholar] [CrossRef]

- Björklund, A.E. Survey of approaches to improve reliability in lca. Int. J. LCA 2002, 7, 64–72. [Google Scholar] [CrossRef]

- Ostermann, M.; Grenz, J.; Triebus, M.; Cerdas, F.; Marten, T.; Tröster, T.; Herrmann, C. Integrating Prospective Scenarios in Life Cycle Engineering: Case Study of Lightweight Structures. Energies 2023, 16, 3371. [Google Scholar] [CrossRef]

- Broch, F. Integration von Ökologischen Lebenswegbewertungen in Fahrzeugentwicklungsprozesse; Springer Fachmedien Wiesbaden: Wiesbaden, Germany, 2017; ISBN 978-3-658-18217-5. [Google Scholar]

- Kaluza, A.; Kleemann, S.; Broch, F.; Herrmann, C.; Vietor, T. Analyzing Decision-making in Automotive Design towards Life Cycle Engineering for Hybrid Lightweight Components. Procedia CIRP 2016, 50, 825–830. [Google Scholar] [CrossRef]

- von Drachenfels, N.; Husmann, J.; Khalid, U.; Cerdas, F.; Herrmann, C. Life Cycle Assessment of the Battery Cell Production: Using a Modular Material and Energy Flow Model to Assess Product and Process Innovations. Energy Technol. 2022, 11, 2200673. [Google Scholar] [CrossRef]

- Kaluza, A.; Kleemann, S.; Fröhlich, T.; Herrmann, C.; Vietor, T. Concurrent Design & Life Cycle Engineering in Automotive Lightweight Component Development. Procedia CIRP 2017, 66, 16–21. [Google Scholar] [CrossRef]

- Fukushima, Y.; Hirao, M. A structured framework and language for scenario-based Life Cycle assessment. Int. J. Life Cycle Assess. 2002, 7, 317–329. [Google Scholar] [CrossRef]

- Thonemann, N.; Schulte, A.; Maga, D. How to Conduct Prospective Life Cycle Assessment for Emerging Technologies? A Systematic Review and Methodological Guidance. Sustainability 2020, 12, 1192. [Google Scholar] [CrossRef]

- Gausemeier, J.; Fink, A.; Schlake, O. Szenario-Management: Planen und Führen mit Szenarien, 2nd revised ed.; Hanser: München, Germany; Wien, Austria, 1996; ISBN 3446187219. [Google Scholar]

- Spielmann, M.; Scholz, R.; Tietje, O.; de Haan, P. Scenario Modelling in Prospective LCA of Transport Systems. Application of Formative Scenario Analysis (11 pp). Int. J. Life Cycle Assess. 2005, 10, 325–335. [Google Scholar] [CrossRef]

- Edmonds, J.A.; Calvin, K.V.; Clarke, L.E.; Janetos, A.C.; Kim, S.H.; Wise, M.A.; McJeon, H.C. Integrated Assessment Modeling. In Encyclopedia of Sustainability Science and Technology; Springer: New York, NY, USA, 2012; pp. 5398–5428. [Google Scholar]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Sacchi, R.; Terlouw, T.; Siala, K.; Dirnaichner, A.; Bauer, C.; Cox, B.; Mutel, C.; Daioglou, V.; Luderer, G. PRospective EnvironMental Impact asSEssment (premise): A streamlined approach to producing databases for prospective life cycle assessment using integrated assessment models. Renew. Sustain. Energy Rev. 2022, 160, 112311. [Google Scholar] [CrossRef]

- Stehfest, E.; van Vuuren, D.; Kram, T.; Bouwman, L.; Alkemade, R.; Bakkenes, M.; Biemans, H.; Bouwman, A.; den Elzen, M.; Janse, J.; et al. Integrated Assessment of Global Environmentl Change with IMAGE 3.0; PBL Netherlands Environmental Assessment Agency: Hauge, The Netherlands, 2014. [Google Scholar]

- Luderer, G.; Bauer, N.; Baumstark, L.; Bertram, C.; Leimbach, M.; Pietzcker, R.; Strefler, J.; Aboumahboub, T.; Abrahão, G.; Auer, C.; et al. REMIND—REgional Model of INvestments and Development—Version 3.0.0. 2022. Available online: https://www.pik-potsdam.de/research/transformation-pathways/models/remind (accessed on 13 March 2023).

- Mutel, C. Brightway: An open source framework for Life Cycle Assessment. JOSS 2017, 2, 236. [Google Scholar] [CrossRef]

- Steubing, B.; de Koning, D. Making the use of scenarios in LCA easier: The superstructure approach. Int. J. Life Cycle Assess. 2021, 26, 2248–2262. [Google Scholar] [CrossRef]

- Cox, B.; Bauer, C.; Mendoza Beltran, A.; van Vuuren, D.P.; Mutel, C.L. Life cycle environmental and cost comparison of current and future passenger cars under different energy scenarios. Appl. Energy 2020, 269, 115021. [Google Scholar] [CrossRef]

- Schropp, E.; Naumann, G.; Gaderer, M. Prospective Life Cycle Assessment: A Case Study of Hydrogen Production with Water Electrolysis. Procedia CIRP 2022, 105, 92–97. [Google Scholar] [CrossRef]

- Ritchey, T. General Morphological Analysis (GMA). In Wicked Problems—Social Messes: Decision Support Modelling with Morphological Analysis; Springer: Berlin/Heidelberg, Germany, 2011; pp. 7–18. ISBN 978-3-642-19653-9. [Google Scholar]

- Delpierre, M.; Quist, J.; Mertens, J.; Prieur-Vernat, A.; Cucurachi, S. Assessing the environmental impacts of wind-based hydrogen production in the Netherlands using ex-ante LCA and scenarios analysis. J. Clean. Prod. 2021, 299, 126866. [Google Scholar] [CrossRef]

- Dér, A.; Kaluza, A.; Reimer, L.; Herrmann, C.; Thiede, S. Integration of Energy Oriented Manufacturing Simulation into the Life Cycle Evaluation of Lightweight Body Parts. Int. J. Precis. Eng. Manuf.-Green Technol. 2022, 9, 899–918. [Google Scholar] [CrossRef]

- Grienitz, V.; Schmidt, A.-M. Weiterentwicklung der Konsistenzanalyse auf Basis evolutinärer Strategien für die Entwicklung von Markt-und Umfeldszenarien. In Vorausschau und Technologieplanung, 5. Symposium für Vorausschau und Technologieplanung, Paderborn, Germany; Gausemeier, J., Ed.; Berlin-Brandenburgischen Akademie der Wissenschaften: Berlin, Germany, 2009. [Google Scholar]

- Kröger, M. Methodische Auslegung und Erprobung von Fahrzeug-Crashstrukturen. Ph.D. Thesis, Universität Hannover, Hanover, Germany, 2002. [Google Scholar]

- Camberg, A.A.; Tröster, T. Optimization-based material design of tailored stacked hybrids for further improvement in lightweight car body structures. In Proceedings of the 3rd International Conference on Hybrid Materials and Structures, Bremen, Germany, 18–19 April 2018; DGM—Deutsche Gesellschaft für Materialkunde e.V.: Sankt Augustin, Germany, 2018. [Google Scholar]

- Benteler International AG. Structures—BENTELER International AG. Available online: https://www.benteler.com/en/products/automotive-products/structures/ (accessed on 30 September 2022).

- World Steel Association. Life Cycle Inventory (LCI) Study: 2020 Data Release; World Steel Association: Brussels, Belgium, 2020. [Google Scholar]

- European Aluminium. Environmental Profile Report: Life-Cycle Inventory Data for Aluminium Production and Transformation Process in Europe; European Aluminium: Woluwe-Saint-Pierre, Belgium, 2018. [Google Scholar]

- Bachmann, J.; Hidalgo, C.; Bricout, S. Environmental analysis of innovative sustainable composites with potential use in aviation sector—A life cycle assessment review. Sci. China Technol. Sci. 2017, 60, 1301–1317. [Google Scholar] [CrossRef]

- Das, S. Life cycle assessment of carbon fiber-reinforced polymer composites. Int. J. Life Cycle Assess. 2011, 16, 268–282. [Google Scholar] [CrossRef]

- Stiller, H. Material Intensity of Advanced Composite Materials: Results of a Study for the Verbundwerkstofflabor Bremen e.V.; Wuppertal Papers No. 90. 1999. Available online: https://epub.wupperinst.org/frontdoor/deliver/index/docId/926/file/WP90.pdf (accessed on 14 September 2022).

- Suzuki, T.; Takahashi, J. Prediction of Energy Intensity of Carbon Fiber Reinforced Plastics for Mass-Produced Passenger Cars. In Proceedings of the 9th Japan International SAMPE Symposium, Tokyo, Japan, 29 November–2 December 2005. [Google Scholar]

- Witik, R.A.; Gaille, F.; Teuscher, R.; Ringwald, H.; Michaud, V.; Månson, J.-A.E. Economic and environmental assessment of alternative production methods for composite aircraft components. J. Clean. Prod. 2012, 29, 91–102. [Google Scholar] [CrossRef]

- Nothdurft, N. Integrierte Umweltkostenrechnung von Faserverbundfertigungsprozessen am Beispiel einer CFK-Flügelrippe. Ph.D. Thesis, Technische Universität Braunschweig, Brunswick, Germany, 2016. [Google Scholar]

- WorldAutoSteel. UCSB Automotive Energy & GHG Model; WorldAutoSteel: Middletown, OH, USA, 2017. [Google Scholar]

- Tillman, A. Significance of decision-making for LCA methodology. Environ. Impact Assess. Rev. 2000, 20, 113–123. [Google Scholar] [CrossRef]

- Hohmann, A. Nachhaltige Verbundwerkstoffe für Hochleistungsanwendungen. In Proceedings of the Technologietag Leichtbau—Global Lightweight Summit, Stuttgart, Germany, 9–10 November 2021. [Google Scholar]

- Hermansson, F. Assessing the Future Environmental Impact of Lignin-Based and Recycled Carbon Fibres in Composites Using Life Cycle Assessment. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2020. [Google Scholar]

- Hexcel Corporation. HexPly M77 Fast Curing Epoxy Resin Matrix for Prepregs: Product Data Sheet. 2022. Available online: https://www.hexcel.com/user_area/content_media/raw/HexPly_M77_EpoxyResin_DataSheet.pdf (accessed on 11 January 2023).

- International Aluminium Institute. Global Aluminium Cycle. 2021. Available online: https://alucycle.international-aluminium.org/public-access/public-global-cycle/ (accessed on 2 February 2023).

- Duflou, J.R.; de Moor, J.; Verpoest, I.; Dewulf, W. Environmental impact analysis of composite use in car manufacturing. CIRP Ann. 2009, 58, 9–12. [Google Scholar] [CrossRef]

- Wang, P.; Ryberg, M.; Yang, Y.; Feng, K.; Kara, S.; Hauschild, M.; Chen, W.-Q. Efficiency stagnation in global steel production urges joint supply- and demand-side mitigation efforts. Nat. Commun. 2021, 12, 2066. [Google Scholar] [CrossRef]

- Bataille, C.; Stiebert, S.; Li, F.G.N. Global Facility Level Net-Zero Steel Pathways: Technical Report on the First Scenarios of the Net-Zero Steel Project. 2021. Available online: http://netzerosteel.org/wp-content/uploads/pdf/net_zero_steel_report.pdf (accessed on 18 September 2022).

- La Rosa, A.D.; Greco, S.; Tosto, C.; Cicala, G. LCA and LCC of a chemical recycling process of waste CF-thermoset composites for the production of novel CF-thermoplastic composites. Open loop and closed loop scenarios. J. Clean. Prod. 2021, 304, 127158. [Google Scholar] [CrossRef]

- Ballout, W.; Sallem-Idrissi, N.; Sclavons, M.; Doneux, C.; Bailly, C.; Pardoen, T.; van Velthem, P. High performance recycled CFRP composites based on reused carbon fabrics through sustainable mild solvolysis route. Sci. Rep. 2022, 12, 5928. [Google Scholar] [CrossRef]

- Meng, F.; McKechnie, J.; Turner, T.A.; Pickering, S.J. Energy and environmental assessment and reuse of fluidised bed recycled carbon fibres. Compos. Part A Appl. Sci. Manuf. 2017, 100, 206–214. [Google Scholar] [CrossRef]

- Cerdas, F.; Kaluza, A.; Erkisi-Arici, S.; Böhme, S.; Herrmann, C. Improved Visualization in LCA through the Application of Cluster Heat Maps. Procedia CIRP 2017, 61, 732–737. [Google Scholar] [CrossRef]

- Lehmann, J.; Rillig, M. Distinguishing variability from uncertainty. Nat. Clim Chang. 2014, 4, 153. [Google Scholar] [CrossRef]

- Del Pero, F.; Delogu, M.; Kerschbaum, M. Design of a Lightweight Rear Crash Management System in a Sustainable Perspective. Sustainability 2020, 12, 5243. [Google Scholar] [CrossRef]

- Witik, R.A.; Payet, J.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Assessing the life cycle costs and environmental performance of lightweight materials in automobile applications. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1694–1709. [Google Scholar] [CrossRef]

- European Commission; Directorate-General for Communication. Circular Economy Action Plan: For a Cleaner and More Competitive Europe; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Zimmermann, B.M.; Dura, H.; Baumann, M.J.; Weil, M.R. Prospective time-resolved LCA of fully electric supercap vehicles in Germany. Integr. Environ. Assess. Manag. 2015, 11, 425–434. [Google Scholar] [CrossRef] [PubMed]

| Life Cycle Phase | Parameter | Used Datasets and Assumptions |

|---|---|---|

| Production | Energy supply | European average values for all forms of energy from ecoinvent [45] |

| Material production | Steel sheet production based on Worldsteel data [60]; Aluminum ingot production based on EA data [61]; Epoxy matrix and carbon fiber production based on literature data ([15,17,62,63]) | |

| Manufacturing processes | Steel and aluminum parts: Industry data; Hybrid part: literature data ([64,65,66,67]) and laboratory measurements | |

| Use | Energy supply | European average value for electricity from ecoinvent [45] |

| Vehicle application | Midsize BEV | |

| ERV | 1.59 MJ/(100 km × 100 kg) based on WorldAutoSteel [68] | |

| Mileage | 200,000 km | |

| Charging efficiency | 90% | |

| End-of-Life | Processes | No end-of-life processes as an equivalent shredding process can be assumed for all material designs |

| Calculation method | Cut-off |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grenz, J.; Ostermann, M.; Käsewieter, K.; Cerdas, F.; Marten, T.; Herrmann, C.; Tröster, T. Integrating Prospective LCA in the Development of Automotive Components. Sustainability 2023, 15, 10041. https://doi.org/10.3390/su151310041

Grenz J, Ostermann M, Käsewieter K, Cerdas F, Marten T, Herrmann C, Tröster T. Integrating Prospective LCA in the Development of Automotive Components. Sustainability. 2023; 15(13):10041. https://doi.org/10.3390/su151310041

Chicago/Turabian StyleGrenz, Julian, Moritz Ostermann, Karoline Käsewieter, Felipe Cerdas, Thorsten Marten, Christoph Herrmann, and Thomas Tröster. 2023. "Integrating Prospective LCA in the Development of Automotive Components" Sustainability 15, no. 13: 10041. https://doi.org/10.3390/su151310041

APA StyleGrenz, J., Ostermann, M., Käsewieter, K., Cerdas, F., Marten, T., Herrmann, C., & Tröster, T. (2023). Integrating Prospective LCA in the Development of Automotive Components. Sustainability, 15(13), 10041. https://doi.org/10.3390/su151310041